Suggestions or feedback?

MIT News | Massachusetts Institute of Technology

- Machine learning

- Sustainability

- Black holes

- Classes and programs

Departments

- Aeronautics and Astronautics

- Brain and Cognitive Sciences

- Architecture

- Political Science

- Mechanical Engineering

Centers, Labs, & Programs

- Abdul Latif Jameel Poverty Action Lab (J-PAL)

- Picower Institute for Learning and Memory

- Lincoln Laboratory

- School of Architecture + Planning

- School of Engineering

- School of Humanities, Arts, and Social Sciences

- Sloan School of Management

- School of Science

- MIT Schwarzman College of Computing

Researchers improve efficiency of next-generation solar cell material

Press contact :, media download.

*Terms of Use:

Images for download on the MIT News office website are made available to non-commercial entities, press and the general public under a Creative Commons Attribution Non-Commercial No Derivatives license . You may not alter the images provided, other than to crop them to size. A credit line must be used when reproducing images; if one is not provided below, credit the images to "MIT."

Previous image Next image

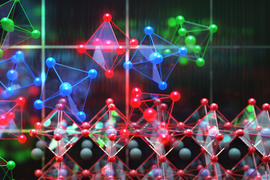

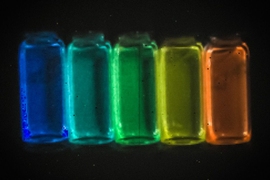

Perovskites are a leading candidate for eventually replacing silicon as the material of choice for solar panels. They offer the potential for low-cost, low-temperature manufacturing of ultrathin, lightweight flexible cells, but so far their efficiency at converting sunlight to electricity has lagged behind that of silicon and some other alternatives.

Now, a new approach to the design of perovskite cells has pushed the material to match or exceed the efficiency of today’s typical silicon cell, which generally ranges from 20 to 22 percent, laying the groundwork for further improvements.

By adding a specially treated conductive layer of tin dioxide bonded to the perovskite material, which provides an improved path for the charge carriers in the cell, and by modifying the perovskite formula, researchers have boosted its overall efficiency as a solar cell to 25.2 percent — a near-record for such materials, which eclipses the efficiency of many existing solar panels. (Perovskites still lag significantly in longevity compared to silicon, however, a challenge being worked on by teams around the world.)

The findings are described in a paper in the journal Nature by recent MIT graduate Jason Yoo PhD ’20, professor of chemistry and Lester Wolfe Professor Moungi Bawendi, professor of electrical engineering and computer science and Fariborz Maseeh Professor in Emerging Technology Vladimir Bulović, and 11 others at MIT, in South Korea, and in Georgia.

Perovskites are a broad class of materials defined by the fact that they have a particular kind of molecular arrangement, or lattice, that resembles that of the naturally occurring mineral perovskite. There are vast numbers of possible chemical combinations that can make perovskites, and Yoo explains that these materials have attracted worldwide interest because “at least on paper, they could be made much more cheaply than silicon or gallium arsenide,” one of the other leading contenders. That’s partly because of the much simpler processing and manufacturing processes, which for silicon or gallium arsenide requires sustained heat of over 1,000 degrees Celsius. In contrast, perovskites can be processed at less than 200 C, either in solution or by vapor deposition.

The other major advantage of perovskite over silicon or many other candidate replacements is that it forms extremely thin layers while still efficiently capturing solar energy. “Perovskite cells have the potential to be lightweight compared to silicon, by orders of magnitude,” Bawendi says.

Perovskites have a higher bandgap than silicon, which means they absorb a different part of the light spectrum and thus can complement silicon cells to provide even greater combined efficiencies. But even using only perovskite, Yoo says, “what we’re demonstrating is that even with a single active layer, we can make efficiencies that threaten silicon, and hopefully within punching distance of gallium arsenide. And both of those technologies have been around for much longer than perovskites have.”

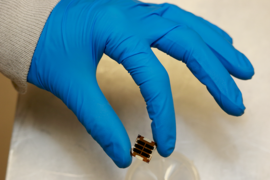

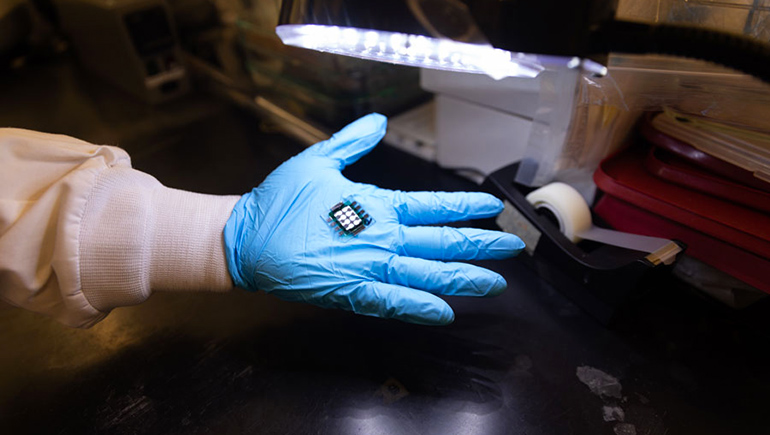

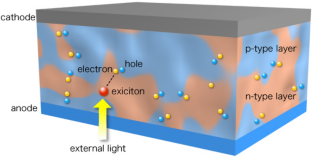

One of the keys to the team’s improvement of the material’s efficiency, Bawendi explains, was in the precise engineering of one layer of the sandwich that makes up a perovskite solar cell — the electron transport layer. The perovskite itself is layered with a transparent conductive layer used to carry an electric current from the cell out to where it can be used. However, if the conductive layer is directly attached to the perovskite itself, the electrons and their counterparts, called holes, simply recombine on the spot and no current flows. In the researchers’ design, the perovskite and the conductive layer are separated by an improved type of intermediate layer that can let the electrons through while preventing the recombination.

This middle electron transport layer, and especially the interfaces where it connects to the layers on each side of it, tend to be where inefficiencies occur. By studying these mechanisms and designing a layer, consisting of tin oxide, that more perfectly conforms with those adjacent to it, the researchers were able to greatly reduce the losses.

The method they use is called chemical bath deposition. “It’s like slow cooking in a Crock-Pot,” Bawendi says. With a bath at 90 degrees Celsius, precursor chemicals slowly decompose to form the layer of tin dioxide in place. “The team realized that if we understood the decomposition mechanisms of these precursors, then we’d have a better understanding of how these films form. We were able to find the right window in which the electron transport layer with ideal properties can be synthesized.”

After a series of controlled experiments, they found that different mixtures of intermediate compounds would form, depending on the acidity of the precursor solution. They also identified a sweet spot of precursor compositions that allowed the reaction to produce a much more effective film.

The researchers combined these steps with an optimization of the perovskite layer itself. They used a set of additives to the perovskite recipe to improve its stability, which had been tried before but had an undesired effect on the material’s bandgap, making it a less efficient light absorber. The team found that by adding much smaller amounts of these additives — less than 1 percent — they could still get the beneficial effects without altering the bandgap.

The resulting improvement in efficiency has already driven the material to over 80 percent of the theoretical maximum efficiency that such materials could have, Yoo says.

While these high efficiencies were demonstrated in tiny lab-scale devices, Bawendi says that “the kind of insights we provide in this paper, and some of the tricks we provide, could potentially be applied to the methods that people are now developing for large-scale, manufacturable perovskite cells, and therefore boost those efficiencies.”

In pursuing the research further, there are two important avenues, he says: to continue pushing the limits on better efficiency, and to focus on increasing the material’s long-term stability, which currently is measured in months, compared to decades for silicon cells. But for some purposes, Bawendi points out, longevity may not be so essential. Many electronic devices such as cellphones, for example, tend to be replaced within a few years anyway, so there may be some useful applications even for relatively short-lived solar cells.

“I don’t think we’re there yet with these cells, even for these kind of shorter-term applications,” he says. “But people are getting close, so combining our ideas in this paper with ideas that other people have with increasing stability could lead to something really interesting.”

Robert Hoye, a lecturer in materials at Imperial College London, who was not part of the study, says, “This is excellent work by an international team.” He adds, “This could lead to greater reproducibility and the excellent device efficiencies achieved in the lab translating to commercialized modules. In terms of scientific milestones, not only do they achieve an efficiency that was the certified record for perovskite solar cells for much of last year, they also achieve open-circuit voltages up to 97 percent of the radiative limit. This is an astonishing achievement for solar cells grown from solution.”

The team included researchers at the Korea Research Institute of Chemical Technology, the Korea Advanced Institute of Science and Technology, the Ulsan National Institute of Science and Technology, and Georgia Tech. The work was supported by MIT’s Institute for Soldier Nanotechnology, NASA, the Italian company Eni SpA through the MIT Energy Initiative, the National Research Foundation of Korea, and the National Research Council of Science and Technology.

Share this news article on:

Related links.

- Moungi Bawendi

- Vladimir Bulović

- Bawendi Group

- Department of Chemistry

- Department of Electrical Engineering and Computer Science

Related Topics

- Photovoltaics

- Electronics

- Nanoscience and nanotechnology

- Renewable energy

- Electrical engineering and computer science (EECS)

Related Articles

Experiments show dramatic increase in solar cell output

Quantum dots can spit out clone-like photons

Unleashing perovskites’ potential for solar cells

Nanoparticles open new window for biological imaging

Cheap, flexible solar

Previous item Next item

More MIT News

Helping robots zero in on the objects that matter

Read full story →

Where flood policy helps most — and where it could do more

MIT launches new Music Technology and Computation Graduate Program

New security protocol shields data from attackers during cloud-based computation

How social structure influences the way people share money

Mars’ missing atmosphere could be hiding in plain sight

- More news on MIT News homepage →

Massachusetts Institute of Technology 77 Massachusetts Avenue, Cambridge, MA, USA

- Map (opens in new window)

- Events (opens in new window)

- People (opens in new window)

- Careers (opens in new window)

- Accessibility

- Social Media Hub

- MIT on Facebook

- MIT on YouTube

- MIT on Instagram

- Newsletters

Super-efficient solar cells: 10 Breakthrough Technologies 2024

Solar cells that combine traditional silicon with cutting-edge perovskites could push the efficiency of solar panels to new heights.

- Emma Foehringer Merchant archive page

Beyond Silicon, Caelux, First Solar, Hanwha Q Cells, Oxford PV, Swift Solar, Tandem PV

3 to 5 years

In November 2023, a buzzy solar technology broke yet another world record for efficiency. The previous record had existed for only about five months—and it likely won’t be long before it too is obsolete. This astonishing acceleration in efficiency gains comes from a special breed of next-generation solar technology: perovskite tandem solar cells. These cells layer the traditional silicon with materials that share a unique crystal structure.

In the decade that scientists have been toying with perovskite solar technology , it has continued to best its own efficiency records, which measure how much of the sunlight that hits the cell is converted into electricity. Perovskites absorb different wavelengths of light from those absorbed by silicon cells, which account for 95% of the solar market today. When silicon and perovskites work together in tandem solar cells, they can utilize more of the solar spectrum, producing more electricity per cell.

Technical efficiency levels for silicon-based cells top out below 30%, while perovskite-only cells have reached experimental efficiencies of around 26%. But perovskite tandem cells have already exceeded 33% efficiency in the lab. That is the technology’s tantalizing promise: if deployed on a significant scale, perovskite tandem cells could produce more electricity than the legacy solar cells at a lower cost.

But perovskites have stumbled when it comes to actual deployment. Silicon solar cells can last for decades. Few perovskite tandem panels have even been tested outside.

The electrochemical makeup of perovskites means they’re sensitive to sucking up water and degrading in heat, though researchers have been working to create better barriers around panels and shifting to more stable perovskite compounds.

In May, UK-based Oxford PV said it had reached an efficiency of 28.6% for a commercial-size perovskite tandem cell, which is significantly larger than those used to test the materials in the lab, and it plans to deliver its first panels and ramp up manufacturing in 2024. Other companies could unveil products later this decade.

Climate change and energy

Your future air conditioner might act like a battery

New technologies store cooling power for when it’s needed most.

- Casey Crownhart archive page

This rare earth metal shows us the future of our planet’s resources

The story of neodymium reveals many of the challenges we’ll likely face across the supply chain in the coming century and beyond.

Why Microsoft made a deal to help restart Three Mile Island

A once-shuttered nuclear plant could soon return to the grid.

Andrew Ng’s new model lets you play around with solar geoengineering to see what would happen

The climate emulator invites you to explore the controversial climate intervention. I gave it a whirl.

- James Temple archive page

Stay connected

Get the latest updates from mit technology review.

Discover special offers, top stories, upcoming events, and more.

Thank you for submitting your email!

It looks like something went wrong.

We’re having trouble saving your preferences. Try refreshing this page and updating them one more time. If you continue to get this message, reach out to us at [email protected] with a list of newsletters you’d like to receive.

New solar cell breaks records for efficiency and voltage

- Nanotechnology

- Weinberg College

In the race to make solar energy more practical amidst soaring gas prices and threats of climate catastrophe, a team of researchers is taking steps toward a more efficient, higher-voltage solar cell.

Now, a Northwestern University, University of Toronto and the University of Toledo team is introducing in a new type of solar cell produced without silicon. Not only does the new cell have extremely high efficiency and record-setting voltage, it also bypasses the need for silicon, which is energetically costly to produce and purify.

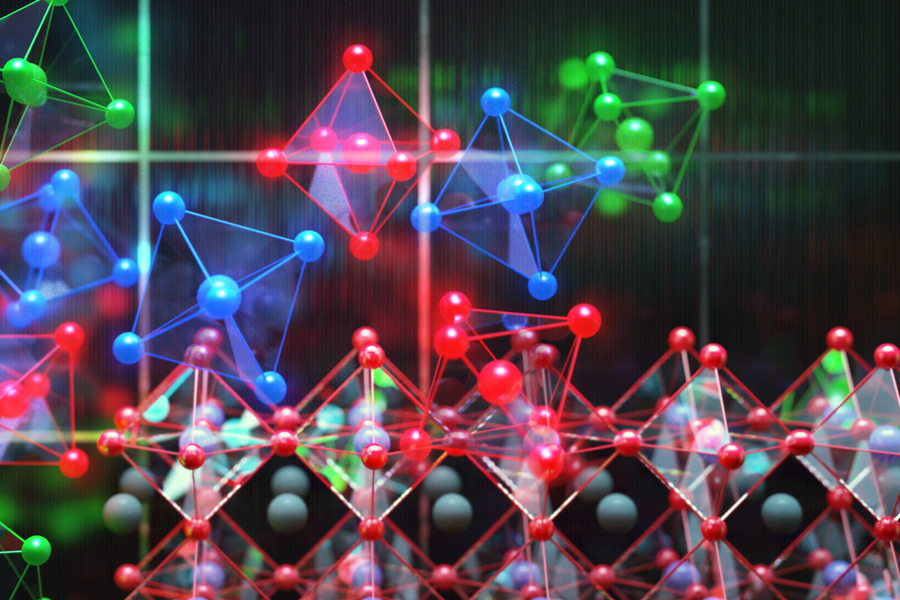

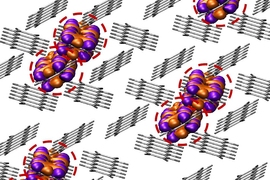

In a new paper published this week in Nature , the international team of researchers used two different layers of perovskites — a type of nanocrystal dispersed in a liquid and coated onto a surface using low-cost, well-established techniques. The researchers then tuned each perovskite layer to a different part of the solar spectrum, producing a tandem solar cell.

The team’s prototype solar cell measures one square centimeter in area and produces an open-circuit voltage of 2.19 electron volts, a record for all-perovskite tandem solar cells. Its power-conversion efficiency reached 27.4%, which also breaks the current record for traditional silicon solar cells .

“Further improvements in the efficiency of solar cells are crucial for the ongoing decarbonization of our economy,” said corresponding author Ted Sargent. “While silicon solar cells have undergone impressive advances in recent years, there are inherent limitations to their efficiency and cost, arising from material properties. Perovskite technology can overcome these limitations, but, until now, it had performed below its full potential. Our latest study identifies a key reason for this and points a way forward.”

Sargent joined Northwestern this fall as the Lynn Hopton Davis and Greg Davis Professor of Chemistry at the Weinberg College of Arts and Sciences and a professor of electrical and computer engineering in the McCormick School of Engineering.

By adjusting the thickness and chemical composition of the perovskite crystal films, manufacturers can selectively “tune” which wavelengths of light are absorbed and converted into electricity. This is a beneficial contrast to silicon, which always absorbs the same limited section of the solar spectrum.

“In our cell, the top perovskite layer absorbs well in the ultraviolet part of the spectrum, as well as some visible light,” said Chongwen Li, a postdoctoral researcher in Sargent’s lab and one of five co-first authors of the new paper. “The bottom layer has a narrow band gap, which is tuned more toward the infrared part of the spectrum. Between the two, we cover more of the spectrum than would be possible with silicon.”

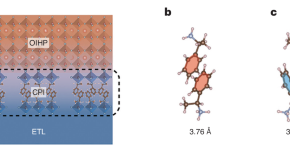

The tandem design enables the cell to produce a very high open-circuit voltage, which in turn improves its efficiency. But the key innovation came when the team analyzed the touchpoints between the perovskite layer, where light is absorbed and transformed into excited electrons, and the adjacent layer, known as the electron transport layer.

“What we found is that the electric field across the surface of the perovskite layer — we call it the surface potential — was not uniform,” co-lead author and Ph.D. student Aidan Maxwell said. “The effect of this was that in some places, excited electrons were moving easily into the electron transport layer, but, in others, electrons were being lost to the circuit.”

To address this challenge, the team coated the surface of the perovskite layer with a substance known as 1,3-propanediammonium (PDA).

“PDA has a positive charge, and it is able to even out the surface potential,” postdoctoral fellow Hao Chen said. “When we added the coating, we got much better energetic alignment of the perovskite layer with the electron transport layer, and that led to a big improvement in our overall efficiency.”

The cell was independently certified at the National Renewable Energy Laboratory in Colorado, delivering an efficiency of 26.3%. The team used industry standard methods to measure the stability of the new cell and found that it maintained 86% of its initial efficiency after 500 hours of continuous operation.

"Continuing to advance the efficiency and stability of next-generation solar cells is a crucial priority for decarbonizing the electricity supply,” said Professor Alberto Salleo, chair of the department of materials science and engineering at Stanford University, who was not involved in the study. “The team developed a deep chemical understanding of what was limiting a crucial interface in perovskite solar cells. These insights from basic science, acted on with innovative materials engineering strategies, will continue to drive the field forward.”

Next, the team hopes to scale their production for commercial use, further enhance the tandem cell’s efficiency and improve its stability.

“In this work, we’ve focused on the interface between the perovskite layer and the electron transport layer, but there is another important layer that extracts the ‘holes’ those electrons leave behind,” Sargent said. “One of the intriguing things in my experience with this field is that learning to master one interface doesn't necessarily teach you the rules for mastering the other interfaces. I think there's lots more discovery to be done.”

Maxwell said that the ability of perovskite technology to hold its own against silicon, even though the latter has had a multi-decade head start, is encouraging. The industry’s ability to incorporate new materials and diversify the products it offers will accelerate the economy toward decarbonization.

“In the last 10 years, perovskite technology has come almost as far as silicon has in the last 40,” Maxwell said. “Just imagine what it will be able to do in another 10 years.”

Additional reporting by Tyler Irving / University of Toronto Engineering.

Editor’s Picks

Northwestern faculty to speak at TEDxChicago

New biomaterial regrows damaged cartilage in joints, chronicling chicago, one column at a time, related stories.

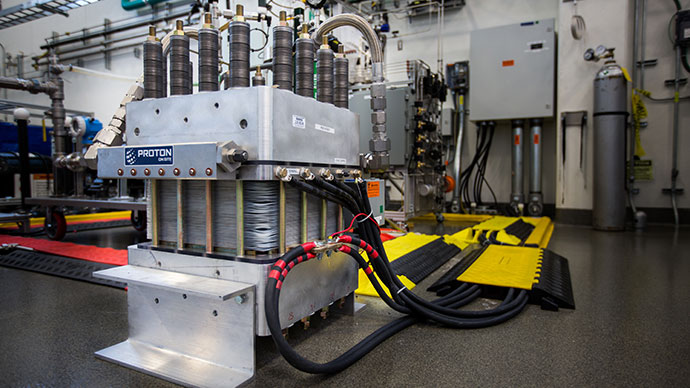

Researchers move closer to green hydrogen via water electrolysis

Deep-ocean floor produces its own ‘dark oxygen’, northwestern to lead midwestern carbon-capture hub.

To revisit this article, visit My Profile, then View saved stories .

- The Big Story

- Newsletters

- Steven Levy's Plaintext Column

- WIRED Classics from the Archive

- WIRED Insider

- WIRED Consulting

These Record-Breaking New Solar Panels Produce 60 Percent More Electricity

If you buy something using links in our stories, we may earn a commission. This helps support our journalism. Learn more . Please also consider subscribing to WIRED

THIS ARTICLE IS republished from The Conversation under a Creative Commons license .

The sight of solar panels installed on rooftops and large energy farms has become commonplace in many regions around the world. Even in the gray and rainy UK, solar power is becoming a major player in electricity generation.

This surge in solar is fueled by two key developments. First, scientists, engineers, and those in industry are learning how to make solar panels by the billions. Every fabrication step is meticulously optimized to produce them very cheaply. The second and most significant is the relentless increase in the panels’ power conversion efficiency—a measure of how much sunlight can be transformed into electricity.

The higher the efficiency of solar panels , the cheaper the electricity. This might make you wonder: Just how efficient can we expect solar energy to become? And will it make a dent in our energy bills?

Commercially available solar panels today convert about 20 to 22 percent of sunlight into electrical power. However, new research published in Nature has shown that future solar panels could reach efficiencies as high as 34 percent by exploiting a new technology called tandem solar cells. The research demonstrates a record power-conversion efficiency for tandem solar cells.

What Are Tandem Solar Cells?

Traditional solar cells are made using a single material to absorb sunlight. Currently, almost all solar panels are made from silicon—the same material at the core of microchips. While silicon is a mature and reliable material, its efficiency is limited to about 29 percent.

To overcome this limit, scientists have turned to tandem solar cells, which stack two solar materials on top of each other to capture more of the sun’s energy.

In the new Nature paper, a team of researchers at the energy giant LONGi has reported a new tandem solar cell that combines silicon and perovskite materials. Thanks to their improved sunlight harvesting, the new perovskite-silicon tandem has achieved a world record 33.89 percent efficiency.

Perovskite solar materials, which were discovered less than two decades ago , have emerged as the ideal complement to the established silicon technology. The secret lies in their light absorption tunability . Perovskite materials can capture high-energy blue light more efficiently than silicon.

In this way, energy losses are avoided and the total tandem efficiency increases. Other materials, called III-V semiconductors, have also been used in tandem cells and achieved higher efficiencies. The problem is they are hard to produce and expensive, so only small solar cells can be made in combination with focused light.

The scientific community is putting tremendous effort into perovskite solar cells. They have kept a phenomenal pace of development with efficiencies (for a single cell in the lab) rising from 14 percent to 26 percent in only 10 years. Such advances enabled their integration into ultra-high-efficiency tandem solar cells, demonstrating a pathway to scale photovoltaic technology to the trillions of watts the world needs to decarbonize our energy production.

The Cost of Solar Electricity

The new record-breaking tandem cells can capture an additional 60 percent of solar energy. This means fewer panels are needed to produce the same energy, reducing installation costs and the land (or roof area) required for solar farms.

It also means that power plant operators will generate solar energy at a higher profit. However, due to the way that electricity prices are set in the UK , consumers may never notice a difference in their electricity bills. The real difference comes when you consider rooftop solar installations where the area is constrained and the space has to be exploited effectively.

The price of rooftop solar power is calculated based on two key measures: first, the total cost to install solar panels on your roof, and second, how much electricity they will generate over 25 years of operation. While the installation cost is easy to obtain, the savings from generating solar electricity at home are a bit more nuanced. You can save money by using less energy from the grid, especially in periods when it is costly, and you can also sell some of your surplus electricity back to the grid. However, grid operators pay a very small price for this electricity, so sometimes it is more advantageous to use a battery and store the energy for use at night.

Using average considerations for a typical British household, I have calculated the cash savings to consumers using rooftop solar panels. If we can improve panel efficiency from 22 percent to 34 percent without increasing the installation cost, savings in electricity bills will rise from £558ְ ($747) per year up to £709 ($950) per year. A 27 percent bump in cash savings that would make solar rooftops extremely attractive, even in gray and cloudy Britain.

Tandem solar panels may become standard in the future—but scaling up production of these cells will be challenging.

So When Can We Buy These New Solar Panels?

As research continues, considerable efforts are being made to scale up this technology and ensure its long-term durability. The record-breaking tandem cells are made in laboratories and are smaller than a postage stamp. Translating such high performance to meter-square areas remains a vast challenge.

Yet we are making progress. Earlier this month, Oxford PV, a solar manufacturer at the forefront of perovskite technology, announced the first sale of its newly developed tandem solar panels. They have successfully tackled the challenges of integrating two solar materials and making durable and reliable panels. While they are still far from 34 percent efficiency, their work shows a promising route for next-generation solar cells.

Another consideration is the sustainability of the materials used in tandem solar panels. Extracting and processing some of the minerals in solar panels can be hugely energy-intensive . Besides silicon, perovskite solar cells require the elements lead, carbon, iodine, and bromine as components to make them work properly. Connecting perovskite and silicon also requires scarce materials containing an element called indium , so there is plenty of research still required to address these difficulties.

Despite the challenges, the scientific and industrial communities remains committed to developing tandem solar devices that could be integrated into almost anything—cars, buildings, and planes.

The recent developments toward high-efficiency perovskite-silicon tandem cells indicate a bright future for solar power, ensuring that solar continues to play a more prominent role in the global transition to renewable energy.

You Might Also Like …

In your inbox: The best and weirdest stories from WIRED’s archive

Elon Musk is a national security risk

Interview: Meredith Whittaker is out to prove capitalism wrong

How do you solve a problem like Polestar ?

Event: Join us for The Big Interview on December 3 in San Francisco

Recent advances in organic solar cells: materials, design, and performance

- Research Article

- Published: 12 July 2023

- Volume 53 , pages 1403–1419, ( 2024 )

Cite this article

- Ahmed Salih Mahdi 1 ,

- Lina M. Shaker 1 &

- Ahmed Alamiery ORCID: orcid.org/0000-0003-1033-4904 2 nAff3

1442 Accesses

7 Citations

Explore all metrics

Organic solar cells have emerged as promising alternatives to traditional inorganic solar cells due to their low cost, flexibility, and tunable properties. This mini review introduces a novel perspective on recent advancements in organic solar cells, providing an overview of the latest developments in materials, device architecture, and performance optimization. In contrast to existing literature, this review places a strong emphasis on the role of molecular engineering in achieving high power conversion efficiencies. It delves into the latest materials used in organic solar cells, including novel polymers and small molecules, showcasing their unique properties and potential for improved performance. Furthermore, the review explores cutting-edge device architectures, specifically tandem and multi-junction cells, which offer unprecedented opportunities for achieving higher efficiencies. The discussion on these advanced architectures highlights their potential and paves the way for future advancements in the field of organic solar cells. To maximize the performance of organic solar cells, this review also presents recent strategies for performance optimization, focusing on interface engineering, morphological control, and stability enhancement. By providing a comprehensive analysis of these strategies, the review enables readers to gain a deeper understanding of the underlying principles and techniques driving the improvement in device performance. By introducing this novel perspective on recent developments, this mini review offers researchers and practitioners a valuable resource for staying up-to-date with the latest advancements in organic solar cells. It not only presents the current state of the field but also identifies future directions and challenges, fostering further research and innovation in this rapidly evolving field.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Recent progress in organic solar cells (Part II device engineering)

A Review on “Designs and Fabrication” for the Next Generation of Organic Solar Cells Technology

Introduction to Organic Solar Cells

Explore related subjects.

Y. Zhang, L. Zuo, L. Ding, H. Wu, Organic solar cells based on small molecules. J. Mater. Chem. A 9 (9), 4942–4956 (2021)

Google Scholar

C.J. Brabec, S. Gowrisanker, J.J. Halls, D. Laird, S. Jia, S.P. Williams, Polymer–fullerene bulk-heterojunction solar cells. Adv. Mater. 22 (34), 3839–3856 (2010)

Article Google Scholar

P. Chaudhary, P. Kumar, P. Kumar, I. Kaur, Organic solar cells: a review on recent advances and challenges. Renew. Sustain. Energy Rev. 139 , 110686 (2021)

G. Li, R. Zhu, Y. Yang, Polymer solar cells. Nat. Photonics 6 (3), 153–161 (2012)

Article ADS Google Scholar

F.C. Krebs, Fabrication and processing of polymer solar cells: a review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 93 (4), 394–412 (2009)

Z. He, B. Xiao, F. Liu, H. Wu, Y. Yang, S. Xiao, Y. Cao, single-junction polymer solar cells exceeding 10% power conversion efficiency. Adv. Mater. 27 (6), 1035–1041 (2015)

Y. Chang, C. Chu, Y. Yang, X. Gong, Recent advances in roll-to-roll fabrication of polymer solar cells. Adv. Mater. 26 (36), 6342–6363 (2014)

Y. Liang, Z. Xu, J. Xia, S.T. Tsai, Y. Wu, G. Li, Y. Yang, For the bright future-bulk heterojunction polymer solar cells with power conversion efficiency of 7.4%. Adv. Mater. 22 (20), E135–E138 (2010)

J. Hou, O. Inganäs, R.H. Friend, F. Gao, Organic solar cells based on non-fullerene acceptors. Nat. Mater. 17 (2), 119–128 (2018)

X. Chen, X. Guo, S. Zhang, Y. Li, F. Liu, L. Huo, Y. Yang, Ladder-type polymer PT-TQBD enables efficient solar cells with a very low energy loss. Nat. Energy 3 (5), 422–427 (2018)

ADS Google Scholar

W. Zhao, S. Li, H. Yao, S. Zhang, Y. Zhang, B. Yang, J. Hou, Molecular optimization enables over 13% efficiency in organic solar cells. J. Am. Chem. Soc. 139 (21), 7148–7151 (2017)

G. Li, Y. Yang, P. Smith, High-efficiency solution processable polymer photovoltaic cells by self-organization of polymer blends. Nat. Mater. 4 (11), 864–868 (2005)

L. Ye, Y. Xiong, W. Li, S. Li, Y. Wu, J. Hou, High-performance multiple-donor bulk heterojunction solar cells. Nat. Photonics 9 (10), 662–667 (2015)

J. Kim, S. Hong, K. Lee, H. Kang, H. Kim, T.W. Lee, Versatile non-fullerene acceptors for organic photovoltaics. Nat. Commun. 9 (1), 1–11 (2018)

B. Kan, H. Feng, X. Wan, X. Liu, W. Ni, S. Yang, Y. Wang, C. Li, L. Feng, Y. Chen et al., A series of simple oligomer-like small molecules based on diketopyrrolopyrrole for solution-processed solar cells with high efficiency. J. Am. Chem. Soc. 136 (42), 15529–15532 (2014)

L. Mao, Z. Xie, L. Wang, F. Xie, H. Chen, Zinc phthalocyanine/C60 bilayer heterojunction photovoltaic devices. Appl. Phys. Lett. 89 (9), 093504 (2006)

Y. Li, L. Ye, W. Zhao, S. Li, S. Zhang, S. Mukherjee, H. Ade, J. Hou, A molecular nematic liquid crystalline material for high-performance organic photovoltaics. Nat. Commun. 9 (1), 1–9 (2018)

Z. He, C. Zhong, S. Su, M. Xu, H. Wu, Y. Cao, Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat. Photonics 6 , 591–595 (2012)

Y. Liu, Y. Chang, C. Chao, C. Wang, W. Lee, H. Chen, A.J. Heeger, A high-mobility electron-transporting polymer for printed transistors. Nature 466 , 622–626 (2010)

Y. Lin, F. Zhao, Y. Wu, K. Jiang, J. Zhu, H. Ade, H. Yan, A chlorinated acceptor for high-efficiency organic photovoltaics. Nat. Energy 3 , 748–754 (2018)

F. Liu, M. Zhang, Y. Yang et al., Aggregation and morphology control enables multiple cases of high-efficiency polymer solar cells. Nat. Commun. 10 , 1095 (2019)

Y. Zhang, X. Zhan, Non-fullerene acceptors for organic solar cells. Nat. Rev. Mater. 2 , 190838 (2019)

N. Gasparini, T. Näreoja, D. Pankov et al., 3D molecular ordering of a high-performance solution-processed small-molecule organic semiconductor. Nat. Mater. 15 , 999–1005 (2016)

C. Yan, S. Barlow, Z. Wang et al., Non-fullerene acceptor with low energy loss for organic solar cells with efficiency over 16%. Nat. Commun. 9 , 5357 (2018)

G. Li, V. Shrotriya, J. Huang et al., High-efficiency solution processable polymer photovoltaic cells by self-organization of polymer blends. Nat. Mater. 4 , 864–868 (2005)

Y. Yang, Z. Zhang, H. Bin et al., Over 16% efficiency organic photovoltaic cells enabled by a chlorinated acceptor with increased open-circuit voltages. Nat. Commun. 7 , 13751 (2016)

S. Zhang, L. Ye, J. Hou, A wide bandgap polymer with a deep HOMO level enables 14.2% efficiency in polymer solar cells. J. Am. Chem. Soc. 139 , 2387–2390 (2017)

Y. Lin, X. Zhan, Y. Yang, Non-fullerene acceptors for organic solar cells. Nat. Rev. Mater. 3 , 18003 (2018)

M. Zhang, Y. Wang, T. Zhang, Z. Ling, J. Liu, L. Feng, X. Guo, Z. Wei, W. Ma, A non-fullerene acceptor with superior properties: wide-bandgap, low-LUMO, and high mobility. Angew. Chem. Int. Ed. 57 , 14717–14721 (2018)

C.J. Brabec, S. Gowrisanker, J.J.M. Halls, D. Laird, S. Jia, S.P. Williams, Polymer-fullerene bulk-heterojunction solar cells. Adv. Mater. 22 , 3839–3856 (2010)

C.J. Brabec, N.S. Sariciftci, J.C. Hummelen, Plastic solar cells. Adv. Funct. Mater. 11 , 15–26 (2001)

M.A. Green, K. Emery, D.L. King, S. Igari, W. Warta, Solar cell efficiency tables (version 37). Prog. Photovolt. 19 , 84–107 (2011)

Z. He, C. Zhong, S. Su, M. Xu, H. Wu, W. Cao, Y. Huang, Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Adv. Mater. 24 , 1740–1743 (2012)

L. Hu, M. Wu, G. Wang, X. Zhou, Y. Liu, Y. Ma, X. Yang, Y. Cao, Polymeric photovoltaic cells based on conjugated polymers incorporating palladium or platinum complex units. Adv. Mater. 23 , 1482–1486 (2011)

Y. Cui, H. Yao, T. Zhang, Y. Wang, K. Xian, Y. Xu, L. Hong, J. Wei, C. An, J. Hou, Y. Li, Y. Chen, High-performance tandem organic solar cells with complementary absorption bands. Nat. Commun. 9 , 2572 (2018)

S. Chen, E. Mosconi, Y. Fang, M. Xiao, H. Wang, Y. Zhou, Y. Zhao, Y. Gao, J. Huang, Perovskite/perovskite tandem solar cells. Nat. Mater. 17 , 703–709 (2018)

X. Yang, P. Cheng, L. Wang, G. Zhou, W. Ma, J. Zhao, H. Ade, H. Yan, F. Gao, Triple-junction polymer solar cells incorporating both fluorescence and phosphorescence. Adv. Energy Mater. 9 , 1900808 (2019)

H. Yao, Y. Chen, Design and synthesis of a low-bandgap small molecule acceptor for efficient polymer solar cells with high open-circuit voltage. Energy Environ. Sci. 11 , 1898–1904 (2018)

M.A. Green, A. Ho-Baillie, Tandem solar cells: review of design principles and roadmap to commercialization. npj Flex Electron. 1 , 1–12 (2017)

S. Albrecht, C.J. Brabec, Tandem solar cells: the frontier of crystalline silicon photovoltaics. Adv. Mater. 29 , 1606480 (2017)

J.F. Geisz, D.J. Friedman, J.S. Ward, W. Olavarria, I. Garcia, M.A. Steiner, T. Moriarty, J.T. Kiehl, M.J. Romero, Progress toward 50% efficiency for mechanically stacked multijunction solar cells. IEEE J. Photovolt. 7 (6), 1487–1494 (2017)

U. Würfel, S. Rein, Tandem Solar Cells: Fundamentals, Design, and Applications (John Wiley & Sons, New York, 2015)

O.D. Miller, C. Xu, G.J. Rey, P. Ireland, D. Johnstone, E.C. Warmann, M.L. Lee, M.A. Green, K.R. Catchpole, Cost-effective four-terminal perovskite-silicon tandem solar cells enabling ultrahigh efficiency. Joule 4 , 510–522 (2020)

M. Dupuis, E.E. Looney, Multi-junction and tandem solar cells for space applications, in 2019 IEEE Aerospace Conference , IEEE, pp 1–16 ( 2019)

W. Li, A. Furlan, K.H. Hendriks, Material science of organic solar cells. Adv. Energy Mater. 6 (20), 1600377 (2016)

P. Cheng, X. Zhan, Y. Wu, Interface engineering for organic electronics. Adv. Mater. 30 (39), 1707005 (2018)

N. Li, C.J. Brabec, Air-stable and efficient tandem organic solar cells based on zinc phthalocyanine and a fullerene derivative. Adv. Energy Mater. 9 (5), 1802989 (2019)

S. Li, F. Liu, T.P. Russell, Solution-processed semiconducting polymer bulk heterojunctions: from morphology control to improved electronic performance. Acc. Chem. Res. 49 (11), 2199–2207 (2016)

F. De Rossi, A. Giuri, V. D’Innocenzo, A. Luzio, G. Grancini, A. Petrozza, Light management in organic solar cells. Chem. Soc. Rev. 49 (13), 4533–4553 (2020)

A. Facchetti, π-Conjugated polymers for organic electronics and photovoltaic cell applications. Chem. Mater. 23 (3), 733–758 (2011)

I. Salzmann, G. Heimel, Interface engineering in organic field-effect transistors. Chem. Rev. 116 (23), 13714–13751 (2016)

S. Liu, S. Wang, H. Zhou, Interface engineering of metal oxide electrodes for high-performance energy storage devices. Energy Storage Mater. 21 , 291–308 (2019)

Z. Li, J. Song, M. Sun, X. Hu, W. Zhu, Morphology control of organic solar cells by mixed solvent towards high performance. Org. Electron. 64 , 44–51 (2019)

L. Zhou, K. Zhou, J. Wang, W. Ma, H. Zhang, Polymer additives for efficient organic solar cells: recent developments and future prospects. Adv. Mater. 30 (42), 1802102 (2018)

N. Li, F. Zhang, C. Liu, X. Zhan, Efficient and stable polymer solar cells based on a polymer encapsulation strategy. ACS Appl. Mater. Interfaces 10 (3), 2433–2440 (2018)

C. Cui, C. Li, J. Zhang, Y. Wang, Z. Liu, Y. Li et al., Enhancing stability and efficiency of organic solar cells through the molecular engineering of an alkylated indacenodithienothiophene-based donor. J. Mater. Chem. A 8 (3), 1423–1431 (2020)

Z. Li, Y. Lin, W. Li, P. Cheng, F. Liu, X. Hu et al., A chlorinated acceptor with improved electron mobility and stability for high-performance organic solar cells. Adv. Mater. 29 (19), 1605658 (2017)

Y. Zhou, C. Fuentes-Hernandez, T.M. Khan, J. Liu, J. Hsu, J. Shim et al., Efficient and stable large-area perovskite solar cells with inorganic charge extraction layers. Science 363 (6422), 265–270 (2019)

Y. Li, Z. Zhao, H. Li, J. Fang, Y. Liu, Y. Zhang et al., Spray-coating fabrication of efficient organic solar cells with enhanced uniformity and reproducibility. Sol. Energy Mater. Sol. Cells 209 , 110464 (2020)

W. Li, Y. Zhang, J. Zhao, Interface engineering for organic electronics. Adv. Mater. 29 (7), 1602546 (2017)

Z. Li et al., A star-shaped electron acceptor with alkylthio side chains for efficient organic solar cells with reduced energy loss. J. Mater. Chem. A 7 (28), 16843–16849 (2019)

W. Liu et al., Efficient and stable organic solar cells based on an n-type small molecule acceptor with a high electron mobility. J. Mater. Chem. A 8 (29), 14402–14410 (2020)

G. Zhang et al., Polymer acceptors with minimized absorption overlap for efficient organic solar cells with high stability. Energy Environ. Sci. 14 (2), 1113–1123 (2021)

H. Zhou et al., A polymer tandem solar cell with 10.6% power conversion efficiency. Nat. Commun. 5 , 1–8 (2014)

M. Saliba et al., Cesium-containing triple cation perovskite solar cells: improved stability, reproducibility and high efficiency. Energy Environ. Sci. 9 (6), 1989–1997 (2016)

A. Abate, T. Leijtens, S. Pathak, H.J. Snaith, Tandem solar cells: advances and challenges. Nat. Energy 5 (7), 596–605 (2020)

P. Pandit, A. Chandak, P. Shrivastava, Environmental effects on the performance of solar photovoltaic systems: a review. Energy Convers. Manage. 233 , 113758 (2021)

L.M. Shaker, A.A. Al-Amiery, W.K. Al-Azzawi, A clearer vision: a mini-review on contact lenses. J. Opt. (2023). https://doi.org/10.1007/s12596-023-01222-w

L.M. Shaker, W.K. Al-Azzawi, A. Al-Amiery, M.S. Takriff, W.N.R. Wan Isahak, Highly transparent antibacterial hydrogel-polymeric contact lenses doped with silver nanoparticles. J. Vinyl Addit. Technol. (2023). https://doi.org/10.1002/vnl.21995

L.M. Shaker, S. Abdulhadi, W.K. Al-Azzawi, A. Alamiery, M.S. Takriff, W.N.R.W. Isahak, Colorless poly (vinyl pyrrolidone) hydrogel contact lenses synergized with silver nanoparticles. J. Opt. (2023). https://doi.org/10.1007/s12596-023-01176-z

L.M. Shaker, A.A. Alamiery, M. Takriff, W.N.R. Wan Isahak, Nano-titanium oxide in polymeric contact lenses. Nanomanufacturing 2 (3), 71–81 (2022)

L.M. Shaker, A. Alamiery, M. Takriff, W.N.R. Wan Isahak, Novel Blue-wavelength-blocking contact lens with Er 3+ /TiO 2 NPs: manufacture and characterization. Nanomaterials 11 (9), 2190 (2022)

L.M. Shaker, A. Al-Adili, A.A. Al-Amiery, Human eye response to the iris diameter variation at polychromatic light programmatically. J. Phys: Conf. Ser. 1795 (1), 012025 (2021)

S.L.M. Shaker, S. Osamah, A.A. Al-Amiery, ingle-mode optical fibers coupling: study of the field of view. IOP Conf. Series: Mater. Sci. Eng. 1045 (1), 012009 (2021)

L.M. Shaker, A.A. Al-Amiery, A.A.H. Kadhum, M.S. Takriff, Manufacture of contact lens of nanoparticle-doped polymer complemented with zemax. Nanomaterials 10 (10), 2028 (2020)

L.M. Shaker, A.H. Al-Hamdani, A.A. Al-Amiery, Vision improvement using titanium dioxide nanoparticles-doped PMMA for contact lenses. Eng. Technol. J. 38 (5), 681–689 (2020)

L.M. Shaker, A.H. Al-Hamdani, A.A. Al-Amiery, Nano-particle doped polymers to improve contact lenses optical quality. Int. J. Nanoelectron. Mater. 13 (1), 1–12 (2020)

L.M. Shaker, A.H. Al-Hamdani, A.A. Al-Amiery, A comparative study of optical quality for different polymeric contact lenses. J. Phys: Conf. Ser. 1234 (1), 012042 (2020)

L.M. Shaker, A.H. Al-Hamdani, A.A. Al-Amiery, Plastic materials for modifying the refractive index of contact lens overview. Res. Dev. Mater. Sci. 11 , 2–1 (2019)

Download references

Author information

Ahmed Alamiery

Present address: Department of Chemical and Process Engineering, Faculty of Engineering and Built Environment, University Kebangsaan Malaysia (UKM), P.O. Box 43000, Bangi, Selangor, Malaysia

Authors and Affiliations

Research Energy Department, Training and Research Office, Baghdad, 10001, Iraq

Ahmed Salih Mahdi & Lina M. Shaker

Energy and Renewable Energies Technology Center, University of Technology, Baghdad, 10001, Iraq

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Ahmed Alamiery .

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Mahdi, A.S., Shaker, L.M. & Alamiery, A. Recent advances in organic solar cells: materials, design, and performance. J Opt 53 , 1403–1419 (2024). https://doi.org/10.1007/s12596-023-01262-2

Download citation

Received : 12 May 2023

Accepted : 03 June 2023

Published : 12 July 2023

Issue Date : April 2024

DOI : https://doi.org/10.1007/s12596-023-01262-2

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Organic solar cells

- Optimization

- Roll-to-roll printing

- Spray-coating

- Find a journal

- Publish with us

- Track your research

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Journal Proposal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Photovoltaic solar cells: a review.

1. Introduction

2. solar cells, 2.1. the working principle of pv cells.

- Absorption of photons in a p-n junction electronic semiconductor to generate the charge carriers (electron-hole pairs). The absorption of a photon with energy (E = hυ) higher than the gap energy ‘E g ’ of the doped semiconductor material means that its energy is used to excite an electron from the valence band ‘Eυ’ to the conduction band ‘E c ’ leaving a void (hole) at the valance level. Additional kinetic energy is given to the electron or hole by the excess photon energy (hυ–hυ 0 ). ‘hυ 0 ′ is the minimum energy or work function of the semiconductor required to generate an electron-hole pair. The work function here represents the energy gap. The excess energy is dissipated as heat in the semiconductor [ 21 , 22 ].

- Consequent separation of the light-generated charge carriers. In an external solar circuit, the holes can flow away from the junction through the p-region, and electrons can flow out across the n-region and pass through the circuit before they recombine with the holes.

- Finally, the separated electrons can be used to drive an electric circuit. After the electrons passed through the circuit, they will recombine with the holes.

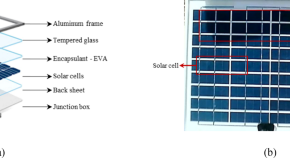

2.2. Solar Cell Panels

2.3. components of solar power system, 2.4. p-n junction solar cell, 2.4.1. formation of the depletion region, 2.4.2. p-n junction solar cell under applied voltage, 2.4.3. pv cell under illumination.

- The net flow of the electrons and holes in a p-n junction semiconductor under equilibrium conditions will generate two currents: ‘ I diff ’ and ‘ I drift ’. These currents balance and cancel each other at the equilibrium state.

- If an external source is deployed to the p-n junction, the generated current is the diode current ‘ I d ’.

- Under illumination, the p-n junction will present another current called light or photocurrent ‘ I ph ’.

2.5. I-V and P-V Characteristics

- Short-circuit current density ‘ Isc ’ occurs at (R = 0 and V = 0)

- Open-circuit voltage ‘ Voc ’ (no-load, I = 0 and R = ∞)

- Fill factor ‘ FF ’ that represents the ratio of ‘ Pmax ’ to the electrical output of ‘ Voc ’ and ‘ Isc ’

2.6. Design Considerations

2.7. materials employed in pv cells, 2.7.1. iii-v pv gallium arsenide, 2.7.2. future trends, 2.8. challenges in solar cells, 3. simulation of solar cells and modules, 3.1. simulation of solar cells by matlab/simulink, 3.2. simulation of solar cells by comsol/multiphysics.

- Creating a user-defined, spatially dependent variable for the generation rate, using an integral expression involving the solar radiation ‘ F ( λ )’, which is used to find the rate of photon generation ‘ ϕ ( λ )’.

Share and Cite

Al-Ezzi, A.S.; Ansari, M.N.M. Photovoltaic Solar Cells: A Review. Appl. Syst. Innov. 2022 , 5 , 67. https://doi.org/10.3390/asi5040067

Al-Ezzi AS, Ansari MNM. Photovoltaic Solar Cells: A Review. Applied System Innovation . 2022; 5(4):67. https://doi.org/10.3390/asi5040067

Al-Ezzi, Athil S., and Mohamed Nainar M. Ansari. 2022. "Photovoltaic Solar Cells: A Review" Applied System Innovation 5, no. 4: 67. https://doi.org/10.3390/asi5040067

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

Journal of Materials Chemistry A

Advanced research trends in dye-sensitized solar cells.

* Corresponding authors

a Microelectronics Research Unit, Faculty of Information Technology & Electrical Engineering, University of Oulu, P. O. Box 4500, Finland E-mail: [email protected]

b Nano and Molecular Systems Research Unit, University of Oulu, Finland

c Optoelectronics and Measurement Techniques Research Unit, Faculty of Information Technology and Electrical Engineering, University of Oulu, Oulu, Finland

d Center for Ubiquitous Computing, Department of Information Technology and Electrical Engineering, University of Oulu, Finland

e New Energy Technologies Research Group, Department of Applied Physics, Aalto University, P.O. Box 15100, Aalto, Finland

f BCMaterials-Basque Center for Materials, Applications and Nanostructures, UPV/EHU Science Park, Leioa, Spain

g IKERBASQUE, Basque Foundation for Science, Bilbao, Spain

h Department of Chemistry, Ångström Laboratory, Uppsala University, P. O. Box 523, 75120 Uppsala, Sweden

Dye-sensitized solar cells (DSSCs) are an efficient photovoltaic technology for powering electronic applications such as wireless sensors with indoor light. Their low cost and abundant materials, as well as their capability to be manufactured as thin and light-weight flexible solar modules highlight their potential for economic indoor photovoltaics. However, their fabrication methods must be scaled to industrial manufacturing with high photovoltaic efficiency and performance stability under typical indoor conditions. This paper reviews the recent progress in DSSC research towards this goal through the development of new device structures, alternative redox shuttles, solid-state hole conductors, TiO 2 photoelectrodes, catalyst materials, and sealing techniques. We discuss how each functional component of a DSSC has been improved with these new materials and fabrication techniques. In addition, we propose a scalable cell fabrication process that integrates these developments to a new monolithic cell design based on several features including inkjet and screen printing of the dye, a solid state hole conductor, PEDOT contact, compact TiO 2 , mesoporous TiO 2 , carbon nanotubes counter electrode, epoxy encapsulation layers and silver conductors. Finally, we discuss the need to design new stability testing protocols to assess the probable deployment of DSSCs in portable electronics and internet-of-things devices.

- This article is part of the themed collections: Journal of Materials Chemistry A Recent Review Articles , Journal of Materials Chemistry A HOT Papers and 2021 Journal of Materials Chemistry A most popular articles

Article information

Download Citation

Permissions.

M. Kokkonen, P. Talebi, J. Zhou, S. Asgari, S. A. Soomro, F. Elsehrawy, J. Halme, S. Ahmad, A. Hagfeldt and S. G. Hashmi, J. Mater. Chem. A , 2021, 9 , 10527 DOI: 10.1039/D1TA00690H

This article is licensed under a Creative Commons Attribution 3.0 Unported Licence . You can use material from this article in other publications without requesting further permissions from the RSC, provided that the correct acknowledgement is given.

Read more about how to correctly acknowledge RSC content .

Social activity

Search articles by author, advertisements.

IEEE Account

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

How NASA Uses and Improves Solar Power

The sun is the most energetic object in our solar system ..

Humans have been finding creative ways to harness the Sun's heat and light for thousands of years. But the practice of converting the Sun’s energy into electricity — what we now call solar power — is less than 200 years old. Yet in that short time, solar power has revealed the Sun’s limitless potential to power an increasingly technological society. Since the 1950s, NASA has harnessed the energy of the Sun to power spacecraft and drive scientific discovery across our solar system. Today, NASA continues to advance solar panel technology and test new innovations. Video credit: NASA's Goddard Space Flight Center/Lacey Young

A Brief History of Solar Power

Even before the light bulb, scientists had inklings of the power locked up in a ray of sunlight.

In 1839, French scientist Alexandre Edmond Becquerel (who was 19 at the time) was working in his father’s laboratory, experimenting with two metal sheets placed in an electricity-conducting liquid. As he shined light on the device, he detected a weak electric current — what we now know to be a flow of electrons through the material. This phenomenon was the first demonstration that light could generate electricity, known today as the photovoltaic effect.

In 1872, scientists discovered the first solid material — selenium — that could pass an electrical current.

By 1884 selenium had been incorporated in the world’s first solar array, which was installed on a New York City rooftop. Scientists continued to develop and experiment with selenium and other photovoltaic materials for the next 70 years, but practical applications were limited by their low efficiency – only about 1% of light energy could be converted to electricity.

A breakthrough came in 1954.

That's when scientists at Bell Labs used an abundant material called silicon to create the first solar cell that achieved 6% efficiency. Solar panels today use this same basic design, with adjustments that have allowed industrial and commercial solar panels to achieve between 15% and 23% efficiency.

How Solar Panels Work

Silicon is an abundant material used in many technological applications because it is a very good “semiconductor,” or material whose ability to carry electric current can be easily manipulated by adding energy. In typical solar cells, silicon is layered in three thin sheets. A middle layer is made of pure silicon. The outer two silicon layers are injected with other elements (typically phosphorous on one side, and boron on the other) that differ in their capacity to “donate” or “accept” electrons. As light strikes the pure silicon layer, it energizes the silicon’s electrons, which then begin to move within the material. Those electrons are attracted to the silicon layer designed to “accept” electrons, leading to a buildup of negative and positive charges in the outer layers. These two sides are then connected with wires to form a circuit that facilitates the flow of electrons from one side to the other, generating usable power.

Silicon-based solar cells power many of NASA’s spacecraft, including the James Webb Space Telescope. Learn more about why this abundant material is used in solar panels in this excerpt from NASA’s Elements of Webb video series.

Solar Power in Space

A mere four years after the first viable solar cells were created, they made their way to space.

The Soviet Union kicked off the space race with the launch of Sputnik on Oct. 4, 1957, quickly followed by the United States’ Explorer 1 on Jan. 31, 1958. But as both satellites ran exclusively on battery power, they were dead within a few weeks. In March 1958, the United States launched the first solar-powered spacecraft, Vanguard 1 (pictured at right), which transmitted data for the next six years.

Solar cells became the de facto way to power spacecraft, and remain so today.

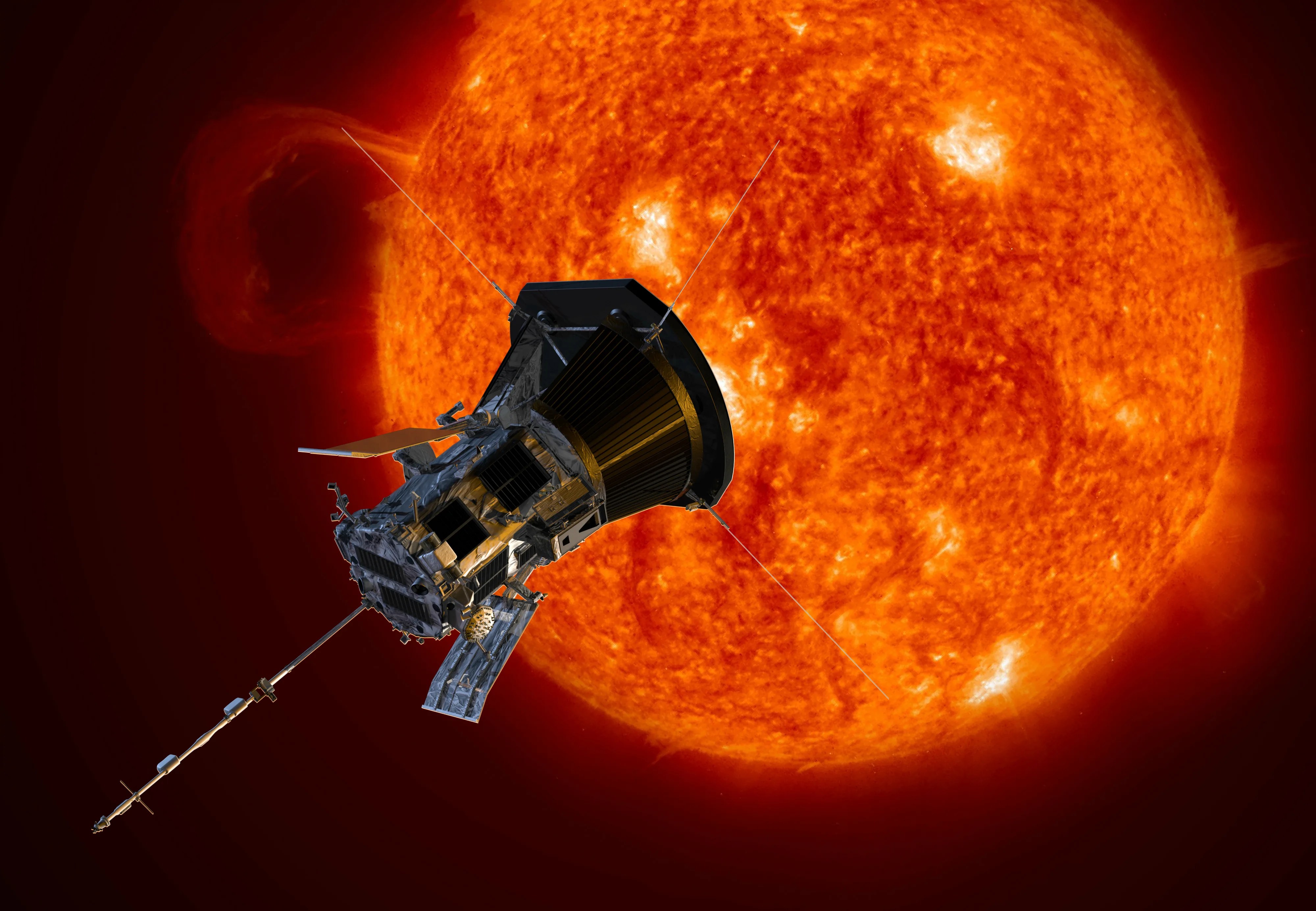

Some missions, such as NASA’s Parker Solar Probe, require specialized solar panels that can operate in extreme environments. Flying on an elliptical orbit into the Sun’s hot outer atmosphere, Parker Solar Probe uses solar panels angled away and partially shaded from the Sun. It also uses a special cooling system to ensure the system isn’t overwhelmed by heat and was designed to be extra robust to deal with the intense ultraviolet rays it receives when close to the Sun, which can degrade materials rapidly. The spacecraft’s elliptical orbit also takes it far from the Sun, even beyond Venus. Engineers designed the solar array to compensate for how the light changes at different distances to the Sun, which alters the color and intensity of the sunlight it receives.

But sunlight drops dramatically with distance.

At Jupiter, which receives 25 times less light than Earth, the Juno spacecraft (pictured at right) needs three 30-foot-long panels to generate 500 watts of energy — about how much a typical refrigerator uses. Its orbit around Jupiter also helps keep the solar panels almost constantly exposed to sunlight to maximize power generation. Solar power becomes less viable for missions that venture even farther, where there’s not even enough light to charge a battery. Deep space missions like NASA’s Voyager 1 and 2 rely instead on energy from the radioactive decay of plutonium-238 to keep them running well into interstellar space.

How NASA is Improving Solar Power

Perovskites for improved efficiency.

NASA scientists and other researchers around the world are working to improve the efficiency and durability of solar panels. In addition to using silicon, scientists have discovered that adding a layer of minerals known as perovskites can dramatically improve panel efficiency. Perovskites help capture bluer visible wavelengths, complimenting silicon’s redder wavelength coverage and allowing a solar cell to capture more light. In 2023, several independent research teams created small perovskite-silicon solar cells that exceeded 30% efficiency, and the best experimental cells today are approaching 50% efficiency.

ROSAs for Flexibility

NASA is also developing technology for flexible and rollable solar panels that can improve their use in constrained spaces. Using different materials for the base layer of a solar panel can make a panel lighter and more flexible — essential attributes for space missions that need to be packed into a small space in a rocket. The first two sets of solar arrays used by NASA’s Hubble Space Telescope in the 1990s and 2000s were designed with solar cells mounted to a flexible blanket-like material so they could be rolled up and stowed to fit inside the space shuttle cargo bay for launch. In 2009, NASA and its partners started working on the next iteration of flexible solar panels called roll-out solar arrays (ROSAs). These arrays, which unfurl like a roll of paper towels, are even lighter and more affordable than previous arrays. They have been used on NASA’s DART (Double Asteroid Redirection Test) mission, on commercial geostationary satellites, and on the International Space Station to augment its traditional solar array. NASA plans to include ROSAs on Gateway, an orbiting outpost crucial to NASA’s Artemis campaign.

Vertical Arrays for Lunar Applications

NASA is also involved with envisioning the next generation of solar power usage in space. To advance the Artemis campaign, NASA tasked three companies with developing and building prototypes of vertical deployable solar array systems to power human and robotic exploration of the Moon. Most space solar array structures are designed to be used horizontally, but on the Moon, vertically oriented structures atop tall masts will be needed to maximize sunlight collection at the lunar poles, where the Sun stays close to the horizon. Scientists are also investigating the feasibility of space-based solar power, which would collect sunlight from space and beam the energy back to Earth, potentially serving remote locations across the planet to supplement power transmission infrastructure on the ground.

The Future of Solar Power in Space

Sailing with the sun.

Along with working to improve the efficiency of solar panels, NASA is also looking beyond photovoltaics to an old technology: sails. Humans have crossed open waters by sail for thousands of years. And now, NASA is working on a system to traverse space using solar sails. Unlike photovoltaics, which work by capturing the energy of light, solar sails use the pressure of light. When a photon, or individual particle of light, bounces off a reflective solar sail, it imparts a small push. With enough photons, these tiny nudges can move an entire spacecraft, much like how traditional sails harness the multitude of tiny air molecules that make up the wind. In the future, solar sails could replace heavy propulsion systems and enable longer-duration and lower-cost missions.

The Advanced Composite Solar Sail System

In 2024, the Advanced Composite Solar Sail System, a microwave-sized spacecraft, launched to test a new composite boom — a sail’s framework — made from materials that are stiffer and lighter than previous boom designs. The spacecraft has a solar sail measuring about 860 square feet — about the size of six parking spots. The seven-meter-long boom that holds out the solar sail can collapse into a bundle that would fit in your hand, which allowed it to fit compactly inside the spacecraft. The mission demonstrated the boom’s deployment and is now testing the sail’s performance using a series of maneuvers to adjust the spacecraft orbit using the sail angle. The technology could eventually allow for future sails up to half the size of a soccer field, enabling travel to the Moon, Mars, and beyond.

Explore NASA's Sun-related stories and download high-resolution images of the solar system, agency missions, and more.

Advanced Composite Solar Sail System (ACS3)

Just as a sailboat is powered by wind in a sail, solar sails employ the pressure of sunlight for propulsion, eliminating the need for conventional rocket propellant.

Oct. 2 Annular Solar Eclipse

On Oct. 2, 2024, the Moon will pass in front of the Sun, casting its shadow across parts of Earth.

Our closest star is so much more than meets the eye.

Related Terms

- Heliophysics

- Heliophysics Division

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

Solar energy articles from across Nature Portfolio

Related subjects.

- Artificial photosynthesis

- Photovoltaics

- Solar fuels

- Solar thermal energy

- Thermophotovoltaics

Latest Research and Reviews

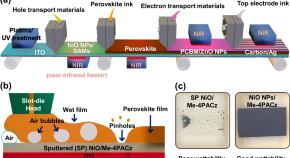

Influence of interfacial roughness on slot-die coatings for scaling-up high-performance perovskite solar cells

Slot-die coating is promising for the large-scale and low-cost manufacture of perovskite solar cells. Here, the effect of wettability of the hole transport layer is investigated, finding that increased surface roughness improves wettability and prevents pinhole formation, favoring solar cell efficiency.

- Sushil Shivaji Sangale

- Dilpreet Singh Mann

Impurity-healing interface engineering for efficient perovskite submodules

- Haifei Wang

- Shuojian Su

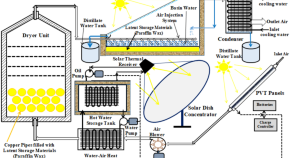

Integrated solar dryer and distillation system with PCM and injection, powered by PVT panels and solar concentrator

- Reda S. Salama

- Habib Ben Bacha

- Abd Elnaby Kabeel

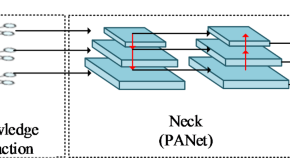

A photovoltaic cell defect detection model capable of topological knowledge extraction

- Zhaoyang Qu

- Lingcong Li

Materials and methods for cost-effective fabrication of perovskite photovoltaic devices

The scalable and cost-effective synthesis of perovskite solar cells is dependent on materials chemistry and the synthesis technique. This Review discusses these considerations, including selecting a suitable perovskite pre-cursor, additive engineering, and the deposition process.

- Chunyang Zhang

- Nam-Gyu Park

The real-time shadow detection of the PV module by computer vision based on histogram matching and gamma transformation method

News and Comment

Combining photovoltaic elements.

- Giulia Tregnago

Testing in the real world

- James Gallagher

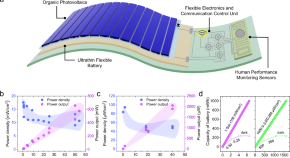

Transforming wearable technology with advanced ultra-flexible energy harvesting and storage solutions

Flexible organic photovoltaics and energy storage systems have profound implications for future wearable electronics. Here, the authors discuss the transformative potential and challenges associated with the integrative design of these systems for energy harvesting.

- Muhammad Jahandar

- Dong Chan Lim

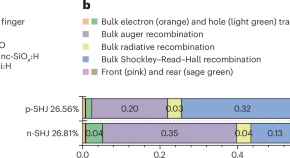

Top performance whatever the doping

The highest power conversion efficiencies for silicon heterojunction solar cells have been achieved on devices based on n-type doped silicon wafers, yet these wafers are usually more expensive than p-type ones. Now, researchers reduce charge recombination in the bulk of p-type silicon, demonstrating comparable efficiency to devices based on n-type silicon.

- Bernd Stannowski

Chirality for stable interfaces

Interfacial engineering is key to ensure the long-term stability of perovskite solar cells. Research now shows that chiral molecules can both improve the mechanical stability of the interfaces and afford passivation of defects at the perovskite surface, making solar cells more tolerant to thermal cycling stress.

- Juan-Pablo Correa-Baena

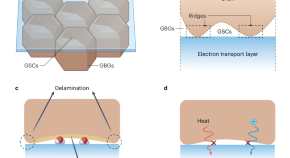

Smoothing down interfaces

The surfaces of polycrystalline perovskite films impact the long-term performance of perovskite solar cells, yet their microstructure is not well understood. Research now reveals the existence of concave grain structures at the surface of the perovskite layer facing the electron transport layer, and their detrimental effect on the stability of the interface and eventually the devices.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Notification: View the latest site access restrictions, updates, and resources related to the coronavirus (COVID-19) »

Publications

NREL solar researchers actively publish their latest scientific findings and breakthroughs in a newsletter, journal articles, conference papers, technical reports, and presentations.

Solar Newsletter

Read the newsletter . Also, subscribe to receive the newsletter and see the archives .

Featured Publications

Complementary Interface Formation Toward High-Efficiency All-Back-Contact Perovskite Solar Cells , Cell Reports Physical Science (2021)

Steady-State Off-Design Modeling of the Supercritical Carbon Dioxide Recompression Cycle for Concentrating Solar Power Applications With Two-Tank Sensible-Heat Storage , Solar Energy (2020)

Solar Photovoltaic Module Recycling: A Survey of U.S. Policies and Initiatives , NREL Technical Report (2021)

By Research Area

Concentrating solar power

Photovoltaic research

Grid modernization

NREL Publications Database

Find solar research publications in the NREL publications database.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

The PMC website is updating on October 15, 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Materials (Basel)

Photovoltaic Cell Generations and Current Research Directions for Their Development

Associated data.

Not applicable.

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and manufacturing technologies. The introduction describes the importance of photovoltaics in the context of environmental protection, as well as the elimination of fossil sources. It then focuses on presenting the known generations of photovoltaic cells to date, mainly in terms of the achievable solar-to-electric conversion efficiencies, as well as the technology for their manufacture. In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are discussed. We also present the latest developments in photovoltaic cell manufacturing technology, using the fourth-generation graphene-based photovoltaic cells as an example. An extensive review of the world literature led us to the conclusion that, despite the appearance of newer types of photovoltaic cells, silicon cells still have the largest market share, and research into ways to improve their efficiency is still relevant.

1. Introduction

Concerns about climate change and the increase in demand for electricity due to, among other things, an ever-growing population, necessitate efforts to move away from conventional methods of energy production. Rising carbon dioxide levels in the atmosphere caused by the use of fossil fuels is one of the factors causing ongoing climate change. Switching to renewable energy will produce energy with a smaller environmental footprint compared to fossil fuel sources. We are able to harness the full potential of sunlight energy to develop the best possible energy harvesting technologies capable of converting solar energy into electricity [ 1 ].

The currently used solar energy is very marginal—0.015% is used for electricity production, 0.3% for heating, and 11% is used in the natural photosynthesis of biomass. In contrast, about 80–85% of global energy needs are met by fossil fuels. The difficulty with fossil fuels is that their resources are limited and hostile to the environment due to their CO 2 emissions. For instance, for every ton of coal burned, one ton of carbon dioxide is released into the atmosphere. This emitted carbon dioxide is toxic to the environment and is a primary cause of global warming, the greenhouse effect, climate change, and ozone depletion [ 2 ].

The necessity of finding new renewable energy forms is extremely relevant and urgent today. That is why mankind must find alternative sources of energy to provide a clean and sustainable future. Within this context, solar energy is the best option among all alternative renewable energy sources due to its widespread accessibility, universality, and eco-friendly nature [ 3 ].

The most common metric used to evaluate the performance of photovoltaic technologies is conversion efficiency, which expresses the ratio of solar energy input to electrical energy output. The efficiency combines multiple component characteristics of the system, such as short-circuit current, open-circuit voltage, and fill factor, which in turn are dependent upon basic material features and manufacturing defects [ 4 ].

The cost-effectiveness of making a photovoltaic cell and its efficiency depend on the material from which it is made. Much research in this field has been carried out to find the material that is the most efficient and cost-effective for building photovoltaic cells. The specifications for an ideal material for PV solar cells include the following [ 5 ]:

- The cells are expected to have a band gap between 1.1 and 1.7 eV;

- Should have a direct band structure;

- Need to be easily accessible and non-toxic; and

- Should have high photovoltaic conversion efficiency [ 5 ].

A key problem in the area of photovoltaic cell development is the development of methods to achieve the highest possible efficiency at the lowest possible production cost. Improving the efficiency of solar cells is possible by using effective ways to reduce the internal losses of the cell. There are three basic types of losses: optical, quantum, and electrical, which have different sources of origin. Reducing losses of any kind requires different, often advanced, methods of cell manufacturing and photovoltaic module production. An upper efficiency limit for commercially accessible technologies is determined by the well-known Shockley–Queisser (SQ) limit, taking into account the balance between photogeneration and radiative recombination [ 6 ].

However, the greatest potential lies in the ability to reduce quantum losses, as they are intimately connected with the material properties and internal structure of the cell. Relevant here is the concept of band gap, which defines the minimum required energy of a photon incident onto the cell surface for it to take part in the photovoltaic conversion process. There is a relationship between the efficiency of the cell and the value of the band gap, which in turn is highly dependent on the material from which the photovoltaic cell is made. The basic, commonly used material for solar cells is silicon, which has a band gap value of about 1.12 eV, but by introducing modifications in its crystal structure, the physical properties of the material, especially the band gap width, can be affected [ 7 ].