A Survey of 3D Printing Technologies as Applied to Printed Electronics

Ieee account.

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Featured Topics

Featured series.

A series of random questions answered by Harvard experts.

Explore the Gazette

Read the latest.

Early warning sign of extinction?

So much for summers of love

Are you a human? Select all that apply.

In this 3D printing process, the little dot of blue light triggers a chemical reaction that makes the resin harden into plastic.

Credit: Tracy H. Schloemer and Arynn O. Gallegos

Making 3D printing truly 3D

Juan Siliezar

Harvard Staff Writer

Researchers from Rowland Institute eliminate need for 2D layering

Don’t be fooled by the name. While 3D printers do print tangible objects (and quite well), how they do the job doesn’t actually happen in 3D, but rather in regular old 2D.

Working to change that is a group of former and current researchers from the Rowland Institute at Harvard.

First, here’s how 3D printing works: The printers lay down flat layers of resin, which will harden into plastic after being exposed to laser light, on top of each other, again and again from the bottom to the top. Eventually, the object, such as a skull , takes shape. But if a piece of the print overhangs, like a bridge or a wing of a plane, it requires some type of flat support structure to actually print, or the resin will fall apart.

The researchers present a method to help the printers live up to their names and deliver a “true” 3D form of printing. In a new paper in Nature, they describe a technique of volumetric 3D printing that goes beyond the bottom-up, layered approach. The process eliminates the need for support structures because the resin it creates is self-supporting.

“What we were wondering is, could we actually print entire volumes without needing to do all these complicated steps?” said Daniel N. Congreve, an assistant professor at Stanford and former fellow at the Rowland Institute, where the bulk of the research took place. “Our goal was to use simply a laser moving around to truly pattern in three dimensions and not be limited by this sort of layer-by-layer nature of things.”

The key component in their novel design is turning red light into blue light by adding what’s known as an upconversion process to the resin, the light reactive liquid used in 3D printers that hardens into plastic.

In 3D printing, resin hardens in a flat and straight line along the path of the light. Here, the researchers use nano capsules to add chemicals so that it only reacts to a certain kind of light — a blue light at the focal point of the laser that’s created by the upconversion process. This beam is scanned in three dimensions, so it prints that way without needing to be layered onto something. The resulting resin has a greater viscosity than in the traditional method, so it can stand support-free once it’s printed.

“We designed the resin, we designed the system so that the red light does nothing,” Congreve said. “But that little dot of blue light triggers a chemical reaction that makes the resin harden and turn into plastic. Basically, what that means is you have this laser passing all the way through the system and only at that little blue do you get the polymerization, [only there] do you get the printing happening. We just scan that blue dot around in three dimensions and anywhere that blue dot hits it polymerizes and you get your 3D printing.”

The researchers used their printer to produce a 3D Harvard logo, Stanford logo, and a small boat, a standard yet difficult test for 3D printers because of the boat’s small size and fine details like overhanging portholes and open cabin spaces.

The researchers, who included Christopher Stokes from the Rowland Institute, plan to continue developing the system for speed and to refine it to print even finer details. The potential of volumetric 3D printing is seen as a game changer, because it will eliminate the need for complex support structures and dramatically speed up the process when it reaches its full potential. Think of the “replicator” from “Star Trek” that materializes objects all at once.

But right now, the researchers know they have quite a ways to go.

“We’re really just starting to scratch the surface of what this new technique could do,” Congreve said.

Share this article

You might like.

Fossil record stretching millions of years shows tiny ocean creatures on the move before Earth heats up

Despite ‘hippie’ reputation, male bonobos fight three times as often as chimps, study finds

Philosopher Barba-Kay on CAPTCHA dilemma, Aristotle’s good life, and how the internet is changing us — not for the better

So what exactly makes Taylor Swift so great?

Experts weigh in on pop superstar's cultural and financial impact as her tours and albums continue to break records.

Exercise cuts heart disease risk in part by lowering stress, study finds

Benefits nearly double for people with depression

Do phones belong in schools?

Banning cellphones may help protect classroom focus, but school districts need to stay mindful of students’ sense of connection, experts say.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 18 August 2020

3D bioprinting of cells, tissues and organs

- Madhuri Dey ORCID: orcid.org/0000-0002-9523-8083 1 , 2 &

- Ibrahim T. Ozbolat 2 , 3 , 4 , 5

Scientific Reports volume 10 , Article number: 14023 ( 2020 ) Cite this article

54k Accesses

145 Citations

14 Altmetric

Metrics details

- Experimental models of disease

- Regeneration

- Tissue engineering

3D bioprinting has emerged as a promising new approach for fabricating complex biological constructs in the field of tissue engineering and regenerative medicine. It aims to alleviate the hurdles of conventional tissue engineering methods by precise and controlled layer-by-layer assembly of biomaterials in a desired 3D pattern. The 3D bioprinting of cells, tissues, and organs Collection at Scientific Reports brings together a myriad of studies portraying the capabilities of different bioprinting modalities. This Collection amalgamates research aimed at 3D bioprinting organs for fulfilling demands of organ shortage, cell patterning for better tissue fabrication, and building better disease models.

The discovery of a 3D printer dates back to early 1980s when Charles Hull, an American engineer, built the 1st 3D printer, capable of creating solid objects by following a computer-aided design (CAD). The printer deposited successive layers of an acrylic-based photopolymer which was then simultaneously crosslinked by UV light, thus creating a solid 3D object. This simple technology, called stereolithography (SLA), revolutionized the additive manufacturing industry. Gradually, by the late 1990s, 3D printing made its appearance in healthcare where surgeons began 3D printing dental implants, custom prosthetics, and kidney bladders. Subsequently the term ‘3D bioprinting’ emerged where the material being printed, called ‘bioink’ 1 , consisted of living cells, biomaterials, or active biomolecules. Analogous to additive manufacturing, 3D bioprinting involves layer-by-layer deposition of bioink to create 3D structures, such as tissues and organs 2 .

3D bioprinting can be broadly categorized as either extrusion 3 , droplet 4 , or laser-based bioprinting. Extrusion based bioprinting employs mechanical, pneumatic or solenoid dispenser systems to deposit bioinks in a continuous form of filaments, while droplet based bioprinting relies on the generation of bioink droplets by thermal, acoustic or electrical stimulation. Laser based bioprinting utilizes laser power to 3D print structures such as in SLA by a photopolymerization principle. It can also be used for precise positioning of cells such as in laser direct-write and Laser Induced Forward Transfer (LIFT). The selection of “bioinks” for each of these different bioprinting modalities usually varies based on the ink’s rheology, viscosity, crosslinking chemistry, and biocompatibility. Extrusion based bioprinting primarily requires shear thinning bioinks while droplet or inkjet bioprinting needs materials with low viscosity. Over the past few years, the design and synthesis of bioinks has evolved to meet the increasing needs of new bioprintable materials. Significant advancements have also been made to integrate secondary techniques accompanying the above-mentioned modalities of bioprinting. For example, creating 3D structures with low viscosity bioinks has always been a challenge. To overcome this issue, such bioinks can now be extruded in a granular support bath containing yield stress hydrogels which solidify around the extruded structure and prevent it from collapsing 5 . Apart from organ printing, bioprinting is also being used to fabricate in-vitro tissue models for drug screening, disease modelling, and several other in-vitro applications.

The 3D bioprinting of cells, tissues and organs Collection at Scientific Reports is dedicated to this field of research. This collection clearly portrays the diverse applications of different bioprinting modalities and how they could be utilized for improving various aspects of healthcare. Kim et al. 3D printed a novel two-layered polycaprolactone (PCL) -based tubular tracheal graft 6 . This tracheal graft, seeded with induced pluripotent stem cell (iPSC) -derived mesenchymal (MSCs) and chondrocyte stem cells supported the regeneration of tracheal mucosa and cartilage in a rabbit model of a segmental tracheal defect. Galarraga et al. used a norbornene-modified hyaluronic acid (NorHA) macromer as a representative bioink for cartilage tissue engineering 7 . Printed structures containing MSCs, on long term culture, not only led to an increase in compressive moduli, but also expressed biochemical content similar to native cartilage tissue. Vidal et al. used 3D printed customized calcium phosphate scaffolds with and without a vascular pedicle to treat large bone defects in sheep 8 . They used CT angioscan to scan the entire defect site and subsequently 3D print a personalized scaffold to anatomically fit the defect site. A bioink comprising decellularized matrix from mucosal and muscular layers of native esophageal tissues was used by Nam et al. to mimic the microenvironment of native esophagus 9 . Leucht et al. used gelatin based bioinks to study vasculogenesis in a bone-like microenvironment 10 . Kilian et al. used a calcium phosphate cement (CPC) and an alginate-methylcellulose based bioink containing primary chondrocytes to mimic the different layers of osteochondral tissue 11 .

This special issue also contains three notable research articles on the patterning of cells—two utilizing acoustics, and one, magnetism. Even though bioprinting enables the homogenous distribution of cells representing the macro-architectural properties, it lacks control of the tissue micro-architecture such as orientation of cells within the bioprinted constructs. Chansoria and Shirwaiker delved deep into the physics of ultrasound-assisted bioprinting (UAB) that utilizes the acoustophoresis principle to align MG63 cells within single and multi-layered extrusion-bioprinted alginate constructs 12 . Cells were aligned both orthogonally and in parallel to the printed filaments, thus mimicking cellular anisotropy in tissues such as ligaments, tendons, and cardiac muscle. Similarly, Sriphutkiat et al. used acoustic excitation to align skeletal myoblast cells (C2C12) and human umbilical vein endothelial cells (HUVECs) encapsulated in methacrylated gelatin (GelMA) bioink 13 . Goranov et al. magnetically labelled MSCs and HUVECs, and aligned them in a magnetic scaffold to mimic vascularization of bone constructs 14 .

It is important to note that the applications of 3D bioprinting are not limited to organ printing. It also holds great promise in less explored avenues, such as using scaffolds for drug delivery, studying disease mechanisms, or creating personalized medicines. In this Collection, Lee et al. 3D printed a rifampicin loaded PCL scaffold for possible treatment of osteomyelitis 15 . Xu and coworkers 3D printed paracetamol containing PVA tablets with three different geometries, each demonstrating different release profiles which could be tailored based on the patient's needs 16 . Further, Foresti et al. applied 5D additive manufacturing techniques to create personalized models of patients’ pathology 17 . Ding, Illsley and Chang 3D bioprinted GelMA-based models to investigate the trophoblast cell invasion phenomenon, enabling studies of key placental functions 18 .

Additionally, there are other notable articles in this Collection enumerating different aspects of bioprinting. Afghah et al. used a Pluronic-nanoclay based composite support bath to bioprint representative structures, for complex and hollow tissues, using cell laden alginate hydrogel 19 . Zhao et al. developed a 3D printed hanging drop dripper system for analyzing tumor spheroids in-situ 20 . Yumoto et al. performed RNA-seq analysis on inkjet-printed cells to analyze the effect of bioprinting on gene expression 21 . We would like to extend our utmost gratitude and thank all the authors and reviewers who devoted their time and effort towards this 3D bioprinting collection.

Even though 3D bioprinting is advancing at a commendable rate with researchers trying to develop new printing modalities as well as improve existing modalities, there still remains a multitude of challenges that need to be overcome. Currently, a limited number of bioinks exist which are both bioprintable and which accurately represent the tissue architecture needed to restore organ function post-printing. While bioinks made from naturally derived hydrogels are conducive to cell growth, synthetic hydrogels are mechanically robust. Thus, hybrid bioinks should be designed to amalgamate all these aspects. Moreover, the bioprinting process itself needs to be more cell-friendly. Shear stress applied to the cells during the printing process are detrimental to cell growth and might even alter the gene expression profiles. Stem cells, such as iPSCs, are sensitive to such physical forces and usually do not survive the printing process. As stem cell studies have mostly been performed on 2D environments, there exists a lot of unknowns for a 3D stem cell culture. Effective techniques need to be developed for high throughput generation and bioprinting of organoids 22 for personalized drug testing and predictive disease models. Additionally, vascularization of bioprinted constructs for proper nutrient exchange, as well as integration of printed vasculature with host vasculature post organ implantation, is another major obstacle. Overall, 3D bioprinting is a rapidly evolving field of research with immense challenges, but tremendous potential to revolutionize modern medicine and healthcare.

Hospodiuk, M., Dey, M., Sosnoski, D. & Ozbolat, I. T. The bioink: a comprehensive review on bioprintable materials. Biotechnol. Adv. 35 , 217–239 (2017).

PubMed CAS Google Scholar

Ozbolat, I. T. 3D Bioprinting: Fundamentals, Principles and Applications (Elsevier Inc., Amsterdam, 2016).

Google Scholar

Ozbolat, I. T. & Hospodiuk, M. Current advances and future perspectives in extrusion-based bioprinting. Biomaterials 76 , 321–343 (2016).

Gudapati, H., Dey, M. & Ozbolat, I. A comprehensive review on droplet-based bioprinting: past, present and future. Biomaterials 102 , 20–42 (2016).

Heo, D. N. et al. 3D bioprinting of carbohydrazide-modified gelatin into microparticle-suspended oxidized alginate for the fabrication of complex-shaped tissue constructs. ACS Appl. Mater. Interfaces 12 , 20295–20306 (2020).

Kim, I. G. et al. Transplantation of a 3D-printed tracheal graft combined with iPS cell-derived MSCs and chondrocytes. Sci. Rep. 10 , 1–14 (2020).

Galarraga, J. H., Kwon, M. Y. & Burdick, J. A. 3D bioprinting via an in situ crosslinking technique towards engineering cartilage tissue. Sci. Rep. 9 , 1–12 (2019).

Vidal, L. et al. Regeneration of segmental defects in metatarsus of sheep with vascularized and customized 3D-printed calcium phosphate scaffolds. Sci. Rep. 10 , 1–11 (2020).

ADS Google Scholar

Nam, H. et al. Multi-layered free-form 3D cell-printed tubular construct with decellularized inner and outer esophageal tissue-derived bioinks. Sci. Rep. 10 , 1–14 (2020).

Leucht, A., Volz, A. C., Rogal, J., Borchers, K. & Kluger, P. J. Advanced gelatin-based vascularization bioinks for extrusion-based bioprinting of vascularized bone equivalents. Sci. Rep. 10 , 1–15 (2020).

Kilian, D. et al. 3D Bioprinting of osteochondral tissue substitutes-in vitro-chondrogenesis in multi-layered mineralized constructs. Sci. Rep. https://doi.org/10.1038/s41598-020-65050-9 (2020).

Article PubMed PubMed Central Google Scholar

Chansoria, P. & Shirwaiker, R. Characterizing the process physics of ultrasound-assisted bioprinting. Sci. Rep https://doi.org/10.1038/s41598-019-50449-w (2019).

Sriphutkiat, Y., Kasetsirikul, S., Ketpun, D. & Zhou, Y. Cell alignment and accumulation using acoustic nozzle for bioprinting. Sci. Rep. 9 , 1–12 (2019).

ADS CAS Google Scholar

Goranov, V. et al. 3D patterning of cells+in magnetic scaffolds for tissue engineering. Sci. Rep. https://doi.org/10.1038/s41598-020-58738-5 (2020).

Lee, J. H. et al. Development of a heat labile antibiotic eluting 3D printed scaffold for the treatment of osteomyelitis. Sci. Rep. 10 , 1–8 (2020).

Xu, X., Zhao, J., Wang, M., Wang, L. & Yang, J. 3D printed polyvinyl alcohol tablets with multiple release profiles. Sci. Rep. https://doi.org/10.1038/s41598-019-48921-8 (2019).

Foresti, R. et al. In-vivo vascular application via ultra-fast bioprinting for future 5D personalised nanomedicine. Sci. Rep. 10 , 3205 (2020).

ADS PubMed PubMed Central CAS Google Scholar

Ding, H., Illsley, N. P. & Chang, R. C. 3D bioprinted GelMA based models for the study of trophoblast cell invasion. Sci. Rep. 9 , 1–13 (2019).

Afghah, F., Altunbek, M., Dikyol, C. & Koc, B. Preparation and characterization of nanoclay-hydrogel composite support-bath for bioprinting of complex structures. Sci. Rep. 10 , 1–13 (2020).

Zhao, L. et al. A 3D printed hanging drop dripper for tumor spheroids analysis without recovery. Sci. Rep. 9 , 1–14 (2019).

Yumoto, M. et al. Evaluation of the effects of cell-dispensing using an inkjet-based bioprinter on cell integrity by RNA-seq analysis. Sci. Rep. 10 , 1–10 (2020).

Ayan, B. et al. Aspiration-assisted bioprinting for precise positioning of biologics. Sci. Adv. 6 , eaaw5111 (2020).

ADS PubMed PubMed Central Google Scholar

Download references

Author information

Authors and affiliations.

Department of Chemistry, Penn State University, University Park, PA, 16802, USA

Madhuri Dey

The Huck Institutes of the Life Sciences, Penn State University, University Park, PA, 16802, USA

Madhuri Dey & Ibrahim T. Ozbolat

Engineering Science and Mechanics Department, Penn State University, University Park, PA, 16802, USA

Ibrahim T. Ozbolat

Biomedical Engineering Department, Penn State University, University Park, PA, 16802, USA

Materials Research Institute, Penn State University, University Park, PA, 16802, USA

You can also search for this author in PubMed Google Scholar

Contributions

M.D. wrote the manuscript. I.T.O. reviewed and edited the manuscript.

Corresponding author

Correspondence to Ibrahim T. Ozbolat .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Dey, M., Ozbolat, I.T. 3D bioprinting of cells, tissues and organs. Sci Rep 10 , 14023 (2020). https://doi.org/10.1038/s41598-020-70086-y

Download citation

Published : 18 August 2020

DOI : https://doi.org/10.1038/s41598-020-70086-y

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Spheroid construction strategies and application in 3d bioprinting.

- Chunxiang Lu

- Yuanyuan Liu

Bio-Design and Manufacturing (2024)

3D Printing Technology in the Pharmaceutical and Biomedical Applications: A Critical Review

- Nahid Tyagi

- Vipul Bhardwaj

- Gaurav Sharma

Biomedical Materials & Devices (2024)

Infantile hemangioma models: is the needle in a haystack?

Journal of Translational Medicine (2023)

Fully 3D-printed organic electrochemical transistors

- Matteo Massetti

- Silan Zhang

- Simone Fabiano

npj Flexible Electronics (2023)

3D and 4D Bioprinting Technologies: A Game Changer for the Biomedical Sector?

- Reza Noroozi

- Zia Ullah Arif

- Xiongbiao Chen

Annals of Biomedical Engineering (2023)

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing: Translational Research newsletter — top stories in biotechnology, drug discovery and pharma.

- Reference Manager

- Simple TEXT file

People also looked at

Original research article, a 3d printing short course: a case study for applications in the geoscience teaching and communication for specialists and non-experts.

- Reservoir Geomechanics Research Group, Civil and Environmental Engineering Department, University of Alberta, Edmonton, AB, Canada

3D printing developed as a prototyping method in the early 1980s, yet it is considered as a 21st century technology for transforming digital models into tangible objects. 3D printing has recently become a critical tool in the geoscience research, education, and technical communication due to the expansion of the market for 3D printers and materials. 3D printing changes the perception of how we interact with our data and how we explain our science to non-experts, researchers, educators, and stakeholders. Hence, a one-day short course was designed and delivered to a group of professors, students, postdoctoral fellows, and technical staff to present the application of 3D printing in teaching and communication concepts in the geoscience. This case study was aimed at evaluating how a diverse group of participants with geoscience and engineering background and no prior experience with computer-aided modeling (CAD) or 3D printing could understand the principles of different 3D printing techniques and apply these methods in their respective disciplines. In addition, the course evaluation questionnaire allowed us to assess human perception of tangible and digital models and to demonstrate the effectiveness of 3D printing in data communication. The course involved five modules: 1) an introduction lecture on the 3D printing methods and materials; 2) an individual CAD modeling exercise; 3) a tour to 3D printing facilities with hands-on experience on model processing; 4) a tour to experimentation facilities where 3D-printed models were tested; and 5) group activities based on the examples of how to apply 3D printing in the current or future geoscience research and teaching. The participants had a unique opportunity to create a digital design at the beginning of the course using CAD software, analyze it and 3D print the final model at the end of the course. While this course helped the students understand how rendering algorithms could be used as a learning aid, educators gained experience in rapid preparation of visual aids for teaching, and researchers gained skills on the integration of the digital datasets with 3D-printed models to support societal and technical objectives.

Introduction

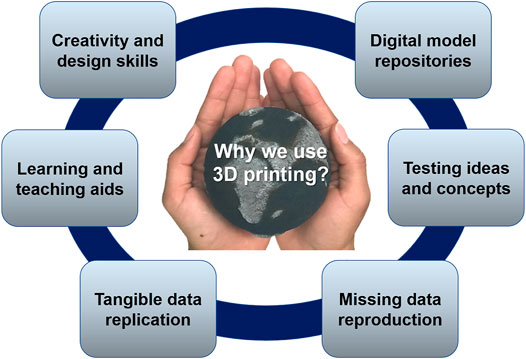

3D printing is a 21st century technology for transforming digital models into physical objects. This technology is rapidly evolving, with more access to 3D printing machines and materials ( Wohlers Report, 2019 ). This is an innovative tool in medical ( Baden et al., 2015 ) and biomedical sciences ( Hoy, 2013 ), engineering ( Meyers et al., 2016 ; Boyajian et al., 2020 ), and communication ( Baden et al., 2015 ; Malmström et al., 2020 ). 3D printing revolutionizes how we interact with our data and how we explain our science to non-experts ( Horowitz and Schultz, 2014 ). Creating repeatable, tangible models is emerging in the geoscience education and research as well as in the related industries, such as petroleum recovery, groundwater storage, and carbon dioxide sequestration ( Ishutov et al., 2018 ). One of the biggest advantages of 3D printing is that all the processes involved in the creation of a 3D object, from generating the design to obtaining the printed part, facilitate the learning of concepts and tools, which also develops creativity and communication skills. Earth science data are often modeled in 3D, and 3D printers can provide this 3D visualization and tangible aspect of digital data ( Figure 1 ).

FIGURE 1 . Major benefits of using 3D printing in geosciences. It is useful for developing creativity and design skills through 3D modeling. 3D printing is a convenient tool for rapid manufacture of learning and teaching aids. Any 2D or 3D model can be replicated for a better communication, especially among non-specialists. Any digital data can be reproduced with 3D printing, even if the physical sample does not exist anymore. Research ideas and concepts can be repeatedly tested on the 3D-printed samples. All data can be retrieved or repeated from the digital repositories, which include files of 3D-printed models.

3D printing or so-called additive manufacturing of an object involves deposition of a material layer by layer ( Squelch, 2017 ). Therefore, this technology enables manufacturing models in various sizes and proportions (e.g., small objects can be printed large, so that more details are visible or large objects can be scaled down, so that one can hold the planet in the hand). Sustainable learning through a tangible approach is critical for understanding of complex geologic ideas, where learners can collect, gather and evaluate information about the exterior of the model and internal structures ( Szulżyk-Cieplak et al., 2014 ). Moreover, the same model can be used to communicate these ideas to others, including non-experts in a technical subject ( Dadi et al., 2014 ). 3D printing is essential for commination with impaired people, especially students who require special needs for education ( Kostakis et al., 2015 ; Jo et al., 2016 ; Pantazis and Priavolou, 2017 ; Koehler et al., 2018 ). In the Earth science curriculum, those students can learn common topics such as volcanoes or plate tectonics by using 3D-printed models in the classroom or at home. Buehler et al. (2016) demonstrates an example of a short course for students with intellectual disabilities in an inclusive context that results in enhancing digital literacy skills and reducing stigmas about these individuals at a community level.

Application of 3D printing in high-school education has already shown enhanced haptic perception of the learning material. Elrod (2016) emphasized that if 3D printing would be used in the K-12 environment, students could be better prepared for careers in emerging fields of technology [e.g., science, technology, engineering, and mathematics (STEM disciplines)]. Schelly et al. (2015) demonstrated that even a 3-day short course for middle- and high-school teachers from a variety of disciplines (sciences, engineering, and arts) gained a high interest in utilizing this technology in their classrooms. Chiu et al. (2015) presented a successful model for learning, self-learning, and mastery learning approaches for freshman students with different levels of technological literacy using 3D printers. Reggia et al. (2015) suggested that providing engineering students with an opportunity to perform a project-based design course using 3D printing was an essential curricular element in many engineering programs. Chien and Chu (2018) proposed that 3D printing could enable high-school students to improve their ability to transform from STEM to STEAM (science, technology, engineering, arts, and mathematics) using 3D printers and to create a bridging curriculum with respect to high-school and college students.

Roy and Brine (2017) developed a coursework model to build intellectual capital for the next generation who would vastly depend on 3D printing, because they would shape a smart community in both developing and developed economy context. Martin et al. (2014) explained an idea of “think globally, produce locally,” where 3D printing would become more affordable with the versatility of machines and the ability to engage students with many different STEM-based activities. Gatto et al. (2015) showed that engineering education is on the course of adapting to the social and industrial revolution brought by additive manufacturing, because the latter allowed for sharing digital data in repositories and repeatedly reproducing the data to test ideas and concepts ( Figure 1 ).

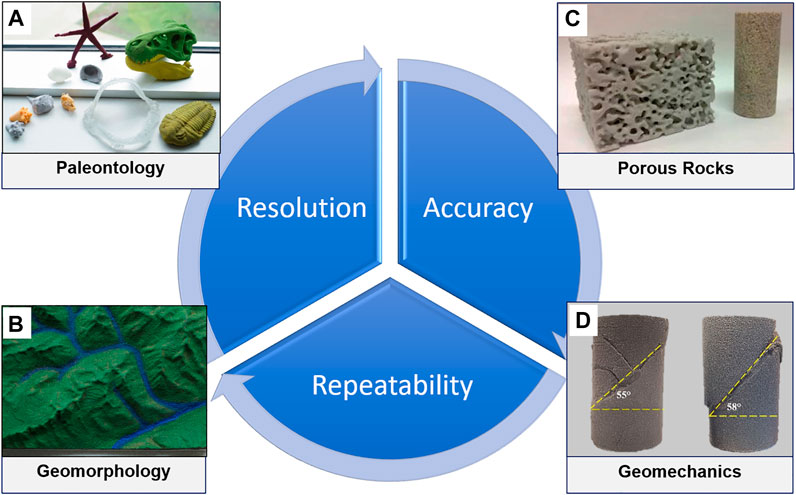

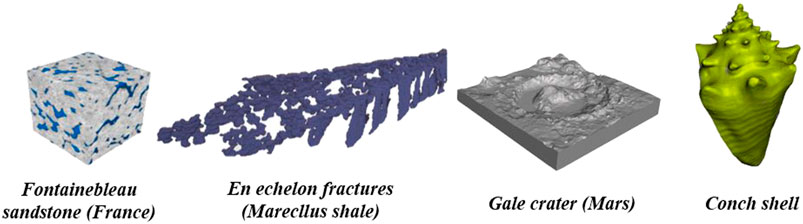

For the geoscience education, not many examples are found in the literature for using 3D printing in any full-time curriculum or short courses. Ford and Minshall (2019) demonstrate how teaching models of terrains, fossils, and mineral crystals can complement digital models for a better perception of 3D features. 3D printing is currently used in four geoscience areas, primarily for research and communication: paleontology, geomorphology, porous rocks, geomechanics ( Figure 2 ). These 3D-printed models help organizing a full description, classification, and preservation of geologic specimens. Resolution of 3D printers determines the accuracy of internal and external features of 3D-printed models and hence affects the repeatability of the digital design in different materials ( Figure 2 ). These characteristics are critical not only for creating teaching aids in the Earth Science curriculum, but also for conducting experimental research with 3D-pritned specimens ( Ishutov et al., 2018 ). 3D printing also has value for communication of geoscience to non-specialist audiences to convey technical information, to support legal arguments, and to provide general knowledge of the nature. Currently, there is no universal short course that can provide fast, but positive learning experience of digital modeling and 3D printing to understand and explain geologic concepts among both experts and generalists.

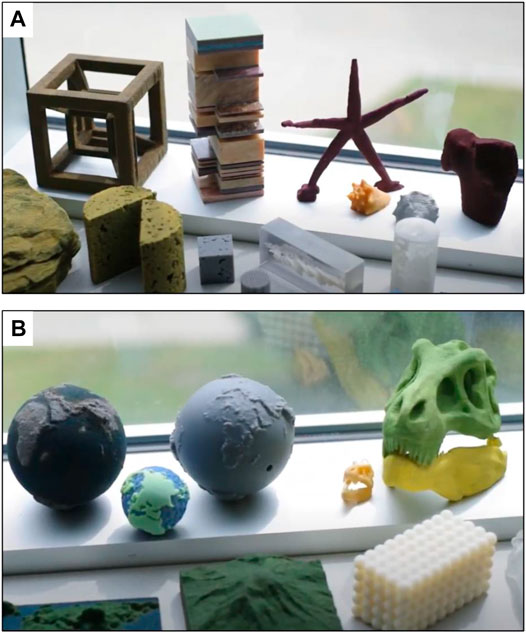

FIGURE 2 . Applications of 3D printing in the geoscience research areas: (A) paleontology, (B) geomorphology, (C) porous rocks, and (D) geomechanics. A blue chart indicates the characteristics of 3D-printed models that are critical for each of the geoscience areas. Materials used in a specific application have different physical and chemical properties, which affect the resolution of a 3D-printed model. 3D printer’s hardware and post-processing of 3D-printed models determine the accuracy of external and internal features. A combination of the three previous characteristics affects the repeatability of a digital design 3D-printed in multiple copies.

This course was developed to test how a group of participants from STEM disciplines, but with various academic backgrounds could perceive the fundamentals of available 3D printing techniques and materials and their relative merits. With little or no prior knowledge of CAD modeling and 3D printing, participants learnt about applications of 3D printing in studies of reservoir rocks ( Squelch 2017 ), fossils ( Rahman et al., 2012 ), geomechanics ( Hodder et al., 2018 ), geomorphology ( Hasiuk and Harding, 2016 ), and porous media ( Ishutov, 2019 ). This one-day short course was divided into five modules and involved students, postdoctoral fellows, technicians, and professors interested in current advances of 3D printing in research and teaching. In addition, participants explored the application of 3D printing in a technical communication. The objectives of the study included: 1) to evaluate if learners with versatile educational and cultural backgrounds could perceive the basic concepts of 3D printing techniques and material properties to provide an assessment of 3D-printed models for research in their respective discipline; 2) to test if fast learning of CAD modeling and 3D printing could help the participants utilize 3D-printed models to explain geologic concepts to generalist audiences; and 3) to prove that 3D-printed models were effective tools for the geoscience education.

Materials and Methods

The short course was designed for the participants without prior experience of CAD modeling or 3D printing. In addition, the course was open for students, professors, postdoctoral fellows, technicians, and research associates from the geoscience and engineering disciplines. The short course took place at the University of Alberta, Edmonton, Canada and involved 50 participants. The course learning outcomes were: 1) to understand capabilities and limitations of different 3D printing techniques; 2) to demonstrate how to digitally design 3D-printable models using CAD software, web platforms, and computed tomography data; 3) to provide the assessment of digital models and their relative replicas 3D-printed from real data; and 4) to characterize how 3D printing can increase the effectiveness of teaching and data communication.

Course Organization and Materials

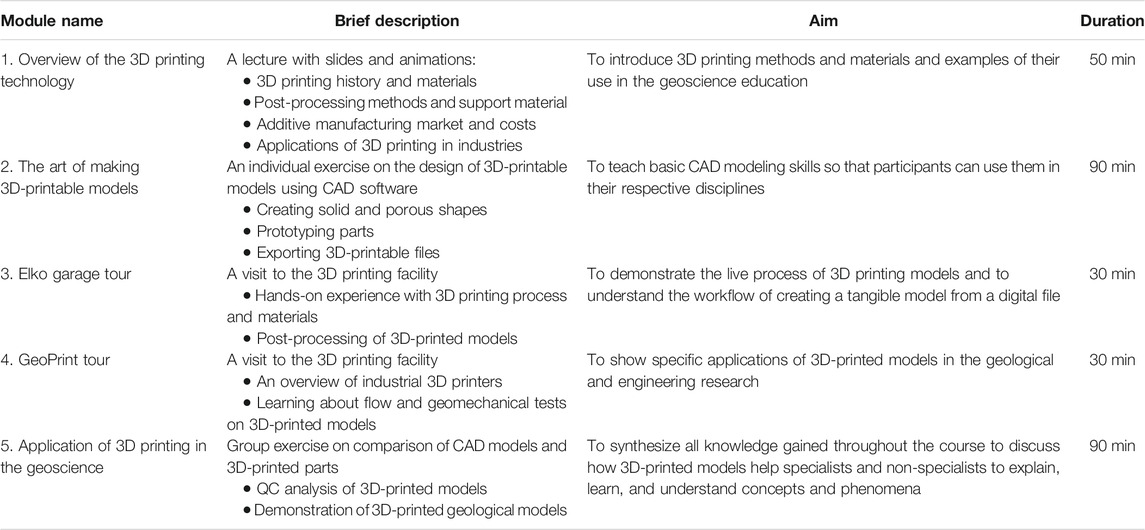

The short course was organized in five modules: 1) an introduction lecture on the 3D printing methods and materials; 2) an individual CAD modeling exercise; 3) a tour to 3D printing facilities with hands-on experience on model processing; 4) a tour to experimentation facilities where 3D-printed models are tested; and 5) group activities based on the examples of how to apply 3D printing in current or future geoscience research and teaching ( Table 1 ). Each module was taught by one of the four instructors, and facility tours were led by four instructors, two instructors per facility. All instructions on how to complete each module were organized in a digital e-book (pdf).

TABLE 1 . A brief description of topics covered in each module of the short course.

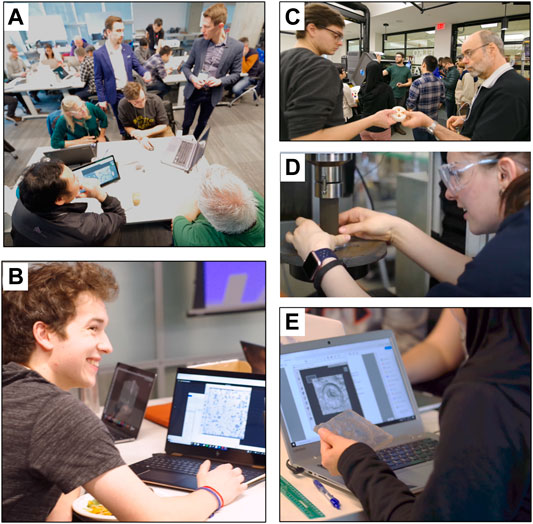

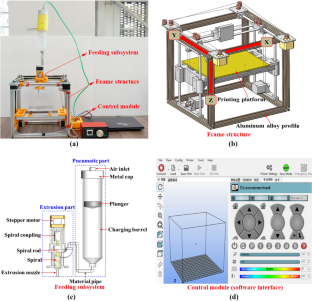

Module 1 included a lecture on the history of “rapid prototyping” and how 3D printing evolved as a tool for engineering industries. In addition, the workflow of creating a digital model and transferring it into a tangible object was covered. The model preparation for 3D printing was explained with examples of using printing specifications, such as the thickness of each layer, the vertical and horizontal dimensions, and the print speed. The lecture also contained post-processing methods, such as ultraviolet (UV) light curing or removal of support material that held the internal porous structure and external elements during printing to avoid deformation or damage of intricate designs. Instructors discussed 3D printing methods that differed by power source, resolution, precision, accuracy, build volume, materials, and price. The importance and applications of 3D-printed models were covered briefly for the areas of geoscience and engineering. At the end of the lecture, participants had a discussion session with instructors ( Figure 3A ).

FIGURE 3 . Photographs of the short course modules. (A) Module 1 “Overview of the 3D printing technology.” Course instructors presented a lecture on common additive manufacturing methods and materials and showed examples of 3D-printed models. (B) Module 2 “The art of making 3D-printable models.” Participants learned basic skills of CAD modeling using TinkerCAD. (C) Module 3 “Elko Garage Tour.” Live 3D printing process was shown to participants. (D) Module 4 “GeoPrint Tour.” Participants were shown industrial scale printing and experimental program performed with 3D-printed models. (E) Module 5 “Application of 3D printing in the geoscience.” Discussion of specific applications of geoscience models in edication and research.

Module 2 involved an individual CAD modeling exercise using an online platform on laptops or tablets ( Figure 3B ). The scale of 3D-printed models varied over the orders of magnitude: from nanometer-size features to the size of the 3D printer’s build volume. This activity was aimed at teaching the participants to create complex geological models (like rocks and fossils) using common shapes (e.g., cylinders, cubes) or multi-scale elements, which were then translated for 3D printing. At the end of this exercise, participants were able to export their model of choice for 3D printing and receive at the end of the course.

Module 3 represented a tour to the Elko Engineering Garage (University of Alberta, Edmonton, Canada) that introduced the participants to the activities associated with creating and 3D printing digital designs as well as post-processing of 3D-printed models ( Figure 3C ). Participants were exposed a variety of 3D printers and post-processing tools, as well as they had an opportunity to investigate a 3D laser scanner. Instructors made connections of the material covered in the lecture, such as material properties, 3D printing resolution, and model dimensions with the real applications in workspace. Participants were able to observe the 3D printing process of the digital models that they designed in module 2 and had a hands-on experience on post-processing their models to make give them a smooth, finished look.

Module 4 involved a visit to the GeoPRINT facility (University of Alberta, Edmonton, Canada), where an industrial-grade sand printer and a high-resolution stereolithography printer were located ( Figure 3D ). This tour introduced participants to two specific 3D printers used for geomechanical and flow research at Reservoir Geomechanics Research Group. Participants explored about the differences in material preparation, printing, and post-processing between these two technologies.

Module 5 included a group exercise on the comparison of CAD models for porous rocks, fossils and geomorphic features with their 3D-printed counterparts ( Figure 3E ). Participants assessed the differences in material finishes, accuracy of external and internal elements, and scales of 3D printing (using criteria in Figure 2 ). In addition, there was a discussion of potential application of 3D-printed models in the geoscience experiments to validate numerical simulations and complement existing laboratory tests. Instructors facilitated the discussion of 3D-printing techniques that participants have seen in modules 3 and 4 and how they could be applied to fundamental research in the areas of multi-phase fluid flow and reactive transport, discrete fracture networks, geomorphology, and paleontology ( Figure 3E ).

3D Printers and Software

Out of seven ASTM categories of 3D printing, four methods were shown in this short course: stereolithography, binder jetting, material extrusion, and material jetting. All 3D printers belonging to these categories were demonstrated in Modules 3 and 4. Materials used for demonstration of 3D printing techniques included polymers, plastics, sand, and resins.

The software used in module 2 for CAD modeling exercises was Autodesk TinkerCAD ( https://www.tinkercad.com ). It is a free online platform that requires only registration with email. The software used for processing of digital designs before 3D printing was Autodesk Meshmixer ( http://www.meshmixer.com ). It is a freeware that can be installed on most operating systems.

Post-Course Questionnaire

The course survey is proved to be one of the effective forms of analysis of the short course efficiency ( Chiu et al., 2015 ; Schelly et al., 2015 ; Meyers et al., 2016 ; Pantazis and Priavolou, 2017 ; Ford and Minshall, 2019 ; Assante et al., 2020 ). The surveys are usually conducted before and after the course to assess how learning objectives are fulfilled. In each module, the following criteria were used to build the course evaluation survey:

• fundamentals of 3D printing and its basic operating principles;

• advantages and disadvantages of 3D printing technologies;

• performance and functional constraints of 3D printing for specific applications.

• complete 3D-printing sequence of designing, fabricating, and measuring models;

• source of mismatch between digital and 3D-printed models.

• causes of errors and irregularities in 3D-printed models;

• hands-on experience of 3D printing in class for improved student understanding of subject matter.

• important 3D printing research challenges;

• resources to support experiments for teaching and classroom projects.

• understanding if humans learn better when using 3D-printed models;

• current and future 3D printing applications.

At the end of the course, instructors distributed an electronic evaluation form to all participants and asked them to complete it within 1 h. The questions in the survey were composed in a Google Docs form to allow for anonymous and individual response from each participant, who was required to indicate only their academic level. The post-course questionnaire was segmented into sections: 1) overall recommendation for the short course; 2) assessment of course materials (e-booklet, lecture slides, exercise instructions; 3) course content (cohesiveness of modules, ease of learning the material, laboratory tours, and visual aids); 4) time spent on each module; and 5) evaluation of instructors’ teaching abilities; 6) effectiveness of course learning outcomes. Section 1 responses were based on Yes/No scale. Responses in sections 2, 3, 5 were collected using the following scheme: strongly disagree, disagree, neutral, agree, and strongly agree. Responses in section 4 were registered using the following scheme: not enough, adequate, too much, no opinion. The last section was evaluated using Likert scale out of 5, where a higher value is a more positive response.

Results and Discussion

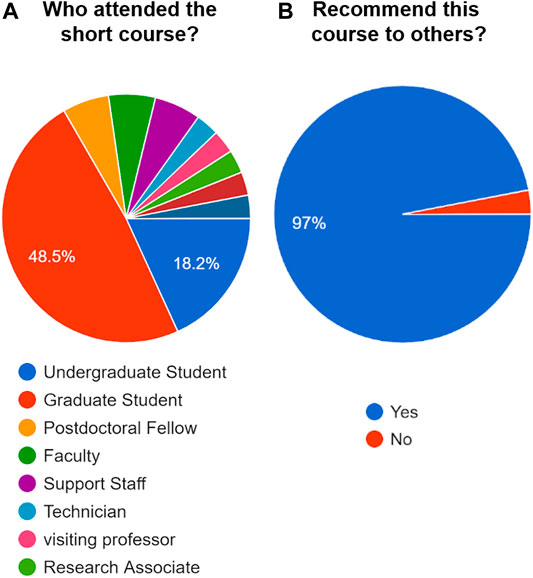

The short course involved 50 participants from geosciences and engineering ( Figure 4A ); it was expected to receive mixed comments about the course contents and organization of modules. Nonetheless, 97% of all participants responded that the course would be recommended to others ( Figure 4B ). In this case, others were referred to peer students, colleagues, and other academic staff. This outcome was positive to propose the course to various professional organizations as a customized workshop, e.g., for industry professionals interested in the use of 3D printing in research and technical communication. The instructors observed that despite the differences in age and academic background, the participants communicated with each other in a friendly manner. Based on the results of the post-course questionnaire, the short course outcomes were assessed for the adequacy and organization of the course materials, structure, and coherence of the course modules, and efficiency of the course instructors and learning objectives.

FIGURE 4 . Demographics of the short course participants. (A) Indication of the academic level and/or position. (B) Responses of participants from (A) to the question: “Will you recommend this short course to others?”

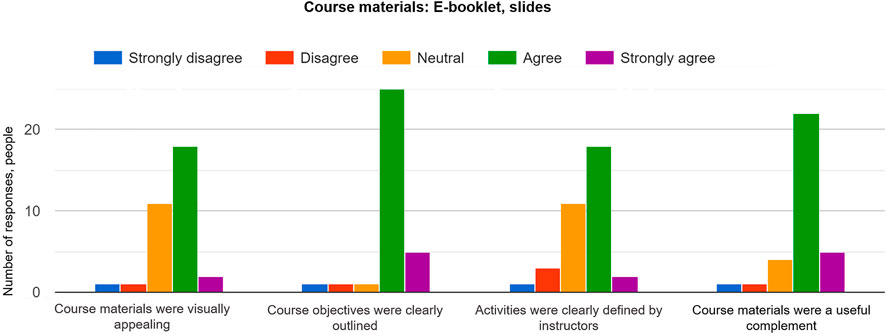

Course Materials

An e-book contained a set of short, descriptive instructions with images and figures about each module ( Figure 5 ) that was useful to most participants. Course objectives were clear, so that the short course agenda was understood by learners with different backgrounds (24 positive responses out of 32 responses in total). In addition, the survey showed that the e-book was a valuable component of the course as it helped navigating through activities and exercises (27 positive responses out of 33 responses in total). On the other hand, not all participants found the e-book visually appealing and suggested adding pseudo 3D cartoons that would visually simplify and outline different 3D printing processes (20 positive responses out of 33 responses in total; Figure 6 ). Other comments pointed out on the use of bolded text, underlining or different colors to highlight the key information in the e-book. Also, more than half of the class noted that activities were clearly defined by the instructors and suggested to include more details about the operation of software as numbered bullet points so there would be a step-by-step tutorial (21 positive responses out of 35 responses in total; Figure 6 ). A few additional notes were that the introductory lecture slides in module 1 were cohesive and well organized. For the next run of the course, instructors will prepare a short workflow with bullet points for each activity and exercise and will place them in the e-book as a support material. More images and snapshots will be added for each activity to allow the participants to navigate between the exercises.

FIGURE 5 . An example of the module instructions from the course e-book. The full version of the e-book was available for participants a day before the course. Each module contained synopsis and a set of exercises.

FIGURE 6 . Responses of participants for evaluation of the course materials, such as e-booklet and slides. All the course activities were described in the e-booklet provided on the short course day.

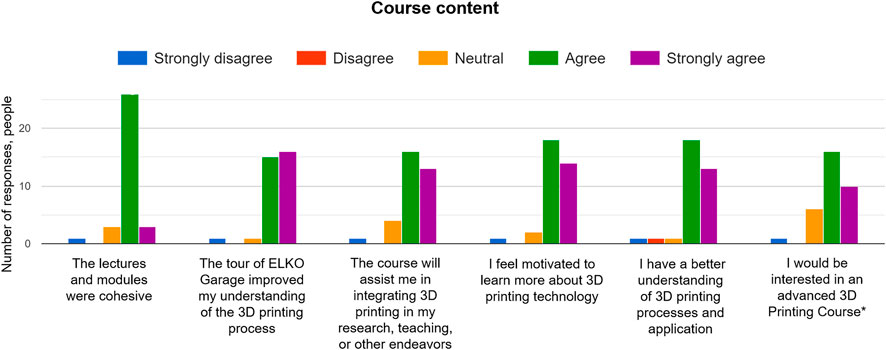

Course Content

The course content was developed using several approaches: lecture slides, individual exercises, group exercises, and facility tours. The majority of the class responded that modules were cohesive (29 positive responses out of 33 responses in total; Figure 7 ). Participants were mostly engaged during the visits to the Elko Garage and GeoPrint facilities (modules 3 and 4), because these tours improved their understanding of the 3D printing process (30 positive responses out of 32 responses in total). Observing the printing methods and interaction with 3D-printed models provided a motivation for the learners to incorporate this technology in their research, teaching, or other activities (29 positive responses out of 34 responses in total; Figure 7 ). In addition, the majority of participants could understand all aspects of digital design, processing, and post-processing of 3D-printed models via the CAD modeling exercise (module 2) (31 positive responses out of 34 responses it total). Instructors observed that even those participants who did not have any experience with digital modeling of simple shapes could learn it fast, because at the end of the exercise everyone was on the same level.

FIGURE 7 . Responses of participants for evaluation of the course content. Participants assessed each activity at the end of the short course. *A question about the advanced 3D printing course is whether participants would like to have a short course on the applications of 3D printing in their respective discipline (not geoscience).

The group exercise involving comparison of digital models with their 3D-printed counterparts and the discussion of applications in the geosciences (Module 5) was expected to be challenging, because the participants were divided into mixed groups of 10 people to avoid accumulating representatives of the same department and academic level in one group. E.g., one group might have consisted of two undergraduate students from civil engineering and geology, three professors from electrical engineering, computer engineering and geophysics, three postdoctoral fellows from mechanical engineering, and petroleum engineering, and two research associates from atmospheric science and computer science, respectively. Most of the class responded positively to such combination of groups, because it allowed them to share a broader spectrum of ideas given the versatility of backgrounds (32 positive responses out of 35 responses in total; Figure 7 ). Some participants responded that they would prefer to classify the groups by the department, so that they would share the same interest in 3D printing and might make the group work more cohesive. This model could be another option for the group activity, where the groups could be formed by the department only, but the course contents would need to be more general, rather than focusing on the geoscience and engineering applications.

Participants would also asked to have more group activities to share the knowledge learnt, which confirmed that this intentional split into mixed groups worked well for leaning the unknown concepts. A few people were not interested in the geoscience applications and would have liked to participate in the content related to their discipline only or in a more generic content. This was a viable comment, and more than half of the class responded that they would like to have an advanced 3D printing course to explore the applications in their relative subjects of interest (26 positive responses out of 30 responses in total; Figure 7 ). Perhaps a separate short course covering specific applications of 3D printing in STEM disciplines might be developed to satisfy this interest. The most expected comment was that participants were thinking of getting their own 3D printer to manufacture models for research, teaching, and communication.

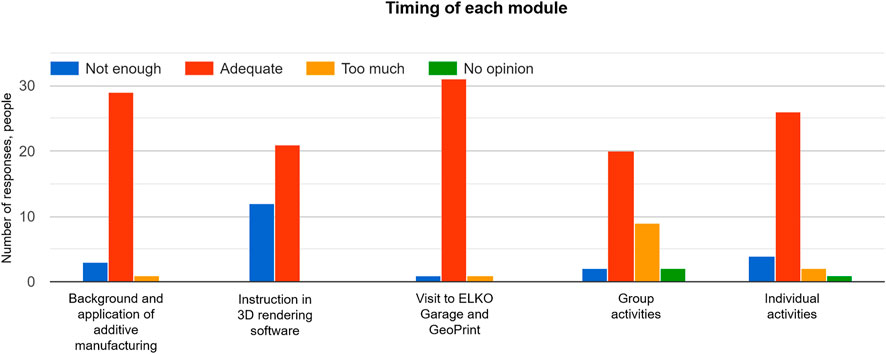

Each module had a different time period for completion, because it depended on the speed of the instructor’s delivery and the pace of participants ( Figure 8 ). It was designed to spend more time on individual and group exercises (Modules 2 and 5), so that the pace between the participants could be averaged as some people needed more time to learn new tools. In general, almost all learners (29 out of 33) agreed that the 50-min lecture in module 1 was sufficient to grasp the main concepts. Some participants (12 out of 33) noted that they would need more time to go through the functionalities of the software in Module 2 to complete the CAD exercises. In future, this module could be timed in a different way, where the participants would have an extensive, detailed introduction into the software and then they would be given a set of exercises to complete. Also, for those who could complete a mandatory set of exercises faster, additional activities would be provided. For the group exercises (module 5), about half of the class completed their assignments on time, while a quarter of the class felt that the time could be reduced ( Figure 8 ). To adjust this module, more exercises would be provided, specifically a small section discussing case studies in the geoscience.

FIGURE 8 . Responses of participants for evaluation of the time spent on each module of the short course.

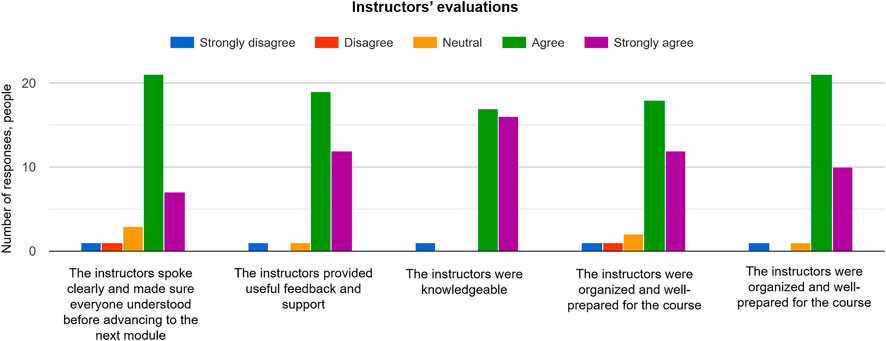

Efficiency of Instructors

The next set of questions in the survey was aimed at revealing any flaws in the style and structure of the instruction. It was found that the majority of the class was satisfied with the teaching style and delivery of the modules by instructors (28 positive responses out of 33 responses in total; Figure 9 ). One participant noted that it would be useful to have solutions for each exercise, mainly for the ones related to the group activity. The answers could not be compiled for each activity as they varied by the group and the amount of material covered in each case. A few participants would like to have more one-to-one communications with instructors, but it might not always possible, given the size of the class and time allocated for each activity. It is foreseen that the class size will be reduced to have more time assisting each participant in all activities, even though the majority of participants (31 out of 33; Figure 9 ) felt supported during the course.

FIGURE 9 . Responses of participants for evaluation of the instructors’ delivery of the short course.

The survey showed that instructors were knowledgeable (32 positive responses out of 33 responses in total) and well-prepared (30 positive responses out of 34 responses in total) for the course, which fulfilled the course objective of sustainable learning and communication through tangible models. It is confirmed that 3D printing promoted the curiosity among the learners and facilitated an interest in creation of a model simultaneously with the instructor. Developing creative potential entailed improving a problem-based approach to demonstrate theoretical concepts that could be accessible by different groups of participants. This short course demonstrated that diverse groups were able to assimilate, apply, and describe new knowledge more effectively, including collaborative and individual learning. There is a need in studying how these methods can complement traditional instruction in terms of retention of material and motivating learners to study and develop their communication and problem-solving skills.

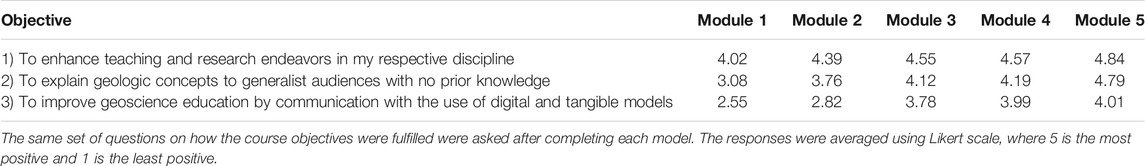

Efficiency of Learning Objectives

The course learning objectives were evaluated during interactive exercises of the course as well as post-course questionnaire. After completion of each module, participants were asked to complete the same set of three questions based on the course objectives. Their responses were averaged using Likert scale, where more positive responses were approaching 5 and less positive responses were approaching 1 ( Table 2 ). Participants were scoring how each of the three objectives was fulfilled when they completed modules subsequently. It was evident that more confidence was gained toward the end of the short course when all three course objectives were assessed (increasing scores from Module 1 to Module 5 in Table 2 ). While not all participants had geoscience background, collaborative learning is proven to be effective in enhancing creativity and hence enabling a large class to adopt the new technology. Post-course questionaries demonstrated that faculty, students, research fellows, and technicians could effectively work in teams to understand basic concepts of 3D printing techniques and material properties. They used this information to provide an assessment of 3D-printed models and to generate ideas for research in their respective disciplines.

TABLE 2 . Comparison of student responses on fulfilling the course learning objectives.

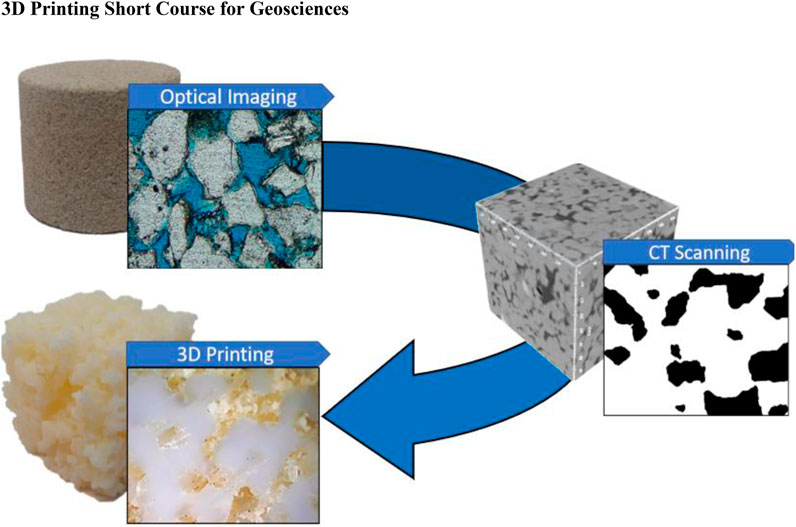

Individual CAD modeling exercise (module 2) helped the participants understand how geological and engineering models could be designed and utilized to explain ideas and concepts to generalist audiences. In module 5, instructors provided an example of 3D-printed porous rock created from a digital model ( Figure 10 ). All participants were asked to use this workflow to characterize how the rock porosity could have been formed and to explain why the rock grains had angular or rounded geometry and how they were transported to form a larger formation. Participants with a geoscience background were assessing responses of participants that did not have any background in the geoscience. It was noted that comparison of images, 3D digital models, and 3D-printed samples altogether provided better understanding of the rock properties rather than each model separately. Also. participants with good technical background in CAD within the team could help teaching other teammates, providing additional peer learning element in the process.

FIGURE 10 . Workflow for generation of 3D-printed samples from digital models. Source data are either optical or CT images of natural rocks (e.g., Berea sandstone). Images are segmented into pores and grains; the grain volume is transferred to 3D printing software as a CAD model. Selected 3D printer creates a tangible model layer-by-layer (polymer in this example). Pore space is filled with support material (soft polymer) that is removed by post-processing.

Module 5 was very useful for synthesizing previous modules and providing exercises linking CAD modeling from module 2 with 3D printing methods presented in module 1 and materials observed in modules 3 and 4. Participants were asked to choose one model for which both CAD and 3D-printed models were available ( Figure 11 ). Their task was to prepare a 1-min presentation of the model intended for general audience. The exercise was aimed at evaluating if 3D-printed models could improve geoscience learning for non-specialists. This collaborative learning approach demonstrated that expertise from students with different backgrounds could contribute to the cognitive process. Instead of learning under the instructions of tutors, participants collaboratively worked and learnt together. Participants noted that those teammates without geoscience background provided more intuitive and comprehensive description of selected models. It might be due to the fact that specialists could not often formulate higher-level explanation of concepts and phenomena.

FIGURE 11 . Examples of 3D-printed models used in course exercises. (A) Fossil and rock specimens. (B) Geomorphology and porous models.

Post-course questionnaire showed that 3D printing was an efficient tool in teaching and communication geological data and hypotheses to many types of diverse audiences. This study proved that non-specialists could learn, understand, and explain scientific concepts without prior knowledge about them. This finding is important because 3D printing can be used in many university curricula where students with any background can learn sciences in any environment. In particular, tangible aspect of 3D-printed models is vital for the geoscience education where most of the data are in a 3D format. Future development of the short course will involve several examples of non-geoscience data (e.g., engineering, medicine) to challenge participants in interpretation of concepts that are far beyond their expertise. This approach will help identifying if 3D-printed models are useful in communicating more complex phenomena to non-specialist audience.

3D printing is an emerging technology in the geoscience that provides additional teaching support, enhances technical communication using visual aids, and enables repeatable experimentation in research. While the process of incorporating this technology into the regular curriculum in academic institutions may take years, short courses can help this process by improving student and faculty engagement and by developing skills for a more qualitative knowledge acquisition. The short course presented in this study was useful for a diverse group of participants including professors, students, postdoctoral fellows, and technicians from the geoscience and engineering disciplines, because it allowed them to communicate geological concepts using digital models and their tangible counterparts. Participants demonstrated that this technology allowed them having the capacity for modification and sharing digital data and supporting educators who wanted to produce teaching models without prior expertise and in a rapid manner.

While this one-day short course had five modules, participants acknowledged that the time spent on each module was adequate as the modules contained the right amount of instructions and activities. It was designed in a way that participants would create their digital model, learn about different 3D printing techniques, observe how these techniques worked live and how 3D-printed models were experimented with in the laboratory, and finally 3D print their own model and discuss its properties. It was noted by the participants that course materials, such as e-booklet and slides with instructions, helped them digesting technical information in a cohesive way.

The main objectives of the short course was fulfilled, because the majority of participants responded that they would start using 3D printing for their research, teaching, or communication. Moreover, many participants had an interest in taking an advanced short course on the applications of this technology in their respective disciplines and to recommend this short course to others. Each module can certainly be modified and adjusted according to the background of the audience. This short course can be a primer for educators willing to introduce creative modeling in their teaching schedule and prepare students for problem-solving skills using tangible models. Making testable analogs of natural phenomena for the geoscience researchers is critical and can be achieved through acquiring CAD modeling skills in this course. Besides creating visual and teaching aids, this technology is a powerful tool in communication, as shown in the short course, because the participants with diverse academic backgrounds could discuss ideas and concepts without prior knowledge about them, only using 3D-printed models.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics Statement

Written informed consent was obtained from the relevant individuals for the publication of any potentially identifiable images or data included in this article.

Author Contributions

SI was the primary designer of the short course contents and the paper outline. He presented a poster at 2019 American Geophysical Union Conference on that study. SI developed exercises for the short course and prepared introduction and methods sections. KH developed presentation slides for the short course and wrote sections on results and discussion. RC was responsible for the introduction and conclusions. Figures were collected and analyzed by all authors. GZ-N was responsible for the lab tours.

The course was partially funded by MIP-CONACYT-280097 Grant, Mexico and NSERC 549236, Natural Sciences and Engineering Research Council of Canada. The funds covered the costs of 3D-printed models for participants of the short course.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

We would like to thank the University of Alberta and Faculty of Engineering for the opportunity to host this short course on campus. Our special gratitude is to the Elko Engineering Garage for providing a demonstration tour and 3D printing the short course models. We are grateful to the Reservoir Geomechanics Research Group [RG] 2 for support in preparation of this course. We also thank NSERC for support in continuous running of GeoPRINT GeoInnovation Environment at the Department of Civil and Environmental Engineering.

Assante, D., Cennamo, G. M., and Placidi, L. (2020). “3D Printing in Education: an European Prospective,” in Proceedings from the IEEE Global Engineering Education Conference (EDUCON) . Porto: Portugal , 1133–1138.

Google Scholar

Baden, T., Chagas, A. M., Gage, G., Marzullo, T., Prieto-Godino, L. L., and Euler, T. (2015). Open Labware: 3-D Printing Your Own Lab Equipment. Plos Biol. 13, e1002086. doi:10.1371/journal.pbio.1002086

PubMed Abstract | CrossRef Full Text | Google Scholar

Boyajian, M. K., Lubner, R. J., Roussel, L. O., Crozier, J. W., Ryder, B. A., and Woo, A. S. (2020). A 3D Printed Suturing Trainer for Medical Students. Clin. Teach. 17, 1–5. doi:10.1111/tct.13176

CrossRef Full Text | Google Scholar

Buehler, E., Comrie, N., Hofmann, M., McDonald, S., and Hurst, A. (2016). Investigating the Implications of 3D Printing in Special Education. ACM Trans. Access. Comput. 8, 1–28. doi:10.1145/2870640

Chien, Y.-H., and Chu, P.-Y. (2018). The Different Learning Outcomes of High School and College Students on a 3D-Printing STEAM Engineering Design Curriculum. Int. J. Sci. Math. Educ. 16, 1047–1064. doi:10.1007/s10763-017-9832-4

Chiu, P. H. P., Chiu Lai, K. W., Fan, T. K. F., and Cheng, S. H. (2015). “A Pedagogical Model for Introducing 3D Printing Technology in a Freshman Level Course Based on a Classic Instructional Design Theory,” in Proceedings From the IEEE Frontiers In Education Conference (FIE) . El Paso, TX, USA , 1–6. doi:10.1109/FIE.2015.7344287

Dadi, G. B., Goodrum, P. M., Taylor, T. R., and Maloney, W. F. (2014). Effectiveness of Communication of Spatial Engineering Information through 3D CAD and 3D Printed Models. Vis. Eng. 2, 114. doi:10.1186/s40327-014-0009-8

Elrod, R. E. (2016). Classroom Innovation through 3D Printing. Libr. Hi Tech. News , 33 (3), 5–7. doi:10.1108/LHTN-12-2015-0085

Ford, S., and Minshall, T. (2019). Invited Review Article: Where and How 3D Printing Is Used in Teaching and Education. Addit. Manuf. 25, 131–150. doi:10.1016/j.addma.2018.10.028

Gatto, A., Bassoli, E., Denti, L., Iuliano, L., and Minetola, P. (2015). Multi-disciplinary Approach in Engineering Education: Learning with Additive Manufacturing and Reverse Engineering. Rapid Prototyping J. 21, 598–603. doi:10.1108/RPJ-09-2014-0134

Hasiuk, F., and Harding, C. (2016). Touchable Topography: 3D Printing Elevation Data and Structural Models to Overcome the Issue of Scale. Geology. Today. 32, 16–20. doi:10.1111/gto.12125

Hodder, K. J., Nychka, J. A., and Chalaturnyk, R. J. (2018). Process Limitations of 3D Printing Model Rock. Prog. Additive Manufacturing 3, 172–182. doi:10.1007/s40964-018-0042-6

Horowitz, S. S., and Schultz, P. H. (2014). Printing Space: Using 3D Printing of Digital Terrain Models in Geosciences Education and Research. J. Geosci. Education. 62 (1), 138–145. doi:10.5408/13-031.1

Hoy, M. B. (2013). 3D Printing: Making Things at the Library. Med. Ref. Serv. Q. 32 (1), 93–99. doi:10.1080/02763869.2013.749139

Ishutov, S. (2019). Establishing Framework for 3D Printing Porous Rock Models in Curable Resins. Transp Porous Med. 129, 431–448. doi:10.1007/s11242-019-01297-9

Ishutov, S., Jobe, T. D., Zhang, S., Gonzalez, M., Agar, S. M., Hasiuk, F. J., et al. (2018). Three-dimensional Printing for Geoscience: Fundamental Research, Education, and Applications for the Petroleum Industry. Bulletin. 102, 1–26. doi:10.1306/0329171621117056

Jo, W., Hee, I., J., Harianto, R. A., So, J. H., Lee, H., Ju Lee, H., et al. (2016). Instead of Seeing and Hearing, Students Can Use Their Sense of Touch to Recognize the 3D Tactile Aids, Which Might Improve Their Learning and Memory Processes. J. Vis. Impairment Blindness. 110, 115–121. doi:10.1159/000390709

Koehler, K. E., Wild, T. A., and Tikkun, S. (2018). Implications of 3-D Printing for Teaching Geoscience Concepts to Students with Visual Impairments. J. Sci. Educ. Stud. Disabil. 2, 49–81. doi:10.14448/jsesd.10.0004

Kostakis, V., Niaros, V., and Giotitsas, C. (2015). Open Source 3D Printing as a Means of Learning: An Educational experiment in Two High Schools in Greece. Telematics Inform. 32, 118–128. doi:10.1016/j.tele.2014.05.001

Malmström, H., Enger, J., Karlsteen, M., and Weidow, J. (2020). Integrating CAD, 3D-Printing Technology and Oral Communication to Enhance Students' Physics Understanding and Disciplinary Literacy. Eur. J. Phys. 41, 065708. doi:10.1088/1361-6404/aba6bd

Martin, R. K., Bowden, N. S., and Merril, C. (2014). 3D Printing in Technology and Engineering Education. Technol. Eng. Teach. 73, 30–35. doi:10.1163/9789004415133_006

Meyers, K. L., Morgan, A. S., and Conner, B. P. (2016). 3D Printing to Introduce Design in a Cornerstone Project. Glob. J. Eng. Educ. 18, 22–29. doi:10.1007/978-1-4842-0946-2_2

Pantazis, A., and Priavolou, C. (2017). 3D Printing as a Means of Learning and Communication: The 3 Ducation Project Revisited. Telematics Inform. 34, 1465–1476. doi:10.1016/j.tele.2017.06.010

Rahman, I. A., Adcock, K., and Garwood, R. J. (2012). Virtual Fossils: a New Resource for Science Communication in Paleontology. Evo Edu Outreach 5, 635–641. doi:10.1007/s12052-012-0458-2

Reggia, E., Calabro, K., and Albrecht, J. (2015). “A Scalable Instructional Method to Introduce First-Year Engineering Students to Design and Manufacturing Processes by Coupling 3D Printing with CAD Assignments,” in Proceedings of the ASEE Annual Conference & Exposition . Seattle, WA . doi:10.18260/p.23447

Roy, D., and Brine, J. (2017). “3D Printing for Multidisciplinary Education: a Technology with Diverse Potential,” in Proceedings Of the INTED2017 Conference . Valencia, Spain . doi:10.21125/inted.2017.0039

Schelly, C., Anzalone, G., Wijnen, B., and Pearce, J. M. (2015). Open-source 3-D Printing Technologies for Education: Bringing Additive Manufacturing to the Classroom. J. Vis. Languages Comput. 28, 226–237. doi:10.1016/j.jvlc.2015.01.004

Squelch, A. (2017). 3D Printing Rocks for Geo-Educational, Technical, and Hobbyist Pursuits. Geosphere 14, 360–366. doi:10.1130/GES01364.1

Szulżyk-Cieplak, J., Duda, A., and Sidor, B. (2014). 3D Printers—New Possibilities in Education. Adv. Sci. Techn. Res. J. 8, 96–101. doi:10.12913/22998624/57510.12913/22998624/568

Wohlers Report (2019). 3D Printing and Additive Manufacturing. ISBN 978-0-9913332-5-7.

Keywords: 3D printing, learning aid, visualization, reservoir, porous rock, geomodeling, fossils, geomorphology

Citation: Ishutov S, Hodder K, Chalaturnyk R and Zambrano-Narvaez G (2021) A 3D printing Short Course: A Case Study for Applications in the Geoscience Teaching and Communication for Specialists and Non-experts. Front. Earth Sci. 9:601530. doi: 10.3389/feart.2021.601530

Received: 01 September 2020; Accepted: 13 May 2021; Published: 28 May 2021.

Reviewed by:

Copyright © 2021 Ishutov, Hodder, Chalaturnyk and Zambrano-Narvaez. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sergey Ishutov, [email protected]

This article is part of the Research Topic

3D Printing in Geology and Geophysics: A New World of Opportunities in Research, Outreach, and Education

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Adv Sci (Weinh)

- v.8(10); 2021 May

3D Tissue and Organ Printing—Hope and Reality

Assaf shapira.

1 Shmunis School of Biomedicine and Cancer Research, Faculty of Life Sciences, Tel Aviv University, Tel Aviv 6997801 Israel

2 Department of Materials Science and Engineering, Faculty of Engineering, Tel Aviv University, Tel Aviv 6997801 Israel

3 The Center for Nanoscience and Nanotechnology, Tel Aviv University, Tel Aviv 6997801 Israel

4 Sagol Center for Regenerative Biotechnology, Tel Aviv University, Tel Aviv 6997801 Israel

Three‐dimensional (3D) bioprinting is an emerging, groundbreaking strategy in tissue engineering, allowing the fabrication of living constructs with an unprecedented degree of complexity and accuracy. While this technique greatly facilitates the structuring of native tissue‐like architectures, many challenges still remain to be faced. In this review, the fruits of recent research that demonstrate how advanced bioprinting technologies, together with inspiring creativity, can be used to address these challenges are presented and discussed. Next, the future of the field is discussed, in terms of expected developments, as well as possible directions toward the realization of the vision of fully functional, engineered tissues, and organs. Last, a few hypothetical scenarios for the role 3D bioprinting may play in future tissue engineering are depicted, with an emphasis on its impact on tomorrow's regenerative medicine.

3D bioprinting is an emerging strategy in tissue engineering. While it greatly facilitates the structuring of tissue‐like architectures, many challenges still remain. Here, the fruits of the latest research that address these challenges are presented. The future of the field is then discussed and hypothetical scenarios for the role of 3D bioprinting in future tissue engineering and regenerative medicine are depicted.

1. Introduction

Since ancient times, humans have been fascinated by the unimaginable complexity of living creatures. The orchestrated function of multiple structures with incredible geometries ignited the imagination of our ancestors, making them raise existential questions. The invention of the microscope further enhanced this enthusiasm, revealing the existence of a new, concealed world of sophisticated, functional, tiny bio‐architectures. For medical experts and clinicians, however, these observations were accepted with an ambivalent feeling. On the one hand, they shed light on the mechanisms that support life with far‐reaching implications on medical care. On the other hand, they stressed the difficulties one may face while trying to regenerate such complicated, delicate systems. Nevertheless, the idea to artificially construct living tissues, or even whole organs, has never been abandoned, setting up the base for the rising field of tissue engineering (TE). The concept of TE is generally focused on the construction of acellular or cellularized patches that can be implanted alongside or instead of a damaged tissue, leading to regeneration of its hampered or lost function. To achieve an optimal therapeutic effect, the engineered patch is usually designed to mimic the native tissue in terms of the cellular, biochemical, mechanical, and structural features. [ 1 , 2 ] While numerous studies have demonstrated the feasibility of this concept, in the vast majority of these cases the structure of the engineered tissues is still considerably different from that of their native counterparts. This can be largely attributed to the fact that traditional fabrication methods do not provide an adequate capacity to precisely control the spatial positioning of the building materials. Moreover, while some forms of basic biostructures can be generated by spontaneous cellular organization processes, these are very difficult to control and manipulate. Given the high compositional and structural complexity of living tissues, a fabrication method capable of precisely depositing different materials and cells in pre‐defined locations in the 3D space is highly desirable. This capacity was introduced with the development of techniques for additive manufacturing (AM), commonly known as “3D printing.” [ 3 , 4 ]