Lean Manufacturing Tools

Lean manufacturing tools, techniques and philosophy | lean and related business improvement ideas.

5S Training Presentations

5s pptx and 5s pdf downloads.

If you want to learn all about 5S then the following 5S presentations in ppt (PowerPoint) format and PDF format are available to you for free download. Please note that these 5S Training presentation files are protected by copyright and are to be downloaded for your own personal use only.

- Any commercial use of these 5S presentations and the content therein is prohibited without prior permission. Requests for permission to use can be made through the contact page of http://leanmanufacturingtools.org/contact-page/

- These presentations are for personal use only and cannot be reproduced or circulated by anyone other than www.leanmanufacturingtools.org

- Content may be quoted or reproduced for private and educational assignments as long as a proper citation is given referring to leanmanufacturingtools.org

- The information within these presentations and website are for information purposes only and any action taken is at your own risk.

These lean manufacturing training presentations are organized so that you can tackle the ideas behind 5S one step at a time, for your own education or even to train others within your own organization. Breaking them up into bite sized chunks allows you to learn or teach 5S in manageable and understandable sections even if your available time is limited.

These presentations can be use in conjunction with the following pages here;

Running your own 5S program

How to approach 5S training

Run your own 5S training course in house

5S Training PowerPoint (pptx) Presentations;

Basic introduction to 5s presentations;.

What is 5S – Learn what is 5S.

Benefits of 5S – Learn the benefits of implementing 5S within your organization.

Presentations Detailing Each 5S Stage;

5S Seiri Sort – The first stage of implementing 5S.

5S Seiton Set in Order – The second stage of implementing 5S

5S Seiso Shine – The third stage of implementing 5S

5S Seiketsu Standardize – The forth stage of implementing 5S

5S Shitsuke Sustain – The fifth and final stage of 5S implementation

Lean 6S ppt Training Presentation;

6S – How does 6S differ from 5S and why?

Presentations Supporting Your 5S Training;

5S Red Tag – Learn how to use 5S Red Tags

Runners Repeaters Strangers – Learn how to apply RRS techniques when implementing 5S

Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Program Implementation – Step by step guide to implementing 5S within your operations.

5S Training Exercise Presentation;

Training Exercise – 5S Paper exercise; a quick and simple training exercise designed for 5S which will demonstrate the simplicity and effectiveness of 5S.

5S Training PDF Files for Download;

All of the above 5S presentations are also available as 5S PDF files for download;

What is 5S Presentation

Benefits of 5S

5S Seiri or Sort – First stage of 5S

5S Seiton or Set In Order – Second stage of 5S

5S Seiso or Shine – Third stage of 5S

5S Seiketsu or Standardize – Forth stage of 5S

5S Shitsuke or Sustain – Final stage of 5S

5S Runners Repeaters and Strangers

Implementing 5S Program

5S Training Exercise

Should you require a personalized or editable version of these 5S PowerPoint presentations or 5S PDF files just contact the author through the contact page here; Leanmanufacturingtools.org contact page .

Suggestions for improvements or additions to the above 5S training presentations are welcomed.

Related posts:

- Lean Training, Coaching, and Presentations

- Free Lean Presentations

- 5S Training

Post navigation

13 comments for “ 5s training presentations ”.

i want fully details of 5s

Hi K.P. Feel free to download any of the presentations and PDF files here to provide you with all of the info that you need on 5S.

PLEASE BRIEF ON 5S / 6S , LATEST VERSION. 6 SIGMA.

let me know more about it

5’S means house keeping in our Indian language . each and every letters are starting from “S” letters .so,called 1s,2s 3s,4s&5s . on japan language India language 1) seiri -short out 2)seiton -set in order 3) seiso -shine 4)seiketshu -standardization 5)sitsuke -sustain short out -1)material segregated require /un require.if, unwanted material will be put red tag and remove from our working area 2)if,required material then will be put yellow tag .3)if,not required but,well material then will be through to red zone area . Set in Order – required material will be keep by rack /cup board /shelves etc 3)shine identified material clean daily /weekly/yearly 4)standardization this 1s,2s,3s will be keep regularly. 5)sustain this work will be make habit.

How can I download the course?

Samer, Just click on the links to download each of the 5S presentations.

hi Earley i would like develop on these 5 s principles using my domain knowledge in the Oil and Gas upstream sector and would like to conduct workshops to our fraternity please confirm if you have any objection regards Damodaran M

I would like to use this training for our maintenance department at Westrock Solvay ny.

I have “before” pictures ready and will have “after” pictures as well.

Would you like to see our ,ppt when complete?

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

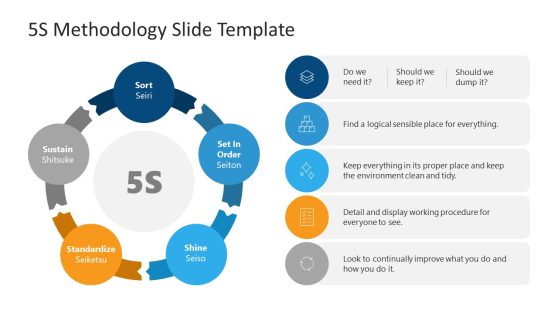

What Is the 5S Methodology?

The 5S methodology is best summarized by the philosophy, “a place for everything and everything in its place.”

You may have heard of “KonMari,” a home organization system invented by Marie Kondo. The KonMari method transforms cluttered homes into tidy and simplified living spaces. The 5S principles are similar to KonMari. However, saying that 5S is just about tidying is like saying successful manufacturing is just about speed - there is much more depth. So, let’s explore the true intent and meaning of 5S.

5S Japanese Words

5S originated as 5 Japanese words:

5S Meaning in English

In English, these 5S meanings are:

- Sort (Seiri): Eliminate that which is not needed.

- Straighten (Seiton): Organize what remains after sorting.

- Shine (Seisou): Clean and inspect the work area.

- Standardize (Seiketsu): Write standards for 5S.

- Sustain (Shitsuke): Consistently apply the 5S standards.

At their core, these 5S activities build the discipline needed for substantial and continuous improvement by creating (and sustaining) efficient and effective work areas.

Why Is 5S Important in Manufacturing?

While 5S was first developed in the context of the automotive industry, it is now widely considered an essential step for any lean manufacturing program, regardless of industry.

Embedding 5S as part of daily tasks within your company means much more than improved organization, sustained cleaning routines, and efficient activity flows. By using the 5S methodology, operators are encouraged to improve their overall work environment and reduce muda or waste .

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS) . 5S also creates a stable platform from which Kaizen activities can be launched.

The bottom line - 5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

What Are the 5 Benefits of a 5S System?

The key benefits of a 5S system include:

- Creating space within your facility by removing unnecessary tools and equipment

- Reducing waste from unnecessary motion by organizing the workspace

- Reducing downtime and improving quality by consistently maintaining equipment

- Engaging operators by granting them more responsibility for their work environment

- Creating a safer work environment by ensuring it is clean and well-maintained

Now that you have a better understanding of why 5S is important and how it can benefit your manufacturing operations, let’s learn more about each of the 5S steps.

Sort (Seiri)

What is sort.

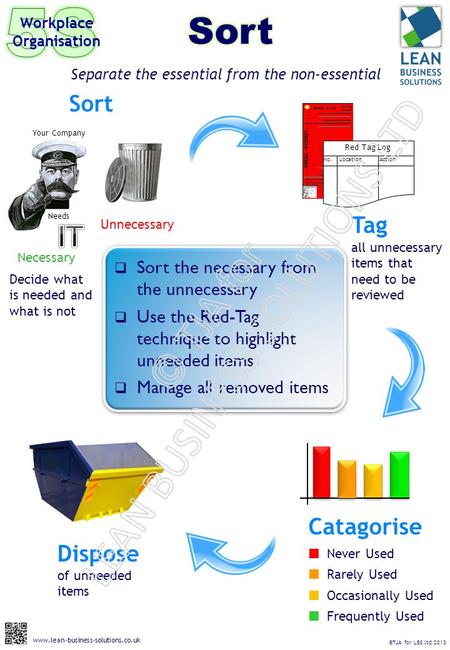

The Sort step separates items in your workspace that you know you need from items that you do not or may not need. Move the latter to a “red tag” holding area.

Why Do You Need Sort?

Sort enables you to have a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up space that can be used for other things.

How Do You Implement Sort?

Separate necessary items (e.g., tools, parts, and materials) from unnecessary items. We recommend sorting items into four categories:

- Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will stay in this work area.

- Items needed in another work area. These are typically misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to the team member responsible for that work area.

- Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with red tags, which at a minimum, should include the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage the area.

- Items you do not need. These are items that you are 100% confident are not needed. They should be immediately discarded, recycled, or donated, or sold if in good condition.

What Are Some Examples of Sort?

- Remove waste (or muda) from your workspace.

- Discard broken or old parts using 5S red tags.

- Responsibly recycle materials and papers.

- Separate everyday tools from special-case tools.

- Avoid overfilling your workspace with excess materials.

- Create an overflow area outside of the workspace for duplicate materials, tools, and parts.

Straighten (Seiton)

What is straighten.

The Straighten step thoroughly organizes the items that remain after sorting, making frequently used items easily accessible and providing every item a clear and easy-to-find home.

Why Do You Need to Straighten?

Straighten enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion, as items are placed in more ergonomic locations. It is also the second step on the path to opening up space that can be used strategically toward the goal of improving production.

How Do You Implement Straighten?

After you’ve sorted items, it’s time to decide how you want to organize them. We recommend the following methodology:

- Provide easy access to frequently used items. The key to reducing waste from excess motion is to place frequently used items within easy reach.

- Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- Utilize visual designs. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- Use containers. If it is appropriate for the type of item, consider organizing it within a container.

- Unleash the labeler. If an item is too big to put into a container, consider giving it a frame and putting a label on the item in addition to the frame.

- Be agile . Your initial straighten pass will likely deliver a significant improvement - but you are also likely to overlook some potential improvements. Plan a 5S team meeting with a focus on straightening at the one and two week points, and brainstorm further improvements as part of your initial implementation.

What Are Some Examples of Straighten?

- Give every item a distinct “home.”

- Use color as a way of organizing and creating meaning.

- Integrate shadow boards and other visual indicators into the plant floor.

- Dedicate a surface or area entirely to shadow boxes and tool storage.

- Dedicate another surface or area entirely to working.

Shine (Seisou)

What is shine.

The Shine step elevates the work area by ensuring thoroughly cleaned and inspected tools, equipment, and other items. It also can include routine maintenance on equipment, which is one of the ways it flows directly into TPM .

Why Do You Need to Shine?

Shine creates a work environment that engages and empowers operators by giving them more responsibility and agency over their work area. It also helps them to identify problems before they interfere with production. For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How Do You Implement Shine?

After you’ve straightened items, it’s time to elevate the work area by cleaning, inspecting, and in some cases, performing routine maintenance. We recommend the following:

- Grab the metaphorical spray bottle. Using appropriate cleaners and cleaning tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory. Be Miyagi.

- Find the source. The guiding principle of this 5S step is “clean to understand”. If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair?

What Are Some Examples of Shine?

- Wipe down equipment.

- Examine the wear of your tools.

- Disassemble larger objects to inspect the state of their parts.

- Investigate a recurring unclean spot or mess.

- Make sure to follow proper cleaning procedures to prevent damage to equipment.

Standardize (Seiketsu)

What is standardize.

The Standardize step is a bridge between the first three 5S steps (Sort, Straighten, Shine) and the last step (Sustain). In this step, your goal is to capture best practices for 5S as standardized work for your team.

Why Do You Need to Standardize?

Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How Do You Implement Standardize?

It’s time to make sure all your hard work continues to pay dividends into the future. Set expectations for the future with a documented 5S process. To do so, we recommend that you:

- Document in pairs. Have one team member walk through each 5S task as another team member documents it to ensure nothing important is missed.

- Capture the essence. We are huge proponents of simplicity (and agile ). Capture the essence of each task and no more. Otherwise, your documentation will be difficult to maintain.

- Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is providing a name for each task that serves as a quick reminder and a more detailed description for training.

- Organize to simplify. Organize your checklists by role, by shift, and by frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

What Are Some Examples of Standardize?

- Write down your 5S practices.

- Create “implementation” checklists and “audit” checklists.

- Create “kits” that contain the materials needed to perform a specific task.

- Use photos and other simple visuals as part of your training materials.

- Build a schedule for tasks.

Sustain (Shitsuke)

What is sustain.

The Sustain step ensures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks.

Why Do You Need to Sustain?

Iterative 5S processes lock in your gains and ensure further and continued progress.

How Do You Implement Sustain?

Once you’ve standardized, it’s time to continually act upon those standards. We recommend you:

- Create a schedule. Embed 5S practices as scheduled tasks (by role, shift, and frequency).

- Teach through demonstration. Instruct employees on how to conduct 5S tasks through demonstration and training. Showing employees what is expected of them will prepare them to conduct tasks on their own.

- Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off course, so patiently and helpfully offer corrections when needed.

- Adapt as necessary. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

What Are Some Examples of Sustain?

- Hold a demonstration meeting to explain complex or multi-step processes.

- Perform periodic check-ins after initial training.

- Teach employees to run 5S audits.

- Respond to mistakes with additional training.

- Encourage supervisors and operators to communicate openly and constructively to find ways to improve your 5S implementation.

- Set quarterly audit reminders for reviewing the red tag holding area.

The Bonus S of 5S

Now that you know how to implement each step in the 5S methodology and foster a culture of continuous improvement in your factory, you are ready to learn the bonus S: Safety!

5S is meant to help you improve productivity in your factory, but it is also meant to help create a safe, positive work environment for your team. While preventing workplace injuries is very important - also important is that 5S will make your plant a great place to work. Everyone enjoys a safe, clean, and logically laid out work environment, and it will motivate your employees, leading to better results on the plant floor.

How Does Each of the 5S Steps Contribute to Safety?

- Sort removes items from the plant floor, creating more space. Of course, this space can be used to hold new tools and equipment, but it can also be used to create larger aisles and more open spaces in the factory, removing tripping hazards. Even something as simple as decluttering drawers can prevent injuries (e.g., accidental encounters with a sharp object when rummaging for the tool you need).

- Straighten gives every item a logical home near the location where operators will use it. This prevents operators from rushing around looking for what they need, avoiding chaos on the plant floor that could cause safety hazards. For example, operators could slip, trip, or bump into one another if they have to constantly hurry around looking for tools.

- Shine cleans the workspace and maintains equipment. This prevents leaks or spills from leaving slick spots on the floor and ensures operators have functioning tools so they don’t have to dangerously jerry-rig solutions.

- Standardize makes clear to everyone what needs to be done and to whom each task belongs so tasks are completed on a regular basis. Confusion regarding ownership of responsibilities can cause important jobs to be missed. For example, equipment that is not consistently maintained will likely create safety concerns.

- Sustain ensures your initial 5S efforts are not in vain, keeping your staff happy and on top of any new safety concerns as they arise. One of the most dangerous things you can have in your factory is unmotivated employees who do not care about maintaining the condition of their workplace. Ensuring their efforts to implement a 5S program are recognized and sustained will provide continued motivation.

Overall, the 5S process is worth the initial organizational work for the rewards in safety, production improvement, and employee motivation.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.

Home PowerPoint Templates Diagrams 5S Diagram Template for PowerPoint

5S Diagram Template for PowerPoint

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.

5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and Sustain. Each has its meaning, and the PowerPoint template depicts all of them in a sequence. Japanese started this concept of 5 stages, leading to the technique of Just in Time Manufacturing, one of the most used in the manufacturing industry. Different stages of the process are shown on the curved arrows .

This professional presentation template shows showing the flow of a process. The presentation template starts with an overview of the process, followed by a description of each stage. The first part elaborates on the Sort step dealing with selecting the necessary resources for the process and removing unnecessary ones. Required items can be listed in bullets for further analysis and monitoring. The next step is arranging all the resources appropriately and fully using them, the Straighten step. Shine includes the monitoring of the process and the environment around it. Systemize reflects quality inspection and modifications of the product to maintain a standard. The final stage is Sustain, which deals with storing and maintaining the products in a flow.

One thing to notice about this circular org chart template is the thin portion around the 5S diagram. It can add some text like the company’s motto or some motivational quote. The layout of this PPT template animates with each stage by focusing only on one stage at a time as the presentation goes on and dims the other stages. It completes a rotation by covering all the stages and highlighting the main points adjacent to the 5S diagram. It can also be used as a 30-60-90-day plan template , with each curved arrow showing a regular interval of some days to make a project timeline .

You must be logged in to download this file.

Favorite Add to Collection

Details (6 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

5S Methodology PowerPoint Template

Kaizen PICK Chart Template for PowerPoint

5-Step Horizontal Infographic Diagram for PowerPoint

1-866-402-4776 M-F 6am - 4pm PST

Label Samples | Floor Tape Samples

Free Resources

Oops, something went wrong. Please try again.

You are now logged in!

Lean 5S Methodology Overview

5S is not complicated to understand or even to practice. The key is to do it everyday, with everyone participating, and in every place within your organization.

In this way, 5S connects deeply with the continuous improvement philosophy of kaizen .

Watch our introductory video for a six-minute overview of 5S.

Trial our Course: 5S Productivity

Start a 30-day trial of the Lean Smarts Academy and preview our 5S Productivity course.

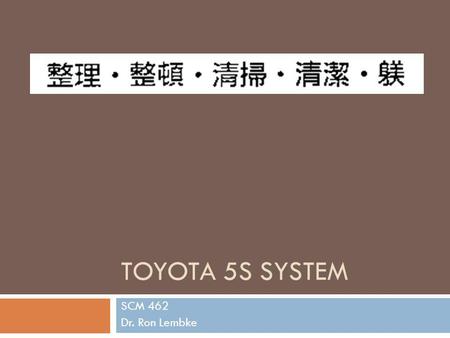

A History of 5S Programs | Origins of 5S

The modern version of 5S is an English adaptation of an original program that has been popular in Japan for decades. There are five S’s in 5S due to the alliteration of the Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke .

Each of the five Japanese words have added meaning in Japanese culture that is difficult to capture in English translations. This is perhaps a reason for some of the confusion around the English equivalents, especially with “standardize” and “sustain.” ( See Michel Baudin’s explanation ).

Henry Ford’s CANDO Program

Some people believe that the Japanese program was inspired by an original five-step program promoted by Henry Ford called CANDO.

- Cleaning up

- Ongoing improvement

Variations of the 5S Words

Some of the imperfections of translating five Japanese words into English have led to variations of the 5S terms.

For example, “sweep” is commonly interchanged with “shine,” and “straighten” is commonly interchanged with “set in order.”

Regardless of the words that are used, we maintain that the function of these terms matters more than the title you give to them! How much does it matter what words you use as long as you: 1) still reap the intended benefits of 5S, and 2) can understand each other when speaking about 5S?

Reasons for Starting Lean with 5S

It is commonly expressed by consultants and lean literature that “if you can’t do 5S, you probably don’t have the discipline to do anything else.”

There is some merit to this! 5S is a rite-of-passage for organizations learning lean.

Aside from the fact that 5S programs are a common and easy introduction to lean practices, there are other good reasons for adopting 5S methodology early in your lean journey.

#1 It flushes out old mindsets and culture

While it is true that 5S leads to a physical transformation of your workplace, it also inspires an invisible transformation in the thinking and behavior of everyone working there.

When sorting and removing junk that doesn’t belong, organizing what remains so it’s easy to use, and taking pride in your work areas with regular cleaning, you also dislodge old beliefs, excuses, behaviors, and mindsets.

#2 You have to engage everyone

5S must involve every person in the organization for it to succeed. You have to engage everyone!

This is to your advantage in developing a lean culture of kaizen and continuous improvement.

If your intent is truly to develop and grow people (as it should be!), you can develop a kaizen culture of improvement “everyone, every day, everywhere” with 5S!

#3 It’s cheap and easy to do

You need almost no upfront investment of money to get started with 5S. All you need is some knowledge and time.

While you can purchase 5S supplies to support your efforts, many organizations discover a wealth of reusable materials, equipment, tools, and supplies already inside the building the moment they begin to 5S and sort.

In the majority of situations, you’re only limited by your creativity–not your wallet!

It’s also easy to do. In fact, in 30-60 minutes our 5S Productivity training course can prepare anyone with the skill and confidence needed to get started now.

#4 It’s the basics; it never goes away!

No matter what else you do that’s “lean,” you will never outgrow your need to 5S on a daily basis.

Entropy never takes a break causing mess, confusion, and equipment breakdown. Therefore, you’ll forever need to sort, set in order, and shine at your organization!

#5 It creates peace of mind and clarity

An orderly and clean work environment does help to reduce stress and confusion in the workplace.

The stress and confusion in many organizations is largely due to the disarray of information, tools, and materials. The clutter and clogging of a production floor creates needless searching, movement, transportation, defects, and other wastes.

It’s not necessary and should not be considered “normal” to struggle and stress at work. 5S methodology is a major first step for organizations to get control back of their environment.

The Meaning of Sort

5S methodology begins with the simple practice of sorting out all the unneeded items in a workplace.

Get rid of all the junk and clutter:

- extra inventory

- broken equipment

- extra tools

- outdated signage

- unfinished work

- leftover materials

Get our Free 5S Implementation Guide

Plan your 5S implementation strategy by following our simple step-by-step guide.

Get our 5S Implementation Guide

Our step-by-step instructions for implementation 5S in organizations of any size.

5S Methodology Training

Training is not an area you want to slack off in when it comes to rolling out 5S at your organization!

Since 5S requires the participation and support of every person in your organization, there is not one person who can be excluded from training in 5S.

Warning: if you do exclude groups or senior leaders from going through training, you inadvertently send the message that 5S has less importance or that 5S does not have everyone’s full support.

Additionally, if you’re starting with a focused 5S event, you need everyone to be skilled and ready to go the day you kick it off. You don’t want to waste time in training when you could be making change on the production floor.

Tip: we recommend training management first before the rest of your workforce. This can be done to help acquire buy-in up front.

Tip: the training of management should be a “train the trainer” event in which production management not only learns 5S but is also taught how to then teach their teams. Frontline operators ultimately look to their immediate supervisor for direction and leadership. By making your frontline team leaders and supervisors coach and trainer (as opposed to delegating lean to an outside department), you stand the greatest chance of achieving alignment and buy-in throughout your organization.

To train associates well you need training that is…

While PowerPoint presentations, books, and external trainers are available training options, nothing quite beats the effectiveness and affordability of high quality video training.

Table of Contents

The 5s methodology , benefits of 5s methodology: , why use the 5s methodology, before 5s implementation, after 5s implementation, implementation strategies: , 5s implementation plan, tools for 5s, 5s and lean manufacturing, what is 5s methodology: implementing 5s methodology.

5S is one of the first tools that can be applied in a company that is starting down the path of a continuous improvement culture. A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment. It was first popularized by Taiichi Ohno, who designed the Toyota Production System, and Shigeo Shingo, who also put forward the concept of poka-yoke .

The 5S methodology is easy for everyone to start using. It doesn’t require any technical analysis and can be implemented globally in all types of companies, ranging from manufacturing plants to offices, small businesses to large multinational organizations — and in both private and public sectors. Its simplicity, practical applicability, and visual nature make it an engaging aid for operators, directors, and customers alike.

The 5S methodology is divided into 5 steps essential for achieving its goals. We will discuss each step in detail.

Learn for free! Subscribe to our YouTube Channel & Be a Part of the 400k+ Happy Learners Community.

The first step in the 5S methodology is to sort. This step involves identifying the necessary items in your workspace and eliminating any excess or unnecessary items. This helps to reduce clutter, minimize distractions, and streamline the workspace.

Set in Order:

The second step is to set it in order. This step involves organizing the necessary items logically and systematically. This includes assigning a specific location for each item and labeling them for easy identification. This helps to reduce search time and eliminate the need for excess inventory.

The third step in the 5S methodology is to shine. This step involves cleaning and maintaining the workspace. This includes regular cleaning, inspection, and maintenance to ensure everything is in working order and defects-free.

Standardize:

The fourth step in the 5S methodology is to standardize. This step involves creating a set of guidelines and procedures for maintaining the workspace. This includes documenting the previous three steps and establishing a regular schedule for their implementation.

The final step in the 5S methodology is to sustain. This step involves creating a culture of continuous improvement, where the previous four steps are consistently followed, and the workspace is continually optimized.

The 5S methodology provides numerous benefits to organizations that adopt it. Some of the benefits include:

- Improved productivity

- Reduced waste

- Enhanced safety

- Increased employee satisfaction

- Improved customer satisfaction

- Improved quality

- Reduced costs

5S is a methodology for creating an organized and productive workspace by sorting, straightening, shining, standardizing, and sustaining. Using 5S as a foundation, advanced processes and tools to implement lean production can be developed.

5S is the perfect tool to identify the first improvement projects in your company to eliminate waste. Although sometimes viewed as a housekeeping technique, it is actually an innovative management system that helps people think lean, paving the way for the adoption of Lean principles in the organization . Understanding the 5S methodology is one of the foundations of Six Sigma principles, and can be extremely beneficial for organizations of all kinds.

A Black Belt uses 5S to find waste, reorganize workflows, and promote a culture of continuous improvement as part of the Six Sigma toolbox. Their proficiency in fusing Six Sigma methodologies with Lean principles helps them to direct enterprises toward improved output and quality. A Six Sigma Black Belt starts the process of optimization by deliberately implementing 5S, laying the groundwork for extensive changes and long-term success.

And here’s the best part: implementing 5S is a breeze! With this logical, step-by-step guide, you’ll learn what the big deal about 5S is, how to devise an action plan for 5S implementation, and how best to wield this powerful tool for improved productivity , elimination of wasteful processes, and all-around development!

Pro Tip: For more on harnessing the principles of Six Sigma for workplace and personal productivity, here’s an insightful article that investigates ways to enhance performance using the principles of Six Sigma .

Implementing the 5S methodology requires careful planning and execution. Some effective strategies for implementing the 5S methodology include:

- Form a dedicated team to oversee the implementation process.

- Provide adequate training to employees to ensure that they understand the methodology and its benefits.

- Start with a pilot project and gradually expand to other areas of the organization.

- Establish clear metrics to measure the success of the implementation.

- Continually monitor and improve the methodology to ensure its effectiveness.

Become a Quality Management Professional

- 10% Growth In Jobs Of Quality Managers Profiles By 2025

- 11% Revenue Growth For Organisations Improving Quality

Certified Lean Six Sigma Green Belt

- 4 hands-on projects to perfect the skills learnt

- 4 simulation test papers for self-assessment

Lean Six Sigma Expert

- IASSC® Lean Six Sigma Green Belt and Black Belt certification

- 13 Projects, 12 Simulation exams, 18 Case Studies & 114 PDUs

Here's what learners are saying regarding our programs:

Xueting Liu

Mechanical engineer student at sargents pty. ltd. ,.

A great training and proper exercise with step-by-step guide! I'll give a rating of 10 out of 10 for this training.

Abdus Salam

I have completed the Lean Six Sigma Expert Master’s Program from Simplilearn. And after the course, I could take up new projects and perform better. My average pay rate for a research position increased by 21%.

Step 1: How Well is Your Business Doing?

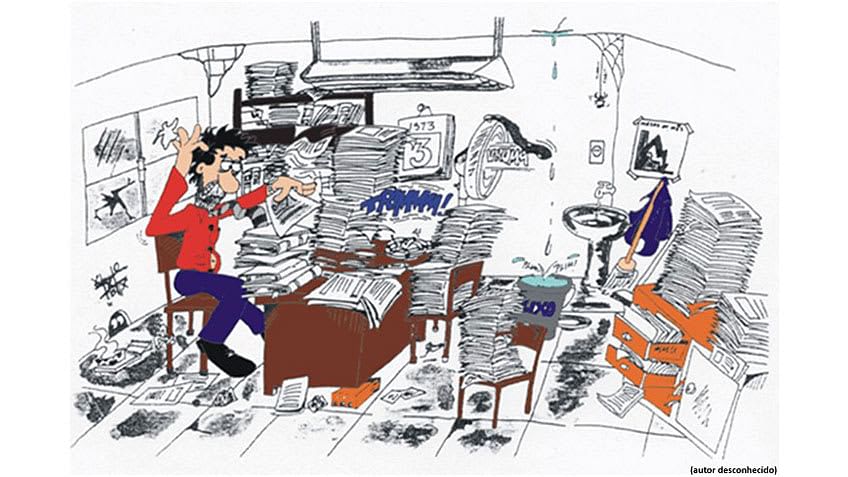

Our cartoons above help illustrate how 5S can benefit your organization. Before you get started, let’s perform a test. If you answer yes to any of the following questions, you may find 5S really useful and effective:

- Do people in your workplace struggle to locate documents or files, whether in physical or digital format?

- Are there loose, sagging electrical cables in the workplace?

- Are there files, drawers, and cabinets that are unlabeled, or do they contain unmarked content that is hard to identify?

- Is valuable space taken up by useless items?

- Are there papers in your workplace that are not used and are gathering dust?

- Does everybody know how to keep the workplace organized and are fully aware of their roles and responsibilities?

If you answered yes to any of these questions, 5S may be exactly what you need!

Step 2: The 5S Methodology: Broken Down

What Does 5S Stand For?

The name 5S refers to a set of five terms borrowed from Japanese, all beginning with the letter S when transliterated. The equivalent terms in English also begin with an S. In essence, these five terms represent the five steps toward operational and process excellence:

Step 3: The Action Plan

You can start implementing 5S by providing training to your staff to understand the system. This may be followed up with one-day sessions with each employee or team to ensure they are on the same page as far as implementation is concerned.

In the first one-day session, employees should look be ready to meet the first three 5S requirements:

- Take a picture of the current status of your workplace.

- Sort to separate anything that is needed and necessary from what is not needed.

- Organize the things you need so that there is a place for everything and everything has a place. You should be able to find anything in just a few seconds.

- Clean the workplace and get rid of things that make it difficult to maintain cleanliness, such as boxes on the floor that prevent you from being able to clean the entire surface — label them and store them in labeled drawers, instead.

- Prepare an action plan for the items you aren’t able to deal with that day, but will be able to in the near future. This could include selling items you no longer use, donating them, recycling, or throwing them away.

- Take a second picture after the entire day’s work, for review.

Pro Tip: Learn how to apply these principles and get a certification to show for it with a professional Lean Six Sigma Certification Course !

Step 4: Standardize

During the second one-day session, two weeks later, employees should take the third picture and compare it to the first two shots. Many organizations set up peer audits to check how the 5S principles are being met as well as to ensure the plan is moving forward. Work together to define ways to standardize the improvements over time: organize cleaning schedules, define roles and responsibilities, and prepare written procedures or diagrams to help everyone remember what to do.

Step 5: Sustain

During the third one-day session, two months later, check to see how your workplace looks and schedule another peer review. This way, you can make sure the 5S are sustained by ensuring defined schedules are being met and everyone is following the procedures.

- Red Tags: These are used to label items that are no longer needed or are not in use. Red tags help in the sorting process.

- Shadow boards: These are used to organize tools and equipment. The shadow board has an outline of the tool or equipment, making it easy to identify if something is missing.

- Visual controls: These are used to make it easy to identify the correct location for tools and equipment. Examples include color coding, labels, and signs.

- Cleaning checklists: These are used to ensure that the workspace is clean and tidy. The checklist helps in maintaining the shine aspect of 5S.

- Standardized work procedures: These are used to ensure that everyone follows the same process for performing tasks. Standardized work procedures help in the standardization aspect of 5S.

- Floor marking tape: This is used to mark boundaries, aisles, and storage locations. Floor marking tape helps in the set-in-order aspect of 5S.

- Kanban systems: These are used to manage inventory levels. A Kanban system helps maintain the right inventory level, ensuring no waste of resources.

- Visual management boards: These are used to display key performance indicators (KPIs) and progress toward goals. The visual management board helps in sustaining the improvements made through 5S.

5S methodology is a crucial tool within the Lean Manufacturing philosophy, which aims to maximize value while minimizing waste. The 5S system provides a structured approach to organizing the workplace, improving efficiency, reducing errors, and increasing productivity. By reducing waste and optimizing workflow, 5S supports the overall goal of Lean Manufacturing, which is to create value for the customer while minimizing resources and time. Incorporating 5S into the Lean Manufacturing process can help organizations achieve continuous improvement and sustainable success.

Learn the DMAIC methodology with real-world case studies and the skills you need to help your organization grow with our Lean Six Sigma Green Belt certification online program aligned with the IASSC exam.

Simplilearn’s professional training courses are facilitated by certified experts with many years of experience in their respective fields. And, our courses are designed to help you pass your exam on the first try. Are you ready to begin? Good luck! If you want to learn more about lean methodologies and Six Sigma, check out this 5-minute video. It’s an introduction to Certified Lean Six Sigma Green Belt and will give you a taste of Simplilearn’s online training.

1. What is the 5S methodology?

The 5S methodology is a workplace organization system that aims to improve efficiency and eliminate waste by maintaining a clean and organized work environment. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain.

2. What is the purpose of 5S?

The purpose of the 5S methodology is to improve workplace efficiency and productivity by creating a clean, organized, and safe work environment. It aims to eliminate waste, reduce errors, and increase employee satisfaction by providing a clear and structured system for organizing workspaces and materials.

3. What is the 6th S?

While the 5S methodology traditionally consists of Sort, Set in order, Shine, standardizing, and Sustaining, some practitioners have added a sixth "S" - Safety. Safety is a critical component of workplace organization, and ensuring that employees work in a safe environment is essential for their well-being and productivity. Including Safety as the sixth "S" ensures that it is given equal importance and consideration in the overall workplace organization system.

4. How does 5S relate to kaizen?

The 5S methodology is often used as a foundational tool within the Kaizen continuous improvement philosophy. The 5S system provides:

- A structured approach for identifying and eliminating waste.

- Reducing errors.

- Improving productivity, which are all critical components of the Kaizen approach.

Using 5S supports and reinforces the ongoing Kaizen mindset of constant improvement.

Our Quality Management Courses Duration And Fees

Explore our top Quality Management Courses and take the first step towards career success

Get Free Certifications with free video courses

Quality Management

Lean Management

Project Management

Learn from industry experts with free masterclasses, digital marketing.

The Top 10 AI Tools You Need to Master Marketing in 2024

Unlock Digital Marketing Career Success Secrets for 2024 with Purdue University

Your Gateway to Game-changing Digital Marketing Careers in 2024 with Purdue University

Recommended Reads

Free eBook: Guide to the Six Sigma Certifications

Important Six Sigma Tools to Know

The Art of Saying No: The Best Guide to Reclaim Control Over Your Productivity

Free Mind-Map: Salesforce Mind Map

Six Sigma vs Lean Six Sigma: Which Certification to Choose?

Top Six Leadership Skills That You Should Master for Workplace Success

Get Affiliated Certifications with Live Class programs

- PMP, PMI, PMBOK, CAPM, PgMP, PfMP, ACP, PBA, RMP, SP, and OPM3 are registered marks of the Project Management Institute, Inc.

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

5s (Workplace Organization) Implementation

Published by Derek Copeland Modified over 8 years ago

Similar presentations

Presentation on theme: "5s (Workplace Organization) Implementation"— Presentation transcript:

The Five Ss.

Toyota 5S System SCM 462 Dr. Ron Lembke.

LT6 5S + 1 CONTINUOUS IMPROVEMENT OFFICE.

Understanding 5S.

5S training Office Environments.

5S BASIC TRAINING What is 5S and why do we want to do it?

Sort the necessary from the unnecessary Use the Red-Tag technique to highlight unneeded items Manage all removed items Separate the essential from.

Ch-3 5s1 5S Workplace Organization. Ch-3 5s2 5S 5S Contents: S1 --- Sort out. Get rid of the stuff you don’t needed. S2 --- Set in order. Place the stuff.

Productive Maintenance

Making your Portable Restroom business Lean and mean – How to boost productivity and increase your bottom line.

Introduction to 6S.

SCM 494 Dr. Ron Tibben-Lembke

5S Essentials Five action verbs.

Why 5S? Workplace organization required when:

1 © 2005 Superfactory™. All Rights Reserved. Lean Office - 5S and Visual Controls Superfactory Excellence Program™

Lean Training 5S. Agenda What is it? What’s it for? How does it work? When do you use it? What’s an example?

CONTINUOUS IMPROVEMENT PROGRAM

Introduction to 5S. What is 5S? An easy definition is: Finding a place for everything and putting everything in its place. 5S is also the foundation for.

There are five primary 5S phases: 1.Sort. 2.Straighten. 3.Shine. 4.Standardize. 5.Sustain. The 5 S's Kamalnathan, MIM.

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

Got any suggestions?

We want to hear from you! Send us a message and help improve Slidesgo

Top searches

Trending searches

46 templates

suicide prevention

8 templates

49 templates

18 templates

41 templates

29 templates

Implementation of the 5S Technique Project Proposal

Implementation of the 5s technique project proposal presentation, free google slides theme and powerpoint template.

In business, 5S is a methodology created in Japan and consists of five words beginning with S, whose translations in English are 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. The aim of this methodology is to make the most efficient and effective use of workspace. Are you thinking of implementing it in your company? Perhaps you need a slideshow to explain what this methodology is and what the changes would be. Our template has a corporate look and has simple enough layouts to streamline your content easily. Everything is customizable!

Features of this template

- 100% editable and easy to modify

- Different slides to impress your audience

- Contains easy-to-edit graphics such as graphs, maps, tables, timelines and mockups

- Includes 500+ icons and Flaticon’s extension for customizing your slides

- Designed to be used in Google Slides and Microsoft PowerPoint

- Includes information about fonts, colors, and credits of the resources used

How can I use the template?

Am I free to use the templates?

How to attribute?

Attribution required If you are a free user, you must attribute Slidesgo by keeping the slide where the credits appear. How to attribute?

Related posts on our blog.

How to Add, Duplicate, Move, Delete or Hide Slides in Google Slides

How to Change Layouts in PowerPoint

How to Change the Slide Size in Google Slides

Related presentations.

Premium template

Unlock this template and gain unlimited access

5S Methodology | What Is 5S Methodology? | 5S Methodology Explanation | Simplilearn

Mar 29, 2020

680 likes | 1.65k Views

This presentation on 5S Methodology will take you through everything you need to know about the workplace organization method, 5S. This video also covers a number of different topics like the basics of the 5S methodology, its benefits and the process of 5S, like Sort, Set in order, Shine, Standardize, and Sustain. So now, let's jump in and learn about the 5S methodology.<br><br>Learn to develop your organizational projects with the Lean Six Sigma Green Belt certification online program. Aligned to the IASSC exam, this online six sigma certification integrates lean and the DMAIC methodology with case studies to provide you the skills required for an organization's growth.<br><br>About Simplilearn SIx Sigma green belt course:<br>This Lean Six Sigma Green Belt course provides an overview of Six Sigma and the DMAIC methodology and is aligned to the leading Green Belt certifications at ASQ and IASSC. In this Lean Six Sigma Green Belt course, you will learn how to measure current performance to identify process issues and how to formulate solutions.<br><br>Six Sigma Green Belt Training Key Features:<br>- 56 hours of high-quality blended learning<br>- 33 PDUs offered<br>- 4 simulation test papers, 4 real-life projects<br>- Aligned to ASQ and IASSC<br><br>Eligibility:<br>Lean Six Sigma professionals are in high demand due to their ability to use problem-solving techniques to reach business solutions and assuring quality control throughout the process. The Lean Six Sigma Green Belt certification is ideal for Quality system managers, Quality engineers, Quality supervisors, Quality analysts and managers, Quality auditors, and any individual wishing to improve quality and process within an organization.<br><br>Learn more at https://www.simplilearn.com/quality-management/lean-six-sigma-green-belt-training<br>

Share Presentation

Presentation Transcript

Click here to watch the video

A file I need for a meeting is missing! OH NO!

A file I need for a meeting is missing! My messy work-desk is the talk of the office! OH NO!

A file I need for a meeting is missing! My messy work-desk is the talk of the office! OH NO! And thanks to that, I don’t even feel like working!

Jim! What happened?

Everything’s a mess! I’m a mess! I don’t know what to do!

Don’t worry Jim! I’ve a solution for you...

The 5S Methodology!

Let me tell you about everything I’m going to teach you:

What’s in it for you • What is the 5S methodology • Benefits of 5S methodology • The Process of 5S • Sort • Set in order • Shine • Standardize • Sustain

Now, let’s have a look at what exactly is the 5S methodology

What is the 5S Methodology? Introduced in Japan, the 5S Methodology is a popular workplace organization method The methodology focuses on cleanliness and organization, while focusing on maximizing efficiency and profit

What is the 5S Methodology? It is a framework that focuses on visual management and emphasizes on using a mindset and tools to create efficiency and value It involves observing, analyzing, collaborating, searching for waste, and removing it as well

What is the 5S Methodology? What makes this methodology so special? Let’s find out! It is a framework that focuses on visual management and emphasizes on using a mindset and tools to create efficiency and value It involves observing, analyzing, collaborating, searching for waste, and removing it as well

Benefits of the 5S Methodology Optimized organization

Benefits of the 5S Methodology In this methodology, necessary components are kept in a way that they’re easily accessible and are easy to utilize Optimized organization

Benefits of the 5S Methodology Improved efficiency Optimized organization

Benefits of the 5S Methodology By improving products and service, the methodology can reduce costs. It can also enhance a company’s bottom line Improved efficiency Optimized organization

Benefits of the 5S Methodology Improved efficiency Greater storage density Optimized organization

Benefits of the 5S Methodology Since unnecessary items are being moved from the workspace, the freed-up space can be used more efficiently Improved efficiency Greater storage density Optimized organization

Benefits of the 5S Methodology Improved efficiency Greater storage density Optimized organization Increased safety

Benefits of the 5S Methodology The workspace is much safer with the waste removed from it Improved efficiency Greater storage density Optimized organization Increased safety

Benefits of the 5S Methodology Improved efficiency Greater storage density Optimized organization Increased safety Improved workspace morale

Benefits of the 5S Methodology Now, let’s have a look at the process of 5S Improved efficiency Greater storage density Optimized organization Increased safety Improved workspace morale

The Process of 5S The process of 5S consist of 5 steps, each one starting with the letter ‘S. The steps are: Sort Set In Order Shine Standardize Sustain

Sort 整理 (Seiri)

The Process of 5S - Sort The first step in the 5S process is ‘Sort’ or ‘Seiri’, which translates to tidiness. The aim in this step is to remove clutter and clear up the area by removing things that don’t belong there

The Process of 5S - Sort First off, clean the work area Look closely at the items in the workspace. Every item except the ones that are required for work are to be removed From these removed items, few would need to be removed or recycled. There may be some items that need to be returned to their original location and others that you’re not sure about. These items need to be red-tagged

The Process of 5S - Sort Then, red-tag unknown items Items that don’t have clear ownership or cannot be identified need to be red-tagged. The red-tag refers to highly visible tag attached to the item indicating where and when the item was found These items are then arranged at a location. It acts as a ‘lost and found’ for materials

The Process of 5S - Sort Then, reassign tagged items It is possible that red-tagged items may stay in ‘lost and found’ for a long time. Some ways to utilize them are: The items stay in ‘lost and found’ for 30 days. After this, other supervisors can claim any of the items for themselves. If they are undisturbed for 10 more days, they can be sold, recycled or thrown away If the items are expected to be useful at a later point, they can be stored in the ‘lost and found’ with a specific plan for time and usage

The Process of 5S - Sort Let’s have a look at the next step

Set In Order 整頓 (Seiton)

The Process of 5S – Set in Order The second step ‘Set in Order’, called ‘Seiton’ translates to ‘orderliness’. The goal of this step is to organize the work area. Items must be easy to find, use and return

The Process of 5S - Sort First off, create 5S map It a floor plan or diagram that provides an overview of the work area, process or station. It also shows the location of different tools and supplies, travel paths and how they’re related to each other It can also show the description of the work done in an area. It also needs to be updated periodically

The Process of 5S - Sort Then, communicate the plan Once storage locations are assigned, they are labeled. It will enable employees to identify what’s inside each of them quickly. Work areas, movement lanes, and storage supplies can be marked with floor marking tape

The Process of 5S - Sort Now, for the next step! Then, communicate the plan Once storage locations are assigned, they are labeled. It will enable employees to identify what’s inside each of them quickly. Work areas, movement lanes, and storage supplies can be marked with floor marking tape

Shine 清掃 (Seiso)

The Process of 5S – Shine The next step ‘Shine’, or ‘Seiso’ translates to ‘cleanliness’. This step is aimed to remove the dust that eventually builds up under the clutter, and ensuring that it doesn’t return

The Process of 5S – Shine Routine cleaning • It involves the cleaning of every area within the work area each week. Each employee needs to clean his/ her own workspace and the equipment they use.. • With this, employees would be able to: • Quickly recognize problems that might arise • Difficult situations can be understood easily • Items that are out of place can be recognized quickly

The Process of 5S – Shine Let’s have a look at the next step Routine cleaning • It involves the cleaning of every area within the work area each week. Each employee needs to clean his/ her own workspace and the equipment they use.. • With this, employees would be able to: • Quickly recognize problems that might arise • Difficult situations can be understood easily • Items that are out of place can be recognized quickly

Standardize 清潔 (Seiketsu)

The Process of 5S – Standardize The next step ‘Standardize’, or ‘Seiketsu’ translates to ‘standardization’. In this step, to incorporate long-term change, writing down what is being done, and by whom, new practices can be incorporated into the normal work procedure

The Process of 5S – Standardize Write things down Writing down the decisions made ensure that they can included as part of the standard related to an area. It is also possible for these standards to be changed based on changing business needs

The Process of 5S – Standardize Tools for standardizing • Communication is an important part of this step. The decisions made about the work practices need to be communicated with the employees. This can be done with: • 5S checklists • Job cycle charts • Procedure labels and signs

- More by User

5S Essentials

5S Essentials . Five action verbs . Principle of 5 S. 5S Philosophy focuses on effective work place organization, simplifies work environment, reduces waste while improving quality and safety.

545 views • 13 slides

5S Housekeeping

5S Housekeeping . Een plek voor alles en voor alles een plek. 5S. 5 stappenplan om orde en netheid op de werkplek te organiseren en te borgen. 5S Stappen. 1e S eiri : Scheiden / uitsorteren 2e S eiton: Sorteren (ordenen) 3e S eiso: Schoonmaken/ houden 4e S eiketsu: Systematiseren

549 views • 6 slides

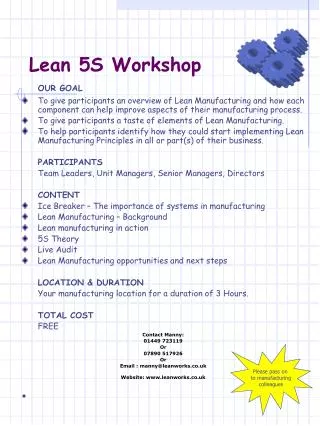

Lean 5S Workshop

Lean 5S Workshop. OUR GOAL To give participants an overview of Lean Manufacturing and how each component can help improve aspects of their manufacturing process. To give participants a taste of elements of Lean Manufacturing.

648 views • 1 slides

Metodologia dos 5s

Metodologia dos 5s . O Enfoque básico desta metodologia é a qualidade de vida das pessoas no ambiente de trabalho que permite maior produtividade com qualidade. A representação 5S’s originou-se das iniciais das palavras japonesas. SEIRI. SEITON. SEISO. SEIKETSU. SHITSUKE.

644 views • 7 slides

1.19k views • 55 slides

5S Simplified 5S Audit Tool

5S Simplified 5S Audit Tool . 5S Audit Training. 5S Levels Of Achievement. What Color (Level) is your area?. 5S Audit Form – Scores & Levels of Achievement. 5S Audit Tool: Using the same Chart for the 5S Audit Rating Chart & 5S Levels of Achievement Chart

2.27k views • 6 slides

iPhone 5s Reviews

Fommy is a complete online accessories store for latest and trendy iPhone accessories at the best price in the market

238 views • 4 slides

HISTÓRICO DO 5S

5S. BASE PARA A QUALIDADE TOTAL. EMPRESA. HISTÓRICO DO 5S. JAPÃO: Década de 60. BRASIL: Década de 80. ORIGEM: JAPÃO Pais ensinam aos seus filhos os princípios de ordem e limpeza. O QUE É O 5S ?. 1S - UTILIZAÇÃO SEIRI. 5S - AUTO-DISCIPLINA E COMPROMETIMENTO SHITSUKÊ.

426 views • 8 slides

5S training

5S training. Office Environments. What is 5S?. 5S is a process for implementing and maintaining a clean, safe, and organized work area. 5S provides a way for organizations to operate efficiently and effectively.

2.06k views • 0 slides

Hypertherm - 5S+ Process

Hypertherm - 5S+ Process. 5S+ Implementation and Audit review Process . Training Objectives. Provide Safety awareness of potential hazards in your work environment Provide basic understanding for why the Lean journey begins with implementing and sustaining the 5S+ process

1.46k views • 46 slides

5S Workplace

5S Workplace. CI Department, Supply Cabinet March 2009. Objectives. Standardized work practices or operating in a consistent and standardized fashion. Everyone knows exactly what his or her responsibilities are to keep above 3S's….

668 views • 15 slides

iP hone 5S. September 2013. Kindly contributed by Emma Shaw, Medway Adult Learning Service. Search for Emma on www.skillsworkshop.org

230 views • 7 slides

Programa 5S

Programa 5S. Como surgiu o 5S?. Japão = dificuldades internas e externas. SEIRI = ORGANIZAÇÃO. Colocar as coisas em seu devido lugar, separar o que é necessário do que é desnecessário.

4.05k views • 29 slides

IPHONE 5/5S

IPHONE 5/5S. 應英二乙 4A1C0023 粘佳惠 應英二乙 4A1C0040 黃香菱 應英二乙 4A1C0061 李德馨. AGE GROUP. gender. country. color. Aluminum housing . display. Isight camera. Video recording . Built-in apps. Accessories. Touch id. weight. The speed of procession . All-new A7 and m7 chips. ios7.

411 views • 25 slides

IPHONE 5S . Presented by Ted Kousios. IPHONE 5S. The IPhone 5S is a high end smartphone developed by the company Apple Inc. The phone was released to the public on September 20,2013 along with the 5c on September 20,2013. . IPhone 5S H istory.

410 views • 15 slides

5S ( methodology )

5S ( methodology ). Report in IT 214 Presented by: JODELYN M. CABICO MARJORIE CORPUZ MARJORIE TEJERO CAROL BUENVIAJE. 5S (methodology).

1.76k views • 23 slides

Iphones 5s. What are IPhone 5s. An IPhone 5 is technology of today. People use it all the time, maybe not all the time, but most of the time. How can this device be used in a classroom?.

279 views • 6 slides

5S with Computers

5S with Computers. The physical and non-physical assets. Introduction to 5S. In a modern Lean office, keeping your computers organized allows you to focus on value-added activities and minimize the wastes of motion and transportation associated with computers.

929 views • 15 slides

5S Assignment

5S Assignment. Allen Mooneyhan Office Area. BEFORE PICTURES!. Results. Before…. After…. Results. Before…. After…. Results. Before…. After…. Results. Before…. After….

415 views • 7 slides

IPhone 5s Assessment

IPhone 5s Assessment. 4A1C0010 陶思寧 499C0142 陳育榛. Gender. Age. Job. Annual salary . What color do you like . How do you consider the photographic function . How do you get this product. What do you think is the reasonable price . Thank you for listening.

186 views • 10 slides

5S tal-leg. 5S Øvelse. På næste billede præsenteres 99 tal. Alle deltagere skal i løbet af de næste 30 sekunder tælle fra 1 til 49 ved at finde tallene. Når de 30 sekunder er gået - husk hvor langt du nåede. 5S Øvelse – Efter Sortering . Vi har fjernet de tal vi ikke skal bruge.

410 views • 13 slides

Programa 5S. Centro universitário Municipal de São José Academicos : Andreza Dalla Costa Cristiane Kamers Jean Carlos Silva José Valdir Dias Júnior Marileide Pinheiro. 5 S . Os 5S são um conjunto de termos denominados “sensos”.

1.18k views • 20 slides

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

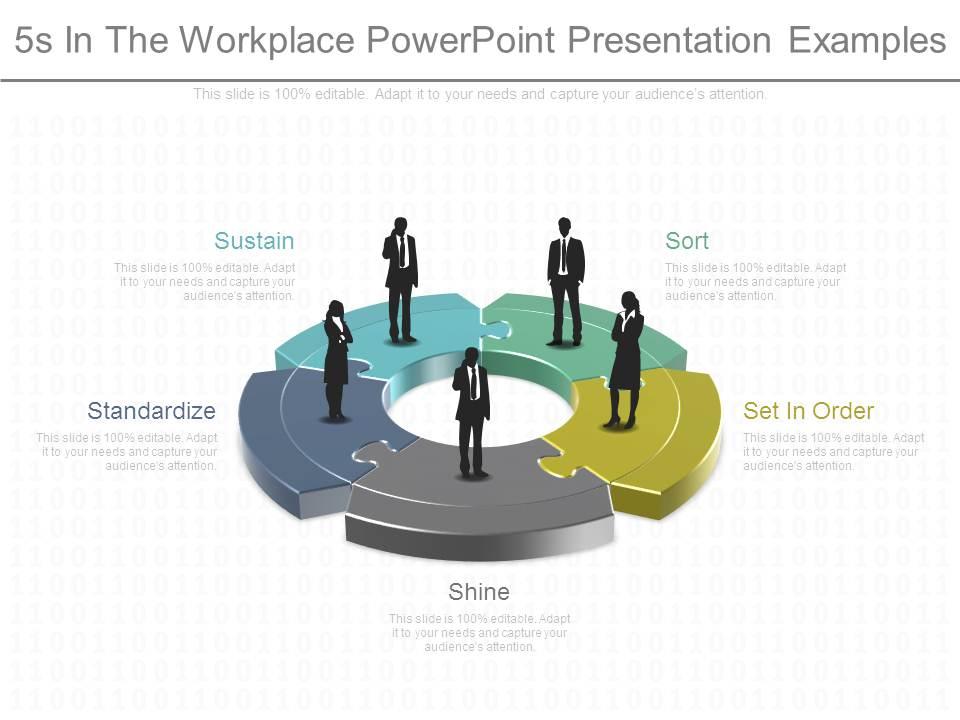

5s in the workplace powerpoint presentation examples

Give them a burst of fun with our 5s In The Workplace Powerpoint Presentation Examples. They ensure a cracker of an event.

These PPT Slides are compatible with Google Slides

Compatible With Google Slides

- Google Slides is a new FREE Presentation software from Google.

- All our content is 100% compatible with Google Slides.

- Just download our designs, and upload them to Google Slides and they will work automatically.

- Amaze your audience with SlideTeam and Google Slides.

Want Changes to This PPT Slide? Check out our Presentation Design Services

Get Presentation Slides in WideScreen

Get This In WideScreen

- WideScreen Aspect ratio is becoming a very popular format. When you download this product, the downloaded ZIP will contain this product in both standard and widescreen format.

- Some older products that we have may only be in standard format, but they can easily be converted to widescreen.

- To do this, please open the SlideTeam product in Powerpoint, and go to

- Design ( On the top bar) -> Page Setup -> and select "On-screen Show (16:9)” in the drop down for "Slides Sized for".

- The slide or theme will change to widescreen, and all graphics will adjust automatically. You can similarly convert our content to any other desired screen aspect ratio.

- Add a user to your subscription for free

You must be logged in to download this presentation.

Do you want to remove this product from your favourites?

PowerPoint presentation slides

Presenting 5s in the workplace powerpoint presentation examples. This is a 5s in the workplace powerpoint presentation examples. This is a five stage process. The stages in this process are sustain, standardize, shine, set in order, sort.

People who downloaded this PowerPoint presentation also viewed the following :

- Business Slides , Workplace Ethic

- Standardize ,

- Set in Order ,

5s in the workplace powerpoint presentation examples with all 7 slides:

March forward with our 5s In The Workplace Powerpoint Presentation Examples. They are aware of the exact drill.

Ratings and Reviews

by Dewayne Nichols

May 17, 2021

by Dalton Aguilar

IMAGES

VIDEO

COMMENTS

5S Training Presentation. Aug 27, 2015 •. 37 likes • 99,164 views. Parth Devariya. 5S is short for: Sort, Set in Order, Shine, Standardize and Sustain. 5S represents 5 disciplines for maintaining a visual workplace. #5S #5S Training #Business #BusinessManagement. Read more. Leadership & Management.

All of the above 5S presentations are also available as 5S PDF files for download; What is 5S Presentation. Benefits of 5S. 5S Seiri or Sort - First stage of 5S. 5S Seiton or Set In Order - Second stage of 5S. 5S Seiso or Shine - Third stage of 5S. 5S Seiketsu or Standardize - Forth stage of 5S. 5S Shitsuke or Sustain - Final stage of ...

This presentation on 5S Methodology will take you through everything you need to know about the workplace organization method, 5S. This video also covers a number of different topics like the basics of the 5S methodology, its benefits and the process of 5S, like Sort, Set in order, Shine, Standardize, and Sustain.

Jan 31, 2017 •. 92 likes • 62,447 views. sudarshan jadwal. This Presentation covers 5S methodology, implementation technique, example and checklist for implementation. Engineering. 1 of 52. 5S Presentation for beginners and professionals for implementation - Download as a PDF or view online for free.

Give your team the 5S foundation they need to get Lean with this ...

5S. 5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

This PPT Deck describes the 5S methodology for achieving operational excellence in your firm. Kaizen, a Japanese concept for total quality management, facilitates continuous improvement or betterment. This deck explains the 5S methodology: seiri (sort), seiton (set in order), seisou (shine), seiketsu (standardize), and shitsuke (sustain).

The 5S condition of a work area is critical to employees and is the basis of customers' first impressions. The Five S's; 5S benefits; 5S example; 5S resources; The Five S's. The 5S quality tool is derived from five Japanese terms beginning with the letter "S" used to create a workplace suited for visual control and lean production.

Download your free 5S PowerPoint Presentation. This Powerpoint ...

Discuss the five points of 5S methodology with our creative 5S Methodology PowerPoint Template with catchy visuals for training and business sessions. The 5S strategy is about creating a well-maintained, standardized workspace to boost operational processes. It is a lean strategy that aims to create an organization of objects or steps that are ...

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.. 5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and ...

Evaluate your facility with this free 5S audit card. Quality ...

The modern version of 5S is an English adaptation of an original program that has been popular in Japan for decades. There are five S's in 5S due to the alliteration of the Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. Each of the five Japanese words have added meaning in Japanese culture that is difficult to capture in English translations.

5S is one of the first tools that can be applied in a company that is starting down the path of a continuous improvement culture. A 5S implementation helps to define the first rules to eliminate waste and maintain an efficient, safe, and clean work environment. It was first popularized by Taiichi Ohno, who designed the Toyota Production System ...

10 5S Workplace Organization. Key Items for Implementation & Success People must "let go" of personal preferences. Make the facility "VISUAL". Make the workplace "Easy to Use". Think of new methods to make work easy (don't criticize methods that fail). Think outside the box & don't accept excuses for "why it has to be that way".

Free Google Slides theme and PowerPoint template. In business, 5S is a methodology created in Japan and consists of five words beginning with S, whose translations in English are 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. The aim of this methodology is to make the most efficient and effective use of workspace.

Template 3: 5S Implementation Plan. The first step in implementing the 5S system is to establish goals. Then, you need to develop a framework for your 5S implementation plan. This PPT deck covers the implementation plan for the goals, workforce, business framework, etc. It also helps you standardize the 5S process. Deploy it now.

What is 5S? 5S is a systematic form of visual management utilizing everything from floor tape to operations manuals. It is not just about cleanliness or orga...

This presentation on 5S Methodology will take you through everything you need to know about the workplace organization method, 5S. This video also covers a number of different topics like the basics of the 5S methodology, its benefits and the process of 5S, like Sort, Set in order, Shine, Standardize, and Sustain. So now, let's jump in and learn about the 5S methodology. Learn to develop your ...

Download our editable 5S Model PPT template to showcase the key components of this model and explain its role in organizing the workplace elements logically and removing clutters. ... Grab our feature-rich 5S Model PowerPoint template to explain how this model assesses and organizes workplace elements logically, removes unnecessary and ...

PowerPoint presentation slides: Presenting 5s in the workplace powerpoint presentation examples. This is a 5s in the workplace powerpoint presentation examples. This is a five stage process. The stages in this process are sustain, standardize, shine, set in order, sort.