- Artificial Intelligence

- Generative AI

- Business Operations

- Cloud Computing

- Data Center

- Data Management

- Emerging Technology

- Enterprise Applications

- IT Leadership

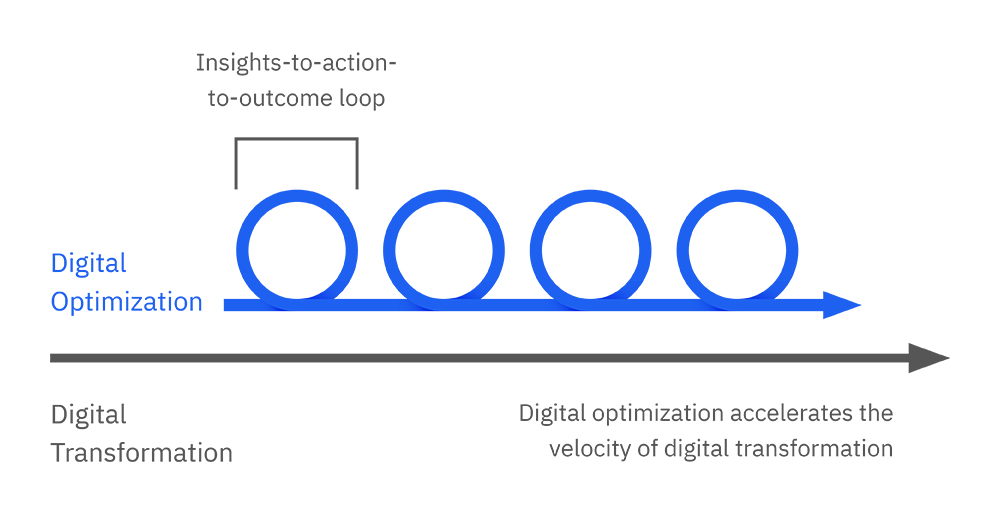

- Digital Transformation

- IT Strategy

- IT Management

- Diversity and Inclusion

- IT Operations

- Project Management

- Software Development

- Vendors and Providers

- Enterprise Buyer’s Guides

- United States

- Middle East

- Italia (Italy)

- Netherlands

- United Kingdom

- New Zealand

- Data Analytics & AI

- Newsletters

- Foundry Careers

- Terms of Service

- Privacy Policy

- Cookie Policy

- Copyright Notice

- Member Preferences

- About AdChoices

- Your California Privacy Rights

Our Network

- Computerworld

- Network World

Ford’s high-tech business transformation, fueled by cloud

The american auto giant’s cloud-first strategy has helped drive its shift to ‘software-defined vehicle’ manufacturing, replete with revenue-generating services that make it a cloud software provider as well..

Ford Motor Co.’s wholesale pivot to technology has transformed not only the automaker’s business operations but its corporate identity.

“We have become much more of a software company than we were 10 to 20 years ago,” says John Musser, director of engineering for Ford’s commercial division, Ford Pro. “People don’t think of a large, 100-year-old manufacturing company as high tech.”

But it is — and Ford now positions itself as a software-defined vehicle (SDV) manufacturer, Musser says.

One need only look within Ford’s executive ranks to see the technology talent driving its digital future: Doug Field, Ford’s chief electric vehicle (EV) and digital systems officer, and Rob Bedicheck, executive director of platform architecture, were both recruited from Apple. Mike Amend, Ford’s chief enterprise technology officer, was once CTO for Dell’s global online business.

Musser himself has spent his entire career developing software, at Ford, on Wall Street, with the Bill Gates Foundation, and at several startups, including one he sold to MuleSoft.

But it is the cloud — and Ford’s cloud-first strategy — that is propelling Ford’s transformation where the rubber meets the road.

Fueled by cloud

Ford’s cloud journey, which began roughly a decade ago, continues to this day, Musser says, as the automaker seeks to take advantage of advances in the key technologies fueling its transformation, including the internet of things (IoT), software as a service, and the latest offerings on Google Cloud Platform (GCP).

Ford is unique among large automotive manufacturers in its selection of GCP, which Dave McCarthy, research vice president of cloud and edge services at IDC, says provides Ford a strong foundation for data-driven operations.

“Google Cloud’s strength in data analysis and AI tools is a perfect fit for this new world of software-defined vehicles,” McCarthy says. “It will enable Ford to better understand how their vehicles are performing in the field and lead to future improvements.”

Three years ago, Ford reorganized its cloud-first, SDV manufacturing organization into three interconnected though separate business units: Ford Pro, for commercial customers; Model-E, for electric vehicles; and Blue, for traditional customers and vehicles employing all engine types.

The cloud, Musser maintains, has been the primary catalyst for the SDV blueprint, driving technology advances in each unit, such as EVs, automated driving capabilities, and tailored services for multiple customer segments.

“We now have the ability through digital connectivity to provide a one-stop shop for commercial customers,” Musser says about Ford Pro’s ability to provide unique technical and financial services for commercial customers. “It’s the software, the digital glue, which is the key to enabling that to happen.”

Ford’s digital transformation, like those of most enterprises, is far from complete. The American automobile giant continues to move internal workloads to Google’s cloud and to deploy Salesforce throughout the workforce as it assembles next-generation EVs such as the F-150 Lightning pickup truck as well as hybrid and traditional combustion vehicles embedded with myriad IoT devices and sensors.

As testament of its digital bona fides, Ford has developed software platforms such as the Ford Pro API, which makes data from highly connected commercial vehicles available for both internal and partner applications, says Paul Dumas, senior director analyst for software engineering and API strategy at Gartner.

“Even more, using the logistical power of APIs to marshal and transport this data to customers, Ford Pro created a SaaS product that is a revenue stream for Ford Pro,” Dumas adds. “This SaaS product provides customers with data and analytics to help them maximize fleet performance and efficiency.”

For example, with every vehicle that has rolled off Ford Pro’s assembly line for the past three to five years “connected by default” with digital cockpits, data from these devices and sensors, available via Ford Pro’s APIs, can inform customers about how much capacity they need for fleet usage and for planning their long-term charging strategies, Musser says.

In this way, Ford’s API strategy, fueled by the cloud, has expanded Ford Pro’ value proposition for its larger commercial customer segment, making Ford a cloud software vendor in its own right.

“We have this combination like any large enterprise cloud software vendor,” says Musser, who has also served as Ford’s director of data and analytics for autonomous vehicles, and director of platform engineering for FordLabs. “We use the cloud software that we’re building. The embedded software in the vehicle goes all the way up the cloud.”

Technology at the center

Technology acquisitions and partnerships are another key enabler of Ford’s high-tech transformation.

In 2021, Ford acquired Silicon Valley startup Electriphi for its EV charging management and EV fleet monitoring software. The services, which are now part of Ford Pro’s services offering, are being enhanced with advanced charging and energy management services for the division’s commercial customers.

Ford Pro’s services arm also uses digital tools to provide automated reporting and maintenance of commercial pickups and vans to help customers optimize EV mileage and annual battery use. The ability of all SDVs — combustion-based, hybrid, and fully electric — to feed data up to the cloud provides developers with a plethora of unique opportunities to build algorithms that optimize, and in some cases, automate, vehicles.

On the security side, for instance, Ford announced a partnership in early 2022 with ADT called Canopy to develop a series of AI-powered connected security cameras and corresponding mobile application that guards the pickup and van fleets of commercial customers. This advanced security service saves commercial fleet operators in labor and provides more comprehensive security for the fleets at home or on the road, Musser says.

In addition, Ford has employed UiPath and Pega robotic process automation (RPA) software to automate business processes and, in conjunction with IoT devices, many subsystems within vehicles. For several years, Ford has been developing algorithms to upgrade vehicles with more sophisticated technologies and services such as order allocation optimizers and parts optimizer algorithms, as well as services such as Blue Cruise automated driving capabilities.

Ford’s forthcoming use of AI will further enhance those services, says Musser, noting supply chain optimization and customer demand matching among the key machine learning algorithms Ford is developing today.

AI everywhere

Ford also plans to leverage generative AI across the company, though that initiative remains in its infancy, Musser says.

To that end, the automaker has launched several pilots using natural-language AI in call centers and within the developer ranks. One pilot under way in the call center, for example, “enables agents to search faster through large amounts of documents and various data types to better classify identifying patterns in call center data segmentation, and sentiment analysis,” Musser says.

Ford’s Office 365 workforce and developers are also actively using Microsoft Copilot in production, he says, adding that, while human developers must still ensure accuracy and quality control of algorithm development, the Copilots have demonstrated value.

“Copilot tools help save you minutes in writing test-case boilerplate code with anywhere from 20% to 40% in assistance predicting what piece of code is necessary to write functions,” Musser says. “Trust me, we’ve seen productivity improvements in development.”

As AI continues to advance, it’s not clear what future technologies will be embedded in software-defined vehicles, but what is evident, Musser says, is that the innovations used to make internal processes at Ford more efficient and profitable will also be intricately embedded with the vehicles sold to customers.

After all, that’s long been considered a key recipe for high-tech company success.

Related content

Creating new opportunities with ai-driven automation, 2024 cio100 asean awards: nominations are now open, leading infrastructure to accelerate electric power intelligence, transunion transforms its business with it, from our editors straight to your inbox.

Paula Rooney is a senior writer at CIO.com

More from this author

Dairyland powers up for a generative ai edge, la public defender cio digitizes to divert people to programs, not prison, rocket mortgage lays foundation for generative ai success, show me more, the 10 highest-paying industries for it talent.

M&A action is gaining momentum, are your cloud security leaders prepared?

CIOs eager to scale AI despite difficulty demonstrating ROI, survey finds

CIO Leadership Live Middle East with Ahmed Wattar, Group Information Technology Director at Alfa Medical Group

CIO Leadership Live Middle East with Dr. Mohammad Alshehri, CISO and Cybersecurity Consultant

CIO Leadership Live Middle East with Wissam Al Adany, Chief Information Officer, ADES Holding

3 Leadership Tips: Renate Cuneen, Vice President, Global Corporate Technology, Canada Life

GenAI and Trust: How Companies Are Thinking About the Trustworthiness of AI and GenAI Tools

Sponsored Links

- Everybody's ready for AI except your data. Unlock the power of AI with Informatica

United States

Enhance Your Drive

Introducing the All-New Ford and Lincoln Digital Experience

Unifying Digital and Driving Experiences

Our lives center around digital ecosystems and the proliferating number of devices we use to stay connected to the most important people, content and services. The average U.S. household now owns 16 connected devices, according to a 2022 study from Parks Associates. With home and work lives intertwined, consumers expect consistent access across their smartphones, watches, tablets and laptops. At Ford, we believe this seamless connection should continue when our customers hit the road.

Now, with the all-new Ford and Lincoln Digital Experience, customers can access their digital lives, including their favorite apps and services from Google and Amazon, through the new integrated native experience, as well as with Apple CarPlay ® powered by iPhone, and Android Auto ™ through other compatible devices. 1

From the moment customers enter a vehicle with a Ford or Lincoln Digital Experience, their vehicle becomes a personalized experience, with apps and content easily displayed front and center to help make time behind the wheel more enjoyable, even when parked.

Elevate Your Driving Experience

The user experience with Ford and Lincoln Digital Experience is crafted around the driver to be simple and intuitive, with a touchscreen control panel and buttons on the steering wheel.

- The Ford and Lincoln Digital Experience first come to life through beautiful display screens, including a 48-inch immersive panoramic display first available on the 2024 Lincoln Nautilus. It is the highest-resolution display Lincoln has offered.

- The panoramic display makes critical information available right where you need it, such as preferred apps and services – including BlueCruise 2 for hands-free highway driving – displayed on the screen in the driver’s line of sight.

- The ability to place apps and services in the desired spot on the touchscreen or panoramic screen is intended to be as simple as possible. Supportive information like media, weather and fuel economy can be seen with a quick glance via widgets on the right side of the display. This helps drivers keep their eyes up and out to look at the road ahead, while providing the custom information they desire.

- Establishing profiles enables each driver to set preferences to appear when entering the vehicle. These include apps, contacts, and favorite destinations, plus customized seating, steering wheel and mirror positions.

- Getting around town is simple, using integrated Google Maps for real-time traffic, road conditions, dynamic and eco-friendly routes and points of interest.

- Designed to prioritize the use of voice, Google Assistant serves as the default voice assistant and Alexa Built-In is also available as an alternative for in-vehicle controls such as to set in-vehicle temperature, search information, find and set a destination and request a specific broadcast or satellite radio station. 3 It can also help with making calls, sending texts, setting a meeting, or controlling connected home devices.

Download Your Favorite Apps

The experience connects to a customer’s digital life to make the cabin more personalized.

- Enjoy streaming music, audiobooks, and podcasts using entertainment apps downloaded on Google Play including Spotify, Amazon Music, Audible, and iHeartRadio, as well embedded SiriusXM with 360L 5 for a personalized listening experience so they are always available in the vehicle – regardless of whether a smartphone is connected in the vehicle.

- While parked, play games on the touchscreen by selecting from a growing list available on Google Play, including a Ford-exclusive version of the racing game Asphalt Nitro 2. Connect to a Bluetooth-enabled gaming controller for a more immersive experience.

- Watch videos and stream your favorite movies and TV shows when parked with apps such as YouTube, Prime Video and more to stay entertained while out and about on daily journeys.

- Surf the web while parked using the available Vivaldi Browser app – as well as Google Chrome coming soon – including with a Bluetooth-connected keyboard to make typing easier.

- Stay productive on the go, and never miss a work call with leading video conferencing apps coming soon, enabling audio access while driving and displaying the incoming video feed of participants while parked.

A platform built for the future: The Ford and Lincoln Digital Experience is the fastest infotainment system Ford and Lincoln has ever offered. The system is capable of more than five times faster main processing, nearly 14 times faster graphics processing and features four times the memory and eight times the storage compared to today’s Ford and Lincoln in-vehicle infotainment system. It’s designed to enable more new apps and services in the future thanks to over-the-air software update capability. 6

- 5G wireless technology brings incredibly fast connectivity and with a Ford or a Lincoln Premium Connectivity plan, it will provide the best possible in-vehicle experience.

- The availability to activate a Wi-Fi hotspot can help ensure that passengers can happily stream on their own devices inside the vehicle.

Ready for Software Updates

The Ford and Lincoln Digital Experience represents a step forward in Ford’s approach to design and development of in-vehicle infotainment systems. The company is developing more of the software in-house to deliver a higher velocity of updates and improvements.

Ford has built a general computing platform to deliver more of the benefits of a software-defined system. This includes transitioning from using two separate modules for the instrument cluster and infotainment system to a single module to facilitate faster software changes and better speed of response to commands via updates.

It was important to choose an operating system with a scalable and open architecture that offers customization to serve the evolving needs of customers over time.

Bringing more of the software development in-house allows for the creation of unique experiences like the widgets in the panoramic display and the ability to help make the vehicle better over time through software updates.

Customers will experience new apps and services faster than before because apps and system-level updates are now independent of each other. System-level updates are pushed through vehicle software updates like what happens today, while other applications can come through Google Play. This enables the customer to benefit from new apps coming from third-party developers versus app experiences being tied to vehicle system software updates.

Only the Beginning

The Ford and Lincoln Digital Experience deliver a driver-first experience that can be personalized and customized to fit unique customer needs and ultimately make the driving experience more enjoyable. The Lincoln Digital Experience is available on the all-new 2024 Lincoln Nautilus available now. Stay tuned for the first Ford Digital Experience vehicle integration.

1 Don’t drive while distracted or while using handheld devices. Use voice-operated systems when possible. Some features may be locked out while the vehicle is in gear. Eligible 2024 model year vehicles receive complimentary access to three years of Alexa Built-in and one year of Lincoln Premium Connectivity Connected Service plan which begins on the New Warranty start date. Cellular network may limit functionality and prevent operation of connected features.

2 Available Feature. BlueCruise requires a Connected Service plan, FordPass® App or Lincoln Way® App, and modem activation. Equipped vehicles come with either a complimentary trial period or an included BlueCruise Connected Service plan duration, after which purchase is required. See ford.com/bluecruise or your Lincoln retailer for more details. BlueCruise driver-assist features are supplemental and do not replace safe driving or driver’s attention, judgment and need to control the vehicle. Only remove hands in a Hands-Free Blue Zone. Always watch the road and be prepared to resume control. See Owner’s Manual for details and limitations.

3 Eligible vehicles receive 3 years of complimentary access to Alexa Built-in. Lincoln Premium Connectivity offered on eligible vehicles with a 1-year complimentary service. Trials begin upon New Vehicle Warranty start date. Access to Alexa Built-in requires an Amazon account, Lincoln Digital Experience, Lincoln Way® activated through the Lincoln Way® App (see Lincoln Way Terms for details). Some Google Assistant, Google Maps, Google Play, and Alexa Built-in features require Lincoln Premium Connectivity connected service plan or Wi-Fi network. Connected service and features depend on compatible AT&T network availability. Evolving technology/cellular networks/vehicle capability may limit functionality and prevent operation of connected features. Lincoln Way® App, compatible with select smartphone platforms, is available via a download. Message and data rates may apply.

4 Android Auto™ and Apple CarPlay®: Requires phone with active data service plan and compatible software. In-Vehicle Digital Experience does not control third-party products while in use. Third parties are solely responsible for their respective functionality. Data rates may apply. Not all features are compatible with all phones.

5 SiriusXM trial subscription will stop at the end of the trial period. Trial is non-transferable. If you do not wish to enjoy your trial, cancel by calling the number below. Service subject to the SiriusXM Customer Agreement and Privacy Policy; visit www.siriusxm.com for full terms and how to cancel which includes online methods or calling 1-866-635-2349. Services, content and features are subject to device capabilities, location availability or active data connection. Fees, content and features are subject to change. Available in the 48 contiguous United States, D.C., and Puerto Rico (with coverage limits and capable receiver). Visit listenercare.siriusxm.com for most current service area information. Radio features, content, and display may vary by vehicle. Some features may not be available while driving.

6 Lincoln Connect, the Lincoln Way App and complimentary Connected Service are required for remote features, including over-the-air updates. (see Lincoln Way Terms for details). Lincoln Way App is available via a download; message and data rates may apply. Connected Service and features depend on compatible AT&T network availability. Evolving technology/ cellular networks/ vehicle capability may limit functionality and prevent operation of connected features. Connected Service excludes Wi‑Fi hotspot.

Google, Google Play, Google Map, Google Chrome and other marks are trademarks of Google LLC.

Amazon, Alexa Built-In, Audible, Amazon Music, Prime Video and all related marks are trademarks of Amazon.com, Inc. or its affiliates.

Apple, Apple CarPlay, iPhone and Siri are trademarks of Apple Inc., registered in the U.S. and other countries.

About Ford Motor Company Ford Motor Company (NYSE: F) is a global company based in Dearborn, Michigan, that is committed to helping build a better world, where every person is free to move and pursue their dreas. The company’s Ford+ plan for growth and value creation combines existing strengths, new capabilities and always-on relationships with customers to enrich experiences for and deepen the loyalty of those customers. Ford develops and delivers innovative, must-have Ford trucks, sport utility vehicles, commercial vans and cars and Lincoln luxury vehicles, as well as connected services. Additionally, Ford is establishing leadership positions in mobility solutions, including self-driving technology, and provides financial services through Ford Motor Credit Company. Ford employs about 182,000 people worldwide. More information about the company, its products and Ford Credit is available at corporate.ford.com .

You May Also Like

Thousands of new tech team members helping transform Ford with more on the way

How Ann Arbor, Michigan Became a Living Lab for City Mobility

Shifting Gears: How Ford’s digital-first approach put customers in the driving seat during lockdown

Something that really resonated with me from this year’s Adobe Summit, was the number of customers sharing how the COVID-19 pandemic had accelerated their digital transformation plans faster than they ever thought possible. When speed was of the essence, leading car manufacturer, Ford of Europe, was one of the companies leading the way.au

The pandemic – and subsequent lockdowns – left the company needing to close dealerships and cancel automotive shows where it would traditionally have launched and sold its vast range of vehicles. But, at the same time, it started to see more demand for vehicle ownership – especially from younger audiences – who realised a car would be the most convenient and safest way to travel during the pandemic. Claire Hepworth, Head of Customer Engagement, Ford, described the situation to us at Adobe Summit: “ The pandemic caused disruption in the sense of how it closed the physical side of the industry down, but also in terms of how people got from A to B. Many people realised how much they wanted a car when they could not, or did not want to, take public transport. During the pandemic, a car was like a safe bubble. ”

Ford’s answer to its greatest challenge was a bold one; to expedite the digital transformation it had kick-started a couple of years ago and create a truly digital-first approach to vehicle launches, sales and after-care, with customers’ needs right at the centre.

Focusing on a completely online vehicle launch

Ford had already been exploring e-commerce as part of its digital transformation, but the true test came with the launch of its first all-electric SUV – the Mustang Mach-E – which would now be completely online.

“Five years ago, we couldn’t have predicted Covid, but we could see a need for a more omni-channel experience. We knew two-thirds of consumers would be open to buying a vehicle online, and so focused on building out our ecommerce offering. When the pandemic hit, it became a central part of our plan, integral to how we kept selling.”

Everything from registering interest, to purchasing and vehicle customisation was carried out online. With test drives on hiatus, customers were invited to virtual showrooms and provided with in-depth content around the vehicle’s functions and features, to replicate the experience they would normally have received at a dealership.

But it wasn’t just about purchasing cars online. Ford started offering a true ‘online marketplace’, where customers could buy any kind of goods, products or services from its e-commerce site, including service plans and car accessories as well as the vehicles themselves.

Accelerating communications with customers

Ford’s ambition is to treat customers like family, and by moving to a digital-first model it was able to do just that. For the business, this means being able to predict the needs of its customers and their vehicles, according to where the customer is in the purchasing or ownership cycle, and personalising outreach accordingly. Adobe Analytics measures and informs its ‘next-best action’ communication, while Adobe Campaign and Adobe Target deliver timely, personalised communications, based on customers’ and their vehicle’s needs.

“Customers want hyper-personalised experiences when buying a car. They want to know that you understand them, their vehicle, and their future needs. Adobe Experience Cloud lets us truly understand our customers and tailor communications to where they are in the sales-cycle. So whether they’ve simply registered interest in a new vehicle, or they’ve been a customer for a while and their car is due a service, they’ll receive personalised communication from us on just that – and at exactly the right time.”

The road ahead.

As it moves forward, Ford wants to add AI and machine learning to its customer experience. Critical to achieving this will be the commitment and progress the business has already made to breaking down data siloes and bringing all teams – from pre-sales to after-sales, marketing, maintenance customer service – together to make the most effective use of its data and create a single view of the customer. In the future, AI and machine learning coupled with prognostic data will be used to predict when a vehicle is likely to need servicing or maintenance ahead of time. Through dynamic 1:1 communication, Ford plans to pro-actively advise customers to bring their vehicles in for checks, before a problem manifests itself.

Thanks to it its investment in digital, Ford is now in a position to run a truly omni-channel experience for customers. The company is going to take a hybrid-approach that enables customers to engage with the brand both digitally and physically now that dealerships have reopened – based on their preference. As Hepworth says: “ We’re going to keep accelerating the online innovation as we move forward, but want a ‘best of both worlds’ approach, which acknowledges that customers will sometimes want to do things online, but will at other times want to visit a dealership. We’re on-boarding dealers to the system and making sure they can use it to communicate with customers too – it will keep the personal element there and show people Ford is one connected company they have a relationship with, no matter how they choose to interact with us ”.

We’re clearly entering a new era in customer experience, one that’s been expedited by the pandemic. Ford is a great example of how the automotive industry has evolved accordingly. With more consumers open to purchasing big-ticket items like cars entirely online, these kinds of experiences will only become more commonplace, even as pandemic-related restrictions start to lift. And I, for one, am excited to see what comes next.

https://blog.adobe.com/en/publish/2021/05/20/isobar-helps-mitsubishi-motors-australia-drive-new-car-buying-journey#gs.9uba3q

https://blog.adobe.com/en/publish/2021/05/07/bon-voyage-embarking-on-journeys-that-guests-love#gs.9ubaex

https://blog.adobe.com/en/publish/2021/05/06/adobe-helps-cooperative-bank-grow-customer-engagement-with-in-app-messaging#gs.9uba9j

Connected Manufacturing Forum 2024

June 25 - 26, 2024

Westin Buckhead Atlanta, GA

Ford Motor Enters Digital Era With Its Advanced Manufacturing Center

(Image source: Ford Motor Company)

Industrial Evolution

From the initial development of machinery and processes, through to mass production, then the integration of computers and automation, the first three industrial revolutions pushed the boundaries of our manufacturing capabilities to new levels.

The fourth industrial revolution or Industry 4.0 is currently underway, and builds on those technological leaps. Through cyber-physical systems, the Internet of Things (IoT), cloud computing, cognitive computing, and other technologies, Industry 4.0 has been connecting machines to one another with digitally enabled technology, to create a more seamless manufacturing environment.

Industry 4.0 represents a major shift in outlook and operations for all businesses involved in the manufacture of products, and its technology is being adopted by organizations across the globe. In the tradition of its founder whose visionary ambition was to “put the world on wheels,” teFord Motor Company has embraced this new reality, and created a hub for innovation in its brand-new Advanced Manufacturing Center (AMC).

Reinventing The Assembly Line For A Connected Future

In an effort to accelerate manufacturing innovation, Ford Motor Company has brought advanced engineering expertise and technology together in a single location - an incubator for prototypes, before tested innovations can be rolled out to auto plants across the globe. The 135,000-square-foot facility was opened in the summer of 2018.

Ford's new facility is located in the manufacturing heartland of Redford, Michigan, and represents an investment of around $45 million. The Advanced Manufacturing Center has a workforce bolstered by over 100 manufacturing technology experts, and is home to a host of specialized equipment.

Ford was responsible for the innovation that heralded the Second Industrial Revolution: the creation of the first moving assembly line - a development which changed forever the way that vehicles would be mass-produced. With its new Advanced Manufacturing Center, the company looks to extend its tradition of innovation even further.

As Joe Hinrichs, Ford's President of Global Operations puts it: "Today, we are reinventing tomorrow's assembly line - tapping technologies once only dreamed of on the big screen - to increase our manufacturing efficiency and quality."

Enhancing Production Through Additive Manufacturing

Wasteful traditional methods of manufacture rely on cutting components out of native materials (steel, wood, etc.) - then throwing away the excess. This takes a toll not only on the environment, but also on the enterprise, as much of this waste material can't be reclaimed or reprocessed, and translates into lost revenue.

Additive manufacturing eliminates this wastage by creating components out of layers of material, which are fused together to form a cohesive whole. Precise amounts of material may be used in making each layer, and these layers - which often have extremely intricate and complex shapes - can be accurately designed using computers.

3D printing is the most widely recognized and accessible form of additive manufacturing - and Ford Motor Company has been a trend-setter in this field, since its acquisition of one of the earliest 3D printers back in 1988.

Though the technology was initially focused on the techniques of "rapid prototyping", additive manufacture and 3D printing are now being used for more than just the simple production of concept models. With the development of new materials and processes, additive manufacturing is emerging as a valuable tool to assist in production applications, and to act in support of mainstream production.

Ford currently has almost 100 additive manufacturing machines spread around 90 global locations. Of these, 23 are located at the Advanced Manufacturing Center.

The materials used in 3D printing tens of thousands of parts include, steel, sand, carbon, and nylon powder. Most of these components are created for products which are currently at the prototype stage. It's expected that they will play a key role in the development of new automobile technology - and to this end, Ford has partnered with 10 3D manufacturing companies to maximize the gains of its advanced manufacturing initiative.

Harold Sears, the Technical Leader of Additive Manufacturing Technologies at Ford, identifies two key areas where 3D printing is making an impact on the company's manufacturing operations: The first is in supporting current production processes with more efficient tooling, jigs, and fixtures. And the second lies in actually using these improved processes in the manufacturing space.

Product development processes have accelerated, due to the ability of designers to make 3D printed models of several different designs, which can then be tested by engineers simultaneously. This saves the company money in not having to make several iterations of the same design, and greatly reduces a component's time to market.

The practical benefits of additive manufacturing are already being felt. For instance, the new Shelby Mustang GT500 has 3D-printed brake-bracket parts - an innovation which has enabled the super-performance muscle car to claim the title of the fastest street-enabled Ford Mustang ever. Unveiled in January at the North American International Auto Show, the 2019 Shelby GT500 uses 420mm (16.8 inch) two-piece brake rotors - the largest of any American sports coupe.

(Image source: AUTOCAR UK )

Additive fabrication methods have also contributed to the design of the 2019 F-150 Raptor, a pickup truck that features an instrument-panel spotlight-switch blanking plug which was designed and 3D printed specifically for the Chinese market.

(Image source: Ford Motor Company )

Besides motor parts, in-house 3D printing technology is also used to generate production line tools for engineers and assembly line employees. At an individual level, this makes it possible to design and fabricate tools ergonomically, to match the specific physical requirements of each worker such as hand size, or grip strength.

In production, it's possible to design and print tools which are tailored specifically for certain projects. For example, at Ford’s Michigan Assembly Plant five different 3D printed tools are used in constructing the Ranger pickup. The custom tools fabricated prior to the launch of the Ranger removed weeks from an already tight production schedule - and ensured that quality was consistent and inherent in every vehicle that rolled off the assembly line.

On the production line floor, workers can collaborate with advanced manufacturing experts to identify ways in which additive manufacturing techniques can save the company time and money. This includes the design, specification, and printing of 3D replacement parts that can keep production lines running, rather than having to wait days or even weeks for parts to be ordered or fabricated elsewhere.

Ford's collaboration with 3D manufacturing partners has allowed the company's experts to develop a range of applications with different materials. One of those currently under development has the potential to save the company more than $2 million. It's anticipated that, as 3D printing becomes more affordable, 3D parts will become more widespread - throughout the enterprise, and in the industry at large.

This growth in additive technologies is expected to fuel a demand for new staff recruitment and training methods, to enable organizations to source the skills necessary for 3D printing operations and other Industry 4.0 enabled tasks. Ford has begun addressing this need by training employees to use Design for Additive Manufacturing (DfAM) methodologies. These methods require trainees to take a more wide-ranging view of the design process - one that encompasses the production process, software, and hardware. Taking Design To New Planes With Augmented And Virtual Reality

Industry 4.0 technology also has an impact on the conceptual phase of automobile production, and the Advanced Manufacturing Center uses augmented reality (AR) and virtual reality (VR) technologies at the design stage. The digital environments enable Ford's engineers to create virtual production lines, run test case scenarios, identify potential hazards, and fine-tune the manufacturing process long before the first vehicle is ever assembled.

Ford experts use specialized gaming equipment to configure virtual reality production lines with the real-world potential to make millions of vehicles - all from within the Advanced Manufacturing Center. Augmented reality overlays and virtual reality simulations allow them to identify potentially hazardous maneuvers and fine tune production workflows, long before the assembly lines are constructed.

With internet connectivity, the design process can be made both collaborative and global. Augmented and virtual reality spaces accessed via the internet empower Ford manufacturing teams around the world to collaborate on training or assembly techniques, simultaneously sharing the same virtual experience.

These technologies compress production timetables, enable technicians to unlock solutions in real time, and allow Ford to optimize its manufacturing workstations for each location globally.

Humans And Machines, Working Together In Harmony

Robots have been part of the production line ecosystem for some years now, and in the Industry 4.0 era Ford has developed a particular interest in collaborative robots - or cobots, as they are familiarly known. These machines are designed to operate alongside human workers, and the company has installed over 100 of them across 24 of its facilities.

Having a smaller footprint and often a greater degree of mobility than robots of previous generations, cobots are designed for safety, removing the need to enclose them in expensive and hard to access protective cages. They can also operate in conditions that would be hazardous to humans - and work for longer time periods. For example at Ford's Livonia Transmission Plant, a cobot is used to perform ergonomic tasks which health and safety concerns only allow a human worker to attempt for one hour at a time.

Specialists at the Advanced Manufacturing Center are investigating the use of cobots to identify any potential challenges before they are deployed in factories around the world. Monitoring the performance of cobots at the Advanced Manufacturing Center allows the company to identify and address potential production issues before the automated machines are installed in Ford's other facilities.

One of the biggest issues that the use of robots has traditionally raised is its impact on human employment. It's been estimated that robots may hold nearly 40% of all American jobs by the early 2030s. This has become particularly relevant as, according to research by Loup Ventures 34% of the industrial robots sold by 2025 will be collaborative - and the industrial robotics market is expected to grow by 175% over the next decade. The primary focus of that growth is expected to be on collaborative, assistive platforms.

(Image source: Loup Ventures )

The automotive industry is set to lead this trend, with adoption being driven by advancements in computer vision, artificial intelligence (AI), and motion sensing capabilities. In future, it's believed that the rise in low-cost collaborative robotics technologies will increase access to automation technology across a range of new applications, which will drive adoption across a new set of verticals.

Technology aside, robots are viewed as very much a complementary part of Ford's manufacturing ecosystem, rather than any form of replacement for its human workforce. Collaborative robots need people to work alongside the machinery - and they also need human workers dedicated to their maintenance, development, and operations.

In the words of Joe Hinrichs: “While we are increasing our use of collaborative robots, we strongly believe there is a need for both people and robots. People are better at doing certain jobs, while robots are able to perform certain tasks, including those that are ergonomically taxing for people.”

Humans And Machines, Moving Forward

The interaction between humans and machines that's being promoted by the Ford Motor Company extends beyond the factory floor to the design ethic and functionality of its new breed of automobiles. In addition to its 3D printed components, the F-150 pickup truck is serving as a flagship model for the use of Industry 4.0 digital technologies in enhancing the driving experience.

Ford's Global Director of Interaction & Ergonomics, Parrish Hanna heads the team that's steering Ford and the F-150 toward the cutting edge of human machine interaction (HMI). He oversees the work of over130 researchers, engineers, and designers who are discovering new ways to incorporate digital technology into the F-150 - from instrument panels through to lighting, acoustic design, in-car entertainment systems, and other features.

To understand and establish that the technologies being placed in the F-150 are useful and desirable, the team employs specialists in human culture who ride along in the back seat as unbiased observers, looking for patterns, interactions, and new behaviors surrounding the vehicle technology. New technologies are tested at "hotspots" such as truck rallies and auto shows, where researchers can get grassroots opinions from passionate truck people about what works, and what doesn’t.

The feedback loop involves analysis of the resulting customer data, and the presentation of those findings in the form of revised concepts which are floated to actual truck users to assess their reactions.

This methodology has led to the development of My View, an on-board configuration system which allows F-150 drivers to customize the content and order of the truck’s driver cockpit screens – and to access them with the touch of finger. Personalization options like this are part of a fresh and far-reaching approach to human machine interaction and technology integration, which Hanna describes as: "A much more holistic system, including new disciplines and other groups within Ford, such as advance research, design and marketing.”

The (Connected) Road Ahead

With its commitment to cutting edge technologies like collaborative robots, 3D printing, augmented and virtual reality, Ford has firmly established itself as an important innovator in the field of connective automotive manufacturing - both now, and into the future.

In the Advanced Manufacturing Center, the Ford Motor Company has created a formidable testing ground where the latest Industry 4.0 technology can be put through its paces, before it rolls out to global factories.

Ford Motor Company's Chief Engineer for Advanced Manufacturing, Michael Mikula, will be speaking at Connected Manufacturing Forum 2019 , which will be held in July at the Hilton Austin, Austin, TX.

Download this FULL CASE STUDY for free as a PDF

Ford bets on Google Cloud for its digital transformation

Google and Ford today announced a new partnership around bringing Android Automotive to Ford’s Ford and Lincoln-branded cars, starting in 2023. But at the same time, the two companies also announced that Ford has chosen Google Cloud as its preferred cloud provider.

“With Google Cloud, Ford will digitally transform from the front office to the car to the manufacturing plant floor,” Google Cloud CEO Thomas Kurian said in a press conference today. “And there are a number of different applications, including modernizing product development, improving manufacturing and supply chain management, using computer vision AI for employee training, inspection of equipment on the assembly line and other applications.”

Kurian also noted that Google and Ford are working to find new ways to monetize Ford’s data through features like maintenance requests and trade-in alerts.

Ford vehicles will be powered by Google’s Android operating system

“At Ford, we’ve got world-class in-house data insights and analytics teams,” David McClelland, Ford’s VP for strategy and partnerships, said. “We’ve recruited significant software expertise and we’re making great progress in this area. And we’re moving rapidly towards commercializing our new self-driving business. And with this news that Thomas [Kurian] and I are announcing today, we’re turbocharging all of that.”

McClelland stressed that Google “brought the entire company to the table for us across cloud, Android, Maps and much more.” It’s maybe also no surprise, given Google’s expertise in this area, that Ford is looking to leverage Google Cloud’s AI tools as well. This work will go beyond the actual driving experience, too, and include work on modernizing Ford’s product development, manufacturing and supply chain, as well as predictive maintenance in Ford’s plants.

Like other car manufacturers, Ford is also looking to find ways to use the data it collects to create a connection to its drivers that goes beyond the buying experience and (maybe) the occasional maintenance visit to a dealership. For this to work, it needs to be able to understand its customers and offer personalized experiences.

Today’s announcement marks a bit of a turnaround for Ford, which had previously banded together with a group of other car manufacturers with the explicit goal of keeping Google’s role in the automotive industry to a minimum. Now, only a few years later, the two are coming together in one of the deeper partnerships in the industry.

It’s also worth mentioning that not too long ago, Ford had a deep partnership with Microsoft, which provided the basis of Ford’s Sync technology.

“From the first moving assembly line to the latest driver-assist technology, Ford has set the pace of innovation for the automotive industry for nearly 120 years,” said Sundar Pichai, CEO of Google and Alphabet. “We’re proud to partner to apply the best of Google’s AI, data analytics, compute and cloud platforms to help transform Ford’s business and build automotive technologies that keep people safe and connected on the road.”

Ford and Toyota launch consortium to help developers build in-car apps

Digital Innovation and Transformation

Mba student perspectives.

- Assignments

- Assignment: Competing with Data

Ford’s Bets on Big Data

This post examines Ford’s bets on utilizing extensive data and analytics as an essential asset to their business. It covers 3 data examples, the value captured, and potential challenges.

In the automotive industry, Ford is a well-known player, being one of the first to bring the assembly line to vehicle production. As technology constantly changes, incumbent players must adapt to maintain their advantage. Consequently, Ford has taken recent bets on big data investments.

In terms of maintenance, Ford utilizes data as a measure to improve downtime internally. In 2019, they developed a “Miniterms 4.0” system that notifies factory employees when manufacturing functionality reduces (2). Value capture occurs from reduced production delays as a result, leading to improved service levels and satisfaction; in the first year, the project delivered more than $1M in savings (4). As new car model launches occur at a regular cadence, this launch process and cycle continues to renew the usage of the novel predictive maintenance tool. Currently, this tool has been deployed for 15,000 machines in Ford’s Valencia plant (4). However, future challenges may arise from scaling to other sites given the complexity of vehicle parts production and the global nature of the business, with 10+ different country locations of assembly plants alone (5).

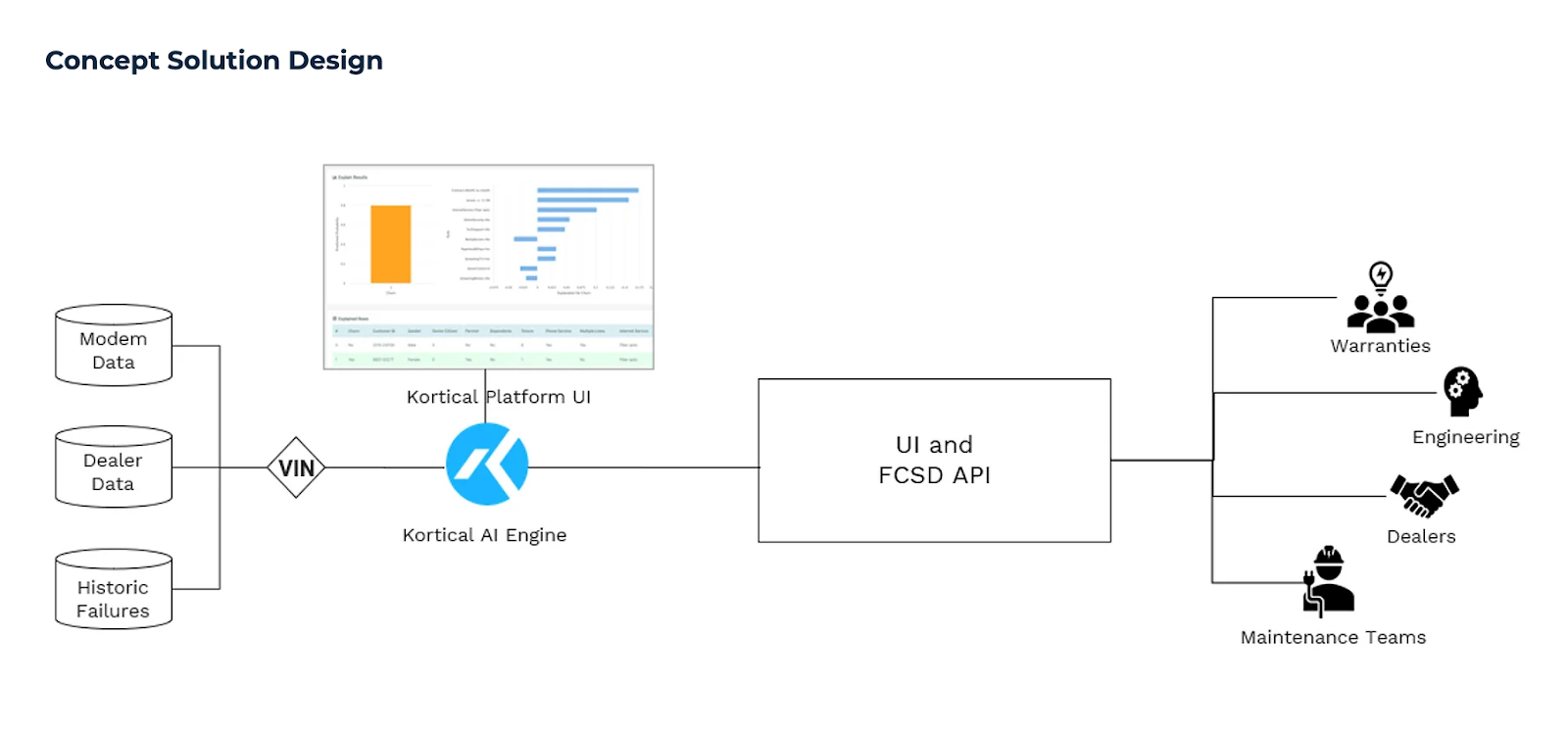

Externally, for the customer, Ford has pushed for R&D efforts with other organizations to understand how to utilize vehicle connected sensor data to detect failures before they manifest (3). This process can enable the company to proactively get parts in advance to reduce service time (3). Not only does this improve and optimize maintenance scheduling, but it also can help reduce time loss as a customer waits for their cars in service (3). Studies have shown upside can be $7M due to the downtime saved (3). The challenge is its usage might be more applicable for uncommon parts that may not typically be in stock; if the part is in stock, the time savings is not realized. The accuracy of predicting which parts may fail in the near-term may be questioned, as the study has shown a false positive rate of 2.5% with this model (3). Thus, costs can be incurred to have parts ordered by a repair shop if ultimately it isn’t needed.

Another bet Ford has taken is with its partnerships: in 2021, Ford announced that Google will provide services on AI, data analytics, and the cloud platforms for Ford; at the same time, Ford customers will be able to access Google Assistant voice technology, Google maps, and Google Play services within the car (1). With Google’s analytics and cloud services, Ford also plans to improve efficiency in vehicle development, supply chain, and manufacturing operations (6). Improved supply chain and operations will enable the company to continue to meet demand and production targets. One implemented use case has been an application that uses Google Cloud technology to monitor material inputs and process parameters for a vehicle production step (2). Part images are taken during the production process that are hosted on Google Cloud, which are then analyzed by engineers to ensure quality (2). The implications of this is improved reliability of the car as out-of-spec parts are better caught before moving further downstream.

Further value capture from the Google partnership comes from the personalization ability in-car (2) which can better meet customer needs and generate positive brand equity. Driver data collection can also enable the company to create improved safety systems (e.g. blind spot, emergency braking, lane assist) (2). Additional value capture can occur from data monetization – through user driving data, Ford can generate another revenue stream by selling data to adjacent companies like those in the insurance space (6). Challenges may stem from data privacy concerns if driving behavior data is sold to other companies, but given the rise of insurance programs that currently exist today based on usage, this seems to be less of a concern.

Pathways to a Just Digital Future

As an incumbent, Ford can be perceived as being a slow mover due to their scale and matrix nature. One concern is how their competition has responded, and if Ford can keep up. A core question in mind is: are big data investments now just table stakes in the automotive industry? In the examples shown above, big data has served as a means to meet service levels and reduce operational costs. Especially post-pandemic, robust operations has an even greater importance as supply chains were stress-tested. Ford’s shift towards investing in data and analytics may be a move to keep up with its peers, but challenges the in the near-term can continue with the rise of disruptive technologies by smaller, more nimble peers (e.g. autonomous technology).

- https://www.freep.com/story/money/cars/ford/2021/02/01/ford-google-android-real-time-traffic-technology/4336624001/

- https://www.thomasnet.com/insights/how-big-data-is-steering-ford-motor/

- https://kortical.com/case-studies/ford-predicting-failures-ai-example

- https://media.ford.com/content/fordmedia/feu/en/news/2020/11/19/ford-uses-big-data-to-ensure-body-line-keeps-rolling–saves-more.html

- https://corporate.ford.com/operations/locations/global-plants.html

- https://www.aidataanalytics.network/data-monetization/articles/fords-data-driven-roadmap-towards-future-mobility

- Attribution for header photo: https://www.vecteezy.com/free-photos Free Stock photos by Vecteezy

Student comments on Ford’s Bets on Big Data

This is very interesting – also cool post because my own submission is about using telematics in auto insurance, and I didn’t know companies like Ford were selling data to insurance companies!

In trying to think through whether there would be demand from insurance companies from such data, I think it would probably depend on whether they can get the data from elsewhere. For example, many telematics companies (e.g., https://www.cmtelematics.com/what-makes-us-different/ ) are now linking up to apps on driver’s phones for comprehensive geolocation, acceleration, velocity, etc. data — where do connected vehicles come into play, and what is the additional value of the vehicle data to an insurance provider? Would love to discuss!

Cool stuff! I’m curious, as we shift to autonomous and electric vehicles, the complexity of the car itself goes down substantially with a lot fewer parts and more emphasis on the interior of the car and the passenger experience. Ford’s partnership with Google makes sense as they want to understand customer needs while within the vehicle but not necessarily driving (more like what a passenger would do) which could include working, shopping, entertainment, browsing social media, etc. Do you think that partnering with a company as opposed to doing it internally gives up most of the value created in this shift and that Ford could be stuck with only the low margin structure of the cars going forward while tech companies like Google get the Lion’s share?

I always have deep concerns when two entrenched incumbents (in this case Google and Ford) come together and believe that “if we put our two existing technologies together, everything will go great!”, specifically in the case of in-car optimizations. I think one of the reasons why Tesla has been so successful with its vehicles is because it has aggressively vertically integrated its hardware and software stack, so that the end product is genuinely reflective of a single design vision. In Ford’s case, because Ford already outsources many of its subcomponents, its vehicles are essentially a collection of technical pieces manufactured by multiple OEMs. Coordinating those pieces took decades, and adding Google technology in a way that requires it to interact seamless with all of the existing pieces is a tall task, and not one that can be easily undertaken by a company with limited history in software integration (Ford). While I hope this venture succeeds (since competition benefits the end consumer), I am skeptical if Ford can truly make their vehicles play nice with Google, or if this will end up feeling like tacked-on software that doesn’t deliver on meaningful customer value.

Thank you for sharing these insights. I find the use of data to analyze part failures very interesting. I wonder if this same data could be used not only for part maintenance, but also for product development. For instance, Ford is making a push into battery electric vehicles (BEV). One of the main and most challenging components of a BEV is the battery back. It’ll be interesting how Ford utilizes their data analysis for battery efficiency and range.

Leave a comment Cancel reply

You must be logged in to post a comment.

- Deutschland

- Asia, Australia & New Zealand

- Europe, Middle East & Africa

- United States & Canada

- Latinoamérica

How a century-old brand is transforming the auto industry

Before the pandemic, automakers were already facing massive disruption , including driverless cars, electric vehicles, and shared mobility. But COVID-19 dealt another blow: Automotive was one of the hardest hit sectors in 2020, especially in the U.S., where auto sales sank by 15% .

In the midst of these unprecedented challenges, however, 118-year-old Ford Motor Company leaned in and began to reinvent itself.

As the virus accelerated, dealerships were forced to close their lots and shift to servicing and selling cars online , while larger supply chain concerns caused shortages in critical parts like microchips, which slowed vehicle production.

Brands were looking for new ways to drive their marketing and sales forward. In the midst of these unprecedented challenges, Mitsubishi Poland turned to Google Insights and discovered that consumer needs were changing in real-time so they built an engaging marketing campaign with powerful emotional messaging - delivered at exactly the right time - to better connect with prospective customers.

And 118-year-old Ford Motor Company leaned in and began to reinvent itself. Under the leadership of two new executives — Jim Farley as CEO and Suzy Deering as global CMO — the company saw an opportunity for business transformation and started mapping out a strategy.

Questioning everything, from its organisational structure to its customer experience, Ford made difficult decisions to put technology at the center of its business and get ahead of auto consumers’ evolving needs .

While still in the early stages of its journey, Ford has developed something of a blueprint for auto brands of the future. Recently, I spoke to Farley and Deering about the company’s transformation strategy. They shared three key changes they’re focused on.

1. Reimagining what auto brands do

Business transformation has been a buzzword for decades, but for years, it wasn’t an urgent reality for Ford. Then along came the pandemic, and its significance accelerated.

We have to invest in electric architectures and build software know-how in the company. And we need to integrate that know-how in ways we’ve never had to before.

“Events of 2020 made it clear that modernisation is required to be a sustainable company,” explains Farley. A critical factor to modernising has been disrupting its organisational model to aid the shift toward vehicle electrification and other digitally connected products. Since consumers expect more safety and convenience from automakers, the future of the auto industry will increasingly exist outside the doors of the vehicle.

According to Farley, this has required Ford to “unglue” its organisation to allow for a new way of being. “The biggest transformation for us is to a software services–dominated company and brand,” he explains. “We have to invest in electric architectures and build software know-how in the company. And we need to integrate that know-how in ways we’ve never had to before.”

Such a fundamental pivot, Deering acknowledges, impacts company culture. “We have to make sure that we bring people along with us, and at the same time, give them the space to fail. There is strength in knowing that change is not going to be easy, but we’re going to do it together, and we’re going to look forward.”

2. Driving the connected car experience forward

By committing to look forward, the automaker is building on Henry Ford’s original vision — that every American consumer can own a vehicle — by reimagining what vehicle ownership looks like. Through software and other technology, Ford is working to ensure that it’s a fully connected, always-on experience.

When we have the ability to update our products dynamically with software, the customer relationship is no longer episodic. It’s every day.

“For so long, cars have really been isolated from the rest of people’s lives. We can change that by making them digital products,” Farley explains. To facilitate this shift, Ford has tapped into strategic partners like Google and is integrating software into its vehicles. Beginning in 2023, for example, millions of Ford and Lincoln models will be powered by the Android operating system, with Google apps and services built in.

Beyond offering drivers more assistance and convenience, connected vehicles also give Ford the ability to deepen its customer relationships. “When we have the ability to update our products dynamically with software, the customer relationship is no longer episodic. It’s every day,” says Farley.

3. Transforming the customer relationship model

To deliver on its vision of an always-on customer experience, Ford is also evolving how it approaches relationship-building. While many automakers stick to a traditional acquisition model to attract consumers through ads and rebates, Ford is bringing customer relationships to the forefront by shifting to a loyalty-based model.

“Another big transition for us as a company — and an industry — is to stop being obsessed with conquest and start putting all of our resources into taking care of the customers who already love the brand and own the product,” Farley explains. “This is a model that is available because of the always-on nature of digital. Our products and services are now integrated.”

We want to know our customers well enough to meet their needs while they’re in the vehicle, while they’re outside the vehicle, and before they even think about buying a vehicle.

Gearing marketing efforts to meet people’s ongoing needs in a more personalised way is critical to Ford’s loyalty-based push, because, as Deering points out, “The customer expects us to know them.”

For Deering and her team, this means relying more than ever on first-party data and signals to create an ecosystem that nurtures deeper relationships. “We want to know our customers well enough to meet their needs while they’re in the vehicle, while they’re outside the vehicle, and before they even think about buying a vehicle from us,” she explains.

While Deering and Farley both readily admit that Ford’s business transformation is a yearslong journey, they’re committed to playing the long game and continuing to drive brand love and loyalty through the 21st century.

Others are viewing

Marketers who view this are also viewing

5 trends shaping the auto industry’s approach to a new normal

Build better creative for your performance marketing, how the power of data transformed volvo’s digital marketing, bidding for success: new ways to find your most valuable customers, top digital marketing trends and predictions for 2024, driving growth in a changing privacy landscape: the digital marketing playbook, thomais zaremba, others are viewing looking for something else, complete login.

To explore this content and receive communications from Google, please sign in with an existing Google account.

You're visiting our Europe, Middle East & Africa website.

Based on your location, we recommend you check out this version of the page instead:

in Building Authority , Free Business Training , Professional Development

How ford embraced digital transformation (and 4 reasons why b2b businesses should do the same).

- by Charles Gaudet

Join Thousands of CEOs Getting Free Daily Business Coaching Videos

the predictable profits playbook

Beyond 7-Figures podcast

Want practical tips, strategies and ideas that our clients use to scale their businesses? We invite you to sign up for our free daily business coaching videos where you’ll get in-the-trenches insights that drive huge results. Click here to sign up.

Companies that have realized the importance of digital transformation are thriving in the B2B space. Here are some tips for your company to follow suit.

In general, B2B businesses haven’t been as quick to go digital as B2C companies. That isn’t true for everyone, though… Take Ford, for instance. They’ve become a great example of B2B digital transformation.

And they didn’t start small…

The automotive giant has one of its biggest factories in Cologne, Germany. The factory makes more than a million transmissions a year. They supply Mazda and Volvo in addition to Ford, and it’s not just about volume… The factory creates many types of custom variations as well.

With this huge, complex system, it’s no surprise that they often faced delays when production processes failed to run smoothly.

So, Ford decided to do something about it.

They used digital transformation to change that factory into an innovation hub. To deal with the problems, Ford implemented the Material Flows Wireless Parts system. This allows them to track critical parts and make sure that the right quantities of those parts get to the right place at the right time.

They started with 220 radio-frequency identification (RFID) tags. Each one corresponds to a unique part number. Then Ford set up portable PCs at critical stages in the assembly and production lines and installed a special wireless infrastructure as part of this B2B digital transformation.

Now when a worker needs a particular part, they hit a WhereCall materials replenishment button. This causes a “Parts Needed” message to show up in the warehouse. Suppliers also get a notification that assists in tracking inventory.

All of this combines to make sure everything works smoothly. On the assembly line, workers stay put and call for more parts as necessary. The result is seamless production at the factory, all built on modern digital technology integrated into their existing manufacturing process.

They’re now also using artificial intelligence to simplify the process even further. Once up and running, the AI will use modeling techniques to eliminate the WhereCall step altogether.

The importance of digital transformation extends well beyond automated production processes, though… Below are several reasons for taking advantage of B2B digital transformation in your own business.

Better Customer Experience

It’s safe to say that the B2B customer experience is more complicated than B2C. This is because you have to approach clients on two levels:

- Organizational

Both have a say in the decision to continue or stop buying from a particular provider, and like B2C, customer experience is usually the defining factor.

The best customer experience is one that takes friction out of the equation. It speeds up production and delivery, and it simplifies the pipeline as much as possible. This applies to all client experiences, from first engagement through to post-sale.

With digital transformation, the B2B client experience isn’t just about selling. You may have to employ complex transactional processes, but that complexity shouldn’t inconvenience your customers.

A good example of this is the financial technology company Kabbage . The company created an online loan application system that only takes minutes to approve. The process is completely web-based and removes all friction. Prior to that, you’d need to have a few sit-downs at the bank and potentially wait for 20 days or more.

Meeting Customer Expectations

There’s been a lot of hype about the importance of digital transformation. It’s a technological leap that blurs the line between services and products. It changes how you run your business, regardless of organizational level.

But how does it help you meet and exceed customer expectations?

Customers are already accustomed to a seamless online shopping experience. They expect the same when doing business.

This only means that you have to dream big and adopt digital transformation. In fact, it’s dangerous not to do so because the competition is always quick to step into your place.

Having complex B2B systems shouldn’t be a limitation to innovation.

A digital future improves efficiency and customer expectations. With digital systems, you can increase customer retention and profits. You can also improve turnaround times for products and services.

Offering Data-Powered Solutions

B2B digital transformation is all about leveraging data. This means you’re able to generate greater value for your business and customers. You can secure your competitive advantage by becoming faster, more productive, and more adaptable.

A big part of these improvements comes from increased efficiency. In the past, the sales department covered customer relations and marketing covered messaging. That’s not a good setup for the digital age.

Data-powered solutions build links between departments. Because of this, operations become more cohesive and free of bottlenecks. This can be attributed (at least in part) to better communication and access to data.

Connecting the Online and Offline Worlds

With digital transformation, buyers can interact with your company through different channels, such as online web stores, field sales, and more.

…And here’s another big benefit about digital: these buyers tend to spend more than those who only focus on one channel.

So take advantage of this opportunity!

Create an ecosystem with great cross-channel integration. On average, a B2B customer uses six channels in their decision-making process. If you have a disjointed sales model, it becomes more difficult for them to move through your funnel.

It can also be hard for customers to move from online to offline interactions. Of course, poor cross-channel integration contributes to this.

To that end, mobile technologies play a significant role in B2B digital transformation. Most buyers use a mobile device at least once during a purchasing journey.

Your job is to make the switch from mobile to in-person seamless.

Welcome the Digital Future

Digital transformation is relevant across industries. You can see that with companies as diverse as Ford and Kabbage. If you dig a little deeper, you’ll find plenty of smaller B2B companies that have done well too.

Digitization brings with it automation, speed, and agility. You can remove redundant steps and improve the client lifecycle. This means you can attract clients faster and keep them for longer.

…And all this adds up to higher profitability for your company.

To learn more, apply for free business coaching lessons at predictableprofits.com

Discover the framework we use to scale companies. Get your FREE Speed-to-Scale Blueprint now!

Charles Gaudet

Continue reading for more resourceful information., the passion to driving innovation in wellness feat. steve welch.

Learn how to overcome challenges in life and entrepreneurship with John Rampton

Make Your Business Unforgettable feat. Bill Kenney

Get daily coaching videos delivered right to your inbox.

Receive practical tips, strategies and ideas that our clients use to scale their businesses to the next million and beyond regardless of what the market is doing.

The premier business coaching company for 7- & 8-figure entrepreneurs looking for more predictability, scalability, and profitability.

- 603-294-4096

- [email protected]

UNLOCK PREDICTABLE GROWTH:

Empower your team & diversify your strategy today.

Ford CEO Hackett: Digital transformation means making the business fit first

Ford outlined its digital transformation plan, which revolves around smart connected vehicles, speeding up its product development and becoming more fit as a company on costs.

The interplay between Ford's quest for fitness and digital transformation is a notable one. CEO Jim Hackett, on the job at Ford for 100 days, is betting on a strategy where it can use efficiency and cost savings to fund the future.

As noted previously, there will be more trade-offs for multiple companies as future bets compete with delivering returns today . Nike , Taser , Campbells Soup , QVC and others are also making pivots to be more digital.

Hackett said Ford will embrace multiple technologies and focus on "integrating hardware and software in complex devices." Ford's pitch almost sounded a bit Apple-ish.

The catch is that Ford must stick to a long-term goal of 8 percent operating margins on its vehicles. That margin is very un-Apple-like.

Hackett on a conference call outlined Ford's vision:

Ford will prepare for disruption by becoming fit. There's no doubt that we've entered this period of disruption, you all know that. But we have to design the business to be more fit because it's going to give us time, resources and flexibility to evolve to where we know we have to be. We're going to be the vehicle business moving both people and goods. Some myth about not being in the car business is gone. In the future, people around the globe will still want and need our cars, trucks and SUVs and commercial vehicles. And I'm answering that question of whether Mobility would chip away at that cookie in any kind of way that would make us retreat. Not at all. Those vehicles though will be smart and connected. The reason, there's a wider berth now between dumb and smart products as we learn about robotics and their role in our vehicles. This will influence customer expectations of what they want in their vehicles in the future. Smart vehicles will be a given at Ford Motor Company. These smart vehicles will pair or thrive with a new transportation operating system. The history of transportation systems requires that pairing between whatever asset it was that moved people or goods in the environment that it was in, that could have been trails for horses, roads and stoplights for the cars as we knew them growing up, or GPS for satellites. Consequently, we see a dawning of a new transportation operating system for cities that's dealing with the fact that they're becoming more congested as more people move to cities and yet, they need more capacity.

In broad strokes, Ford said it is targeting the following:

All new vehicles in the U.S. will have built in connectivity by 2019. Ninety percent of Ford's new global vehicles will have connectivity by 2020.

Cut automotive cost growth by 50 percent through 2022 with common parts, fewer prototypes and cuts in order complexity. Ford expects $4 billion saved in incremental efficiencies over 5 years and $10 billion in materials.

Pare down customization. The current model of the Focus has 360 orderable combinations and Ford wants to get the to 26. The Escape has 2,302 combinations and Ford plans on 228.

Focus on electrification beyond the $4.5 billion investment already planned. Ford will also move manufacturing of its next-gen Focus to China . "Why didn't we move more quickly in the battery electric vehicles? Simply, it's uneconomic, and we were too much focused on the now. We believe that it was an all or nothing question. And now we know that there's a future around propulsion that we have to pay attention to. Propulsion is a selection then by customers based on their use case and there's going to be a variety of choices that they want to have," said Hackett.

Double down on partnerships with Lyft and Domino's Pizza for autonomous vehicles.

Technologies such as 3D printing, robotics, big data and virtual reality will be deployed in Ford's "factories of the future." The goal: Cut new vehicle development time 20 percent and product changeover time by 25 percent.

These factories will move from lean manufacturing approaches to processors powered by machine learning, artificial intelligence, 3D printing, virtual factories and "manufacturing 4.0." The cost savings will be derived from a smaller manufacturing footprint.

Previously:

- Why Ford is test-driving Microsoft's HoloLens globally for faster car design

- Ford Motor Company: Data and the future of autonomous vehicles

- Ford to trial Stratasys system to use 3D printing of one-piece auto parts

- Ford invests $1 billion in Argo AI to advance its virtual driver system

- Ford sees autonomous vehicles as key cog of smart city

- Robotics in business: Everything humans need to know

- Video: How Ford is making the future more mobile

- The future of delivery? Ford and Domino's Pizza partner for self-driving vehicle test

Concepts in this article include:

CXO budget priorities for 2018:

- How digital transformation is reshaping the IT budget: The journey of 3 CIOs

- Infographic: 2018 IT budgets are up slightly; spending focus is on security, hardware, and cloud

- Free PDF download: Tech Budgets 2018, a CXO's Guide

- IT budgets 2017-18: What the surveys tell us

- AI? Blockchain? Cloud computing? What technologies are CIOs really investing in right now?

- CIO Jury: 83% of CIOs say IT budget will stay the same or increase in 2018

- Building a viable IT budget for 2018: Eight critical steps

- IT budgets: Prioritise security, relocate technical staff, and avoid digitising silos

- Turning big data into business insights: The state of play

- Infographic: Most companies are collecting data, but aren't using big data solutions

- Free PDF download: Turning Big Data into Business Insights

- Five organizations that are using big data to power digital transformation

- Choosing the best big data partners: Eight questions to ask

- Seven pitfalls to avoid when using big data to power digital transformation

- Tech's war on drugs: How big data is being used to fight the US opioid epidemic

- Booktopia uses big data to test assumptions before implementing changes

Digital transformation:

- The enterprise technologies to watch in 2017

- Intro: Digital Transformation, a CXO's Guide

- Artificial intelligence, analytics help speed up digital workplace transformation

- Five emerging technologies for rapid digital transformation

- Maker of Taser weapons goes digital, renames itself Axon in cloud platform bet

- Digital transformation: Retooling business for a new age

- Infographic: Digital transformation is a work in progress for most companies