A literature review of smart warehouse operations management

- Review Article

- Open access

- Published: 12 January 2022

- Volume 9 , pages 31–55, ( 2022 )

Cite this article

You have full access to this open access article

- Lu Zhen 1 &

- Haolin Li 1

10k Accesses

36 Citations

Explore all metrics

E-commerce, new retail, and other changes have highlighted the requirement of high efficiency and accuracy in the logistics service. As an important section in logistics and supply chain management, warehouses need to respond positively to the increasing requirement. The “smart warehouse” system, which is equipped with emerging warehousing technologies, is increasingly attracting the attention of industry and technology giants as an efficient solution for the future of warehouse development. This study provides a holistic view of operations management problems within the context of smart warehouses. We provide a framework to review smart warehouse operations management based on the characteristics of smart warehouses, including the perspectives of information interconnection, equipment automation, process integration, and environmental sustainability. A comprehensive review of relevant literature is then carried out based on the framework with four perspectives. This study could provide future research directions on smart warehouses for academia and industry practitioners.

Article PDF

Download to read the full article text

Similar content being viewed by others

Flexible automated warehouse: a literature review and an innovative framework

Smart Warehouse – Tomorrow of Supply Chain

Toward Smart Logistics: Engineering Insights and Emerging Trends

Avoid common mistakes on your manuscript.

Aldarondo F J, Bozer Y A (2020). Expected distances and alternative design configurations for automated guided vehicle-based order picking systems. International Journal of Production Research, in press, doi: https://doi.org/10.1080/00207543.2020.1856438

Amato F, Basile F, Carbone C, Chiacchio P (2005). An approach to control automated warehouse systems. Control Engineering Practice, 13(10): 1223–1241

Article Google Scholar

Ang M, Lim Y F (2019). How to optimize storage classes in a unit-load warehouse. European Journal of Operational Research, 278(1): 186–201

Article MathSciNet MATH Google Scholar

Azadeh K, de Koster R B M, Roy D (2019a). Robotized and automated warehouse systems: Review and recent developments. Transportation Science, 53(4): 917–945

Azadeh K, Roy D, de Koster R B M (2019b). Design, modeling, and analysis of vertical robotic storage and retrieval systems. Transportation Science, 53(5): 1213–1234

Bartolini M, Bottani E, Grosse E H (2019). Green warehousing: Systematic literature review and bibliometric analysis. Journal of Cleaner Production, 226: 242–258

Basso F, Epstein L D, Pezoa R, Varas M (2019). An optimization approach and a heuristic procedure to schedule battery charging processes for stackers of palletized cargo. Computers & Industrial Engineering, 133: 9–18

Ben-Daya M, Hassini E, Bahroun Z (2017). Internet of Things and supply chain management: A literature review. International Journal of Production Research, 57(15–16): 4719–1742

Google Scholar

Bottani E, Vignali G (2019). Augmented reality technology in the manufacturing industry: A review of the last decade. IISE Transactions, 51(3): 284–310

Boysen N, Briskorn D, Emde S (2017). Parts-to-picker based order processing in a rack-moving mobile robots environment. European Journal of Operational Research, 262(2): 550–562

Boysen N, de Koster R B M, Weidinger F (2019). Warehousing in the e-commerce era: A survey. European Journal of Operational Research, 277(2): 396–411

Boysen N, Stephan K (2016). A survey on single crane scheduling in automated storage/retrieval systems. European Journal of Operational Research, 254(3): 691–704

Boywitz D, Boysen N (2018). Robust storage assignment in stack- and queue-based storage systems. Computers & Operations Research, 100: 189–200

Boywitz D, Schwerdfeger S, Boysen N (2019). Sequencing of picking orders to facilitate the replenishment of A-Frame systems. IISE Transactions, 51(4): 368–381

Bozer Y A, Aldarondo F J (2018). A simulation-based comparison of two goods-to-person order picking systems in an online retail setting. International Journal of Production Research, 56(11): 3838–3858

Cainiao (2018). The new pattern of logistics in China. Available at: taobao.com/markets/cnwww/cn-news-detail?spm=a21da.144546.0.0.77103045qpjGh5&id=90

Chen H L, Xue G L, Wang Z B (2017). Efficient and reliable missing tag identification for large-scale RFID systems with unknown tags. IEEE Internet of Things Journal, 4(3): 736–748

Chen W Y, Gong Y M, de Koster R B M (2020). Performance estimation of a passing-crane automated storage and retrieval system. International Journal of Production Research, in press, doi: https://doi.org/10.1080/00207543.2020.1854886

Chen Z X, Li X P, Gupta J N D (2015). A bi-directional flow-rack automated storage and retrieval system for unit-load warehouses. International Journal of Production Research, 53(14): 4176–4188

Chen Z X, Li X P, Gupta J N D (2016). Sequencing the storages and retrievals for flow-rack automated storage and retrieval systems with duration-of-stay storage policy. International Journal of Production Research, 54(4): 984–998

Cheng Z M, Fu X, Wang J, Xu X H (2021). Research on robot charging strategy based on the scheduling algorithm of minimum encounter time. Journal of the Operational Research Society, 72(1): 237–245

China Daily (2017). How Shanghai’s Yangshan port can run without humans. Available at: english.pudong.gov.cn/2017-12/12/c_118557.htm

Choy K L, Ho G T S, Lee C K H (2017). A RFID-based storage assignment system for enhancing the efficiency of order picking. Journal of Intelligent Manufacturing, 28(1): 111–129

Custodio L, Machado R (2019). Flexible automated warehouse: A literature review and an innovative framework. International Journal of Advanced Manufacturing Technology, 106(1–2): 533–558

Dadhich P, Genovese A, Kumar N, Acquaye A (2015). Developing sustainable supply chains in the UK construction industry: A case study. International Journal of Production Economics, 164: 271–284

de Koster R B M, Le-Duc T, Roodbergen K J (2007). Design and control of warehouse order picking: A literature review. European Journal of Operational Research, 182(2): 481–501

Article MATH Google Scholar

Derhami S, Smith J S, Gue K R (2019). Space-efficient layouts for block stacking warehouses. IISE Transactions, 51(9): 957–971

Digani V, Hsieh M A, Sabattini L, Secchi C (2019). Coordination of multiple AGVs: A quadratic optimization method. Autonomous Robots, 43(3): 539–555

Digani V, Sabattini L, Secchi C, Fantuzzi C (2015). Ensemble coordination approach in multi-AGV systems applied to industrial warehouses. IEEE Transactions on Automation Science and Engineering, 12(3): 922–934

Dou J J, Chen C L, Yang P (2015). Genetic scheduling and reinforcement learning in multirobot systems for intelligent warehouses. Mathematical Problems in Engineering, 2015: 597956

Draganjac I, Miklic D, Kovacic Z, Vasiljevic G, Bogdan S (2016). Decentralized control of multi-AGV systems in autonomous warehousing applications. IEEE Transactions on Automation Science and Engineering, 13(4): 1433–1447

Durach C F, Kembro J, Wieland A (2017). A new paradigm for systematic literature reviews in supply chain management. Journal of Supply Chain Management, 53(4): 67–85

Emde S, Polten L, Gendreau M (2020). Logic-based benders decomposition for scheduling a batching machine. Computers & Operations Research, 113: 104777

Ene S, Kucukoglu I, Aksoy A, Ozturk N (2016). A genetic algorithm for minimizing energy consumption in warehouses. Energy, 114: 973–980

Epp M, Wiedemann S, Furmans K (2017). A discrete-time queueing network approach to performance evaluation of autonomous vehicle storage and retrieval systems. International Journal of Production Research, 55(4): 960–978

Fager P, Sgarbossa F, Calzavara M (2021). Cost modelling of onboard cobot-supported item sorting in a picking system. International Journal of Production Research, 59(11): 3269–3284

Fottner J, Clauer D, Hormes F, Freitag M, Beinke T, Overmeyer L, Gottwald S N, Elbert R, Sarnow T, Schmidt T, Reith K B, Zadek H, Thomas F (2021). Autonomous systems in intralogistics — state of the art and future research challenges. Logistics Research, 14(1): 2

Foumani M, Moeini A, Haythorpe M, Smith-Miles K (2018). A cross-entropy method for optimising robotic automated storage and retrieval systems. International Journal of Production Research, 56(19): 6450–6472

Fragapane G, de Koster R B M, Sgarbossa F, Strandhagen J O (2021). Planning and control of autonomous mobile robots for intralogistics: Literature review and research agenda. European Journal of Operational Research, 294(2): 405–426

Gagliardi J P, Renaud J, Ruiz A (2012). Models for automated storage and retrieval systems: A literature review. International Journal of Production Research, 50(24): 7110–7125

Gagliardi J P, Renaud J, Ruiz A (2015). Sequencing approaches for multiple-aisle automated storage and retrieval systems. International Journal of Production Research, 53(19): 5873–5883

Gareis M, Hehn M, Stief P, Korner G, Birkenhauer C, Trabert J, Mehner T, Vossiek M, Carlowitz C (2021). Novel UHF-RFID listener hardware architecture and system concept for a mobile robot based MIMO SAR RFID localization. IEEE Access, 9: 497–510

Gharehgozli A H, Xu C, Zhang W D (2021). High multiplicity asymmetric traveling salesman problem with feedback vertex set and its application to storage/retrieval system. European Journal of Operational Research, 289(2): 495–507

Gharehgozli A H, Zaerpour N (2020). Robot scheduling for pod retrieval in a robotic mobile fulfillment system. Transportation Research Part E: Logistics and Transportation Review, 142: 102087

Gharehgozli A H, Yu Y G, Zhang X D, de Koster R B M (2017). Polynomial time algorithms to minimize total travel time in a two-depot automated storage/retrieval system. Transportation Science, 51(1): 19–33

Ghelichi Z, Kilaru S (2021). Analytical models for collaborative autonomous mobile robot solutions in fulfillment centers. Applied Mathematical Modelling, 91: 438–457

Giusti I, Cepolina E M, Cangialosi E, Aquaro D, Caroti G, Piemonte A (2019). Mitigation of human error consequences in general cargo handler logistics: Impact of RFID implementation. Computers & Industrial Engineering, 137: 106038

Glock C H, Grosse E H, Abedinnia H, Emde S (2019). An integrated model to improve ergonomic and economic performance in order picking by rotating pallets. European Journal of Operational Research, 273(2): 516–534

Glock C H, Grosse E H, Neumann W P, Feldman A (2021). Assistive devices for manual materials handling in warehouses: A systematic literature review. International Journal of Production Research, 59(11): 3446–3469

Gong Y M, Jin M Z, Yuan Z (2021). Robotic mobile fulfilment systems considering customer classes. International Journal of Production Research, 59(16): 5032–5049

Grosse E H, Glock C H, Neumann W P (2017). Human factors in order picking: A content analysis of the literature. International Journal of Production Research, 55(5): 1260–1276

Gružauskas V, Baskutis S, Navickas V (2018). Minimizing the trade-off between sustainability and cost effective performance by using autonomous vehicles. Journal of Cleaner Production, 184: 709–717

Gu J X, Goetschalckx M, McGinnis L F (2007). Research on warehouse operation: A comprehensive review. European Journal of Operational Research, 177(1): 1–21

Gu J X, Goetschalckx M, McGinnis L F (2010). Research on warehouse design and performance evaluation: A comprehensive review. European Journal of Operational Research, 203(3): 539–549

Guo X L, Yu Y G, de Koster R B M (2016). Impact of required storage space on storage policy performance in a unit-load warehouse. International Journal of Production Research, 54(8): 2405–2418

Ha Y, Chae J (2019). A decision model to determine the number of shuttles in a tier-to-tier SBS/RS. International Journal of Production Research, 57(4): 963–984

Habibi Tostani H, Haleh H, Hadji Molana S M, Sobhani F M (2020). A Bi-Level Bi-Objective optimization model for the integrated storage classes and dual shuttle cranes scheduling in AS/RS with energy consumption, workload balance and time windows. Journal of Cleaner Production, 257: 120409

Hahn-Woernle P, Gunthner W A (2018). Power-load management reduces energy-dependent costs of multi-aisle mini-load automated storage and retrieval systems. International Journal of Production Research, 56(3): 1269–1285

Han S D, Yu J J (2020). DDM: Fast near-optimal multi-robot path planning using diversified-path and optimal sub-problem solution database heuristics. IEEE Robotics and Automation Letters, 5(2): 1350–1357

Hao J J, Yu Y G, Zhang L L (2015). Optimal design of a 3D compact storage system with the I/O port at the lower mid-point of the storage rack. International Journal of Production Research, 53(17): 5153–5173

Hassan M, Ali M, Aktas E, Alkayid K (2015). Factors affecting selection decision of auto-identification technology in warehouse management: An international Delphi study. Production Planning and Control, 26(12): 1025–1049

He Z J, Aggarwal V, Nof S Y (2018). Differentiated service policy in smart warehouse automation. International Journal of Production Research, 56(22): 6956–6970

Heshmati S, Toffolo T A M, Vancroonenburg W, Vanden Berghe G (2019). Crane-operated warehouses: Integrating location assignment and crane scheduling. Computers & Industrial Engineering, 129: 274–295

Jaghbeer Y, Hanson R, Johansson M I (2020). Automated order picking systems and the links between design and performance: A systematic literature review. International Journal of Production Research, 58(15): 4489–4505

Jiang M, Leung K H, Lyu Z Y, Huang G Q (2020). Picking-replenishment synchronization for robotic forward-reserve warehouses. Transportation Research Part E: Logistics and Transportation Review, 144: 102138

Jiang Z Z, Wan M Z, Pei Z, Qin X W (2021). Spatial and temporal optimization for smart warehouses with fast turnover. Computers & Operations Research, 125: 105091

Kabir Q S, Suzuki Y (2018). Increasing manufacturing flexibility through battery management of automated guided vehicles. Computers & Industrial Engineering, 117: 225–236

Keung K L, Lee C K M, Ji P, Ng K K H (2020). Cloud-based cyber-physical robotic mobile fulfillment systems: A case study of collision avoidance. IEEE Access, 8: 89318–89336

Kress D, Boysen N, Pesch E (2017). Which items should be stored together? A basic partition problem to assign storage space in group-based storage systems. IISE Transactions, 49(1): 13–30

Kumawat G L, Roy D (2021). A new solution approach for multi-stage semi-open queuing networks: An application in shuttle-based compact storage systems. Computers & Operations Research, 125: 105086

Lam H Y, Choy K L, Ho G T S, Cheng S W Y, Lee C K M (2015). A knowledge-based logistics operations planning system for mitigating risk in warehouse order fulfillment. International Journal of Production Economics, 170: 763–779

Lamballais Tessensohn T, Roy D, de Koster R B M (2017). Estimating performance in a robotic mobile fulfillment system. European Journal of Operational Research, 256(3): 976–990

Lamballais Tessensohn T, Roy D, de Koster R B M (2020). Inventory allocation in robotic mobile fulfillment systems. IISE Transactions, 52(1): 1–17

Lee C K M, Lin B B, Ng K K H, Lv Y Q, Tai W C (2019). Smart robotic mobile fulfillment system with dynamic conflict-free strategies considering cyber-physical integration. Advanced Engineering Informatics, 42: 100998

Lee C K M, Lv Y Q, Ng K K H, Ho W, Choy K L (2018). Design and application of Internet of Things-based warehouse management system for smart logistics. International Journal of Production Research, 56(8): 2753–2768

Lee C W, Wong W P, Ignatius J, Rahman A, Tseng M L (2020). Winner determination problem in multiple automated guided vehicle considering cost and flexibility. Computers & Industrial Engineering, 142: 106337

Lee H F, Schaefer S K (1996). Retrieval sequencing for unit-load automated storage and retrieval systems with multiple openings. International Journal of Production Research, 34(10): 2943–2962

Lee H Y, Murray C C (2019). Robotics in order picking: Evaluating warehouse layouts for pick, place, and transport vehicle routing systems. International Journal of Production Research, 57(18): 5821–5841

Lenoble N, Hammami R, Frein Y (2021). Fixed and rolling batching for order picking from multiple carousels. Production Planning and Control, 32(8): 652–669

Lerher T (2016). Travel time model for double-deep shuttle-based storage and retrieval systems. International Journal of Production Research, 54(9): 2519–2540

Lerher T (2018). Aisle changing shuttle carriers in autonomous vehicle storage and retrieval systems. International Journal of Production Research, 56(11): 3859–3879

Lerher T, Ficko M, Palcic I (2021). Throughput performance analysis of Automated Vehicle Storage and Retrieval Systems with multiple-tier shuttle vehicles. Applied Mathematical Modelling, 91: 1004–1022

Li X W, Hua G W, Huang A Q, Sheu J B, Cheng T C E, Huang F Q (2020). Storage assignment policy with awareness of energy consumption in the KIVA mobile fulfilment system. Transportation Research Part E: Logistics and Transportation Review, 144: 102158

Liu J M, Liao H T, White Jr J A (2021). Stochastic analysis of an automated storage and retrieval system with multiple in-the-aisle pick positions. Naval Research Logistics, 68(4): 454–470

Liu T, Gong Y M, de Koster R B M (2018). Travel time models for split-platform automated storage and retrieval systems. International Journal of Production Economics, 197: 197–214

Lu S P, Xu C, Zhong R Y, Wang L H (2018). A passive RFID tag-based locating and navigating approach for automated guided vehicle. Computers & Industrial Engineering, 125: 628–636

Mahroof K (2019). A human-centric perspective exploring the readiness towards smart warehousing: The case of a large retail distribution warehouse. International Journal of Information Management, 45: 176–190

Małopolski W (2018). A sustainable and conflict-free operation of AGVs in a square topology. Computers & Industrial Engineering, 126: 472–481

Man X Y, Zheng F F, Chu F, Liu M, Xu Y F (2021). Bi-objective optimization for a two-depot automated storage/retrieval system. Annals of Operations Research, 296(1–2): 243–262

Article MathSciNet Google Scholar

Manavalan E, Jayakrishna K (2019). A review of Internet of Things (IoT) embedded sustainable supply chain for Industry 4.0 requirements. Computers & Industrial Engineering, 127: 925–953

Manzini R, Accorsi R, Baruffaldi G, Cennerazzo T, Gamberi M (2016). Travel time models for deep-lane unit-load autonomous vehicle storage and retrieval system (AVS/RS). International Journal of Production Research, 54(14): 4286–4304

Manzini R, Accorsi R, Gamberi M, Penazzi S (2015). Modeling class-based storage assignment over life cycle picking patterns. International Journal of Production Economics, 170: 790–800

McFarlane D, Giannikas V, Lu W R (2016). Intelligent logistics: Involving the customer. Computers in Industry, 81: 105–115

Meneghetti A, Monti L (2015). Greening the food supply chain: An optimisation model for sustainable design of refrigerated automated warehouses. International Journal of Production Research, 53(21): 6567–6587

Mirzaei M, de Koster R B M, Zaerpour N (2017). Modelling load retrievals in puzzle-based storage systems. International Journal of Production Research, 55(21): 6423–6435

Mo L F, Li C Y (2019). Passive UHF-RFID localization based on the similarity measurement of virtual reference tags. IEEE Transactions on Instrumentation and Measurement, 68(8): 2926–2933

Nicolas L, Yannick F, Ramzi H (2018). Order batching in an automated warehouse with several vertical lift modules: Optimization and experiments with real data. European Journal of Operational Research, 267(3): 958–976

Pan C H, Wang C H (1996). A framework for the dual command cycle travel time model in automated warehousing systems. International Journal of Production Research, 34(8): 2099–2117

Pan J C H, Shih P H, Wu M H, Lin J H (2015). A storage assignment heuristic method based on genetic algorithm for a pick-and-pass warehousing system. Computers & Industrial Engineering, 81: 1–13

Qiu X, Luo H, Xu G Y, Zhong R Y, Huang G Q (2015). Physical assets and service sharing for IoT-enabled Supply Hub in Industrial Park (SHIP). International Journal of Production Economics, 159: 4–15

Ramtin F, Pazour J A (2015). Product allocation problem for an AS/RS with multiple in-the-aisle pick positions. IIE Transactions, 47(12): 1379–1396

Reaidy P J, Gunasekaran A, Spalanzani A (2015). Bottom-up approach based on Internet of Things for order fulfillment in a collaborative warehousing environment. International Journal of Production Economics, 159: 29–40

Roodbergen K J, Vis I F A (2009). A survey of literature on automated storage and retrieval systems. European Journal of Operational Research, 194(2): 343–362

Roozbeh Nia A R, Haleh H, Saghaei A (2017). Dual command cycle dynamic sequencing method to consider GHG efficiency in unit-load multiple-rack automated storage and retrieval systems. Computers & Industrial Engineering, 111: 89–108

Rouwenhorst B, Reuter B, Stockrahm V, van Houtum G J, Mantel R J, Zijm W H M (2000). Warehouse design and control: Framework and literature review. European Journal of Operational Research, 122(3): 515–533

Roy D, Krishnamurthy A, Heragu S, Malmborg C (2015a). Queuing models to analyze dwell-point and cross-aisle location in autonomous vehicle-based warehouse systems. European Journal of Operational Research, 242(1): 72–87

Roy D, Krishnamurthy A, Heragu S, Malmborg C (2015b). Stochastic models for unit-load operations in warehouse systems with autonomous vehicles. Annals of Operations Research, 231(1): 129–155

Roy D, Nigam S, de Koster R B M, Adan I, Resing J (2019). Robot-storage zone assignment strategies in mobile fulfillment systems. Transportation Research Part E: Logistics and Transportation Review, 122: 119–142

Saidi-Mehrabad M, Dehnavi-Arani S, Evazabadian F, Mahmoodian V (2015). An Ant Colony Algorithm (ACA) for solving the new integrated model of job shop scheduling and conflict-free routing of AGVs. Computers & Industrial Engineering, 86: 2–13

Salah B, Janeh O, Noche B, Bruckmann T, Darmoul S (2017). Design and simulation based validation of the control architecture of a stacker crane based on an innovative wire-driven robot. Robotics and Computer-integrated Manufacturing, 44: 117–128

Sartoretti G, Kerr J, Shi Y F, Wagner G, Kumar T K S, Koenig S, Choset H (2019). PRIMAL: Pathfinding via reinforcement and imitation multi-agent learning. IEEE Robotics and Automation Letters, 4(3): 2378–2385

Shahzad M, Liu A X (2015). Fast and accurate estimation of RFID tags. IEEE/ACM Transactions on Networking, 23(1): 241–254

Shi Y Y, Arthanari T, Liu X J, Yang B (2019). Sustainable transportation management: Integrated modeling and support. Journal of Cleaner Production, 212: 1381–1395

State Post Bureau of PRC (2020). China’s annual express delivery volume exceeded 70 billion items for the first time. Available at: spb.gov.cn/xw/dtxx_15079/202011/t20201117_3513569.html

Tao F, Zuo Y, Xu L D, Lv L, Zhang L (2014). Internet of Things and BOM-based life cycle assessment of energy-saving and emission-reduction of products. IEEE Transactions on Industrial Informatics, 10(2): 1252–1261

Tappia E, Marchet G, Melacini M, Perotti S (2015). Incorporating the environmental dimension in the assessment of automated warehouses. Production Planning and Control, 26(10): 824–838

Tappia E, Roy D, de Koster R B M, Melacini M (2017). Modeling, analysis, and design insights for shuttle-based compact storage systems. Transportation Science, 51(1): 269–295

Tappia E, Roy D, Melacini M, de Koster R B M (2019). Integrated storage-order picking systems: Technology, performance models, and design insights. European Journal of Operational Research, 274(3): 947–965

Technical.ly (2019). Amazon fulfillment center brings robotics to Sparrows Point. Available at: technical.ly/baltimore/2019/03/22/amazon-fulfillment-center-brings-robotics-to-sparrows-point-artificial-intelligence

Thanos E, Wauters T, Vanden Berghe G (2021). Dispatch and conflict-free routing of capacitated vehicles with storage stack allocation. Journal of the Operational Research Society, 72(8): 1780–1793

Tutam M, White J A (2019a). Multi-dock unit-load warehouse designs with a cross-aisle. Transportation Research Part E: Logistics and Transportation Review, 129: 247–262

Tutam M, White J A (2019b). A multi-dock, unit-load warehouse design. IISE Transactions, 51(3): 232–247

van Gils T, Ramaekers K, Braekers K, Depaire B, Caris A (2018a). Increasing order picking efficiency by integrating storage, batching, zone picking, and routing policy decisions. International Journal of Production Economics, 197: 243–261

van Gils T, Ramaekers K, Caris A, de Koster R B M (2018b). Designing efficient order picking systems by combining planning problems: State-of-the-art classification and review. European Journal of Operational Research, 267(1): 1–15

Wang K, Yang Y, Li R (2020a). Travel time models for the rack-moving mobile robot system. International Journal of Production Research, 58(14): 4367–4385

Wang W, Wu Y H, Zheng J, Chi C (2020b). A comprehensive framework for the design of modular robotic mobile fulfillment systems. IEEE Access, 8: 13259–13269

Wang Y Y, Liu Z W, Huang K, Mou S D, Zhang R X (2020c). Model and solution approaches for retrieval operations in a multi-tier shuttle warehouse system. Computers & Industrial Engineering, 141: 106283

Wang Y Y, Mou S D, Wu Y H (2015). Task scheduling for multi-tier shuttle warehousing systems. International Journal of Production Research, 53(19): 5884–5895

Wauters T, Villa F, Christiaens J, Alvarez-Valdes R, Vanden Berghe G (2016). A decomposition approach to dual shuttle automated storage and retrieval systems. Computers & Industrial Engineering, 101: 325–337

Weidinger F, Boysen N, Briskorn D (2018). Storage assignment with rack-moving mobile robots in KIVA warehouses. Transportation Science, 52(6): 1479–1495

Wen J M, He L, Zhu F M (2018). Swarm robotics control and communications: Imminent challenges for next generation smart logistics. IEEE Communications Magazine, 56(7): 102–107

Winkelhaus S, Grosse E H (2020). Logistics 4.0: A systematic review towards a new logistics system. International Journal of Production Research, 58(1): 18–43

Xie L, Thieme N, Krenzler R, Li H Y (2021). Introducing split orders and optimizing operational policies in robotic mobile fulfillment systems. European Journal of Operational Research, 288(1): 80–97

Xu X, Zhao X, Zou B, Gong Y, Wang H (2020). Travel time models for a three-dimensional compact AS/RS considering different I/O point policies. International Journal of Production Research, 58(18): 5432–5455

Xu X H, Gong Y M, Fan X X, Shen G W, Zou B P (2018). Travel-time model of dual-command cycles in a 3D compact AS/RS with lower mid-point I/O dwell point policy. International Journal of Production Research, 56(4): 1620–1641

Xu X H, Shen G W, Yu Y G, Huang W (2015). Travel time analysis for the double-deep dual-shuttle AS/RS. International Journal of Production Research, 53:3

Xu X H, Zou B P, Shen G W, Gong Y M (2016). Travel-time models and fill-grade factor analysis for double-deep multi-aisle AS/RSs. International Journal of Production Research, 54(14): 4126–4144

Yalcin A, Koberstein A, Schocke K O (2019). An optimal and a heuristic algorithm for the single-item retrieval problem in puzzle-based storage systems with multiple escorts. International Journal of Production Research, 57(1): 143–165

Yang H, Kumara S, Bukkapatnam S T S, Tsung F (2019). The Internet of Things for smart manufacturing: A review. IISE Transactions, 51(11): 1190–1216

Yang P, Miao L X, Xue Z J, Qin L (2015a). An integrated optimization of location assignment and storage/retrieval scheduling in multishuttle automated storage/retrieval systems. Journal of Intelligent Manufacturing, 26(6): 1145–1159

Yang P, Miao L X, Xue Z J, Qin L (2015b). Optimal storage rack design for a multi-deep compact AS/RS considering the acceleration/deceleration of the storage and retrieval machine. International Journal of Production Research, 53(3): 929–943

Yang P, Miao L X, Xue Z J, Ye B (2015c). Variable neighborhood search heuristic for storage location assignment and storage/retrieval scheduling under shared storage in multi-shuttle automated storage/retrieval systems. Transportation Research Part E: Logistics and Transportation Review, 79: 164–177

Yetkin Ekren B (2017). Graph-based solution for performance evaluation of shuttle-based storage and retrieval system. International Journal of Production Research, 55(21): 6516–6526

Yetkin Ekren B (2021). A multi-objective optimisation study for the design of an AVS/RS warehouse. International Journal of Production Research, 59(4): 1107–1126

Yetkin Ekren B, Akpunar A (2021). An open queuing network-based tool for performance estimations in a shuttle-based storage and retrieval system. Applied Mathematical Modelling, 89: 1678–1695

Yetkin Ekren B, Akpunar A, Sari Z, Lerher T (2018). A tool for time, variance and energy related performance estimations in a shuttle-based storage and retrieval system. Applied Mathematical Modelling, 63: 109–127

Yoshitake H, Kamoshida R, Nagashima Y (2019). New automated guided vehicle system using real-time holonic scheduling for warehouse picking. IEEE Robotics and Automation Letters, 4(2): 1045–1052

Yu H, Yu Y (2019). Optimising two dwell point policies for AS/RSs with input and output point at opposite ends of the aisle. International Journal of Production Research, 57(21): 6615–6633

Yu M F, de Koster R B M (2009). The impact of order batching and picking area zoning on order picking system performance. European Journal of Operational Research, 198(2): 480–490

Yu Y, de Koster R B M, Guo X (2015). Class-based storage with a finite number of items: Using more classes is not always better. Production and Operations Management, 24(8): 1235–1247

Yu Y G, Han X Y, Hu G P (2016). Optimal production for manufacturers considering consumer environmental awareness and green subsidies. International Journal of Production Economics, 182: 397–408

Yuan R, Graves S C, Cezik T (2019). Velocity-based storage assignment in semi-automated storage systems. Production and Operations Management, 28(2): 354–373

Yuan Z, Gong Y M (2017). Bot-in-time delivery for robotic mobile fulfillment systems. IEEE Transactions on Engineering Management, 64(1): 83–93

Zaerpour N, Yu Y G, de Koster R B M (2017a). Small is beautiful: A framework for evaluating and optimizing live-cube compact storage systems. Transportation Science, 51(1): 34–51

Zaerpour N, Yu Y G, de Koster R B M (2015). Storing fresh produce for fast retrieval in an automated compact cross-dock system. Production and Operations Management, 24(8): 1266–1284

Zaerpour N, Yu Y G, de Koster R B M (2017b). Optimal two-class-based storage in a live-cube compact storage system. IISE Transactions, 49(7): 653–668

Zaerpour N, Yu Y G, de Koster R B M (2017c). Response time analysis of a live-cube compact storage system with two storage classes. IISE Transactions, 49(5): 461–480

Zhang F, Shang W W, Zhang B, Cong S (2020). Design optimization of redundantly actuated cable-driven parallel robots for automated warehouse system. IEEE Access, 8: 56867–56879

Zhang Z, Guo Q, Chen J, Yuan P J (2018). Collision-free route planning for multiple AGVS in an automated warehouse based on collision classification. IEEE Access, 6: 26022–26035

Zhao X F, Zhang R X, Zhang N, Wang Y Y, Jin M Z, Mou S D (2020a). Analysis of the shuttle-based storage and retrieval system. IEEE Access, 8: 146154–146165

Zhao Y L, Liu X P, Wang G, Wu S B, Han S (2020b). Dynamic resource reservation based collision and deadlock prevention for multi-AGVs. IEEE Access, 8: 82120–82130

Zhong R Y, Huang G Q, Lan S L, Dai Q Y, Chen X, Zhang T (2015). A big data approach for logistics trajectory discovery from RFID-enabled production data. International Journal of Production Economics, 165: 260–272

Zhou W, Piramuthu S, Chu F, Chu C B (2017). RFID-enabled flexible warehousing. Decision Support Systems, 98: 99–112

Zou B P, de Koster R B M, Xu X H (2018a). Operating policies in robotic compact storage and retrieval systems. Transportation Science, 52(4): 788–811

Zou B P, Gong Y M, Xu X H, Yuan Z (2017). Assignment rules in robotic mobile fulfilment systems for online retailers. International Journal of Production Research, 55(20): 6175–6192

Zou B P, Xu X H, Gong Y M, de Koster R B M (2018b). Evaluating battery charging and swapping strategies in a robotic mobile fulfillment system. European Journal of Operational Research, 267(2): 733–753

Download references

Author information

Authors and affiliations.

School of Management, Shanghai University, Shanghai, 200444, China

Lu Zhen & Haolin Li

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Lu Zhen .

Additional information

This research is supported by the National Natural Science Foundation of China (Grant Nos. 72025103 and 71831008).

Rights and permissions

This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Zhen, L., Li, H. A literature review of smart warehouse operations management. Front. Eng. Manag. 9 , 31–55 (2022). https://doi.org/10.1007/s42524-021-0178-9

Download citation

Received : 19 February 2021

Accepted : 07 June 2021

Published : 12 January 2022

Issue Date : March 2022

DOI : https://doi.org/10.1007/s42524-021-0178-9

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- smart warehouse

- operations management

- interconnection

- integration

- sustainability

- Find a journal

- Publish with us

- Track your research

warehouse operations Recently Published Documents

Total documents.

- Latest Documents

- Most Cited Documents

- Contributed Authors

- Related Sources

- Related Keywords

A literature review of smart warehouse operations management

AbstractE-commerce, new retail, and other changes have highlighted the requirement of high efficiency and accuracy in the logistics service. As an important section in logistics and supply chain management, warehouses need to respond positively to the increasing requirement. The “smart warehouse” system, which is equipped with emerging warehousing technologies, is increasingly attracting the attention of industry and technology giants as an efficient solution for the future of warehouse development. This study provides a holistic view of operations management problems within the context of smart warehouses. We provide a framework to review smart warehouse operations management based on the characteristics of smart warehouses, including the perspectives of information interconnection, equipment automation, process integration, and environmental sustainability. A comprehensive review of relevant literature is then carried out based on the framework with four perspectives. This study could provide future research directions on smart warehouses for academia and industry practitioners.

Towards an increased understanding of learning: a case study of a collaborative relationship between a retailer and a logistics service provider

PurposeThis study aims to explain how learning occurs in collaborative retailer–logistics service provider (LSP) relationships. The research is guided by two research questions, addressing absorptive and desorptive capacities and the interaction between these capacities.Design/methodology/approachThe study is based on a case study of a Swedish, collaborative retailer–LSP dyad. The empirical data are structured around five specific learning situations within the retailer–LSP dyad.FindingsThe findings provide an explanation for how learning occurs within a collaborative retailer–LSP relationship based on subprocesses of absorptive and desorptive capacities. The interaction between these processes is found to rely on two types of support: one-directional and bidirectional. The findings also indicate positive outcomes of learning, such as improved cost efficiencies in warehouse operations, better customer services and improved long-term strategic planning.Practical implicationsThis study shows how retailers and LSPs can learn from each other and together create an improved logistics system for end customers.Originality/valueThis research takes into account absorptive and desorptive capacities in a collaborative retailer–LSP relationship. This study enhances the understanding of inter-organisational learning processes in a retail logistics context.

WAREHOUSE OPERATIONS OF PASSENGER SERVICE CAR DEPOT WITH LOGISTICS ELEMENTS

The article discusses the issues of rational organization of the warehouse process of storing inventory, the sequential implementation of warehouse operations, the improvement of labor organization and technological solutions, the effective use of various equipment involved in the performance of technological operations at the warehouse of the carriage depot of the Joint Stock Company «Uzpasstrans». The issues of creating a database for storing goods, an effective system for organizing their account are considered. The ER-diagram of the database of warehouse inventory of spare parts and components has been developed. The functions and procedures for working with database data on components and spare parts located in the warehouse of the carriage depot have been determined.

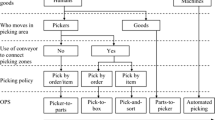

A Survey of the Literature on Order-Picking Systems by Combining Planning Problems

Companies have been trying continuously to reduce their logistics costs in the current competitive markets. Warehouses are important components of the logistics systems and they must be managed effectively and efficiently to reduce the production cost as well as maintain customer satisfaction. Order-picking is the core of warehouse operations and an order-picking system (OPS) is essential to meet customer needs and orders. Failure to perform the OPS process properly results in high costs and customer dissatisfaction. This research aims to investigate the state of the art in the adoption of OPS and provide a broad systemic analysis on main operating strategies such as simultaneous consideration of order assignment, batching, sequencing, tardiness, and routing need. This study reviews 92 articles, classifies combinations of tactical and operational OPS problems, and provides guidelines on how warehouse managers can benefit from combining planning problems, in order to design efficient OPS and improve customer service. Combining multiple order-picking planning problems results in substantial efficiency benefits, which are required to face new market developments.

Determination of Performance Indicators for Warehouse Evaluation: A Case of Medium Sized Warehouses in Nakuru Town

Evaluation of warehouse processes is required for decision making purposes and the improvement of warehouse operations. To evaluate warehouse processes, it is essential to identify key indicators in the warehouse operations. This research was intended to identify the significant indicators of warehouse performance that would support management decision making on the improvement of warehouse operations. In this research 20 indicators were identified in four warehouse activities based on Frazelle model. The most important indicators in each warehouse were then determined. The study was conducted through a descriptive design using a survey of 3 medium warehouses in Nakuru. The study employed purposive sampling to select the sample and sample elements. The sample size of 10 warehouse management officers were used in the study. Structured questionnaire was adopted as data collection instrument. The research findings indicated that most important performance indicators for receiving is productivity, for storage is space utilization, for order picking is cycle time and for shipping is productivity. Process improvement steps were proposed based on benchmarking among warehouses handling similar goods. It was noted that different types of warehouses require different indicators. The study concluded that measurement of warehouse processes is important and enables operations improvements and cost reduction. Keywords: Warehouse procedures, warehouse performance, warehouse improvement, medium sized warehouses, Nakuru town, Kenya

Risk Assessment for the Use of Drones in Warehouse Operations in the First Phase of Introducing the Service to the Market

Services, unlike products, are intangible, and their production and consumption take place simultaneously. The latter feature plays a crucial role in mitigating the identified risk. This article presents the new approach to risk assessment, which considers the first phase of introducing the service to the market and the specificity of UAV systems in warehouse operations. The fuzzy logic concept was used in the risk analysis model. The described risk assessment method was developed based on a literature review, historical data of a service company, observations of development team members, and the knowledge and experience of experts’ teams. Thanks to this, the proposed approach considers the current knowledge in studies and practical experiences related to the implementation of drones in warehouse operations. The proposed methodology was verified on the example of the selected service for drones in the magazine inventory. The conducted risk analysis allowed us to identify ten scenarios of adverse events registered in the drone service in warehouse operations. Thanks to the proposed classification of events, priorities were assigned to activities requiring risk mitigation. The proposed method is universal. It can be implemented to analyze logistics services and support the decision-making process in the first service life phase.

Design and application of data analytics in an internet-of-things enabled warehouse

Purpose While several warehouses are now technologically equipped and smart, the implementation of real-time analytics in warehouse operations is scarcely reported in the literature. This study aims to develop a practical system for real-time analytics of process monitoring in an internet-of-things (IoT)-enabled smart warehouse environment. Design/methodology/approach A modified system development research process was used to carry out this research. A prototype system was developed that mimicked a case company’s actual warehouse operations in Indonesia’s manufacturing companies. The proposed system relied heavily on the utilization of IoT technologies, wireless internet connection and web services to keep track of the product movement to provide real-time access to critical warehousing activities, helping make better, faster and more informed decisions. Findings The proposed system in the presented case company increased real-time warehousing processes visibility for stakeholders at different management levels in their most convenient ways by developing visual representation to display crucial information. The numerical or textual data were converted into graphics for ease of understanding for stakeholders, including field operators. The key elements for the feasible implementation of the proposed model in an industrial area were discussed. They are strategic-level components, IoT-enabled warehouse environments, customized middleware settings, real-time processing software and visual dashboard configuration. Research limitations/implications While this study shows a prototype-based implementation of actual warehouse operations in one of Indonesia’s manufacturing companies, the architectural requirements are applicable and extensible by other companies. In this sense, the research offers significant economic advantages by using customized middleware to avoid unnecessary waste brought by the off-the-shelves generic middleware, which is not entirely suitable for system development. Originality/value This research’s finding contributes to filling the gap in the limited body of knowledge of real-time analytics implementation in warehousing operations. This should encourage other researchers to enhance and develop the devised elements to enrich smart warehousing’s theoretical knowledge. Besides, the successful proof-of-concept implementation reported in this research would allow other companies to gain valuable insights and experiences.

An Overview of Warehouse Operations for Cold Chain

An analytical design & optimization approach to enhance warehouse operations, genetic algorithm solution for transfer robot operation.

The proposed article presents the research of decision-making processes for control system of transport robot, acting inside warehouse. The analysis shows the growing importance of warehouse systems for flexible integrated system. Such warehouse operations, like loading/uploading pallets and sending goods to distribution center can be fully automated by applying robots and some examples are known. Simultaneously, the wide introduction of transport robots with extended possibilities is still limited. Application of intelligent robot can significantly improve properties of warehouse systems, making them closer to Industry 4.0 standards. The functioning of a transport robot can be described as a Travelling Salesmen Problem with numerous solutions that must be effectively limited. Genetic algorithms are proposed as a basis for path generation. The algorithms and software are implemented to model warehouse transfer robots using an Arduino-robot. The results of testing show the effectiveness of the developed algorithms, software and hardware system.

Export Citation Format

Share document.

Logistics 4.0 in warehousing: a conceptual framework of influencing factors, benefits and barriers

The International Journal of Logistics Management

ISSN : 0957-4093

Article publication date: 7 October 2022

Issue publication date: 19 December 2022

In the last decade, the Industry 4.0 paradigm had started to rapidly expand to the logistics domain. However, Logistics 4.0 is still in an early adoption stage: some areas such as warehousing are still exploring its applicability, and the technological implementation of this paradigm can become fuzzy. This paper addresses this gap by examining the relationship among influencing factors, barriers, and benefits of Logistics 4.0 technologies in warehousing contexts.

Design/methodology/approach

Starting from a Systematic Literature Review (SLR) approach with 56 examined documents published in scientific journals or conference proceedings, a conceptual framework for Logistics 4.0 in warehousing is proposed. The framework encompasses multiple aspects related to the potential adopter’s decision-making process.

Influencing factors toward adoption, achievable benefits, and possible hurdles or criticalities have been extensively analyzed and structured into a consistent picture. Company’s digital awareness and readiness result in a major influencing factor, whereas barriers and criticalities are mostly technological, safety and security, and economic in nature. Warehousing process optimization is the key benefit identified.

Originality/value

This paper addresses a major gap since most of the research has focused on specific facets, or adopted the technology providers’ perspective, whereas little has been explored in warehousing from the adopters’ view. The main novelty and value lie in providing both academics and practitioners with a thorough view of multiple facets to be considered when approaching Logistics 4.0 in logistics facilities.

- Logistics 4.0

- Warehousing

- Technology adopters

Perotti, S. , Bastidas Santacruz, R.F. , Bremer, P. and Beer, J.E. (2022), "Logistics 4.0 in warehousing: a conceptual framework of influencing factors, benefits and barriers", The International Journal of Logistics Management , Vol. 33 No. 5, pp. 193-220. https://doi.org/10.1108/IJLM-02-2022-0068

Emerald Publishing Limited

Copyright © 2022, Sara Perotti, Roman Felipe Bastidas Santacruz, Peik Bremer and Jakob Emanuel Beer

Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and no commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

Introduction

Logistics is an ever-growing business that has gained increasing importance at a global level. Logistics market size was €5.6 trillion in 2018 and is projected to have a 4.6% compound annual growth rate (CAGR) until 2023 ( Transport Intelligence, 2019 ). In Europe, logistics market size was €0.9 trillion in 2019 with a 2.4% CAGR forecasted for the 2018–2023 timespan ( Transport Intelligence, 2019 ) and about 10.3 million citizens employed in 2018, thus making this industry highly relevant for the global economy ( Eurostat, 2018 ). Within the logistics market, in-house warehousing and Third-Party Logistics (3PL) represent key activities with 30% of the total market value, and 38% in Europe ( Transport Intelligence, 2019 ). Among logistics processes, warehousing is one of the most critical cost components ( Rodrigue, 2020 ; Perotti et al. , 2022 ), accounting for about 20% of logistics costs ( Dhooma and Baker, 2012 ). Logistics facilities have been challenged by a substantial evolution over time ( Baglio et al. , 2019 ), as they have transformed from simple repositories for inventory into multi-functional logistics hubs ( Baker, 2004 ; Onstein et al. , 2019 ). This brought along challenges with higher requirements in terms of efficiency and service level fulfillment ( Kembro et al. , 2018 ).

In the past decade, also the manufacturing sector has started experiencing substantial changes, driven by factors such as sustainability concerns ( Ghobakhloo, 2020 ). These changes have taken the manufacturing industry to experience a new transformation, for which Kagermann et al. (2011) have coined the term “Industry 4.0”, claiming to describe the fourth industrial revolution. In Industry 4.0, centralized control systems give way to decentralized decision-making. The aim of improving performances, and in some cases, the increase in complexity of business environments and more demanding requirements, are reshaping logistics and warehousing processes ( Dev et al. , 2021 ). To cope with this scenario, digitalization and the transition toward the Logistics 4.0 paradigm have become powerful means to compete in the market and help companies address the fragile trade-off between improved service levels and reasonable operating costs. Based on embedded sensors integrated with other technologies, objects such as machines, products, or orders, autonomously control themselves and are fully vertically integrated into the company’s information systems ( Kagermann et al. , 2011 ).

Since the term was coined in 2011, Industry 4.0 has become a dominant topic ( Phuyal et al. , 2020 ; Tang and Veelenturf, 2019 ). This is reflected by the growing number of publications, including an increasing number of logistics-related contributions since 2015 ( Grzybowska and Awasthi, 2020 ). In this context, the exploration of Industry 4.0 technologies such as Autonomous Mobile Robots ( Fragapane et al. , 2021 ), Machine Learning, Artificial Intelligence (AI), and the Internet of Things (IoT) has also increased ( Culot et al. , 2020 ; Phuyal et al. , 2020 ; Salamone et al. , 2018 ). These technologies modify how the manufacturing industry operates, leading to a higher complexity of the manufacturing processes ( Culot et al. , 2020 ). In this context, some papers center their attention on the investigation of drivers and barriers to Industry 4.0 technologies adoption by considering different industrial perspectives. For instance, Tortorella et al. (2021) and Frederico et al. (2021) investigate the effect of Industry 4.0 technologies on supply chain resilience, showing a positive relationship between disruptive technology adoption and supply chain performance. Chauhan et al. (2021) focusing on companies in an emerging economy, propose to further explore this topic by investigating barriers as well as effects on companies’ performance. Also, Raj et al. (2020) study the barriers to Industry 4.0 adoption, considering both developed and developing countries. They suggest analyzing enabling factors for Industry 4.0. Lastly, Horváth and Szabó (2019) explore the barriers and driving forces of Industry 4.0 adoption from a general industry perspective while Stentoft et al. (2020) investigate the same topic from an SME perspective.

Logistics, directly affecting company’s productivity and service level as well as customer satisfaction, must also be able to adapt to the characteristics of the new Industry 4.0 manufacturing environment. Hence, it is questionable whether the current logistics systems and structures will be able to handle the increased complexity generated by Industry 4.0, more specifically without increasing costs or decreasing quality ( Wang et al. , 2020 ; Winkelhaus and Grosse, 2020 ). Companies need to align their logistics performance and development with the new requirements to support the vital link between manufacturers and customers that depends on logistics and warehousing operations ( Winkelhaus and Grosse, 2020 ), resulting in the concept of “Logistics 4.0”. Logistics 4.0 is still a fuzzy term ( Bag et al. , 2020 ), and it is unclear which concepts it comprises ( Oleśków-Szłapka and Stachowiak, 2019 ). For instance, a recent definition of Logistics 4.0 by Winkelhaus and Grosse (2020) , refers to “the logistical system that enables the sustainable satisfaction of individualized customer demands without an increase in costs and supports this development in industry and trade using digital technologies”. Such definition, on the one hand, relates Logistics 4.0 to specific market factors (sustainability, individualized demand), while on the other hand is vague in the “digital technologies” required to implement them.

Warehouses play a key role in the Logistics 4.0 transition ( Valchkov and Valchkova, 2018 ). Kumar et al. (2021) highlight relevant gaps related to Logistics 4.0 in warehouses and, more specifically, the need for frameworks to identify and address the challenges of its technological adoption. Indeed, most of the extant research mainly addresses two streams: either general benefits related to Logistics 4.0 adoption or the description of innovative technologies and solutions.

The first stream analyses possible benefits related to Logistics 4.0 in the warehousing context ( Domański, 2019 ; Douaioui et al. , 2018 ; Issaoui et al. , 2021 ) and how operations could profit from Logistics 4.0 ( Feng and Ye, 2021 ). For instance, Loureiro et al. (2020) concentrate on how Logistics 4.0 solutions help improve transaction costs and business coordination. Other researchers focus on the implications of Industry 4.0 for the logistics sector, emphasizing concepts such as digitalization and automation ( Bag et al. , 2020 ; Barreto et al. , 2017 ; Schmidtke et al. , 2018 ). Finally, Winkelhaus and Grosse (2020) investigate the possible benefits and challenges of Logistics 4.0 and provide a framework combining external triggers, underlying technological innovations, and impacts on human interactions and logistic tasks. Looking at the second stream, Cano et al. (2021) identify technologies framed into the Industry 4.0 concept that can be implemented also in logistics. Golpîra et al. (2021) investigate the areas of application, current development stage, and gaps of IoT in Logistics 4.0 transformation. Other authors discuss IoT applications in logistics from the perspectives of both, advantages and challenges that limit their adoption ( Ding et al. , 2021 ; Song et al. , 2021 ; Tran-Dang et al. , 2020 ). Chung (2021) focuses on the applications which various Industry 4.0 technologies could have in logistics processes. Intralogistics is explored by Fottner et al. (2021) who investigate the level of automation in intralogistics and the technologies that can enable it. Winkelhaus et al. (2021) analyze the socio-technological effects of Industry 4.0 on order picking systems.

Although the academic literature has started exploring how companies are approaching Logistics 4.0 adoption, a comprehensive conceptual framework addressing the adoption process of Logistics 4.0 in warehousing is missing. The aim of this paper is to offer a comprehensive conceptualization of Logistics 4.0 adoption in warehousing by embracing the adopters’ perspective and addressing the main influencing factors, achievable benefits as well as potential criticalities and barriers. This paper intends to address this research gap with a Systematic Literature Review (SLR) approach to provide robustness to the proposed conceptual framework. SLRs have been proved valuable as the initial step of defining a framework ( Oleśków-Szłapka and Stachowiak, 2019 ; Winkelhaus and Grosse, 2020 ; Zoubek and Simon, 2021 ). Starting from the available literature on this topic, we categorize the relevant elements into a conceptual framework that can be used as a guideline by academics and practitioners.

The novelty and value of this paper lie in providing both academics and practitioners with a thorough view of the different facets to be considered when approaching the adoption of Logistics 4.0 solutions in logistics facilities. Specifically, influencing factors towards adoption, achievable benefits, and possible hurdles or criticalities will be extensively analyzed and structured into a consistent picture.

The remainder of the paper is structured as follows. The next section motivates and describes the SLR methodology adopted to ground the conceptual framework. Then, we present and discuss the results of our analysis. Finally, we draw conclusions and suggest future research directions.

Methodology

Systematic literature review (slr) approach.

As Logistics 4.0 in warehousing is a cutting-edge topic, an SLR approach is ideal to gather the most relevant information ( Tranfield et al. , 2003 ). The final goal of the SLR is to perform a critical analysis of research papers on Logistics 4.0 in warehousing to better comprehend the existing trends and research gaps ( Carter and Rogers, 2008 ). Hence, the five-step methodology suggested by Denyer and Tranfield (2009) was adopted and hereinafter described.

Question formulation

1 Context: The specification of individuals, relationships, institutional settings, or wider systems that are studied. Higher service levels requested by the market and the increasing logistics complexity require companies to develop new solutions for their logistics activities and, more specifically, for their warehouses.

2 Intervention: The events, actions, and activities that are studied. In this paper, the intervention is the application of Logistics 4.0 technologies.

3 Mechanisms: The mechanisms that explain the relationship between interventions, outcomes, and the circumstances under which these mechanisms are active. This should help companies find the most suitable solutions that leverage the benefits of Logistics 4.0 while mitigating risks and controlling costs.

4 Outcome: The effects of intervention, both intended and unintended ones. The aims associated with Logistics 4.0 in warehouses include, on the one hand, cost and time reduction for decision-making and for operations while maintaining service levels; on the other hand, providing higher service levels (e.g. by better utilizing the data emanating from ubiquitous sensors, higher quality of decision-making) while maintaining or optimizing costs ( Winkelhaus and Grosse, 2020 ). The combination of these two objectives and their trade-offs is a constant challenge for managers and decision-makers.

What are the main factors influencing a company’s level of readiness for the adoption of Logistics 4.0 in their warehouses?

What are the benefits that companies could achieve by implementing Logistics 4.0 solutions in their warehouses?

What are the main barriers and criticalities faced by companies when implementing Logistics 4.0 solutions in their warehouses?

The focus is set on influencing factors, benefits, and barriers with the purpose of specifically investigating the adoption process of Logistics 4.0 in warehouses, in line with previous logistics literature dealing with adoption processes (e.g. Li et al. , 2020 ; Perotti et al. , 2015 ).

Locating documents

1 Group A comprehends keywords referring to Logistics 4.0, i.e.: “smart logistic*” OR “logistic* 4.0” OR “autonomous logistic*” OR “warehous* 4.0” OR “smart warehous*”.

2 Group B encompasses the specific aspects under investigation, i.e.: “adopt*” OR “demand*” OR “benefit*” OR “advantage*” OR “opportunit*” OR “barrier*” OR “criticalit*” OR “challeng*” OR “maturity” OR “readiness” OR “impact*” OR “factor*” OR “driver*”.

Paper selection and evaluation

328 documents were initially retrieved from Scopus and 201 from Web of Science, including duplicates. Merging and removing duplicates delivered 363 documents dated between October 2003 and April 2021. At this stage (Phase 3), a rigorous selection process, structured into screening, eligibility, and qualification, was applied using the inclusion and exclusion criteria reported in Table 1 .

In the screening stage, phase, criteria 1 to 4 ( Table 1 ) were considered to limit the results to those publications central to the purposes of this study. More specifically, criterion 1 evaluates the date of publication, due to the fact that the term Industry 4.0 has been first coined and used by Kagermann et al. (2011) . Criterion 2 considers the attribution of the research, while criterion 3 ensures the quality of the papers, as scientific journals have a more rigorous review process than other document types ( Colicchia et al. , 2018 ) and conference proceedings cover emerging trends and challenges. Criterion 4 evaluates the language of publication. English is the language of choice as it is the most adopted and formally approved language for publications in the field of supply chain management ( Colicchia et al. , 2018 ). The screening phase delivered 274 papers out of 363 for the long list of papers.

In the eligibility stage , criteria 5 and 6 were applied. Both criteria are directly related to the main topics of the research questions. In this phase, the abstract, introduction, and conclusions of the papers were analyzed. This led to the exclusion of 185 papers, with 89 papers remaining in the sample.

Finally, in the qualification stage, all 89 papers were entirely read by two reviewers and carefully examined. As a result of this process, 33 papers have been excluded, because they were not specifically centered on the topics of interest. This led to a shortlist of 56 papers for critical in-depth analysis.

Review results

1 Descriptive characteristics, i.e. general details such as article title, year of release, source title, and first author’s country.

2 Methodology adopted, namely literature reviews, conceptual works, analytical papers, empirical contributions (case studies/interviews and surveys), action research (implementation of a technology), and simulations. If a paper presented multiple methodologies, the prevailing one was considered for classification.

3 Research question addressed, by identifying the topics addressed i.e. (1) influencing factors regarding the company’s level of readiness for the adoption of Logistics 4.0 technologies assigned to RQ1 , (2) benefits of the implementation of Logistics 4.0 solutions assigned to RQ2 , and (3) barriers and criticalities that companies face when searching to implement Logistics 4.0 solutions assigned to RQ3 . The results led to the development of a conceptual framework integrating three main dimensions associated with Logistics 4.0 adoption, namely motivations to adoption, benefits achieved, and barriers that emerged.

The following sections illustrate the descriptive analysis of the papers and describe the proposed conceptual framework as a result of the SLR study.

Descriptive analysis

Figure 2 shows the number of publications over time and by source. Initially, researchers gave priority to the development of Industry 4.0 concepts rather than Logistics 4.0. However, the number of publications per year related to Logistics 4.0 has steadily increased over time, and recently accelerated the pace, with 73% of the shortlisted papers published after 2018. The peak is in 2019, while 2020 recorded a small drop, possibly because of the COVID-19 pandemic. It is interesting to notice that the number of papers published in the first quarter of 2021 is almost the same as the sum of the two previous years, highlighting the growing interest of academics in Logistics 4.0 in warehouses.

Looking at the sources of the documents, a balance was found between papers published in scientific journals (34 papers, 48.6% of the sample) and conference proceedings (36 papers, 51.4%). The journals chiefly belong to the engineering and production management area, while a few are centered in other disciplines, such as policy management. As expected, most of the earliest papers were published in conference proceedings, indicating their ability to catch emerging trends.

Focusing on the first author’s affiliation country, most contributions (30) were Europe-based, followed by Asia (17), indicating strong interest from these regions.

Figure 3 illustrates the main research methodology used. Most of the early papers belong to the theoretical and conceptual domain whereas more recently the number of empirical contributions has increased substantially. Action research only started to appear in the last years. This shows that Logistics 4.0 in warehousing is attracting rising attention and it is likely going to become a well-developed research topic. Following a similar methodology as some documents found in the literature ( Golpîra et al. , 2021 ; Kumar et al. , 2021 ; Winkelhaus et al. , 2021 ), in our study, all the research methodologies (theoretical, conceptual, and empirical or action research) are considered relevant. Since the results of some methodologies can complement others, this helps to get a clearer idea of current Logistics 4.0 adoption as well as of future trends.

Finally, as far as the research question(s) being addressed, topics connected to RQ2 (35 related papers) and RQ3 (25 results) are prevailing, thus indicating that benefits from adoption as well as related barriers and criticalities have already started to be analyzed. Conversely, it seems that so far very little has been explored regarding the influencing factors on the company level for the readiness for adopting Logistics 4.0 in their warehouses.

Conceptual framework of logistics 4.0 adoption in warehousing

1 Influencing factors, referring to the elements that might influence the company’s decision to adopt Logistics 4.0 solutions in their warehouses. Companies are chiefly affected by their warehouse management and operation, their digital awareness and readiness, their employees’ educational level, and governmental support and policies.

2 Benefits, indicating the advantages that Logistics 4.0 solutions applied in warehouses might offer. In terms of operations, these benefits are process optimization, transaction cost reduction, flexibility increase, traceability and visibility enhancement, human error reduction, human resource management and safety enhancement, and sustainability improvement. Additionally, from the customer perspective, the main benefits are increased customer loyalty and satisfaction.

3 Barriers and criticalities, dealing with all the challenges that companies might face when embracing Logistics 4.0 in warehousing. Several types of hurdles can be identified: strategic (e.g. no standardized implementations exist), economic (e.g. high implementation costs), technological (e.g. obsolete infrastructures), cultural (e.g. companies are not ready for advanced technologies), and safety and security related (e.g. risk of cyber-attacks).

In the framework, the elements that compose each of the three dimensions are organized by their relative importance in the examined literature i.e. the frequency with which each aspect was a relevant point of discussion. This gives a clear view of the most and least relevant factors from the academic perspective. Additionally, the framework shows how each of the influencing factors is related to specific barriers and criticalities, giving an insight into how these two dimensions are interrelated and affected by one another. Finally, the benefits that Logistics 4.0 adopters could obtain are shown and organized from most to least investigated in the literature, which is relevant as Logistics 4.0 adopters can relate the specific requirements in their warehouses with the benefits identified by academics.

Our approach is in line with typical technology acceptance models (TAMs). In its basic form ( Figure 4 ) it is similar to the original TAM developed by Davis et al. (1989) : The influencing factors resemble the external variables while benefits correspond to perceived usefulness, and barriers and criticalities indicate the obstacles to the ease of use. We did not follow TAM2 ( Venkatesh and Davis, 2000 ), as we consider its main extensions compared to the original TAM, namely a more differentiated approach to external factors like social influence and cognitive processes, not relevant for our study. For the same reason, we have not used the unified theory of acceptance and use of technology (UTAUT) model suggested by Venkatesh et al. (2003) , as we think that factors like gender and age do not affect Logistics 4.0 adoption or moderate key influencing factors substantially. Our approach is in accordance with general concerns that the more elaborated models suggest additional moderators without explaining the reasons behind the proposed interaction effects ( Bagozzi, 2008 ). Following Bagozzi (2008) , we believe that the parsimony of the framework, its simple set-up, is strength rather than weakness and fits well into the managerial decision-making context.

Table 2 reports a detailed analysis of the framework elements and related references. In the subsequent paragraphs, each element is carefully described, as well as its related factors.

Influencing factors ( RQ1 )

Warehouse management and operation, the company’s digital awareness and readiness, employees’ educational level, and governmental support and policies have emerged as the main influencing aspects, thus addressing RQ1 .

First, the warehouse management and operations currently in place represent a major influencing factor. From this viewpoint, companies need to carefully consider their as-is configuration first – e.g. financial as well as operational factors, product characteristics as well as supply chain structure – together with the related performance and criticalities before deciding whether and how to embrace the digital transition that Logistics 4.0 implies ( Boonsothonsatit et al. , 2020 ). For example, Zoubek et al. (2021) propose a methodology to address the rationalization of a warehouse system by offering a range of 4.0 scenarios with different digital solutions that can be evaluated and selected based on the specific warehouse setting and requirements.

The second key influencing factor refers to the company’s digital awareness and readiness ( Zouari et al. , 2020 ). The lack of technological culture is one of the biggest hurdles the logistics industry is facing, and the company’s maturity and attitude toward the digital landscape affect the implementation of Logistics 4.0 in warehouses. As companies are not always fully aware of the digital options and how such solutions might impact their business, their perception might be biased and, consequently, implementation of Logistics 4.0 technologies in warehouses might be perceived as risky ( Barczak et al. , 2019 ). Some researchers have started analyzing the company’s technological maturity level, e.g. by means of frameworks such as the one proposed by Mahroof (2019) with technology, organization, and environment as the main pillars or five levels ( Stachowiak et al. , 2019 ) ranging from “ignoring” (i.e. full unawareness of Logistics 4.0) to “integrated” (i.e. companies that have effectively implemented fully integrated Logistics 4.0 solutions). Also, more general characteristics such as automation level or capability to manage data are included ( Zoubek and Simon, 2021 ). Finally, Modrak et al. (2019) propose a self-assessment model for smart logistics maturity, in which one of the five clusters is entirely focused on warehouses.

As far as employees’ educational level is concerned, Logistics 4.0 requires at its base a certain level of digital education. The development of human skills is one of the main requirements to maintain competitiveness ( Krishnan and Wahab, 2019 ; Wrobel-Lachowska et al. , 2018 ), and employees must be educated in a way that permits them to stay in line with cutting-edge trends. When approaching the 4.0 paradigm, training in technological knowledge and software/hardware usage is required ( Woschank and Pacher, 2020a ) and a combination of scientific, industry-specific, and firm-related capabilities should be promoted ( Wrobel-Lachowska et al. , 2018 ). Some scholars have investigated the learning process and suggested specific methods in the context of logistics engineering education, seeking to guarantee comprehensive training, characterized by both a theoretical and practical approach ( Nazir et al. , 2019 ; Woschank and Pacher, 2020b ). Anecdotal evidence from a large number of planning and consulting projects in the warehousing industry conducted by the authors indicates that, traditionally, warehouses have not been considered work environments that require any significant level of technological education on the operational level, suggesting that a high employee’s educational level, if present, would likely rather be qualified as an influencing factor (e.g. higher technology awareness and understanding of the benefits potentially achievable) than a barrier to implementation.

Finally, policies used by different countries to promote the transition to the 4.0 paradigm and their governments’ intervention can significantly affect the implementation of Logistics 4.0 in warehouses. For instance, actions such as (1) cost reductions in the import of external technology or (2) the promotion of international exchange of knowledge can support the local development of technologies and competence ( Krishnan and Wahab, 2019 ). Moreover, the government could financially support companies through incentives and strategic programs. Also, the collaboration among companies, academia, and the public sector might be fundamental for accelerated Logistics 4.0 implementation by increasing the adopters’ readiness level ( Stachowiak et al. , 2019 ).

Benefits ( RQ2 )

The main advantages emerging from Logistics 4.0 implementation refer to warehousing process optimization, transaction costs reduction, flexibility increase, traceability and visibility enhancement, human error reduction, human resource management, safety enhancement, sustainability improvement, and increased customer loyalty and satisfaction.

The possibility to improve process performance through the implementation of Logistics 4.0 technologies in warehouses is a widely addressed topic, especially from a conceptual perspective ( Barreto et al. , 2017 ; Correa et al. , 2020 ; Issaoui et al. , 2021 ; Kuczyńska-Chałada et al. , 2018 ; Nantee and Sureeyatanapas, 2021 ; Oleśków-Szłapka and Stachowiak, 2019 ; Song et al. , 2021 ; Wen et al. , 2018 ; Winkelhaus and Grosse, 2020 ; Woschank and Zsifkovits, 2021 ).

For instance, Wang (2016) suggests potential cost savings and a reduction in inventory costs. Some other scholars offer empirical studies to corroborate their views ( Affia and Aamer, 2021 ; Domański, 2019 ; Gialos and Zeimpekis, 2020 ; Hamdy et al. , 2018 ; Kekana et al. , 2020 ; Krishnan and Wahab, 2019 ; Lee et al. , 2018 ; Plakas et al. , 2020 ; Zhang et al. , 2021 ). However, it is necessary to critically assess the benefits directly associated with the technologies mentioned in the Logistics 4.0 literature to clearly point out whether and how they add something new to the technologies already adopted in warehouses, i.e. it is necessary to carve out what Logistics 4.0 adds to standard automation in warehouses.