To read this content please select one of the options below:

Please note you do not have access to teaching notes, drivers, barriers and performance outcomes of sustainable packaging: a systematic literature review.

British Food Journal

ISSN : 0007-070X

Article publication date: 23 July 2021

Issue publication date: 8 February 2022

This paper presents a comprehensive overview of the cross-disciplinary literature on the drivers, barriers and performance outcomes of sustainable packaging to understand the current state of research in this field and identify research opportunities.

Design/methodology/approach

A systematic review is conducted within no time limit. The Methodi Ordinatio methodology was applied that resulted in retaining 48 relevant and high impact articles published in 26 academic journals with various scopes.

Seven key drivers are identified and defined: the integrative and collaborative supply chain, environmental capabilities and resources, market-based instruments, cost reduction, consumer pressure, competitive advantage, and regulatory pressure. Three main barriers are identified and defined: cost/benefit ambiguity, additional costs and complex trade-offs between packaging requirements. The review shows that the drivers and barriers to packaging sustainability are contingent on the firm size. Sustainable packaging positively affects the environmental, social and economic performance; however, its operational performance requires a proactive and integrated supply chain. The results highlight the importance of integrated packaging decisions at three different levels to improve packaging sustainability: vertical and horizontal integration, upstream and downstream integration, and product-packaging integration. The authors developed research propositions and provided insightful directions for future research.

Originality/value

Most studies focus on specific drivers, barriers and outcomes of sustainable packaging, while this paper brings them together to build a comprehensive framework. The latter provides a deeper understanding of the factors that incentivize or deter firms from pursuing sustainable packaging and its performance outcomes.

- Sustainable packaging

- Performance outcomes

- Systematic literature review

Acknowledgements

The authors would like to thank the anonymous reviewers and the editor of British Food Journal for their valuable suggestions and comments on earlier drafts on this paper.

Funding : Doctoral Fellowships, Social Sciences and Humanities Research Council (SSHRC), Grant Number/Ref. CRSH: 752-2020-1649. Insight Development Grants, Social Sciences and Humanities Research Council (SSHRC).

Afif, K. , Rebolledo, C. and Roy, J. (2022), "Drivers, barriers and performance outcomes of sustainable packaging: a systematic literature review", British Food Journal , Vol. 124 No. 3, pp. 915-935. https://doi.org/10.1108/BFJ-02-2021-0150

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

Sustainability in packaging 2023: Inside the minds of global consumers

Sustainability continues to be an increasingly important issue for the packaging value chain. At the same time, consumer awareness is also growing. As societies emerge from the COVID-19 pandemic, consumer sentiment is evolving away from a hyperfocus on hygiene. To understand this better, we launched a survey across 11 countries to explore consumers’ attitudes toward sustainable packaging. This builds on our 2020 work focusing on consumer sentiment globally, 1 “ Sustainability in packaging: Inside the minds of global consumers ,” McKinsey, December 16, 2020. as well as our 2023 work related to consumer sentiment in the United States. 2 David Feber, Abhinav Goel, Daniel Nordigården, and Suku Ponkshe, “ Sustainability in packaging: US survey insights ,” McKinsey, April 26, 2023.

About the authors

Our 2023 survey covers a statistically significant sample size across 66 percent of global GDP and 50 percent of the global population, as well as across demographics in each of the 11 countries. Responses from more than 11,500 consumers reveal three main findings. First, across all countries, hygiene and shelf life top the list of factors important in consumers’ purchasing decisions. Second, on the environmental impact of product packaging, consumer concerns related to ocean litter are most evident in Europe, Japan, and the United States. Meanwhile, consumers in other Asian countries and Latin America seem most concerned about other forms of pollution. And finally, consumers around the world have different opinions on what type of packaging is most sustainable. That said, there is agreement on what the least-sustainable options are.

As this survey shows, it is clear that packaging companies will need to tailor their approaches to respond to an evolving and varied consumer landscape. In this article, we suggest five critical questions they will need to answer while building their future strategies.

Post-COVID-19 trends in packaging sustainability

In the early stages of the pandemic, hygiene concerns paused the drive to eradicate single-use packaging across several regions. 3 For full details, see David Feber, Oskar Lingqvist, and Daniel Nordigården, “ Shaping the next normal of packaging beyond COVID-19 ,” McKinsey, May 26, 2020. However, we are now seeing a shift away from this. The majority of consumers are less concerned about hygiene and food safety than they were during the pandemic, even though their level of concern is still above where it was before COVID-19 pandemic (Exhibit 1).

Nevertheless, even with the significant reductions of COVID-19 concerns, consumers still prioritize hygiene and food safety and shelf life as the two most important aspects of product packaging (Exhibit 2).

Similar to 2020, 4 For more on the results of the 2020 survey, see “ Sustainability in packaging: Inside the minds of global consumers ,” McKinsey, December 16, 2020. price and quality continue to be most important for consumers when making a product purchasing decision. Compared to 2020, overall price has become even more important as a decision criterion, up 11 percent. In developed nations such as France, Germany, Italy, Japan, Sweden, the United Kingdom, and the United States, price as a decision criterion has climbed by double digits. By comparison, price is still significant in developing nations such as Brazil, China, India, and Mexico, but its importance has risen by low to mid-single digits compared to 2020.

The future of sustainability in packaging

As time moves on from the outbreak of COVID-19, sustainability pressure is building once again. Manufacturers and retailers of fast-moving consumer goods continue to innovate new packaging formats to improve circularity, particularly focusing on recycled content such as post-consumer resin. These innovations come as players seek to deliver on their own sustainability commitments and address consumer expectations, nongovernmental organization voices, and new packaging regulations.

Currently, new regulation governing sustainability dimensions of packaging is expanding on multiple fronts such as proportions of recycling or recycled content and is no longer confined to select countries or regions. As a result, these regulations have become more of a global phenomenon, even if their levels vary. However, exactly what consumers are concerned about in terms of environmental impact differs, depending on region (Exhibit 3).

Consumers in developing economies, especially China, Brazil, and India, are more concerned about both air and water pollution, while ocean litter is top of mind for most consumers in Europe, Japan, and the United States.

In all surveyed countries and across end-use areas, the majority of respondents claim to be willing to pay more for sustainable packaging, although willingness to pay more for packaging is much higher in developing nations. Willingness to pay is highest in the fresh fruit or product and fresh meat or poultry categories. In most countries, higher-income groups have a greater willingness to pay for sustainable-packaging offerings compared to the same product with nonsustainable packaging.

In Europe, better product labeling and rebate or incentive programs could encourage consumers to buy more products with sustainable packaging; in some other countries, increased availability of sustainable products and improved pricing could encourage consumers to buy packaging that is more sustainable. Accordingly, companies can continue to pursue a nuanced approach, remaining flexible about the sustainability levers deployed within each country.

Packaging substrates: What do consumers prefer globally?

Our recent research on packaging and sustainability shows that no single packaging type (whether plastic, glass, metal, or paper) is an absolute leader across every attribute of packaging sustainability. All types have both positive and negative features that vary in terms of sustainability, application, and region. Still, the question often asked is which packaging substrate is seen as the most sustainable by consumers. Our survey indicates consumers around the world are not fully aligned in their views on what the most sustainable packaging materials might be (Exhibit 4):

- Compostable and plant-based packaging (for example, sugar cane and cornstarch) tends to rank higher in several countries, with the exception of Japan. In Japan, consumers view plastics made from recycled content or fully recyclable plastics as being equally sustainable as compostable packaging.

- Globally, plastic films made from renewable or compostable material also rank high.

- Paper scores high on average and especially high in countries such as India and the United Kingdom.

Five critical questions to consider

We suggest that packaging suppliers and consumer companies take a strategic look at their portfolios, being careful to assess them in the context of five critical questions:

- What are unique generational trends that can affect products over the next five to seven years?

- Which products are most at risk based on anticipated regulatory changes and consumer perception?

- What innovation and disruption are being pursued by competitors and innovators across key product areas?

- What are the potential growth opportunities in which the company would be uniquely positioned to provide winning solutions regarding sustainability and circularity?

- What are the nuances across demographics that can help better align products to end-market segments?

Consumer sentiments have been shifting as the world emerges from the COVID-19 pandemic, and in some cases, these are continuing to diverge across countries, regions, and demographics. In this rapidly evolving landscape, companies can develop nuanced strategies to help create growth opportunities and to emerge as winners.

David Feber is a senior partner in McKinsey’s Detroit office, Abhinav Goel is a partner in the Pittsburgh office, Daniel Nordigården is a partner in the Toronto office, Suku Ponkshe is an associate partner in the Atlanta office, and Mukund Prasad is a partner in the Toronto office.

The authors wish to thank Audrey Gotko, Felix Gruenewald, Lucas Menanix, Emily Roeper, Matthew Seidner, Lizzie Shilko, and Binghong Xie for their contributions to this article.

Explore a career with us

Related articles.

Sustainability in packaging: Inside the minds of US consumers

Sustainability in packaging: Inside the minds of global consumers

The potential impact of reusable packaging

Journal of Packaging Technology and Research

- Offers comprehensive insights into packaging technology, materials, design, and equipment.

- Places significant emphasis on sustainable packaging and the packaging needs of emerging economies.

- Published in collaboration with the Indian Institute of Packaging.

- Follows a single blind peer review process.

- Regularly publishes original research, review articles, and case studies.

- Tanweer Alam

Societies and partnerships

Latest issue

Volume 8, Issue 1

Latest articles

Temperature control and data exchange in food supply chains: current situation and the applicability of a digitalized system of time–temperature-indicators to optimize temperature monitoring in different cold chains.

- Claudia Waldhans

- Antonia Albrecht

- Judith Kreyenschmidt

Innovations in Packaging to Monitor and Maintain the Quality of the Food Products

- Neelam Yadav

- Raminder Kaur

Novel Approach Coating by Edible Biopolymers of Sesame Fermented with Lactobacillus plantarum to Improve the Shelf Life of Strawberries and Preserve Their Nutritional Quality During Storage

- Roua Khalfallah

- Manel Mechmeche

- Faten Kachouri

Application of Gasotransmitters in Nanomaterials-Based Food Packaging

- Devyani Wakchoure

- Namrah Azmi

- Atul Chaskar

Whey Protein Concentrate Coating Incorporated with Modified Atmosphere Packaging for Extending Tangerines Shelf-Life: Physicochemical, Microbiological and Sensory Evaluation Through Refrigerated Storage

- Parvin Boghori

- Fakhri Shahidi

- Sahar Roshanak

Journal information

- CAB Abstracts

- Google Scholar

- IFIS Publishing

- Japanese Science and Technology Agency (JST)

- OCLC WorldCat Discovery Service

- TD Net Discovery Service

Rights and permissions

Springer policies

© Indian Institute of Packaging

- Find a journal

- Publish with us

- Track your research

Mettler-Toledo Showcases World-Class Product Inspection Systems at Interphex

Pharmaworks Introduces Blister Machine Compatibility with New 100% Recyclable Mono-Material Packaging Film

Design for recycling – sustainable packaging solutions from SÜDPACK at CheeseExpo, Milwaukee, WI

iF International Forum Design GMBH Announces 2024 Programming Including First-ever Metaverse Experience and Trend Conference

drupa 2024 Highlights: Highcon Features New Digital Die Cutting Solutions

- Digital Edition

- Buyers Guide

- Caps & Closures

- Case Packaging

- Coding/Marking/Labeling

- Dust Collectors

- End-of-Line

- Filling & Form/Fill/Seal

- Inspection/Detection/Vision

- Palletizing

- Robotics/Automation

- Serialization/Track & Trace

- Thermoforming

- Tray Forming/Sealing

- Beverage Packaging

- Personal Care

- Pharmaceutical/Medical

- Adhesives/Sealants

- Cans & Bottles

- Films & Coatings

- Paperboard/Corrugated Cartons

- Rigid Containers

- Sustainable

- Upcoming Conference News

- eNewsletter

- Industry Studies

- How To Guide

- Free On Demand Webinars

- Packaging Technology Today Blog

- Thought Leadership Interviews

- Oriental Motor USA Corp

Paper-based Packaging Has a Great Sustainability Story

Built around comedian and actress Retta, the Go Papertarian! initiative is getting consumers to think about product packaging both before purchase and at the point of sale. Image Courtesy of The Paper and Packaging Board.

It Deserves Great Storytellers

By Mary Anne Hansan, president of the Paper and Packaging Board (P+PB)

In 2014 the U.S. Department of Agriculture put a question to U.S. manufacturers and importers of paper and paper-based packaging: should they join forces to help market and educate consumers about a great American natural resource?

The Paper and Packaging Board exists because they said “yes.” Three times.

Today, our consumer campaign is about sharing paper and packaging’s environmental story that is especially important in a world where more people than ever are concerned about doing the right thing for the planet.

Our campaign messaging is informed by careful research and close collaboration with our Board.

We know, for instance, that 84% of our most important consumer segment — we call them “Expressives” because they are united by their way of seeing the world as opposed to any particular demographic characteristic — are increasingly concerned about consumption of paper and paper-based packaging. In short, they feel guilty about waste.

But we also know their guilt is fueled by misunderstandings. In fact, 58% of these consumers incorrectly think forests are shrinking, not growing; and 61% think this natural resource is “fragile,” when it’s actually one of the most robust and replenishable resources on earth.

Focusing on sustainability

Still, there is good news, and a reservoir of good will for us to tap. Three out of four Expressives feel positively about our industry and products, and they prefer paper-based products over plastics by a two-to-one ratio. We can and must build on this.

Our latest research shows that we are building on it. It shows that when consumers learn the facts about our industry’s sustainability practices, they feel better about the industry.

And here is where a dogged focus on sustainability translates into an increase in consumer preference: when people feel like they are part of the environmental solution by choosing paper products, their likelihood of consuming them increases. Simply put, they feel good about what they’re buying, so they buy more.

We’ve also learned how to move the dial by connecting our industry and product sustainability benefits to consumer values and aspirations. We’ve pinpointed the specific language and messages that work. And with that roadmap in hand, our campaign has already begun telling a powerful sustainability story at a scale, the way only we can.

And while we always seek to highlight both paper and packaging, there’s no question that packaging—and sustainable packaging innovations in particular—are at the core of all our work.

The Future of Recycling video showcases high-tech recycled paper mills, where piles of ordinary household garbage are turned into useful new products. Image courtesy of P+PB.

P+PB initiatives

We’re promoting multiple initiatives, along with other supporting materials, across multiple channels, including traditional television, cable, streaming, paid digital channels, magazines, podcasts, social media, and the campaign’s own HowLifeUnfolds website. Here’s some of the highlights:

The centerpiece, Go Papertarian! Initiative, built around comedian and actress Retta, is getting consumers to think about product packaging both before purchase and at the point of sale. Our spots see Retta at work, home, and the grocery store, pointing out the sustainable virtues of paper and paper-based product packaging, and using humor to gently correct underinformed foils, like her intern and neighbors, about the proper ways to recycle — all the while showcasing the industry’s impressive diversity of products.

PackIt! The Packaging Recycling Design Challenge has contestants compete to design recyclable product packaging from the ground up in 10 hours, with a $5,000 prize for the winner.

The Box to Nature residential recycling labeling initiative includes a persuasive recycling reminder brands can use on all kinds of boxes. And, we have multiple partnerships with recycling influencers showing consumers how to become “super recyclers.”

The Future of Recycling video showcasing the newest, biggest and most high-tech recycled paper mills in North America from Graphic Packaging in Kalamazoo, Michigan; and a bold and potentially game-changing experimental facility from Georgia-Pacific in Toledo, Oregon, where a paper company’s recycling is not just paper and boxes but turning piles of ordinary household garbage into useful new products.

What’s next?

We’re hard at work thinking up the next iteration of our story, to ensure both that consumers continue to say “yes” to paper-based packaging and products, and to make sure that our industry says “yes” the next time they’re asked whether we are delivering on our promise to them.

This moment needs products with a great sustainability story. And that story deserves great storytellers.

About the Author As President of the Paper and Packaging Board (P+PB), Mary Anne Hansan leads P+PB’s How Life Unfolds® national consumer and B2B marketing campaign, reaching millions of consumers each year. The campaign, collectively funded by 46 manufacturers and importers, promotes the use of paper products and paper-based packaging by highlighting how their sustainable nature, the industry’s practices and recycling help contribute to a healthier planet. Learn more at www.paperandpackaging.org .

featured-jan2024 , January 2024 , Paper and Packaging Board (P+PB)

Share on Socials!

Related Articles

Designing Labels for Effective Quality Inspection

Cct announces results of new study detailing consumer preferences for the aluminum lug eeasy lid, plastic ingenuity shares progress and industry trends in new circularity report.

Follow PTT!

Sign up to receive our industry publications for FREE !

Latest Digital Edition

Green Chemistry

Sustainable biodegradable coatings for food packaging: challenges and opportunities.

* Corresponding authors

a School of Engineering, Thornbrough Building, University of Guelph, Guelph, Ontario, Canada E-mail: [email protected]

b Bioproducts Discovery and Development Centre, Department of Plant Agriculture, Crop Science Building, University of Guelph, Guelph, Ontario, Canada

This review article provides a thorough overview of barrier coating materials that have been used in food packaging with a focus on biodegradable (bio-based or petroleum-based) materials, such as lipids, proteins, polysaccharides, agriculture waste and polyesters. The goal is to provide an opportunity to acknowledge progress made in this field, focusing on modifications made to coatings. These modifications aim to address the shortcomings of biodegradable substrates (either plastic or paper) and improve their performance, enabling them to compete with traditional petroleum-based food packaging materials. This includes their barrier against water vapor and oxygen, mechanical and surface characteristics (sealability and adhesion), as well as antimicrobial properties. The barrier of most biodegradable polymers underperforms in comparison with petroleum-based non-biodegradable polymers, which possess either high water vapor barrier or high oxygen barrier. Coating technology is a promising solution particularly in barrier improvement of biodegradable polymers. Currently, there are only metallized, or inorganic nanosheet coatings available for biodegradable films that meet food packaging requirements. There are some challenges in this field, for example, being able to retain the coating's biodegradability despite applied modifications to improve it's performance, the large-scale fabrication of biodegradable coatings, the coating's delamination and heat-sealability during service time, and the migration of the coating into the packaged food. Moreover, green chemistry and its sustainability needs in biodegradable polymeric coatings are also discussed regarding new ideas and possible directions for widespread application of coatings in food packaging. This is the first review that specifically summarizes biodegradable coatings on plastic and paper substrates with a focus on coating modifications to improve the performance of the base substrate to meet the required properties for food packaging applications.

Article information

Download Citation

Permissions.

F. Jahangiri, A. K. Mohanty and M. Misra, Green Chem. , 2024, Advance Article , DOI: 10.1039/D3GC02647G

This article is licensed under a Creative Commons Attribution-NonCommercial 3.0 Unported Licence . You can use material from this article in other publications, without requesting further permission from the RSC, provided that the correct acknowledgement is given and it is not used for commercial purposes.

To request permission to reproduce material from this article in a commercial publication , please go to the Copyright Clearance Center request page .

If you are an author contributing to an RSC publication, you do not need to request permission provided correct acknowledgement is given.

If you are the author of this article, you do not need to request permission to reproduce figures and diagrams provided correct acknowledgement is given. If you want to reproduce the whole article in a third-party commercial publication (excluding your thesis/dissertation for which permission is not required) please go to the Copyright Clearance Center request page .

Read more about how to correctly acknowledge RSC content .

Social activity

Search articles by author.

This article has not yet been cited.

Advertisements

- Apply to UMaine

UMaine News

$1.6M donation will accelerate progress within the pulp and paper industry

Packaging Corporation of America (PCA) has donated $1.6 million to the University of Maine to establish the UMaine Sustainable Packaging Initiative.

The UMaine Sustainable Packaging Initiative is a research-based public and private consortium that focuses on using forest-based materials to accelerate the transition to renewable and recyclable packaging made from forest fiber.

“As a UMaine graduate, I am happy to be part of PCA’s involvement in the UMaine Process Development Center. This investment will enable the PDC to expand research and development activities and industry support to include packaging grades. Sustainable packaging represents a huge potential for the paper industry; it is exciting to be a part of this change both as a PCA employee and a UMaine advocate,” said Barbara Hamilton, senior director of process control technology at PCA.

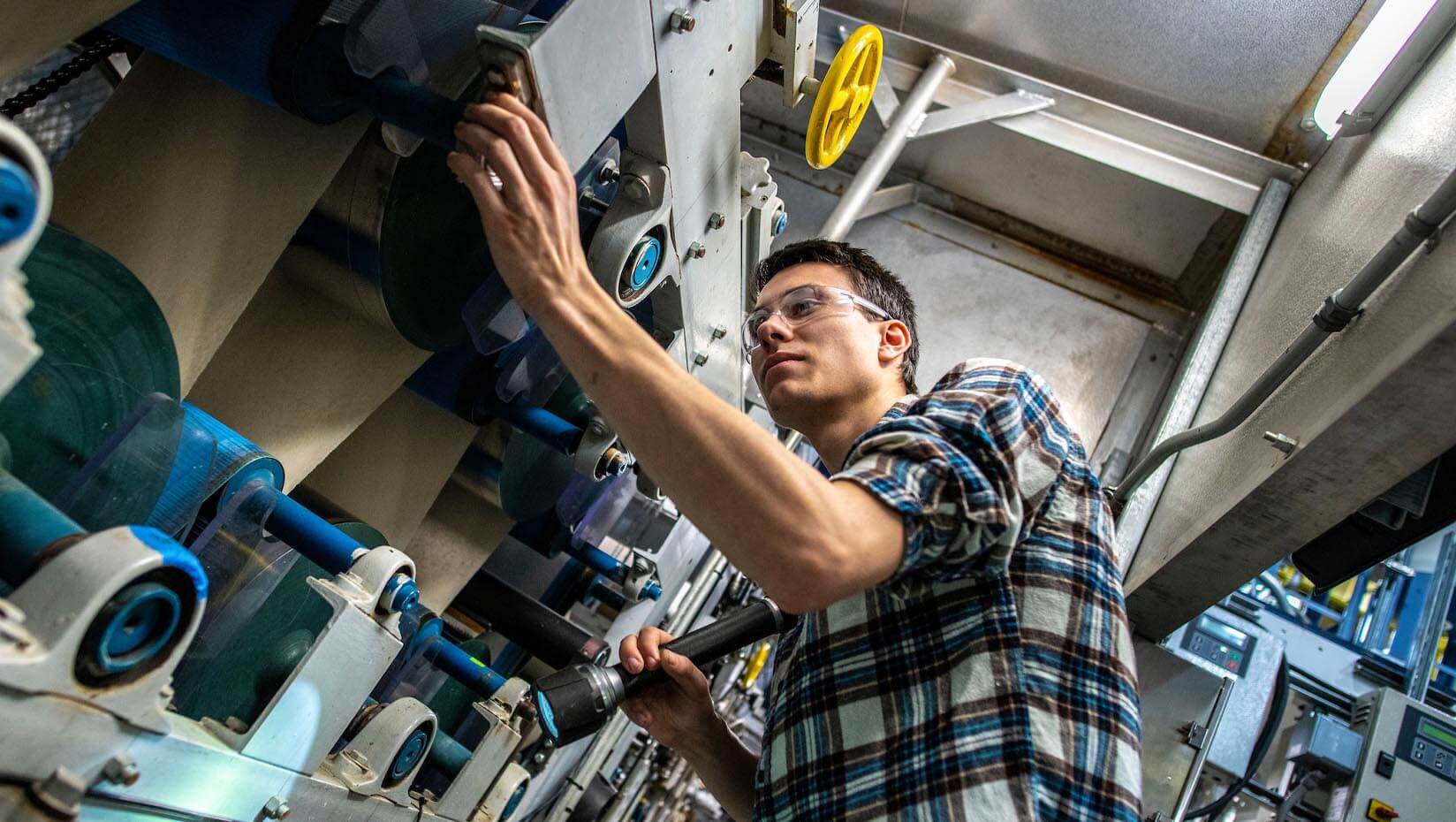

PCA’s donation will support the university’s Process Development Center (PDC). The PDC is a unique, open-access research facility that offers research and development technical services and resources in traditional pulp and paper, as well as emerging process technologies and material science. Funds will provide infrastructure improvements and new equipment to foster growth in becoming the leading R&D/pilot production lab for renewable packaging in the U.S.

“This gift is transformative for the PDC,” said center Director Colleen Walker. “Not only will the PDC be better able to serve company and university researchers developing and commercializing new forest-based solutions for packaging, but we are engaging our Black Bear students in this process to provide hands-on research learning experiences.”

PCA’s donation will also help leverage the $75 million matching challenge grant from the Harold Alfond Foundation to support the Maine College of Engineering and Computing, a signature initiative of UMS TRANSFORMS . The initiative is focused on attracting thousands of new engineering and computing students to the state and expanding educational opportunities in emerging fields such as artificial intelligence, renewable energy and advanced materials. The Maine College of Engineering and Computing is a statewide, integrated solution to providing the technical workforce and innovations critical to moving Maine’s economy forward and improving R&D for state-based industry.

“We are grateful to PCA for this generous gift that will allow the continued support of research and innovation at the University of Maine,” said UMaine President Joan Ferrini-Mundy. “This gift will position us as a world leader in sustainable packaging, as well as offer research learning opportunities to current and future students.”

PCA is a long-time supporter of UMaine through the UMaine Pulp and Paper Foundation. The foundation supports aspiring engineers who are interested in pursuing careers in the paper industry.

“The UMaine Pulp and Paper Foundation’s students have long benefitted from the extraordinary vision of PCA and its CEO and Chairman, Mark Kowlzan,” said UMPPF President Carrie Enos. “We are proud to connect PCA with our partners at the PDC as the University of Maine continues to build its reputation as a leader in cutting-edge uses for forest fiber.”

PCA’s donation is just one of several investments recognizing the leadership of the state and UMaine in the national forest sector. In October, Maine was designated a Forest Bioproducts Advanced Manufacturing Tech Hub by the Biden-Harris Administration through the U.S. Department of Commerce’s Economic Development Administration. In March, U.S. Sen. Susan Collins, vice chair of the Senate Appropriations Committee, and U.S. Sen. Angus King announced they had secured $10 million in one-time Congressionally Directed Spending to build and equip the Forest Biomaterials Innovation Center , an extension of the existing UMaine Process Development Center, to enable researchers and entrepreneurs to develop new forest-based products utilizing wood and wood residuals. These investments represent many of the recommendations from FOR/Maine to create jobs and economic opportunities for Maine’s forest economy and rural communities.

Contact: Shelby Hartin, [email protected]

- UMaine Today Magazine

- Submit news

- Share full article

Advertisement

Supported by

So Much Produce Comes in Plastic. Is There a Better Way?

As governments impose limits on plastic food packaging, climate-friendlier alternatives are in the works. Here are some that might be coming to a grocery store near you.

By Kim Severson

If it seems like plastic surrounds nearly every cucumber, apple and pepper in the produce aisle, it does.

What began with cellophane in the 1930s picked up speed with the rise of plastic clamshells in the 1980s and bagged salads in the 1990s. Online grocery shopping turbocharged it.

But now the race is on for what people who grow and sell fruits and vegetables are calling a moon shot: breaking plastic’s stranglehold on produce.

In a March survey among produce professionals on LinkedIn, the shift to biodegradable material was voted the top trend . “It’s big,” said Soren Bjorn, chief executive officer of Driscoll’s, the world’s biggest grower of berries, which has switched to paper containers in many European markets.

Spain has a plastic tax. France has severely limited plastic-wrapped produce and the European Union is about to add its own restrictions . Canada is trying to hammer out a plan that could eliminate plastic packaging of produce by 95 percent by 2028. In the United States, 11 states have already restricted plastic packaging. As part of a sweeping anti-waste plan, the Biden administration is calling for new ways to package food that uses climate-friendly, antimicrobial material designed to reduce reliance on plastic.

So we agree that eliminating plastic is the answer?

Reducing the use of plastic is an obvious way to push back against a changing climate. Plastic is created from fossil fuels, the biggest contributor to greenhouse gases . It chokes the oceans and seeps into the food chain. Estimates vary, but about 40 percent of plastic waste comes from packaging.

Yet plastic has so far been the most effective tool to fight another environmental threat: food waste.

Wirecutter shares tips for keeping your produce fresh for weeks.

Selling produce is like holding a melting ice cube and asking how much someone will pay for it. Time is of the essence, and plastic works well to slow the decay of vegetables and fruit. That means less produce is tossed into the garbage, where it creates almost 60 percent of landfill methane emissions, according to a 2023 report by the Environmental Protection Agency.

A Swiss study in 2021 showed that each rotting cucumber thrown away has the equivalent environmental impact of 93 plastic cucumber wrappers.

Food is the most common material in landfills. The average American family of four spends $1,500 each year on food that ends up uneaten. Of that, fruits and vegetables make up nearly half of all household food waste, according to research from Michigan State University. And it’s not just the wasted food that adds to climate change. The farming and transportation wasted to produce food that is discarded impacts the climate, too.

Preventing food waste and reducing the use of plastic aren’t mutually exclusive goals. Both are high on the agenda of the Biden administration, which in December issued a draft of a national strategy to halve the nation’s food loss by 2030.

Are Americans on board?

Consumers increasingly report that using less plastic and packaging matters to them, but their shopping habits tell a different story. American shoppers bought $4.3 billion worth of bagged salad last year, according to the International Fresh Produce Association. Marketing experiments and independent research both show that price, quality and convenience drive food choices more than environmental concerns.

Grocers are having to make tough decisions, too. Shoppers have complained about having to buy produce that has already been packed in plastic and priced. Not selling by weight is easier for the store, whose workers don’t have to weigh each item. But it often forces shoppers to buy more than they need.

Battle lines seem to be drawn between the never-plastic crowd and shoppers who prefer the ease of fresh salad greens delivered to their door.

“The packaging conversation is being held hostage by one side or the other,” said Max Teplitski, chief science officer of the International Fresh Produce Association. He leads the Alliance for Sustainable Packaging for Foods , a collection of industry trade groups that formed in January.

The group’s priority is to make sure that any changes in packaging will keep food safe and preserve its quality.

What alternatives to plastic are coming?

Here are a few new ideas headed to the produce aisle:

Bags from trees. An Austrian company is using beechwood trees to make biodegradable cellulose net bags to hold produce. Other companies offer similar netting that decomposes within a few weeks.

Film from peels. Orange peels, shrimp shells and other natural waste are being turned into film that can be used like cellophane, or made into bags. An edible coating made from plant-based fatty acids is sprayed on cucumbers, avocados and other produce sold at many major grocery stores. They work in a way similar to the wax coating commonly used on citrus and apples.

Clamshells from cardboard. Plastic clamshells are a $9.1 billion business in the United States, and the number of growers who use them is vast. Replacing them will be an enormous challenge, particularly for more fragile fruits and vegetables. Plenty of designers are trying. Driscoll’s has been working to develop paper containers for use in the United States and Canada. In the meantime, the company is using more recycled plastic in its clamshells in the United States.

Ice that feels like gelatin. Luxin Wang and other scientists at the University of California, Davis, have invented reusable jelly ice . It is lighter than ice and doesn’t melt. It could eliminate the need for plastic ice packs, which can’t be recycled. After about a dozen uses, the jelly ice can be tossed into a garden or the garbage, where it dissolves.

Boxes with atmosphere. Broccoli is usually shipped in wax-coated boxes packed with ice. The soggy cartons can’t be recycled. Iceless broccoli shipping containers use a mix of gases that help preserve the vegetable instead of chilling it with ice, which is heavy to ship and can transmit pathogens when it melts. Other sustainable, lighter shipping cartons are being designed to remove ethylene , a plant hormone that encourages ripening.

Containers from plants. Rice-paddy straw left over after harvests, grasses, sugar cane stalks and even food waste are all being turned into trays and boxes that are either biodegradable or can be composted.

Problem solved, right?

Hardly. Even if every grower and grocer started using packaging that could be recycled or composted, America’s infrastructure for turning it into something besides trash is spotty at best. Less than 10 percent of all plastic is recycled, a figure that is even lower for produce packaging, said Eva Almenar , a professor at Michigan State University’s School of Packaging . Only a small fraction of packaging labeled compostable stays out of the landfill.

Just 3 percent of wasted food lands at industrial composting centers. Several states have no commercial operations that can compost food waste.

“We don’t have right the technology, and we don’t have the collection systems,” Dr. Almenar said.

Even if the infrastructure were in place, people’s habits aren’t. “Consumers have no clue about what means green, compostable or recyclable,” she said.

Practically, no one has yet devised an affordable plastic alternative that can be recycled or composted and also keeps fruits and vegetables safe and fresh. Plastic allows packers to modify the mix of gases inside a package in a way that extends the shelf life and the quality of fresh produce.

“The pushback you are getting is that if you eliminate plastic and go to fiber, it depletes the shelf life really fast,” said Scott Crawford, vice president of merchandising for Baldor Specialty Foods and a veteran of both Whole Foods Market and Fresh Direct. “The question is which side of the balloon are you trying to squeeze?”

The ideal solution, he said, would be to go back to the days before plastic, when grocers stacked their produce by hand and no one demanded that seasonal fruit like blueberries be available year-round.

“I don’t think we’re going to live to see that,” he said.

Follow New York Times Cooking on Instagram , Facebook , YouTube , TikTok and Pinterest . Get regular updates from New York Times Cooking, with recipe suggestions, cooking tips and shopping advice .

Kim Severson is an Atlanta-based reporter who covers the nation’s food culture and contributes to NYT Cooking . More about Kim Severson

Unpacking the Plastic Problem

It’s in our clothes, phones and sunscreen. but also, increasingly, in marine food chains and immense garbage patches in the oceans. how do we fix this.

Recycling options are limited for personal medical devices like inhalers and EpiPens, which are made from high-quality plastic. Some companies are trying to change that .

Here’s what scientists know so far about the health effects of nanoplastics, and what you can do to reduce your exposure .

As more consumers try to cut down on plastic waste, start-ups and big brands are hoping to usher in a new age of refillable household cleaners .

Plastic waste is everywhere, and today’s recycling systems fall far short of fixing the global mess . Here’s why, and what needs to change .

Plastic is all around us, despite its adverse effects on the planet. In a 24-hour experiment, this journalist tried to go plastic free .

Want to cut down on your plastic use? Here are nine steps to get you started.

- Environment

Amazon Is Capable of Reducing Plastic Waste in the US. So Why Isn’t It?

It has done so elsewhere—when forced, a new report shows., joseph winters.

- Share on Facebook

- Share on Twitter

Lea Suzuki / The San Francisco Chronicle via Getty Images via Grist

This story was originally published by Grist and is reproduced here as part of the Climate Desk collaboration.

In response to growing pressure to address the plastic pollution crisis, Amazon has been cutting down on plastic packaging. Last July, the company said it used 11.6 percent less plastic for all of its shipments globally in 2022, compared to 2021. Much of Amazon’s reductions took place in countries that have enacted—or threatened to enact—restrictions on certain types of plastic packaging. But the company’s progress may not extend to the US, which has not regulated plastic production on a federal level.

Amazon generated 208 million pounds of plastic packaging trash in the United States in 2022, about 10 percent more than the previous year, according to a new report from the nonprofit Oceana. This packaging includes Amazon’s ubiquitous blue-and-white mailers, as well as other pouches, bags, and plastic cushioning. If all of it were converted into plastic air pillows and laid end to end, Oceana estimates it would circle the Earth more than 200 times.

“The crisis is so significant that we need change now,” said Dana Miller, Oceana’s director of strategic initiatives and an author of the report.

Miller and her co-authors are calling on Amazon to stop using plastic packaging in the US, citing phaseouts in some of the company’s biggest overseas markets as evidence that such a transition is possible. Amazon has done “some pretty impressive things in Europe and India, but in the US they are not making the same sort of commitments,” Miller added. “The company has made great progress, but it’s just not enough.”

To calculate Amazon’s US plastics footprint, Oceana used market research on the amount of plastic consumed in 2022 by the American e-commerce industry—more than 800 million pounds — and multiplied that by Amazon’s share of the market, 30.5 percent. Oceana then made some downward revisions to account for Amazon’s publicly disclosed efforts to reduce plastic packaging. For instance, in 2022, Amazon said it replaced 99 percent of its mixed-material mailers with paper ones and delivered 12 percent of its US shipments in 2022 without adding any of its own packaging.

The resulting estimate, 208 million pounds, is about 11 times the weight of Seattle’s most iconic landmark, the Space Needle.

This is worrisome because the type of plastic typically used in Amazon packaging—known as “film”—is almost never recycled. Most of it is sent to landfills or incinerators , or is discarded into the environment. According to one 2020 study , plastic film is among the most common forms of marine plastic litter near ocean shores, where it kills more large marine animals than any other type of plastic. Oceana estimates that 22 million pounds of Amazon’s global plastic packaging waste generated in 2022 will end up in aquatic environments.

Plastic production causes additional concerns. The extraction of fossil fuels used to make plastic, plus the conversion of those fossil fuels into plastic products, releases carbon and air, water, and soil pollution that disproportionately affects low-income communities and communities of color.

Miller said she’d like Amazon to reduce plastics “because of a moral responsibility … to reduce their impact on the environment.” But the company has been slow to respond to moral appeals from customers and shareholders, including three shareholder resolutions since 2021 invoking plastics’ damages to marine ecosystems and human health. The resolutions, which each received more than 30 percent of shareholder votes, asked Amazon to cut plastics use globally by one-third by 2030. When announcing that it had cut plastics use globally by 11.6 percent, Amazon did not make a quantitative or time-bound commitment to further reductions.

Instead, Amazon seems to have taken its biggest steps to reduce plastic packaging in response to stringent plastic regulations, or the threat of them. “Amazon is a clever company,” Miller said. “They see things in the pipeline and they want to move early.”

In 2019, for example, Amazon India pledged to phase out plastic packaging after Prime Minister Narendra Modi called on constituents to “ make India free of single-use plastic ,” hinting that he would announce major restrictions on the material later that year. Within months, Amazon India said it had eliminated plastic packaging from the country’s fulfillment centers, replacing it largely with paper.

In the European Union, a directive on single-use plastics has made it unlawful since 2021 to sell several types of single-use plastic, including bags, and after a long drafting process, the bloc last month agreed to “ historic ” targets to reduce packaging waste by 15 percent by 2040. Amazon said in 2022 that it had eliminated single-use plastic delivery bags at its fulfillment centers across the continent.

Despite efforts from progressive lawmakers , the US still lacks a federal plan to phase down plastic packaging, which could help explain why Amazon hasn’t acted more aggressively on the issue stateside. A spokesperson for the company told Grist last month that Amazon has started a “multiyear effort” to transition US fulfillment centers from plastic to paper packaging, but the company has not announced a timeline for that transition.

Then again, Amazon’s American presence is also much larger than its operations overseas; the fact that US orders make up nearly 70 percent of Amazon’s total sales may make it more complicated to change packaging materials here.

“It would be a bigger deal for them to eliminate plastics in the United States,” said Jenn Engstrom, director of the California chapter of the nonprofit US Public Interest Research Group, who was not involved in the Oceana report. “But they’re also one of the most innovative and biggest companies in the world; just because it’s hard to do doesn’t mean they shouldn’t do it.”

Amazon, the largest e-commerce company in the world, sold more than half a trillion dollars ’ worth of goods last year. Its main American competitor, Walmart, said last month that it had eliminated single-use plastic from its mailing envelopes globally. In China, the retailer JD.com is replacing disposable packaging altogether with reusable alternatives .

Engstrom pointed to some some state-level policies that could affect Amazon’s plastics use—most notably in California, where a law enacted in 2022 requires that companies reduce their overall packaging distributed in the state by 25 percent by 2032. Washington state tried to pass a similar law last year, but the proposal died in committee . Five other states have passed less specific bills on “ extended producer responsibility ,” or EPR, that attempt to make plastic producers financially responsible for the waste they generate—often by having them fund improvements in recycling infrastructure.

Although Amazon is funding several efforts to improve plastics recycling , Oceana says that this is “not the solution the company should be relying on.” Plastic film cannot reliably be recycled due to technical and economic constraints; virtually no curbside recycling program accepts it. In a best-case scenario, plastic film can be downcycled into plastic decking material or benches, but recent investigations suggest that store drop-off programs meant to facilitate this process often end up dumping Amazon packaging in landfills or burning it in incinerators.

When American consumers mistakenly put Amazon’s plastic packages in their curbside recycling bins— as many do —a 2022 Bloomberg investigation found that they may end up at illegal dump sites and industrial furnaces in Muzaffarnagar, India, with potentially dire consequences for nearby residents’ health.

Pat Lindner, Amazon’s vice president of mechatronics and sustainable packaging, called Oceana’s study a “misleading report with exaggerated and inaccurate information,” and told Grist that Amazon is committed to reducing its plastic footprint at US fulfillment centers. A spokesperson said the company is proud of reducing its plastic footprint in Europe and India and that it would continue to share updates on its progress in the US. The spokesperson also said Amazon is committed to good-faith engagement with shareholders on plastic-related resolutions.

Oceana said the company declined the nonprofit’s requests for country-level data on its plastics use. The company also declined to share data on plastic packaging used in third-party shipments; Amazon’s disclosures for plastic packaging used in 2021 and 2022 only account for packages shipped from Amazon fulfillment centers.

“We are hoping that Amazon will provide more detailed data…and illuminate some of these questions,” Miller said.

Fossil Fuel Lobbyists Swarm UN Treaty Talks on Plastics Pollution

James Bruggers

Amazon Got a Perfect Score on Disability Inclusion—From a Group It Helps Fund

Julia Métraux

Amazon Drivers Protest Brutal Conditions—Including Extreme Heat

Tushar Khurana

Europe Just Passed a Sweeping Ban on Everyday Plastic Pollution

Jennifer Rankin

We Recommend

The Arizona Supreme Court Just Allowed a Near-Total Abortion Ban From 1864 to Go Into Effect

Katie Herchenroeder

Biden Administration Rejects Growing Accusations of Israeli Genocide in Gaza

Julianne McShane

Who Wants to Be a Trillionaire?

The Breathtaking Pace of Antarctic Warming Is Very, Very Worrisome

Robin McKie

Trump Helped Overturn Roe. Now He Wants to Run Away From the Consequences.

Don’t Be Dumb Like Donald Trump Today

This Land Is My Land: Inside the Growing Movement to Fight Conservation

Boyce Upholt

In Georgia, a Rare Bipartisan Push for Disability Rights

Sign up for our free newsletter.

Subscribe to the Mother Jones Daily to have our top stories delivered directly to your inbox.

By signing up, you agree to our privacy policy and terms of use , and to receive messages from Mother Jones and our partners.

Get our award-winning magazine

Save big on a full year of investigations, ideas, and insights.

Support our journalism

Help Mother Jones ' reporters dig deep with a tax-deductible donation.

Independent. In print. In your mailbox.

Inexpensive, too! Subscribe today and get a full year of Mother Jones for just $14.95.

Bold. Brave. Beautiful.

Award-winning photojournalism. Stunning video. Fearless conversations.

Looking for news you can trust?

We noticed you have an ad blocker on..

Can you pitch in a few bucks to help fund Mother Jones' investigative journalism? We're a nonprofit (so it's tax-deductible), and reader support makes up about two-thirds of our budget.

We noticed you have an ad blocker on. Can you pitch in a few bucks to help fund Mother Jones' investigative journalism?

Don't let an algorithm decide what news you see.

Sign up for the free Mother Jones Daily newsletter and follow the news that matters.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Materials (Basel)

Recent Advancements in Plastic Packaging Recycling: A Mini-Review

Valentina beghetto.

1 Department of Molecular Sciences and Nanosystems, University Ca’Foscari of Venice, Via Torino 155, 30172 Mestre, Italy; [email protected] (R.S.); [email protected] (C.B.); ti.evinu.duts@900078 (M.A.-A.); [email protected] (M.F.)

2 Crossing S.r.l., Viale della Repubblica 193/b, 31100 Treviso, Italy

Roberto Sole

Chiara buranello, marco al-abkal, manuela facchin, associated data.

Not applicable.

Today, the scientific community is facing crucial challenges in delivering a healthier world for future generations. Among these, the quest for circular and sustainable approaches for plastic recycling is one of the most demanding for several reasons. Indeed, the massive use of plastic materials over the last century has generated large amounts of long-lasting waste, which, for much time, has not been object of adequate recovery and disposal politics. Most of this waste is generated by packaging materials. Nevertheless, in the last decade, a new trend imposed by environmental concerns brought this topic under the magnifying glass, as testified by the increasing number of related publications. Several methods have been proposed for the recycling of polymeric plastic materials based on chemical or mechanical methods. A panorama of the most promising studies related to the recycling of polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS) is given within this review.

1. Introduction

In recent years, the health of our planet has become a problem of crucial importance, with plastic recovery and disposal being of primary relevance [ 1 ].

Since the introduction of Bakelite in 1907 by Leo H. Baekeland, the first fully synthetic polymer, the plastic industry has evolved to revolutionize the way we live [ 2 , 3 , 4 , 5 ].

Polymers and plastic products own their well-known ubiquity and massive use to their excellent chemical–physical properties, which guarantee light weight, low price, and endurance [ 6 ]. Thanks to their great versatility, plastics are among the most used materials and find applications in many industrial sectors such as packaging, automotive vehicles, construction, and electronic devices [ 1 , 7 , 8 ]. Worldwide, over 360 Mt of fossil-based polymers are produced yearly, with an annual growth rate of 8.4%, two times higher than world global gross growth rate of production over the same period [ 5 ] ( Figure 1 a). The European plastic converter demand in 2018 reached 51.2 Mt, mainly to produce polyethylene (PE), polypropylene (PP), polyvinylchloride (PVC), polyethylene terephthalate (PET), and polystyrene (PS) ( Figure 1 b). These are mainly employed for packaging (39.9%), construction (19.8%), automotive vehicles (9.9%), and electronic devices (6.2%) [ 9 ] ( Figure 1 c).

( a ) World polymer production in metric tons; ( b ) distribution of main polymers produced; ( c ) 2018 European plastic converter demand and use.

A gradual switch to biobased plastics has been witnessed by the increasing use at an industrial level of alternative raw materials [ 10 , 11 ] such as polylactic acid (PLA) [ 12 ], polybutyl succinate (PBS) [ 13 , 14 ], polyhydroxyalkanoate (PHA) [ 15 , 16 , 17 ], and polyethylene furanoate (PEF) [ 18 , 19 , 20 ], together with different composite materials produced from starch [ 21 , 22 , 23 , 24 ], CMC [ 25 , 26 , 27 , 28 , 29 , 30 ], wood [ 31 , 32 ], lignin [ 33 , 34 ], and many different agro-industrial wastes [ 35 , 36 , 37 ].

Nevertheless, 99% of plastics produced today are fossil-based polymers, and they will continue to play an important role in many manufacturing compartments for a long time. In fact, according to the 2020 European Bioplastics report, the EU total production capacity of biopolymers is expected to reach 2.45 Mt by 2024 ( Figure 2 ), which is far lower than the plastic market needs [ 38 ].

Projection of world global production capacity of bioplastics by 2024.

The large gap between market demand and biobased plastics available today clearly shows the complexity of the problem and that all alternatives to approach the problem of plastic use and recycling must be pursued to reduce the environmental impact of polymers and plastic waste. In a recent article by Mendes and coworkers, the benefits of the use of bioplastics for the packaging industry were analyzed with the intent of delivering a guide for the design of more sustainable packaging to food packaging designers and producers [ 39 ]. The authors concluded that, from a climate point, the use of biobased plastics contributes to the generation of more sustainable food packaging compared to fossil-based ones; however, on the other hand, the relevance of some environmental problems originating from biobased plastics, such as eutrophication, use of water and pesticides, and effects on biodiversity, significantly reduces their environmental benefits.

Additionally, fossil-based plastics are generally scantly biodegradable and accumulate in the environment, posing serious waste management problems. Over the last 65 years, approximately 8300 Mt of fossil-based polymers were produced, 4900 Mt of which were landfilled, incinerated, or dispersed in the environment [ 5 , 40 ]. Thus, oceans, animals, and humans are inevitably exposed to different sources of contamination from plastic waste [ 41 , 42 , 43 , 44 , 45 , 46 ]. Climate changes, environmental modifications, and health pandemics are becoming more and more frequent, showing that humanity will have to rethink its unsustainable growth [ 47 , 48 ] by adopting a circular economy approach to resource consumption through eco-design, recovery, and recycling of polymeric materials with an integrated approach [ 49 , 50 , 51 , 52 , 53 ]. Circular economy is pushing toward a radical change in production and waste management to reduce water, waste, and energy consumption and to achieve zero-waste manufacturing cycles [ 10 , 54 , 55 , 56 , 57 ]. In this frame, European countries have developed different waste management systems and recycling techniques [ 58 , 59 , 60 , 61 , 62 , 63 , 64 ]. Nevertheless, a great part of post-consumer managed plastic is currently sent to incineration or landfill, while mismanaged waste is either discarded into the environment or is inadequately disposed of, potentially ending up in the ocean [ 46 ]. From 2006 to 2018, the amount of recycled post-consumer plastic waste doubled, reaching 32.5% (29.1 Mt), while 42.6% was used for energy production and 24.9% was landfilled [ 9 ] ( Figure 3 ).

Reuse of recovered post-consumer plastic waste.

In 2018, 5 Mt of plastic waste was recycled in Europe, 80% of which re-entered the EU as secondary materials, while the remaining 20% was exported outside the EU. The main industrial uses of recycled plastics in the EU are building and construction (46%), packaging (24%), agricultural applications (13%), and others (17%) [ 9 ].

Plastics may be subdivided into three categories: plastics in use, managed post-consumer plastic waste, and mismanaged plastic waste [ 65 , 66 ]. Managed plastic waste is generally disposed of by recycling, although a substantial gap exists between the quantity of plastic produced each year and the quantity of plastic thrown away since, depending on the type of product, there will be different storage and use times. Packaging products end their lifecycle generally in less than 1 year, while materials used for the construction and transport industry may last much longer. This means that the amount of waste produced each year is less than the amount of plastic in use. In 2015, 407 Mt of primary plastic entered the use phase, while only 307 Mt exited the use phase, with a consequent increase of 100 Mt of plastic in use [ 5 ].

According to the literature, it was estimated that, in 2010, between 4.8 and 12.7 Mt of plastics were leached into the ocean, predicting that, with inadequate waste management strategies, these numbers will increase by an order of magnitude by 2025 [ 46 , 67 ]. On this note, in January 2018, the European Commission issued the “European strategy for plastics in a circular economy” [ 68 ], including the ambitious target to make all plastics in EU recyclable by 2030. Soon after, in March 2018, China banned imports of plastic, generating a decrease in plastic waste export from EU of 39%, thereby overloading the EU waste management system and incinerators [ 65 , 69 ].

To reduce the amount of plastic waste disposed in landfills or incinerated, there are two main strategies: the use of biodegradable biobased plastics (as mentioned above) [ 38 , 70 ] and recycling [ 71 , 72 , 73 , 74 ]. It should be reaffirmed that not all biobased polymers are biodegradable, while some fossil-based ones are, as clearly reported in Figure 4 .

Examples of biobased and fossil-based polymers subdivided into biodegradable and not biodegradable.

Moreover, the recovery and recycling of biobased polymers is a relatively new issue and is still the object of studies compared to fossil-based polymers [ 39 , 75 ]; thus, different strategies will need to be put in place to implement the environmental sustainability of polymer manufacturing and recycling. According to the recent Circular Economy Package EU legislation and a paper by Briassoulis and coworkers, mechanical recycling is the best alternative for the valorization of both post-consumer fossil-based and biobased polymer waste, followed by chemical recycling [ 75 , 76 ].

The topic of sustainable manufacturing of plastics and packaging is so important that, from a research on Google Scholar using as key words “sustainable plastics”, “recycled plastic”, and “plastic recycling techniques”, a total of almost 95,000 papers were published between 2019 and 2021. This mini-review intends to give an outlook on different mechanical and chemical recycling techniques, giving a general panorama of the state of the art and recent innovative solutions by focusing mainly on papers published in the last 12 months relevant to plastic packaging. The scope of the work is to give a general overview of most recent technologies for the recycling of post-consumer packaging waste (PP, LDPE, HDPE, PET, and PS) to be used as secondary materials for the manufacturing of different materials. Since it is possible that the EU will implement plastic recycling up to 100% by 2050, avoiding the use of virgin naphtha for its production, the use of plastic waste as a source of energy seems bound to assume a minor importance in the future, while recycling of polymers to produce high-value products will be of strategic importance. For this reason, techniques to produce energy from plastic waste will not be discussed in this mini-review. The authors believe that a good understanding of the possible alternatives to plastic recycling and valorization, together with the difficulties encountered in sorting and reprocessing of post-consumer plastic waste, should help the industry, as well as end users, to adopt more responsible behavior and, consequently, promote the introduction of environmentally sustainable solutions.

2. Overview of Plastic Recycling Techniques

The word recycling refers to a set of modifications and transformations (mechanical treatment, chemical treatment, or heating) required to recover feedstock from a previously processed polymer which can be reused by the industry [ 73 , 77 , 78 ]. Plastic recycling methods available today are classified in primary to quaternary processes [ 79 , 80 ] ( Scheme 1 ).

Specifically, primary processes allow recovering and recycling pre-consumer or pure polymers which can be reused for the same scope. Secondary processes start from recovered post-consumer polymeric waste, which is sorted, trimmed, and re-extruded, giving a product with reduced physical–mechanical characteristics compared to the starting polymer, which in most cases cannot be reused for the same scope. Primary and secondary recycling represents physical processes that can be repeated several times. Tertiary processes adopt chemical recycling starting from polymers which may no longer undergo mechanical recycling, while quaternary ones are used for energy production. Polymers and plastics sent to landfill (end-of-life plastics) lose their value and become waste.

Different techniques adopted for plastic waste separation, processing, and possible reuse as secondary materials depend on the type of waste recovered. A first important distinction should be made between thermoplastic and thermoset polymers. Thermoplastics are usually processed by extrusion, as these polymers melt when heated and harden when cooled. A great advantage of thermoplastics is that the extrusion process can be repeated many times. The most used thermoplastics are PP, PET, LDPE, HDPE, PVC, and PS. Adversely, thermosets may not be reprocessed by extrusion since, when heated, an irreversible chemical reaction takes place. Main thermoset plastics are polyurethanes (PUR), resins (epoxy, phenol-formaldehyde, and polyester), and vulcanized rubber, widely used by the automotive and electronic industry. The most abundant polymers in post-consumer waste are polyolefins (PP, LDPE, HDPE, PET, and PS) used for packaging [ 58 , 81 , 82 ], with a consumption of over 23 Mt only in the EU in 2020.

3. Primary and Secondary Recycling

Mechanical recycling is the main and most widely used technology for plastic recycling, consisting of several steps, including collection, screening, automatic or manual sorting, washing, shredding, extrusion, and granulation [ 83 , 84 , 85 , 86 ] ( Scheme 2 ). Mechanical recycling is classified as primary or secondary according to the type of starting material being processed. Primary recycling gives the highest-quality recycled polymers and starts from closed-loop recycled products such as PET bottles or byproducts collected by manufacturing industries as pre-consumer well-separated material.

Secondary processes instead recover post-consumer plastics and, therefore, generate lower-quality polymers. It must nevertheless be considered that, from an economic standpoint, these processes have a reduced complexity and overall limited costs, generating significant income and reduced CO 2 production. According to the Ellen MacArthur foundation report, plastic production and incineration of plastic waste are estimated to produce over 400 Mt of CO 2 yearly [ 87 , 88 ]. Thus, recycled plastics can reduce fossil-fuel consumption and CO 2 emissions. According to estimates by Rahimi and coworkers [ 89 ], the adoption of plastic waste recycling worldwide would allow saving about 3.5 million barrels of oil each year.

Mechanical recycling generally includes four main steps: (i) screening and sorting; (ii) shredding; (iii) washing and drying; (iv) melting and reprocessing ( Scheme 2 ).

Screening and sorting of plastic waste is a fundamental step for the recyclability of the different plastics and the quality of the final polymer. This step is challenging, considering that the separation of mixed plastic waste often involves the combined use of different technologies [ 90 , 91 ].

To achieve an adequate separation of a specific polymer within a flow stream containing many different components (plastics, as well as metals, paper, organic residues, and dirt), characteristics of the final product must be accurately considered such as purity and destination. This will allow defining the best separation strategy to achieve high selection. Important properties commonly employed for plastic separation are magnetic or electric properties, particle size, density, and color. Relying on these properties, many different separation techniques have been developed such as dry or wet gravity separation, electronic or magnetic density separation, flotation, and sensor-based sorting together with auxiliary segregation techniques such as magnetic or eddy-current separation. These segregation methods are briefly described, mainly focusing on recently implemented technologies for PE, PP, PET, and PS recovery.

Gravity separation is a consolidated methodology that may be carried out in a dry environment (dry process) or in the presence of water (wet process) [ 63 , 92 ] ( Figure 5 a). Dry segregation techniques employ air classifiers or ballistic separators in which air is used as the medium to separate lighter materials from heavier ones. They can be positioned at the beginning of the process or at the end, to segregate end-of-life plastics from main plastic streams ( Figure 5 b). Wet gravity separation includes sink and float, jigging, and hydrocyclone techniques.

( a ) Different methodologies of gravity separation; ( b ) dry segregation; ( c ) sink and float separation; ( d ) hydrocycloning; ( e ) eddy current separator.

With sink and float separation, polymers are separated into two different streams depending on whether they have a higher or lower density than water. Materials such as PET, PVC, and PS will sink, while others such as PE, PP, and expanded polystyrene will float ( Figure 5 c). This type of separation guarantees an effective first separation, but it is not adequate to produce high-quality secondary materials and needs to be combined with other separation techniques [ 93 , 94 , 95 ].

Zhang and coworkers developed a pretreatment of PET via preliminary NaOH and ethanol hydrolysis to promote plastic flotation. Optimal conditions allowed the quantitative recovery of highly pure PET fractions [ 96 ].

Heidarpour and coworkers reported the influence of microwave irradiation in the presence of chemical additives such as PEG-400, methylcellulose, or tannic acid on the float–sink behavior of polyoxymethylene, polycarbonate, and polyvinyl alcohol. According to this study, microwave irradiation reduced the contact angle values of tested plastic surface in the presence of chemical additives (depressant) by implementing their sink–float separation capacity, thereby increasing their hydrophilicity [ 97 ]. The authors mention the possibility of using this technology for whichever plastic material.

Jigging is one of the oldest gravity separation techniques and is similar to dry gravity methods where, in most cases, water is used instead of air [ 90 , 94 ]. A water stream is pushed up and down by pistons, and plastics are separated mainly depending on their morphological and physical characteristics.

Hydrocycloning is based on centrifugal and centripetal forces together with the fluid resistance of different materials processed ( Figure 5 d). New trends in hydrocycloning separation focus especially on the recovery of precious metals from electronic device waste [ 98 , 99 ], and it seems to be a very valuable tool for more sustainable separation of plastic waste from metals.

The eddy current separator is made of a high-speed magnetic rotor which generates an electric current, the so-called eddy current, used to remove nonferrous metals (aluminum and copper) from waste plastic, glass, and paper, among others ( Figure 5 e) [ 100 ]. These separators are generally located at the beginning of the recycling process.

With a separator and drum screen, plastics are fed into a large rotating drum where materials are separated by size, thanks to holes in the drum, so that only smaller particles pass through and are separated from larger ones.

Different gravity segregation methods were analyzed by Nie and coworkers for the sustainable recovery and recycling of high-value metals from waste printed circuit board (WPCBs) [ 101 ]. This study analyzed the dynamics and statics of gravity concentration methods. The settling velocity of three kind of particles was studied, demonstrating that the stratification by density is spontaneous and can achieve the lowest potential energy. The concentration of differently sized metal particles could be effectively enriched, and the metal purity increased from 56.5% to 68.2% for decreasing particle size, albeit with a modest decrease in yield (from 86.41% to 83.04%). No recent papers were found for the use of innovative solutions for the recovery of PE, PP, PET, or PS by jigging, hydrocycloning, eddy current separation, and drum and different gravity segregation techniques, but they were reported to give a general overview of different separation technologies available.

Optical sensors are used for the characterization of plastic stream in a continuous manner where air jets allow for separation. Optical sensors may be subdivided in molecular spectroscopies and atomic spectroscopies [ 102 ], the prevalently used Raman spectroscopy (RS) [ 103 ], Fourier-transform infrared spectroscopy (FTIR) [ 96 ], near-infrared spectroscopy (NIRS) [ 104 ], and terahertz spectroscopy (THz) [ 105 ], and elemental spectroscopies such as laser-induced breakdown spectroscopy (LIBS) [ 106 ] and X-ray fluorescence spectroscopy (XRFS) [ 102 ].

Bobulski and coworkers implemented new portable devices for computer image recognition in combination with artificial intelligence for waste recognition and easy municipal waste separation. The devices were used both at home and in waste sorting plants, and they could be a very useful tool for an efficient and economically sustainable separation of plastic waste stream [ 107 ].

Most companies use a combination of different separation techniques to obtain sufficiently pure polymers from post-consumer plastic waste. The purity of the finished product depends on an adequate compromise between costs and benefits, and this leads to purities ≤95% which require further separation and purification steps. Sorting technologies reported above are generally inadequate for the separation of complex materials such as multilayered packaging or fiber-reinforced composites; therefore, these materials are generally incinerated for energy recovery or landfilled as end-of-life plastics.

Innovative recycling methods such as selective polymer dissolution were demonstrated to be efficient in extracting different polymers and fibers from multilayered films and composite materials [ 108 ]. In fact, Knappich and coworkers reported the efficient recovery and recyclability of epoxy and polyurethane resins from carbon fiber-reinforced plastics with different proprietary CreaSolv ® formulations at a laboratory scale.

Multi-material plastic waste separation technologies are also being developed to enable a proper sorting of composites, which will generate new value streams to recover and recycle plastics which are today incinerated or landfilled [ 109 ]. Many approaches have been tested, for example, for the separation of polyester from cotton fibers to recycle textile waste. Solvent-based technologies are an interesting solution, with the possibility of selecting specific solvents which may solubilize either cotton or polyesters [ 110 ]. A crucial aspect for industrial success and applicability is the nature of the solvent in terms of volatility, flammability, toxicity, and recyclability [ 111 ].

Once the mechanical separation is complete, the materials are shredded by passing them through a system of rotating blades. The obtained flakes are then sorted by size with a grid, washed and dried, made ready for reprocessing by extrusion or agglomeration, and sold.

Agglomeration is generally used to reprocess plastic films which are cut in small pieces, heated by friction and water-cooled. The agglomerates are usually combined into plastic flakes and pelletized by extrusion. Agglomeration is highly energy-consuming and, therefore, less widespread [ 90 ].

Extrusion remains the most widely used method for processing both virgin and recycled plastic. Plastic flakes are fed into the extruder and pushed by a screw into a heated cylinder, thus melting the plastic. At the end of the extruder, a pelletizer cools and cuts the final polymer into pellets.

Both shredding and extrusion may lead to partial degradation of the polymer due to chain scission and thermo-oxidative reactions, reducing the polymer chain length and, consequently, its mechanical properties [ 112 , 113 ]. Moreover, impurities deriving from other packaging components further contribute to the diminished physical–mechanical characteristics of reprocessed plastics [ 104 ].

A detailed study was published by Eriksen and coworkers on the thermal degradation, processability, and mechanical properties of re-extruded PET, PE, and PP from post-consumer waste. PET is well suited for closed-loop recycling to meet bottle and food-grade PET quality, although moisture control is a key requirement when reprocessing PET into products. For this polymer, degradation, which generally occurs during recycling by extrusion, may be avoided by careful decontamination. The quality of reprocessed PE samples from non-food bottles strongly depends on the presence of impurities from other polymers and from lids and labels. PE reprocessing by extrusion suggested that closed-loop recycling may be achieved with selected PE bags with low levels of polymer cross-contamination. Adversely, PP reprocessed by extrusion showed low mechanical properties with large variations in impact strength, reducing possible applications of reprocessed PP. Thus, the heterogeneity of PP waste, even if food packaging is managed separately, as well as polymer degradation during recycling, represents crucial limitations for PP waste recycling [ 114 ].

A possible remedy to downgrading due to extrusion was reported for the first time by Wang and coworkers. The authors reported a process to modify polyolefins from post-consumer plastic waste via a one-step radical grafting and cross-linking process, producing covalent adaptable networks or CANs [ 112 ]. This procedure relies on the functionalization of polyolefins with polar reagents, which modify the properties of the starting material, thus imparting new characteristics such as wettability, printability, and compatibility with other polymers. Upcycling of LDPE from plastic bags was achieved by free-radical reaction in a twin-screw extruder in the presence of maleic anhydride and butanediol. PE-CANs showed higher solvent resistance, tensile strength, and modulus compared to virgin PE due to the presence of cross-linking bonds generated during the extrusion process. Upcycling of post-consumer plastic waste by reactive extrusion is an interesting area of research which will surely receive much attention in the future; however, characteristics of CAN polymers must be acquired to define new possible manufacturing applications [ 115 ].

4. Chemical Depolymerization

In addition to mechanical methods, recycling can be performed via chemical depolymerization [ 111 , 116 ].

Chemical recycling has great potential in the circular economy of plastics; it can close the loop by producing starting monomers from the polymers that may be reprocessed to produce high-value-added chemicals [ 70 ]. It is estimated that, by 2050, almost 60% of plastic production can be based on recycled products [ 117 ]. Millions of euros are being invested to enhance chemical recycling and other cutting-edge technological solutions with the aim of producing 1.2 Mt of recycled plastic in EU by 2025 and 3.4 Mt by 2030 [ 9 ].