Redesign, Specs & Reviews

Toyota’s 7 Steps to Problem Solving

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

Welcome to a comprehensive overview of Toyota’s problem-solving process. With this step-by-step approach, Toyota has overcome countless challenges and continuously improved its operations. But what makes these steps so effective? And how can they be applied to various industries and contexts?

In this article, we’ll explore Toyota’s problem-solving techniques in detail, breaking down each of the . From problem Toyota’s 7 Steps to Problem Solving definition to result evaluation, we’ll explain how Toyota approaches each stage of the process and provide real-life examples of its success.

Whether you’re a business owner, a manager, or an aspiring problem-solver, understanding Toyota’s approach can help you tackle any obstacle more efficiently and effectively. Let’s dive in!

Table of Contents

Step 1: Define the Problem

Before attempting to solve a problem, it is crucial to have a deep understanding of the issue at hand. At Toyota, problem identification is seen as the most critical step in the problem-solving process.

According to Toyota’s problem-solving approach, the first step is to define the problem clearly. This involves gathering all the relevant data, defining the scope of the problem, and identifying the specific symptoms or issues that require attention.

To do this effectively, Toyota encourages a thorough and collaborative problem analysis that involves all relevant stakeholders, including employees, customers, and suppliers. The goal is to identify the underlying causes of the problem and gain a comprehensive understanding of the issue.

“If you can’t describe what you are doing as a process, you don’t know what you’re doing.” – W. Edwards Deming

Following this quote by Deming, it is clear that defining the problem is the first step in establishing a successful process for problem-solving. Without a clear definition of the problem, not only will efforts to identify solutions be ineffective, but the underlying issues will not be addressed and will continue to cause problems in the future.

Step 2: Break Down the Problem

Once the problem has been clearly defined, the next step in Toyota’s problem-solving process is to break it down into smaller, more manageable components. This allows for a more in-depth analysis of each part, as well as identification of any interdependencies or patterns that may exist.

Breaking down a problem can be a challenging task, especially if it is complex or multifaceted. However, Toyota has developed several techniques to streamline this process. A common approach is to use a structured problem-solving method that breaks down the problem into smaller modules.

By analyzing each part separately, Toyota can better understand the root causes of the problem and determine the most effective countermeasures to implement.

Another benefit of breaking down a problem is that it helps prevent potential oversights or biases. By examining each component independently, one can avoid making assumptions and jumping to conclusions based on personal biases or past experiences.

Applying Step 2 to Real-Life Problems

Let’s consider a hypothetical example of a manufacturing company that has identified a problem in its production line. The problem is that a particular machine consistently malfunctions, leading to delays in the production process and decreased productivity.

Using Toyota’s approach, the problem would first be defined: the malfunctioning machine is causing delays in the production process, leading to decreased productivity.

The next step would be to break down the problem into smaller, more manageable components. In this case, the production process could be divided into modularized functions such as machine operation, material handling, and packing.

Each of these functions could then be analyzed independently, looking for any potential causes of the problem. For example, a closer examination of the machine operation module may reveal that a faulty sensor is causing the machine to malfunction. A countermeasure could then be developed to replace the faulty sensor, and the results evaluated to ensure the solution was effective.

Through this approach, the problem can be tackled systematically and thoroughly to identify and address the root cause of the issue.

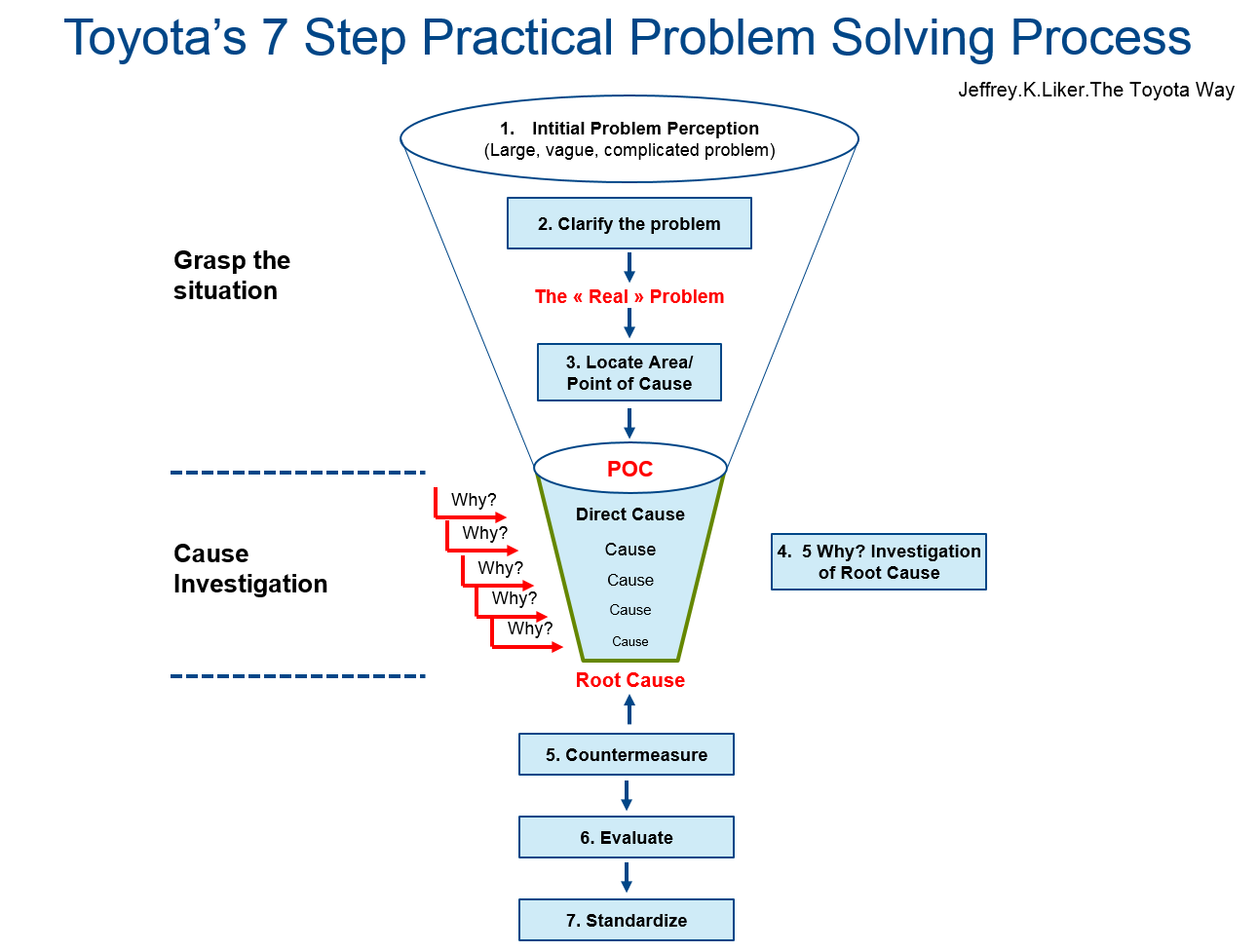

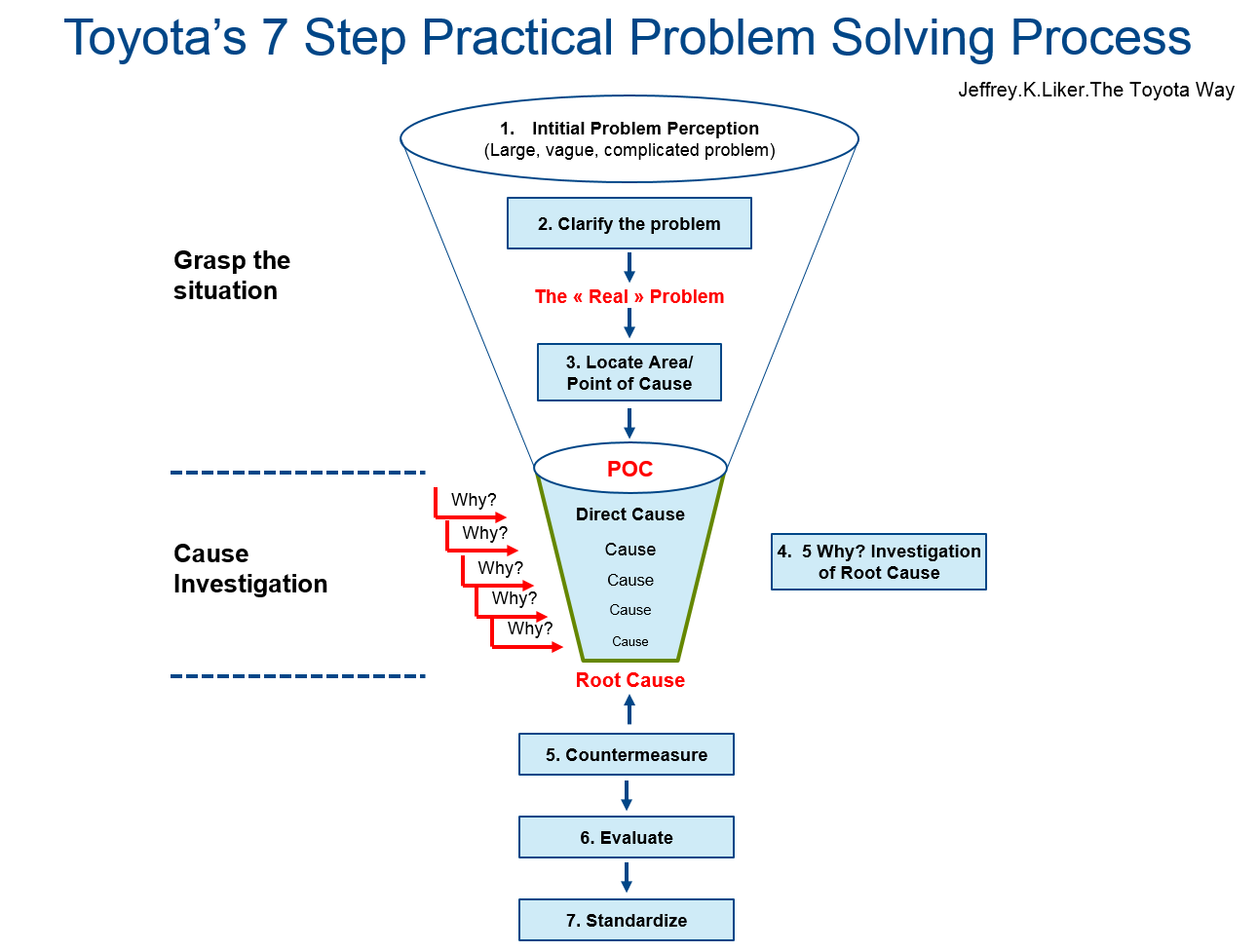

Step 4: Analyze the Root Cause

Identifying the root cause is critical to solving any problem effectively. Toyota’s approach to root cause analysis involves digging deeper into the issue to understand why it exists. This step is often the most time-consuming and challenging, but it is also the most crucial.

To help identify the root cause, Toyota uses techniques such as the 5 Whys and the Fishbone Diagram. The 5 Whys technique involves asking “why” five times to help identify the underlying cause of the problem, while the Fishbone Diagram helps to visually identify the multiple causes that may be contributing to the issue.

By analyzing the root cause, Toyota can develop targeted countermeasures that address the problem at its source. This step ensures that the problem is not merely superficially resolved, but that the solution is sustainable.

Once the problem has been clearly defined and broken down into manageable components, the next step in Toyota’s problem-solving process is to identify the underlying cause of the issue. This is where root cause analysis comes in, and Toyota has developed several techniques for conducting this critical step.

The 5 Whys technique is one approach Toyota uses to get to the root cause of a problem. It involves asking “why” five times, with each subsequent answer leading to a deeper understanding of the issue until the underlying cause is identified. This technique helps to uncover the origin of the problem and helps to avoid merely addressing the symptoms.

Another valuable tool used by Toyota in root cause analysis is the Fishbone Diagram. This technique helps to visualize all the potential causes of the problem, including people, processes, materials, environment, and equipment, among others. By considering all possible factors, Toyota can identify the primary root cause and develop effective countermeasures.

Step 5: Develop Countermeasures

Once the root cause has been identified, the next crucial step is to develop potential countermeasures or solutions. Toyota emphasizes the importance of considering multiple options and evaluating their feasibility. This ensures that the chosen countermeasures not only address the root cause but are also practical and effective in the given context.

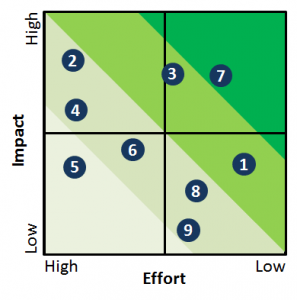

There are various techniques that Toyota employs during this step, such as brainstorming, creating action plans, and running simulations. The goal is to generate a range of potential solutions that can be evaluated based on their impact, cost, feasibility, and sustainability.

It is important to note that in this step, Toyota focuses on developing countermeasures, not solutions. This means that the proposed actions are meant to be temporary, allowing for continuous improvement and refinement until a permanent solution is achieved.

Toyota also stresses the need to involve all relevant stakeholders in this step, ensuring that all perspectives and ideas are considered. This promotes a collaborative and inclusive problem-solving culture that values diversity and fosters innovation.

Step 6: Implement the Countermeasures

Once Toyota selects the most viable countermeasures to address the identified root cause(s), it’s time to implement them. This phase requires effective planning, coordination, and communication among all relevant stakeholders to ensure a successful outcome.

Toyota uses a detailed and structured approach to implementation, including developing an implementation plan, allocating necessary resources, and clarifying roles and responsibilities. The company understands that successful implementation depends not only on technical aspects but also on people-related factors, such as buy-in, ownership, and collaboration.

During the implementation phase, Toyota monitors progress and adjusts if necessary. The company emphasizes the importance of involving all stakeholders in the process, gathering feedback, and addressing concerns promptly.

Best Practices for Implementing Countermeasures

Here are some best practices that Toyota recommends for implementing countermeasures:

By following these best practices, companies can increase the likelihood of successful implementation and avoid common pitfalls, such as resistance, misunderstandings, or delays.

Step 7: Evaluate the Results and Standardize

After implementing the chosen countermeasures, it is essential to evaluate their effectiveness and make any necessary adjustments. Toyota emphasizes the importance of assessing the results of the problem-solving process and standardizing successful solutions to ensure consistency and future reference. This step is critical in promoting continuous improvement and efficiency.

When evaluating the results, Toyota uses a variety of measures, including data analysis, feedback from stakeholders, and performance indicators. This helps to determine whether the implemented countermeasures have addressed the root cause(s) and achieved the desired outcomes.

If the results are not satisfactory, Toyota begins the process again, starting with step one. However, if the countermeasures are effective, Toyota standardizes the solution to promote consistency and prevent similar problems from occurring in the future.

Standardizing successful solutions involves documenting the problem-solving process, including the steps taken and the results achieved. This information is shared across the organization to ensure that everyone is aware of the solution and how it was reached.

Benefits of Toyota’s 7 Steps

Toyota’s 7-step problem-solving process offers several benefits for individuals and organizations facing various challenges. By following a systematic and structured approach, this process enables people to identify, analyze, and solve problems efficiently and effectively. Some of the advantages of Toyota’s problem-solving techniques include:

- Continuous Improvement : Toyota’s 7 steps promote a culture of continuous improvement by encouraging individuals to identify and eliminate problems through root cause analysis and countermeasure development.

- Efficiency : By breaking down complex problems into manageable components and analyzing each part separately, Toyota’s problem-solving approach helps individuals save time and resources.

- Cost Savings : By identifying and eliminating the root cause of a problem, organizations can avoid recurring expenses associated with addressing the symptoms of that problem.

- Collaboration : Involving all relevant stakeholders in the problem-solving process, Toyota’s 7 steps encourage teamwork, communication, and knowledge sharing.

- Standardization : By standardizing successful solutions, Toyota’s problem-solving process enables organizations to replicate effective strategies across different departments and projects.

Overall, Toyota’s 7-step problem-solving process provides a structured approach to addressing challenges that can benefit businesses and individuals alike. By promoting continuous improvement, efficiency, collaboration, and standardization, this process can help organizations stay competitive and achieve their goals.

Real-Life Examples of Toyota’s Problem-Solving Success

Toyota’s 7-step problem-solving process has been successfully implemented in various industries, resulting in significant improvements and positive outcomes. Here are some real-life examples of Toyota’s problem-solving success:

Example 1: Toyota Production System

The Toyota Production System (TPS) is a prime example of how Toyota’s problem-solving process has led to remarkable success. By applying the 7 steps, Toyota was able to create an efficient and flexible production system that minimized waste and increased productivity. This approach not only boosted Toyota’s profitability but also set a new standard for manufacturing industries worldwide.

Example 2: Toyota’s Health Care Initiative

In 2001, Toyota applied its problem-solving process to the health care industry, partnering with the University of Michigan Health System. By using the 7 steps, Toyota helped the health system streamline its processes, reduce errors, and improve patient care. The results were impressive, with the initiative saving over $5 million in the first year alone.

Example 3: Toyota’s Environmental Efforts

Toyota’s problem-solving approach is not limited to operational improvements but also extends to environmental challenges. In 2002, Toyota faced an issue with excessive landfill waste generated by its suppliers. By applying the 7 steps, Toyota was able to develop a comprehensive waste reduction plan that not only addressed the immediate problem but also reduced overall waste production. This initiative saved over $1 million and reduced 7,000 tons of waste in one year.

These examples demonstrate the versatility and effectiveness of Toyota’s problem-solving process in various industries and problem-solving scenarios.

FAQ: Frequently Asked Questions about Toyota’s Problem-Solving Process

Here are some common questions and concerns related to Toyota’s 7-step problem-solving process:

Q: Is Toyota’s problem-solving approach only applicable to manufacturing industries?

No, Toyota’s problem-solving process can be applied to various industries and scenarios. The 7 steps focus on identifying and addressing root causes, setting clear goals, developing effective solutions, and continuous improvement. These principles can be useful in any setting.

Q: Do I need to follow all 7 steps for every problem I encounter?

Not necessarily. The 7 steps are a guideline to help ensure a systematic and effective approach to problem-solving. However, depending on the nature and complexity of the problem, some steps may not be necessary or may require more attention than others.

Q: How long does it take to implement Toyota’s problem-solving process?

The timeline for implementing the 7 steps depends on the nature and complexity of the problem, as well as the resources and expertise available. Some problems may be resolved quickly, while others may require more time and effort. The key is to ensure a thorough and systematic approach to problem-solving.

Q: What happens if the selected countermeasures do not work?

If the implemented countermeasures do not produce the desired result, Toyota recommends revisiting the analysis and problem definition stages to identify any missed or underlying issues. The process may need to be repeated with adjusted countermeasures until the problem is resolved.

Q: How can I ensure that the solutions are standardized for future reference?

Once the problem has been resolved, it is important to document the process and the selected countermeasures, as well as any results or outcomes. This information can be used as a reference for future problem-solving endeavors and can help ensure the standardization of effective solutions.

Q: Can Toyota’s problem-solving process be used for personal problems or issues?

Yes, the 7 steps can be applied to personal problems or issues as well. The process emphasizes identifying root causes, setting clear goals, and developing effective solutions, which can be useful in any problem-solving scenario.

Conclusion Toyota’s 7 Steps to Problem Solving

In conclusion, Toyota’s 7 Steps to Problem Solving is an invaluable approach that promotes efficiency and continuous improvement in any organization. This methodology fosters a culture of critical thinking, teamwork, and proactive response to issues.

It is a versatile tool that can be applied across various industries – not just in the automotive sector. Implementing these steps can lead to significant cost savings, improved customer satisfaction, and overall business growth. Therefore, every organization aiming for operational excellence should consider adopting Toyota’s practical and systematic problem-solving strategy.

About the author

Latest Posts

Is Toyota Extended Warranty Transferable?

As a Toyota owner, you want to ensure your vehicle is protected in case of any unexpected expenses. That’s where Toyota’s extended warranties come in. But what happens if you decide to sell your Toyota before the warranty expires? Can the new owner benefit from the extended warranty as well? is toyota extended warranty transferable…

Does Toyota have a grace period?

If you are considering purchasing a Toyota vehicle, you may be wondering if the company has a grace period. A grace period is a specified period of time in which a customer can return a product for a full refund without penalty or fees. does toyota have a grace period we will explore the concept…

Why are Toyota so reliable?

Toyota is known for manufacturing some of the most dependable vehicles on the road. You might have heard people rave about their Toyota’s reliability, or maybe you’re considering purchasing a Toyota and wondering what makes them so trustworthy. Why are Toyota so reliable we’ll explore the reasons behind Toyota’s reputation for reliability and durability, including…

- Find a Dealer

- MyToyota Login

- Parts & Services

- Resource Library

About Toyota

Electric forklifts.

Electric Pallet Jacks

Electric Pallet Stackers

Reach Trucks

Order Pickers

Internal Combustion: Cushion Tires

Internal Combustion: Pneumatic Tires

Heavy Duty Forklifts

Tow Tractors & Tuggers

Hand Pallet Jacks

Automated Guided Vehicles

Aerial Work Platforms

- Toyota Assist

- Smart Environment Sensor

- Rental & Used

- Find a Forklift

- Compare Forklifts

- Industry Solutions

- Automation Solutions

- Energy Solutions

- Consulting Solutions

- Financial Solutions

- Fleet Solutions

Food Storage

General Warehouse

Cold Storage

General Manufacturing

Building Materials

Automate Receiving Processes

Automate Material Transportation

Automate Storage Systems

Automate Picking Solutions

Automate Shipping Systems

Become a Greener Business

Lithium-Ion Batteries

Convert from IC to Electric

Analyze Warehouse Space

Increase Employee Education

Improve Operation Safety

Improve a Process

Toyota Commercial Finance

Financing with Toyota

MyToyota Credit Card

Benefits of Buying Toyota

Highest Quality Parts

Toyota forklift dealers are a one-stop-shop, full service forklift solutions provider.

- Model & Serial Number

- Part Number

How to Find Your Equipment Model Number

Finding the right parts for your equipment is easy when you have your model and serial number which can be found on the data plate. Luckily, a forklift data plate is installed on every truck on the market to help you understand what your forklift can do and provide vital information.

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

How to Find Your Equipment Serial Number

Model Number: The model number of your toyota forklift is extremely important for relaying information to your dealers about repair or technical assistance and for looking up replacements part!

Serial Number: The serial number on your lift is the most important number.The model serial number combination will allow us to provide you with the parts that will fit your particular piece of equipment.

Need some help? For further assistance or more information, contact your local Toyota Dealer .

- Request a Parts Quote

- Toyota Genuine Parts

- Toyota Starlift Parts

Industry Leading Service

Increase your productivity, overall up-time and lifespan of your forklift.

- Request Service Quote

- Maintenance Plans

- 360 Support

- All Resources

- Customer Stories

- Whitepapers

- Management Guides

- Video Library

Toyota Careers

Management Team

Toyota Dealers

Sustainability

Corporate Social Responsiblity

- National Accounts

- Toyota Production System

- Forklift Safety

- Toyota Powered Engines

Press Enter to Search

Problem Solving Through Toyota Lean Management

Albert Einstein once wrote, “We cannot solve our problems with the same thinking we used when we created them.” Simply put, coming up with creative and innovative solutions to problems oftentimes requires you to look at the problem with a fresh perspective. As we’ve discussed in previous Toyota Lean Management blog posts , recognizing and cutting down on waste is critical to increasing your efficiency, reducing costs, and improving throughput. However, in order to make these improvements and see positive changes in ROI, a key step is recognizing where problems exist and working to solve them.

To recognize and solve these problems, it is often helpful to view them with a different lens to reach a newfound conclusion. Toyota’s 8 steps for problem-solving act as the lens that allows you to view different aspects of your operation from a new perspective.

Consider these eight steps as you start on the path to continuous improvement.

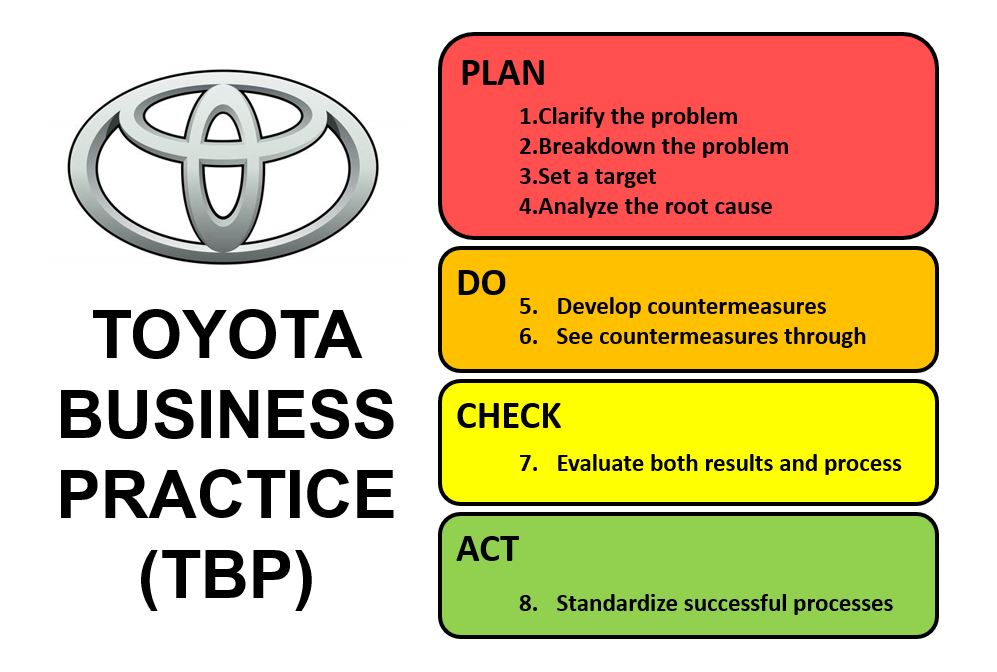

1. Clarify the problem

The first step in solving a problem is realizing that one exists. You can define a problem by asking yourself the following questions:

- Does my current process deviate from the standard?

- Is there a gap in my current process with what I am trying to accomplish vs. what I am accomplishing?

- Are my customer’s needs being met with my current process?

If the answer to any of these questions is no, then you know you have a problem that could use some improvement.

2. Break down the problem

Now that you’ve verified the problem, you can begin to break down the issue into smaller, more detailed pieces. It can be helpful to analyze the different inputs and outputs of your process so you can effectively see where you are currently placing your efforts. Don’t bite off more than you can chew. It is much easier to manage and solve smaller problems rather than attack one large problem with little direction.

3. Set a target

The third step is all about commitment and consistency. Now that you’ve broken down the problem, how are you going to go about solving it? How are you going to meet your new deadline, and how long will it take to complete? Allot adequate time for each activity to ensure you are giving each aspect of the project enough attention.

4. Analyze the root cause

Analyzing the root cause allows you to identify each of the factor(s) that caused a problem in the first place. Sometimes there is more than one cause, and it is important to consider each one as you work to address the issue.

5. Develop countermeasures

Establishing the root cause is only half the battle. Now, you must develop countermeasures for each of those root causes to prevent the same issues from occurring again.

6. Implement countermeasures

Now that you’ve established your countermeasures, it is time to put them into action. You may want to seek ideas from other team members to ensure you are not missing any steps. Also, it can be helpful to track how effective each countermeasure is performing along the way and making adjustments where necessary.

7. Evaluate Results and Process

The seventh step is all about implementing a system to review and evaluate how your new process is working. Countermeasures will fail, but it is important to develop an effective system that always looks for areas of improvement in order to reach the desired result.

8. Standardize Successful Processes

After receiving successful results from your previous evaluation, it is time to standardize the process within your team and the entire organization. As you work through the standardization process, continue to look for possible unresolved issues that you may have missed the first time.

Remember, the road to establishing a lean organization doesn’t stop once you improve a few processes. Lean isn’t just about identifying where you can do better; it’s about instilling a culture of respect and developing to create a workplace that your associates enjoy working in. Achieving business goals and leaner processes requires dedication and teamwork from every individual in the organization. Encourage open communication and empower your employees to bring problems to your attention when they are detected.

Related Articles

- Learn center

- Project management

How to use Toyota’s legendary A3 problem-solving technique

Georgina Guthrie

February 21, 2020

If you came home one day and found your kitchen taps on full-blast and your house full of water, what’s the first thing you’d do? Grab a bucket and start scooping — or turn off the tap?

When it comes to problem-solving, many of us take a rushed, reactionary approach rather than fixing the issue at the source. So in other words, we see the water, panic, and start scooping. If this sounds like something you’ve done recently, then don’t feel too bad: when the pressure’s high, we often jump towards the quickest fix, as opposed to the most effective one.

This is where the A3 technique comes in. It’s a problem-solving approach designed to efficiently address the root cause of issues.

What is the A3 technique?

The A3 technique is a structured way to solve problems. It’s part of the Lean methodology , developed by Toyota back in the mid-’40s. This doesn’t mean you need to implement a Lean way of working to take advantage of this process — it can work as a standalone exercise.

Granted, A3 isn’t an inspiring name, but the story of its origins is actually pretty interesting. Rumour has it that Taiichi Ohno, inventor of the Toyota Production System, refused to read past the first page of any report. In response, his team created A3 address and summarize problem-solving on one side of A3-sized paper. The A3 technique played a huge part in Toyota’s success and all kinds of industries have since adopted it. Here’s how to get started.

How to solve a problem with A3

The first thing to remember is this: A3 is collaborative and relies on good communication. It’s not something you should do by yourself.

There are three main roles involved:

- Owner (that’s you or someone under your charge)

As you’ve probably guessed, these aren’t roles that already exist in your company; you must create them for the purpose of this process. Here’s what they mean.

The owner is responsible for leading the exercise. They are the lynchpin between the two other roles, fostering good communication and keeping documents up to date. It’s tempting to think of the owner as the head of this trio, but that’s not true: everyone is equal here.

The mentor is someone with solid problem-solving experience. It’s their job to coach the owner and steer them towards finding a solution. It’s not their job to find the answers themselves.

And finally, there are the responders . This is someone (or a group of people) who have a vested interest in the outcome of the A3 project. Responders might include the client, stakeholders, or managers. A potential problem here is gaining access to them: if you work somewhere with a strict hierarchy — and you’re somewhere near the bottom of that structure — you may face challenges. There’s no easy way around this. Essentially, you need your organization to support this way of working and make it easy for you to access those at the top if needed.

How to create an A3 report

True to its origins, the A3 report is a one-page document. It typically contains 5-7 sections that systematically lead you towards a solution. These are the most commonly used steps, but feel free to modify them.

- Background: Explain your project in a few sentences, including its context.

- Problem statement: Explain the current problem. You can use process mapping to see the different tasks that surround the issue. This isn’t essential, but it will make it easier for you to locate the root cause.

- Goals: Define your desired outcome, and include metrics for measuring success. You won’t know everything until you reach the end, so you may find you need to come back and refine stages 1-3.

- Root cause analysis: This is a big stage of the process. You need to work out what you think the root problem is. You can use different methods to help you here, including 5 whys or a fault tree analysis .

- Countermeasures: Once you’ve worked out your root cause, you can start proposing solutions.

- Implementation: Work out how you’ll implement these solutions, including an action list with clearly defined roles and responsibilities. Project management software is a useful tool here because it can help everyone on the team track each other’s progress in real-time.

- Follow-up: Using your metrics for success, decide whether the problem was solved. Report your results back to the team/organization. In the spirit of Lean (continuous improvement), you should go back and modify your plan if the results weren’t as expected. And if they were, you should make this process the new standard.

Final thoughts

A3 is an efficient, methodical way to solve problems at their source. When issues rear their head, rising stress can lead people to panic. Having a clearly designed system in place to guide you towards a solution minimizes the chances of people settling for a ‘quick fix’ or failing to act altogether.

Beyond being a guiding light in times of pressure, A3 is a great team-building exercise because it encourages individuals to work together towards a common goal — across all areas of the organization. Combine this with collaborative tools designed to help teams track progress and work together more effectively, and you’ll be unstoppable.

Solve problems like a pro with Root Cause Corrective Action

Lean to Six Sigma: process improvement methodologies explained

Subscribe to our newsletter.

Learn with Nulab to bring your best ideas to life

Embracing The Toyota Way: A Practical Problem-Solving Framework for Improved Efficiency

This entry was posted by pabloadmin on March 19, 2023 at 11:17 pm

Introduction

The Toyota Production System (TPS) has long been regarded as a paragon of efficiency and effectiveness in the manufacturing industry. One of the primary principles of TPS is “The Toyota Way,” a management philosophy emphasizing continuous improvement and respect for people. In this blog post, we will share a practical problem-solving framework inspired by The Toyota Way that can be applied to various industries and organizations. This comprehensive blog post will delve into the critical elements of this framework and provide insights on how you can leverage it to improve problem-solving and boost efficiency within your organization.

Understanding the Problem-Solving Framework

This framework consists of five distinct stages, which together form a systematic approach to problem-solving:

- A. Define the Problem

- B. Break Down the Problem

- C. Set Targets

- D. Analyze the Root Causes

- E. Implement Countermeasures

Each stage is vital in identifying and resolving issues and ensuring practical and sustainable solutions. Let’s look at each stage and how they contribute to the framework.

Stage-by-Stage Analysis

A. define the problem:.

Before diving into problem-solving, clearly defining the issue at hand is essential. This involves understanding the gap between the current situation and the desired state and identifying the symptoms and effects of the problem. A well-defined problem sets the stage for more effective problem-solving and helps ensure that the correct issues are being addressed.

B. Break Down the Problem:

Once the problem has been defined, the next step is to break it down into smaller, more manageable components. This process helps clarify the issue’s scope, making it easier to understand and address. By breaking down the problem, you can more easily identify the underlying causes and focus on finding targeted solutions.

C. Set Targets:

After breaking down the problem, it’s crucial to establish measurable targets that define the desired outcome. These targets should be Specific, Measurable, Achievable, Relevant, and Time-bound ( SMART ). Setting clear and achievable goals ensures that your problem-solving efforts are directed toward meaningful improvements and allows you to track progress over time.

D. Analyze the Root Causes:

With targets in place, it’s time to dive deeper and identify the root causes of the problem. This stage thoroughly analyzes the underlying issues, using tools such as the “5 Whys” technique or the Fishbone Diagram. By identifying the root causes, you can develop targeted countermeasures that address the core issues rather than merely treating the symptoms.

E. Implement Countermeasures:

The final stage of the framework involves developing and implementing countermeasures to address the root causes of the problem. This may include changes to processes, systems, or behaviours. Once countermeasures are in place, monitoring their effectiveness and making adjustments is essential, ensuring that the problem is fully resolved and improvements are sustainable.

Benefits of the Toyota Way-Inspired Problem-Solving Framework

Adopting a structured problem-solving framework like the one inspired by The Toyota Way offers several benefits:

- Enhanced problem-solving capabilities: The systematic approach ensures that problems are thoroughly analyzed and addressed, leading to more effective and lasting solutions.

- Improved efficiency: By identifying and resolving the root causes of issues, organizations can optimize their processes and systems, reducing waste and improving productivity.

- Increased employee engagement: The framework emphasizes teamwork and collaboration, fostering a culture of continuous improvement and empowering employees to contribute to the organization’s success.

Implementing the Framework in Your Organization

To successfully implement this problem-solving framework within your organization, consider the following steps:

- Develop a strong understanding of the framework: Ensure that key stakeholders and team members are familiar with the five stages of the problem-solving framework and understand how they contribute to the overall process. This may involve conducting training sessions or workshops to educate employees on the principles and techniques of The Toyota Way-inspired framework.

- Establish a culture of continuous improvement: Encourage a mindset of ongoing growth and development within your organization. Promote open communication, collaboration, and a willingness to learn from mistakes. Foster an environment where employees feel empowered to share ideas and contribute to problem-solving efforts.

- Adapt the framework to your organization’s unique needs: While its fundamental principles remain the same, it’s essential to tailor the approach to your organization’s specific context and requirements. This may involve adjusting the tools and techniques used in the analysis stage or adapting the implementation process to fit your organization’s structure and culture.

- Monitor progress and measure results: Regularly assess the effectiveness of the problem-solving framework by tracking progress towards established targets and measuring the impact of implemented countermeasures. Use this information to identify further improvement areas and refine the framework.

- Celebrate successes and share learnings: Recognize and celebrate your team’s achievements as they successfully navigate the problem-solving framework and implement effective solutions. Share the lessons learned and best practices across the organization, fostering a culture of knowledge-sharing and continuous improvement.

The Toyota Way-inspired problem-solving framework offers a structured and systematic approach to identifying and resolving issues within your organization. By embracing this framework, you can enhance problem-solving capabilities, boost efficiency, and foster a culture of continuous improvement. By implementing the framework thoughtfully and deliberately, you can unlock your organization’s potential and achieve lasting success in today’s competitive business environment.

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- February 2023

- January 2023

- December 2022

- Uncategorized

How Toyota Turns Workers Into Problem Solvers

Sarah Jane Johnston: Why study Toyota? With all the books and articles on Toyota, lean manufacturing, just-in-time, kanban systems, quality systems, etc. that came out in the 1980s and 90s, hasn't the topic been exhausted?

Steven Spear: Well, this has been a much-researched area. When Kent Bowen and I first did a literature search, we found nearly 3,000 articles and books had been published on some of the topics you just mentioned.

However, there was an apparent discrepancy. There had been this wide, long-standing recognition of Toyota as the premier automobile manufacturer in terms of the unmatched combination of high quality, low cost, short lead-time and flexible production. And Toyota's operating system—the Toyota Production System—had been widely credited for Toyota's sustained leadership in manufacturing performance. Furthermore, Toyota had been remarkably open in letting outsiders study its operations. The American Big Three and many other auto companies had done major benchmarking studies, and they and other companies had tried to implement their own forms of the Toyota Production System. There is the Ford Production System, the Chrysler Operating System, and General Motors went so far as to establish a joint venture with Toyota called NUMMI, approximately fifteen years ago.

However, despite Toyota's openness and the genuinely honest efforts by other companies over many years to emulate Toyota, no one had yet matched Toyota in terms of having simultaneously high-quality, low-cost, short lead-time, flexible production over time and broadly based across the system.

It was from observations such as these that Kent and I started to form the impression that despite all the attention that had already been paid to Toyota, something critical was being missed. Therefore, we approached people at Toyota to ask what they did that others might have missed.

Q: What did they say?

A: To paraphrase one of our contacts, he said, "It's not that we don't want to tell you what TPS is, it's that we can't. We don't have adequate words for it. But, we can show you what TPS is."

Over about a four-year period, they showed us how work was actually done in practice in dozens of plants. Kent and I went to Toyota plants and those of suppliers here in the U.S. and in Japan and directly watched literally hundreds of people in a wide variety of roles, functional specialties, and hierarchical levels. I personally was in the field for at least 180 working days during that time and even spent one week at a non-Toyota plant doing assembly work and spent another five months as part of a Toyota team that was trying to teach TPS at a first-tier supplier in Kentucky.

Q: What did you discover?

A: We concluded that Toyota has come up with a powerful, broadly applicable answer to a fundamental managerial problem. The products we consume and the services we use are typically not the result of a single person's effort. Rather, they come to us through the collective effort of many people each doing a small part of the larger whole. To a certain extent, this is because of the advantages of specialization that Adam Smith identified in pin manufacturing as long ago as 1776 in The Wealth of Nations . However, it goes beyond the economies of scale that accrue to the specialist, such as skill and equipment focus, setup minimization, etc.

The products and services characteristic of our modern economy are far too complex for any one person to understand how they work. It is cognitively overwhelming. Therefore, organizations must have some mechanism for decomposing the whole system into sub-system and component parts, each "cognitively" small or simple enough for individual people to do meaningful work. However, decomposing the complex whole into simpler parts is only part of the challenge. The decomposition must occur in concert with complimentary mechanisms that reintegrate the parts into a meaningful, harmonious whole.

This common yet nevertheless challenging problem is obviously evident when we talk about the design of complex technical devices. Automobiles have tens of thousands of mechanical and electronic parts. Software has millions and millions of lines of code. Each system can require scores if not hundreds of person-work-years to be designed. No one person can be responsible for the design of a whole system. No one is either smart enough or long-lived enough to do the design work single handedly.

Furthermore, we observe that technical systems are tested repeatedly in prototype forms before being released. Why? Because designers know that no matter how good their initial efforts, they will miss the mark on the first try. There will be something about the design of the overall system structure or architecture, the interfaces that connect components, or the individual components themselves that need redesign. In other words, to some extent the first try will be wrong, and the organization designing a complex system needs to design, test, and improve the system in a way that allows iterative congruence to an acceptable outcome.

The same set of conditions that affect groups of people engaged in collaborative product design affect groups of people engaged in the collaborative production and delivery of goods and services. As with complex technical systems, there would be cognitive overload for one person to design, test-in-use, and improve the work systems of factories, hotels, hospitals, or agencies as reflected in (a) the structure of who gets what good, service, or information from whom, (b) the coordinative connections among people so that they can express reliably what they need to do their work and learn what others need from them, and (c) the individual work activities that create intermediate products, services, and information. In essence then, the people who work in an organization that produces something are simultaneously engaged in collaborative production and delivery and are also engaged in a collaborative process of self-reflective design, "prototype testing," and improvement of their own work systems amidst changes in market needs, products, technical processes, and so forth.

It is our conclusion that Toyota has developed a set of principles, Rules-in-Use we've called them, that allow organizations to engage in this (self-reflective) design, testing, and improvement so that (nearly) everyone can contribute at or near his or her potential, and when the parts come together the whole is much, much greater than the sum of the parts.

Q: What are these rules?

A: We've seen that consistently—across functional roles, products, processes (assembly, equipment maintenance and repair, materials logistics, training, system redesign, administration, etc.), and hierarchical levels (from shop floor to plant manager and above) that in TPS managed organizations the design of nearly all work activities, connections among people, and pathways of connected activities over which products, services, and information take form are specified-in-their-design, tested-with-their-every-use, and improved close in time, place, and person to the occurrence of every problem .

Q: That sounds pretty rigorous.

A: It is, but consider what the Toyota people are attempting to accomplish. They are saying before you (or you all) do work, make clear what you expect to happen (by specifying the design), each time you do work, see that what you expected has actually occurred (by testing with each use), and when there is a difference between what had actually happened and what was predicted, solve problems while the information is still fresh.

Q: That reminds me of what my high school lab science teacher required.

A: Exactly! This is a system designed for broad based, frequent, rapid, low-cost learning. The "Rules" imply a belief that we may not get the right solution (to work system design) on the first try, but that if we design everything we do as a bona fide experiment, we can more rapidly converge, iteratively, and at lower cost, on the right answer, and, in the process, learn a heck of lot more about the system we are operating.

Q: You say in your article that the Toyota system involves a rigorous and methodical problem-solving approach that is made part of everyone's work and is done under the guidance of a teacher. How difficult would it be for companies to develop their own program based on the Toyota model?

A: Your question cuts right to a critical issue. We discussed earlier the basic problem that for complex systems, responsibility for design, testing, and improvement must be distributed broadly. We've observed that Toyota, its best suppliers, and other companies that have learned well from Toyota can confidently distribute a tremendous amount of responsibility to the people who actually do the work, from the most senior, expeirenced member of the organization to the most junior. This is accomplished because of the tremendous emphasis on teaching everyone how to be a skillful problem solver.

Q: How do they do this?

A: They do this by teaching people to solve problems by solving problems. For instance, in our paper we describe a team at a Toyota supplier, Aisin. The team members, when they were first hired, were inexperienced with at best an average high school education. In the first phase of their employment, the hurdle was merely learning how to do the routine work for which they were responsible. Soon thereafter though, they learned how to immediately identify problems that occurred as they did their work. Then they learned how to do sophisticated root-cause analysis to find the underlying conditions that created the symptoms that they had experienced. Then they regularly practiced developing counter-measures—changes in work, tool, product, or process design—that would remove the underlying root causes.

Q: Sounds impressive.

A: Yes, but frustrating. They complained that when they started, they were "blissful in their ignorance." But after this sustained development, they could now see problems, root down to their probable cause, design solutions, but the team members couldn't actually implement these solutions. Therefore, as a final round, the team members received training in various technical crafts—one became a licensed electrician, another a machinist, another learned some carpentry skills.

Q: Was this unique?

A: Absolutely not. We saw the similar approach repeated elsewhere. At Taiheiyo, another supplier, team members made sophisticated improvements in robotic welding equipment that reduced cost, increased quality, and won recognition with an award from the Ministry of Environment. At NHK (Nippon Spring) another team conducted a series of experiments that increased quality, productivity, and efficiency in a seat production line.

Q: What is the role of the manager in this process?

A: Your question about the role of the manager gets right to the heart of the difficulty of managing this way. For many people, it requires a profound shift in mind-set in terms of how the manager envisions his or her role. For the team at Aisin to become so skilled as problem solvers, they had to be led through their training by a capable team leader and group leader. The team leader and group leader were capable of teaching these skills in a directed, learn-by-doing fashion, because they too were consistently trained in a similar fashion by their immediate senior. We found that in the best TPS-managed plants, there was a pathway of learning and teaching that cascaded from the most senior levels to the most junior. In effect, the needs of people directly touching the work determined the assistance, problem solving, and training activities of those more senior. This is a sharp contrast, in fact a near inversion, in terms of who works for whom when compared with the more traditional, centralized command and control system characterized by a downward diffusion of work orders and an upward reporting of work status.

Q: And if you are hiring a manager to help run this system, what are the attributes of the ideal candidate?

A: We observed that the best managers in these TPS managed organizations, and the managers in organizations that seem to adopt the Rules-in-Use approach most rapidly are humble but also self-confident enough to be great learners and terrific teachers. Furthermore, they are willing to subscribe to a consistent set of values.

Q: How do you mean?

A: Again, it is what is implied in the guideline of specifying every design, testing with every use, and improving close in time, place, and person to the occurrence of every problem. If we do this consistently, we are saying through our action that when people come to work, they are entitled to expect that they will succeed in doing something of value for another person. If they don't succeed, they are entitled to know immediately that they have not. And when they have not succeeded, they have the right to expect that they will be involved in creating a solution that makes success more likely on the next try. People who cannot subscribe to these ideas—neither in their words nor in their actions—are not likely to manage effectively in this system.

Q: That sounds somewhat high-minded and esoteric.

A: I agree with you that it strikes the ear as sounding high principled but perhaps not practical. However, I'm fundamentally an empiricist, so I have to go back to what we have observed. In organizations in which managers really live by these Rules, either in the Toyota system or at sites that have successfully transformed themselves, there is a palpable, positive difference in the attitude of people that is coupled with exceptional performance along critical business measures such as quality, cost, safety, and cycle time.

Q: Have any other research projects evolved from your findings?

A: We titled the results of our initial research "Decoding the DNA of the Toyota Production System." Kent and I are reasonably confident that the Rules-in-Use about which we have written are a successful decoding. Now, we are trying to "replicate the DNA" at a variety of sites. We want to know where and when these Rules create great value, and where they do, how they can be implemented most effectively.

Since we are empiricists, we are conducting experiments through our field research. We are part of a fairly ambitious effort at Alcoa to develop and deploy the Alcoa Business System, ABS. This is a fusion of Alcoa's long standing value system, which has helped make Alcoa the safest employer in the country, with the Rules in Use. That effort has been going on for a number of years, first with the enthusiastic support of Alcoa's former CEO, Paul O'Neill, now Secretary of the Treasury (not your typical retirement, eh?) and now with the backing of Alain Belda, the company's current head. There have been some really inspirational early results in places as disparate as Hernando, Mississippi and Poces de Caldas, Brazil and with processes as disparate as smelting, extrusion, die design, and finance.

We also started creating pilot sites in the health care industry. We started our work with a "learning unit" at Deaconess-Glover Hospital in Needham, not far from campus. We've got a series of case studies that captures some of the learnings from that effort. More recently, we've established pilot sites at Presbyterian and South Side Hospitals, both part of the University of Pittsburgh Medical Center. This work is part of a larger, comprehensive effort being made under the auspices of the Pittsburgh Regional Healthcare Initiative, with broad community support, with cooperation from the Centers for Disease Control, and with backing from the Robert Wood Johnson Foundation.

Also, we've been testing these ideas with our students: Kent in the first year Technology and Operations Management class for which he is course head, me in a second year elective called Running and Growing the Small Company, and both of us in an Executive Education course in which we participate called Building Competitive Advantage Through Operations.

- 15 Apr 2024

Struggling With a Big Management Decision? Start by Asking What Really Matters

- 02 Apr 2024

- What Do You Think?

What's Enough to Make Us Happy?

- 24 Jan 2024

Why Boeing’s Problems with the 737 MAX Began More Than 25 Years Ago

- 05 May 2020

- Research & Ideas

China Tariffs and Coronavirus a Double Hit to American Retailers

- 11 Apr 2024

- In Practice

Why Progress on Immigration Might Soften Labor Pains

- Infrastructure

- Organizational Design

- Competency and Skills

- Manufacturing

- Transportation

Sign up for our weekly newsletter

A3 8 Step Practical Problem Solving – Skill Level 1: Knowledge

How the a3 came to be toyota’s go-to management process..

by Isao Yoshino August 2, 2016

The discussion below between John Shook and Isao Yoshino first appeared on The Lean Enterprise Institute website www.lean.org .

As context, John Shook defines the A3 process as “… the A3 is a visual manifestation of a problem-solving thought process involving continual dialogue between the owner of an issue and others in an organisation. It is a foundational management process that enables and encourages learning through the scientific method.” pp11 of Managing to Learn

Understanding A3 Thinking has evolved over time. In 2016, John said he would change the term “scientific method” to “scientific thinking” in that definition because the scientific method is but one of a number of ways of structuring to do science. In addition, John clarified that the A3 process is a process to help teams do science together. It’s much more than a structure for a problem solving process – it can become a way of enabling people to work together effectively.

The history of the A3 process provides context. Context to the “problem(s)” Toyota was attempting to solve by developing such a process. You may not have exactly the same problems as Toyota did when it started its journey, but we are sure any organisation will be more successful if they are deliberate in the development of management skills, capability building and thinking. It’s not enough just to hire great people, we need to build capability and behaviours over time.

We hope you find that this interview helps you think through why developing such processes are so important.

In the late 1970s, Toyota decided to invest in cultivating the managerial capabilities of its mid-level managers. Masao Nemoto, the same influential executive who led Toyota’s successful Deming Prize initiative in 1965, led a development program especially for non-production gemba managers called the “Kanri Nouryoku Program” – “Kan-Pro” for short. Nemoto chose to structure this critical management development initiative around the A3 process.

The A3 is well established now in the lean community. As a process, as a tool, as a way of thinking, managing and developing others. The question often comes up of where did it come from and how did it become a common practice. The basic answer is that it dispersed mainly from Toyota. But how did it become so prevalent in Toyota? And how did it evolve from its humble beginnings as a tool to tell a PDCA quality improvement story on an A3-sized sheet of paper, as it had been commonly used by many Japanese companies since the 1960s?

What had started as a simple tool to tell PDCA stories grew at Toyota into something more: the A3 process came to embody the company’s way of managing in an extraordinarily profound sense. How did this happen?

My first “kacho” (manager) at Toyota (in Japan starting in 1983), Mr. Isao Yoshino, was a member of Nemoto’s four-man team that created and delivered the “Kan-Pro” manager-development initiative that directly answers that question. The program has been unknown outside Toyota … until now.

—John Shook

Interview with Mr. Isao Yoshino

Q: what was the purpose of the kanri nouryoku program.

A: The main purpose was to nurture “Management Capabilities” of employees who were at manager (kacho) level and above. There were four rudimental capabilities for managers:

- Planning capability, judging capability

- Broad knowledge, experiences and perspectives

- Driving force to get job done, leadership, kaizen capability

- Presentation capability, persuasion capability, negotiation capability

Q: Why did Toyota decide it needed this program?

A: After introducing Total Quality Control (TQC) in 1961 and receiving the Deming Prize in 1965, TQC-based perspective had taken root widely across the company. In the late ‘70s, Mr. Nemoto (one of the main people behind launching TQC) noticed that management capabilities and TQC awareness was decreasing among managers, particularly within the non-manufacturing gemba or office divisions. Mr. Nemoto decided to take actions to reinvigorate the managers (especially administrative) and help heighten awareness of their role. And so, in 1978, he formed a task force that promoted a two-year program (the Kanri Nouryoku Program) for two thousand managers from all over the company. I was one of the four staff members on the task force in Toyota City.

Q: What sort of tools and activities did the Kanri Nouryoku employ?

A: All the managers went through “a presentation session” twice per year (June and December). The officers in charge of each department attended to have a Question and Answer session with the managers. Officers tried to focus on the problems each manager was facing as well as the effort and process needed to solve the problems. Officers focused more on “What is the major cause of the problem?”, rather than “Who made those mistakes?” This problem-focused attitude (as opposed to the who-made-the-mistake attitude) of the officers encouraged managers to share their problems rather than hide them.

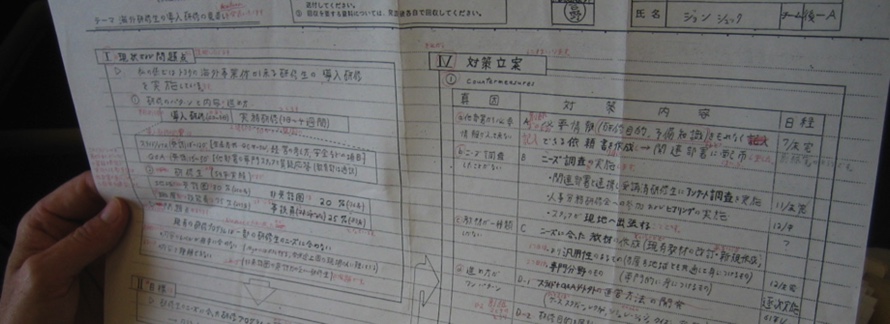

The key to giving the presentations was that they had to be done using an A3. The managers learned how to select what information/data was needed and what was not needed, since an A3 has only limited space. This helped them acquire the seiri and seiton functions of the 5S concept as applied to knowledge work. A3 was also a great tool for officers. They could easily see, at a glance, all the key points that the presenter wanted to convey. As it is just one single document, you can quickly see from the left top corner to the right bottom of an A3 and grasp the key things the writer wants to communicate. This is something that you cannot get from a written document or PowerPoint presentation.

Q: What was your personal experience with the program?

A: First, I was fortunate to get acquainted with many admirable managers, who inspired me in many ways. I also learned how to express myself more effectively by studying A3 documents from two thousand managers. Strikingly, I discovered that managers whose A3s were excellent were also excellent managers at work.

Nemoto-san highly praised managers who took a risk to report their mistakes (not success stories) on A3s with a hope of finding a solution. Nemoto valued their sincere and proactive attitudes. “Nemoto Lectures” were held for managers three or four times a year. Mr. Nemoto went through every single impression memo from the audience as feedback for his next speech.

Mr. Nemoto also appreciated the efforts by managers who tried to nurture excellent subordinates. This created a new company-wide notion that “developing your subordinates is a virtue.” It was amazing to see managers in their 40s and 50s willing to give 100 percent of their energy to work on hoshin kanri and A3 reporting, because they were convinced the program was practical and useful and worth using to bring themselves up to a higher level. Seeing all this happen at work truly helped me grow professionally.

Q: What was the effect of the program on Toyota?

A: Well for one, every mid-level manager who was involved in this program over the two years came to clearly understand their roles and responsibilities and also learned the importance of the hoshin kanri system. People at Toyota don’t hesitate to report bad news, which has been Toyota’s heritage since day one. The Kanri Nouryoku program has further reinforced this tradition because of its praise toward managers and others who were honest about their mistakes. And after the program was implemented to the back-office managers, the level of their awareness of their role rose up to the same level of that of manufacturing-related managers, which significantly strengthened the management foundation.

Everybody became familiar with using the A3 process when documented communication was needed – A3 thinking eventually became an essential part of Toyota’s culture. People learned how to distinguish what is important from what is not.

Isao Yoshino

Lecturer , Nagoya Gakuin University

Isao Yoshino is a Lecturer at Nagoya Gakuin University of Japan. Prior to joining academia, he spent 40 years at Toyota working in a number of managerial roles in a variety of departments. Most notably, he was one of the main driving forces behind Toyota’s little-known Kanri Nouryoku program, a development activity for knowledge-work managers that would instill the A3 as the go-to problem-solving process at Toyota.

Now move onto the next Topic

Toyota Practical Problem Solving (PPS)—Clarify

A Quick Recap

Clarify the Problem

Break down the problem.

- Set a Target

- Root-Cause Analysis

- Develop Countermeasures and Implement

- Monitor Process and Results

- Standardize and Share

A problem is often a deviation from a target. You have a target (quality, productivity, cost, etc.), and your actual performance is not meeting these targets. If possible, try to express you target quantitatively (i.e., have a current performance measure that differs from the target for this performance measure). For example, if you have problems with frequent breakdowns of machines, measure the availability of the machine(s). If it is a quality problem, measure customer complaints, first pass yield, or similar quality measures. If you are not happy with your output, measure parts produced per hour or similar. If you can, make a graph, diagram, timeline, or similar visualization; it will be quite helpful.

Try not to narrow it down too much. This will be done in the next step. If you narrow it down too much, you may exclude a root cause that is a major influence on the performance. At the same time, try not to cast a too wide net either. Yes, I know, I am not very helpful here, as it should not be too big nor too small. Unfortunately, while in other cases most people tend to go in one direction (e.g., too much inventory), here I have seen both directions. Some people take a too high-level approach (e.g., analyze company-wide quality issues), while others take a too-narrow view (e.g., quality issue missing weld at process 30). If given a choice, I’d say rather go large then small. The nest step, “Break Down the Problem,” will narrow it down anyway, and it will probably be much more structured than a half-hazarded guess during the problem clarification.

This includes what Toyota calls “stratification.” Try grouping or displaying your data into smaller groups or aspects to analyze them. Try to look at the problem from different angles:

- When is it happening? Is it a certain time of the day? Is it something that did not happen before and now it is happening, and if so, when did it start?

- Where is it happening? Is it at a certain process in the value stream or work instructions? Is it with a specific supplier? Does it happen mostly in selected market regions or market segments?

- What is it happening to? Is it a certain product group or product? Is it a specific module or part? Is it a certain type of customer complaint? Is it a specific type of defect?

- How much is it happening (e.g., how much is produced)?

- Who is it happening to? Is it happening with a certain employee or shift? (Side note: If so, it is probably not a fault of the employee, but e.g. defective tools, lack of training, etc.)

Above are four bullet points (when, where, what, who) that you should consider. In reality, you may even have multiple aspects to stratify for the same bullet. For example, the question “what” for a quality issue could be looking at the type of complaint, the type of product, or the type of defect, etc.

For more complicated problems you can also try to split it into sub-problems. For example, if you find out during your stratification that there are multiple types of defects that ruin your quality, you may investigate these types of defect separately.

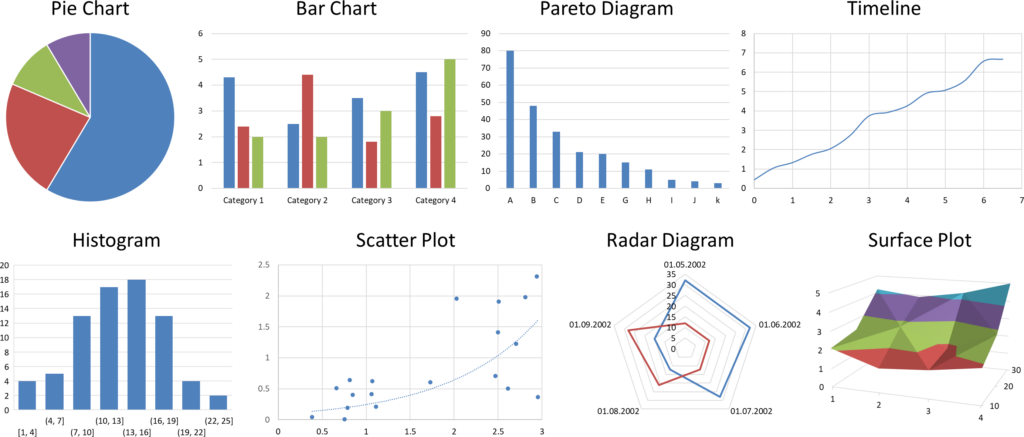

Whenever possible, use graphical charts and displays to visualize the data during stratification. There are many different ways to visualize data, like pie charts, bar charts, Pareto diagrams, timelines and trends, histograms, scatter diagrams, radar charts, surface plots, and many more. below are a few visualizations.

The goal of breaking down the problem is to better understand when, where, what, and who is happening. During the clarification of the problem I told you to look at the big picture. The breaking down of the problem narrows this down to the actual problem you are having. Toyota calls this the prioritized problem , and it is often confused with the root cause. This prioritized problem is an essential input for setting the targets… which I will discuss in the next post. Now, go out, define and understand your problem, and organize your industry!

PS: Many thanks to the team from the Toyota Lean Management Centre at the Toyota UK Deeside engine plant in Wales, where I participated in their 5-day course. This course gave us a lot of access to the Toyota shop floor, and we spent hours on the shop floor looking at processes. In my view, this the only generally accessible course by Toyota that gives such a level of shop floor involvement.

Leave a Comment

Notify me of new posts by email.

The Lean Post / Articles / Art of Lean on Problem-Solving, Part 8: Toyota Coaching Practices

Problem Solving

Art of Lean on Problem-Solving, Part 8: Toyota Coaching Practices

By Art Smalley

July 23, 2021

Art describes some of the fundamental principles of Toyota coaching practices.

Art shares some specifics about Toyota coaching practices. Find a lightly edited script below.

Part eight of eight. Watch the others:

Part one, Coaching Problem-Solving

Part two, Lessons from NBA Coaches

Part three, Lessons from Martial Arts

Part four, Military Science and Leadership

Part five, Tuckman’s Model of Team Formation

Part six, Team-Building Tools and Practices

Part seven, Dreyfus Model and the Stages of Learning

Hi, everyone. This is Art Smalley, president of Art of Lean Incorporated. Today, in conjunction with the Lean Enterprise Institute, I have another video for you on the topic of coaching and problem-solving. We’re getting near the end of our series, but I want to talk about a couple more things related to coaching and problem-solving and shortening the lead time to learn.

I talked last time about an external framework called the Dreyfus Mode l, and I’ve shared some internal Toyota things. I had a question sent to me, “Art, can you show more about Toyota’s actual coaching practices, not the theory?” I said, “I’ll do my best.” So in this, we’re going to talk about that topic, so stick around. I think you’ll enjoy it.

Coaching Practices at Toyota

In response to the question what are actual coaching practices like in Toyota? , to be honest, it’s quite varied. I experienced it in Japan. Those of you who have worked for Toyota around the world might have similar or different experiences, but you learn on the job in Toyota. You learn by standard training, you learn from your peers, you often learn from people assigned to you. They’re, in Japanese, called a Sempai or someone superior to you. Like if I’m a junior engineer, there’s a senior engineer who often oversees my work . You learn from managers and specialists in various realms. Eventually, you learn from advanced courses if you stay with the company long enough and advance through positions. You learn from various special problems and assignments you’re given over time. So it’s not a one-size-fits-all.

Now, what I do have, interestingly, is my basic problem-solving handbook that I was given 30 years ago, over 30 years ago, when I went to work for Toyota in Japan. It has a grand total of 44 pages, only five steps in this one, believe it or not, seven QC tools, and some examples and a glossary. That’s all I got when I started working. It’s a form of basic problem-solving training, and I didn’t get any coaching specifically on this. You’re expected to then go and apply and work on a problem, and then you’d get some coaching after that.

Later on, I did get a bigger one, fewer pages, but this was intermediate problem-solving in Toyota. This one has 13 pages. I guess the higher you go, the less they’re going to give you in terms of knowledge. This one did have the actual eight steps though it is outdated. The eight steps that you’re doing today are not exactly the same, but this would be considered the routes of the eight-step method that Toyota has in its Toyota business practices, practical problem-solving routines of today.

To be honest with you, there are also advanced topics. I got to experience some of this in Toyota — very advanced techniques in problem-solving. You don’t hear about these, sadly, on the outside, but there are experts in Toyota, using very advanced techniques. There’s specialist training and coaching going on for a very small segment of the population, very statistical in nature, very quantitative. But, again, it is for the select few in quality control, product development, reliability engineering, and things like that.

The man who knows the most about it, a gentleman named Kakuro Amasaka, is retired. But he did publish a book that has some material pertaining to that if you’re interested. It’s not a great book, not well translated, sadly. But it gives a little bit of a picture of that. An example is a steering pump hose and an improvement project problem they were solving. He points out the different ways you can tackle this problem through reliability engineering and Weibull analysis and various tools: regression analysis, principal component analysis, multivariate analysis, and things like that. And, of course, design of experiments.

It Depends on Your Level and Position!

You’ve got to realize that actual coaching practices and problem execution really depend upon your level or position in Toyota and what you’re doing. It’s not one-size-fits-all. But be that as it may, let’s circle back to, I think, what the questioner was looking for.

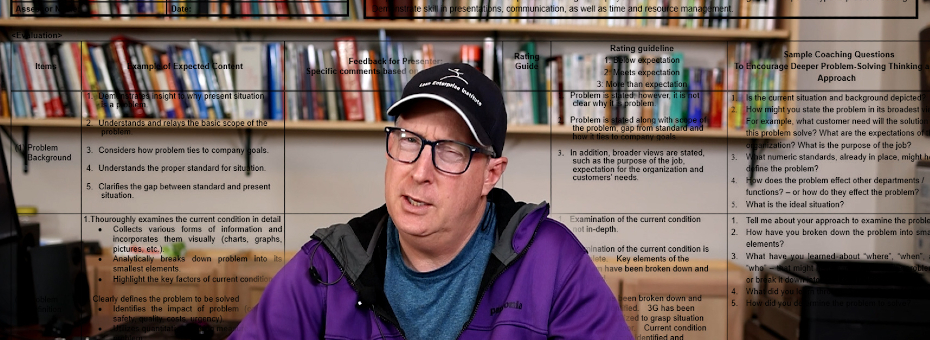

What are basic problem-solving and coaching practices really like in Toyota? Here’s a picture of a lady doing a problem-solving report-out to a team leader and a manager, which is what happens to pretty much everybody. You complete some basic training. You get assigned a problem, maybe team-based, individual-based; it depends. You work on that problem, and there are periodic report-outs, and you receive coaching during those report-outs. You might do two steps of problem-solving, have a report-out, get to step four, have a report-out, step six, have a report-out, step eight, have a final report-out, things like that. You get coaching and advice through those steps and, of course, struggle on your own.

Interestingly, there is an actual Toyota form used for coaching. I have an old version of it that I translated from Japanese, and to my knowledge, Toyota has not released this to the outside world, so I can’t freely distribute it. But I think it is floating around, to be honest with you. I’ve seen multiple versions of it, even in English. It specifically shows what the Toyota coach is expected to do in terms of feedback and working on problem-solving with a given team or individual. It has steps. It has content that you’re supposed to look for. It has an area for feedback to be filled in. You as the coach, must provide a [numerical] rating. It does have questions you can ask, very targeted questions to ask for feedback.

In this way, it is very much like situational leadership. Toyota is not a one-size-fits-all model, and the coaching forms, especially at the intermediate and advanced level, are quite flexible if you look at them and think about it. There are directive, coaching, supporting, and what I would call delegative, or good S4-style, coaching components, which are in the spirit of situational leadership.

Specifying the Steps

Now, to get more practical, the directive aspect of it is something like this. In the Toyota coaching form for problem-solving, you have to specify what the steps are and the expected outcome. You just don’t let people struggle. Of course, they get their basic training, but as a coach, you’re also explaining the steps, the expected outcome, what it looks like, and providing that quality instruction that people need.

Secondly, a level up from there, you’re also evaluating the content. So, you’re coaching and evaluating the content. You’re just not simply asking questions. You’re seeing what the student did versus the standard, and you’re giving them a rating of one, two, and three. One is “does not meet the expectation.” Two is “meets expectation.” Three is “exceeds expectation.” But as a coach, you have to say why. So in problem-solving steps one, two, three, four, five, six, seven, all eight steps, you have to rank it one, two, or three. You have to say why it does not meet expectation, why it meets expectation and yet still could be better, or three, obviously, if it exceeds expectation, explain how it exceeded expectation what was really good about it. But that’s good coaching.

That’s one of the difficult things about being a coach. You don’t give them the answer, but you also give them enough instruction so that they know the next steps to go forward.

Thirdly, there’s a supportive aspect of it. People who are kind of getting the steps and doing the content mostly right, but still need a few areas would get what we’d call S3 or supportive leadership, supportive coaching. You’re going to ask them targeted questions. The mistake I see in coaching is we’re just asking open-ended questions and expect the learner to figure it out. The Toyota coaching feedback questions are all targeted and quite directed. So for each of the eight steps, there’s a half dozen, five or six, questions. There’s anywhere from 40 to 50 targeted questions in there, in the coaching guide you ask the learner to help them think about the problem they’re faced with and what they might get a better idea or understanding from that targeted question.

Not anybody’s allowed to be a coach in Toyota. I think that’s one of the problems or misconceptions we have, that just because you can do problem-solving, you’re a good coach at it. That’s not always true in Toyota or the real world. It’s somewhat restricted to the better problem-solvers and the coaches with that capability, especially when you get to the statistical quality control, SQC, realm. It’s very advanced in Toyota, and a very, very small percentage of the population is as qualified to do that.

Toyota Coaching Overview

In a video, without going into an actual step-by-step problem, that’s the best I can do, trying to explain actual coaching practices in Toyota, what they look like, by level and by type, and by the situation. There are very advanced courses. I’m sad we don’t get to talk about them, but they’re very restricted in terms of access, and who gets to take those courses — and who gets to coach those is even more restrictive. I tapped out in the middle — at about the intermediate SQC level and multivariate regression analysis.

There are, of course, beginner courses that everybody sees and knows. That’s where you start. There are beginning guides, as I talked about, but it’s not one-size-fits-all. The best coaches know how to be directive, coaching, and supportive, and they know how to ask targeted questions that help people advance down the path of problem-solving. To me, that’s good coaching and the direction I hope we can go in the future with lean and problem-solving and other topics of a similar nature. So I hope that helps. See you in the next video.

Intro to Problem-Solving

Learn a proven, systematic approach to resolving business and work process problems.

Written by:

About Art Smalley

Art is the author of the LEI workbook Creating Level Pull: a lean production-system improvement guide for production control, operations, and engineering professionals, which received a 2005 Shingo Research Award. He was inducted into the Shingo Prize Academy in 2006. Art learned about lean manufacturing while living, studying, and working in Japan…

Leave a Comment Cancel reply