Groundnut Oil Production Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Agriculture Sector » Agro Processing

Are you about starting a cooking oil production business? If YES, here is a complete sample groundnut oil production business plan template & feasibility report you can use for FREE .

Okay, so we have considered all the requirements for starting a groundnut oil production business . We also took it further by analyzing and drafting a sample cooking oil production business marketing plan template backed up by actionable guerrilla marketing ideas for groundnut oil production businesses. So let’s proceed to the business planning section.

Groundnut oil is an edible vegetable oil that is produced from seeds that are edible bearing in nature. To get groundnut oil, the seed is usually prepared, pressed and then filtered. Whilst starting this business might be very lucrative, anyone intending to start this business will need to ensure that they have studied the business well.

The business is one that would require technical skills, so the entrepreneur must ensure that he gets the right people to handle all the production process of getting refined and high quality groundnut oil.

To start this kind of business, getting a business consultant is very important. The business consultant will offer advice and suggestions to setup the oil production chain, the machines to be bought, run the business and thrive against your competitors in the industry.

Getting a business plan is very important as it allows you understand the business you intend going into. But writing a business plan can be very intimidating so it would be best if you hire a business plan writer or go online to get free business plan samples to help you in writing one. Below is a sample cooking groundnut oil business plan;

A Sample Groundnut Oil Production Business Plan Template

1. industry overview.

Groundnut oil production is usually done when oil is removed from the groundnut seed. The manufacturing process can either be done on a small or medium scale depending on the cost of the project and desired output. Groundnut oil is not only used for cooking or as a shortening but also as a base for confectioneries or to make peanut butter.

Globally, india ranks amongst the top exporters of cooking groundnut oil, although it is regarded as a premium oil whose cost is very high. Groundnut oil is not only available in filtered forms but also in refined forms as well. In the market, filtered oils are regarded as superior in quality.

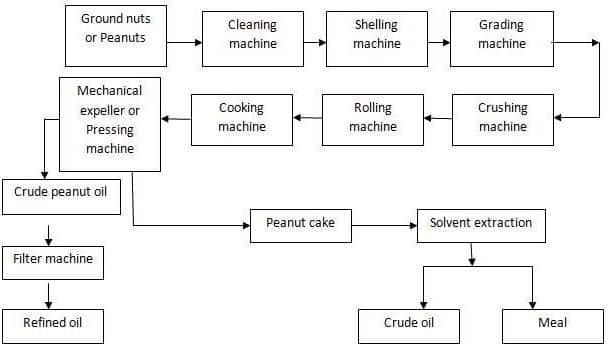

Raw materials that are required or producing groundnut oil is the groundnut seed. The seed produces about 50% of oil and 55% of the meal. Producing edible cooking groundnut oil is grouped into two groups, mechanical pressing and solvent extraction.

Groundnuts are oilseeds with high oil content that require mechanical pressing before being extracted. The production process for groundnut can be grouped into three stages such as preparation, pressing and crude oil refining.

2. Executive Summary

McQueen Groundnut Oil Inc is a leading and standard groundnut oil producing company here in Fort Lauderdale – Florida that intends to produce cooking groundnut oil to domestic and commercial customers not only here in the united states of America but also all over the world. We will also engage in offering other services in addition to our core service to our various customers.

Our intention of starting our own groundnut oil producing company is so as to be able to sell highly refined and quality groundnut oil that is cholesterol free to our various customers not only here in Florida or the United States but all over the world as well. Our intention is not only to establish our business for profit making but to also compete favorably with our competitors but nationally and internationally.

Because of the best practices standard we have set for ourselves, we have ensured that we procured the best pressing and refining machineries that will allow us to be able to produce quality and refined groundnut oil. Our packaging methods are also up to standard as we carry out all our activities with hygiene in mind so that we are able to set a standard for our customers.

Getting the best distribution networks are very important for this kind of business and so we have secured the best channels that will see our groundnut oils get to the end users. We will continue to seek for the best means at ensuring that our products get to our consumers at the right time.

We will ensure that we source for our raw materials from reliable vendors and suppliers, who use organic means to grow the crops, so as we will be able to give our customers the organic refined groundnut oil that is part of our corporate identity.

We intend to incorporate good work ethics as our corporate goal and also be renowned for our transparency standards. In order to ensure that we adhere to our corporate culture, we will recruit the best professionals possible that not only understand the industry we are in but also understand our company’s policies and are dedicated to ensuring that we are able to achieve our goals and objectives.

We will ensure that we get our employees to undergo continuous training that will not only enhance their skills but make them increase productivity for our organization. We will also ensure that our employees are well paid and undergo performance appraisals that will make them put in their best.

Finally, our Chief Executive Officer, Ms Laurie McQueen is a topmost entrepreneur who has more than 15 years experience in this industry and also in a managerial role. She knows how best to help us achieve our intended goals and objectives.

3. Our Products and Services

McQueen Groundnut Oil Inc intends to produce and supply highly refined groundnut oil to its various customers here in the United States of America as well as all over the world.

Our aim as a business is to ensure that we not only generate revenue but maximize profit as well and to this end, we intend to create multiple sources of income so as to be able to have a solid bottom line. The ways we will source for extra means of revenue will be according to our ambition and the laws of the United States of America.

Therefore the products and services we intend to offer at McQueen Groundnut Oil Inc are;

- Sale of processed groundnut oil for domestic and commercial purposes

- Sale of byproduct – groundnut cake

- Sale of groundnut sludge

- Consultancy and Advisory Services

4. Our Mission and Vision Statement

- Our vision is to ensure that we produce highly refined and quality groundnut oil that is cholesterol free for our various customers and also be amongst the top three groundnut oil producers globally.

- In order to ensure that we achieve our vision, we intend to ensure that we get the best equipment and also hire the best employees so that we will be able to achieve our goal of producing highly refined and quality groundnut oil.

Our Business Structure

Building a business structure that will be just right for our groundnut oil business is very important to us, which is why we are making sure that we put in all efforts to recruit the right hands that will help us achieve our goals and objectives.

It is important that our management team understand and identify with our core vision and objectives and as such is able to effectively communicate these policies and goals to the lower end staff and ensure that it is effectively implemented.

Due to the fact that we intend to offer additional services to our core service, we will hire more employees than the conventional groundnut oil producing company. This is so that the different tasks will be effectively handled without pushing too many responsibilities in the hands of a few employees.

Below is the business structure we intend to build for McQueen Groundnut Oil Inc;

Chief Executive Officer

Plant Manager

Purchasing Manager

Human Resources and Admin Manager

Accountants

Marketing Executives

Truck Drivers

Customer Care Executives

Maintenance Team

Security Guard

5. Job Roles and Responsibilities

- Creates strategies and policies for the overall direction of the organization

- Responsible for negotiating with high level clients on behalf of the organization

- Ensures that policies created are effectively implemented

- Monitors production processes and ensures that it aligns with both company and industry standard

- Develops and implements budgets for production

- Seeks ways to reduce costs without reducing quality

- Sources for reliable vendors and suppliers of raw materials

- Drafts purchasing contracts and ensures that it is to the benefit of the organization

- Drafts and implements purchasing strategies on behalf of the organization

- Responsible for recruiting, giving orientation as well as ensuring that customers get attuned to the company’s policies

- Responsible for employee welfare and incentive packages as well as carrying out performance appraisals on behalf of the company

- Ensures that the administrative functions of the organization are carried on smoothly

- Responsible for creating ensuring the implementation of financial statements, records and budget on behalf of the organization

- Prepares tax records and ensures that they are submitted to the right authorities

- Responsible for cash inflow and outflow and petty cash

- Drafts effective marketing strategies and modifies them continuously in order to generate revenue for the organization

- Engages in direct marketing with customers on behalf of the organization

- Manages existing customer relationship in order to help increase customer loyalty and retention on behalf of the organization

- Responsible for delivering products to customers at accurate destinations

- Carry out maintenance on the vehicle when necessary and report major faults to the management

- Keep traffic laws and regulations and also a logbook

- Responsible for taking orders, answering enquiries and providing accurate information to clients

- Ensures that customers’ complaints are readily resolved on behalf of the company

- Keeps an updated customer database on behalf of the company

- In charge of maintaining all the equipment and machineries used by the organization

- Arranges for new parts and replacements for the machineries

- Reports major machinery and equipment faults to the management

- Patrols the facility and its perimeter during work and after work hours to ensure that there is no trespasser

- Monitors incoming and outgoing people and visitor and responsible for surveillance equipment

- Remains updated on security tips and ensures that company staff is aware of security tips as well

6. SWOT Analysis

Due to the fact that we intend to run a standard cooking groundnut oil producing company, we are striving to ensure that we put up processes; plan and structures that will allow us attain this excellence. This is clearly why we have engaged the services of a reputable business consultant here in Fort Lauderdale – Florida, to look through our business concept and determine if the business we are going into is worthwhile and also if we are going to not only thrive in this business, but also compete favorably against our competitors.

In view of our request, the business consultant used four attributes (strengths, weaknesses, opportunities and threats) in order to determine how we are likely to survive and grow as a business. Therefore the SWOT analysis that was conducted on behalf of McQueen Groundnut Oil Inc is as follows;

Our strength lies in the fact that we offer our customers’ high quality processed groundnut oil which is cholesterol free. This means that customers who use other substitutes because they feel those are better for their diet will stick to our own brand of groundnut oil instead. We are in a location that is not only strategic but also convenient for our customers and employees to access.

Our facility is one that is conducive enough for our employees, while also being of high standard hygienically to produce our cooking groundnut oil. Those which we have chosen to work for our company is very competent and experienced especially as regards this industry.

They are also dedicated and committed to our corporate goals and philosophy. Finally, our owner and Chief Executive Office, Ms. Laurie McQueen has more than 15 years experience both in groundnut oil processing and in management and will ensure that we are able to achieve our intended goals and objectives.

The groundnut oil processing industry is a saturated one and so would require us to adapt strategies that would allow us to stand out against our competitors. Also, because we are just starting up, we do not yet have the necessary finances and staff strengths as our already established competitors.

- Opportunities

There are several opportunities that abound for us in this industry as cooking groundnut oil is widely consumed by a whole lot of people. We are however seeking innovative ways to attract the health conscious customers who have shifted to alternative sources because they feel that groundnut oil isn’t hygienic enough in helping to achieve their fitness goals. Our advisory and consultancy services will serve to open up more opportunities for us in this industry.

Facing threats as a business faces are to be expected if the business is a serious one. The threats that we are likely to face as a business will arise from unfavorable government policies, stiff competition from competitors, as well as customers’ shift to close substitutes on personal preference grounds. We have laid down strategies in place that will enable us handle whatever threats we are likely to face.

7. MARKET ANALYSIS

- Market Trends

Cooking groundnut oil, which is referred to as vegetable oil by some, is one of the oil products in high demand; as a large number of people use it for consumption as well as for commercial purpose. While there are substitutes for groundnut oil, the fact that this oil is cheaper makes it why more people use this oil.

Groundnuts are nuts that can be found at all time and is regarded as highly nutritional, which is why it is amongst the top nuts recommended by doctors for women that are not only pregnant but for those that are also health conscious or going on a diet. Any entrepreneur going into this business will therefore make good money from it.

Starting this business would require ensuring that technical details are being put into place. However, there are few groundnut oils processing businesses here in the United States of America, which makes it very ideal for us to go into this kind of business and make a tidy profit from it. It is also necessary to ensure that professionals are being employed to handle all the technical details.

8. Our Target Market

Cooking groundnut oil is used by a whole lot of people and so this means that there is a lot of demand for this product, and therefore we cannot necessarily limit the target market without making a thorough market research. Our location here in Fort Lauderdale – Florida is one that is strategic and will allow us to map out effective plans in order to serve our numerous clients.

The market research we have conducted from reliable facts and statistics will allow us better understand the characteristics of our target market and the right strategies that we would draft to be able to cater to this market. Therefore from our research, the following groups of people are those that we will be selling our products and offering our services to;

- Soap Manufacturers

- Confectionaries

- Cosmetic industries

- Food industries

- Grocery Stores and Supermarkets

Our competitive advantage

Our intention of starting a cooking groundnut oil production company is so as to be able to give our various customers not only here in the United States of America but all over the world, quality cooking groundnut oil that is cholesterol free. To be able to achieve this, we have drafted strategies that will allow us have a competitive advantage over that of our competitors.

Our first competitive advantage is in the quality of groundnut oil we are giving our customers all over the world. Because this is oil that is to be consumed, we have taken great care in ensuring that from the raw materials down to the processing all go through a high standard of quality checks. We take great pride in ensuring that our customers can trust our cooking groundnut oil.

We have engaged the services of the best professionals who not only know this industry thoroughly but also understand how best to make a business become the world standard we have intended for it. Our employees also understand our corporate philosophies and goals and are willing and dedicated to ensuring that we achieve it.

We have put in place processes and plans that will ensure that our employees receive trainings as at when due. These trainings will allow them to have enhanced skills that will also improve their productivity for the company. We will also ensure that our employees are well paid and have better welfare packages than that of their counterparts in similar startups such as ours.

Finally, we will ensure that we put our customers first by not only meeting but exceeding their expectations. We will ensure that we take good care of our loyal customers and offer them incentives. We will ensure that we keep an updated customer database so as to keep in touch with our customers and allow them be aware of our products and other services that we might be offering.

9. SALES AND MARKETING STRATEGY

- Sources of Income

McQueen Groundnut Oil Inc is a leading and standard groundnut oil producing business that has been established with the aim of generating revenue and maximizing profit not only here in Fort Lauderdale – Florida, all over the United States of America as well as globally as well.

We intend to make profits from sales of different products and offering of services to our various customers. McQueen Groundnut Oil Inc will generate revenue from the following products and services;

10. Sales Forecast

Groundnut oil is a cooking oil that is being consumed daily by most people and used for domestic and commercial purposes and therefore will always be in demand.

Our location here at Fort Lauderdale – Florida is one that is very strategic and has us very optimistic of being able to not only generate the needed revenue within one year but also one that will allow us maximize our profit, as the forecast has shown that this is highly achievable.

We carried out several researches whilst conducting our sales forecast and used several assumptions and information from similar start-ups such as ours not only here in Florida but also all over the United States of America so as to be able to get accurate data to arrive at the below stated projections.

The stated projections for McQueen Groundnut Oil Inc based on accurate assumptions and data are as follows;

- First Fiscal Year-: $600,000

- Second Fiscal Year-: $1,100,000

- Third Fiscal Year-: $2,000,000

N.B: The above sales projections were done based on certain assumptions and what was obtainable in the industry at the stated period. The assumptions were that there won’t be any stringent government policies, no arrival of a competitor offering same services as we were and also that the economy remains stable. Should there be any change in the above assumptions, our sales projections for the stated period will be affected.

- Marketing Strategy and Sales Strategy

When writing a business plan, one important element that is not usually overlooked is the marketing and sales aspect. Not only are strategies created to better market a product or service, a budget is also created so that strategies can be effectively implemented. Marketing also serves a dual purpose as it not only generates revenue for the company but also creates awareness for the business as well.

Due to how delicate marketing is, we intend to hire reputable marketing experts who understand the nature of our business and the industry we are operating in to help create effective marketing strategies that we will use to be able to compete favorably against our competitors all over the United States of America.

We will not be limiting our marketing efforts to merely just the conventional means. We will be making use of unconventional means via technology to also market and sell our cooking groundnut oil to our target market. Our marketing team will be well versed in handling all our online affairs so as to attract more potential customers to our business from other states and even countries.

We will also empower our marketing team to conduct more market researches in order to be able to determine new target markets for our business. Our marketing team will also monitor marketing strategies and remove or modify those that are thought to be ineffective. We will in fact provide them with all that is necessary to be able to achieve our corporate sales goals and objectives.

Therefore the marketing and sales strategies that we intend to adopt for McQueen Groundnut Oil Inc are;

- Ensure that we introduce our groundnut oil company officially to wholesalers and distributors as well as other industry stakeholders

- Throw a grand opening party so as to create awareness about our business to our target market

- Advertise our cooking groundnut oil business in newspapers (local and national) as well as on radio and television stations

- Ensure that we engage in direct marketing and sales to our various customers

- Use our social media platforms such as Facebook, Twitter, LinkedIn and Google Plus to market our cooking groundnut oil business

- Ensure that our groundnut oil business is listed in local directories (Yellow Pages) and on online directories as well

11. Publicity and Advertising Strategy

Publicity is very important for every business, as it is what allows the target market that consists of both existing and potential customers. This is why even though a business has been established for a long period of time, it still engages in publicity so as to be able to not only retain its customers but also attract new customers to patronize it. The publicity we tend to create for our business is one that will project the image of our business positively.

In a bid to ensure that we create effective publicity strategies, we intend to engage the services of a brand consultant who understands the business and the industry we are in. the brand consultant has been empowered to use conventional and unconventional means to ensure that we get the awareness we need for our business not only here in Fort Lauderdale – Florida but also all over the United State of America.

Below are the platforms we intend to use in creating awareness as well as advertising McQueen Groundnut Oil Inc;

- Create an official website and use this to create awareness about our groundnut oil producing company

- Place adverts in local and national newspapers and on radio and television stations here in Florida and nationally as well

- Participate in and sponsor relevant community programs here in Fort Lauderdale

- Use our social media platforms such as Facebook, Twitter, LinkedIn and Google Plus to promote our groundnut oil producing company

- Place attractive and distinctive bill boards in strategic locations all around Florida and outside its environs

- Write articles and post on different relevant blogs and websites

12. Our Pricing Strategy

Determining what price to set for your products and services is very important and requires making detailed strategies to ensure that one picks just the right price that will not be detrimental to the business or chase customers away. In setting the right price for our business, we will consider our overhead and running costs as well as what our customers are also offering the target market.

However, while we intend to set the right price that will just be right for our business and fair to our customers, we will offer a discount in the first two months of our operations in order to attract customers to our business. After taking a thorough look at this strategy, we are convinced that we will not be running at a loss even though our profit margins might be low for these periods.

- Payment Options

Any smart entrepreneur knows that it is very important for customers to have convenient means by which they pay for products and services. Therefore knowing this, we intend to offer various payment platforms so as to be able to cater to our various clients and their different preferences.

The different payment options that we therefore intend to make available are;

- Payment via cash

- Payment via checks

- Payment via bank draft

- Payment via online payment portal

It should be noted that the above payment options were carefully chosen by us to make payments not only easier for our clients but also to ensure that we are able to run our business without hitches.

13. Startup Expenditure (Budget)

Starting a cooking groundnut oil production business can be capital intensive especially as this business is one that needs equipment in order to be able to produce the groundnut oil for consumption. We therefore intend to use the bulk of capital to procure equipment, get a truck for delivery, get raw materials and also pay the salaries of our employees and utility bills for at least 6 months.

The major areas where we therefore intend to spend our start-up capital include;

- Total fee for registering our groundnut oil producing business in the United States of America – $750

- Obtaining of licenses and permits, accounting software and other legal expenses – $3,250

- Marketing budget and promotion expenses for the grand opening of Queens Groundnut Oil Inc. as well as for general promotional activities for the business – $10,000

- Cost of hiring business consultant – $3,000

- Operational cost for the first 6 months (which includes employees salaries and utilities bills) – $150,000

- Insurance (general liability, workers’ compensation, and equipment insurance) – $2,000

- Cost of groundnut oil machines (separating machines, pressing machines, processing and refining machines) – $70,000

- Cost of leasing a facility for 2 years and carrying out renovations – $100,000

- Purchase of truck for distribution and delivery of groundnut oil – $50,000

- Raw materials (groundnuts) and packaging materials – $20,000

- Other start-up expenses (stationery, computer, printer, phones, furniture) – $10,000

- Storage equipment (shelves, bins, racks) – $5,000

- Cost of launching an official website – $1,000

- Cost of throwing a party to launch our business – $5,000

- Miscellaneous – $10,000

From the above estimate, it is apparent that we would need the amount of $440,000 in order to successfully start and run our groundnut oil processing to a certain standard here in Fort Lauderdale – Florida. It should be noted that the bulk of the capital will go into procuring equipment, renting a facility for at least two years, procuring a vehicle and also paying the salaries of employees and utility bills for at least 6 months.

Generating Funding / Startup Capital for Queen’s Groundnut Oil Inc Business

Queen’s Groundnut Oil Inc is a cholesterol free cooking groundnut oil that is owned and managed by Ms. Laurie McQueen. Ms. McQueen who intends to grow this business into one that is of international standard intends to approach external investors with vision that aligns with hers, whilst seeking other means of sourcing for capital.

Therefore, Ms. McQueen will seek for her start-up capital from the following sources. Below, therefore are the sources where we intend to generate our start-up capital from;

- Generate part capital from sale of stocks of personal property

- Source for loan from commercial bank

- Generate capital from external private investors

N.B: From sale of stock and some private property, Ms. McQueen has been able to generate $140,000. She has gotten a loan of $150,000 from the bank that will be repaid in 7 years time at an interest rate of 2.4% annually; all the approving documents have been signed and the money will soon be credited into the company’s account before the end of the week.

She is also currently in the final stages of obtaining a loan of $150,000 from a private investor in exchange for an equity of 5%. All the terms have been discussed and signed on, and the lawyers are going through the documents to get it ready for signing.

14. Sustainability and Expansion Strategy

The way a business is structured determines how long the business will remain in existence. We are willing to go the extra mile to ensure that we hire competent professionals who understand the way our kind of business is run and how best to ensure that our kind of business becomes one that is a force to be reckoned with nationally and internationally.

The professionals we intend to hire will be one that also understand our ideology as a business and will remain committed to this ideology and ensure that it is well communicated to all stakeholders. We will also ensure that we have laid down processes that will allow for the environment to be conducive work-wise for our employees.

We will pay our employees well and provide them better welfare and incentive packages better than their counterparts in similar start-ups such as our across the country. We will also ensure that our employees undergo training so that they will have better skills that will not only see them enhanced in the industry but will also ensure better productivity for our business as well.

As much as we intend to generate as much revenue as we can, we will make sure that we retain at last 30% of our earnings back into our business. This is to ensure that we do not have to go externally to seek for funds all the time. Also, putting back our earnings into our business will allow us to be able to not only grow and sustain the business but also expand it as well.

Check List / Milestone

- Business Name Availability Check: Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Conducting feasibility studies: Completed

- Generating capital from family members: Completed

- Applications for Loan from the bank: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community: In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Opening party / launching party planning: In Progress

- Establishing business relationship with vendors – wholesale suppliers / merchants: In Progress

- Purchase of trucks: Completed

Related Posts:

- Coconut Oil Production Business Plan [Sample Template]

- Palm Kernel Oil Business Plan [Sample Template]

- Soybean Oil Production Business Plan [Sample Template]

- Wheat Flour Mill Business Plan [Sample Template]

- Leather Processing Business Plan [Sample Template]

- Agriculture Farming

- Livestock Farming

Project Reports

- Hydroponics

- Best Fertilizers

- Vertical Farming

- Sheep Farming

- Goat Farming

- Poultry Farming

- Fish Farming

- Pig Farming

- Dairy Farming

- Rabbit Farming

- Success Stories of Farmers

- Boost Fruit Yield

- District Wise Crop Production

- Schemes & Subsidies

- Agriculture Colleges

- Farm Insurance

- Disease Control And Management

Agriculture

Aquaculture

Horticulture

Agri Business

Groundnut Oil Making Process (Peanut), Business Plan

Table of contents, a step by step guide for groundnut oil making process, business plan:.

Today, let us discuss the groundnut oil production process, extraction methods, and business plant including groundnut oil plant (machine) cost in India.

Groundnut oil is also known as peanut oil or Arachis oil, is a mild-tasting vegetable oil expressed from groundnut kernels. Groundnut oil is generally used in cooking, including frying, basting, and the manufacture of margarine and shortenings. Groundnut oil is light yellow transparent edible oil with clear color and lecture, pleasant fragrance and good taste is relatively easy to digest.

Groundnuts or peanuts are a popular source of food throughout the world. And the groundnut oil, however, can be used for cooking, they can be used as a shortening or as a base for confectioneries and they can be used to make peanut butter. Groundnut kernel contains 45 to 55% of oil. The Groundnut oil obtained from the kernel is yellow to greenish-yellow in color. The meal is a very important component of feeds for poultry and cattle. Groundnut oil is an organic material oil that derived from peanuts, noted to have the aroma and taste of its parent legume. Peanuts or Groundnut oils can be extracted in various ways. Always method used depends on the oil.

Groundnut oils are extracted by using a solvent like hexane, while aromatic oils are extracted with different methods including steam distillation and the cold pressing method. In all of these options, the goal of extraction is to produce pure oil free from contaminants and traces of the original plant material.

India is the second-largest producer of peanuts after China. Groundnut or Peanut is the largest oilseed in India in terms of production. It accounted for about 35.99 percent of the oilseeds production of the country during 2007-08. Generally, 2.5 kg of groundnut to produce 1 liter of the groundnut oil. The cost of procurement and processing of the groundnut or peanut is around Rs. 90/kg. Hence, simple math says that Rs. 225/liter is the raw material cost.

Major Groundnut oil-producing states in India

In India groundnut or peanut is grown over an area of 6.9 million hectares with a total production of 5.3 million tonnes. Groundnut cultivation is mainly confined to south Indian states, viz, Gujarat, Andhra Pradesh, Karnataka, Tamil Nadu, and Maharashtra. The other important states grown Groundnut are Madhya Pradesh, Rajasthan, Uttar Pradesh, and Punjab.

The general process of Groundnut oil production

From harvested groundnuts to pure edible peanut oil or groundnut oil production is a complex process. The main procedure is groundnuts preprocessing, prepressing, solvent extraction, crude peanut oil refining.

You may also like Growing Onions from Seed, Planting, Care, Harvesting .

The Groundnuts must be pre-processed before sending to the expelling department, the kernels need to be cleaned, shelled, cracked and cooked by special seed processing machinery. Then the preprepared peanut kernels will be transported to the prepressing workshop in where these raw materials could be first expelled by screw oil press machines. However, the screwing process of pressing is a high residual oil rate. In this time, the chemical method solvent extraction will be a good method to fully extract peanut oils. The solvent extraction method can create the residual oil rate of the groundnut meal below 1%. Therefore, for edible use, the pressed crude groundnut oil needs to be refined by filter presses or oil refining plant.

Groundnuts solvent extraction process

Generally, the Groundnut or peanut solvent extraction is a procedure which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods that are expellers, hydraulic presses, etc. The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Groundnuts are first decorticated to remove the husk. The Groundnut kernels so obtained have oil content over 48%. The kernels are subjected to mechanical extraction process with the help of screw presses. The resultant cake has residual oil content changeable from 8 to 12% depending on the extent of pressing. The pre-pressed cake is subjected to solvent extraction for recovery of the residual oil.

The raw material for Groundnut oil production:

The principal raw material essential for the production of groundnut oil is groundnut seed. And you could procure this locally. The seed gives 44.5 to 50% oil, 50-55% meal. However, other required raw materials for Groundnut oil production are caustic soda, bleaching earth, and packaging consumables.

Equipment used for Groundnut oil extraction process:

List of the equipment used for Groundnut oil extraction process will be given below;

- Self-regulation vibrating sieve

- Magnetic separator

- Cleaning sieve

- Groundnut shelling machine

- Groundnut Kernel Grading Machine

- Peanuts Crushing Machine

- Five-layer Vertical Steam Cooker

- Electrical Cooker

- Peanut Rolling Machine

- Mechanical expeller

- Filter machine

Groundnut oil extraction process:

Groundnut oil processing process, based on mechanical pressing technology, is normally grouped into three stages they are groundnut seeds preparation, groundnut pressing, and rude groundnut oil refining.

The complete Groundnut oil extraction process can ensure the nutrition, flavor, safety, and fragrance of peanut oil. The different stages of Groundnut oil extraction process mainly composed of cleaning, shelling, grading, crushing, rolling, steaming or cooking, pressing, filtering and refining.

The first step in preparing oil seeds for Groundnut oil extraction is to clean them. Clean accurately so that the oil is not contaminated with foreign materials. Therefore, this helps to proceed with the extraction process as efficiently as possible. During the procedure, carefully inspect the seeds to remove stones, sand, dirt and spoilt seeds. Additionally, you can use dry screening method to remove all material that is over or undersized. Sometimes washing is resorted to but it must be avoided as the plant tissue will have to be dried at a later stage.

You may also check Organic Vegetable Farming in India .

The raw materials for Groundnut oil extraction should be fresh, full-grained, undamaged, mildew-free, and free of insects and have not undergone an aging period. The cleaning procedure can remove the immature, damaged and moldy grains. The equipment used for this process will be self-regulation vibrating sieve, magnetic separator, cleaning sieve, etc.

Groundnuts with shells should use Groundnut sheller to remove the shells to increase the oil yield, improve the quality of the oil and cake and smooth the following peanut oil production process. The equipment used for this process will be the Groundnut shelling machine.

Some of the Groundnut oil production plants may add this process to separate the small peanuts and large peanuts for different treatments. The equipment used for this process will be the Groundnut Kernel Grading Machine.

This procedure is to remove the red skin by crushing the Groundnut kernels. Then obtain rid of the red skin by wind separator. At the same time, large size Groundnut kernels are crushed into a smaller size. The moisture of crushed Groundnuts can be better controlled. The equipment used for this process will be the Peanuts Crushing Machine.

Rolling or grinding:

After crushing, Groundnuts are rolled through the instantaneous extrusion force between the two rollers to form the embryo slice, the shape of the peanut is changed, the oil path is shortened, and this is beneficial to the peanut oil extraction. The seed is not generally pressed whole since oil extraction is more efficient if the seed is in smaller particles. Herein lies the relevance of the grinding procedure. Grinding is the process for reducing the particle size. Also, you can use small motor powered hammer mills for the unit operation.

Another alternate process used for the reduction of particle size is rolling the oilseeds to generate flakes for oil extraction. Many large-scale commercial plants find this mainly effective approach. Additionally, with large oilseeds, it can be necessary to grind the seed first, and then put the pieces through the flaking rollers. The equipment used for this process will be Peanut Rolling Machine.

Steaming or Cooking:

This procedure is to adjust the moisture of peanut embryo slice by changing the temperature to develop the oil extraction rate and ensure the final peanut oil has a strong aroma. The equipment used for this process will be Five-layer Vertical Steam Cooker, Electrical Cooker.

It is not too late to check Basmati Rice Farming .

The steamed or cooked peanut embryo slices are then pressed by Groundnut oil press machine for oil extraction. The screw peanut oil or Groundnut oil machine can ensure the original cell structure of the peanut is destroyed under mechanical force to obtain a pressed crude oil.

During processing, press the conditioned oil seeds or oil-bearing material using a lever press, hydraulic press or a mechanical expeller to remove the oil.

Peanut oil pressing methods

Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology.

Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil output. But because of the high production temperature, the peanut protein is generally severely denatured and the lose a great number of nutrients.

Cold pressing method refers to the oil production technology which is conducted temperature under 60℃. Before pressing method, normally uses the process of removing the red skin, which is beneficial to the reserve of nutrients and the comprehensive utilization of peanut protein in peanut oil.

Generally, crude peanut oil can include some organic impurities that can be easily removed by edible oil filter machine or other type’s oil filter machine.

The crude peanut oil or Groundnut oil that is filtered by the oil filter machine is pure and clean. But it still contains several oil-soluble and in oil-soluble impurities. Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil.

Cost of Groundnut oil extraction machine:

Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8 Lakh/Piece.

You may be interested in Growing Arugula Plants .

16 COMMENTS

Hello I am Ankit Patel a Young entrepreneur looking for peanut oil business, and I need help from your side about business from the first step how to start the business , what is process n all. Thank you

very good activity

Hi I a farmer from Maharashtra.I need to start a small groundnut oil factory in my farm.can any one pls suggest me from whr I can start..I saw lot of small machines which can give 4/6kg oil in an hr..as i am farmer i can grow groundnut in farm.. I need help from your side about business from the first step how to start the business , what is process n all. Thanks you.

hi, i am in groudnut oil extraction business (cold pressed, chemical free) on a small scale. I need guidance from you to procure moister free, good oil content seeds. i want to expand my business. i am from Mumbai and do not get good variety of seeds from mandi i.e. wholwsellers in Mumbai and also rate if very high. thanks

Hi, I am chetan patel from west Africa but I am indian from Junagadh Gujarat. If you want to start oil mill at Africa then I am with you because I want to start oil mill here. Actually I have lots of experience of Oil mill and cotton ginning. Here very good groundnut with per kg 30rs. and price will be not changed whole year because here is not satta bazar. My whatsapp is continue at Africa so you can contact me. With regards

What is the name of the variety of peanut.

I am a farmer and supplier of big lot ground nut. I can provide big lot of high quality ground nuts which contains good amount of oil content. Kindly clarify which grade of ground nut you use for oil making and Minimum quantity require.

I want know about groundnut.

Hi i have a oil manufacturing unit.. and i am in search of peanut farmer for direct supply of peanut in which both side will be benifitted…..

I was given an assignment, I really need it. The question goes as thus, what are the methods of grading in oil, it’s advantages and disadvantages?

Hi, My name is Mr. Subhash Wadkar, I am professional for processing of edible oils working in Africa for many years. Now I want to start my own crushing unit for groundnut, but I really have doubts about the loss and forain material % for calculating its recovery after the process. Can any one guide me on retrieval that what is the standard range of F M content for groundnut process.

pls give me idea where we get ground nuts oil making machine

Hello, I am Mr Collins from Benin city ,Edo state ,Nigeria. I have just pick interest in production of grand nut oil in Benin . I have already made the provision for the supply of a machine for this business. So please I want to be properly guided on the business. And again I want the step by step process of this production and the marketing. Thanks. Collins

Thanks for this forum, it’s of a great opportunity and pleasure to read different thoughts and questions from across the globe. I am from Northern Uganda and our region is the leading in groundnuts production. I hope to submit my questions as I encounter challenges in this industry.

Am Blessing from Nigeria am looking in starting up a batch production of refined groundnut oil in my country but I need guidance on how to go about it and the variety of groundnut to use, and also how to remove odor in cold pressed groundnut oil

Your post is a valuable resource for anyone looking to expand their knowledge on the topic. It’s thorough and well-explained.

LEAVE A REPLY Cancel reply

Save my name and email in this browser for the next time I comment.

Types of Pesticides Used in Agriculture: A Beginner’s Guide

Economical aquaculture: a guide to low-budget fish farming, 15 common planting errors that can doom your fruit trees, how to make houseplants bushy: effective tips and ideas, innovative strategies for boosting coconut pollination and yield, pollination strategies for maximum pumpkin yield, the complete guide to chicken fattening: strategies for maximum growth, natural solutions for tulip problems: 100% effective remedies for leaf..., revolutionizing citrus preservation: towards a healthier, greener future, natural solutions for peony leaf and flower problems: 100% effective..., maximizing profits with avocado contract farming in india: a comprehensive..., natural solutions for hydrangea problems: 100% effective remedies for leaf..., the ultimate guide to choosing the perfect foliage friend: bringing..., from sunlight to sustainability: 15 ways to use solar technology..., the ultimate guide to dong tao chicken: exploring from history..., the eco-friendly makeover: how to convert your unused swimming pool..., mastering the art of delaware chicken farming: essentials for healthy..., 20 best homemade fertilizers for money plant: diy recipes and..., how to craft a comprehensive free-range chicken farming business plan, brighten your flock: raising easter egger chickens for beauty and..., borewell drilling cost, pump price, and pipe cost, polyhouse subsidy, cost, profit, project report, tractor subsidy, bank loan, eligibility, schemes, process, malabar neem project report details guide, cold storage project report, cost and subsidy, mushroom farming project report, cost and profit analysis.

How to Start Groundnut Oil Extraction Production Business

Groundnut oil production is a financially profitable venture with huge export potential. In addition, you can initiate the groundnut oil processing operation on a small and medium scale basis according to the desired output and project cost.

Initiating a groundnut oil production business requires feasibility study preparation, procurement, and installation of machines in the appropriate accommodation, recruitment of personnel, and project commercial take-off. One metric ton of groundnut seed produces an average of 420 Ltr of groundnut oil, 420 kg of groundnut cake, and 40 kg of groundnut sludge.

Table of Contents

Groundnut Oil Production Market Potential

Groundnuts are a popular source of food throughout the world. Groundnut oil is used for cooking food and as a shortening or as a base for confectioneries and it can be used to make peanut butter. Groundnut oil ranks at the top among edible oils exported from India.

It is a premium oil and its cost is also high. Most other edible oils are priced lower than groundnut oil. Groundnut oil is available in the market in refined and filtered forms. Although filtered oils are nutritionally superior in quality.

The latest data shows that there are almost 75 countries that import groundnut oil from India in huge quantities. The total export value stands at 64 million US dollars.

1. Groundnut Oil Production License & Registration

In establishing a groundnut oil production unit, you will need to obtain several different licenses and registration from different Government authorities.

- Company Registration with ROC

- Trade License

- GST Registration

- Factory License

- Food Operator License

- BIS Certification

- ‘No Objection’ from Pollution Control Board

- AGMARK Certification

- Fire License

The Food Standards and Safety Rules, 2011, and rules made under IS 544: 1968 permit additions of antioxidants in groundnut oil for a higher shelf life of the oil. However, under the scheme of labeling environment-friendly products, the presence of antioxidants within a prescribed limit is a requirement as per notification of the Ministry of Environment and Forests.

These are the common license and certification requirements. Check with your local DIC authority about any other required formalities.

2. Arranging Finance For Groundnut Oil Production Unit

Alike any manufacturing industry groundnut oil production business also involves two types of co st factors . One is fixed capital and the other is working capital. A refinance scheme facility is available with NABARD . For fixed capital, you will need to apply term loan or mortgage loan. For working capital requirements, you can go for cash credit or the overdraft facility with your nearby bank or any financial institution.

3. Groundnut Oil Production Unit Setup & Machinery

Selecting the right location for factory operation is an important aspect. The major required utilities are water and electricity. Easy availability of transport facilities and labor is important. Create a floor plan indicating specific space for raw material storage, finished products storage, production unit area, administrative workspace, storeroom for oil cakes, and space for miscellaneous usage.

Generally, you will need to have 0.50 acres of nonagricultural land for establishing an improved groundnut oil expelling unit. Here, you can install a plant with a processing capacity of 240 MT /annum. Additionally, the land must come with proper elevation.

The basic machine & equipment required are as follows:

- Pre-cleaner for cleaning the oil seeds

- Cans and trays for handling oil seeds

- Batch-type solar dryer

- Tapering screw types mechanical oil expeller

- Filter press

- Steel drums for storing edible oil and sedimentation of impurities

- Weighing balance

- Semiautomatic bottle-filling machine

- Molded polycarbonate bottle capping cum sealing machine

If you want to go for pouch packing, you will need to have an automatic pouch filling and sealing machine.

4. Raw Material For Groundnut Oil Production

The principal raw material required for the production of groundnut oil is groundnut seed. And you can procure this locally. The seed gives 44.5-50% oil and 50-55% meal. However, other required raw materials are caustic soda, bleaching earth, and packaging consumables.

5. Groundnut Oil Production Process & Technology

Basically, you can divide the edible oil technology into two groups. These are mechanical pressing and solvent extraction. For oilseeds with high oil content such as groundnut, you will need to apply first mechanical pressing.

Here, you can extract over 85% of the oil. However, you can extract the remaining oil in the expeller cake with a solvent. As per mechanical pressing technology, you can divide the groundnut oil production process into three stages. These are seed preparation, pressing, and crude oil refining.

a) Cleaning

The first step in preparing oil seeds for oil extraction is to clean them. Clean properly so that the oil is not contaminated with foreign materials. Therefore, it helps to proceed with the extraction process as efficiently as possible.

During the process, carefully inspect the seeds to remove stones, sand, dirt, and spoilt seeds. Additionally, you can use a dry screening technique to remove all material that is over or undersized. Sometimes washing is also resorted to but it must be avoided as the plant tissue will have to be dried at a later stage.

b. Dehulling

During the process, remove the outer seed coat of the oilseed. Generally, you can use a power-operated dehuller for the operation. Removal of the outer seed coat is necessary as it does not contain oil and inclusion of it in the unit operations makes the oil extraction process less efficient. Some seeds such as groundnut can be shelled by hand. Some others such as sunflower seeds are usually hulled in machines. Still others, like safflower and colza, cannot be shelled.

c. Grinding or rolling

Seed is not usually pressed whole since oil extraction is more efficient if the seed is in smaller particles. Herein lies the relevance of the grinding process. Grinding is the process of reducing particle size. Additionally, you can use small motor-powered hammer mills for unit operation.

Another alternate process used for the reduction of particle size is rolling the oilseeds to produce flakes for oil extraction. Many large-scale commercial plants find this the most effective approach. Additionally, with large oilseeds, it may be necessary to grind the seed first, and then put the pieces through the flaking rollers.

It is the final step for preparing the raw material for oil extraction. Heating leads to increased oil yield. Heating helps in killing those enzymes present in the plant tissue which have a deteriorating effect on oil quality.

Moreover, if you don’t use the oilseed cake for feed or feed, heating is useful as it increases protein availability. Sometimes, you can press the oil-bearing material without heating it. Oil extracted in this way is called cold press oil.

e. Pressing

During processing, press the conditioned oil seeds/oil-bearing material using a lever press, hydraulic press, or a mechanical expeller to remove the oil.

f. Refining

When you use the lower quality feedstock for oil extraction, you can use this process. Basically, it helps in removing undesirable cloudiness, color, and flavor from the extracted oil. In groundnut oil production, mentioning the shelf life on packets or labels is mandatory.

The Editorial Staff at NextWhatBusiness is a team of Business Consultants having years of experience in small and medium-scale businesses.

How To Write a Business Plan for Groundnut Oil Processing in 9 Steps: Checklist

By alex ryzhkov, resources on groundnut oil processing.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

- Marketing Plan

Welcome to our blog post on how to write a business plan for groundnut oil processing! Did you know that the groundnut oil processing industry in the US has been experiencing significant growth in recent years? According to the latest statistics, the market size of this industry reached $xx billion in 20xx , and it is projected to grow at a CAGR of x% from 20xx to 20xx . With such promising prospects, now is the perfect time to venture into this profitable business model.

To succeed in the groundnut oil processing industry, it's crucial to follow a well-defined roadmap. In this blog post, we will provide you with a nine-step checklist to help you write a comprehensive business plan for your groundnut oil processing venture. By following these steps, you will be able to identify your target market, analyze the competition, set clear objectives, determine the necessary investment, establish legal requirements, find reliable suppliers, devise effective marketing strategies, create financial forecasts, and build a skilled team. Each step is vital in ensuring the success and profitability of your groundnut oil processing business.

So, let's dive in and explore how you can bring your groundnut oil processing dream to fruition. Whether you are a seasoned entrepreneur or a first-time business owner, our checklist will guide you through the essential components of a robust business plan. By dedicating time and effort to each step, you will pave the way for a thriving groundnut oil processing operation that caters to the demands of local supermarkets, grocery stores, restaurants, and other food businesses.

Identify Target Market And Potential Customers

When starting a groundnut oil processing business, it is crucial to identify your target market and potential customers. Understanding who your customers are and what they want will help you tailor your products and marketing strategies to meet their specific needs. Here are some key steps to help you identify your target market and potential customers:

- Research the market: Conduct thorough research to understand the demand for groundnut oil in the US market. Analyze market trends, consumer preferences, and the competition to identify any gaps or opportunities.

- Narrow down your target market: Based on your research, identify the specific segments within the market that you want to target. For example, you may focus on supplying groundnut oil to health-conscious individuals, gourmet food stores, or organic food businesses.

- Identify customer demographics: Determine the demographic characteristics of your target market, such as age, gender, income level, and geographic location. This information will help you tailor your marketing messages and distribution strategies accordingly.

- Understand customer preferences: Conduct surveys or interviews with potential customers to understand their preferences when it comes to groundnut oil. Find out if they prioritize factors such as organic certification, sustainability, or price point.

- Assess buying behavior: Analyze how and where your potential customers buy groundnut oil. Are they more likely to purchase from supermarkets, specialty stores, or online platforms? This information will guide your sales and distribution strategy.

Tips for identifying target market and potential customers:

- Study your competitors: Analyze the customer base of your competitors to identify any untapped markets or customer segments.

- Engage with potential customers: Social media platforms and online forums can provide valuable insights into customer preferences and needs.

- Stay updated on market trends: Keep yourself informed about the latest industry trends and consumer behaviors to stay ahead of the competition.

By thoroughly identifying your target market and potential customers, you can tailor your business strategies to effectively reach and serve the right audience. This will increase the chances of success and profitability for your groundnut oil processing venture.

Conduct Market Research And Competitive Analysis

In order to successfully launch and grow a groundnut oil processing business, it is essential to conduct thorough market research and competitive analysis. This step will provide valuable insights into the current market trends, customer preferences, and the competitive landscape, allowing you to make informed decisions and develop strategies that will give you a competitive edge.

Market Research:

- Identify your target market and potential customers by conducting surveys, interviews, and focus groups. This will help you understand their needs, preferences, and purchasing behavior.

- Study market trends, such as the demand for groundnut oil and related products, pricing dynamics, and changing consumer preferences. This will help you identify opportunities for growth and potential market gaps.

- Analyze the size and scope of the market to determine the potential demand for groundnut oil. This can be done by studying industry reports, market research data, and government statistics.

Competitive Analysis:

- Identify and analyze your direct and indirect competitors in the groundnut oil processing industry. Study their products, pricing strategies, distribution channels, and marketing efforts.

- Evaluate their strengths and weaknesses to identify areas where you can differentiate your business and offer unique value propositions.

- Assess their market share and customer base to understand the level of competition and identify potential niches or underserved segments.

- Consider hiring a professional market research firm to conduct a comprehensive analysis. They will provide unbiased and detailed insights into the market and competition.

- Stay updated with industry news, trade publications, and online forums to monitor any changes or emerging trends in the groundnut oil processing sector.

- Utilize online tools and resources, such as social media listening tools and keyword research tools, to gather information about consumer sentiments and online search behavior related to groundnut oil.

Define Business Objectives And Goals

Defining clear objectives and goals is crucial for the success of your groundnut oil processing business. These objectives serve as a roadmap, guiding your decision-making and strategic planning. Here are the key steps to define your business objectives and goals:

- Identify your mission: Clearly articulate the purpose and mission of your business. This will provide a foundation for setting your objectives and goals.

- Set measurable goals: Make sure your objectives are specific, measurable, achievable, relevant, and time-bound (SMART). This will help you track your progress and evaluate your success.

- Align with market demand: Consider the needs and preferences of your target market when setting your objectives and goals. This will ensure that your business is aligned with market trends and customer demands.

- Focus on profitability: Prioritize financial objectives such as revenue targets, profit margins, and return on investment. This will help you monitor the financial health and sustainability of your business.

- Emphasize quality and customer satisfaction: Include objectives related to delivering high-quality products and excellent customer service. This will help build a strong reputation and customer loyalty.

- Consider growth and expansion: Set goals related to expanding your market reach, diversifying your product offerings, or entering new geographic locations. This will drive your business to continuously innovate and explore new opportunities.

Tips for defining business objectives and goals:

- Involve key stakeholders, such as employees and business partners, in the goal-setting process to gain diverse perspectives and foster a sense of ownership.

- Regularly review and update your objectives and goals to adapt to changing market conditions and business dynamics.

- Break down larger objectives into smaller, actionable steps to make them more manageable and achievable.

- Communicate your objectives and goals to your team members to ensure everyone is aligned and working towards a common vision.

- Track and measure your progress regularly using key performance indicators (KPIs) to stay on track and make necessary adjustments.

By defining clear and meaningful objectives and goals, you will have a solid foundation for your groundnut oil processing business. These objectives will guide your decision-making, drive your actions, and ultimately lead you towards success.

Determine The Initial Investment Required

Before starting your groundnut oil processing business, it is crucial to determine the initial investment required. This will help you plan your finances effectively and ensure that you have enough capital to cover your expenses.

To determine the initial investment, you need to consider various factors such as:

- The cost of acquiring or leasing a processing facility: This includes the purchase or rental cost of a suitable location for your groundnut oil processing plant.

- The cost of purchasing equipment and machinery: Invest in state-of-the-art equipment and machinery to ensure efficient and high-quality oil processing.

- The cost of raw materials: Calculate the cost of sourcing raw groundnuts from local farmers.

- The cost of packaging materials: Estimate the cost of packaging materials required to store and transport your groundnut oil.

- The cost of utilities and maintenance: Consider the expenses related to electricity, water, and maintenance of your processing facility.

- The cost of permits and licenses: Research the necessary permits and licenses required to operate your business legally.

- The cost of hiring employees: Determine the salary and benefits expenses for skilled professionals to assist in your operations.

Tips for determining the initial investment required:

- Obtain multiple quotes from suppliers and vendors to compare prices and choose the most cost-effective options.

- Consider leasing equipment instead of purchasing it outright to minimize initial investment costs.

- Account for contingencies by setting aside a portion of your initial investment for unexpected expenses.

- Research available grants, loans, or funding options that may help offset some of the initial investment costs.

By carefully determining the initial investment required, you can develop a realistic budget and financial plan for your groundnut oil processing business.

Establish the Legal Structure and Necessary Permits/Licenses

When starting a groundnut oil processing business, it is essential to establish the proper legal structure and obtain the necessary permits and licenses. This step ensures that your business operates within the legal framework and meets all regulatory requirements.

1. Choose the appropriate legal structure: Determine whether you want to operate as a sole proprietorship, partnership, limited liability company (LLC), or corporation. Consult with a legal professional or a business advisor to understand the advantages and disadvantages of each structure and choose the one that suits your business goals and risk tolerance.

2. Register your business: Once you have selected your legal structure, register your business with the appropriate government authorities. This registration process typically involves filing the necessary documents and paying the required fees. Check with your local government office or Small Business Administration for specific requirements and procedures.

3. Obtain the necessary permits and licenses: Research and identify the permits and licenses required to legally operate a groundnut oil processing business. This may include food processing permits, health and safety certifications, environmental permits, and business registrations specific to your state or municipality. Contact your local health department, agricultural agencies, and regulatory bodies to understand the specific requirements and application processes.

1. Consult with a legal professional:

- Seek advice from an experienced lawyer or legal expert specializing in business law to ensure compliance with local, state, and federal regulations.

2. Stay informed about regulatory changes:

- Keep yourself updated with any changes in laws or regulations that may impact your business's legal structure or permit requirements.

By establishing the appropriate legal structure and obtaining the necessary permits and licenses, you demonstrate your commitment to operating a compliant and legitimate groundnut oil processing business. This ensures the trust of customers, suppliers, and regulatory authorities, setting the foundation for a successful venture.

Identify And Analyze Potential Suppliers And Vendors

While starting a groundnut oil processing business, it is crucial to identify and analyze potential suppliers and vendors. Establishing reliable relationships with suppliers and vendors is essential for ensuring a steady supply of raw materials and other necessary resources.

Firstly, conduct thorough research to identify potential suppliers who can provide high-quality raw groundnuts consistently. Look for suppliers who have a good reputation and track record in the industry. Assess their production capacity, quality standards, and ability to meet your specific requirements.

Once you have shortlisted potential suppliers, it is important to analyze them further to make an informed decision. Consider factors such as:

- Their location and proximity to your processing facility: Opting for suppliers located closer to your facility can help reduce transportation costs and ensure a timely delivery of raw materials.

- Price and affordability: Compare prices from different suppliers to ensure you are getting competitive rates without compromising on quality.

- Reliability and consistency: Evaluate supplier's track records and customer reviews to determine their reliability in terms of timely deliveries and consistent quality.

- Capacity to scale: Consider the supplier's ability to meet your future demands as your business grows. Ensure they have the capacity to handle larger orders and can accommodate your expansion plans.

- Visit supplier facilities: Schedule visits to potential suppliers' facilities to evaluate their production processes and quality control measures firsthand.

- Ask for samples: Request samples from potential suppliers to assess the quality of their raw groundnuts.

- Negotiate contracts: Negotiate favorable terms and conditions, including pricing, delivery schedules, and quality assurance, with selected suppliers.

- Establish backup options: It's wise to have alternative suppliers in case your primary supplier is unable to meet your requirements.

Building a network of reliable suppliers and vendors is essential for the success of your groundnut oil processing business. Take the time to identify and analyze potential partners who can meet your quality standards, pricing expectations, and growth plans.

Develop A Comprehensive Marketing And Sales Strategy

A strong marketing and sales strategy is essential for the success of your groundnut oil processing business. It will help you effectively promote your products, attract customers, and generate sales. Here are some important steps to develop a comprehensive marketing and sales strategy:

- Identify your target market and potential customers: Conduct market research to identify the demographic, geographic, and psychographic characteristics of your target market. This will help you understand who your potential customers are and how to reach them.

- Define your unique selling proposition (USP): Determine what sets your groundnut oil apart from competitors' products. Highlight the key features, benefits, and qualities that make your product unique and attractive to customers.

- Create a brand identity: Develop a strong brand identity that reflects your business values, mission, and vision. This includes creating a memorable brand name, logo, tagline, and visual elements that resonate with your target market.

- Choose the right marketing channels: Identify the most effective marketing channels to reach your target customers. This may include online platforms such as social media, search engine optimization (SEO), email marketing, and content marketing, as well as offline channels like print advertisements, events, and partnerships.

- Implement a pricing strategy: Determine the optimal pricing strategy for your groundnut oil products. Consider factors such as production costs, competitors' prices, market demand, and perceived value to set competitive yet profitable prices.

- Develop promotional campaigns: Create compelling promotional campaigns to raise awareness and promote your groundnut oil products. Use a mix of content marketing, social media advertising, influencer marketing, and traditional advertising methods to reach your target audience.

- Offer free samples or discounts to incentivize customers to try your groundnut oil products.

- Collaborate with local food businesses and chefs to showcase your groundnut oil in recipes and dishes.

- Utilize customer reviews and testimonials to build trust and credibility in your products.

Remember, your marketing and sales strategy should be flexible and adaptable to changes in the market and customer preferences. Regularly evaluate your efforts, analyze the results, and make necessary adjustments to stay ahead of the competition and maximize your business's growth.

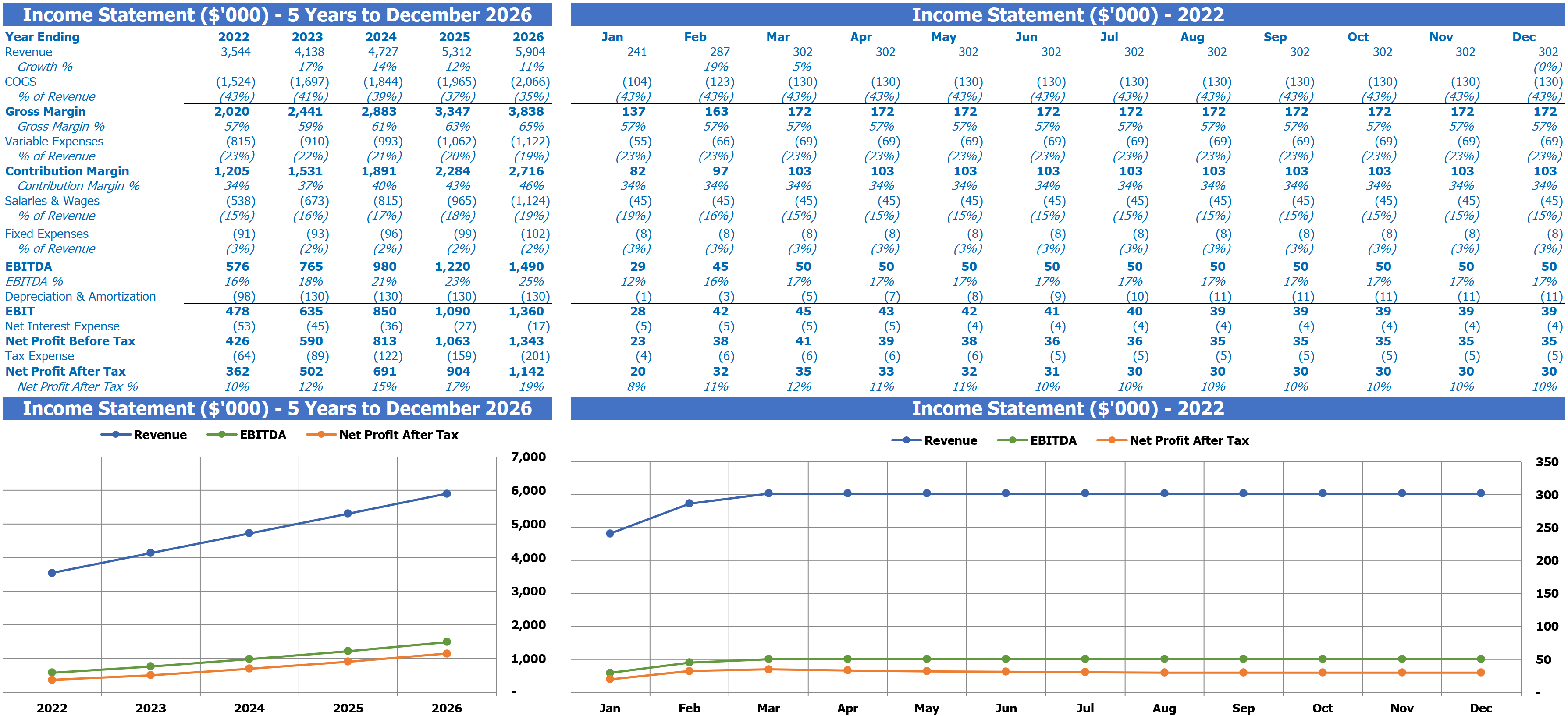

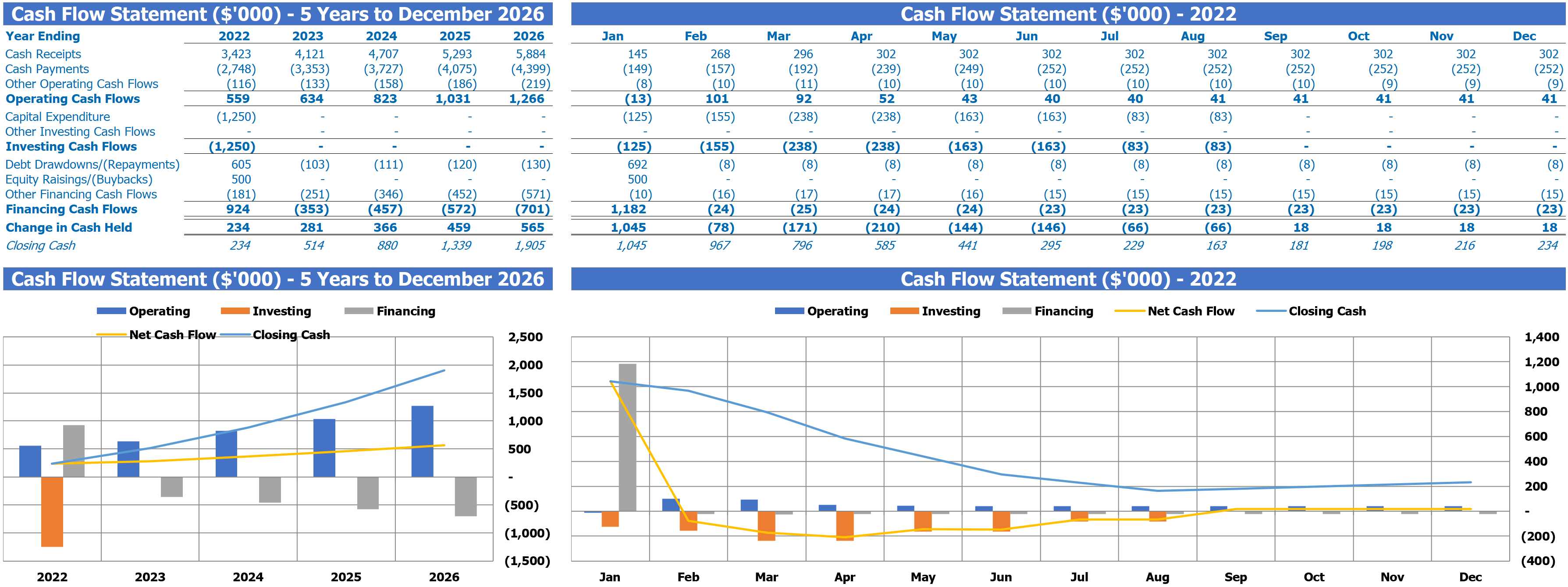

Create A Detailed Financial Forecast And Budget

Creating a detailed financial forecast and budget is crucial for the success of your groundnut oil processing business. It helps you understand the financial implications of your business decisions and ensures that you have a clear roadmap for managing your financial resources.

To create an accurate financial forecast and budget, consider the following:

- Revenue Projections: Estimate your expected sales based on market research, customer demand, and pricing strategy. Break down your revenue projections by products, customer segments, and distribution channels.

- Cost Analysis: Identify all the costs involved in your business operations, including raw materials, labor, equipment, rent, utilities, marketing, and administrative expenses. Use historical data, industry benchmarks, and quotes from potential suppliers to estimate these costs.

- Profit Margins: Determine the profit margins you aim to achieve for your groundnut oil processing business. Calculate your gross profit by subtracting the cost of goods sold from your revenue. Take into account any additional costs such as taxes, loan repayments, and insurance.

- Cash Flow Forecast: Develop a cash flow forecast to understand the timing of your inflows and outflows. This will help you identify potential cash flow gaps and plan for contingencies.

- Capital Expenditure: Estimate the initial investment required to set up your processing facility, purchase equipment, and cover other startup costs. Consider financing options, such as loans or investments, to fund your capital expenditure.

Tips for Creating a Detailed Financial Forecast and Budget:

- Use realistic assumptions: Base your projections on accurate market research and industry trends.

- Update regularly: Review and update your financial forecast and budget regularly to reflect any changes in market conditions or business circumstances.

- Consider multiple scenarios: Prepare alternative scenarios to assess the potential impact of different market conditions or business strategies on your financial performance.

- Seek professional advice: Consult with a financial expert or accountant to ensure the accuracy and reliability of your financial forecast and budget.

By creating a detailed financial forecast and budget, you can make informed decisions, track your progress, and adapt your strategies to achieve your business objectives. It also helps you demonstrate the financial viability of your groundnut oil processing business to potential investors or lenders.

Build A Team Of Skilled And Experienced Professionals

One of the key factors for the success of your groundnut oil processing business is the team you build. It is essential to have a group of skilled and experienced professionals who can contribute their expertise and knowledge to your operations. Here are some important considerations when building your team:

- Identify the necessary roles: Begin by determining the specific positions that need to be filled in your business, such as production manager, quality control specialist, sales and marketing manager, and financial officer. Each role will have distinct responsibilities and requirements.