Suggestions or feedback?

MIT News | Massachusetts Institute of Technology

- Machine learning

- Sustainability

- Black holes

- Classes and programs

Departments

- Aeronautics and Astronautics

- Brain and Cognitive Sciences

- Architecture

- Political Science

- Mechanical Engineering

Centers, Labs, & Programs

- Abdul Latif Jameel Poverty Action Lab (J-PAL)

- Picower Institute for Learning and Memory

- Lincoln Laboratory

- School of Architecture + Planning

- School of Engineering

- School of Humanities, Arts, and Social Sciences

- Sloan School of Management

- School of Science

- MIT Schwarzman College of Computing

Smart textiles sense how their users are moving

Press contact :, media download.

*Terms of Use:

Images for download on the MIT News office website are made available to non-commercial entities, press and the general public under a Creative Commons Attribution Non-Commercial No Derivatives license . You may not alter the images provided, other than to crop them to size. A credit line must be used when reproducing images; if one is not provided below, credit the images to "MIT."

Previous image Next image

Using a novel fabrication process, MIT researchers have produced smart textiles that snugly conform to the body so they can sense the wearer’s posture and motions.

By incorporating a special type of plastic yarn and using heat to slightly melt it — a process called thermoforming — the researchers were able to greatly improve the precision of pressure sensors woven into multilayered knit textiles, which they call 3DKnITS.

They used this process to create a “smart” shoe and mat, and then built a hardware and software system to measure and interpret data from the pressure sensors in real time. The machine-learning system predicted motions and yoga poses performed by an individual standing on the smart textile mat with about 99 percent accuracy.

Their fabrication process, which takes advantage of digital knitting technology, enables rapid prototyping and can be easily scaled up for large-scale manufacturing, says Irmandy Wicaksono, a research assistant in the MIT Media Lab and lead author of a paper presenting 3DKnITS.

The technique could have many applications, especially in health care and rehabilitation. For example, it could be used to produce smart shoes that track the gait of someone who is learning to walk again after an injury, or socks that monitor pressure on a diabetic patient’s foot to prevent the formation of ulcers.

“With digital knitting, you have this freedom to design your own patterns and also integrate sensors within the structure itself, so it becomes seamless and comfortable, and you can develop it based on the shape of your body,” Wicaksono says.

He wrote the paper with MIT undergraduate students Peter G. Hwang, Samir Droubi, and Allison N. Serio through the Undergraduate Research Opportunities Program; Franny Xi Wu, a recent graduate of the Wellesley College; Wei Yan, assistant professor at the Nanyang Technological University; and senior author Joseph A. Paradiso, the Alexander W. Dreyfoos Professor and director of the Responsive Environments group within the Media Lab. The research will be presented at the IEEE Engineering in Medicine and Biology Society Conference.

“Some of the early pioneering work on smart fabrics happened at the Media Lab in the late ’90s. The materials, embeddable electronics, and fabrication machines have advanced enormously since then,” Paradiso says. “It’s a great time to see our research returning to this area, for example through projects like Irmandy’s — they point at an exciting future where sensing and functions diffuse more fluidly into materials and open up enormous possibilities.”

Knitting know-how

To produce a smart textile, the researchers use a digital knitting machine that weaves together layers of fabric with rows of standard and functional yarn. The multilayer knit textile is composed of two layers of conductive yarn knit sandwiched around a piezoresistive knit, which changes its resistance when squeezed. Following a pattern, the machine stitches this functional yarn throughout the textile in horizontal and vertical rows. Where the functional fibers intersect, they create a pressure sensor, Wicaksono explains.

But yarn is soft and pliable, so the layers shift and rub against each other when the wearer moves. This generates noise and causes variability that make the pressure sensors much less accurate.

Wicaksono came up with a solution to this problem while working in a knitting factory in Shenzhen, China, where he spent a month learning to program and maintain digital knitting machines. He watched workers making sneakers using thermoplastic yarns that would start to melt when heated above 70 degrees Celsius, which slightly hardens the textile so it can hold a precise shape.

He decided to try incorporating melting fibers and thermoforming into the smart textile fabrication process.

“The thermoforming really solves the noise issue because it hardens the multilayer textile into one layer by essentially squeezing and melting the whole fabric together, which improves the accuracy. That thermoforming also allows us to create 3D forms, like a sock or shoe, that actually fit the precise size and shape of the user,” he says.

Once he perfected the fabrication process, Wicaksono needed a system to accurately process pressure sensor data. Since the fabric is knit as a grid, he crafted a wireless circuit that scans through rows and columns on the textile and measures the resistance at each point. He designed this circuit to overcome artifacts caused by “ghosting” ambiguities, which occur when the user exerts pressure on two or more separate points simultaneously.

Inspired by deep-learning techniques for image classification, Wicaksono devised a system that displays pressure sensor data as a heat map. Those images are fed to a machine-learning model, which is trained to detect the posture, pose, or motion of the user based on the heat map image.

Analyzing activities

Once the model was trained, it could classify the user’s activity on the smart mat (walking, running, doing push-ups, etc.) with 99.6 percent accuracy and could recognize seven yoga poses with 98.7 percent accuracy.

They also used a circular knitting machine to create a form-fitted smart textile shoe with 96 pressure sensing points spread across the entire 3D textile. They used the shoe to measure pressure exerted on different parts of the foot when the wearer kicked a soccer ball.

The high accuracy of 3DKnITS could make them useful for applications in prosthetics, where precision is essential. A smart textile liner could measure the pressure a prosthetic limb places on the socket, enabling a prosthetist to easily see how well the device fits, Wicaksono says.

He and his colleagues are also exploring more creative applications. In collaboration with a sound designer and a contemporary dancer, they developed a smart textile carpet that drives musical notes and soundscapes based on the dancer’s steps, to explore the bidirectional relationship between music and choreography. This research was recently presented at the ACM Creativity and Cognition Conference.

“I’ve learned that interdisciplinary collaboration can create some really unique applications,” he says.

Now that the researchers have demonstrated the success of their fabrication technique, Wicaksono plans to refine the circuit and machine learning model. Currently, the model must be calibrated to each individual before it can classify actions, which is a time-consuming process. Removing that calibration step would make 3DKnITS easier to use. The researchers also want to conduct tests on smart shoes outside the lab to see how environmental conditions like temperature and humidity impact the accuracy of sensors.

“It’s always amazing to see technology advance in ways that are so meaningful. It is incredible to think that the clothing we wear, an arm sleeve or a sock, can be created in ways that its three-dimensional structure can be used for sensing,” says Eric Berkson, assistant professor of orthopaedic surgery at Harvard Medical School and sports medicine orthopaedic surgeon at Massachusetts General Hospital, who was not involved in this research. “In the medical field, and in orthopedic sports medicine specifically, this technology provides the ability to better detect and classify motion and to recognize force distribution patterns in real-world (out of the laboratory) situations. This is the type of thinking that will enhance injury prevention and detection techniques and help evaluate and direct rehabilitation.”

This research was supported, in part, by the MIT Media Lab Consortium.

Share this news article on:

Press mentions, popular science.

Researchers at MIT have created a knit textile containing pressure sensors called 3DKnITS which can be used to predict a person’s movements, reports Charlotte Hu for Popular Science . “Smart textiles that can sense how users are moving could be useful in healthcare, for example, for monitoring gait or movement after an injury,” writes Hu.

Previous item Next item

Related Links

- Irmandy Wicaksono

- Joseph Paradiso

- Responsive Environments group

- School of Architecture and Planning

Related Topics

- Wearable sensors

- Computer science and technology

- Artificial intelligence

- Biomechanics

Related Articles

A fabric that “hears” your heart's sounds

Sensors woven into a shirt can monitor vital signs

This touchy-feely glove senses and maps tactile stimuli

Introducing the latest in textiles: Soft hardware

More mit news.

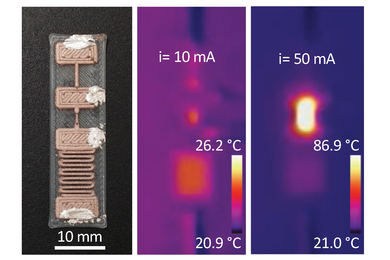

MIT team takes a major step toward fully 3D-printed active electronics

Read full story →

MIT economists Daron Acemoglu and Simon Johnson share Nobel Prize

MIT releases financials and endowment figures for 2024

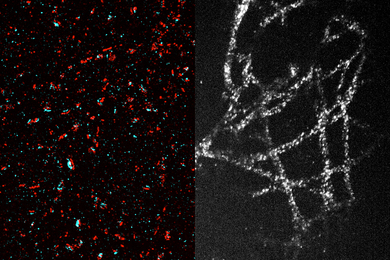

A new method makes high-resolution imaging more accessible

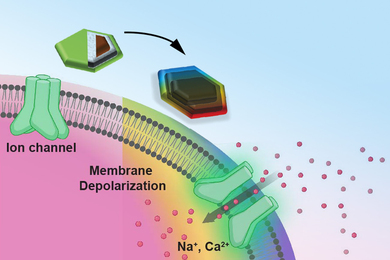

Tiny magnetic discs offer remote brain stimulation without transgenes

The way sensory prediction changes under anesthesia tells us how conscious cognition works

- More news on MIT News homepage →

Massachusetts Institute of Technology 77 Massachusetts Avenue, Cambridge, MA, USA

- Map (opens in new window)

- Events (opens in new window)

- People (opens in new window)

- Careers (opens in new window)

- Accessibility

- Social Media Hub

- MIT on Facebook

- MIT on YouTube

- MIT on Instagram

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Journal Proposal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

New research trends for textiles.

1. Functional Textiles

2. process and modelling, 4. consumers and behavior, conflicts of interest.

- Boisse, P. Editorial. Textiles: Multidisciplinary Open Access Journal in Research and Innovation of Textiles. Textiles 2021 , 1 , 1. [ Google Scholar ] [ CrossRef ]

- Venil, C.K.; Velmurugan, P.; Dufossé, L.; Devi, P.R.; Ravi, A.V. Fungal pigments: Potential coloring compounds for wide ranging applications in textile dyeing. J. Fungi 2020 , 6 , 68. [ Google Scholar ] [ CrossRef ] [ PubMed ]

- Venil, C.K.; Dufossé, L.; Velmurugan, P.; Malathi, M.; Lakshmanaperumalsamy, P. Extraction and Application of Pigment from Serratia marcescens SB08, an Insect Enteric Gut Bacterium, for Textile Dyeing. Textiles 2021 , 1 , 21–36. [ Google Scholar ] [ CrossRef ]

| MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

Share and Cite

Dufossé, L. New Research Trends for Textiles. Textiles 2022 , 2 , 579-581. https://doi.org/10.3390/textiles2040033

Dufossé L. New Research Trends for Textiles. Textiles . 2022; 2(4):579-581. https://doi.org/10.3390/textiles2040033

Dufossé, Laurent. 2022. "New Research Trends for Textiles" Textiles 2, no. 4: 579-581. https://doi.org/10.3390/textiles2040033

Article Metrics

Article access statistics, further information, mdpi initiatives, follow mdpi.

Subscribe to receive issue release notifications and newsletters from MDPI journals

IMAGES

VIDEO