Supply Chain Planning: Strategy, Processes and Practices

Supply chain planning helps your business meet customer demand in the most efficient way possible. But to increase profitability and keep demand from outstripping supply, every step in the supply chain planning process—from ordering raw materials to product delivery—has to be reliable.

The process also has to be adaptable, efficient and accurate to address changing market forces. It sounds like a tall order, but there are best practices that can help.

Video: What is Supply Chain Planning (SCP)?

What is Supply Chain Planning?

Supply chain planning helps you match product supply with customer demand using forecasting, pricing strategy and inventory management techniques. Before delving into the details of supply chain planning, here are two key concepts you need to know.

Supply chain planning vs. supply chain execution

Supply chain planners are long-term prognosticators, asked to peer months or even years into the future. But their predictions aren’t based on what they see in crystal balls. Instead, they analyze manufacturing, logistics and inventory data to make their plans.

Supply chain execution, on the other hand, is the day-to-day implementation of that plan—order fulfillment, transporting goods, warehousing. Think of them as two sides of the same coin.

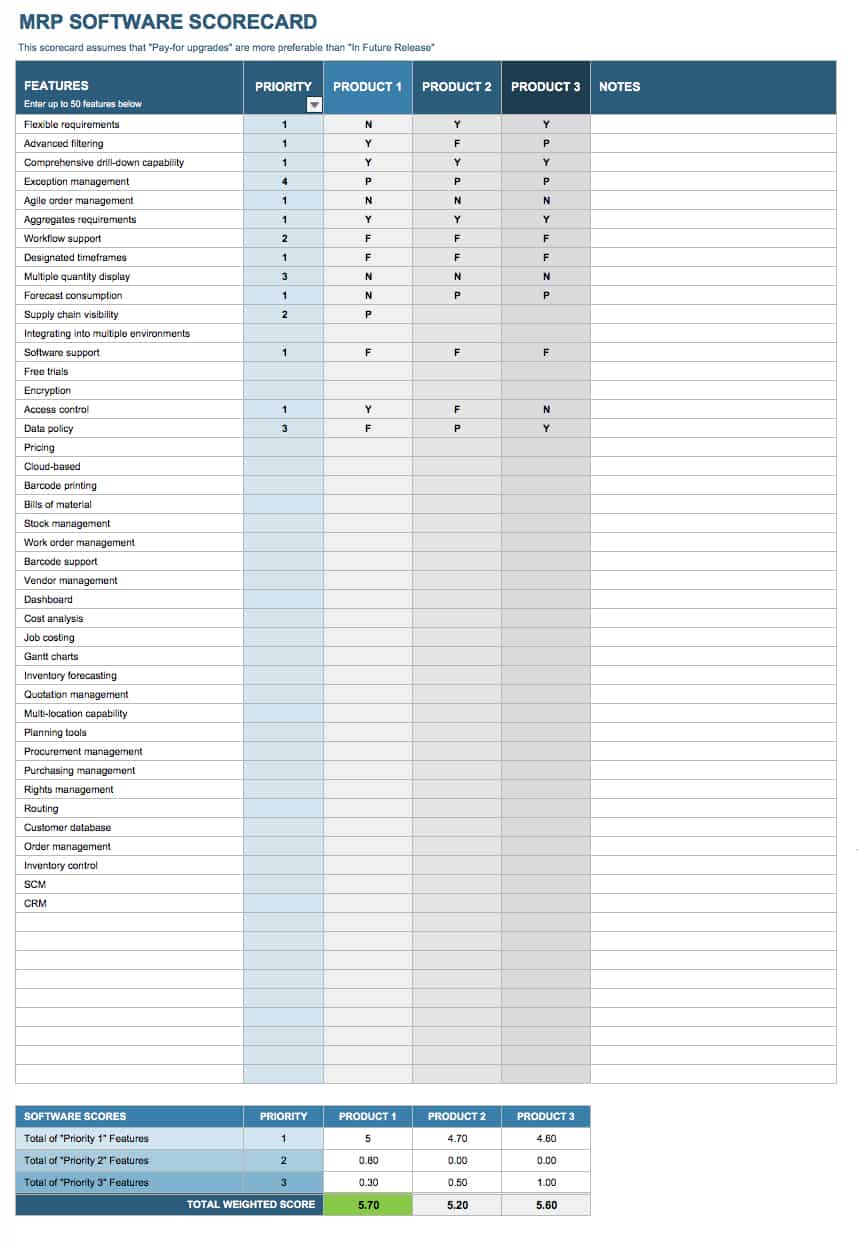

What is supply chain management software?

Supply chain management software supports planning and execution. It forecasts demand and manages inventory so you can keep costs down and deliver products faster. It provides real-time updates about the status of your supply chain, lets you inspect your operations and helps balance supply with demand.

Supply Chain Benefits

Supply chain planning is a way to improve your operations by standardizing procedures, reducing waste and planning for variability.

It also plays a pivotal role in price and delivery—two of the most important aspects of customer satisfaction. A well-run supply chain lowers manufacturing costs, improves the reliability of deliveries and helps you respond to unplanned demand.

Importance of Supply Chain Planning

Supply chain planning affects your top and bottom lines. Stock shortages can result in lost sales or rush shipping charges. Too much inventory ties up cash. And over-forecasting and canceling orders can damage important relationships with suppliers and disrupt your own business.

It’s difficult to argue with the why , but there’s often less agreement on how the process should be structured.

Supply Chain Planning Process

Achieving desired business benefits requires strategic, long-range supply chain planning. However, in a flexible supply chain, managers are empowered to respond tactically to changing conditions and alter those plans on the fly.

Strategic planning:

This phase focuses on the long term and establishes a framework for your supply chain. In this phase, you’ll factor in elements like the location of your business and suppliers. You’ll map transportation routes and determine the size and location of warehouse space for materials and finished products. If you already have a location, this is when you determine how to leverage it.

Tactical planning:

The next phase delves deeper into individual aspects of this framework. For example, you might place standing purchase orders with certain suppliers for just-in-time delivery. You may decide to store safety stock of key materials to avoid shortages. And even the best-laid plans can require tactical adjustment, such as changing sourcing strategy or rebalancing inventory among overseas warehouses if new tariffs raise your costs, for example.

Supply Chain Strategies and Methods

Many planners use a combination of just-in-time delivery and safety stock to cut costs while hedging against shortages. The just-in-time approach delivers materials right before they are needed for manufacturing or other processes. With less inventory, less cash and space are tied up.

But companies risk pauses in production if there are delays in shipping or problems with materials. Alternatively, with the safety stock approach, companies store more inventory to provide an extra buffer against supply chain disruptions; the downside is an increase in inventory costs.

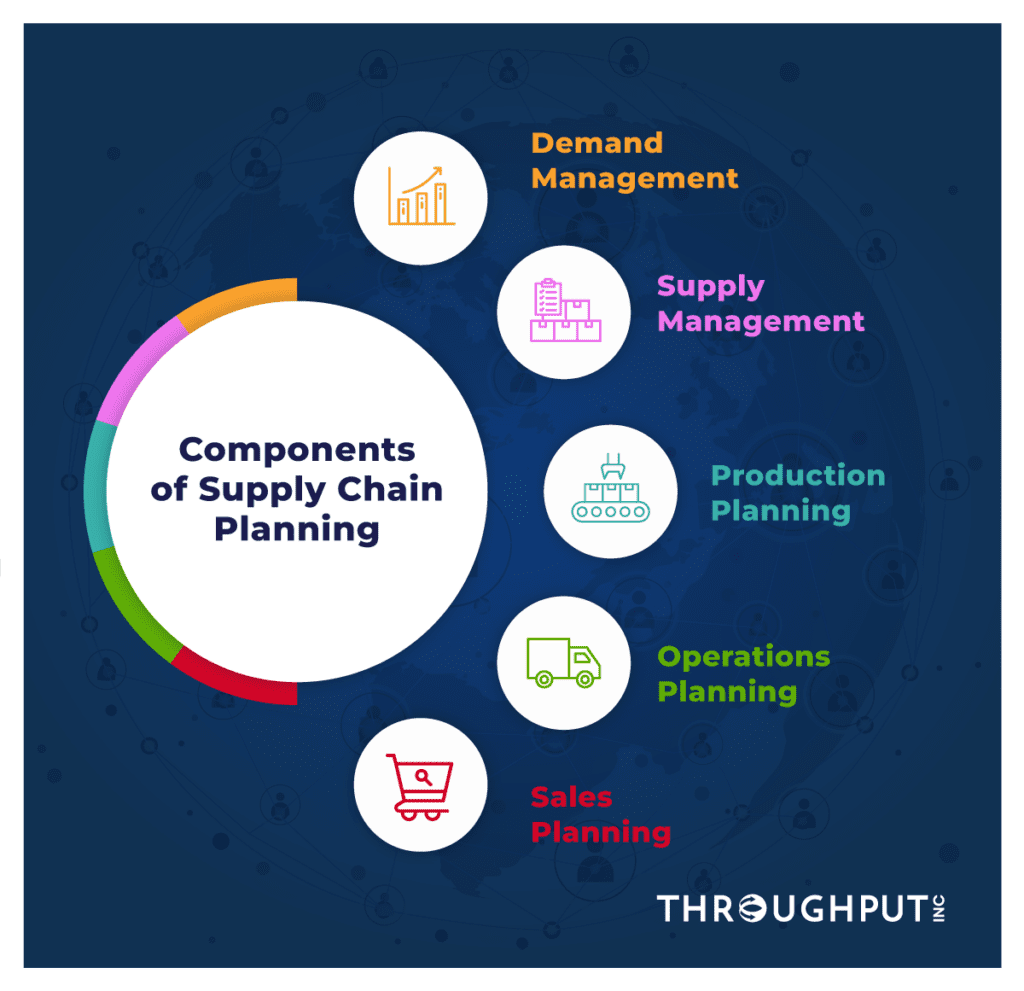

Supply Chain Planning Elements

A product requires supply chain planning at every phase of its life cycle. Steps include:

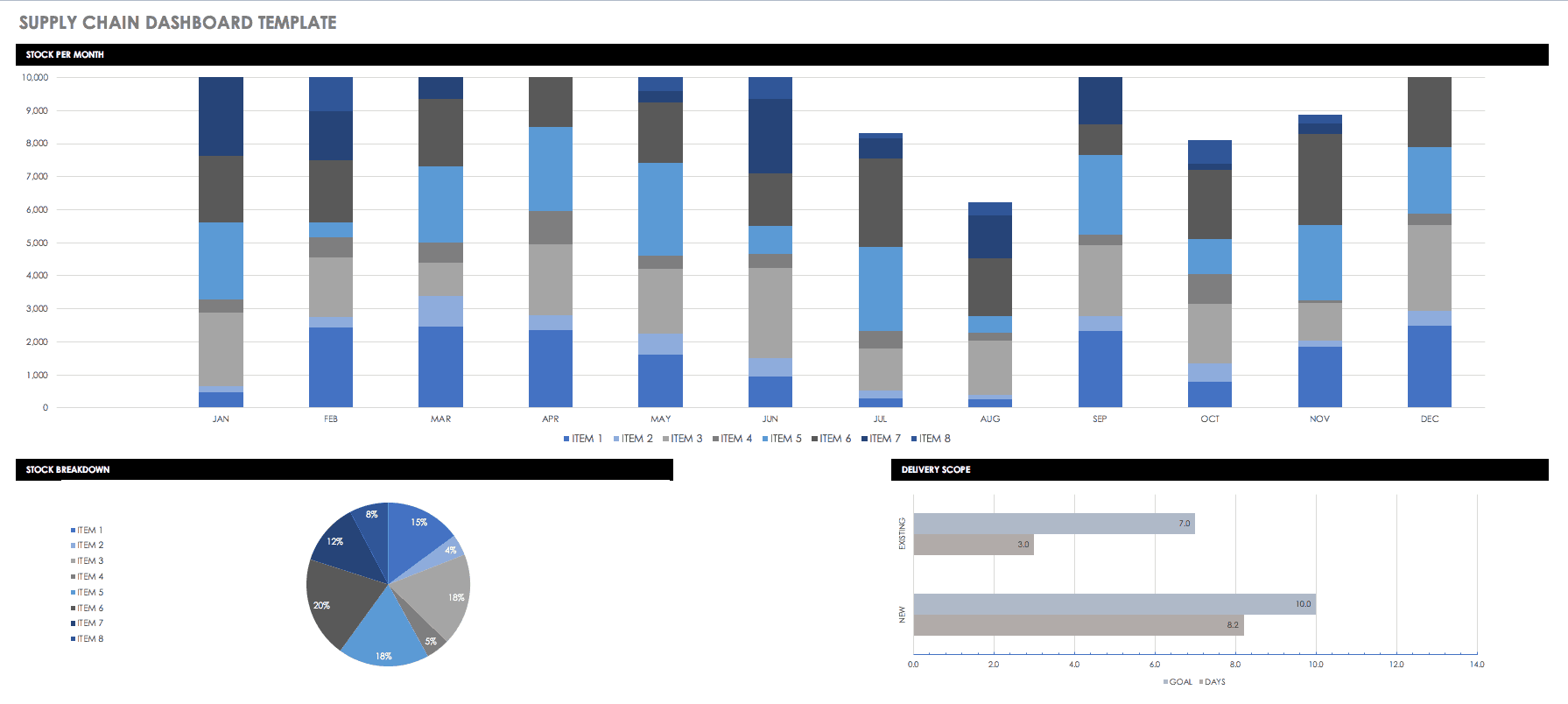

Demand planning and management: Accurately forecasting demand for a product improves your chances of producing and stocking adequate inventory to meet customer needs on a timely basis, without having to store surpluses. Supply chain planners look at historical customer behavior, projected versus actual sales, market conditions and other factors. Increasingly, they use predictive analytics to better understand the demand for a particular product—how much, where and when it should arrive. Then, supply chain planners estimate the internal demands on each link in their supply chains.

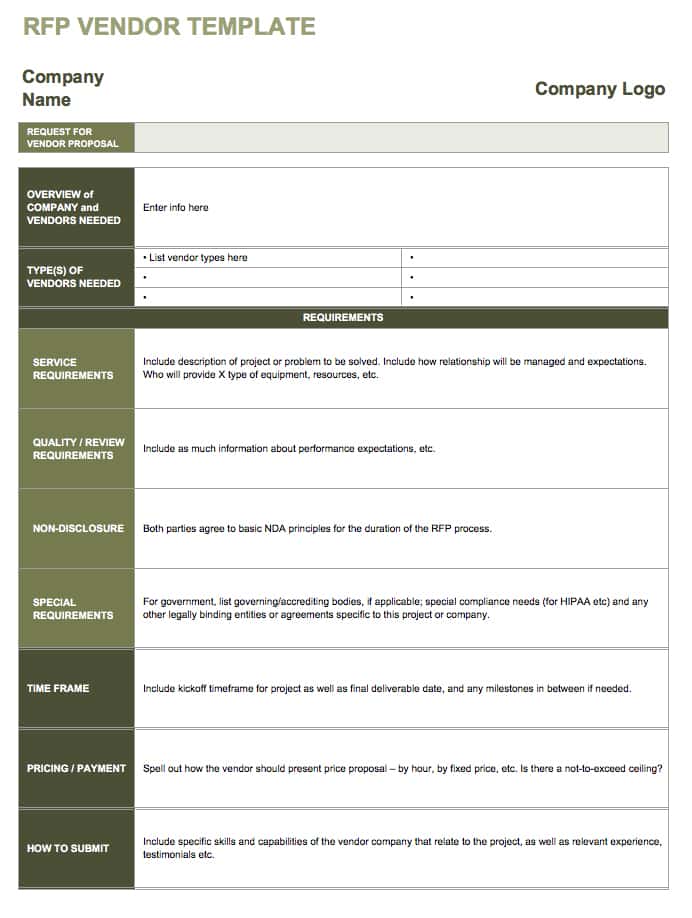

Supply management: Supply management involves sourcing and procuring trusted sources of raw materials, components, software and other goods that go into making your product or service.

Production management: In parallel, capacity planning addresses your own company’s production lines in terms of machinery, staff and efficiency. The key question: How much can we realistically produce during the planning period? Keep in mind that this could be less than your demand forecast.

Inventory management: How a company orders, handles and stores goods can significantly impact costs, operational efficiency and customer satisfaction. Companies aim to manage inventory levels with supply chain partners to keep stock on hand at an optimal level while ensuring reliable customer service.

Inventory management can also provide other financial advantages, such as the ability to capitalize on volume prices from suppliers and accurately include the value of inventory in assets listed in company balance sheets and tax filings. More sophisticated inventory management systems can identify high- and low-performing products and trigger reorders when stock dwindles.

Pricing strategy: Setting an optimal price is part art, part science. Honing an effective strategy is critical, however, to manage the balance between supply and demand . For example, price cuts can stimulate sales during periods of low demand, helping you cover the fixed costs of production lines and your workforce.

Event management: This involves identifying all possible supply chain bottlenecks, breakdowns and delays at every link in the chain and developing contingency plans, such as workarounds, buffers and backups.

Integrated business planning (IBP): This is an approach that links your supply chain planning with the rest of your business, from sales and operations through finance. Because IBP gathers information from across the enterprise, it also can help companies perform better predictive analysis to grow the business and manage risk.

Award Winning Cloud Inventory

7 Steps to Supply Chain Planning Success

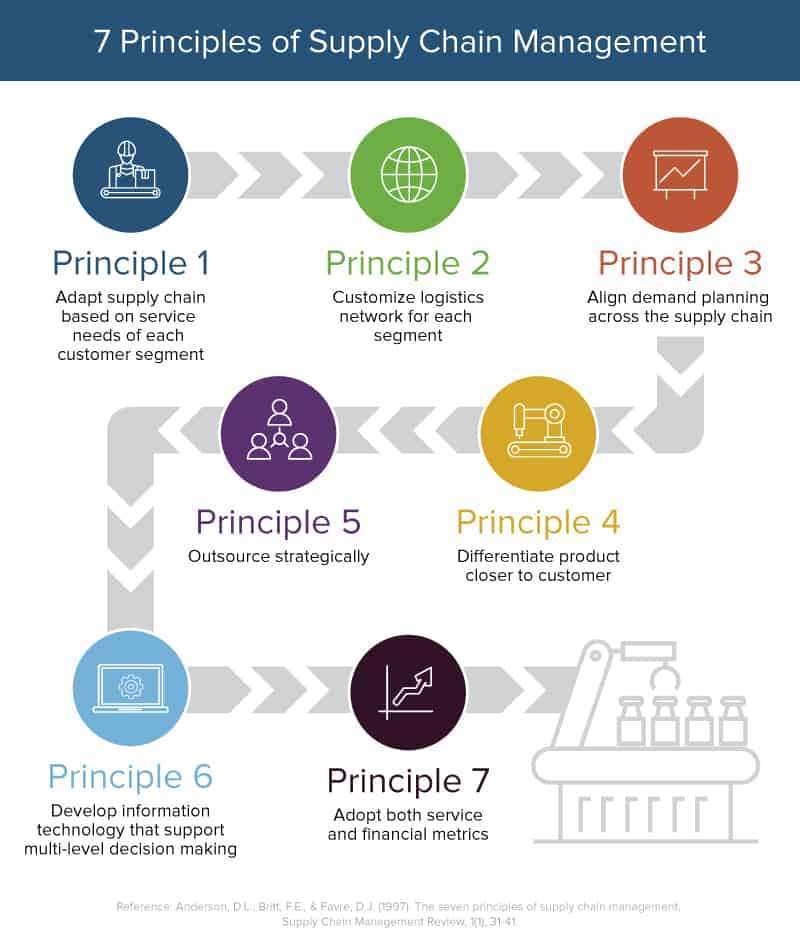

Here are seven basic principles that leading supply chain planners adopt:

- Synchronize supply chain planning and execution, how often you update your data and planning horizons—or how far into the future your company will project.

- Systematically manage data so that you can use consistent information throughout your supply chain planning and management processes. This includes data about items, customers, manufacturing resources and suppliers.

- Build cooperative relationships with suppliers and primary customers so you can more easily adjust forecasts, orders and increase sales.

- Examine the data used in your demand planning for flaws, such as forecast errors or bias.

- Focus on actual point-of-sale data more than your company’s sales orders.

- Continuously analyze the product lifecycle, looking for ways to improve the links between product development and the supply chain.

- Create a culture of steady improvement to better understand customer behavior.

Supply Chain Planning Trends

Despite the fact that companies increasingly use technology to improve supply chain planning and management, demand forecasting remains a formidable challenge for many organizations.

Companies are turning to predictive analytics to better understand buyer behavior and other factors that influence demand. Predictive analytics is also becoming an important tool for planning the production, distribution and other supply chain functions needed to fulfill that demand.

Supply Chain Defined

A supply chain is a coordinated network that includes all the companies, facilities and business activities involved in sourcing, developing, manufacturing and delivering products. Each business relies on its supply…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

Supply Chain Strategic Planning: A 5-Step Process + Template

If you're a supply chain manager, you're probably feeling the pressure of staying ahead of the competition, juggling multiple initiatives, and navigating through constant supply chain disruptions.

Don't worry, you're not alone! A recent survey of 1,000 supply chain leaders by Gartner found that 42% of them are struggling to find the right balance between profitability and other important factors like sustainability, speed, and innovation.

But don't lose hope just yet! It's time to shake things up and take a new approach to supply chain strategic planning that will drive successful on-the-ground execution. The next decade will be make-or-break for supply chains.

It's up to you to determine whether your supply chain will be a winner or a loser. So, let's dive in and find out what it takes to achieve supply chain strategic planning excellence and come out on top!

Here’s what we’re going to cover in this article:

The Supply Chain Strategic Planning Process: Unpacking The Right Approach

The 5 steps of highly effective supply chain strategic planning, 5 pitfalls to avoid during your supply chain planning process (and how to avoid them), upgrade your strategic supply chain management with cascade 🚀.

Supply chain strategic planning can be a challenging task, especially when it requires a focus on the overarching strategy rather than just day-to-day execution.

But the times are changing, and so is the approach to strategic planning. Gone are the days of a yearly, set-it-and-forget-it exercise.

.png)

The shift from linear strategic planning to shorter strategy execution cycles. Source: Cascade

Supply chain managers must now be ready for the unexpected and be able to pivot quickly as things change.

In order to build a resilient and operationally excellent supply chain, companies must focus on strategic alignment between the overarching supply chain strategy and operational planning . In other words, strategic plans need to be connected with execution. This means providing teams with the context and tools they need to act quickly when necessary.

As a result, your organization can be more prepared for the unexpected and adapt faster to changes, improving its supply chain strategy and operations , and securing a competitive advantage.

So how do you achieve this? An effective supply chain strategic planning process can act as a missing puzzle piece if approached wisely.

In this section, we will cover the five essential steps to creating a successful supply chain strategy . From setting goals to keeping an eye on how things are going, these steps will make sure that your strategy works and is efficient. So, sit back, grab a cup of coffee, and let’s dive into each step.

Step 1: Lay the groundwork for a winning supply chain strategy

- Align with the Big Picture: Time to get on the same page as the rest of the biz! Start by aligning your supply chain strategy with the overarching business strategy and objectives. For example, if the business goal is to reduce costs, supply chain strategies should focus on optimization and cost-cutting initiatives.

- Identify your supply chain drivers: What's driving your supply chain? Think about factors like technology, regulations, customer demands, and global supply chain events. Understanding the key drivers will help you make informed decisions and steer your supply chain in the right direction. These drivers include: 1. Sourcing : The procurement of raw materials and other inputs is crucial to the success of the supply chain. 2. Inventory : Efficient inventory management is key to meeting customer demand while avoiding excessive stock levels. 3. Logistics and warehousing : Effective warehouse management processes and logistics management can reduce lead times, improve service levels, and increase efficiency. 4. Information and data : By forecasting demand, demand planning helps to align the supply chain with customer needs and minimize the risk of shortages. For example, do you have enough inventory or safety stock to meet customer needs? Is your production concentrated in one country, or should you consider diversifying or changing your logistics and transport methods?

- Include your rockstar suppliers and stakeholders : Who's who in your supply chain? Make a list of your MVPs (most valuable players) and prioritize them. Don't forget about customers, logistics providers, regulators, and even your competitors—they all play a role in your supply chain success. Different perspectives will help you understand operational constraints, gaps to fill , and the importance of potential improvements or investments.

- Assess the current state of your supply chain: Give your supply chain a check-up! Assess your logistics, supplier reliability, and ability to bounce back from disruptions. Analyze your organizational structure and operating systems. Get input from different perspectives to identify opportunities for improvement and get buy-in from key stakeholders. For example, does your manufacturing plant in the United States outsource some of its work to China? What contingencies have you put in place to ensure consistent quality and supply?

- Conduct a SWOT analysis of your supply chain: The strengths and weaknesses of your supply chain and the resulting opportunities and threats will be critical for planning, forecasts, and strategic risk management .

Step 2: Design your supply chain strategy

With a solid foundation in place, it's time to start designing your supply chain strategy. This is where you'll put the pieces together.

Make sure to set some strategic priorities to help guide your strategic planning and decision-making process.

Strategic focus areas are the key pillars to focus on. These may include optimizing production planning, increasing profit margins, or diversifying supply and production.

Some examples of supply chain strategies include:

- Invest in technology : Use cutting-edge technology and digital tools to improve your supply chain operations and gain a competitive edge.

- Foster collaboration and build strategic relationships : Work closely with your suppliers and stakeholders to develop a supply chain that's built on trust, communication, and collaboration. For example, let’s take a look at IKEA . They have strategically placed distribution centers worldwide and trading offices near suppliers to minimize transportation costs. On top of that, the close proximity of IKEA's trading service offices to its suppliers' facilities allows the company to monitor production, negotiate prices, and check the quality of the goods and materials it purchases.

- Enhance resilience : Prepare your supply chain for unexpected disruptions by investing in end-to-end visibility, supply chain risk management, and contingency planning.

With this in mind, a strategic plan needs to be clear-cut and concise so your teams won't need a week to go through it. Remember, simple is always better.

📚 Recommended reading: Strategy study: How IKEA became a household name

Step 3: Develop the strategic plan for your supply chain

Now it's time to get into the nitty-gritty and put together a detailed plan that outlines all the specific steps needed to execute your supply chain strategy.

This plan should cover focus areas, clear goals, timelines, budgets, resources, owners, and potential risks. And let's not forget about the all-important KPIs (Key Performance Indicators). KPIs are critical to measure the success of your supply chain strategy, so it's important to set them early on.

👉 Here’s how Cascade can help you:

In Cascade , you can easily build your strategic plan, including all the key elements mentioned above. With our structured approach to strategic planning and user-friendly UI, building your plan and setting KPIs has never been easier. You can also monitor performance and make adjustments as needed.

👉 With Cascade’s Supply Chain Strategy Template , you can get started right away and execute your plan with confidence.

Step 4: Time to execute your plan!

It's go time, folks! You've laid the foundation, designed your strategy, and developed a solid plan—now it's time to execute and bring it all to life. Here's what you need to do:

- Get the Word Out : Communication is key when it comes to executing your supply chain strategy. Make sure everyone who needs to know is in the loop, from employees to suppliers to customers. Ensure everyone understands their role in the process and the end goal.

- Align with Operations: Your supply chain strategy is only as good as the day-to-day execution that supports it. That's why it's important to create alignment with your operations teams to ensure they have the tools and resources they need to bring the strategy to life. Integrated business planning is a good way to approach this.

- Support Cross-Collaboration: To promote cross-collaboration and ensure everyone is working towards the same goal, create joined KPIs, and track progress in real-time. And that's where Cascade comes in - our platform offers integrations and live dashboards so everyone has access to the same information and can work together towards a common goal.

Now that you know the steps, it's time to put your plan into action!

👉 Get started by using Cascade's Supply Chain Strategy Template to build your plan and start executing right away.

Step 5: Monitor and review progress - keep an eye on the prize!

As the old saying goes, "what gets measured gets done." And that's why step 5 is all about keeping your eye on the prize and making sure you're on track to hit your goals.

Set up regular progress reviews: Regularly monitor and review progress against the plan, and make adjustments as needed. According to Cascade’s Strategy Report , only 18% of team members review progress on a weekly basis. This is crucial for employee engagement, accountability, and fast adaptability.

Rethink Your Tools: Remember the days of manual reporting? Let's ditch that and move into the modern age of automation and data-driven decision-making.

With the right tools in place, you'll be able to make faster, more informed decisions, and track your progress in real-time. And that's where Cascade can help you—with its powerful reporting capabilities , you'll have all the data you need at your fingertips.

👉If you’re a Cascade user : Use the Report feature to get real-time insights from multiple data sources across various departments in your organization. With it, you'll be able to make and update progress reports quickly, so your team and management board will always have the most up-to-date information.

Here’s an example of the supply chain management report in Cascade that will help you demonstrate the ROI of your initiatives and progress against set targets.

🔥 Want to see how Cascade helps team leaders save hours on making useful reports for meetings in real life? Learn how Kreg Tools uses Cascade to execute its strategy. Click here to watch the video.

There are several challenges that organizations may face when it comes to effective supply chain management and supply chain strategic planning:

Navigating complexity

⛔ Problem: Supply chains are multi-faceted, with several stages and stakeholders. In a McKinsey survey of senior supply chain managers, more than half of them stated they didn’t understand where their Tier 1 suppliers were located or what their key risks were. Because of this, it can be hard to come up with a strategy that takes into account all the important factors and can adapt to changes.

💡 Solution: Maintain regular communication with suppliers and other stakeholders to have a clear understanding of the supply chain and all the different elements involved.

Managing uncertainty and disruptions

⛔ Problem: The business environment is continually evolving, making it hard to predict future consumer demand, price fluctuations, and other uncertainties like material shortages that may impact the supply chain.

💡 Solution: To mitigate the impact of uncertainty, it's important to have a flexible and adaptable supply chain strategy that can quickly respond to changes. Focus on execution over planning, and adapt the plan as you go. With Cascade, you can easily update the supply chain strategic plan and notify your teams with just one click.

Breaking down silos

⛔ Problem: Organizations that work in silos are more likely to be disrupted, waste resources, and change too slowly. Supply chain, manufacturing operations, and sales teams need to share information in real-time to work effectively and create a coordinated response to changes.

💡 Solution: With Cascade, you can create a single source of truth with shared KPIs. This makes it easy to track progress and ensure alignment across cross-functional teams.

Managing limited resources

⛔ Problem: Organizations often have limited resources, such as time, money, and personnel. This can make planning and executing a supply chain strategy challenging.

💡 Solution: Support cost optimization by allocating resources in alignment with strategic priorities and avoid initiatives that increase supply chain costs. With Cascade, you can quickly identify underperforming areas and kill misaligned initiatives. It’s like having a personal advisor; you can see where your resources are being spent, analyze what’s working and what’s not, and make adjustments to maximize efficiency.

Improving visibility

⛔Problem: Outdated operating processes and tools can make it hard and time-consuming to track strategy progress and supply chain KPIs. This problem can compound if your teams rely on multiple disconnected tools, including your company’s ERP, spreadsheets, and other planning tools.

💡 Solution: You should have one place where you can connect all the necessary data, track the progress of your strategy, and assess its impact on business and supply chain KPIs. With features like Dashboards and Reports , Cascade makes monitoring and reporting simple.

It's important to remember that supply chain strategic planning is a continuous process, not a one-time event. Regular monitoring and reviewing progress against the plan can help you make necessary adjustments and fine-tune your strategy for optimal results.

Whether you're starting from scratch or revamping an existing plan, Cascade offers a comprehensive solution to help you every step of the way. With our structured approach to strategic planning and powerful features like integrations, live dashboards, and reports, you'll be well on your way to a successful and thriving supply chain in no time.

Don't wait, sign up today for free and start executing your plan with confidence!

Popular articles

Viva Goals Vs. Cascade: Goal Management Vs. Strategy Execution

What Is A Maturity Model? Overview, Examples + Free Assessment

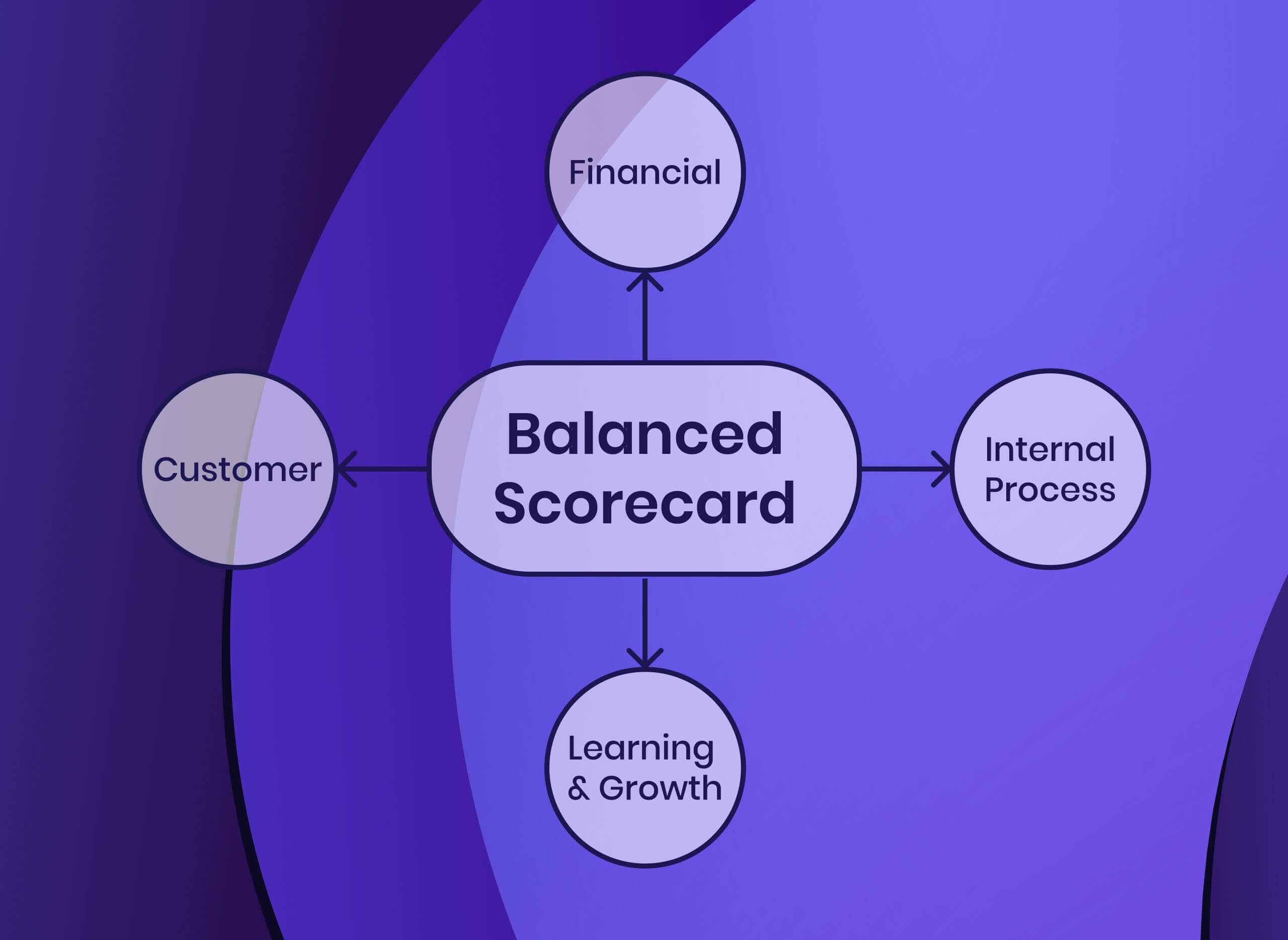

How To Implement The Balanced Scorecard Framework (With Examples)

The Best Management Reporting Software For Strategy Officers (2024 Guide)

Your toolkit for strategy success.

The Complete Guide to Supply Chain Planning in 2024

Effective supply chain planning is more vital than ever in today’s fast-paced business world. It plays a crucial role in streamlining the production and delivery of products, all while ensuring supply and demand are in equilibrium.

With this comprehensive article, we’ll dive deep into the complexities of supply chain planning. We’ll also cover indispensable factors that supply chain experts must weigh carefully when helping companies prepare to compete globally.

Finally, we’ll show how you can understand supply chain planning holistically with a tool that helps global companies save money daily.

What is Supply Chain Planning?

Supply chain planning is a forward-looking process aiming to optimize the delivery of goods, services, and information from suppliers to customers while balancing supply and demand.

The planning involves anticipating customer demand and planning materials, components, production, marketing, distribution, and sales accordingly.

The overall goal of supply chain planning is to ensure that sales revenue opportunities are fully utilized on time and at the lowest possible cost.

The process is essential for businesses to optimize operations, enhance efficiency, reduce costs, and create happy customers.

What is the First Step in Planning Supply Chain Operations?

The first step in planning supply chain operations is demand planning and forecasting.

Demand planning is a supply chain management process organizations use to accurately project future demand and customize their output based on the plans.

When matching demand planning with supply planning, organizations have more control over the output, meaning customer needs are better met.

Demand planning typically involves forecasting demand based on historical data, market trends, and other factors that help make informed decisions about production levels, inventory management, and resource allocation.

What are the Benefits of Supply Chain Planning?

The benefits of supply chain planning are reduced costs, increased customer satisfaction, optimized supply chain operations, simplified inventory management, and increased revenue.

To be honest, there are numerous benefits of supply chain planning. Here’s the full list:

- Increased customer satisfaction ensures that products are delivered at the right time and place. Having satisfied customers builds brand loyalty and gives businesses a competitive edge.

- Simplified inventory management by aligning supply with demand to prevent stockouts or excess inventory.

- Improved quality control that ensures high-quality products and services by implementing quality control measures, monitoring supplier performance, and improving processes to meet customer expectations.

- Streamlined operations, enhanced efficiency, and reduced delays, all of which translate into lower operating costs.

- Optimized supply chain operations mean businesses can reduce costs, improve efficiency, and increase profits.

- Helping organizations identify and mitigate risks, developing contingency plans, and monitoring potential threats to business.

- Adaptability and responsiveness are another result of supply chain planning – it enables organizations to adapt to changing market conditions and customer demands and respond to disruptions.

- Fostering collaboration and integration among supply chain partners – suppliers, manufacturers, distributors, and customers. The results are more streamlined operations, improved communication, and enhanced overall supply chain performance.

What are the Key Elements of Effective Supply Chain Planning?

The key elements of demand planning are production planning, demand and supply planning, inventory management, logistics management, supplier management, risk management, and sales and operations planning.

The planning process needs to optimize the delivery of goods, services, and information from suppliers to customers. It involves coordinating the mentioned elements of the supply chain.

Production Planning

Production planning aligns production capacities with customer demand to ensure optimal efficiency and customer satisfaction.

There are several important points when it comes to production planning:

Aligning production capacities with customer demand

To ensure that the production capacities are in sync with the forecasted customer demand, companies must analyze historical data, observe market trends, and include customer feedback to predict future demand and accurately adjust production.

When this alignment of production and customer data is in place, companies avoid issues such as stockouts or excess inventory that often lead to financial losses and dissatisfaction in the market value chain.

Strategies for efficient production planning and scheduling

To optimize production planning, companies employ various strategies, such as implementing lean manufacturing principles, utilizing advanced scheduling tools, and adopting just-in-time (JIT) production techniques.

The correct strategies result in minimizing waste, reducing lead times, and improving operational efficiency.

Resource management and optimization in production planning

Resource management and optimization involve effectively allocating resources such as labour, machines, and materials to ensure smooth production processes.

With the correct resource utilization, operational efficiency meets customer demand within the desired time frame. As a result, companies minimize idle time, reduce production bottlenecks, and increase productivity.

Demand and Supply Planning

Demand and supply planning are two essential processes in supply chain management. Including them in planning improves decision-making and enhances overall supply chain performance.

Demand planning

Demand planning is a supply chain management process organizations use to project future demand and customize their output accurately.

Demand planning involves supply chain forecasting based on historical data, market trends, and other factors that help make informed decisions about production levels, inventory management, and resource allocation.

Supply planning

Supply planning works with demand planning – organizations must manufacture and supply enough products to meet the forecasted demand.

Supply planning involves coordinating various aspects of the supply chain – procurement, production, distribution, and resource management and considering factors like the availability of raw materials and employee responsibilities.

Coordination of demand and supply planning

Coordinating demand and supply planning involves integrating demand forecasts with supply planning processes to ensure that all parts of the organization work together.

Once a well-executed sales and operations planning (S&OP) process comes into play, organizations balance supply and demand, improve decision-making, and enhance overall supply chain performance.

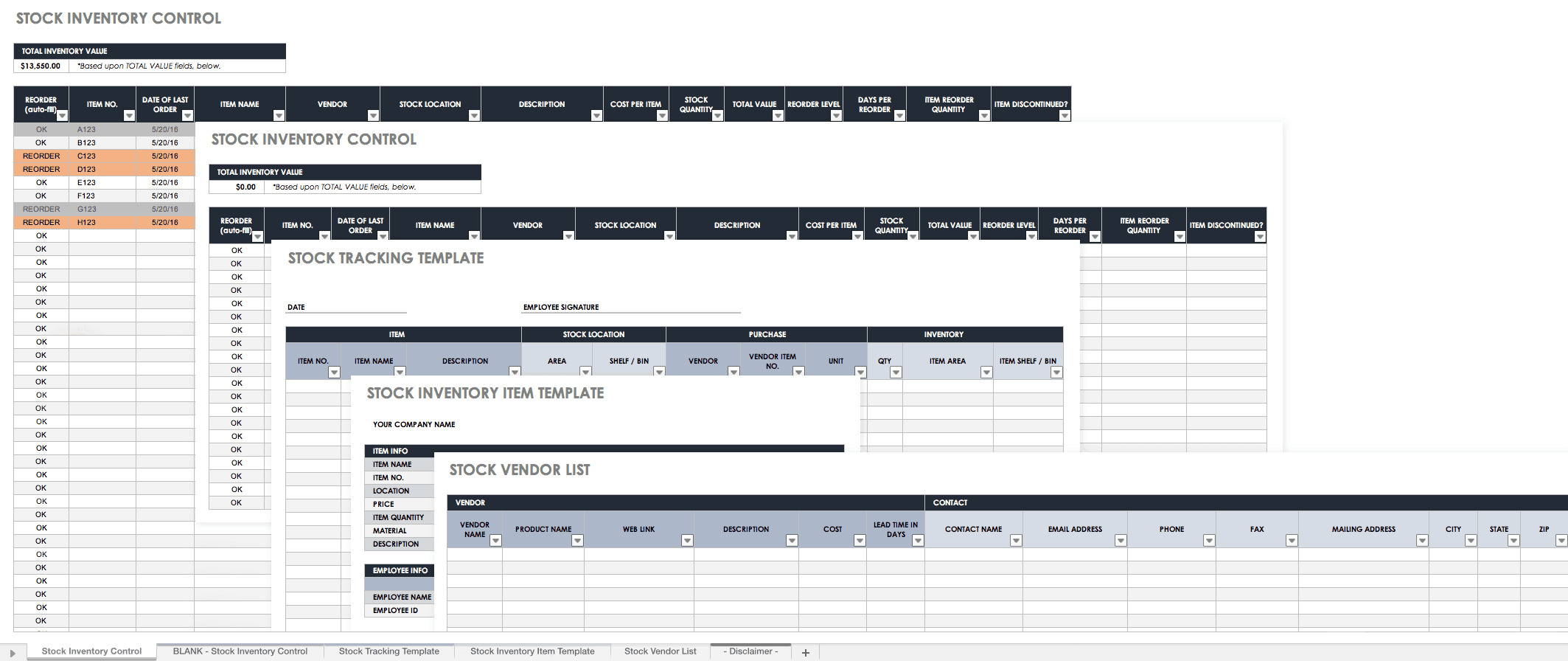

Inventory Management

Supply chain professionals always aim to maintain optimal inventory levels to meet demand while minimizing costs and risks associated with over or understocking.

Effective inventory management means meeting demand while reducing expenses and improving cash flow. Demand planning determines how much inventory is needed and when to order it.

How does inventory management impact supply chain planning?

Your supply chain is optimized when the right products are available at the right time, in the right quantities, and at the suitable locations.

Proper inventory management means the companies can:

- Reduce stockouts and ensure high customer satisfaction.

- Minimize holding costs and optimize working capital.

- Enhance operational efficiency and reduce lead times.

- Improve forecasting accuracy and demand planning.

Inventory optimization strategies and techniques

Inventory optimization needs to balance inventory levels and customer service levels. Analyzing demand patterns, lead times, and other factors to determine the optimal inventory levels.

Some common inventory optimization strategies and techniques include:

- ABC analysis to classify items based on their value and prioritize inventory management efforts

- Just-in-Time (JIT) inventory management to minimize holding costs and reduce inventory levels

- Economic Order Quantity (EOQ) model to calculate the optimal order quantity to minimize ordering and carrying costs

- Vendor-managed inventory (VMI) to allow suppliers to monitor and replenish inventory levels directly

Inventory control methods and best practices

Inventory control methods help maintain optimal inventory levels through proper monitoring, tracking, and replenishment. Some of the best practices include:

- Regular inventory audits to identify discrepancies and prevent stockouts or excess inventory

- Implementing safety stock to buffer against demand fluctuations or supplier delays

- Using serialization and barcoding to track and trace inventory accurately

- Applying advanced inventory management software to automate processes and enable real-time visibility

Logistics Management

Logistics management is a crucial link that ensures the smooth flow of products from suppliers to customers.

Coordinating the movement of goods, materials, and information in the supply chain

One of the primary responsibilities of logistics management is to ensure the timely and cost-effective movement of goods, materials, and information throughout the supply chain. It involves coordinating various activities, such as transportation, warehousing, inventory management, and order processing.

Transportation:

- Choosing the most suitable mode of transportation

- Optimizing routes for efficient delivery

- Tracking and monitoring shipments

Warehousing:

- Strategically locating warehouses for optimal inventory positioning

- Implementing efficient storage and retrieval systems

- Ensuring proper handling and security of goods

Inventory Management:

- Optimizing inventory levels to meet demand while minimizing holding costs

- Implementing effective replenishment strategies

- Utilizing technologies like RFID and barcode scanning for accurate tracking

Order Processing:

- Efficiently managing the order fulfillment process.

- Ensuring accuracy and timeliness in the process

- Streamlining communication between suppliers, manufacturers, and customers

Key concepts and principles of logistics management

- Supply Chain Integration: Collaboration and coordination among all supply chain partners to facilitate seamless information flow and decision-making.

- Lean Logistics: Eliminating waste and non-value-added activities to optimize efficiency and reduce costs.

- Reverse Logistics: Managing the return, disposal, and recycling of products to minimize environmental impact and maximize value recovery.

- Third-Party Logistics (3PL): Outsourcing logistics operations to specialized service providers to leverage their expertise and resources.

Optimizing transportation, warehousing, and distribution activities

Logistics management aims to optimize various activities involved in the movement of goods, including transportation, warehousing, and distribution:

- Transportation optimization with efficient route planning, load consolidation, and carrier selection strategies to minimize transportation costs and improve delivery speed.

- Optimizing warehouse layout, storage systems, and picking processes to increase throughput, reduce handling time, and improve inventory accuracy.

- Distribution Optimization by designing an effective distribution network that ensures the right products are delivered to the suitable locations at the right time while minimizing costs.

Supplier Management

Without proper supplier management, businesses can face various challenges that may hinder their success in meeting customer demands. Establish strong relationships with suppliers and develop strategies for collaboration.

What’s the importance of supplier management in supply chain planning?

Proper supplier management helps businesses to strategically align their supply chain operations with their overall business goals. Supplier management directly impacts the availability and quality of materials and services required for production and distribution.

When suppliers are reliable and capable of meeting the organization’s demands, businesses can minimize disruptions and maintain a seamless flow of goods and services.

What’s the supplier selection criteria in supply chains?

Organizations must consider factors like reliability, quality, capacity, cost, and responsiveness when selecting suppliers.

Best practices in supplier selection involve conducting thorough research and due diligence. Suppliers’ financial stability, reputation, and previous performance must be included in the study.

Collaborative strategies for building strong supplier relationships

Collaboration and cooperation between businesses and suppliers can improve efficiency, flexibility, and innovation. To build strong supplier relationships, organizations can implement collaborative strategies such as:

- Maintaining open and transparent communication channels with suppliers to share information, address issues, and align goals.

- Involving suppliers in decision-making and jointly developing plans to optimize supply chain performance.

- Investing in supplier development programs enhances suppliers’ capabilities and ensures continuous improvement.

- Establishing clear performance metrics to evaluate supplier performance and provide feedback for improvement.

- Collaborating with suppliers to assess and mitigate potential risks in the supply chain to minimize disruptions.

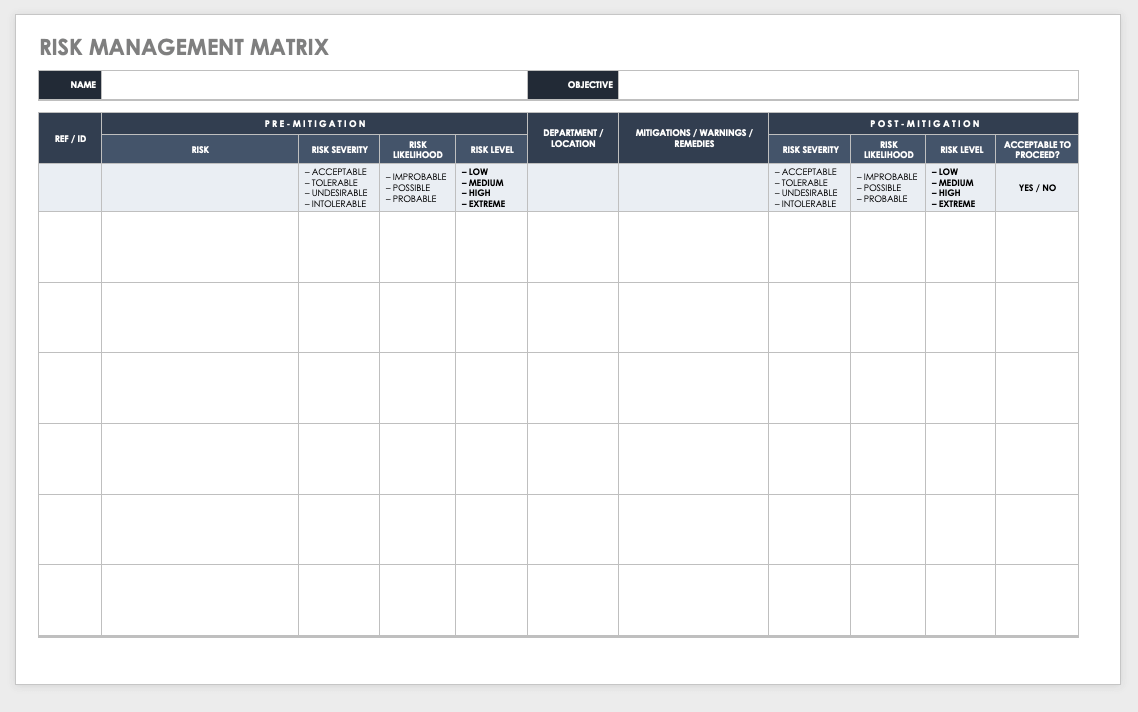

Risk Management

Businesses must identify and mitigate potential risks to ensure a smooth supply chain. Companies can minimize disruptions and enhance their supply chain resilience by implementing effective risk management strategies.

Identifying and mitigating risks in supply chain planning

In supply chain planning, it is essential to identify the various risks that may impact the flow of goods and services. These risks include natural disasters, political instability, supplier bankruptcies, and transportation delays.

Once these risks are identified, businesses can develop strategies to mitigate them.

- Diversify the supplier base to mitigate the risk of supplier bankruptcies or disruptions. Thus, avoid the complete halt of the supply chain by having multiple suppliers in case one supplier cannot deliver.

- Companies can also purchase insurance policies that cover supply chain disruptions. Additionally, developing contingency plans for potential risks can help companies react swiftly and minimize the impact of disorders.

- Data analytics helps enterprises identify potential risks and make informed decisions. Companies can proactively mitigate risks and optimize their supply chain planning by analyzing historical data and market trends.

Strategies for enhancing supply chain resilience

An effective risk management plan also involves strategies to enhance supply chain resilience . These strategies include:

- Building solid relationships with suppliers and key partners improves supply chain resilience while enabling businesses to address risks promptly.

- Maintaining buffer stocks, implementing agile production processes, and having alternate transportation routes ensure supply chain flexibility.

- Monitoring the supply chain performance and identifying potential risks is crucial for enhancing resilience. Monitor the performance by leveraging real-time tracking systems, performing regular audits, and communicating with all stakeholders.

Tools and frameworks for effective risk management

These tools and frameworks facilitate effective risk management in supply chain planning:

- Performing risk assessments to understand and prioritize potential risks. Analyze the impact and likelihood of risks and develop mitigation plans accordingly.

- Conducting scenario planning exercises to simulate risk scenarios and evaluate their preparedness. Companies can identify gaps and improve before an actual risk event occurs by testing various scenarios.

- Implementing supply chain visibility technologies enables tracking goods’ movement and identifying bottlenecks or disruptions. This real-time visibility helps in proactive risk management.

Sales and Operations Planning (S&OP)

Sales and Operations Planning (S&OP) allows businesses to effectively manage their demand and supply to ensure smooth operations and customer satisfaction.

Integrating of sales and operations data enables companies to make informed decisions and align their resources to meet customer demands. This integrated approach helps optimize production, inventory levels, and distribution, resulting in improved customer service, reduced costs, and increased profitability.

The key elements and steps involved in the S&OP process are:

- Collaborative forecasting between sales and marketing teams collaborate with other functional areas to develop a demand forecast. This forecast serves as a basis for the supply planning process.

- Supply review assesses the company’s capacity and capability to meet the forecasted demand. It considers factors like production capacity, inventory levels, and supplier capabilities.

- Consensus planning of the production and inventory plans by the sales and operations teams to reconcile discrepancies between the demand forecast and supply capabilities.

- The executive review by senior management to review and approve the production and inventory plans to ensure alignment with the company’s strategic objectives.

- Performance Measurement of the results against the planned objectives to identify deviations and take corrective actions.

What is an Example of Supply Chain Planning?

Prime examples of supply chain planning are Amazon and Orkla Food. Here’s additional context behind their demand planning success:

Orkla Food is a leading branded consumer products company in the Nordics and one of Norway’s largest companies. The organization has more than 25,000 direct suppliers globally and many sub-suppliers, such as farmers.

Orkla Food faced challenges in coordinating its planning activities due to the large number of SKUs in its portfolio and the complexities of its supply chain.

Orkla Food implemented supply chain planning to optimize its operations and enhance efficiency.

The effective management of demand planning, supply planning, and inventory management, along with other aspects of the supply chain enabled Orkla Food to streamline operations, enhance efficiency, avoid delays, and reduce operating costs.

This approach also help the company adapt to changing market conditions, manage disruptions, and improve customer satisfaction.

Amazon’s supply chain strategy is a prime example of how a company can optimize its operations and enhance efficiency.

Some key components of Amazon’s supply chain planning include:

- Warehousing: Amazon has a vast network of fulfillment centers and warehouses strategically located near metropolitan areas to ensure efficient storage and management of inventory.

- Inventory Management: The company uses advanced technologies and algorithms to manage and replenish inventory, aligning supply with demand and preventing stock outs or excess inventory.

- Delivery: Amazon has developed a robust delivery network, including partnerships with USPS and UPS, its fleet of trucks, vans, bikes, and even robots in some cases, to optimize delivery times and costs.

- Technology: Amazon embraces technology in its supply chain management, utilizing automation, robotics, and data-driven solutions to streamline operations and improve efficiency.

By effectively managing these aspects of its supply chain, Amazon can streamline operations, enhance efficiency, avoid delays, and reduce operating costs.

What are Supply Chain Technologies?

Supply chain technologies are software, tools and systems that streamline supply chain processes, increase efficiency, and reduce costs. Some of the most popular supply chain technologies include:

- Supply Chain Planning Software for managing and replenishing inventory through sales and demand forecasting. It enables companies to balance supply and demand, improve decision-making, and enhance overall supply chain performance.

- Warehouse Management Software (WMS) for managing warehouse operations, including inventory tracking, order processing, and shipping. These systems improve warehouse efficiency, reduce errors, and lower operational costs.

- Transportation Management Systems (TMS) for transportation and logistics operations, including carrier selection, route optimization, and shipment tracking. These systems reduce transportation costs, improve delivery times, and enhance customer service.

- Artificial Intelligence (AI) and Machine Learning are revolutionizing supply chain management by automating tasks, analyzing large amounts of data, and providing guidance on forecasting supply and demand.

- Internet of Things (IoT) devices enable real-time tracking and authentication of products and shipments using GPS and other technologies. They monitor storage conditions, ensure quality management throughout the supply chain, and provide real-time visibility and tracking of goods and products from production to distribution to end consumers.

- Blockchain technology can improve supply chains by enabling faster and more cost-efficient delivery of products, enhancing traceability, improving coordination between partners, and aiding access to financing. Blockchain can track inventory levels, optimize inventory management processes, and facilitate supply chain finance by providing secure and transparent records of transactions between suppliers, manufacturers, and distributors.

What is a Supply Distribution Network Design?

The supply distribution network design is a framework that determines the flow of goods, the locations of warehouses and distribution centers, and transportation routes.

An effective distribution network design ensures that goods are transported from the point of production to the end of consumption most efficiently and cost-effectively.

What to Consider in Designing an Efficient Supply Distribution Network?

- Geographical coverage of the distribution network should reach a wide geographical area to ensure products can get customers efficiently.

- Customer demand patterns must be understood to determine the number and location of distribution centers to optimize product availability.

- Transportation costs must be considered in the distribution network design, including shipping, fuel, and maintenance, to minimize overall supply chain expenses.

- Lead time requirements of different products

- Inventory positioning within the distribution network must ensure that products are available when and where needed, reducing stockouts and excess inventory.

Techniques for Optimizing Warehouse Locations and Transportation Routes

There are several techniques used for optimizing warehouse locations and transportation routes:

- Network optimization modeling uses mathematical models to evaluate scenarios and identify the optimal locations for warehouses and distribution centers.

- Transportation route optimization uses algorithms that analyze transportation routes, considering factors such as distance, cost, and delivery time to identify the most efficient ways.

- Simulation models test different distribution network designs in a virtual environment, allowing businesses to assess their performance and make data-driven decisions.

The Power of AI-driven Supply Chain Planning

With IoT and artificial intelligence (AI) led technologies rapidly gaining momentum especially in the global logistics and supply chain management industries, supply and demand planners stand to benefit from these in several ways.

The powerful evolution in artificial intelligence, machine learning, and data science has the potential to bring in massive disruption and meaningful innovation across these industries.

With specific reference to supply chain planning, AI can help to a great extent in reducing supply chain costs , managing inventory, and eliminating potential bottlenecks. AI in supply chain can help obtain new insights into several areas to boost productivity and optimize resources as well.

As a result, floor operators and planners are able to create more agile, flexible, and profitable supply chain plans to deliver goods and services as per customer expectations.

One such important application of AI in supply chain planning is the process of eliminating bottlenecks across the supply value chain to ensure supply chain planners and managers can meet their revenue targets easily.

Safer, Smarter and Better Supply Chain Planning with ThroughPut

ThroughPut’s Demand-driven supply chain planning software is a fully automated, scalable, enterprise-ready Kaizen Artificial Intelligence product based on digitalizing the world’s leading continuous improvement operations principles.

It enables your operations managers in effective supply chain planning to achieve unprecedented productivity and operational excellence.

ThroughPut analyzes existing industrial data in real-time to detect, identify, prescribe and prevent potential bottlenecks saving millions in delays and lost revenue.

It helps meet your supply chain goals by nailing down bottlenecks and eliminating inventory waste to achieve end-to-end efficiencies. You ultimately benefit from an efficient and optimal smart supply chain plan along with time, money, and resource savings.

Supply Chain Management 101: Principles, Examples, and Templates

By Andy Marker | June 25, 2017 (updated February 22, 2022)

- Share on Facebook

- Share on LinkedIn

Link copied

Globalization has become an undeniable part of commerce over the last few decades, as large companies have grown first to source labor and parts from developing regions, and then to start selling in those same areas as they grew in wealth and buying power. Supply chains have had to keep in step, passing through numerous countries to obtain goods most efficiently and cost effectively, and growing more complex as a result. And on the other end, the supply chain grows more frayed in order to deliver to countless countries for consumption. For the largest companies, managing a supply chain can require dedicated teams in every area the chain touches. It’s safe to say that supply chain management is both an art and a science. This article will cover what a supply chain is, with examples; discuss how supply chain management works and its principles; and vital concepts in the field. Then we’ll move on to current issues and where the field is going. Finally, you’ll find useful resources, templates, and education programs. Ready? Let’s get started.

What Is a Supply Chain?

A supply chain is a collection of suppliers required to create one specific product for a company. The chain is made up of nodes or “links,” which can include multiple manufacturers for parts, then the completed product, then the warehouse where it is stored, then its distribution centers, and finally, the store where a consumer can purchase it. The concept of the chain is important, because each link is connected in a specific direction and order, and the next link cannot be reached without going through the previous one. Each link adds time and costs, and can involve labor, parts, and transportation. Every product a company carries may have its own supply chain, though they may use certain suppliers for multiple products. You can see why this gets so complicated, especially for international supply chains.

The process described above was that of a typical retail supply chain. However, there are many different types in practice. Here are three examples from well-known masters of supply chains: Example: Walmart and “Big Box” Retailers The “Big Box” store, which represents one of the major disruptions of the retail model from the last century, thrives on size, ubiquity, and well-planned supply chains to drive out the competition. How else would a company like Walmart make a profit on a t-shirt made overseas that retails for $5.00? Walmart succeeds by having fewer links in its supply chain, and buying more generic goods directly from manufacturers, rather than from suppliers with brand names and markup. It uses “Vendor Managed Inventory” to mandate that manufacturers are responsible for managing products in warehouses owned by Walmart. The company is also is particularly choosy with suppliers, partnering only with those who can meet the quantity and frequency it demands with low prices, and with locations that limit transportation needs. They manage their supply chain like one firm, with all partners operating on the same communication network. By buying at large enough quantities to take advantage of economies of scale, moving products directly from manufacturers to warehouses, and then delivering to stores which are large enough to be distribution centers, it reduces links in the supply chain and cost per item, translating to low prices for consumers.

Example: Amazon and “Ecommerce Platforms” Having overtaken Walmart as the world’s largest retailer in the last decade, Amazon’s “online big box” concept is a perfect example of unique supply chains. As an e-commerce shop, obviously they cut the retail store out and ship from distribution center to consumer’s homes directly. Where Amazon innovates is both in its supplier-side and its final supply chain link - delivery. Just about anyone can sell things on Amazon because it’s a platform, not just a shop. As a result, Amazon has more things than any other online store, so when people shop online, they think of Amazon. Then, it produces everyday goods cheaply, and underbids suppliers. Next, their warehouses make serious use of automation to store items going to like destinations together, ready for immediate transport. Finally, its investments in delivery staff and technology make 2-day shipping a basic expectation, and even same-day delivery a possibility. Amazon ditches third-party logistics (3PL) and fulfills orders itself.

Example: Tesla and Specialized, Owned Chains Automotive manufacturing has come a long way since Henry Ford used assembly line manufacturing to speed up the production of a single car model in a single color. Now, in a time when even American carmakers are opening factories abroad, Tesla is making innovative, incredibly popular, and luxurious cars right in California, a location with incredibly costly real estate. Rather than having a long supply chain of cheap part makers, they have a vertically integrated supply chain, with a full-service auto plant near its corporate headquarters and plans for a supplier park and a massive battery factory, and Tesla owns it all. Even more interesting is the digital supply chain the company promotes - new firmware and algorithm updates are pushed out to existing car owners over the cloud.

What Is Supply Chain Management?

As the name implies, supply chain management (SCM) is handling and optimizing all the many complicated facets of a supply chain, involving goods and services. Even ensuring timely handoff from manufacturer to shipper to supplier to shipper to buyer is a massive task, but to do it cost effectively and build net value is truly a challenge. Supply chain management is so important because modern commerce exists in a networked global economy. Most businesses are specialized - even department and big box stores are only really equipped to sell to customers, despite their wide variety of products. The value of vertical integration is hard to justify when communication costs and SCM tools are so inexpensive - it almost always makes more sense to outsource for price efficiency.

The concept of supply chain management was in effect long before the term was created in 1982. In the colonial era, international trade by ship was already making for complicated transportation issues and the need for efficiency. During the Industrial Revolution, the ability to quickly produce goods with machine assistance led to the need to manage significant inventory and constant consumption. By the time history arrives at Henry Ford’s famous assembly line for the world’s first car production in 1913, supply chain management had become an art. As the century wore on, more companies were producing more goods and looking for ways to reduce costs. They vertically integrated into owned supply chains to try reducing costs at each stage. In the 1980s and on, globalization became a realistic dream for many companies, because of computer systems, easier communication, and commerce-friendly trade laws. Around the 1990s, it became a common practice for firms to specialize, and focus on core competencies and outsourcing the rest, abandoning the vertical integration of the previous era. At this point, supply chains became truly complex, in order to coordinate hundreds of otherwise unrelated and geographically-distant manufacturers, suppliers, shippers, warehousers, and retailers. Now, in the “SCM 2.0” era, the Internet and new methodologies have led to collaborative platforms and democratized processes. This is allowing smaller competitors to use some of the same manufacturers as major players, and reducing inefficiencies for those manufacturers as a result. Better communication and planning tools are providing a way for small and large companies alike to manage even more complex supply chains.

Variants of SCM

Global SCM: The combination of global manufacturing with supply chain management, which must account for tariffs and local taxes as goods and services travel internationally to ultimately provide greater value at the end of the chain. SAP SCM: Systems, Applications, and Products (SAP) is a software company that revolutionized logistics and enterprise resource planning. It provides an automated way to manage supply chain networking, supply chain planning, and supply chain execution, along with production planning, business forecasting, and demand planning. Logistics and SCM: The art of coordinating efforts between every member of the supply chain to get products from their source to the consumer. Purchasing and SCM: The focus on the monetary aspect of SCM, from costs to value added at each link in the supply chain.

Principles of Good Supply Chain Strategy

Download Supply Chain Management Checklist

The Basics of Supply Chain Management Processes

There are key supply chain processes that you must take into consideration to effectively understand and manage them. These processes are all at play regardless of the type of supply chain you’re using. Customer relationship management (CRM) comes first, because as the principles of SCM state, you must adapt everything in the supply chain to the customer. If no one is buying, there’s no need to produce anything. At the front of your supply chain, where a store’s staff interacts with its consumers, they must have plans in place for ongoing relationships. They need CRM tools to gather customer information for marketing and market research, all to determine the products and services to offer in the future. Customer service management is another process that ties in, as it is where you gather negative and positive feedback to determine future needs. Demand management is closely linked with the previous two, as it takes customer interactions and orders into account to determine the workload all the way up the supply chain. At its core, customers buying more means make more, and customers buying less means make less. Customer forecasting is an important task that analysts must perform well to determine the current demand and what it will be in the future, to prevent waste in the supply chain. Product development is an important part of the supply chain that is informed by consumer demand. You must work with CRM and customer service data to determine what they want, which influences new products, product line extensions, and also what to stop making. You must integrate suppliers in this process because it affects cost, quality, and delivery time. Supplier relationship management goes without saying - if you want to produce your products on time and on budget, you need a solid rapport with everyone you’re outsourcing to in the chain. This impacts manufacturing flow management , which ensures everything gets where it needs to go without delay, and at the correct spec. Order fulfilment involves coordinating with distribution centers and either retail locations or 3PL to get the product direct to consumers. You’ve now made it all the way back to the beginning of the cycle, and need to pay attention to new CRM and customer service data. Returns management , also known as the “reverse supply chain,” is a vital part of the flow of products that doesn’t fit perfectly into the clean supply chain cycle. It involves picking up online orders from 3PL locations or from consumers’ addresses and accepting returns at retail locations. Once these items are put back into inventory, they must be ready to get to a different customer while the product run is still live.

What Supply Chain Managers Look for When Managing Supplier Relationships

One of the most complex parts of SCM is handling all the other people in the supply chain. They have their own needs and motivations, and to keep them all happy and working together with partners they are only loosely affiliated with is a challenge - especially when trying to meet deadlines and turn a profit. The following are what managers should focus on most in such relationships: Org Chart and Leadership Style: How is the supplier’s organization set up? Is it a vertical or horizontal structure? Is the leadership strong and long lasting, or fickle and prone to change? You need to know who you’ll be interfacing with, and who will be the next one in line should some shakeup occur. Business relationships are always between people, and don’t always survive a reorg. Management Style: How do the leaders at this supplier run their shop? Make sure it works with your crew. A micromanager at a relatively replaceable link in your supply chain will waste inordinate time, just as a hands-off manager at a vital link could result in sloppy delivery or substandard product quality. Company Culture: Always important for working with suppliers, determine what kinds of people rise to the top, and how everyone acts when nobody's watching. If, for example, middle managers are constantly in fear for their jobs because of ruthless quarterly performance reviews, they may over-promise, make excuses, or otherwise be unstable work partners. Product Flows: Once you know that you can work with the people, make sure their facilities are in order. Are they equipped for orders of the size and frequency you plan to make? How do they handle emergency, fast-turn around orders? What about other customers - are they only able to use their facilities for your product flows at certain portions of the month due to full inventory? Leave no stone unturned. Information Flows: Just as vital is the ability to control information about the day-to-day flow of materials, and to communicate and coordinate long-term plans. Is the supplier up on their product details, inventory, and SKU organization? Is their security and encryption up to the standards of your company, and your industry? Big data is useless if the right people don’t see it in time. Rewards and Risks: Take into account opportunities and threats of working with this supplier. Maybe they’re well-equipped to handle your exact product because they also work with your competitors. Perhaps they are new and establishing themselves, so offer a substantial discount, but may not be able to deliver on time? Do what’s best for the company, and use risk assessment to keep your whole supply chain operable.

Vital Supply Chain Management Concepts to Know

Having a passing familiarity with the following terms will help you see just what kind of skillset and abilities will be required when working in supply chain management: Border Adjustment Tax: Also known as a destination-based cash flow tax (DBCFT), it is a tax levied on imported goods which is important to know in global supply chains. Customer Relationship Management: Also known as CRM, this concept refers to providing ongoing service to customers and collecting data about their likes and purchases. There are also CRM tools that help automate and record interactions with customers. Cumulative Mean: A figure for knowing how much or how little to produce in advance, involving mean orders with all previous data treated as equally useful. Demand Management: Understanding customer behavior and patterns to control how much is ordered and produced at each link in the supply chain, with the goal of eliminating wasted production. Financial Flows: Credit terms, payment schedules, accounts payable and receivable, and other factors that you must monitor to determine if a supply chain is profitable or not. Information Flows: Transmission of orders, delivery status, and other data that influence the supply chain’s responsiveness to demand. Integrated SCM: This is a method of SCM wherein all of the links are tightly integrated, operating almost as one company rather than a loose association of buyers and sellers. Inventory Management: Monitoring and controlling orders, storage, and use of owned components to create the products your company sells. Lean Six Sigma: A data-backed philosophy of continuous improvement that focuses on preventing defects and mistakes rather than discovering them later, which reduces waste and production time via standardization. Read Everything You Need to Know About Lean Six Sigma to learn more about this methodology. Logistics: The physical movement of products from one link in the supply chain to the next, and the practice of improving their efficiency. Make vs. Buy: A simple evaluation of whether it is more cost-effective and time-efficient to produce a required product with your company’s existing resources, or to outsource the need. New Product Development: The creation of new products both in response to and in anticipation of customer demand, using data gleaned from CRM and the whole supply chain. Read Innovation for Everyone: Everything You Need to Know About New Product Development to learn more about this process. Operational Accounting: Accounting for a company that focuses on planning, directing, and controlling of daily activities by their costs and eliminating waste. Physical Flows: The actual movement of parts and products throughout the supply chain, which the Logistics team must manage and analyze to keep going without pause. Project Management: The process and tools involved in ensuring that a codified piece of work (project or product) gets done on time while keeping all contributors aware of their next step. Reverse Supply Chain: Aftermarket customer service, which may involve accepting returns, refurbishing and discounting, or otherwise finding use for the reacquired inventory. Risk Management: Identifying, evaluating, and then choosing which risks to address first, with the goal of reducing overall risk in a supply chain. S&OP: Sales and Operations Planning is a management process that aligns its constituent parts to ensure that the organization is only focused on operations that improve sales. Learn more about S&OP here . Strategic Sourcing: Formalizing a company’s information gathering in order to use its purchasing power to take advantage of the best values in the marketplace of suppliers. Theory of Constraints: A methodology that identifies the largest limiting factor in production, then finding a way to remove it to improve the efficiency of the entire production.

Current Issues in SCM

In addition to the major terms, it’s important to keep aware of legal, political, and social events which affect supply chain management when seeking a career in the field. Here are some of the bigger issues of the day: Dodd-Frank Decision: This was a 2010 law which included a clause on “Conflict Minerals.” It requires companies to audit their supply chains in order to determine whether gold, tungsten, tantalum, and tin came from the Democratic Republic of the Congo, and report on their due diligence. It adds an extra layer of complexity and costs to SCM for those involved in chains with those minerals. NGO Actions: Activist groups of all kinds work to end common practices within major companies’ supply chains, such as sweatshop labor, or push consumers towards less complicated supply chains by encouraging them to support local businesses and farms. SEC Regulations: Whereas NGO actions can force a company’s hand for PR reasons or changing the marketplace of ideas, the Securities and Exchange Commission can slap that same company with fines, making company’s quick to comply. Third-party audits of supply chains are an important part of keeping in step with these regulations. SECH Ratings: This is a rating that involves economic, social, and environmental judgements to gauge a company’s overall sustainability. Transparency: Though protecting data is important, certain measures of transparency can improve company performance. Among consumer products, many younger, disruptive brands make their supply chain a selling point in marketing by being upfront about how and where they get their components, and where they make their products. The reasoning goes, if a company is hiding something, there must be an unethical component to it. Sustainability Measures: As major companies and countries around the globe move towards sustainable production, all supply chains become impacted. Whether due to changing regulations or seeking good PR, many companies are working to reduce pollution and other issues in their chain.

The Future of Supply Chain Management

Aside from the issues of the day, it’s also vital to see where the field is going. The future of SCM is bright, but certainly evolving. We asked a group of experts and innovators in supply chain management to discuss what they believe the future of SCM holds:

Jake Rheude , Director of Business Development and Marketing for Red Stag Fulfilment

Over the next decade, we will see massive and disruptive forms of innovation both in terms of technology that expedites the speed at which customers receive their products ( drone delivery ) as well as technologies that drastically enhances the online shopping experience for customers, ( virtual reality ).

While these and other technologies no doubt have the opportunity to significantly change the landscape of online shopping and the supply chain, I expect we will see firms diverge on two different strategies. Some will rush to implement these costly new technologies in order to drive down the total time between an order being placed and last mile delivery, while other firms will stand by the current landscape (for most B2C online sellers) of product delivery in approximately two-days, acting cautiously, particularly in regards to the cost of these new technologies versus their impact on the overall value chain for consumers.

Certainly, there are niche industries where significant investments in drone delivery technology will provide a distinct competitive advantage, but I predict that for many B2C online sellers, the impact on the overall value chain of these new technologies will be misaligned with a consumer's perception of value, and therefore make the initial cost of these new technologies unjustified.

Lauren Stafford , Digital Publishing Specialist for Explore WMS

Embracing big data is an essential principle of modern SCM, specifically real-time data which has the potential to improve the efficiency of a supply chain and negate potential risks to strategy. We know that logistics optimization through technological innovations and data integration can make supply chains more efficient and more financially sound.

The future of the multi-modal SCM depends on successful integration with data and systems to achieve synchromodality. To achieve this, there needs to be a connection to all available transport modalities in the form of a real-time data flow. Once any issues with connectivity are addressed, a ranking system is required to consider a variety of variables such as dock schedules and material restrictions. Pricing data is another integral component.

The great advantage of a synchromodal platform is that it’s informed by every available option and makes a selection based on key factors like speed requirements. There is still significant work to be done in terms of how best to access and integrate a supply chain partner’s real-time data but, as these platforms are developed, we’re likely to see faster order processing times for large shipments and systems which can help generate a better ROI. The way we understand it, SCM is changing because now an efficient supply chain can be a competitive asset as opposed to a cost center.

John Boyd , founder of The Boyd Company, Inc

Probably the most dynamic link in the supply chain in recent years has been the "last mile": that movement of goods from a DC to a final destination in the home. E-commerce king Amazon has done much to challenge and ultimately rewrite the rules of last mile delivery. Last mile delivery has also produced a new warehousing subsector: the locker. Studies show that online shoppers not only want their packages now, they also want their packages delivered to places other than their homes. These lockers can be viewed as "micro warehouses" and will come with additional costs. We expect many to be operated by an emerging sector of third-party logistics (3PL) providers specializing in this particular segment of the supply chain.

Lockers are now common in Europe, where densely populated and congested urban centers make them a natural fit. We anticipate that lockers will also become the next boom sector within logistics/distribution site selection in the United States. Amazon already has automated lockers in six states, while the U.S. Postal Service has lockers located within post offices in the Washington, D.C., area.

Upstart third-party logistics providers will be looking for sites where they can locate lockers, such as in transit centers, apartment buildings, convenience stores, or any establishment that provides off-hours access for picking up packages. Also, the growing online meals industry is expected to fuel the need for temperature-controlled lockers for the delivery of perishables.

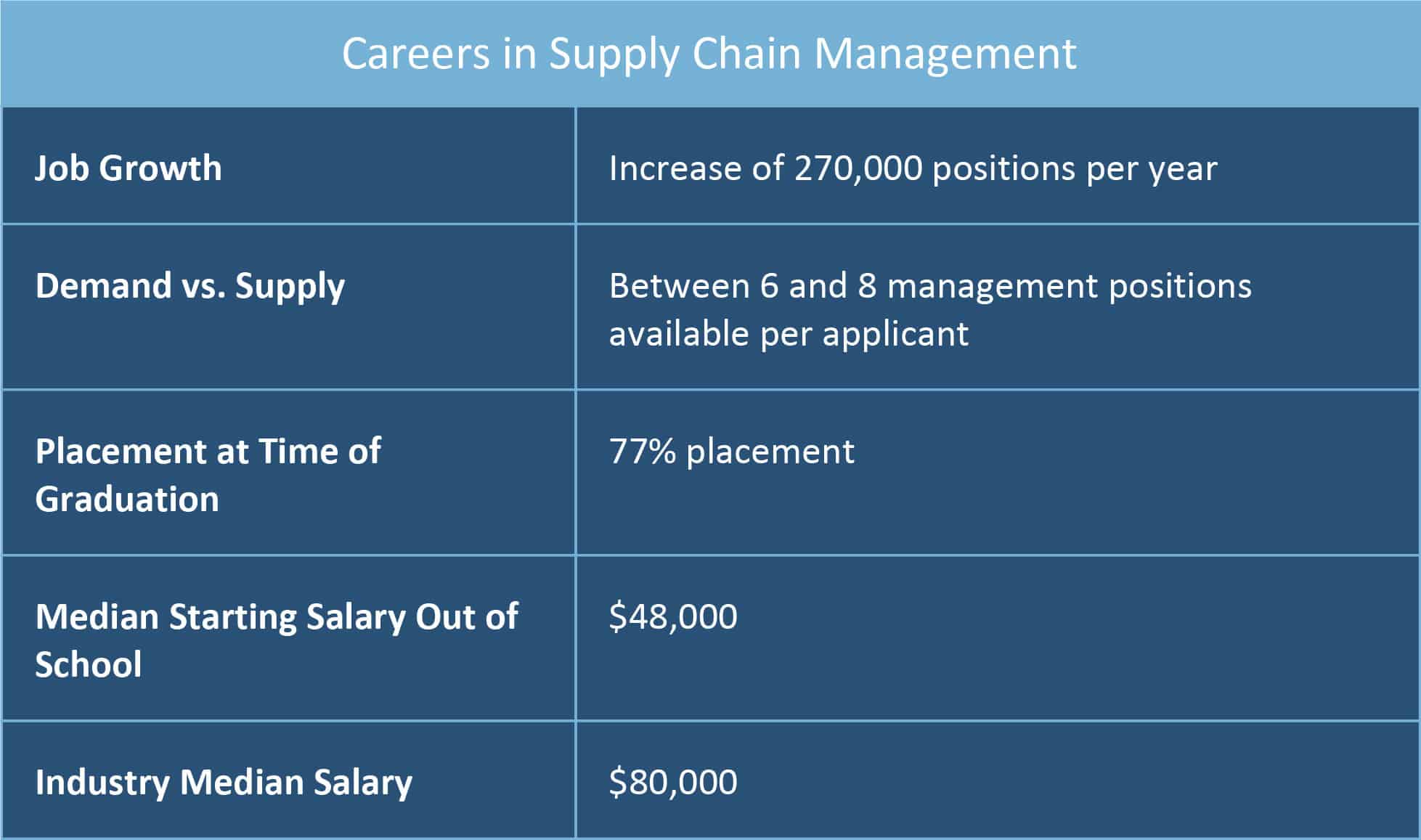

Careers in Supply Chain Management

With a bright future filled with unique challenges, a career in SCM is a strong choice. It might be surprising to hear about an industry that’s all about outsourcing and automation, but new experts are more vital than ever for global organizations and even local ones to grow. Look at these industry stats:

Career Paths

What kind of positions can you take on in supply chain management? Supply Chain Business Analyst: Examine your company’s workflow and come up with creative ways to streamline its business processes. Live and breathe efficiency. Inventory Control Administrator: Ensure that inventory systems’ data is accurate with physical inventory, troubleshoot discrepancies, discover root causes and interact with everyone related to this inventory. Purchasing Specialist: Work out deals with suppliers and compare bids to minimize cost across the supply chain. Procurement Manager: Research, evaluate, and purchase large quantities of products for companies to resell or use in operations. Determine what is in your company’s store, ecommerce shops, and more. Operations Analyst: Evaluate, report on, and improve the management of activities that generate recurring revenue for your organization, i.e. its core competencies. Material Planning Manager: Plan, monitor, and manage products and the materials required to make them in your organization’s manufacturing operations. You ensure the constant flow of materials so the factory never runs out.

Logistics Analyst: Evaluate and report on transportation of goods and services up and down your organization’s supply chain, ensuring that everything gets where it needs to go and when it needs to get there.

Top Higher Education Programs

Supply chain management is a game with global stakes, as such major universities and academies around the world offer Bachelor’s and Master’s degrees in the subject. If you want to secure a job in the sector with a Fortune 500, becoming accredited in SCM is vital. Look at some of the top schools on this list for more details on breaking into the industry:

- Cambridge University

- Copenhagen Business School

- Cranfield School of Management

- Eindhoven University of Technology

- London Business School

- Vlerick Business School

Certifications in Supply Chain Management

If a full Master’s program seems like too big a commitment, explore some of the short-term certifications available below. They give you a shot at entry level jobs if you’re inexperienced, and are a nice brush-up on current SCM standards for seasoned professionals.