- A Step-by-Step Guide to A3 Problem Solving Methodology

- Learn Lean Sigma

- Problem Solving

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies.

A3 Problem solving is a structured and systematic approach to problem-solving that originated with the lean manufacturing methodology. It visualizes the problem-solving process using a one-page document known as an A3 report. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner.

A3 Problem Solving has numerous advantages, including improved communication, better decision-making, increased efficiency, and reduced waste. It is a powerful tool for businesses of all sizes and industries, and it is especially useful for solving complex and multi-faceted problems.

In this blog post, we will walk you through the A3 Problem Solving methodology step by step. Whether you are new to A3 Problem Solving or simply want to improve your skills, this guide will help you understand and apply the process in your workplace.

Table of Contents

What is a3 problem solving.

A3 Problem Solving is a structured and systematic approach to problem-solving that makes use of a one-page document called an A3 report to visually represent the process. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner. The method was created within the framework of the Lean manufacturing methodology and is based on the principles of continuous improvement and visual management.

Looking for a A3 Problem solving template? Click here

Origin and History of A3 Problem Solving

A3 Problem Solving was developed by Toyota Motor Corporation and was first used in the manufacture of automobiles. The term “A3” refers to the size of the paper used to create the report, which is an ISO standard known as “A3”. The goal of the A3 report is to provide a visual representation of the problem-solving process that all members of the organisation can easily understand and share. A3 Problem Solving has been adopted by organisations in a variety of industries over the years, and it has become a widely used and recognised method for problem-solving.

Key Principles of A3 Problem Solving

The following are the key principles of A3 Problem Solving:

- Define the problem clearly and concisely

- Gather and analyze data to gain a deep understanding of the problem

- Identify the root causes of the problem

- Develop and implement effective solutions

- Evaluate results and continuously improve

These principles serve as the foundation of the A3 Problem Solving methodology and are intended to assist organisations in continuously improving and achieving their objectives. Organizations can effectively solve problems, identify areas for improvement, and drive results by adhering to these principles.

Step 1: Define the Problem

Importance of clearly defining the problem.

The first step in the A3 Problem Solving process is critical because it lays the groundwork for the remaining steps. To define the problem clearly and accurately, you must first understand the problem and identify the underlying root cause. This step is critical because if the problem is not correctly defined, the rest of the process will be based on incorrect information, and the solution developed may not address the issue effectively.

The significance of defining the problem clearly cannot be overstated. It aids in the collection and analysis of relevant data, which is critical for developing effective solutions. When the problem is clearly defined, the data gathered is more relevant and targeted, resulting in a more comprehensive understanding of the issue. This will enable the development of solutions that are more likely to be effective because they are founded on a thorough and accurate understanding of the problem.

However, if the problem is not clearly defined, the data gathered may be irrelevant or incorrect, resulting in incorrect conclusions and ineffective solutions. Furthermore, the process of collecting and analysing data can become time-consuming and inefficient, resulting in resource waste. Furthermore, if the problem is not accurately defined, the solutions developed may fail to address the root cause of the problem, resulting in ongoing issues and a lack of improvement.

Techniques for Defining the Problem

The first step in the A3 Problem Solving process is to clearly and accurately define the problem. This is an important step because a clearly defined problem will help to ensure that the appropriate data is collected and solutions are developed. If the problem is not clearly defined, incorrect data may be collected, solutions that do not address the root cause of the problem, and time and resources may be wasted.

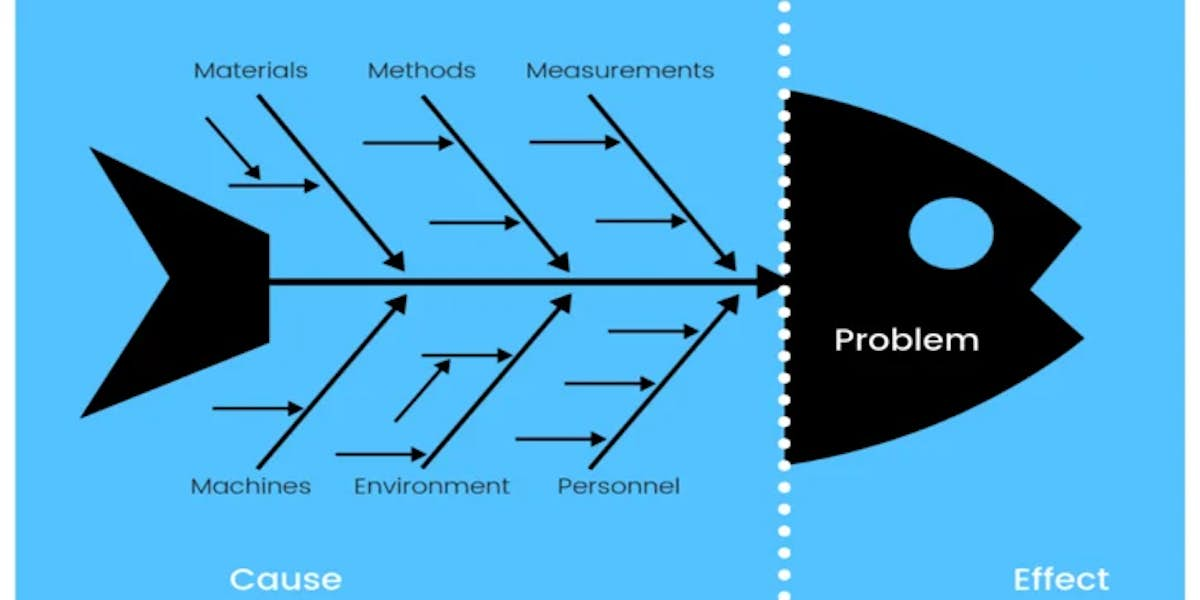

A problem can be defined using a variety of techniques, including brainstorming , root cause analysis , process mapping , and Ishikawa diagrams . Each of these techniques has its own advantages and disadvantages and can be used in a variety of situations depending on the nature of the problem.

Best Practice for Defining the Problem

In addition to brainstorming, root cause analysis, process mapping, and Ishikawa diagram s, best practices should be followed when defining a problem in A3 Problem Solving. Among these best practices are:

- Define the issue in a specific and quantifiable way: It is critical to be specific and concise when defining the problem, as well as to quantify the problem in terms of its impact. This will help to ensure that all stakeholders understand the problem and that data collection is focused on the right areas.

- Focus on the problem’s root cause: The A3 Problem Solving methodology is intended to assist organisations in identifying and addressing the root cause of a problem, rather than just the symptoms. Organizations can ensure that their solutions are effective and long-lasting by focusing on the root cause of the problem.

- Ascertain that all stakeholders agree on the problem’s definition: All stakeholders must agree on the definition of the problem for the A3 Problem Solving process to be effective. This ensures that everyone is working towards the same goal and that the solutions developed are relevant and appropriate.

- Consider the problem’s impact on the organisation and its stakeholders: It is critical to consider the impact of the problem on the organisation and its stakeholders when defining it. This will assist in ensuring that the appropriate data is gathered and that the solutions developed are relevant and appropriate.

Organizations can ensure that their problem is defined in a way that allows for effective data collection, analysis, and solution development by following these best practices. This will aid in the development of appropriate solutions and the effective resolution of the problem, resulting in improvements in the organization’s processes and outcomes.

Step 2: Gather Data

Gathering data in a3 problem solving.

Data collection is an important step in the A3 Problem Solving process because it allows organisations to gain a thorough understanding of the problem they are attempting to solve. This step entails gathering pertinent information about the problem, such as data on its origin, impact, and any related factors. This information is then used to help identify root causes and develop effective solutions.

One of the most important advantages of data collection in A3 Problem Solving is that it allows organisations to identify patterns and trends in data, which can be useful in determining the root cause of the problem. This information can then be used to create effective solutions that address the problem’s root cause rather than just its symptoms.

In A3 Problem Solving, data collection is a collaborative effort involving all stakeholders, including those directly impacted by the problem and those with relevant expertise or experience. Stakeholders can ensure that all relevant information is collected and that the data is accurate and complete by working together.

Overall, data collection is an important step in the A3 Problem Solving process because it serves as the foundation for effective problem-solving. Organizations can gain a deep understanding of the problem they are attempting to solve and develop effective solutions that address its root cause by collecting and analysing relevant data.

Data Collection Methods

In A3 Problem Solving, several data collection methods are available, including:

- Observations

- Process diagrams

The best data collection method will be determined by the problem being solved and the type of data required. To gain a complete understanding of the problem, it is critical to use multiple data collection methods.

Tools for Data Analysis and Visualization

Once the data has been collected, it must be analysed and visualised in order to gain insights into the problem. This process can be aided by the following tools:

- Excel Spreadsheets

- Flow diagrams

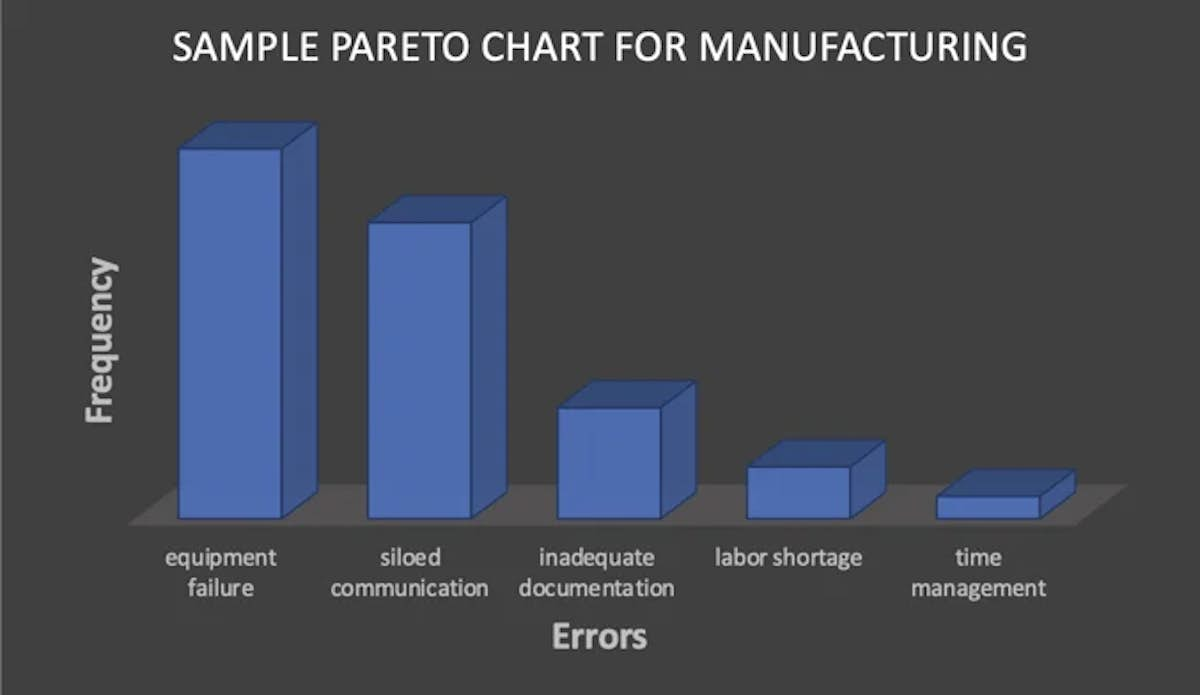

- Pareto diagrams

- Scatter Plots

- Control diagrams

These tools can assist in organising data and making it easier to understand. They can also be used to generate visual representations of data, such as graphs and charts, to communicate the findings to others.

Finally, the data collection and analysis step is an important part of the A3 Problem Solving process. Organizations can gain a better understanding of the problem and develop effective solutions by collecting and analysing relevant data.

Step 3: Identify Root Causes

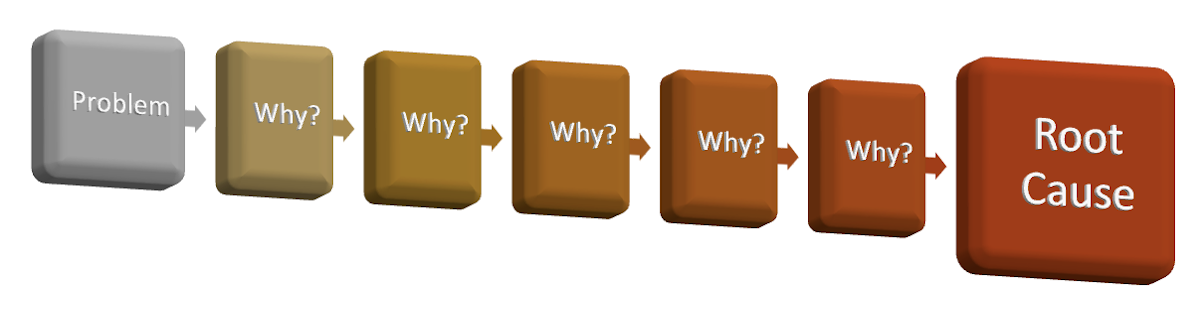

Identifying the root causes of the problem is the third step in the A3 Problem Solving process. This step is critical because it assists organisations in understanding the root causes of a problem rather than just its symptoms. Once the underlying cause of the problem is identified, it can be addressed more effectively, leading to more long-term solutions.

Overview of the Root Cause Analysis Process

The process of determining the underlying causes of a problem is known as root cause analysis. This process can assist organisations in determining why a problem is occurring and what can be done to prevent it from recurring in the future. The goal of root cause analysis is to identify the underlying cause of a problem rather than just its symptoms, allowing it to be addressed more effectively.

To understand Root cause analysis in more detail check out RCA in our Lean Six Sigma Yellow Belt Course Root Cause Analysis section

Techniques for Identifying Root Causes

There are several techniques for determining the root causes of a problem, including:

- Brainstorming

- Ishikawa diagrams (also known as fishbone diagrams)

- Root Cause Tree Analysis

These methods can be used to investigate the issue in-depth and identify potential root causes. Organizations can gain a deeper understanding of the problem and identify the underlying causes that must be addressed by using these techniques.

Best Practices for Conducting Root Cause Analysis

It is critical to follow these best practices when conducting root cause analysis in A3 Problem Solving:

- Make certain that all stakeholders participate in the root cause analysis process.

- Concentrate on determining the root cause of the problem rather than just its symptoms.

- Take into account all potential root causes, not just the most obvious ones.

- To identify root causes, use a systematic approach, such as the 5 Whys or root cause tree analysis.

Organizations can ensure that root cause analysis is carried out effectively and that the root cause of the problem is identified by adhering to these best practises. This will aid in the development of appropriate solutions and the effective resolution of the problem.

Step 4: Develop Solutions

Developing solutions is the fourth step in the A3 Problem Solving process. This entails generating ideas and options for dealing with the problem, followed by selecting the best solution. The goal is to develop a solution that addresses the root cause of the problem and prevents it from recurring.

Solution Development in A3 Problem Solving

A3 solution development Problem solving is an iterative process in which options are generated and evaluated. The data gathered in the previous steps, as well as the insights and understanding gained from the root cause analysis, guide this process. The solution should be based on a thorough understanding of the problem and address the underlying cause.

Techniques for Developing Solutions

There are several techniques that can be used to develop solutions in A3 Problem Solving, including:

- Brainwriting

- Solution matrix

- Multi voting

- Force field analysis

These techniques can help to generate a range of options and to select the best solution.

Best Practice for Developing Solutions

It is critical to follow the following best practices when developing solutions in A3 Problem Solving:

- Participate in the solution development process with all stakeholders.

- Make certain that the solution addresses the underlying cause of the problem.

- Make certain that the solution is feasible and achievable.

- Consider the solution’s impact on the organisation and its stakeholders.

Organizations can ensure that the solutions they develop are effective and sustainable by adhering to these best practises. This will help to ensure that the problem is addressed effectively and that it does not reoccur.

Step 5: Implement Solutions

The final and most important step in the A3 Problem Solving methodology is solution implementation. This is the stage at which the identified and developed solutions are put into action to address the problem. This step’s goal is to ensure that the solutions are effective, efficient, and long-lasting.

The implementation Process

The implementation process entails putting the solutions developed in the previous step into action. This could include changes to processes, procedures, and systems, as well as employee training and education. To ensure that the solutions are effective, the implementation process should be well-planned and meticulously executed.

Techniques for Implementing Solutions

A3 Problem Solving solutions can be implemented using a variety of techniques, including:

- Piloting the solution on a small scale before broadening its application

- Participating in the implementation process with all relevant stakeholders

- ensuring that the solution is in line with the goals and objectives of the organisation

- Monitoring the solution to determine its effectiveness and make any necessary changes

Best Practice for Implementing Solutions

It is critical to follow these best practices when implementing solutions in A3 Problem Solving:

Make certain that all relevant stakeholders are involved and supportive of the solution. Have a clear implementation plan that outlines the steps, timeline, and resources required. Continuously monitor and evaluate the solution to determine its efficacy and make any necessary changes. Encourage all stakeholders to communicate and collaborate openly. Organizations can ensure that solutions are effectively implemented and problems are effectively addressed by adhering to these best practices. The ultimate goal is to find a long-term solution to the problem and improve the organization’s overall performance.

In conclusion, A3 Problem Solving is a comprehensive and structured methodology for problem-solving that can be applied in various industries and organisations. The A3 Problem Solving process’s five steps – Define the Problem, Gather Data, Identify Root Causes, Develop Solutions, and Implement Solutions – provide a road map for effectively addressing problems and making long-term improvements.

Organizations can improve their problem-solving skills and achieve better results by following the key principles, techniques, and best practices outlined in this guide. As a result, both the organisation and its stakeholders will benefit from increased efficiency, effectiveness, and satisfaction. So, whether you’re an experienced problem solver or just getting started, consider incorporating the A3 Problem Solving methodology into your work and start reaping the benefits right away.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

Practical Problem Solving Tools for Factory and Office

February 5, 2022

Many tools exist to address deviations and defects, but only a few are simple yet effective to address daily issues in manufacturing, development, administration.

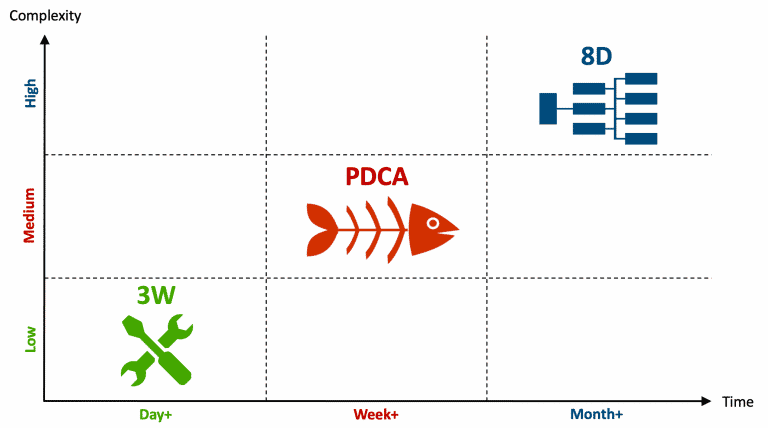

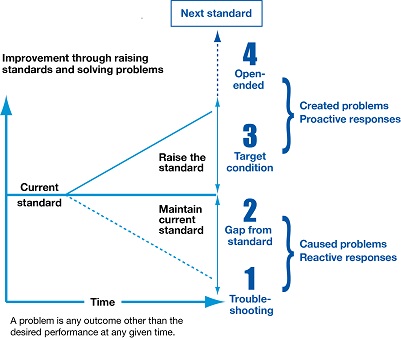

When starting systematic trouble-shooting, it is important to choose the right approach. Using a comprehensive method that requires 50 pages to solve a simple problem is a waste of time, while solving a complex problem with a simple tool will most likely not reveal the hidden causes. The optimal choice of Problem Solving Tools depends on the type of issues to be addressed. Before going into details, let’s first review the most common methods used today.

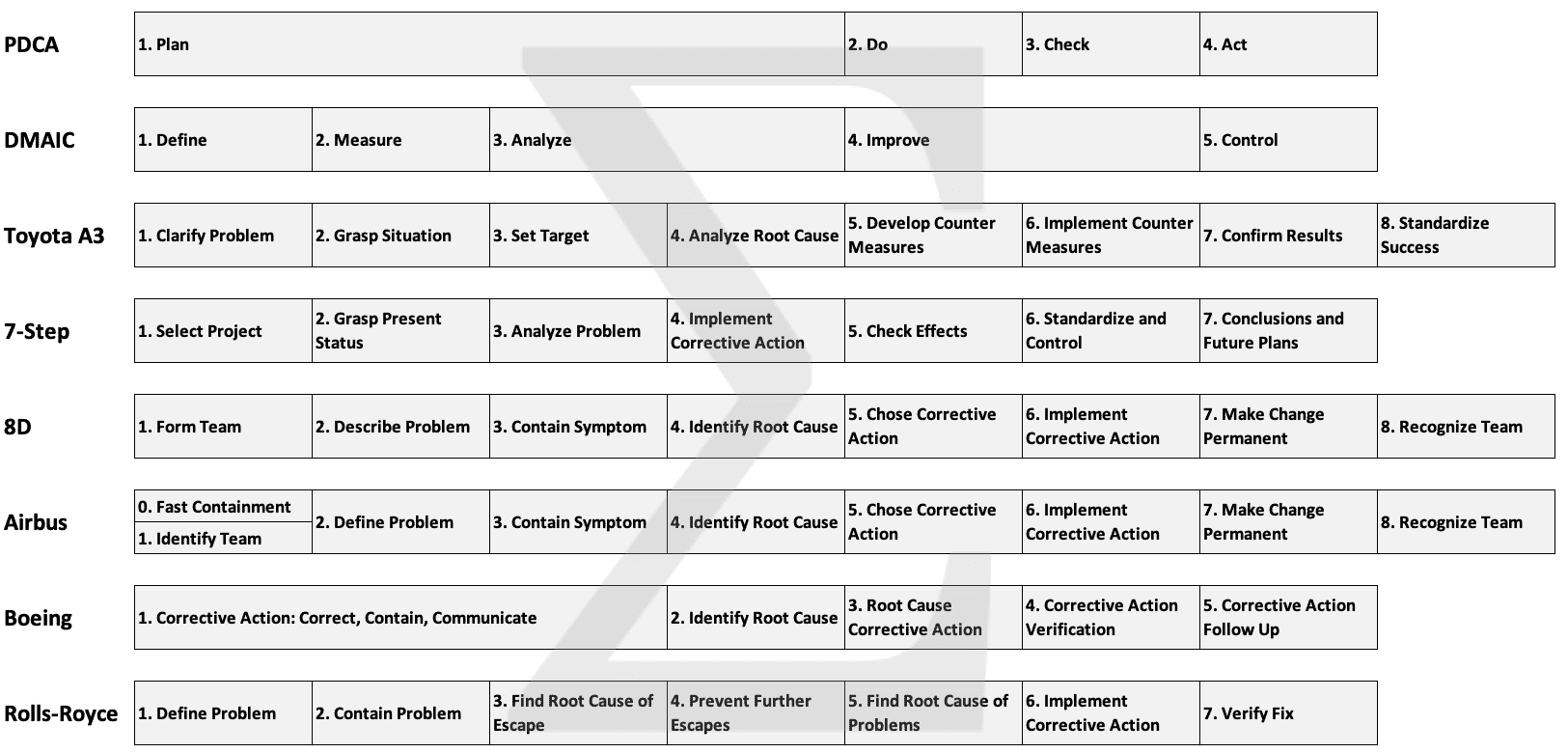

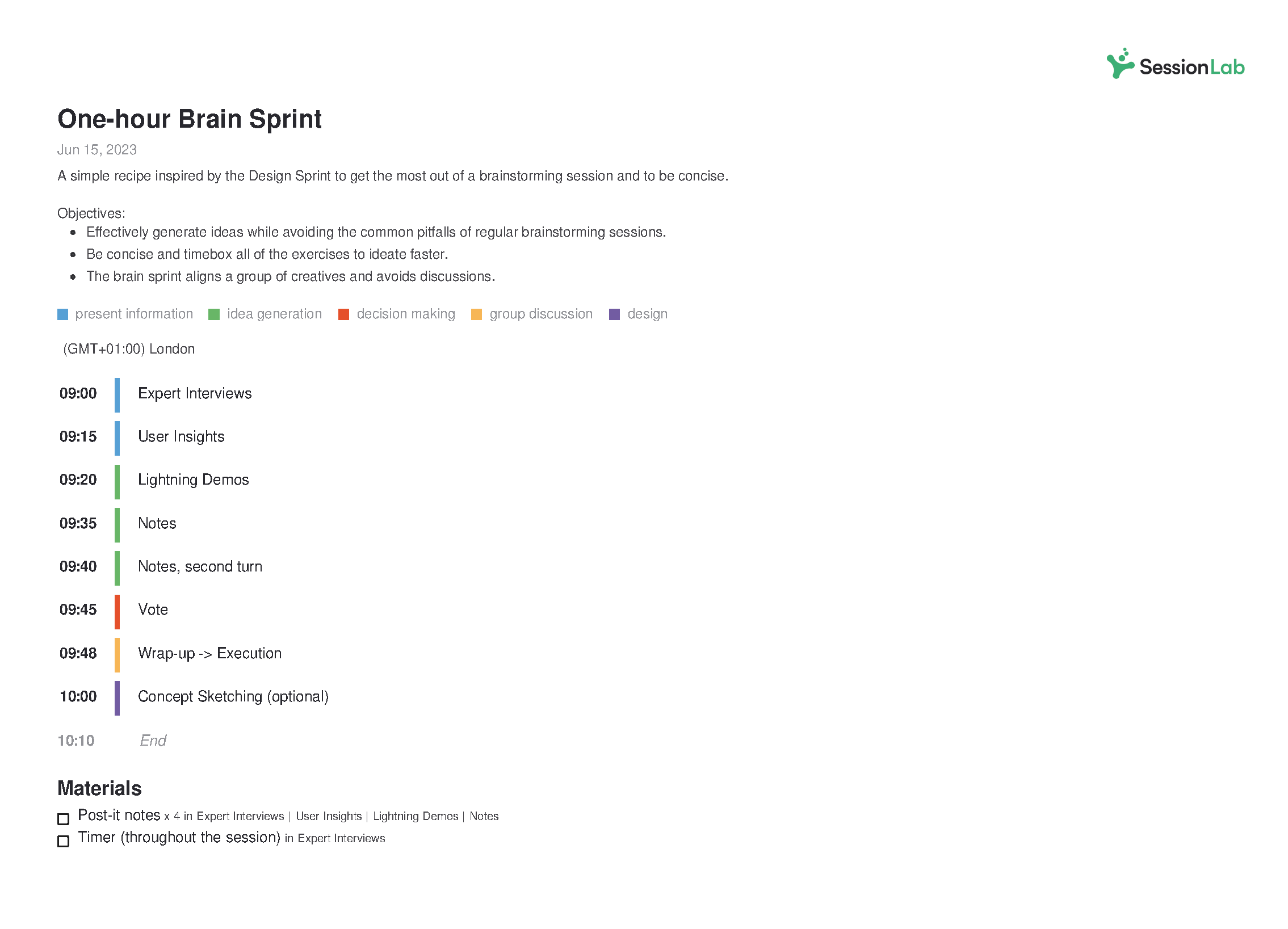

Comparing Popular Methods: 3W, PDCA, 8D, A3, DMAIC, 7STEP

At their core, all scientific approaches follow a similar logic: take quick action to prevent the problem from getting worse and then define the gap, analyze the gap, identify causes, take action, evaluate impact, and embed the solution so that the problem will not reoccur.

- 3W : When the issue is small and the solution is obvious, a formal analysis is not required. The 3W-method defines What to do, Who to do it, by When . This “quick-fix” or “just-do-it” is commonly applied at daily team meetings to contain and correct snags and minor issues.

- PDCA : The Deming or Shewhart cycle “Plan-Do-Check-Act” is the classic method, used by over 80% companies that practice systematic problem solving. PDCA is effective for medium-size problems that require a systematic analysis to uncover underlying causes.

- 8D : The eight disciplines (8D) are commonly used in automotive, and the problem-solving process (PSP) in avionics. Both methods are similar, using 8 steps to address complex problems with focus on a fast reaction to non-conformances, completing the first three steps within three days.

- A3 : The A3-report, developed by Toyota, is an 8-step improvement and problem-solving process that fits on one sheet of paper. The A3-report is most effective to address small- to medium-size problems, and to structure improvement projects.

- DMAIC : The 5-step Six Sigma process “Define-Measure-Analyze-Improve-Control” is a data-centric solving method. DMAIC is used to structure projects and solve complex situations that require statistical analysis to develop the solution, e.g. adjust process parameters to reduce yield loss.

- 7STEP : This seven-step (7S) problem-solving process shares elements with the A3 and 8D, but does not include a formal step for containment. Because of this weakness, the 7STEP process is rarely used today, replaced by 8D to address major deviations and PDCA for smaller issues.

Comparing the most-popular processes for trouble-shooting and root-cause analysis shows how similar they are. For example, the PDCA planning phase covers the first three steps in DMAIC and the first five steps in A3 and 8D. Of all those processes, there are two that stick out, that all others are based on – PDCA and 8D – they are therefore considered the “mother” and “father” of practical problem solving tools used today.

Answer 5 Questions to Select the Best Method

When it comes to choosing the right process, it merely depends on the complexity of the situation to address. The more complex or severe, the more formal steps should be applied to make sure no step is missed. Here are five questions that will help you selecting the best process:

- Is the issue small, medium, or large?

- Is the solution obvious or unknown?

- Is it reoccurring or a single incident?

- Is it a single cause or multiple causes?

- Is statistical data analysis required?

3 Practical Problem Solving Tools: Fix, Fish, Tree

There are three practical, yet effective tools to address daily issues in factory and office: The 3W or “Fix” because it is quick, simple, informal;, the PDCA or “Fish” because it is based on the Ishikawa or Fishbone diagram;, and the 8D or “Tree” because it uses logical trees to analyze complex root causes.

- Fix: use 3W (What-Who-When) for informal trouble-shooting , finding a quick action to fix a small issue within a day .

- Fish: use PDCA (Plan-Do-Check-Act) to analyze simple and repeat issues within a week , using the fishbone diagram.

- Tree: use 8D (Eight Disciplines) to systematically eliminate multiple root-causes or complex problems within a month .

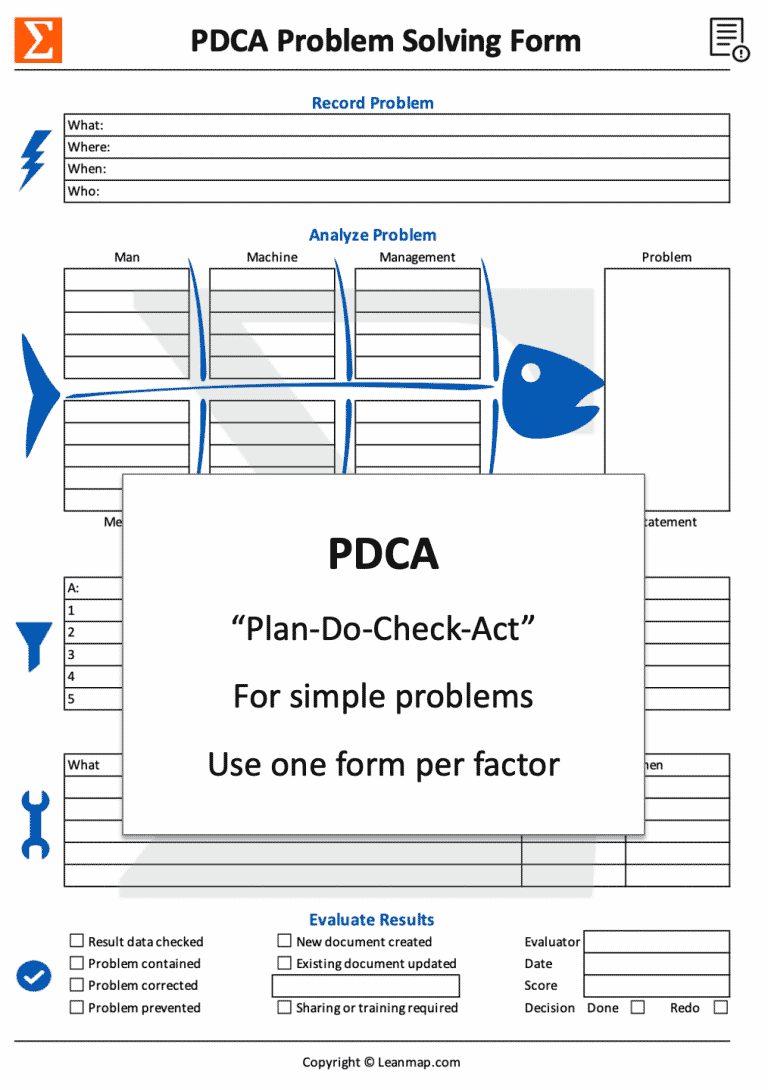

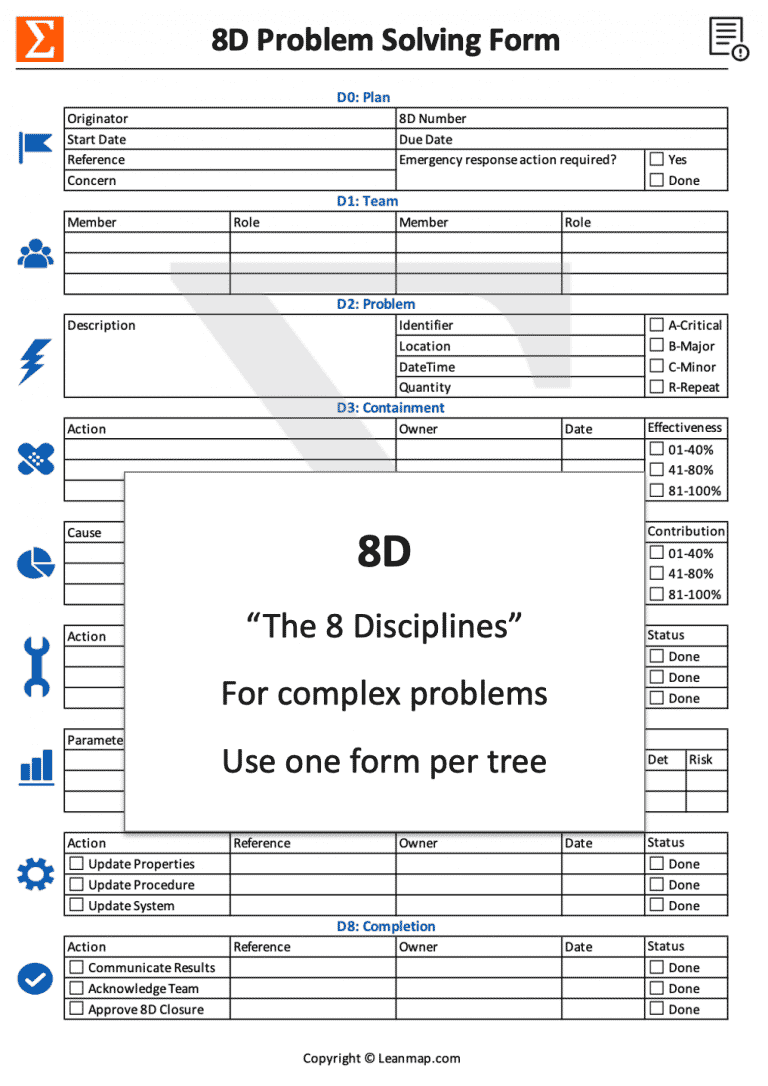

Tools and Templates to Eliminate Root Causes

To encourage people to go beyond containment and quick fixes, the method they use must be simple and practical, but also effective and efficient. Over the course of several years, we have tested dozens of different templates and found that the following two forms work best by far. Why? Because the user is given a clear structure, enhanced with pictograms, and the entire solving process can be completed on a single sheet, the key for broad adoption.

The PDCA and 8D templates have proven to be extremely effective in addressing non-conformances; they are practical problem solving tools for teams in manufacturing, quality control, product development, healthcare, back office, and corporate administration to successfully resolve daily issues and prevent them from coming back. You can download the free toolkit in 22 languages here .

Use PDCA Template to Solve Simple Problems

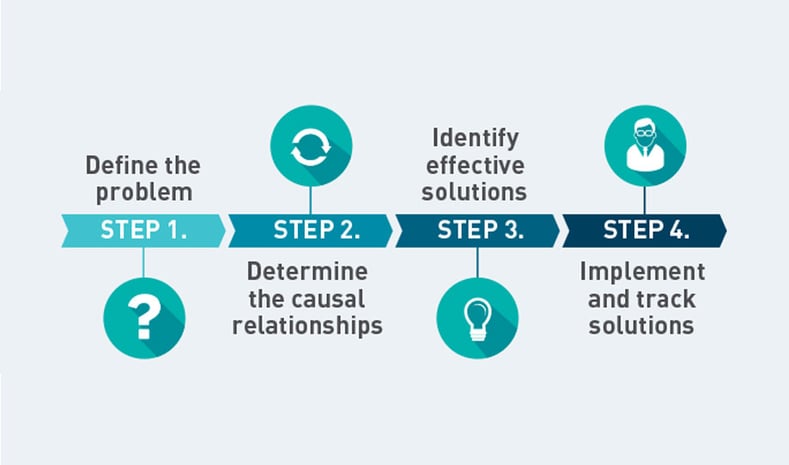

4 Steps to Eliminate Simple Causes

- Plan-1 Record Problem : Describe what happened, where and when, and who is involved solving it.

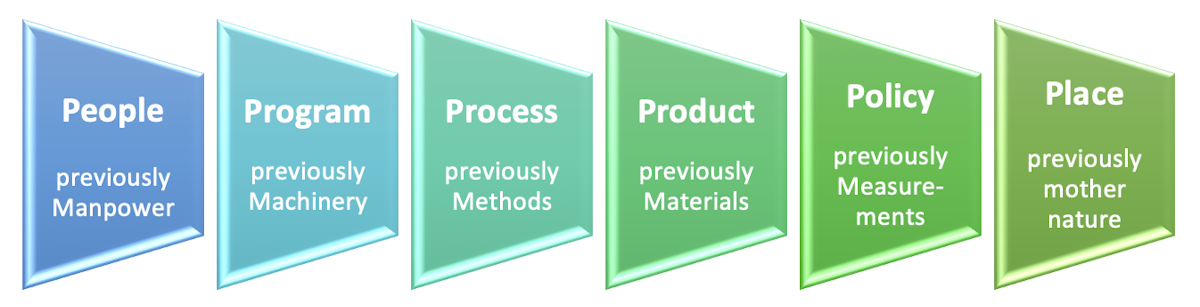

- Plan-2 Analyze Problem : Assign potential causes to categories: Man, Method, Machine, Material, Management, Milieu (Environment).

- Plan-3 Identify Causes : Ask “why” to drill down to root causes; for complex problems, use several forms, one per branch or issue.

- Do Implement Actions : Create and implement an action plan to contain, correct, and prevent the problem from reoccurring.

- Check Results and Act : Review impact, standardize solution; close the case or initiate further actions by starting a new PDCA cycle.

Use 8D Template to Solve Complex Problems

8 Steps to Eliminate Complex Causes

- D0 Plan : Register problem and define emergency response.

- D1 Team : Identify team members to address the problem.

- D2 Problem : Grasp the situation and describe the problem.

- D3 Containment : Prevent the problem from spreading.

- D4 Diagnostics : Identify direct causes and root causes.

- D5 Correction : Define and prioritize corrective actions.

- D6 Validation : Implement actions and evaluate effectiveness.

- D7 Prevention : Systemize solutions to prevent reoccurrence.

- D8 Completion : Transfer knowledge and recognize contributors.

Become an Effective Problem Solver by Applying Practical Tools and Learning Battle-Tested Methods

Eight Disciplines of Problem Solving (8D)

– Eight Disciplines of Problem Solving –

⇓ Introduction to 8D

⇓ What is 8D

⇓ Why Apply 8D

⇓ When to Apply 8D

⇓ How to Apply 8D

Introduction to Eight Disciplines of Problem Solving (8D)

The Eight Disciplines of Problem Solving (8D) is a problem solving methodology designed to find the root cause of a problem, devise a short-term fix and implement a long-term solution to prevent recurring problems. When it’s clear that your product is defective or isn’t satisfying your customers, an 8D is an excellent first step to improving Quality and Reliability.

Ford Motor Company developed this problem solving methodology, then known as Team Oriented Problem Solving (TOPS), in the 1980s. The early usage of 8D proved so effective that it was adopted by Ford as the primary method of documenting problem solving efforts, and the company continues to use 8D today.

8D has become very popular among manufacturers because it is effective and reasonably easy to teach. Below you’ll find the benefits of an 8D, when it is appropriate to perform and how it is performed.

What is Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is a detailed, team oriented approach to solving critical problems in the production process. The goals of this method are to find the root cause of a problem, develop containment actions to protect customers and take corrective action to prevent similar problems in the future.

The strength of the 8D process lies in its structure, discipline and methodology. 8D uses a composite methodology, utilizing best practices from various existing approaches. It is a problem solving method that drives systemic change, improving an entire process in order to avoid not only the problem at hand but also other issues that may stem from a systemic failure.

8D has grown to be one of the most popular problem solving methodologies used for Manufacturing, Assembly and Services around the globe. Read on to learn about the reasons why the Eight Disciplines of Problem Solving may be a good fit for your company.

Why Apply Eight Disciplines of Problem Solving (8D)

The 8D methodology is so popular in part because it offers your engineering team a consistent, easy-to-learn and thorough approach to solving whatever problems might arise at various stages in your production process. When properly applied, you can expect the following benefits:

- Improved team oriented problem solving skills rather than reliance on the individual

- Increased familiarity with a structure for problem solving

- Creation and expansion of a database of past failures and lessons learned to prevent problems in the future

- Better understanding of how to use basic statistical tools required for problem solving

- Improved effectiveness and efficiency at problem solving

- A practical understanding of Root Cause Analysis (RCA)

- Problem solving effort may be adopted into the processes and methods of the organization

- Improved skills for implementing corrective action

- Better ability to identify necessary systemic changes and subsequent inputs for change

- More candid and open communication in problem solving discussion, increasing effectiveness

- An improvement in management’s understanding of problems and problem resolution

8D was created to represent the best practices in problem solving. When performed correctly, this methodology not only improves the Quality and Reliability of your products but also prepares your engineering team for future problems.

When to Apply Eight Disciplines of Problem Solving (8D)

The 8D problem solving process is typically required when:

- Safety or Regulatory issues has been discovered

- Customer complaints are received

- Warranty Concerns have indicated greater-than-expected failure rates

- Internal rejects, waste, scrap, poor performance or test failures are present at unacceptable levels

How to Apply Eight Disciplines of Problem Solving (8D)

The 8D process alternates inductive and deductive problem solving tools to relentlessly move forward toward a solution. The Quality-One approach uses a core team of three individuals for inductive activities with data driven tools and then a larger Subject Matter Expert (SME) group for the deductive activities through brainstorming, data-gathering and experimentation.

D0: Prepare and Plan for the 8D

Proper planning will always translate to a better start. Thus, before 8D analysis begins, it is always a good idea to ask an expert first for their impressions. After receiving feedback, the following criterion should be applied prior to forming a team:

Collect information on the symptoms

Use a Symptoms Checklist to ask the correct questions

Identify the need for an Emergency Response Action (ERA), which protects the customer from further exposure to the undesired symptoms

D1: Form a Team

A Cross Functional Team (CFT) is made up of members from many disciplines. Quality-One takes this principle one step further by having two levels of CFT:

- The Core Team Structure should involve three people on the respective subjects: product, process and data

- Additional Subject Matter Experts are brought in at various times to assist with brainstorming, data collection and analysis

Teams require proper preparation. Setting the ground rules is paramount. Implementation of disciplines like checklists, forms and techniques will ensure steady progress. 8D must always have two key members: a Leader and a Champion / Sponsor:

- The Leader is the person who knows the 8D process and can lead the team through it (although not always the most knowledgeable about the problem being studied)

- The Champion or Sponsor is the one person who can affect change by agreeing with the findings and can provide final approval on such changes

D2: Describe the Problem

The 8D method’s initial focus is to properly describe the problem utilizing the known data and placing it into specific categories for future comparisons. The “Is” data supports the facts whereas the “Is Not” data does not. As the “Is Not” data is collected, many possible reasons for failure are able to be eliminated. This approach utilizes the following tools:

- Problem Statement

- Affinity Diagram (Deductive tool)

- Fishbone/Ishikawa Diagram (Deductive tool)

- Problem Description

D3: Interim Containment Action

In the interim, before the permanent corrective action has been determined, an action to protect the customer can be taken. The Interim Containment Action (ICA) is temporary and is typically removed after the Permanent Correct Action (PCA) is taken.

- Verification of effectiveness of the ICA is always recommended to prevent any additional customer dissatisfaction calls

D4: Root Cause Analysis (RCA) and Escape Point

The root cause must be identified to take permanent action to eliminate it. The root cause definition requires that it can be turned on or off, at will. Activities in D4 include:

- Comparative Analysis listing differences and changes between “Is” and “Is Not”

- Development of Root Cause Theories based on remaining items

- Verification of the Root Cause through data collection

- Review Process Flow Diagram for location of the root cause

- Determine Escape Point, which is the closest point in the process where the root cause could have been found but was not

D5: Permanent Corrective Action (PCA)

The PCA is directed toward the root cause and removes / changes the conditions of the product or process that was responsible for the problem. Activities in D5 include:

- Establish the Acceptance Criteria which include Mandatory Requirements and Wants

- Perform a Risk Assessment / Failure Mode and Effects Analysis (FMEA) on the PCA choices

- Based on risk assessment, make a balanced choice for PCA

- Select control-point improvement for the Escape Point

- Verification of Effectiveness for both the PCA and the Escape Point are required

D6: Implement and Validate the Permanent Corrective Action

To successfully implement a permanent change, proper planning is essential. A project plan should encompass: communication, steps to complete, measurement of success and lessons learned. Activities in D6 include:

- Develop Project Plan for Implementation

- Communicate the plan to all stakeholders

- Validation of improvements using measurement

D7: Prevent Recurrence

D7 affords the opportunity to preserve and share the knowledge, preventing problems on similar products, processes, locations or families. Updating documents and procedures / work instructions are expected at this step to improve future use. Activities in D7 include:

- Review Similar Products and Processes for problem prevention

- Develop / Update Procedures and Work Instructions for Systems Prevention

- Capture Standard Work / Practice and reuse

- Assure FMEA updates have been completed

- Assure Control Plans have been updated

D8: Closure and Team Celebration

Teams require feedback to allow for satisfactory closure. Recognizing both team and individual efforts and allowing the team to see the previous and new state solidifies the value of the 8D process. Activities in D8 include:

- Archive the 8D Documents for future reference

- Document Lessons Learned on how to make problem solving better

- Before and After Comparison of issue

- Celebrate Successful Completion

8D and Root Cause Analysis (RCA)

The 8D process has Root Cause Analysis (RCA) imbedded within it. All problem solving techniques include RCA within their structure. The steps and techniques within 8D which correspond to Root Cause Analysis are as follows:

- Problem Symptom is quantified and converted to “Object and Defect”

- Problem Symptom is converted to Problem Statement using Repeated Whys

- Possible and Potential Causes are collected using deductive tools (i.e. Fishbone or Affinity Diagram)

- Problem Statement is converted into Problem Description using Is / Is Not

- Problem Description reduces the number of items on the deductive tool (from step 3)

- Comparative Analysis between the Is and Is Not items (note changes and time)

- Root Cause theories are developed from remaining possible causes on deductive tool and coupled with changes from Is / Is Not

- Compare theories with current data and develop experiments for Root Cause Verification

- Test and confirm the Root Causes

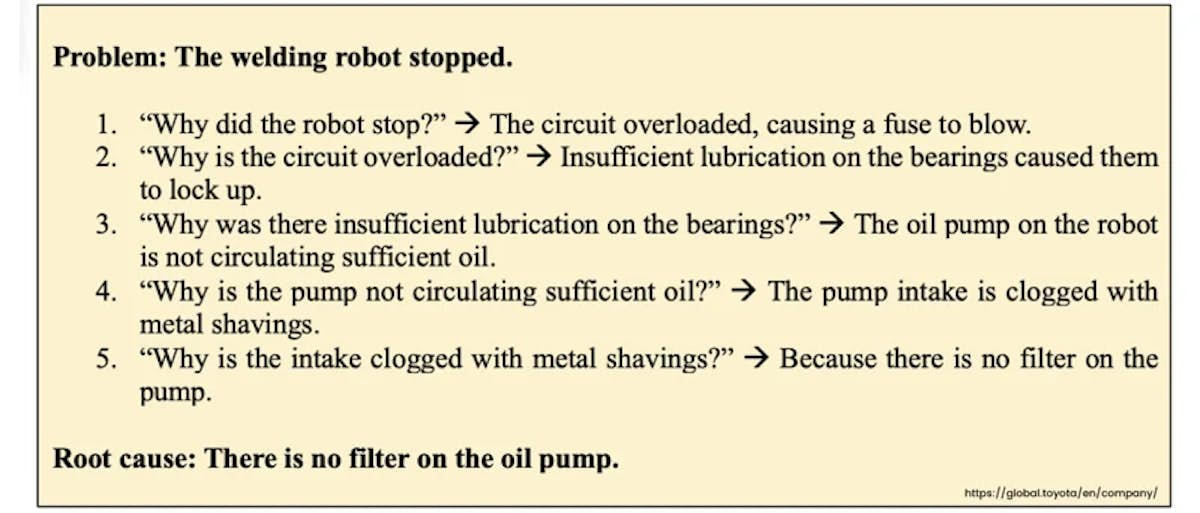

Example: Multiple Why Technique

The Multiple / Repeated Why (Similar to 5 Why) is an inductive tool, which means facts are required to proceed to a more detailed level. The steps required to determine problem statement are:

- Problem Symptom is defined as an Object and Defect i.e. “Passenger Injury”

- Why? In every case “SUV’s Roll Over”

- Why? In every case, it was preceded by a “Blown Tire”

- Why? Many explanations may be applied, therefore the team cannot continue with another repeated why past “Blown Tire”

- Therefore, the Problem Statement is “Blown Tire”

- Why? Low (Air) Pressure, Tire Defect (Degradation of an Interface) and High (Ambient) Temperature

- Counter measures assigned to low pressure and tire defect

This example uses only 4 of the 5 Whys to determine the root causes without going further into the systemic reasons that supported the failure. The Repeated Why is one way to depict this failure chain. Fault Tree Analysis (FTA) could also be used.

Learn More About Eight Disciplines of Problem Solving (8D)

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 8D Consulting , 8D Training or 8D Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

- Don't have an account? Register

- Lost your password? Click here

- Already have an account? Log in

- Application Profiles

- Hartford Global Consulting Services

- Case Studies

- Our History

- Global Team

- Manufacturing Capabilities

- Our Quality

- Who We Work With

- Special Bearings

- Cage Bearings

- Needle Bearings

- Drawn Cup Needle Bearings

- Cage Needle Bearings

- Thrust Bearings

- Plastic Bearings

- Ball & Roller Retainer Assemblies

- Ball Sleeves

- FAQ – Custom Bearing Assemblies

- Chrome Steel Balls

- Stainless Steel Balls

- Carbon Steel Balls

- Brass Balls

- Tungsten Carbide Balls

- Precision Glass Balls

- Plastic Balls

- Small Ball Pack Program

- Balls for Valves

- FAQ – Precision Balls

- Roller Ball Bearings

- Bearing Cages/Separators

- Bearing Races

- Bearing Sleeves / Wear Sleeves

- Needle Bearing Retainers

- Tripot / Tripod Ball – CV Joint

- FAQ – Bearing Parts

- Pins & Shafts

- Knurled Pins

- FAQ – Precision Pins

- Needle Rollers

- Precision Rollers

- Special End Rollers

- Tapered Rollers

- FAQ – Precision Rollers

- CNC Capability

- Agriculture

- Consumer Goods

- Electronics

- Recreational

- Industries & Applications

- Bearing Parts

- Custom Bearing Assemblies

- Precision Balls

- Precision Pins & Rollers

- Capabilities

Hartford Technologies Blog

35 lean manufacturing tools: the ultimate list, what is kaizen.

Kaizen is the Japanese word for “continual improvement.” The term refers to activities that improve every function of a business and is generally applied to manufacturing but can be used to make almost any business more efficient.

By definition, Kaizen includes the involvement of all employees, from upper management to assembly line workers and can be used to improve every process in a supply chain, from purchasing to logistics. The lean manufacturing tool was first used by the Japanese in World War Two and was a major influence of the book “The Toyota Way.”

What is the goal of Kaizen?

Kaizen seeks to improve standardized processes to eliminate waste, fix workflow issues, and solve business problems.

How is Kaizen implemented? The Kaizen method generally involves 5 primary steps:

- Identify the problem area that will be given focus.

- Utilize videotape to analyze the current method.

- Test and evaluate improvement tactics.

- Implement improvements.

- Analyze results and present them to upper management for feedback.

What is Kaizen most applicable to?

The Automotive Industry. The Toyota Production System made the tool famous. If problems occur within the production process, Toyota assembly line personnel and their supervisors are expected to stop the production process and begin a Kaizen.

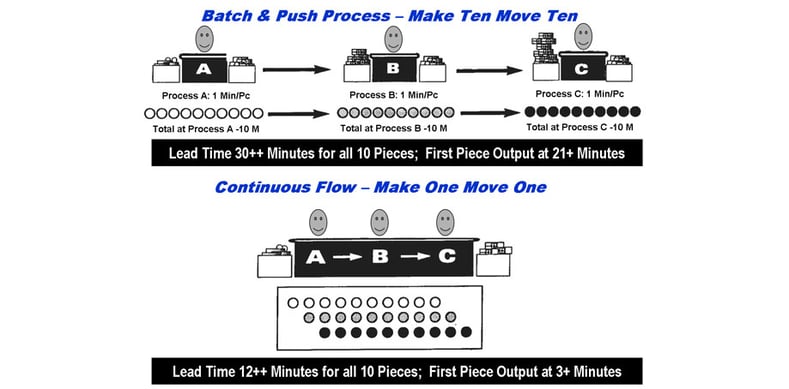

2) One-Piece Flow

What is One-Piece Flow?

One-piece flow is the sequence of a product or service through a process that is one unit at a time. One-piece flow is the opposite of batch processing, where a large number of products are created at once and they are sent through the manufacturing process as a batch or group. In One-Piece Flow the focus is on the manufacturing of the product itself rather than the waiting, transportation, and storage of the product.

What are the advantages of One-Piece Flow?

The advantages are:

- Ability to detect defects earlier and more accurately.

- More flexibility for customization and meeting customer demands.

- Reduces costs by eliminating waste.

- Reduce the amount of work in progress to make each step more efficient.

- Easier to predict shipment times.

To increase efficiency, companies can choose to implement One-Piece Flow or simply reduce the number of products produced in a batch.

What is Jidoka?

Jidoka was invented in 1896 and was used to stop the shuttle of an automatic loom in a case where a thread broke. Not only did this reduce the number of defects when threading, it allowed operators to operate multiple looms at once instead of having to watch only one in case something went wrong. It is essentially automation with a human element.

What are the principles of Jidoka?

The principles can be broken down into four steps:

- Discover an abnormality or problem.

- Stop the operation process.

- Fix the problem at hand.

- Discover the root cause to prevent future issues.

The primary innovation Jidoka brought to lean manufacturing is the idea of examining a manufacturing issue in the middle of the process rather than at the end. Inspecting throughout the manufacturing process can play a key role in preventing defects and fixing problems before they cause significant damage.

4) Poka Yoke

Source: medium.com

What is Poka Yoke?

Poke Yoke was developed by Toyota and is very similar to Jidoka. The idea of Poka Yoke is to prevent mistakes from becoming defects. Mistakes, it argues, are inevitable, but defects that reach customers are preventable. The goal is to create a form of quality control that highlights defects automatically and eventually takes humans out of the equation.

Why use Poka Yoke?

The tool was invented because of human error. Humans who perform repetitive manufacturing tasks day in and day out can very easily miss common mistakes and defects. Automation was necessary to improve the manufacturing process.

A real-life example of Poka Yoke? An alarm that goes off automatically when you leave a car without turning off the headlights. Another example is a conveyor belt that rejects an underweight product. The goal is to prevent mistakes automatically, without human inspection.

5) Visual Management

What is visual management.

Visual Management is a communication technique that uses visual aids to convey messages quicker and more efficiently

What is the goal of Visual Management?

The objectives of Visual Management are:

- Clarify waste.

- Display problems in a simpler way.

- Indicate your efficiency goals.

- Increase effective communication.

An example of Visual Management? Stock controls, auditing boards, and shadow boards. Oftentimes, visual management can improve communication and help improve efficiency. Other times, visual aids can become confusing and too much to remember.

Where is Visual Management best applied? Work instructions can often be simplified and far easier to understand when visual aids are included. For example, if a work must build a piece of furniture from multiple parts, it will often be better understood in a visual format. It is particularly useful for tasks that are difficult to explain with words alone. Another example may be showing works a picture of a completed task.

What is Kanban?

Kanban is the Japanese word for “Signal Card.” In previous decades, manufacturing workers would fill out a signal card when a part was running low. The signal card would be sent to a team or employee whose job was to order more of that part. Today, this process is mostly computerized. The idea of Kanban is to buy more parts only when needed.

The goal of Kanban? The primary goal of Kanban is to reduce waste. If parts are only bought when needed, you are less likely to waste time, money, or space ordering unnecessary parts. However, if parts are bought automatically, without knowing if they are needed, it can cut into a company’s profits.

The strategy creates more efficient processes because the strategy is implemented based on consumer demand. If there is a lot of demand for a product only then should you order more. If there isn’t sufficient demand, companies can prevent unnecessary orders.

7) Demand Management

Source: fourquadrant.com

What is Demand Management?

Demand Management is a lean tool used to identify all demand coming from an external environment, manage it, and input it into a supply chain within a company.

The goal of Demand Management:

Demand Management has three primary goals:

- Improve forecast accuracy.

- Lessen investment in inventory.

- Create a more effective balance between supply and demand.

How is Demand Management implemented? The main element of implementing Demand Management is creating a more transparent supply chain. Companies must ensure transparency from all suppliers working with a company, from the largest to the smallest. By ensuring that every player in the supply chain is transparent, you can begin to create a more efficient supply chain.

Next, companies must determine, which inventory is unnecessary and can be reduced. Having too much inventory is expensive and difficult to maintain. Ultimately, this technique gets products out to consumers more efficiently.

8) Heijunka

What is heijunka.

Heijunka is the Japanese word for “leveling.” Heijunka is meant to level the type and quantity of production, while reducing batching. Ford Motor was once known for manufacturing cars in batches. Toyota used Heijunka to minimize batching and create a more efficient manufacturing process.

What is the goal of Heijunka? To reduce inventories, capital costs, manpower, and production time to a minimum.

When is Heijunka implemented? According to many lean experts, Heijunka is best implemented after a company has already implemented more basic lean principles?

What’s a good example of Heijunka? Say a hat manufacturer receives 500 orders for hats every week. 100 on Monday, 50 on Tuesday, 50 on Wednesday, and 300 on Thursday. Instead of manufacturing 500 hats at the beginning of the week or the exact amount needed each day, the company would produce exactly 100 hats per-day. By producing the same amount every day, the factory can optimize the manufacturing process for 100 hats and therefore create a more efficient process.

9) Just in Time

What is just in time.

As you could probably guess, Just in Time is a lean tool that calls for the production of what a customer wants, when they want it, in the quantity they want it, and where they want it. Instead of creating a large stock of a product that sits in warehouses, you only create as much of an item as a customer actually wants. This reduces unnecessary inventory and ensures that companies only spend on stock that will be paid for.

What is the history of Just in Time?

Just in Time was invented by Toyota during WWII. The tool was invented at a time when producing extra stock was simply too expensive and not possible. Companies could only afford to produce what a customer actually wanted.

The idea for Just in Time came from a visit to US supermarkets by Toyota managers. They noticed that shelves were only filled when a product ran out, not before that.

10) Takt Time

what is takt time.

What is the goal of Takt Time? The goal of Takt is to deliver the right product to the right customer at the right time, all with minimal waste. It ensures that products are manufactured in the most efficient way, while meeting consumer demand.

Another goal of Takt Time is to create a solid flow of operations within a supply chain. Measuring Takt Time will allow managers to determine capacity and synchronization issues within a supply chain and then find proper solutions.

Example of Takt Time? Here is an example:

Total Time: 8 Hrs X 60 Min = 480 Min

Breaks: 50 Min

Time Available : 430 Min

Customer Demand in 8 Hrs: 100 Pieces

Takt Time: 430 / 100 = 4.3 Min = 258 Sec

11) Bottleneck Analysis

What is a bottleneck, the goal of bottleneck analysis.

When should Bottleneck Analysis be implemented? When managers or operators suspect that the manufacturing process is taking too long. At this point, managers will try to determine exactly where the bottleneck is occurring.

What is Andon?

How is it used? In manufacturing, Andon lights are generally used in assembly lines. Different colored lights are used to signal different problems and actions required. Operators may turn on an Andon in order to signal that there is a problem in an assembly line. In an office setting, a red colored light (Andon) may signal that a fax machine or printer is broken.

In cars, warning lights on a car’s dashboard would be examples of Andons. Andons work best when they are highly visible and easy to understand. They must go hand in hand with an action. So, for example, an Andon warning light on a car that signals low gas, would indicate a clear action: fill up the tank with more gas.

Source: agileleanhouse.com

What is Gemba?

How is Gemba implemented?

Gemba is a step by step process:

- Engineers physically go to manufacturing floor to observe processes.

- Engineers collect data and understand the work being done

- Engineers ask questions.

- Engineers learn about problems and come up with solutions.

Gemba Walks refer staff taking the time to walk through the factory, examine what is going on, and determine if there are any issues. In the lean management philosophy, staff are expected to do Gemba Walks at least once a week.

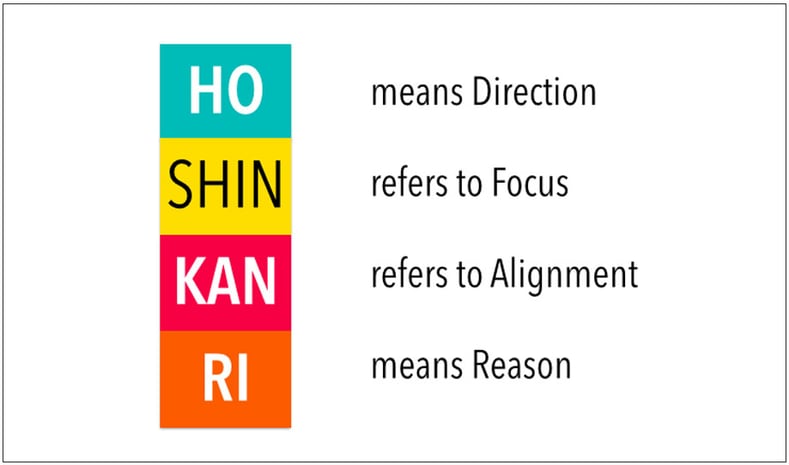

What is Hoshin Kanri?

What is the goal of Hoshin Kanri? The goal of Hoshin Kanri is to determine your strategic objectives and then align them with specific resources and action plans to meet those objectives.

What are the 7-steps of Hoshin Kanri?

The 7-steps of Hoshin Kanri:

- Determine an organizational vision. Figure out what your current mission and long-term vision is.

- Establish breakthrough objectives. Determine what significant improvements a business needs in the next three to five years.

- Come up with annual objectives to complete on a yearly basis.

- Determine metrics to measure objectives.

- Implement objectives.

- Review objectives monthly. Determine your progress each month to see where your business needs improvement.

- Review objectives yearly. Determine your progress each year to see where your business needs improvement.

15) Overall Equipment Effectiveness (OEE)

Source: wikihow.com

What is OEE?

OEE is a system used to measure manufacturing productivity. It measures the percentage of time that a manufacturer is truly productive. So, a 100% would mean that a manufacturer is productive 100% of the time. OEE includes measurement of quality, performance, and availability.

What is the goal of OEE?

By measuring productivity in terms of time, manufacturers can gain insight into how to improve overall manufacturing performance. The system helps to identify waste, track progress, and improve manufacturing equipment efficiency.

What do quality, performance, and availability really mean?

- Quality measures the number of defects. A 100% score indicates that there are zero defects.

- Performance measures slow cycles and stops. A 100% score indicates everything is running as quickly as possible.

- Availability takes into account any stops. A 100% score indicates that the process is always running during set production times.

16) Cellular Manufacturing

What is Cellular Manufacturing?

Cellular Manufacturing is the process of producing similar products in one cell. The product, in Cellular Manufacturing, moves through the production process in a single unit without interruptions. In Cellular Manufacturing, similar products can be produced on the same assembly line.

What are the benefits of Cellular Manufacturing?

The benefits of Cellular Manufacturing include:

- Group similar products together to reduce the time of changeover.

- Effectively utilize space during the entire production process.

- Increase flexibility and transparency.

- Reduce lead time.

- Increase overall productivity.

- Enhance teamwork and communication between employees and departments.

Example of Cellular Manufacturing? A metallic case arrives in a factory and needs to be assembled. Assembly requires a variety of different steps. The goal of Cellular Manufacturing is for all the steps to occur in one area, in a single cell. This reduces the time it takes to transport the parts during the production process.

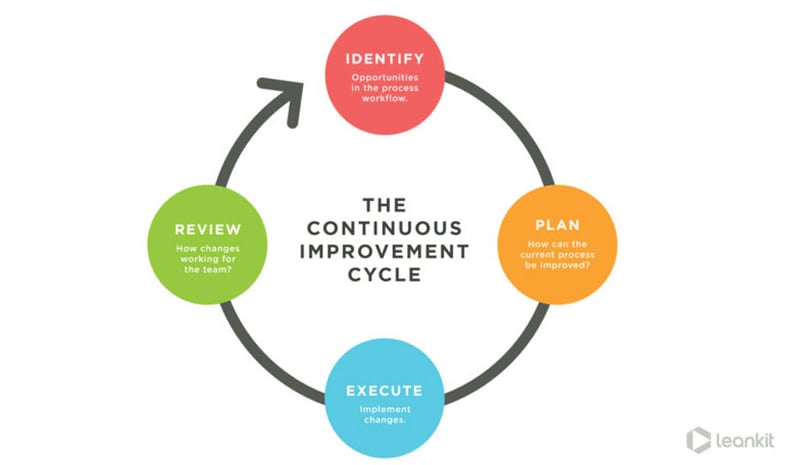

17) Continuous Improvement

Source: mktgcdn.leankit.com

What is Continuous Improvement?

Continuous Improvement is a methodology within lean manufacturing that advocates following formal practices to improve efficiency over time.

What are the benefits of Continuous Improvement?

The benefits of Continuous Improvement include:

- Efficient workflows.

- Saves time.

- Reduces cost.

- Reduces resources needed.

How is Continuous Improvement implemented? Continuous Improvement is implemented in four steps:

- Figure out what needs improvement and create a plan.

- After the plan is complete, implement the plan.

- Collect data to figure out if the plan worked and if it needs improvement.

- Once the plan has worked on a small scale, implement it on a wider scale.

18) Total Productive Maintenance

Source: nevilleclarke.com

What is Total Productive Maintenance?

Total Productive Maintenance is a lean tool used to prevent machine downtime within the production process. The goal is to limit downtime as much as possible to increase production efficiency

How is Total Productive Maintenance implemented?

Total Productive Maintenance includes three main components:

- Preventative maintenance. These included planned maintenance activities that are regularly scheduled. The crew will perform these periodically throughout the year. It includes checking all equipment for problems and fixing any issues. The goal is to prevent problems before they occur.

- Corrective maintenance. Managers and crew check equipment and determine whether problematic equipment needs to be replaced altogether. Oftentimes, it is more cost-effective to replace equipment before they break. Replacing equipment can often increase efficiency and profits.

- Maintenance prevention. This procedure makes sure that all equipment bought is exactly what’s needed. Buying faulty or incorrect equipment can result in increased maintenance responsibilities and and production inefficiencies down the line.

19) Total Quality Management

Source: smartsheet.com

What is Total Quality Management?

Total Quality Management is an organizational effort to improve the quality of a manufactured product. The goal is to increase the quality of every single step in an organizational workflow.

What are the origins of Total Quality Management? Total Quality Management was first implemented in 1923 by Walter Shewhard while he was working at Bell Telephone Laboratories. It was later used by Japanese Manufacturers and implemented on a mass scale in the 1980s.

What are the principles of Total Quality Management?

There are a few main principles of Total Quality Management:

- Focus on the customer. The goal of Total Quality Management is to improve the product offered to customers and therefore keep customers satisfied.

- Strategy. Total Quality Management requires a strategic approach that utilizes a set methodology.

- Continuous improvement. Ensuring quality takes time and it must be analyzed and improved annually.

20) Root Cause Analysis

Source: apollorootcause.com

What is Root Cause Analysis?

Root Cause Analysis is a lean problem-solving method that aims to get to the root of a problem. The philosophy of RCA is predicated on the idea that it’s best to treat the root cause of a problem, not the obvious symptoms. By treating the root cause, manufacturers can eliminate larger problems down the road. Still, Root Cause Analysis will generally not fix problems in one try and is generally an iterative process.

What are the main principles of Root Cause Analysis?

The main principles of Root Cause Analysis include:

- Root Cause Analysis aims to identify the root cause of a problem to prevent it from ever occurring again. It’s a long-term solution.

- Root Cause Analysis must be an investigative and systematic process to work effectively.

- Every problem only has one root cause.

21) Value Stream Mapping

What is value stream mapping.

Value Stream Mapping is a lean tool that uses a flow diagram to depict every step of a process.

What is Value Stream Mapping used for?

Value Stream Mapping serves three main purposes:

- Identify waste.

- Reduce manufacturing time.

- Make the entire manufacturing process more efficient.

What is Value Stream Mapping applicable to? Value Stream Mapping can be applicable in almost any industry, but it is primarily used for logistics, supply chain, product development, and administrative processes.

What data should be collected to create a Value Stream Mapping? Some data points to collect for Value Stream Mapping include:

- Number of operators.

- Number of shifts worked.

- Batch size.

- The time it takes to make one product.

- The time it takes to switch from one product to the next.

- How much time factory can run.

Source: agilelea.com

What is Continuous Flow?

Continuous Flow is the opposite of batch production and is closely associated with Kanban and Just-in-Time. The goal of Continuous Flow is to use ongoing examination and improvement to integrate all elements of production. By aiming for a Continuous Flow production process, waste and other problems come to the surface and can then be solved. Ultimately, many lean principles and tools center around creating a Continuous Flow production process.

The Continuous Flow process generally involves a factory running 24/7 without interruption and with little waste. Areas like oil refining, metal smelting, and natural gas processing are ideal for the Continuous Flow process.

What are the benefits of Continuous Flow?

The benefits of Continuous Flow include:

- Continuity.

- Waste-less process.

- No time wasted.

23) Lean Audit

Source: exegens.com

What is a Lean Audit?

A Lean Audit is a tool used to determine how well lean manufacturing principles are working in a factory or company.

How is a Lean Audit implemented?

A Lean Audit generally has 5 steps:

- Identify the objective of your audit. This involves determining what lean processes you are already using and coming up with metrics to decide how well they are working. The goal of a lean audit should be to improve overall efficiency, reduce waste, and lower production costs.

- Determine who will conduct the audit. Lean Audits are best performed by a third party team in order to ensure objectivity, however, senior management may choose to conduct the audit internally.

- Create a point system to measure progress.

- Use a system to perform the audit. Ideally, a Lean Audit will be performed using lean principles.

- Follow up with the audit to ensure that all problems get fixed. Ideally, Lean Audits should be performed on a small-scale monthly and on a large-scale yearly.

24) Quick Changeover

What is quick changeover.

Changeover is the amount of time it takes to change a piece of equipment between the production of one item to the next. In Lean, the goal is to ensure a Quick Changeover.

An example of Quick Changeover?

A pit crew at a car race is a great example of a Quick Changeover. The quicker a crew can a changeover, the better chance a racer has of winning. A slow changeover will often result in losing a race.

What are the benefits of Quick Changeover?

The main benefits of Quick Changeover are:

- Reduce the amount of defects.

- Reduce inventory costs.

- More production flexibility.

- Better chance of on-time delivery.

25) Right First Time

What is right first time.

Right First Time is a lean philosophy that stresses getting processes right the first time, every time. The concept involves planning and a deep understanding of manufacturing processes.

How is Right First Time implemented?

Right First Time has 3 primary steps:

- Track performance. The first step of Right First Time is figuring out how often you’re getting your manufacturing processes right the first time. Search for areas in the manufacturing process where things do not go smoothly the first time around. By identifying the problems, you can figure out where your manufacturing processes need work.

- Improve performance with a systematic process. Often, the biggest problem manufacturers have is human error. The more systematic a process becomes, the more likely you can get things right the first time.

- Identify areas of waste and use the Right First Time tool to cut them out. Main areas to focus on include inventory, overproduction, defects, and transportation.

26) 7 Wastes Source: blog.triaster.co.uk

What is 7 wastes.

In lean manufacturing, 7 Wastes refers to seven typical places manufacturers have waste. Using the 7 Wastes tool, manufacturers can determine where they have waste and can improve their processes in each area. The method was invented by Toyota and is an integral part of the Toyota production system.

What are the 7 Wastes?

The 7 Wastes are as follows:

- Overproduction. Overproduction refers to producing a product before it is needed. In the Toyota production system, products are produced only when there is customer demand.

- Waiting. Waiting refers to the time between one operation and the next.

- Transporting. Transportation adds no value to a product and only too much transporting only increases the risk of defects.

- Inappropriate processing. This refers to using overly expensive equipment to accomplish tasks that can be processed by simpler and most cost-effective equipment.

- Unnecessary inventory. The goal is to reduce inventory to what’s needed.

- Excessive motion. Human motion should be reduced in the manufacturing process.

- Defects. Reducing defects is crucial for reducing costs.

27) Six Big Losses

Source : e-qms.co.uk

What are the Six Big Losses?

Six Big Losses refers to the six most common reasons for ineffective production. TPM and OEE are generally used to eliminate the Six Big Losses.

- Breakdowns. Breakdowns refer to machine failure and the need for intensive maintenance.

- Setup/Adjustment. Setup/Adjustment refers to changeover and machine warm-up.

- Idling. Idling refers to jams, obstructions, and cleaning.

- Speed. Speed refers to operator efficiency and machine wear down.

- Defects in process and rework. Defects refer to product damages and the need for corrections.

- Start-up losses. Start-up losses refer to improper assembly and losses due to product defects.

28) SMART Goals

What are smart goals.

SMART Goal is a method to set goals productively. To effectively use lean manufacturing methods, management must set proper goals to strive for. Ideally, those goals should be clearly defined and communicated.

What does SMART stand for? For a goal to be achieved it should be:

- Specific. A goal should be concrete and based on facts and figures.

- Measurable. Results must be quantified with clear numbers.

- Attainable. Goals should be attainable and not too ambitious. Impossible goals hurt employee morale.

- Realistic. Similar to attainable, goals must be set realistically based on available resources and time.

- Time-based. Goals must be given a realistic due date based on available resources.

What are KPIs?

KPI is an acronym for Key Performance Metric and it refers to metrics used to assess and analyze manufacturing efficiency. KPIs are essentially metrics set by management to measure the success of lean manufacturing goals.

What are some common manufacturing KPIs?

Some common manufacturing KPIs include:

- Speed. Measuring speed is essential for increasing efficiency and profits.

- Count. This refers to the amount of product produced.

- Reject ratio. Manufacturing processes will sometimes produce scrap. Reducing scrap is essential for increasing productivity.

- Takt time. This can refer to the amount of time it takes to produce a product or the amount of time it takes for one specific operation. Measuring this can help identify where there are bottlenecks or constraints in the manufacturing process.

- Downtime. Breakdown or machine changeover often causes downtime. Lean seeks to reduce downtime as much as possible.

30) The 5S Method

What is The 5S Method?

The 5S Method refers to five Japanese and English terms that begin with an “S” and provide a workplace organization method.

What does each “S” stand for?

- Sort (Seiri): Decide which items in a factory are necessary and which ones are not. Get rid of the ones that are not.

- Straighten (Seiton): Make sure every item in a factory is in the right place. Items should be easy to find and access.

- Shine (Seiso): Clean the factory regularly. By getting rid of dirt, garbage, etc. you can more easily identify problems in the manufacturing process.

- Standardize (seiketsu): Create standards to ensure a clean and neat factory floor.

- Sustain (shitsuke): Create habits that ensure standards are met over the long term. Set responsibilities for managers and operators to ensure that habits are set.

What is SMED?

SMED stands for Single-Minute Exchange or Die. The goal of SMED is to get all changeovers and startups down to 10 minutes. Each step should be one minute or less. By reducing setup time, factories can greatly improve efficiency. SMED as invented by Frederick Taylor in 1911 and was later used by Ford Motors in 1915.

What are the main principles of SMED?

- Identify all changeover tasks.

- Analyze each task to determine purpose.

- Determine low cost solutions.

- Goal should be to reduce changeover time.

What are the steps to implement SMED? The steps to perform SMED are as follows:

- Separate internal from external setup operations

- Convert internal to external setup

- Standardize functions

- Use functional clamps or eliminate fasteners altogether

- Use intermediate jigs

- Adopt parallel operations

- Eliminate adjustments

- Mechanization

32) A3 Problem Solving

Source: sixsigmaconcept.com

What is A3 Problem Solving?

A3 Problem Solving is a problem solving method that uses a structured, continued growth methodology to improve manufacturing practices. The method was invented by Toyota and is based on the work of Edward Deming.

How is A3 Problem Solving implemented?

A3 Problem Solving has 7 steps:

- Determine what is the company generally trying to fix.

- Analyze the current situation. What is currently being done?

- Decide what the company’s goals are. What specifically will be accomplished?

- Determine what the gap is between current processes and where the company wants to be.

- Come up with possible solutions and determine what the barriers will be.

- Decide on a plan. What will the new process look like?

- Follow up. Track results and figure out what’s working.

What is PDCA?

PDCA stand s for Plan-Do-Check-Act and is a four-step method for creating and carrying out change. The PDCA method is a cycle and is repeated over and over again in order to drive continuous improvement.

When is PDCA used?

PDCA is primarily used when:

- Conducting an improvement project.

- Designing a repetitive work process.

- Developing a new process or product design.

- Implementing changes in the manufacturing process.

What are the PDCA steps?

PDCA steps include:

- Plan. Find an area that needs improvement and plan a change.

- Do. Test the change on a small-scale.

- Check. Check how the test went by analyzing the results and determining what you’ve learned.

- Act. Take action based on what you’ve learned. If the change you made did not work, start from the beginning and determine a different test. Use your failures to determine where you will go next.

34) Standardized Work

Source: truenorththinking.ca

What is Standardized Work?

Standardized Work is a tool used to document current best practices, improve the standard, and ensure that the new standard becomes a baseline for improvement.

What does Standardized Work improve?

Standardized Work improves 3 important aspects of the manufacturing process:

- The rate at which products are produced in order to meet customer demand.

- The operator’s work sequence to produce products at that time rate.

- The standard inventory is needed to ensure a smooth manufacturing process.

What are the benefits of Standardized Work? The main benefits of Standardized Work include:

- Better documentation of current processes.

- Easier training for operators.

- Few injuries and strains.

- Baseline to make improvements.

- Reduces variability.

- Adds discipline to a work culture.

- Promotes problem solving.

- Increases teamwork across the organization.

Source: qualityaretegroup.com

What is 5 Whys?

5 Whys is a lean method used to determine the root cause of a problem. Managers repeat the question “Why?” and each answer forms a basis for the next question. This process continues until a conclusion is reached. The 5 Whys technique was developed by Sakichi Toyoda and has been used by Toyota to improve its manufacturing processes. The 5 Whys technique generally requires persistence and determination for it to work effectively.

What are the rules surrounding 5 Whys?

In order to properly perform 5 Whys, managers should follow a variety of rules:

- Use paper or a whiteboard, not a laptop or computer.

- Clearly define the problem and make sure every team member understands it.

- Use a step-by-step process to find the root cause. Avoid jumping to conclusions.

- Identify what the causes are, not the symptoms.

- Use logic, not emotion.

- Focus on making sure answers are as precise as possible.

- Use the customer’s point of view when answering the “Why” questions.

- Facts and knowledge should be the basis for each answer.

Subscribe to Email Updates

Posts by topic.

- Precision Ball (27)

- Engineering Trends (23)

- Procurement Trends (21)

- Custom Bearings (20)

- Medical Manufacturing (20)

- Quality Control (13)

- CNC Machining (11)

- News & Updates (11)

- Bearing Parts (10)

- Lean Manufacturing (9)

Featured Resources

The 8-Step Problem-Solving Method

- November 22, 2021

Table Of Contents

What is the 8-step problem-solving method, the 8 steps and the problem-solving process, the culture of problem-solving.

- Plan, Do, Check, Act (PDCA)

- Gain Problem-Solving Support

As a manufacturing professional, you know how important it is to stay organized, keep your goals in mind and strive for success. But with all of the responsibilities and daily tasks piling up, it takes effort to find and stick to a process that can keep you on track.

Luckily, there’s a tried and trusted way to achieve success in the manufacturing industry.

The eight-step problem-solving process is a structured method that guides you through the various steps of solving issues. Unlike other problem-solving processes that are often broad, the eight-step method takes you through each individual step, from identifying the problem to taking actionable steps to success.

Instead of changing a few things at a middling level that will probably break down again later, you can unearth the roots of problems and build success from the ground up.

For a fundamental breakdown of how to fix problems and lead your manufacturing team to success, here are the eight steps of the problem-solving process.

1. Identify the Problem

The first step in the process is to identify the problem. Identify why this is a problem, how you discovered it and how it impacts your business. Also note when the problem started and how long it has been going on.

If the problem is small, you can try to contain it and may not need additional steps to fix it. However, if the problem is complex, move forward through the process.

2. Define the Problem

The next step involves breaking down the problem and defining what it is. It’s important to be as clear as you can with this step — a vague problem will hinder the process, whereas a clearly defined issue will allow you to take actionable steps to fix it.

Analyze factors like how high of a priority it is to solve the problem. You can also look to data and other resources to clarify or help you understand the concern.

3. Make a Goal

Create an end goal. Envision what fixing this problem would look like and feel like. What would it accomplish? How would it help you? Map out all the ways fixing this problem would benefit you and use it for motivation to achieve your goal. Set a timeline to figure how long it will take to accomplish that goal.

4. Find the Root of the Problem

Often problems are byproducts of deeper, more central problems, so make sure you dig deep enough to find out what is really causing the issue. If the problem is large and complex, break it down into individual parts.

Gather information and use it to identify the deeper issues of the problem and validate what you think the real concern may be. Take time at this step to really focus on the deep problem — executing this step effectively will save you a lot of time down the road.

5. Develop Actionable Steps

Create a list of realistic steps you can take to combat the problem. You can start with a large list and combine or subtract steps, but it’s important you come up with various ways to attack the problem. Use this action plan to draw up a strategy to get at the root of the problem. Each step should be specific and detail-focused — any steps that are vague or tedious will only take up time and cause confusion.

6. Execute Steps

Now that the plan is in place, all you have to do is follow through on your actionable steps. Illustrate the steps you’re taking to your team, explain why you’re taking them and delegate any steps that another employee has to perform to execute your plan.

Communication is key in this step. In most cases, you won’t be executing the plan all by yourself, so make sure you’re expressing the goals and motives of each step with your team so they can see how it connects to the bigger picture.

7. Observe and Evaluate

Monitor your strategy carefully and see how it relates to the original problem. Is it working? Is it only creating more problems? Gather data, talk to your team and be thorough and objective in your evaluation. You might have to readjust your plan as you gain new information, or you may meet your goals and the plan will be successful.

8. Continue the Process

If the plan worked, find ways to continue integrating these steps into your team’s daily routine. If they didn’t work, go back to the goal-setting process or identify some more aspects of the problem — there may be a deeper concern you missed the first time around. Communicate to your team about how the plan went.

In the future, continue using the eight-step process to solve issues and build momentum with your team.

It’s important to build a culture of problem-solving in your manufacturing plant. It can be easy to fall into the trap of “Band-Aid” solutions — quick fixes without digging into the deeper problems.

It’s believed that the eight-step problem-solving process was actually created by the Toyota Motor Corporation to achieve their admired production standards.

From the lore of Toyota, we get some great eight-step problem-solving examples. Taiichi Ohno , the father of the Toyota Production System, observed his workers fixing only the first level of cause when their machines stopped working. To combat this, he developed a problem-solving method to methodically break down each problem of the machine until he found the root cause. Only then could he truly fix the machine.

It’s one of many eight-step problem-solving examples, and it shows the importance of creating a process to increase productivity.

Plan, Do, Check, Act (PDCA) and the 8-Step Problem-Solving Process Differences