How it works

For Business

Join Mind Tools

Article • 11 min read

Getting to the Root of a Problem Quickly

By the Mind Tools Content Team

5 Whys Root-Cause Analysis

Have you ever had a problem that refused to go away? No matter what you did, sooner or later it would return, perhaps in another form.

Stubborn or recurrent problems are often symptoms of deeper issues. "Quick fixes" may seem convenient, but they often solve only the surface issues and waste resources that could otherwise be used to tackle the real cause.

In this article and in the video, below, we look at the 5 Whys technique (sometimes known as 5Y). This is a simple but powerful tool for cutting quickly through the outward symptoms of a problem to reveal its underlying causes – so that you can deal with it once and for all.

Origins of the 5 Whys Technique

Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries, developed the 5 Whys technique in the 1930s. It became popular in the 1970s, and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based on an in-depth understanding of what's actually happening on the shop floor , rather than on what someone in a boardroom thinks might be happening.

The 5 Whys technique is true to this tradition, and it is most effective when the answers come from people who have hands-on experience of the process or problem in question.

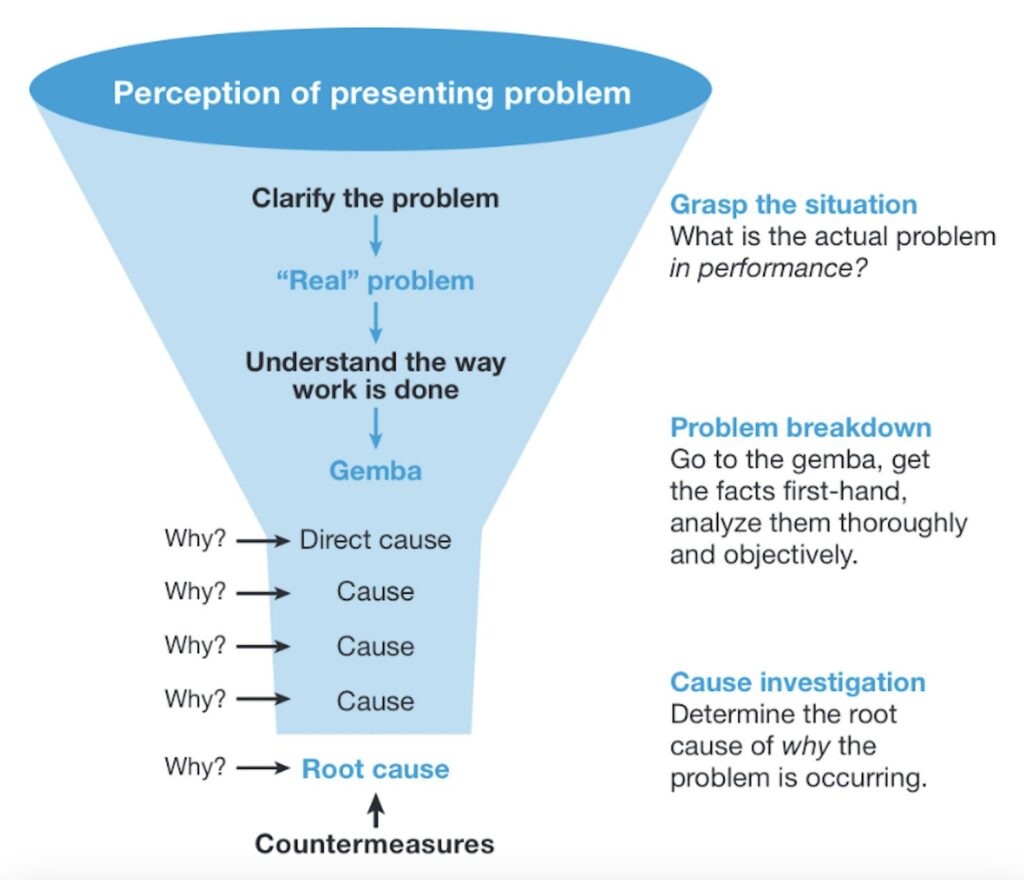

The method is remarkably simple: when a problem occurs, you drill down to its root cause by asking "Why?" five times. Then, when a counter-measure becomes apparent, you follow it through to prevent the issue from recurring.

The 5 Whys uses "counter-measures," rather than "solutions." A counter-measure is an action or set of actions that seeks to prevent the problem from arising again, while a solution may just seek to deal with the symptom. As such, counter-measures are more robust, and will more likely prevent the problem from recurring.

When to Use a 5 Whys Analysis

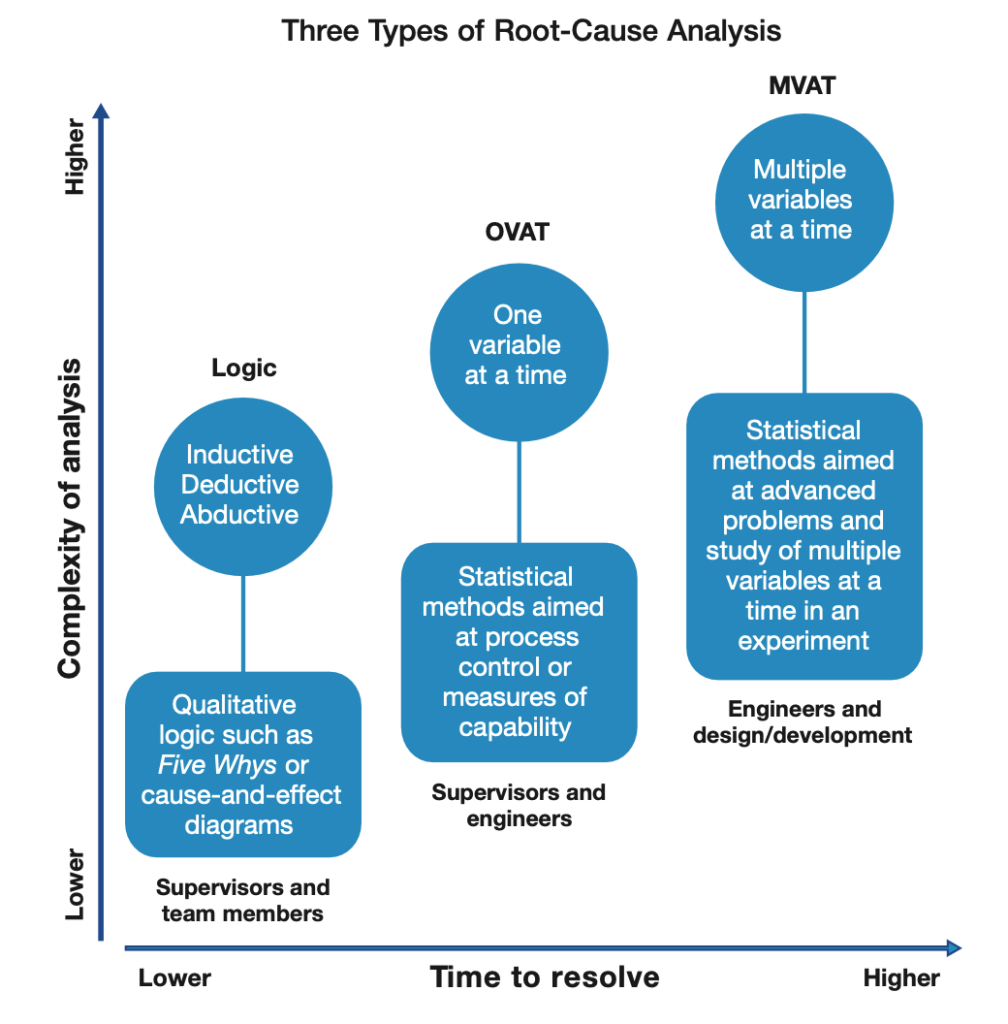

You can use 5 Whys for troubleshooting, quality improvement, and problem solving, but it is most effective when used to resolve simple or moderately difficult problems.

It may not be suitable if you need to tackle a complex or critical problem. This is because 5 Whys can lead you to pursue a single track, or a limited number of tracks, of inquiry when, in fact, there could be multiple causes. In cases like these, a wider-ranging method such as Cause and Effect Analysis or Failure Mode and Effects Analysis may b e more effective.

This simple 5 Whys technique, however, can often direct you quickly to the root cause of a problem. So, whenever a system or process isn't working properly, give it a try before you embark on a more in-depth approach – and certainly before you attempt to develop a solution.

The tool's simplicity gives it great flexibility, too, and 5 Whys combines well with other methods and techniques, such as Root Cause Analysis . It is often associated with Lean Manufacturing , where it is used to identify and eliminate wasteful practices. It is also used in the analysis phase of the Six Sigma quality improvement methodology.

How to Use the 5 Whys

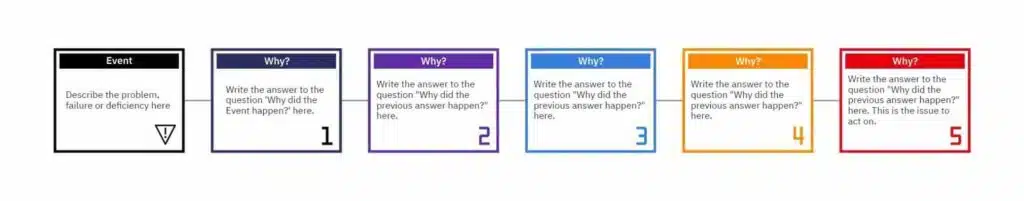

The model follows a very simple seven-step process: [1]

1. Assemble a Team

Gather together people who are familiar with the specifics of the problem, and with the process that you're trying to fix. Include someone to act as a facilitator , who can keep the team focused on identifying effective counter-measures.

2. Define the Problem

If you can, observe the problem in action. Discuss it with your team and write a brief, clear problem statement that you all agree on. For example, "Team A isn't meeting its response time targets" or "Software release B resulted in too many rollback failures."

Then, write your statement on a whiteboard or sticky note, leaving enough space around it to add your answers to the repeated question, "Why?"

3. Ask the First "Why?"

Ask your team why the problem is occurring. (For example, "Why isn't Team A meeting its response time targets?")

Asking "Why?" sounds simple, but answering it requires serious thought. Search for answers that are grounded in fact: they must be accounts of things that have actually happened, not guesses at what might have happened.

This prevents 5 Whys from becoming just a process of deductive reasoning, which can generate a large number of possible causes and, sometimes, create more confusion as you chase down hypothetical problems.

Your team members may come up with one obvious reason why, or several plausible ones. Record their answers as succinct phrases, rather than as single words or lengthy statements, and write them below (or beside) your problem statement. For example, saying "volume of calls is too high" is better than a vague "overloaded."

4. Ask "Why?" Four More Times

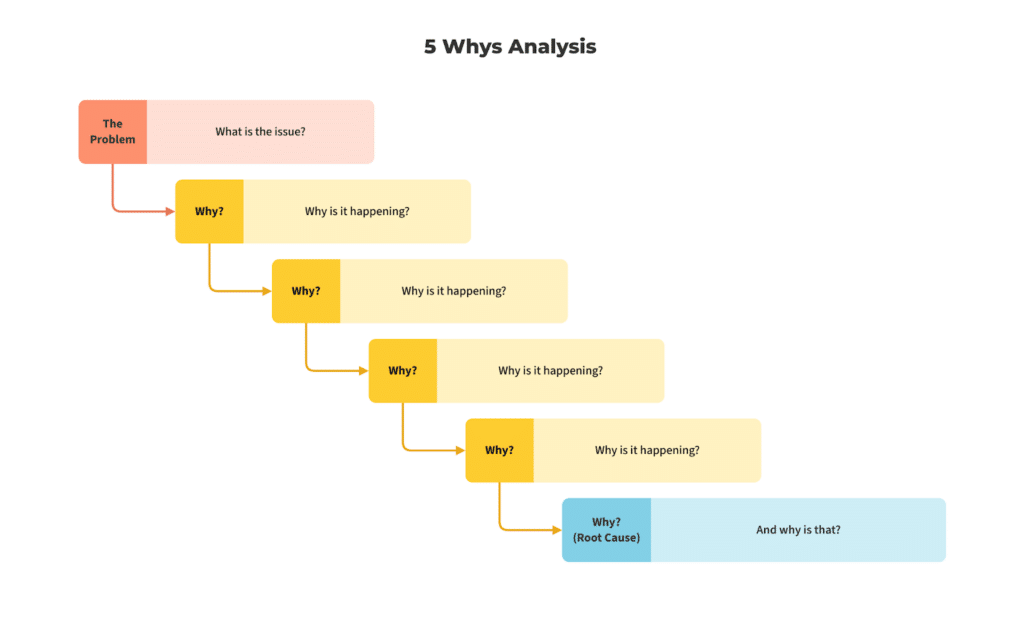

For each of the answers that you generated in Step 3, ask four further "whys" in succession. Each time, frame the question in response to the answer you've just recorded.

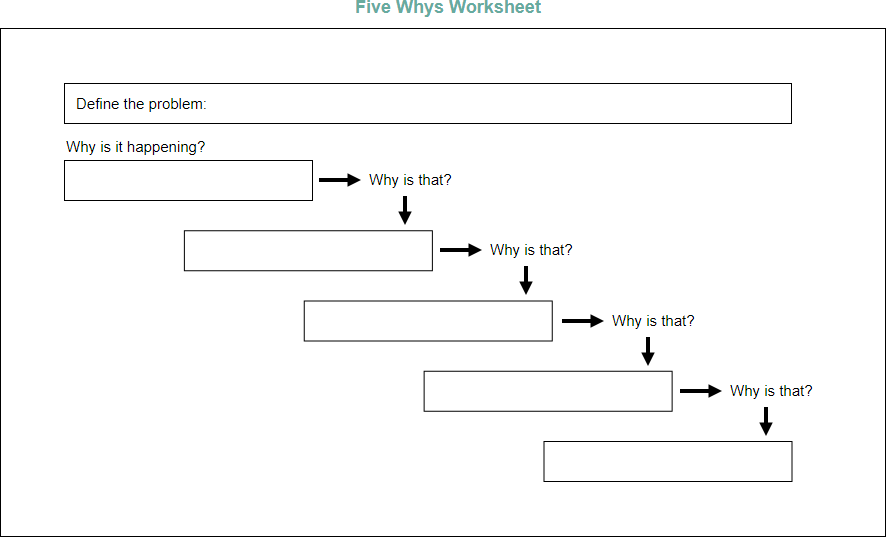

What Is a 5 Whys Template?

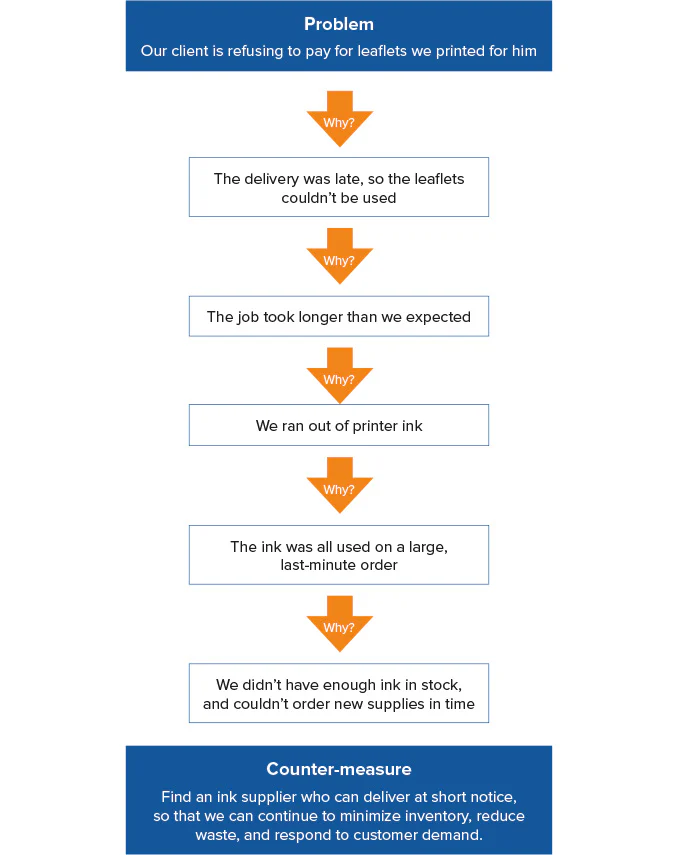

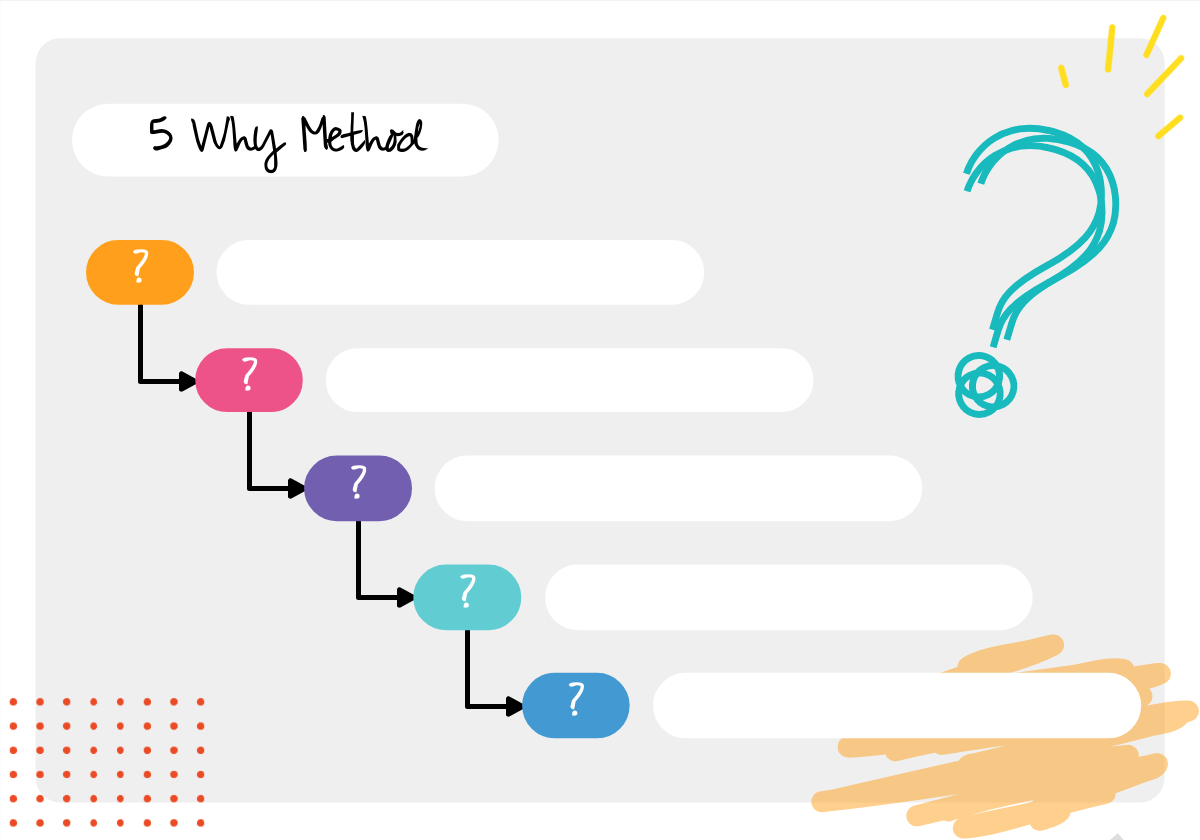

The diagram, below, shows an example of 5 Whys in action, following a single lane of inquiry.

Figure 1: 5 Whys Example (Single Lane)

The 5 Whys method also allows you to follow multiple lanes of inquiry. An example of this is shown in Figure 2, below.

In our example, asking "Why was the delivery late?" produces a second answer (Reason 2). Asking "Why?" for that answer reveals a single reason (Reason 1), which you can address with a counter-measure.

Similarly, asking "Why did the job take longer than expected?" has a second answer (Reason 2), and asking "Why?" at this point reveals a single reason (Reason 1). Another "Why?" here identifies two possibilities (Reasons 1 and 2) before a possible counter-measure becomes evident.

There is also a second reason for "Why we ran out of printer ink" (Reason 2), and a single answer for the next "Why?" (Reason 1), which can then be addressed with a counter-measure.

Figure 2: 5 Whys Example (Multiple Lanes)

Step 5. Know When to Stop

You'll know that you've revealed the root cause of the problem when asking "why" produces no more useful responses, and you can go no further. An appropriate counter-measure or process change should then become evident. (As we said earlier, if you're not sure that you've uncovered the real root cause, consider using a more in-depth problem-solving technique like Cause and Effect Analysis , Root-Cause Analysis , or FMEA .)

If you identified more than one reason in Step 3, repeat this process for each of the different branches of your analysis until you reach a root cause for each one.

6. Address the Root Cause(s)

Now that you've identified at least one root cause, you need to discuss and agree on the counter-measures that will prevent the problem from recurring.

7. Monitor Your Measures

Keep a close watch on how effectively your counter-measures eliminate or minimize the initial problem. You may need to amend them, or replace them entirely. If this happens, it's a good idea to repeat the 5 Whys process to ensure that you've identified the correct root cause.

Appreciation

A similar question-based approach known as "appreciation" can help you to uncover factors in a situation that you might otherwise miss.

It was originally developed by the military to assist commanders in gaining a comprehensive understanding of any fact, problem or situation. But you can also apply it in the workplace.

Starting with a fact, you first ask the question, "So what?" – in other words, what are the implications of that fact? Why is this fact important?

You then continue asking that question until you've drawn all possible conclusions from it.

The major difference between this and the 5 Whys technique is that appreciation is often used to get the most information out of a simple fact or statement, while 5 Whys is designed to drill down to the root of a problem.

Tips for Using the 5 Whys Technique

- Try to move quickly from one question to the next. That way, you'll have the full picture before you jump to any conclusions.

- The "5" in 5 Whys is really just a " rule of thumb ." In some cases, you may need to ask "Why?" a few more times before you get to the root of the problem. In other cases, you may reach this point before you ask your fifth "Why?" If you do, make sure that you haven't stopped too soon, and that you're not simply accepting "knee-jerk" responses.

- Know when to stop! The important point is to stop asking "Why?" when you stop producing useful responses.

Frequently Asked Questions About 5 Whys

1. what is the 5 whys technique.

The 5 Whys Technique is a problem-solving method involving repeatedly asking "why?" It's a way of quickly getting to the root cause of a situation.

2. Who Invented 5 Whys?

The 5 Whys technique was invented in the 1930s by Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries.

5 Whys Infographic

See our infographic on the 5 Whys and use it to get to the root of your problems!

Bear in mind that appreciation can restrict you to one line of thinking. For instance, once you've answered your first "So what?" question, you might follow a single line of inquiry to its conclusion. To avoid this, repeat the appreciation process several times over to make sure that you've covered all bases.

The 5 Whys strategy is a simple, effective tool for uncovering the root of a problem. You can use it in troubleshooting, problem-solving, and quality-improvement initiatives.

Start with a problem and ask why it is occurring. Make sure that your answer is grounded in fact, and then ask the question again. Continue the process until you reach the root cause of the problem, and you can identify a counter-measure that will prevent it from recurring.

Bear in mind that this questioning process is best suited to simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.

[1] Pojasek, R. (2000). 'Asking "Why?" Five Times,' Environmental Quality Management , Volume 10, Issue 1, 79–84. Available here . [Accessed July 1, 2022.]

You've accessed 1 of your 2 free resources.

Get unlimited access

Discover more content

Using root cause analysis.

Find the Root of Your Problems

Root Cause Analysis

Tracing a Problem to Its Origins

Add comment

Comments (0)

Be the first to comment!

Team Management

Learn the key aspects of managing a team, from building and developing your team, to working with different types of teams, and troubleshooting common problems.

Sign-up to our newsletter

Subscribing to the Mind Tools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Most Popular

Newest Releases

SWOT Analysis

How to Build a Strong Culture in a Distributed Team

Mind Tools Store

About Mind Tools Content

Discover something new today

Top tips for delegating.

Delegate work to your team members effectively with these top tips

Ten Dos and Don'ts of Change Conversations

Tips for tackling discussions about change

How Emotionally Intelligent Are You?

Boosting Your People Skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

Inbox assessments.

Evaluating How an Employee Will Perform on the Job

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Coaching and Mentoring

Change Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

- RCA 101 – 5-Why Analysis (Free Training)

- RCA 201 – Basic Failure Analysis

- RCA 301 – PROACT® RCA Certification

- RCA 401 – RCA Train The Trainer

- Other Trainings

- 5 Whys Root Cause Analysis Template

- RCA Template

- Chronic Failure Calculator

Root Cause Analysis with 5 Whys Technique (With Examples)

By Sebastian Traeger

Updated: March 21, 2024

Reading Time: 7 minutes

What Is the 5 Whys Technique?

Example of the 5 whys technique, how to conduct a 5 whys analysis in 5 steps, when to use a 5 whys analysis, using 5 whys template, tips for mastering the 5 whys technique, frequently asked questions about 5 whys.

With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand 5 whys techniques by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

The 5 Whys Technique is like peeling an onion – it helps you uncover the underlying reasons behind a problem, layer by layer. By repeatedly asking “why” at least five times, this method digs deep to reveal the root cause of an issue. It’s a simple yet powerful problem-solving approach that aims to get to the heart of the matter rather than just addressing surface-level symptoms.

5 Whys Technique: A method that involves iteratively asking “why” five times to unveil the fundamental cause of a problem.

In essence, the 5 Whys Technique is not just about fixing what’s broken on the surface; it’s about understanding and addressing the deeper issues that lead to problems in the first place.

The 5 Whys Technique is like a detective, uncovering the truth behind recurring problems. Let’s take a look at how this method works in two different scenarios.

Case Study: Manufacturing Defects

Imagine a company that keeps encountering the same manufacturing defects despite various attempts to fix them. By using the 5 Whys Technique, they discovered that the defects were not caused by faulty machinery, as previously assumed, but rather by human error due to unclear operating instructions. This realization led to improved training procedures and clear work guidelines, ultimately eliminating the defects.

Application in Service Industry

Now, consider a service industry struggling with frequent customer complaints and service failures. Through the 5 Whys Technique, it was revealed that these issues stemmed from inadequate staffing levels during peak hours. By addressing this root cause, such as hiring additional staff or adjusting schedules, the service quality can significantly improve, leading to higher customer satisfaction.

These examples illustrate how the 5 Whys Technique can be applied across different sectors to identify and address underlying issues effectively.

Step 1: Identify the Problem

Before diving into a 5 Whys analysis, it’s crucial to clearly identify the problem or issue at hand . This step sets the stage for the entire process and ensures that the focus remains on addressing the right concern. Take the time to gather relevant data, observe patterns, and consult with team members or stakeholders to gain a comprehensive understanding of the problem.

Step 2: Ask ‘Why’ Five Times

Once the problem is clearly defined, it’s time to start peeling back the layers. The process involves asking “why” five times, not necessarily limited to five questions but enough to delve deeper into the underlying causes of the problem . Each “why” serves as a gateway to uncovering additional factors contributing to the issue. This iterative approach helps in identifying not just one cause, but multiple interconnected elements that may be at play.

By consistently probing deeper with each “why,” you can reveal hidden complexities and nuances that may have been overlooked initially. This method allows for a more thorough understanding of the situation, paving the way for effective solutions that address root causes rather than surface-level symptoms.

This structured approach encourages critical thinking and enables teams to move beyond quick fixes towards sustainable improvements.

The 5 Whys Technique is a versatile problem-solving approach that can be applied in various scenarios to uncover root causes and drive continuous improvement. Here are two key situations where the 5 Whys Analysis can be particularly beneficial:

Recurring Issues

- The 5 Whys Technique is especially useful when dealing with recurring issues. Whether it’s a manufacturing defect that keeps resurfacing or a persistent customer complaint in the service industry, this method helps identify the underlying reasons behind these repetitive problems. By repeatedly asking “why,” it becomes possible to trace the issue back to its root cause, allowing for targeted solutions that prevent reoccurrence.

Process Improvement

- Organizations constantly strive to enhance their processes and workflows for increased efficiency and quality. When seeking to improve existing procedures, the 5 Whys Technique serves as a valuable tool. By systematically analyzing the factors contributing to inefficiencies or bottlenecks, teams can gain insights into how processes can be optimized at their core. This method enables organizations to make informed decisions about process improvements based on a deep understanding of the underlying issues.

In both cases, the 5 Whys Analysis offers a structured yet flexible approach to delve into complex problems, making it an indispensable tool for driving meaningful change and progress within organizations.

When it comes to conducting a 5 Whys analysis, utilizing a structured template can greatly facilitate the process and ensure a comprehensive investigation into the root cause identification. Using RCA software such as EasyRCA can benefit the team by streamlining your 5-why process. Here’s how organizations can benefit from using a template:

Benefits of Using a Template

- Streamlined Process: A well-designed 5 Whys template provides a clear framework for conducting the analysis, guiding teams through the iterative questioning process. This streamlines the investigation, making it easier to navigate and ensuring that no crucial aspects are overlooked.

- Thorough Investigation: By following a predefined template, teams are prompted to explore various facets of the problem systematically. This ensures that all relevant factors are considered, leading to a more thorough and insightful investigation into the underlying causes.

- Consistent Approach: Templates offer a standardized approach to conducting 5 Whys analyses within an organization. This consistency promotes uniformity in problem-solving methods across different teams or departments, enhancing overall efficiency and effectiveness.

Customizing the Template

Organizations have the flexibility to customize 5 Whys templates according to their specific needs and industry requirements. This adaptability allows for tailoring the template to address unique challenges and incorporate industry-specific considerations. Customization may include:

- Adding Industry-Specific Prompts: Tailoring the template by incorporating prompts or questions relevant to particular industries or types of issues being analyzed.

- Incorporating Visual Aids: Enhancing the template with visual aids such as flow charts or diagrams can help teams better understand and communicate complex causal relationships.

- Iterative Refinement: Regularly reviewing and refining the template based on feedback and evolving organizational needs ensures that it remains aligned with current processes and challenges.

Customizing the template empowers organizations to harness the full potential of the 5 Whys Technique in addressing diverse problems while aligning with their unique operational contexts.

Encouraging Open Communication

In mastering the 5 Whys Technique as a problem-solving method, creating an environment that fosters open communication is paramount. When team members feel comfortable expressing their perspectives and insights, it leads to a more comprehensive exploration of the underlying causes of a problem. Encouraging open communication allows for diverse viewpoints to be considered, providing a holistic understanding of the issue at hand.

By promoting an atmosphere where individuals are empowered to voice their observations and concerns, the 5 Whys analysis can benefit from a rich tapestry of ideas and experiences. This inclusive approach not only enhances the depth of the analysis but also cultivates a sense of ownership and collective responsibility for addressing root causes within the team or organization.

Continuous Improvement Mindset

A key aspect of mastering the 5 Whys Technique is embracing a continuous improvement mindset. Rather than viewing problems as isolated incidents, this approach encourages teams to see them as opportunities for growth and development. By instilling a culture of continuous improvement, organizations can leverage the insights gained from 5 Whys analyzes to drive positive change across various aspects of their operations.

Fostering a mindset focused on continuous improvement entails actively seeking feedback, evaluating processes, and implementing iterative enhancements based on the findings. It involves an ongoing commitment to learning from past experiences and leveraging that knowledge to proactively address potential issues before they escalate. Embracing this mindset ensures that the 5 Whys Technique becomes ingrained in the organizational ethos, leading to sustained progress and resilience in problem-solving efforts.

As we wrap up our exploration of the 5 Whys Technique, let’s address some common questions that may arise regarding this powerful problem-solving method.

What is the primary goal of the 5 Whys Technique?

The primary goal of the 5 Whys Technique is to uncover the root cause of a problem by iteratively asking “why” at least five times. This approach aims to move beyond surface-level symptoms and address the underlying issues that lead to recurring problems.

Is the 5 Whys Technique limited to specific industries or sectors?

No, the 5 Whys Technique is versatile and can be applied across various industries and sectors. Whether it’s manufacturing, healthcare, service, or technology, this method offers a structured yet flexible approach to identifying root causes and driving continuous improvement.

How does the 5 Whys Technique contribute to continuous improvement?

By delving into the fundamental reasons behind problems, the 5 Whys Technique provides organizations with valuable insights for driving continuous improvement. It not only helps in resolving immediate issues but also fosters a culture of ongoing enhancement and development within an organization.

Can the 5 Whys Technique be used for complex problems with multiple contributing factors?

Yes, while initially designed as a simple and straightforward method, the 5 Whys Technique can certainly be applied to complex problems with multiple interconnected factors. By systematically probing deeper into each layer of causality, this technique enables a comprehensive understanding of intricate issues.

I hope you found this guide to 5 whys technique insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit Reliability Resources .

- Root Cause Analysis /

Recent Posts

5 Root Cause Analysis Examples That Shed Light on Complex Issues

What Is Fault Tree Analysis (FTA)? Definition & Examples

Guide to Failure Mode and Effects Analysis (FMEA)

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training

[email protected]

Tel: 1 (800) 457-0645

Share article with friends:

5 Whys: Examples, explanations, and how to find the causes of problems

At some point, we’ve all experienced a problem with a process or strategy at work. But figuring out why the problem exists can be a daunting task. When you sit your teammates down for a discussion, emotions run high and miscommunication is common.

The 5 Whys is a powerful, easy-to-use technique for getting at the root of a problem. It empowers you and your team to understand why a problem persists and to decide on a path forward.

- What is the 5 Whys framework?

The 5 Whys is a popular problem-solving method that individuals and teams use to understand the potential causes of a specific issue. Years ago, Toyota developed the approach to help them get at the heart of complex mechanical issues, so you know it’s legitimate! The technique is easy to use: you ask why a problem happened, and then you ask four more times. By asking “why” on a step-by-step basis, you can get to the root cause of a defect, failure, challenge, or malfunction.

- When and Why the 5 Whys Analysis is Used

The 5 Whys framework is useful in a variety of situations. People love it because it helps you have a focused discussion and avoid getting distracted by other topics. You just start with a problem statement, ask why the problem exists, and keep moving through the exercise until you’ve uncovered the problem.

Here are some scenarios where you might find the 5 Whys approach to be useful.

Working on complex products

Remember, the 5 Whys technique was originally developed by Toyota. The car manufacturer needed a clear-cut way of dealing with a product that has thousands of parts. But that doesn’t mean the technique only works for large physical goods. Many organizations use the 5 Whys approach when software malfunctions, when a key deliverable with many moving parts doesn’t work properly, or when a multi-step process breaks down.

Solving complex problems

When a problem is so complex that engineers, designers, or decision-makers are scratching their heads, the 5 Whys approach may serve you well. Maybe your complicated marketing strategy didn’t hit your targets, or an important API isn’t working. Instead of getting overwhelmed, the 5 Whys framework helps you wrap your head around the problem.

Dealing with consistent problems

Maybe the problem doesn’t seem complex, but it keeps coming up. Or maybe you’ve tried multiple solutions and none seem to work. Rather than burning precious time and money on yet another risky bandaid, try the 5 Whys to finally discover what’s going on.

- How to conduct a 5 Whys analysis in 6 steps

One of the great things about the 5 Whys framework is that it’s easy to understand. Unlike many other problem-solving techniques, which can be difficult to grasp, you can explain the 5 Whys to your team in minutes. Follow these guidelines any time you need to use the approach.

Step 1 – Form your problem statement.

Start by asking your team what problem you’re about to analyze. Everyone should get a chance to articulate the problem so you’re all on the same page. Sometimes, you might find yourself using the 5 Whys approach to uncover the root of a difficult or charged obstacle. If that’s the case, give your team the time and space to be honest with each other and to have difficult conversations. Write down the problem statement for everyone to reference.

Step 2 – Ask “why has this happened?” 5 times.

Don’t be too literal with it. Feel free to amend the “why” statement to something like “Why does this keep happening?” or “Why are we having this problem?” Keep going until you’ve asked “why” five or more times. It might feel unnatural, but eventually, you’ll push through any awkwardness to uncover the root of the problem.

Step 3 – Jot down logical causes.

Okay, now you have a pretty good handle on your problem. Write down any logical causes that have followed from your 5 Whys analysis. Regardless of whether those causes came from your first “why” or your fifth, make a detailed note of them. Discuss the causes with your team and make sure you’re all agreed.

Step 4 – Hypothesize an answer.

Now that you have your logical cause, it’s time to come up with some potential solutions. At this stage, you’re just having a conversation. You don’t need to come up with the perfect solution in this meeting. Have everyone go around the room and say (or write down) a possible solution. Ask everyone to vote on the most actionable one.

Step 5 – Test your hypothesis.

Put your solution to the test with some experiments. If you’ve decided that a marketing campaign failed because you didn’t choose the correct target audience, then maybe you can come up with some A/B tests to vet possible solutions. Aim for low-stakes tests that you can use to draw meaningful conclusions.

Step 6 – Repeat until solved.

Iterate until you’ve solved the problem! Don’t be discouraged if it doesn’t happen right away. Sometimes, it might take multiple rounds of “whys” followed by many rounds of testing to uncover a solution. Keep an open line of communication among your teammates and don’t give up.

Try Miro today

- A simple 5 Whys example

The 5 Whys is an adaptable, easy-to-use framework for uncovering the root of a problem. Organizations and teams of all sizes use the framework to overcome complex, high-stakes challenges. Here’s a quick example to help you bring this method of analysis to your own team.

Let’s say your team has been working on an app for many months. You rolled out a beta version late last quarter. You were supposed to ship the app to the rest of your users at the beginning of this quarter, but a problem arose: a bunch of your early users complained of a fatal error that caused the app to crash. As a result, you couldn’t ship it, and your customers were disappointed.

Step 1 — Write down your problem statement.

As we mentioned above, the first step in following the 5 Whys framework is to clearly and succinctly define what problem you’re trying to solve. The entire group should be clear about this issue. In this case, the problem statement is: your app wasn’t ready to ship to your customers.

Step 2 — Start with the broadest possible question.

Start with the broadest possible question. Then aim to answer it. Why wasn’t the app ready for your customers? It wasn’t ready because there was a bug in the code that caused it to crash.

Drill down into that question. Why was there a bug in the code that caused it to crash? There was a bug in the code because the engineers didn’t get user feedback in time to fix it.

Keep drilling down. Why didn’t the engineers get that user feedback? They didn’t get the feedback because the development team didn’t provide an easy way for users to submit their feedback.

Continue drilling down, asking more and more precise questions as you get closer to the answer. Why didn’t the development team provide an easy way for users to leave feedback? They didn’t provide an easy way for users to leave feedback because they weren’t clear on deadlines for the project.

Ask “why” at least one more time. Why wasn’t the development team clear on deadlines for the project? They weren’t clear on deadlines because they weren’t meeting with stakeholders often enough to know when the timeline changed.

Step 3 – Write down logical issues.

Now you have enough information to write down logical causes. It seems that this problem stemmed from a lack of communication between stakeholders. That caused the development team and engineering team to become misaligned.

Step 4 – Once you’re ready, you can come up with a possible solution to this problem.

Once you’re ready, you can come up with a possible solution to this problem. In the future, internal stakeholders will hold weekly check-ins to make sure they’re aligned on where the project is headed.

Step 5 – Put that hypothesis into action.

Here’s where you get to test out your hypothesis and see what effects it has. Moving forward, start holding weekly check-ins and see what happens. If miscommunication and confusion goes down, you’ll know you’re on the right track.Step 6 – Adjust your strategy, if needed

Resist the urge to consider a problem “solved” and move on immediately. It’s important to revisit how the solution is functioning in the weeks ahead, continually checking in with everyone on the team to see how they’re feeling about it. You may need to tweak your strategy over time.

- How 5 Whys helped solve the problem

This example clearly showcases the power of the 5 Whys. What looked like a problem with code turned out to be a symptom of miscommunication.

Although this is just a hypothetical, we all know stuff like this happens every day. But it’s often difficult to uncover the root causes of a problem without months and months of exploration. With the 5 Whys, you can overcome costly challenges in a much shorter amount of time.

- Try the 5 Whys template for free

Clearly, asking “why?” isn’t just a technique used by persistent 4-year-olds – it’s actually a quick and easy way to identify a root cause. Countless teams across different industries have had great results using this framework. Save time, collaborate with your team, and solve hard problems with Miro’s free 5 Whys template .

- How Miro helps distributed teams collaborate

Working with a remote team can be challenging — but it also offers unparalleled opportunities for creativity and collaboration. Miro’s online whiteboard helps teams overcome cultural divides, communication silos, geographic barriers, and micro-cultures to empower you to stay connected and do great things.

Miro has a variety of templates and tools for teams to help you and your team:

- Create a mind map

- Manage a scrum board

- Create user story maps and customer journey maps

- Work with sticky notes, even if you aren’t in the same room

- Generate flow charts and diagrams

- Run brainstorming sessions

And lots more… try Miro for remote collaboration today!

Miro is your team's visual platform to connect, collaborate, and create — together.

Join millions of users that collaborate from all over the planet using Miro.

Keep reading

Achieve continuous improvement with as-is and to-be process mapping.

How to build resilient teams with Agile expert Diana Larsen

Should we scale, and if so, how?: Dissecting the Scaled Agile debate

5 Whys: Uncovering the Core of Problem Solving

This guide will walk you through the essential elements of using 5 whys - the productivity method to keep your team productive and engaged.

In the realm of continuous improvement methodologies and problem-solving techniques, 5 Whys stands out as a quintessential approach that delves deep into the underlying causes of issues, aiming to address the root of the problem itself. This article provides a comprehensive exploration of the 5 Whys method, from its origins to practical applications, serving as a valuable resource for individuals and organizations seeking to enhance their problem-solving capabilities.

What Is "5 Whys" in the Context of Productivity?

The 5 Whys technique is a systematic and iterative questioning method employed to discern the fundamental cause-and-effect relationships underlying a problem. It involves the repetition of "why" questions to gradually uncover the deeper issues contributing to a particular symptom or challenge. As an essential tool in productivity enhancement, 5 Whys offers a structured framework for drilling down into the underlying causes of inefficiencies, thereby facilitating targeted and sustainable solutions.

Origin of 5 Whys

The genesis of the 5 Whys approach can be traced back to the pioneering systems of lean manufacturing and Toyota Production System (TPS) in the mid-20th century. Developed as a fundamental aspect of the TPS, 5 Whys was ingrained in Toyota's problem-solving culture, reflecting its profound impact on the organization's operational efficiency and product quality. Over time, its efficacy transcended manufacturing, permeating diverse industries and problem-solving contexts.

Use Lark to unleash your team productivity.

Who Can Benefit from Using 5 Whys?

Targeting a wide spectrum of professionals, from frontline employees to C-suite executives, the 5 Whys technique is versatile and universally applicable. Whether deployed in the manufacturing sector to identify equipment failures or in service industries to uncover workflow bottlenecks, 5 Whys serves as a potent instrument for discerning the root causes of issues. Furthermore, it is equally beneficial for individuals seeking to address personal or professional challenges in a methodical and holistic manner.

Pros and Cons of 5 Whys

- Depth of Analysis : By repeatedly asking "why," the 5 Whys method enables a comprehensive and systemic exploration of problems, leading to the identification of root causes that might have otherwise remained obscured.

- Simplicity and Accessibility : Its straightforward and uncomplicated nature allows for widespread adoption, making it an accessible and practical tool for organizations at all levels.

- Cultivates a Learning Culture : Encourages a culture of curiosity, open communication, and continuous improvement within organizations, thereby fostering a fertile ground for innovation and problem-solving.

- Surface-Level Responses : In certain cases, the 5 Whys technique may lead to superficial conclusions, especially if the team lacks the depth of expertise or experience in the specific problem domain.

- Overemphasis on Direct Causes : The method might overlook complex systemic issues that necessitate a more multifaceted approach, potentially resulting in incomplete or myopic solutions.

Master Workflow Management with Lark for Improved Efficiency and Collaboration | Lark Blog

Learn more about Lark x Productivity

How to Get Started with 5 Whys

Initiating the 5 Whys process involves a deliberate and structured approach that encourages collaborative problem-solving and critical thinking.

- Select a Problem : Begin by identifying a specific problem or issue that warrants thorough examination.

- Assemble a Diverse Team : Gather a cross-functional team with varied perspectives and expertise relevant to the problem at hand.

- Ask the First "Why" : Encourage the team to articulate the symptoms or manifestations of the problem, prompting the initial "why" question to unravel its root cause.

- Reiterate the Process : Proceed to ask "why" in response to each successive cause that emerges, ideally delving five iterations deep to uncover the fundamental issue.

- Validate and Implement Solutions : Once the root cause is identified, collaboratively explore and implement sustainable solutions to address the problem systematically.

Examples of 5 Whys in Action

Scenario 1 : Manufacturing Downtime

- Description : A manufacturing company experiences frequent equipment breakdowns, disrupting production schedules.

- Application of 5 Whys : By employing the 5 Whys technique, it was revealed that inadequate equipment maintenance, stemming from inconsistent servicing schedules, was the root cause of the recurring breakdowns.

- Impact : Implementing a regular maintenance regimen and standardized protocols significantly reduced unplanned downtime.

Scenario 2 : Service Industry Efficiency

- Description : A service-oriented organization encounters prolonged lead times in delivering services to clients.

- Application of 5 Whys : Through collaborative 5 Whys sessions, it was discovered that convoluted approval processes and overreliance on manual documentation processes were impeding operational efficiency.

- Impact : Streamlining approvals and digitizing documentation procedures led to a substantial reduction in service delivery timelines.

Scenario 3 : Project Management Challenges

- Description : A project team faces recurring delays and cost overruns in their initiatives.

- Application of 5 Whys : By meticulously delving into the project setbacks using the 5 Whys approach, it became evident that inadequate resource allocation and unclear communication channels were at the core of the recurring issues.

- Impact : Implementing a resource optimization strategy and refining communication protocols resulted in smoother project executions with minimized delays and budget overruns.

Step-by-Step Guide for 5 Whys

Identifying the Problem

The first step entails pinpointing a specific problem or undesirable outcome that necessitates a thorough analysis. This could be a recurrent issue, a sudden anomaly, or a persistent symptom of an underlying challenge.

Assembling a Diverse Team

Bringing together a cross-functional and diverse team comprising individuals with unique insights, expertise, and perspectives relevant to the problem being addressed is crucial for fostering comprehensive discussions and ensuring a multi-faceted analysis.

Initiating the "Why" Iterations

Commence the 5 Whys analysis by posing the first "why" question in response to the identified problem, prompting the team to elucidate the underlying causes that have contributed to its manifestation.

Repeated Inquiry and Exploration

Persist by iteratively asking "why," probing deeper into each cause identified in the previous step. The process should ideally culminate after the fifth "why," substantiating the direct linkages between causes and the ultimate issue.

Validation and Solution Formulation

Upon uncovering the root cause through the 5 Whys analysis, the team must substantiate the findings with empirical evidence and collaboratively devise and implement targeted solutions that address the core issue in a systematic manner.

Actionable Tips for 5 Whys

- Cultivate Open Dialogue : Encourage an atmosphere of candid and open communication to facilitate uninhibited exploration of issues and causes within the 5 Whys process.

- Embrace Collective Ownership : Foster a sense of shared responsibility and ownership among team members regarding the outcomes and findings derived from 5 Whys sessions, promoting a collaborative approach to problem-solving.

- Document and Reflect : Thoroughly document the findings and insights gained from each 5 Whys analysis, allowing for subsequent reflections and insights to inform future problem-solving endeavors.

Do's and Dont's

Dont's.

In conclusion, the 5 Whys approach serves as a powerful instrument for unraveling the underlying causes of problems, fostering a culture of continuous improvement, and propelling organizations towards sustainable solutions. Its versatility and simplicity render it accessible to diverse environments and underscore its enduring significance in the realm of problem-solving methodologies.

How is the "5 Whys" technique different from traditional problem-solving methods?

The 5 Whys technique distinguishes itself from traditional problem-solving strategies by its relentless pursuit of root causes through iterative questioning. While conventional methods often address symptoms or superficial manifestations of problems, the 5 Whys approach delves progressively deeper, aiming to unveil the fundamental sources of issues.

What is the ideal team size for conducting a "5 Whys" analysis?

An optimal team size for 5 Whys analysis generally comprises 5 to 7 individuals to ensure a diverse range of perspectives and insights. However, the key determinant lies in assembling a group with the requisite expertise, knowledge, and direct relevance to the problem being addressed.

Can the "5 Whys" approach be used in non-business contexts?

Absolutely. The 5 Whys method can be seamlessly applied to non-business scenarios, ranging from personal problem-solving, family dynamics, community initiatives, to broader societal challenges. Its fundamental principle of drilling down to root causes transcends organizational boundaries, making it universally relevant.

How do you handle resistance to the findings of a "5 Whys" analysis?

Resilience to the findings of a 5 Whys analysis is a common occurrence. It is crucial to foster an environment of open dialogue and empathy, allowing dissenting viewpoints to be expressed and constructively addressed. Engaging skeptics in the validation process and demonstrating empirical evidence can help mitigate resistance.

What are the common challenges faced when implementing the "5 Whys" technique?

One of the primary challenges during 5 Whys implementation is the tendency to prematurely settle on a superficial cause, rather than delving deep enough to unearth the fundamental issue. Overcoming this requires persistence, critical thinking, and a commitment to rigorous exploration.

This meticulously crafted article provides a comprehensive understanding of the 5 Whys methodology, equipping readers with actionable insights to apply this powerful approach in diverse problem-solving contexts.

Lark, bringing it all together

All your team need is Lark

Explore More in Productivity Glossary

- The Power of 5 Whys to get Results

- Learn Lean Sigma

- Root Cause Analysis

The 5 Whys technique is a simple yet effective problem-solving method as part of the Root Cause Analysis (RCA) tool kit that involves asking “why” five times to identify the root cause of a problem. The 5 Whys technique was created by Toyota founder Sakichi Toyoda to enhance the effectiveness and efficiency of the company’s manufacturing processes. It is now applied in a variety of settings, including manufacturing, the service sector, and other businesses.

The method can be applied in a variety of situations, encourages teamwork and collaboration, and is simple to use. The 5 Whys technique can help organizations increase efficiency, and productivity, reduce waste and reduce costs by locating and addressing the root causes of issues.

Table of Contents

What is the 5 whys technique.

The 5 Why technique is a problem-solving method that involves repeatedly asking “why” five times to determine the source of a problem. “Why-why analysis” is another term that is sometimes used to describe the 5 Why technique. It was initially created by Sakichi Toyoda, the company’s founder, as a way to enhance the effectiveness and efficiency of the business’s manufacturing processes.

How it works:

- Identify the problem that you want to solve. Make sure to clearly define the problem and understand its impact on your organization or project.

- Ask “why” five times to get to the root cause of the problem. For each “why,” come up with a possible cause of the problem. You may need to do some research or gather data to help identify the causes of the problem.

- Keep asking “why” until you reach a root cause that can be addressed or resolved. The root cause is the underlying cause of the problem that can be addressed or resolved to prevent the problem from recurring in the future.

- Come up with a solution to the root cause. Once you have identified the root cause of the problem, brainstorm possible solutions to address it. Choose the best solution based on its effectiveness, feasibility, and impact.

- Implement the solution. Put your chosen solution into action and monitor the results to ensure that the problem has been effectively resolved.

Below is an example of how the 5 Whys technique can be applied to problems:

We were able to identify the issue’s root cause, a lack of communication regarding the maintenance schedule—and identify a fix using the 5 Whys method (posting the schedule in a visible location). This solution addresses the root cause of the issue, which is likely to be more effective than just treating the problem’s symptoms (equipment failures).

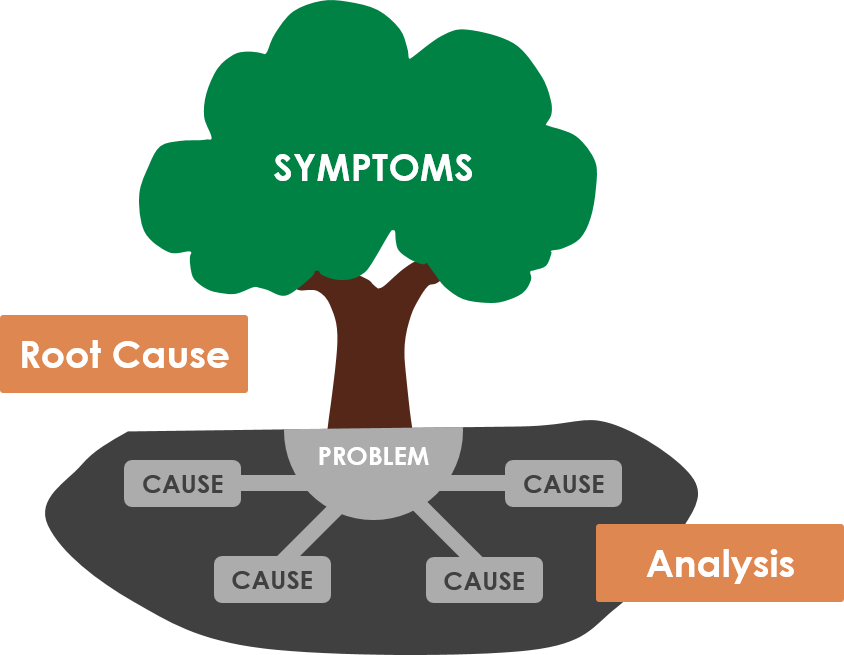

Symptom vs Root Cause

A problem or issue reveals itself physically as a symptom. Although it is the result or effect that is seen, it does not always reveal what the root cause of the issue is.

For example, a strange noise coming from a car’s engine is a sign that something is wrong. Although it is the problem’s obvious indication, it does not always provide information about its root cause. The leading cause of the issue could be anything from a loose belt to an engine component that is broken.

The root cause, on the other hand, started the problem in the first place. It is the underlying reason the issue is occurring. Finding and fixing a problem’s root cause can help prevent it from happening again in the future.

A loose belt, for instance, might be to blame for an odd noise coming from a car’s engine. The immediate issue might be resolved if we simply replace the belt, but the underlying issue (the loose belt) will still not be resolved. The issue will probably recur if the root cause is not addressed.

It’s important to differentiate between symptoms and root causes because, in the long run, dealing with a problem’s root cause is most often more effective and efficient than dealing with its symptoms alone. We can stop the issue from occurring again and potentially save time and resources in the long run by locating and addressing the root cause.

Why is the 5 Whys technique so effective?

There are many benefits to using 5 Whys that make it so effective:

Simple to Use by anyone in the business: 5 Why is one of the most simple tools to use in business to solve problems and can be done by anyone in the business. With some basic training supported by examples, anyone in the business can identify the root causes of problems and identify solutions; this does not require someone with years of experience or a Lean Six Sigma belt to master and benefit from using it.

It promotes a methodical method of problem-solving: The 5 Whys method promotes a methodical, step-by-step approach to problem-solving, which can help guarantee that all relevant factors are taken into account and that the problem’s root cause is found.

It can be used in a variety of situations: The 5 Why’s technique can be used to solve problems in a variety of contexts, including manufacturing, service industries, and other business settings.

It can increase productivity and efficiency: The 5 Whys technique can assist organisations in increasing productivity and efficiency while lowering waste and costs by identifying and addressing the root causes of issues.

It can identify unlikely root causes with ease: In many situations, the root cause may be obvious once you start the 5 Whys analysis, but that is not always the case. For example, with the Jefferson Memorial, the solution to stop the monument from eroding was not an obvious one. Example below:

The Jefferson Memorial was disintegrating. Why? because harsh chemicals are used to clean it.

Why are harsh chemicals used to clean it? to clean pigeon droppings.

Why are there so many pigeons at the memorial? Because the pigeons eat spiders and there are lots of spiders at the memorial.

Why are there so many spiders at the memorial? Because they eat insects, and there are a lot of insects at the memorial.

Why are there so many insects at the memorial? because they are attracted by the lights on the memorial at dusk.

Solution: Turn the lights on later in the evening. As you can see from this example, at first glance, it did not seem logical that turning the lights on later would have any relationship to stopping the memorial from disintegrating. The added benefit of this root cause analysis was also a cost saving in the lights being turned on later and a reduced cleaning cost. So the benefits also went above and beyond the initial expectations. Video for reference: YouTube Video Link

In conclusion, the 5 Whys technique is a useful tool for identifying and resolving the root causes of issues in an organisation. The technique works to get at the root of a problem rather than just treating its symptoms by asking “why” repeatedly. The 5 Whys method can be used in a variety of situations, is easy to apply, and encourages teamwork and collaboration. Organizations can increase effectiveness, and productivity, cut waste and lower costs by using the 5 Whys technique to solve problems. The 5 Whys technique is a useful and effective tool for problem-solving in any organisation.

- Card, A.J., 2017. The problem with ‘5 whys’. BMJ quality & safety , 26 (8), pp.671-677.

- Voehl, F., 2016. The 5 whys . The Innovation Tools Handbook , 2 .

- Benjamin, S.J., Marathamuthu, M.S. and Murugaiah, U., 2015. The use of 5-WHYs technique to eliminate OEE’s speed loss in a manufacturing firm . Journal of Quality in Maintenance Engineering , 21 (4), pp.419-435.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

Problem Solving using the 5 Whys

This post is also available in: German

The 5 Whys template is a simple, yet powerful tool used for root cause analysis. Based on the technique developed by Sakichi Toyoda , it takes an iterative approach to problem-solving. Starting with an initial problem statement, a question beginning with ‘why’ is asked 5 times in order to zero in on the root cause.

Along with the Fishbone Diagram , the 5 Whys template is a seminal technique for problem-solving through a deeper understanding of causal relationships. Let us understand this method in a little more detail. Or directly use the template .

What is the 5 Whys root cause analysis?

The 5 Whys problem-solving method was originally developed for Toyota Motor Corporation’s production facility. The technique starts with a single problem and asks a ‘why’ question based on the answer to the previous question.

The iterative process of asking ‘why’ ensures that each step is logically connected to the previous by a cause and effect relationship. Each ‘why’ takes you one step closer to finding the root cause.

5 Whys analysis in six sigma

Six sigma is all about waste reduction, process optimization and quality improvements. The simplicity of the 5 Whys method lends itself well to the analysis stage of six sigmas. Since the technique eschews complex statistical methods, individuals from across functions and departments can participate in the process. It’s a great technique for driving process improvements and ensuring past mistakes do not reoccur.

How to use the 5 Whys template

Since a 5 Whys session is in essence a brainstorming session, it is important to work with a whiteboard and sticky notes. Mapping out the process on an online whiteboard helps people better visualize what happened. Multiple stakeholders can work on Conceptboard’s collaborative template in real time and add their ideas on digital sticky notes . The template is completely editable.

Steps to using the 5 whys template

- Asking the right question – Before you embark on a 5 whys analysis, it is important to start with the right question. Here, a problem statement template can come in handy.

- Gather the right people – All key stakeholders and especially decision makers should be involved in the session.

- Assign a moderator – It is important for the moderator to drive the conversation, ensure each of the steps are followed and assumptions avoided

- Prepare the board in advance – Load the template by clicking the ‘+’ button and choosing ‘Insert template’. Drag and drop the 5 Whys template and share the board with the team.

- Add sticky notes and write down your comments for each round of the process.

- Once the analysis is complete, identify the action points and export the board as a PDF or print it out.

5 Whys Example

Here’s an example of the 5 Whys process and the solutions that came up from the analysis.

- Why was the hospital’s new health care app delayed by 4 weeks? Answer : Additional complexities were revealed in the testing phase.

- Why did additional difficulties come up? Answer : The creation phase did not include a solution for a major use case.

- Why did the creation phase miss a major use case? Answer : The original brainstorming sessions did not include employees from the department.

- Why were key employees missing from the brainstorming sessions? Answer : The brainstorming session was led by a particular department. In this case, additional departments were brought in later in the development process.

- Why is this process managed by a particular department? Answer : This is how it’s always been done.

Solutions found:

Create a new process that builds on the strengths of all departments and encourages interdepartmental collaboration. Ensure key employees from every department are present in all brainstorming sessions throughout all phases.

If you’ve like this template, we’ve also rounded up 15 of our favourite brainstorming techniques and templates that help you generate new ideas and drive innovation. For additional problem-solving templates, you can use our A3 problem-solving template . Also check out our list of retrospective ideas and templates you can use today with your team.

Use the free template with your team & customize as you go!

Use Template

More interesting articles for you

Unwrap the Joy: Elevate Your Team’s Holiday Spirit with Our Exclusive Christmas Game Template!

Wireframe Template – A structure to build something great | Free Template

The Complete Guide to Hybrid Employee Onboarding in 2023

2 comments . leave new.

I disagree with your statement “Six sigma is all about waste reduction, process optimization and quality improvements.”

Six-Sigma is all about “variation reduction” using statistical tools and techniques and pioneered by Motorola.

Lean is all about “Waste reduction” using Lean tools and techniques as part of Lean Manufacturing/the Toyota Production System developed by Toyota.

(1) The example solution is not a solution, it is the recognition that something new needs to happen, followed by requirements on how that is to be achieved.

(2) A single thread down (one answer per question) is insufficient for most difficult problems (i.e. ones that require a 5-why’s!) Each question will generate several answers, each of which is drilled down on. Then answers to different questions that are the same are linked into a lattice. If you are lucky it all comes together into a single item at the bottom of the diagram. One ends up with several dominant threads from top to leaf nodes, each of which has to be dealt with.

(3) The 5-why’s identifies several possibly independent causes. These must be dealt with using a problem solving method — which 5-why’s is not. It is a problem identification method.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Post Comment

Experience the power of visual collaboration

Experience how Conceptboard boosts your team’s hybrid collaboration and communication.

No credit card

No commitments

Start right now

5 Whys is the practice of asking why repeatedly whenever a problem is encountered in order to get beyond the obvious symptoms to discover the root cause.

For instance, Taiichi Ohno gives this example about a machine that stopped working (Ohno 1988, p. 17):

- Why did the machine stop? There was an overload and the fuse blew.

- Why was there an overload? The bearing was not sufficiently lubricated.

- Why was it not lubricated? The lubrication pump was not pumping sufficiently.

- Why was it not pumping sufficiently? The shaft of the pump was worn and rattling.

- Why was the shaft worn out? There was no strainer attached and metal scraps got in.

Without repeatedly asking why, managers would simply replace the fuse or pump and the failure would recur. The specific number five is not the point. Rather it is to keep asking until the root cause is reached and eliminated.

5 Whys Illustrated

When to Use the 5 Whys

Management should use the 5 Why problem-solving method with Gap from Standard problems. This is problem-solving that focuses on:

- specific problem definition

- setting goals

- root cause analysis

- establishment of countermeasures

- checks, standards, and follow-up activities

The aim is to prevent the problem from recurring by eliminating its underlying causes.

In general, there are three types of root-cause analysis:

- One-variable-at-a-time (OVAT)

- Multivariate-at-a-time (MVAT)

No advanced math skills are required for logic-based analysis such as 5 Whys. However, the ability to think critically, especially in terms of inductive logic (broad generalization from specific observation), deductive logic (general premise to specific conclusion), and abductive logic (general observation to hypothesis), is necessary.

Art of Lean on Problem-Solving Video Series with Art Smalley

Take a deep dive into problem-solving in this eight-part video series by expert Art Smalley.

- Coaching Problem-Solving

- Lessons from NBA Coaches

- Lessons from Martial-Arts

- Military and Science Leadership

- Tuckman’s Model of Team Formation

- Team-Building Tools and Practices

- Dreyfus Model and Stages of Learning

- Toyota Coaching Practices

Additional Resources

- Gemba Coach: 5 Whys

- Approaching Problem-Solving More Effectively

- Change Your “Pet” Problem-Solving Method

See: Kaizen ; Plan, Do, Check, Act (PDCA)

Privacy Overview

Worawut/Adobe Stock

By Jill Babcock Leaders Staff

Jill Babcock

Personal Development Writer

Jillian Babcock is a personal development writer for Leaders Media. Previously, she was a senior content writer at Ancient Nutrition,...

Learn about our editorial policy

Aug 8, 2023

Reviewed by Hannah L. Miller

Hannah L. Miller

Senior Editor

Hannah L. Miller, MA, is the senior editor for Leaders Media. Since graduating with her Master of Arts in 2015,...

The Power of the Five Whys: Drilling Down to Effectively Problem-Solve

What is the “5 whys” method, the power of asking “why”, when the 5 whys should be used, how to utilize the 5 whys technique, five whys examples, other ways of improving problem-solving.

It’s a fact of life that things don’t always go according to plan. When facing mistakes or challenges, asking “why”—especially if you do it repeatedly—can help uncover deeper layers of understanding so you can identify potential solutions.

The question “why” can be used in problem-solving as a powerful technique that helps us dig deeper, challenge assumptions, and think critically. After all, if you’re not sure why a problem exists in the first place, it’s very difficult to solve it.

The “Five Whys” method (also called “5 Whys Root Cause Analysis”) can specifically help in examining beliefs, behaviors, and patterns to shine a light on areas for improvement. The Five Whys have other benefits too, including encouraging collaboration and communication since this strategy promotes open dialogue among team members or partners. It also helps generate effective and lasting solutions that can prevent similar issues from resurfacing in the future.

In this article, learn how to use the Five Whys to save yourself or your company from wasting time and money and to address important issues at their source before they escalate.

The “Five Whys” is a technique commonly used in problem-solving to find the root causes of problems . This type of analysis can be applied to various situations, including within companies and relationships, to gain deeper insights and understandings of challenges and obstacles. The method involves “drilling down” by repeatedly asking “why”—typically five times or more—to get to the underlying causes or motivations behind a particular issue. Overall, it’s a way to figure out causes and effects related to a situation so that solutions can be uncovered.

“Effective problem solving can help organizations improve in every area of their business, including product quality, client satisfaction, and finances.” Jamie Birt , Career Coach

Here are a few reasons why asking “why,” or practicing the Five Whys, is important in problem-solving:

- Identifies underlying issues and root causes: Repeatedly asking “why” helps peel back the layers of a problem to get closer to the heart of what’s not working well. The goal is to define the real issue at hand to address its underlying causes. Understanding root causes is crucial because it enables you to address issues at their source rather than simply dealing with surface-level effects.

- Promotes critical thinking: Critical thinking refers to the process of objectively and analytically evaluating information, arguments, or situations. To engage in critical thinking and analysis, we need to ask “why,” usually over and over again. This encourages us to develop a more nuanced understanding of a problem by evaluating different factors, examining relationships, and considering different perspectives. Doing so helps lead to well-reasoned judgments and informed decisions.

- Uncovers assumptions: The opposite of assuming something is remaining open-minded and curious about it. Albert Einstein once said , “The important thing is not to stop questioning. Curiosity has its own reason for existing.” Asking “why” prompts you to challenge preconceived notions you may not even realize you have. Often, we make assumptions about a problem or its causes without having all the information we need. By gaining a fresh perspective, we can consider alternative solutions.

- Generates insights: The Five Whys can lead to valuable discoveries and potential fixes by uncovering hidden connections. These insights can guide us toward innovative solutions that prevent similar problems from worsening or happening again.

“Curiosity has been identified as a characteristic of high-performing salespeople, and having a tool and system that fosters curiosity in your team is extremely helpful.” Alexander Young, Forbes

Any time a problem needs to be clarified and solved, the Five Whys can help. This flexible technique can be adapted to different situations, including personal and professional ones. For example, it’s useful when there are complications within businesses that are causing a loss of profits or when arguments occur among family members or partners. Eric Ries from Harvard Business Review points out that start-ups can especially benefit from the Five Whys to test and refine procedures, ideas, products, and processes.

To get the most out of the Five Whys, include people with personal knowledge of the problem, processes, and systems involved in the analysis, such as employees and customers. This means that if a leadership team, for example, wants to use the Five Whys to improve customer engagement, actual customers and customer service representatives would be ideal people to include in the discussion.

Here are examples of situations in which the Five Whys can be utilized:

- Troubleshooting business processes or operations issues, such as delivery or customer service concerns.

- Identifying the reasons behind personal challenges or recurring problems, such as disputes between bosses and employees.

- Analyzing project failures or setbacks, such as missed deadlines, to find underlying causes.

- Understanding customer complaints or dissatisfaction to improve products or services.

- Improving communication, teamwork, and client relationships.

Sakichi Toyoda (1867–1930) was a Japanese inventor and industrialist known for his business ventures, including founding the Toyota Motor Corporation. Toyoda is credited with developing the Five Whys method in the 1930s, which he used to support continuous improvement within his companies .

For example, within Toyota Production System (TPS), key goals included eliminating waste, improving efficiency, and ensuring quality. Toyoda used the Five Whys to identify problems within his company and to find ways to resolve them to improve production and customer satisfaction. He once stated , “By repeating why five times, the nature of the problem as well as its solution becomes clear.”

“The beauty of the [Five Whys] tool is in its simplicity. Not only is it universally applicable, it also ensures that you don’t move to action straight away without fully considering whether the reason you’ve identified really is the cause of the problem.” Think Design

The Five Whys works by drilling down to a main underlying cause. The answer to the first “why” should prompt another “why,” and then the answer to the second “why” should continue to prompt more “whys” until a root cause is identified.

Follow these steps to implement the Five Whys:

1. Identify the Initial Problem: Clearly define the problem you want to address. Be specific, such as by including details that help with the analysis. Make sure to clearly articulate the issue by breaking it down into smaller components to ensure everyone involved has a thorough understanding of the situation.

2. Ask “Why?”: Start by asking why the problem occurred. Answer your own question. The answer becomes the basis for the next “why” question.

3. Repeat the Process Five or More Times: Continue asking “why” about the previous answer, iterating at least five times or until you reach a point where the root cause of the problem becomes apparent.

4. Analyze and Take Action: Once you have identified the root cause, analyze potential solutions and take appropriate action.

Here’s a template that you can use to make the process simple:

Problem Statement: (One sentence description of the main problem)

- Why is the problem happening? (Insert answer)

- Why is the answer above happening? (Insert answer)

Root Cause(s)

To test if the root cause is correct, ask yourself the following: “If you removed this root cause, would this problem be resolved?”

Potential Solutions:

List one or more ways you can resolve the root cause of the problem.

The Five Whys method is not a rigid rule but rather a flexible framework that can be adjusted based on the complexity of the problem. You may need to ask “why” only three times or more than five times, such as 7 to 9 times, to nail down the main underlying cause. It’s not the exact amount of “whys” you ask that matters, more so that you’re really investigating the situation and getting to the root of the issue.

Here are two examples of how the Five Whys technique can be used to problem-solve:

Example 1: Machine Breakdown

- Problem Statement: A machine in a manufacturing facility keeps breaking down.

- Why did the machine break down? The motor overheated.

- Why did the motor overheat? The cooling system failed.

- Why did the cooling system fail? The coolant pump malfunctioned.

- Why did the coolant pump malfunction? It wasn’t properly maintained.

- Why wasn’t the coolant pump properly maintained? There was no regular maintenance schedule in place.

- Root Cause: The lack of a regular maintenance schedule led to the coolant pump malfunction and subsequent machine breakdown.

- Solution: Implement a scheduled maintenance program for all machines to ensure proper upkeep and prevent breakdowns.

Example 2: Orders Not Being Fulfilled On Time

- Problem Statement: The order fulfillment process in an e-commerce company is experiencing delays.

- Why are there delays in the order fulfillment process? The warehouse staff is spending excessive time searching for products.

- Why are they spending excessive time searching for products? The products are not organized efficiently in the warehouse.

- Why are the products not organized efficiently? There is no standardized labeling system for product placement.

- Why is there no standardized labeling system? The inventory management software does not support it.

- Why doesn’t the inventory management software support a labeling system? The current software version is outdated and lacks the necessary features.

- Root Cause: The use of outdated inventory management software lacking labeling functionality leads to inefficient product organization and delays in the order fulfillment process.

- Solution: Upgrade the inventory management software to a newer version that supports a standardized labeling system, improving product organization and streamlining the order fulfillment process.

“Great leaders are, at their core, great problem-solvers. They take proactive measures to avoid conflicts and address issues when they arise.” Alison Griswold , Business and Economics Writer

Problem-solving is a skill that can be developed and improved over time. The Five Whys method is most effective when used in conjunction with other problem-solving tools and when utilized in a collaborative environment that encourages open communication and a willingness to honestly explore underlying causes. For the method to work well, “radical candor” needs to be utilized, and constructive feedback needs to be accepted.

Here are other strategies to assist in problem-solving, most of which can be used alongside the Five Whys:

- Gather and analyze information: Collect relevant data, facts, and information related to the problem. This could involve conducting research, talking to experts, or analyzing past experiences. Examine the information you’ve gathered and identify patterns, connections, and potential causes of the problem. Look for underlying factors and consider both the immediate and long-term implications.

- Have a brainstorming session: Collaborate with colleagues, seek advice from experts, or gather input from stakeholders. Different perspectives can bring fresh ideas. Gather a group of teammates and get out a whiteboard and a marker. Create a list of opportunities or problems and potential solutions. Encourage creativity and think outside the box. Consider different perspectives and approaches.

- Draw a cause-and-effect diagram: Make a chart with three columns, one each for challenges, causes, and effects. Use this to come up with solutions, then assess the pros and cons of each potential solution by considering the feasibility, potential risks, and benefits associated with each option.

- Develop an action plan: Once you’ve selected the best solution(s), create a detailed action plan. Define the steps required to implement the solution, set timelines, and then track your progress.

Want to learn more about problem-solving using critical thinking? Check out this article:

Use Critical Thinking Skills to Excel at Problem-Solving

Leaders Media has established sourcing guidelines and relies on relevant, and credible sources for the data, facts, and expert insights and analysis we reference. You can learn more about our mission, ethics, and how we cite sources in our editorial policy .

- American Institute of Physics. Albert Einstein Image and Impact . History Exhibit. https://history.aip.org/exhibits/einstein/ae77.htm

- Indeed. 5 Whys Example: A Powerful Problem-Solving Tool for Career Development. Indeed Career Guide. https://www.indeed.com/career-advice/career-development/5-whys-example