Sign up now to get 3 strategies for FREE!

Your AI-Powered Business Suite

Pre-built AI-powered business consultants trained by experts and fine-tuned for your entrepreneurial success.

Loading workflows...

A Quick Look

Select a Path to Supercharge your Entrepreneurship Journey

One strategy.

For entrepreneurs with one main venture

Can only be used ONCE on Business Plan Factory. Subsequent strategies will require separate payment.

Unlimited Strategies

For serial entrepreneurs

Can be used for UNLIMITED times on Business Plan Factory. Subsequent strategies WON'T require payment.

About the Founders

Marc Kramer

Serial Entrepreneur, Author, & Business Consultant

Marc Kramer is a serial entrepreneur, author, columnist, and podcast host. He has raised billions of dollars for a variety of ventures. He is president of Kramer Communications , which provides business, marketing, financial, and operational plan development and implementation for startups to Fortune 500 companies. Marc is president of Stress-Free Family Business , where he trains the next generation, develops process and plans to grow the family business.

He is also executive director of the Private Investors Forum , which runs the Angel Venture Fair , bringing together the largest gathering of Angel Investors and entrepreneurs in the Mid-Atlantic region. As Executive Director of the Private Investor’s Forum, Marc has worked with almost over 1000 companies from all over the world making introductions to Angel investors all over the US. Marc is also the founder of Consulting University USA , which teaches aspiring consultants how to start a practice and works with ongoing consultants to help them reach the next level.

Marc was on the cover of Profit magazine along being featured in Inc , Entrepreneur Magazine , and other publications for starting the country’s formally organized investor angel’s network, the Pennsylvania Private Group . The Wall Street Journal selected Marc to be one of their main speakers on early stage investing at their national conference in Atlanta in 1994.

He was project faculty member at the University of Pennsylvania’s Wharton School of Business , Global Consulting Practicum and Executive Education an adjunct professor at Drexel University , adjunct professor at Temple University , mentor faculty at the National University of Singapore , and a professional speaker and lectures on topics such as Internet marketing, marketing, sales networking, corporate entrepreneurship and turning around distressed companies.

Marc, who has been writing on angel investing and entrepreneurship for 30 years as a national columnist for the American City Business Journal chain and columnist for SmartCEO magazine, has written for Forbes.com and TheStreet.com , the world’s top online service for money managers, company leaders and individuals that manage their own money and was a columnist for Philadelphia’s third largest daily The Bulletin . Marc also provides a one-minute entrepreneurial commentary for KYW News in Philadelphia.

"Power Networking" , published by NTC Publishing in 1997, a division of McGraw Hill, was a Success magazine, NBIA Book Club , Human Resource Book Club , and Right Management (largest outplacement firm in the world) selection.

"Small Business Turnaround" , published by Adams Media in 1999, was named one of the 30 Best Business Books in 2000 by Executive Book Summaries .

"Financing & Building an E-Commerce Venture" , published by Prentice Hall in 2001, was an Ingram , NBAI Book Club , and California CEO magazine selection. Two leading regional business publications, Eastern Pennsylvania Business Journal and the Times Herald , have contracted Marc to write a monthly business column on Internet and small business.

"Web Sites Built to Last" , published by Adams Media, released 2002.

"Consulting" , published by Entrepreneur , released 2003.

Marc has received such awards as the Race for Peace in 2017, Inc. Magazine Entrepreneur of the Year , American Electronics Association Spirit of America Award and was three years in a row named one of the Top Five Business Leaders Under Age 40 in Philadelphia region by the Philadelphia Jaycees and won the Small Business Journalist of the Year by the Center City Proprietors Association of Philadelphia in 2006.

Marc is a former trustee of Cheyney University , the oldest African American University in the U.S. and was on the board of the Entrepreneurs Forum of Philadelphia and the Technology Resource Alliance . Marc has a Master’s in Management from Penn State University and a BS in journalism from West Virginia University .

Mai Quang Tuan

AI Engineer & Startup Founder

Tham (Sylvia) Nguyen

Software Engineer & Startup Founder

Join the Future of Work in the AI Era

People worldwide are adopting AI agents to assist their business decision-making and strategic planning. It's time for you to join the transformation too!

Getting started: A guide to creating a manufacturing business plan

What is a manufacturing business plan.

A manufacturing business plan is a formal document that outlines the goals and objectives of your business. It includes detailed information about your:

- Products or services

- Target market

- Marketing strategy

- Financial projections

- Operational details

The purpose of a business plan is to give you a roadmap to follow as you build and grow your business. It forces you to think through every aspect of your venture and identify potential problems or roadblocks before they happen.

Manufacturing business plans can also be used to attract investors or secure funding from lenders. If you are looking for outside financing, your business plan needs to be even more detailed and include information on your management team, financial history, and expected growth.

Ideally, you should update your business plan yearly to ensure that it remains relevant and accurate. As your business grows and changes, so too should your plan.

Why does a manufacturing company need a business plan?

No matter how simple or complex your ideas may be, you need a plan, or they will never become a reality. A business plan will clearly understand your costs, competition, and target market. It will also help you to set realistic goals and track your progress over time.

Let’s look at a manufacturing strategy example. You have a great idea that you think will revolutionize the automotive industry . Your new safety harness will be made from a lightweight, yet incredibly strong, material that cannot be cut or torn. You are confident that your product will be in high demand and generate a lot of revenue.

But before you walk into Ford or Toyota to try and get a purchase order , you need to have a plan. You must know:

- How much will it cost to produce your product

- How many units do you need to sell to break even

- Who is your target market is

- What is your competition selling

- How will you reach your target market

You also need to clearly understand the regulatory landscape and what it takes to bring a new product to market. All of this information (and more) should be included in your business plan.

This is not just a document that you create and forget about. It is a living, breathing tool that should be used to guide your actions as you build and grow your business.

What are the key components of a business plan?

Every manufacturing business plan will be different, but almost always, they will include the same five components:

Executive summary

Company description, products and services, market analysis.

- Financial plan

Let’s take a closer look.

The executive summary is the first section of your business plan, but it is typically written last. This is because it should be a concise overview of everything that follows, and you can only do that once you have completed the rest of your plan.

Include the following in your executive summary:

- The problem that your product or service solves

- Your target market

- Your unique selling proposition (what makes you different from your competitors?)

- Your manufacturing business model (how will you make money?)

- Your sales and marketing strategy

- A brief overview of your financial projections

Someone should be able to quickly scan through your executive summary and have a pretty good understanding of what your business is and how it plans to be successful.

This is where you can get a bit more creative, explaining your company’s history, mission, and values. You will also include information on your team or management structure.

It can be simple but should inspire faith in your ability to execute your business plan.

You will need to provide a detailed description of your product or service, as well as any unique features or benefits that it offers. You should also include information on your manufacturing process and quality control procedures.

If you have any patents or proprietary technology, they should be listed here as significant assets for your business.

For example, let’s say you are planning on creating a brand-new line of disposable coffee cups. The dimensions, materials, and other specifications would be listed here, along with any unique benefits (such as being made from recycled materials).

You might also include information on your manufacturing process, such as the fact that the cups will be produced in a certified clean room or that you will employ workers local to where the product is sold.

Chances are, you started down this path because you realized that there was a market opportunity for your product or service. In this section, you will need to provide detailed information on the opening, as well as the analysis that convinced you to pursue it.

This should include:

- Market size (current and projected)

- Key market segments

- Customer needs and wants

- Competitive landscape

This is where you will need to do your homework, as you will be justifying your business decision to enter this particular market. The more data and analysis you can provide, the better.

For our coffee cup example, the market analysis might include:

- Information on how many cups are used every day

- Projected growth

- Key segments (such as office workers or on-the-go consumers)

- Customer needs (such as convenience or sustainability)

It would also examine the competitive landscape, including both direct and indirect competitors.

Financial plan

You’re in this to make money, and so are your potential investors. In this section, you will need to provide detailed information on your manufacturing business model and how it will generate revenue. This should include:

- Initial investment

- Sales forecast

- Carrying costs

- Pricing strategy

- Expense budget

You will also need to provide information on your long-term financial goals, such as profitability or break-even point. Discuss production line details, inventory management strategies , and other factors impacting your bottom line.

How to write a business plan for a manufacturing company

The process of creating a business plan for a manufacturing company is similar to any other type of business. However, there are some key considerations to keep in mind.

First, you need to understand your industry and what it will take to be successful in it. This includes understanding the competitive landscape, the costs of goods sold , and the margins you can expect to achieve.

You also need to have a clear understanding of your target market and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits.

While there will be many things specific to your company, here are five questions to answer for each of the sections listed above.

Executive summary:

- What is the problem that your company will solve?

- How will your company solve that problem?

- Who are your target customers?

- What are your key competitive advantages?

- What is your business model?

Company description:

- What is the legal structure of your company?

- What are your company’s core values?

- What is your company’s history?

- Who are the key members of your management team?

- Where is your manufacturing facility located?

Products and services:

- What product or service does your company offer?

- How does your product or service solve the problem that your target market has?

- What are the key features and benefits of your product or service?

- How is your product or service unique from your competitors?

- What is the production process for your product or service?

Market analysis:

- Who is your target market?

- What needs or wants does your target market have that your product or service will address?

- What is the size of your target market?

- How do you expect the needs of your target market to change in the future?

- Who are your key competitors, and how do they serve the needs of your target market?

Financial plan:

- What are the start-up costs for your company?

- How will you finance your start-up costs?

- What are your monthly operating expenses?

- What is your sales forecast for the first year, and how does that compare to your industry’s average sales growth rate?

- What are your gross margin and profit targets?

Even if you do nothing but answer these questions, you’ll be well on your way to creating a thorough manufacturing business plan.

How to stabilize your growth

When getting started, managing your business with spreadsheets might be okay. But, once sales and manufacturing orders start to increase, the inefficiencies of manually managing your business come to light. That’s why many turn to automation to keep their manufacturing on track.

Common mistakes to avoid

However, new manufacturing entrepreneurs often fall into a handful of traps when creating their business plans.

- Not doing enough research – You can’t know everything about your industry, but you should do your best to understand as much as you can before writing your business plan. This means talking to experts, reading trade publications, and studying the competition

- Not being realistic – It’s important to be optimistic when starting a new business, but you also need to be realistic. This is especially true when it comes to financial projections. Don’t overestimate the amount of revenue you will generate or underestimate the costs of goods sold

- Not having a clear understanding of your target market – You need to know who you are selling to and what needs or wants your product or service will address. This market analysis should include information on your target customer’s demographics, psychographics, and buying habits

- Failing to understand your competition – You need to know who your competitors are, what they are offering, and how you can differentiate yourself. This information will be critical in developing your marketing strategy

- Not having a clear vision for the future – Your manufacturing business plan should include a section on your long-term goals and objectives. What does your company hope to achieve in the next five years? Ten years? Twenty years?

Creating a business plan for manufacturing can be simple. It can be quite simple if you break it down into smaller pieces.

Once you have it in place, staying on track can be quite a bit more difficult. By using ERP software like Katana , you can track all of your key metrics in real time, avoid any potential issues, and make course corrections as needed.

To start following your plan and creating a successful manufacturing company, get a Katana demo today.

Table of contents

Manufacturing guide.

1. What is manufacturing

1. 1. Production vs. manufacturing

1.2. Production scheduling software

1.3. Production tracking software

2. How to start a manufacturing business

2.1.How to manufacture a product

2.2. Manufacturing best practice

2.3. A guide to creating a manufacturing business plan

2.4. Manufacturer ecommerce

2.5. Marketing for manufacturers

2.6. Manufacturing business processes

2.7. Food manufacturing

2.8. Small business manufacturing software

3. Manufacturing processes

3.1. Job shop manufacturing

3.2. Production quality control checklist

4. Lean manufacturing principles

4.1. Just-in-time (JIT) manufacturing

4.2. Tips to reduce manufacturing waste

4.3. Manufacturing KPIs

5. Light manufacturing

6. Advanced manufacturing

7. IoT in manufacturing

8. Manufacturing challenges

9. Total manufacturing cost

9.1. Manufacturing overhead formula

9.2. Manufacturing inventory software

10. Good manufacturing practices

11. MRP systems

11.1. MRP in supply chain management

11.2. Best MRP software

12. Manufacturing ERP systems

12.1. Best ERP software for manufacturing

12.2. Manufacturing execution systems (MES)

More guides from Katana

Get visibility over your sales and stock

Wave goodbye to uncertainty by using Katana Cloud Inventory for total inventory control

Manufacturing Business Plan Template

Written by Dave Lavinsky

Manufacturing Business Plan

You’ve come to the right place to create your Manufacturing business plan.

We have helped over 1,000 entrepreneurs and business owners create business plans and many have used them to start or grow their Manufacturing companies.

Below is a template to help you create each section of your Manufacturing business plan.

Executive Summary

Business overview.

Perfect Snacks, located in Lincoln, Nebraska, is a food manufacturing company that specializes in the production of snack foods and packaged goods. We manufacture an extensive line of snack products, including trail mix, gummies, and chocolate. Our company focuses on quality and only uses the best natural ingredients in our products. We will primarily sell our products to grocery stores and other establishments that sell snacks, but will also sell bulk orders to individual customers through our website.

Perfect Snacks was founded by Joe Boseley. Joe has been working on the manufacturing company concept over the past few years and began networking with grocery store clients and locating the land to build his manufacturing and distribution center. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Product Offering

Perfect Snacks will manufacture an extensive list of sweet, salty, and healthy snacks. Some of our initial products will include:

We will primarily sell our products to grocery stores, recreation centers, and other businesses that sell snacks in bulk. Consumers can find our products in stores or buy them in bulk on our website.

Customer Focus

Perfect Snacks will primarily serve the residents of Lincoln, Nebraska. The community has a large population of families and children, who are the primary consumers of snack foods. Therefore, we will market our products to recreational centers, schools, grocery stores, and other establishments that sell snacks to children and their parents.

Management Team

Perfect Snacks is owned by Joe Boseley, a local entrepreneur who has worked in various warehouses and manufacturing companies in Lincoln, Nebraska. Working in the manufacturing industry and in warehouses, Joe is very familiar with the processing and distribution of packaged foods. As a line manager that oversaw dozens of employees, Joe has the proper knowledge and experience to own, manage, and operate his own manufacturing company.

Joe will utilize his past experience with developing staff roles and functions. He is also very familiar with the manufacturing equipment and plans to purchase the latest technology that is efficient and cost effective. His contacts have allowed him to gain concrete Letters of Intent from local supermarket chains to have his manufactured goods in their stores.

Success Factors

Perfect Snacks will be able to achieve success by offering the following competitive advantages:

- Taste: Perfect Snacks’ snack products will be made with the highest quality ingredients and offer quality over quantity.

- Price: Perfect Snacks is able to offer the highest quality snacks at a competitive price point.

- Community Relations: Perfect Snacks will be a pillar in the community and be heavily involved in family-related activities in the area. It will sponsor events, provide snacks for schools and daycares at a discounted price, and donate a portion of its proceeds to area family-related charities and organizations.

- Proprietary Technology: Perfect Snacks will invest heavily on the latest technology to manufacture the snack foods for distribution. It will ensure the food products are made safely and free from any harmful chemicals and ingredients.

Financial Highlights

Perfect Snacks is seeking a total funding of $1,200,000 of debt capital to open its manufacturing company. The capital will be used for funding capital expenditures, salaries, marketing expenses, and working capital. Specifically, these funds will be used as follows:

- Manufacturing facility design/build-out: $400,000

- Equipment and supplies: $375,000

- Initial inventory: $100,000

- Three months of overhead expenses (payroll, rent, utilities): $250,000

- Marketing costs: $50,000

- Working capital: $25,000

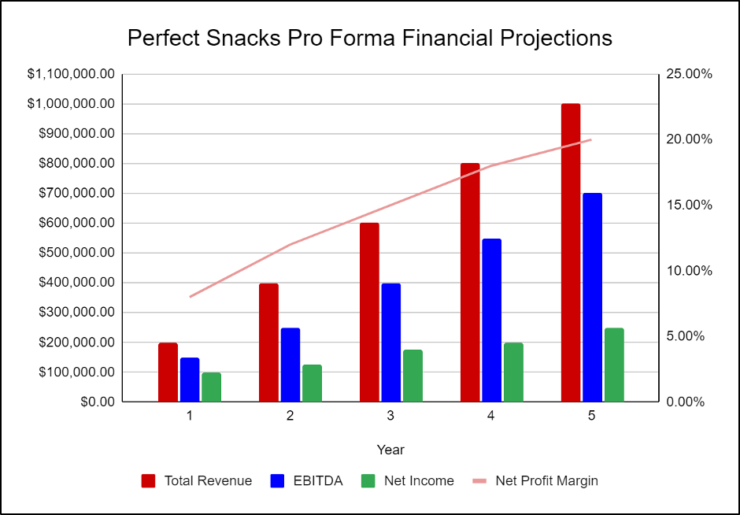

The following graph below outlines the pro forma financial projections for Perfect Snacks.

Company Overview

Who is perfect snacks, perfect snacks history.

After conducting a market analysis, Joe Boseley began surveying the local vacant warehouse space and decided on a parcel of land to construct the warehouse and distribution center. Joe incorporated Perfect Snacks as a Limited Liability Corporation on January 1st, 2023.

Once the land is acquired for the warehouse space, construction can begin to build-out the manufacturing facility.

Since incorporation, the Company has achieved the following milestones:

- Located a vacant lot that would be ideal for a manufacturing facility

- Developed the company’s name, logo, and website

- Hired a general contractor and architect for the build-out of the warehouse, small office, and distribution area

- Determined equipment and necessary supplies

- Determined beginning inventory

- Attained Letters of Intent from supermarket clients

- Began recruiting key employees

Perfect Snacks Services

Industry analysis.

The Manufacturing sector’s performance is largely attributable to the value of the US dollar, commodity prices, policy decisions and US manufacturing capacity. Food manufacturing has a history of success as it produces a basic human need. According to Grand View Research, the industry is currently valued at $121 billion and is expected to expand at a compound annual growth rate of 9.5% from now until 2030.

Commodity prices are currently stabilizing from coronavirus-induced volatility and renewed demand, both in the United States and global economies, which is anticipated to facilitate revenue expansion for manufacturers. Moreover, shifting technological change in the Manufacturing sector is anticipated to benefit large, developed economies, such as the United States. Therefore, now is a great time to start a new food manufacturing company in the U.S.

Customer Analysis

Demographic profile of target market.

Perfect Snacks will serve the community residents of Lincoln, Nebraska and its surrounding areas. The community of Lincoln, Nebraska has thousands of households that have children. Statistics show that the main consumers of snack products are children of all ages. They are regularly placed in school lunchboxes, afterschool snacks and programs, and at weekend sporting events. Therefore, we will market to locations where snacks are bought by children or their parents, such as grocery stores, recreational centers, and schools.

The precise demographics Lincoln, Nebraska is as follows:

Customer Segmentation

Perfect Snacks will primarily target the following customer profiles:

- Grocery stores and recreational centers

Competitive Analysis

Direct and indirect competitors.

Perfect Snacks will face competition from other companies with similar business profiles. A description of each competitor company is below.

Snacks N More

Snacks N More is another local manufacturing company that provides snack food to the immediate area. Established over thirty years ago, the company has the knowledge and expertise in food processing, commercialization, and packaging. They are known as a recognized ingredient supplier for the foodservice industry. Their portfolio of products include a variety of nuts, snacks, confections, and dry-blend ingredients. As a private label manufacturer, Snack’s More produces a full line of non-chocolate candy, nuts, and fruit-flavored snacks. The company is known for their fruit flavored snacks, dried raisins, nut mixes, and producing ingredients for local restaurants and establishments. Their line of nuts and dried fruits are often used for baking purposes.

Jaxon’s Candy

Jaxon’s Candy is a manufacturer of all things candy related. As a contract manufacturer, the company works with many companies to create their custom designed confections. Their large 50,000 square foot facility produces over 300,000 pounds of candy every month. All of the products are highly concentrated either in sugar or chocolate, or both. Jaxon’s Candy also designs and manufactures their own custom packaging. The candy produced is also kosher certified, gluten free, peanut free, and non-GMO.

Jaxon’s Candy currently manufactures candy for the following brands – Tommy Candy, Laffy Town, Chocowhoawhoa, Jellylicious, Healthee Candeee, and Sticky Teeth. Jaxon’s Candy can be found in grocery stores and convenient stores along the west coast of the United States.

Gimmy Candy

Gimmy Candy is located in the midwestern portion of the United States and boasts a facility of over 1 million square feet. Their fleet of transportation trucks distributes throughout the continental United States and is considered one of the largest candy manufacturers in the country. Their product portfolio includes assorted chocolates, gummy candy, hard candy, fruit candy, as well as gums and mints. Gimmy Candy was established in 1947 and has grown to be a model of manufacturing companies the industry uses as a model of sustainability and profitability. Their lineup of candy products can be found in every single grocery store and convenient store in the country. Gimmy Candy is considering expanding its distribution globally and start exporting its candy products to Asia, Canada, Europe, and South America. As one of the largest privately held companies in the United States, Gimmy Candy is also considered a top employer in the country and offers its employees a generous benefits package.

Competitive Advantage

Perfect Snacks will be able to offer the following advantages over their competition:

Marketing Plan

Brand & value proposition.

Perfect Snacks will offer the unique value proposition to its clientele:

- Fresh and comforting taste

- Community family advocate

- Developed with proprietary technology

- Manufactured with fresh, quality ingredients

- Affordable price

Promotions Strategy

The promotions strategy for Perfect Snacks is as follows:

Social Media

Perfect Snacks will invest heavily in a social media advertising campaign. The brand manager will create the company’s social media accounts and invest in ads on all social media accounts. It will use targeted marketing to appeal to the target demographics.

Website/SEO

Perfect Snacks will invest heavily in developing a professional website that displays all of the features and benefits of the snack products. It will also invest heavily in SEO so that the brand’s website will appear at the top of search engine results.

Major Publications

We will also invest in advertising in selected larger publications until we have achieved significant brand awareness. Advertisements such as billboards and commercials will be shown during peak tv watching time and the billboards will be placed in highly trafficked areas.

Sponsorships

Perfect Snacks will also invest in sponsoring certain athletic and school events so that their banners and collateral material are displayed all over the event where numerous parents and children are at.

Perfect Snacks’s pricing will be moderate so consumers feel they receive great value when purchasing our snack products.

Operations Plan

The following will be the operations plan for Perfect Snacks.

Operation Functions:

- Joe Boseley will be the CEO of Perfect Snacks. He will oversee the general operations and executive aspects of the business.

- Joe is joined by Candace Smith who will act as the warehouse manager. She will train and manage the staff as well as oversee general production of our products.

- Joe will hire an Administrative Assistant, Marketing Manager, and Accountant, to handle the administrative, marketing, and bookkeeping functions of the company.

- Joe will also hire several employees to manufacture our products and maintain the equipment and machinery.

Milestones:

Perfect Snacks will have the following milestones complete in the next six months.

- 02/202X Finalize lease agreement

- 03/202X Design and build out Perfect Snacks

- 04/202X Hire and train initial staff

- 05/202X Kickoff of promotional campaign

- 06/202X Launch Perfect Snacks

- 07/202X Reach break-even

Financial Plan

Key revenue & costs.

Perfect Snacks’s revenues will come primarily from its snack food sales. The company will sell the packaged snacks in local grocery stores, convenience stores, and other locations. As the company’s revenues increase, it will look to gain a wider distribution area.

The land purchase, equipment, supplies, opening inventory, and labor expenses will be the key cost drivers of Perfect Snacks. Other cost drivers include taxes, business insurance, and marketing expenditures.

Funding Requirements and Use of Funds

Key assumptions.

The following outlines the key assumptions required in order to achieve the revenue and cost numbers in the financials and pay off the startup business loan.

- Average order value: $250

Financial Projections

Income statement, balance sheet, cash flow statement, manufacturing business plan faqs, what is a manufacturing business plan.

A manufacturing business plan is a plan to start and/or grow your manufacturing business. Among other things, it outlines your business concept, identifies your target customers, presents your marketing plan and details your financial projections.

You can easily complete your Manufacturing business plan using our Manufacturing Business Plan Template here .

What are the Main Types of Manufacturing Businesses?

There are a number of different kinds of manufacturing businesses , some examples include: Garment manufacturing, Food product manufacturing, Diaper manufacturing, Tile manufacturing, and Toy manufacturing.

How Do You Get Funding for Your Manufacturing Business Plan?

Manufacturing businesses are often funded through small business loans. Personal savings, credit card financing and angel investors are also popular forms of funding.

What are the Steps To Start a Manufacturing Business?

Starting a manufacturing business can be an exciting endeavor. Having a clear roadmap of the steps to start a business will help you stay focused on your goals and get started faster.

1. Develop A Manufacturing Business Plan - The first step in starting a business is to create a detailed manufacturing business plan that outlines all aspects of the venture. This should include potential market size and target customers, the services or products you will offer, pricing strategies and a detailed financial forecast.

2. Choose Your Legal Structure - It's important to select an appropriate legal entity for your manufacturing business. This could be a limited liability company (LLC), corporation, partnership, or sole proprietorship. Each type has its own benefits and drawbacks so it’s important to do research and choose wisely so that your manufacturing business is in compliance with local laws.

3. Register Your Manufacturing Business - Once you have chosen a legal structure, the next step is to register your manufacturing business with the government or state where you’re operating from. This includes obtaining licenses and permits as required by federal, state, and local laws.

4. Identify Financing Options - It’s likely that you’ll need some capital to start your manufacturing business, so take some time to identify what financing options are available such as bank loans, investor funding, grants, or crowdfunding platforms.

5. Choose a Location - Whether you plan on operating out of a physical location or not, you should always have an idea of where you’ll be based should it become necessary in the future as well as what kind of space would be suitable for your operations.

6. Hire Employees - There are several ways to find qualified employees including job boards like LinkedIn or Indeed as well as hiring agencies if needed – depending on what type of employees you need it might also be more effective to reach out directly through networking events.

7. Acquire Necessary Manufacturing Equipment & Supplies - In order to start your manufacturing business, you'll need to purchase all of the necessary equipment and supplies to run a successful operation.

8. Market & Promote Your Business - Once you have all the necessary pieces in place, it’s time to start promoting and marketing your manufacturing business. This includes creating a website, utilizing social media platforms like Facebook or Twitter, and having an effective Search Engine Optimization (SEO) strategy. You should also consider traditional marketing techniques such as radio or print advertising.

Manufacturing Business Plan Template & Guidebook

Starting a manufacturing business is an exciting endeavor, but it can be daunting to know where to start. Fortunately, the #1 Manufacturing Business Plan Template & Guidebook provides entrepreneurs and businesses with a detailed roadmap for success. With this template and guidebook, you will have the guidance you need to plan for success and develop a comprehensive business plan that outlines your vision and strategy.

Get worry-free services and support to launch your business starting at $0 plus state fees.

- How to Start a Profitable Manufacturing Business [11 Steps]

- 10+ Best & Profitable Manufacturing Business Ideas [2023]

- 25 Catchy Manufacturing Business Names:

- List of the Best Marketing Ideas For Your Manufacturing Business:

How to Write a Manufacturing Business Plan in 7 Steps:

1. describe the purpose of your manufacturing business..

The first step to writing your business plan is to describe the purpose of your manufacturing business. This includes describing why you are starting this type of business, and what problems it will solve for customers. This is a quick way to get your mind thinking about the customers’ problems. It also helps you identify what makes your business different from others in its industry.

It also helps to include a vision statement so that readers can understand what type of company you want to build.

Here is an example of a purpose mission statement for a manufacturing business:

Our mission at [Company Name] is to be the premier provider of innovative, high-quality manufacturing solutions that meet our customers' needs, while delivering superior customer service and providing a safe and rewarding workplace for our employees.

2. Products & Services Offered by Your Manufacturing Business.

The next step is to outline your products and services for your manufacturing business.

When you think about the products and services that you offer, it's helpful to ask yourself the following questions:

- What is my business?

- What are the products and/or services that I offer?

- Why am I offering these particular products and/or services?

- How do I differentiate myself from competitors with similar offerings?

- How will I market my products and services?

You may want to do a comparison of your business plan against those of other competitors in the area, or even with online reviews. This way, you can find out what people like about them and what they don’t like, so that you can either improve upon their offerings or avoid doing so altogether.

3. Build a Creative Marketing Stratgey.

If you don't have a marketing plan for your manufacturing business, it's time to write one. Your marketing plan should be part of your business plan and be a roadmap to your goals.

A good marketing plan for your manufacturing business includes the following elements:

Target market

- Who is your target market?

- What do these customers have in common?

- How many of them are there?

- How can you best reach them with your message or product?

Customer base

- Who are your current customers?

- Where did they come from (i.e., referrals)?

- How can their experience with your manufacturing business help make them repeat customers, consumers, visitors, subscribers, or advocates for other people in their network or industry who might also benefit from using this service, product, or brand?

Product or service description

- How does it work, what features does it have, and what are its benefits?

- Can anyone use this product or service regardless of age or gender?

- Can anyone visually see themselves using this product or service?

- How will they feel when they do so? If so, how long will the feeling last after purchasing (or trying) the product/service for the first time?

Competitive analysis

- Which companies are competing with yours today (and why)?

- Which ones may enter into competition with yours tomorrow if they find out about it now through word-of-mouth advertising; social media networks; friends' recommendations; etc.)

- What specific advantages does each competitor offer over yours currently?

Marketing channels

- Which marketing channel do you intend to leverage to attract new customers?

- What is your estimated marketing budget needed?

- What is the projected cost to acquire a new customer?

- How many of your customers do you instead will return?

Form an LLC in your state!

4. Write Your Operational Plan.

Next, you'll need to build your operational plan. This section describes the type of business you'll be running, and includes the steps involved in your operations.

In it, you should list:

- The equipment and facilities needed

- Who will be involved in the business (employees, contractors)

- Financial requirements for each step

- Milestones & KPIs

- Location of your business

- Zoning & permits required for the business

What equipment, supplies, or permits are needed to run a manufacturing business?

- Manufacturing equipment

- Raw materials

- Safety equipment and supplies

- Labor and skilled workers

- Legal permits and licensing as required by local ordinance

5. Management & Organization of Your Manufacturing Business.

The second part of your manufacturing business plan is to develop a management and organization section.

This section will cover all of the following:

- How many employees you need in order to run your manufacturing business. This should include the roles they will play (for example, one person may be responsible for managing administrative duties while another might be in charge of customer service).

- The structure of your management team. The higher-ups like yourself should be able to delegate tasks through lower-level managers who are directly responsible for their given department (inventory and sales, etc.).

- How you’re going to make sure that everyone on board is doing their job well. You’ll want check-ins with employees regularly so they have time to ask questions or voice concerns if needed; this also gives you time to offer support where necessary while staying informed on how things are going within individual departments too!

6. Manufacturing Business Startup Expenses & Captial Needed.

This section should be broken down by month and year. If you are still in the planning stage of your business, it may be helpful to estimate how much money will be needed each month until you reach profitability.

Typically, expenses for your business can be broken into a few basic categories:

Startup Costs

Startup costs are typically the first expenses you will incur when beginning an enterprise. These include legal fees, accounting expenses, and other costs associated with getting your business off the ground. The amount of money needed to start a manufacturing business varies based on many different variables, but below are a few different types of startup costs for a manufacturing business.

Running & Operating Costs

Running costs refer to ongoing expenses related directly with operating your business over time like electricity bills or salaries paid out each month. These types of expenses will vary greatly depending on multiple variables such as location, team size, utility costs, etc.

Marketing & Sales Expenses

You should include any costs associated with marketing and sales, such as advertising and promotions, website design or maintenance. Also, consider any additional expenses that may be incurred if you decide to launch a new product or service line. For example, if your manufacturing business has an existing website that needs an upgrade in order to sell more products or services, then this should be listed here.

7. Financial Plan & Projections

A financial plan is an important part of any business plan, as it outlines how the business will generate revenue and profit, and how it will use that profit to grow and sustain itself. To devise a financial plan for your manufacturing business, you will need to consider a number of factors, including your start-up costs, operating costs, projected revenue, and expenses.

Here are some steps you can follow to devise a financial plan for your manufacturing business plan:

- Determine your start-up costs: This will include the cost of purchasing or leasing the space where you will operate your business, as well as the cost of buying or leasing any equipment or supplies that you need to start the business.

- Estimate your operating costs: Operating costs will include utilities, such as electricity, gas, and water, as well as labor costs for employees, if any, and the cost of purchasing any materials or supplies that you will need to run your business.

- Project your revenue: To project your revenue, you will need to consider the number of customers you expect to have and the average amount they will spend on each visit. You can use this information to estimate how much money you will make from selling your products or services.

- Estimate your expenses: In addition to your operating costs, you will need to consider other expenses, such as insurance, marketing, and maintenance. You will also need to set aside money for taxes and other fees.

- Create a budget: Once you have estimated your start-up costs, operating costs, revenue, and expenses, you can use this information to create a budget for your business. This will help you to see how much money you will need to start the business, and how much profit you can expect to make.

- Develop a plan for using your profit: Finally, you will need to decide how you will use your profit to grow and sustain your business. This might include investing in new equipment, expanding the business, or saving for a rainy day.

Frequently Asked Questions About Manufacturing Business Plans:

Why do you need a business plan for a manufacturing business.

A business plan for a manufacturing business is essential because it serves as a guide to help the business plan its activities and reach its desired goals. It provides important information such as market analysis, strategy, financial projections, and operational plans. Additionally, it can serve as an important tool to attract potential investors or lenders and help secure funding.

Who should you ask for help with your manufacturing business plan?

You should consult a qualified business consultant, accountant, and/or lawyer who specialise in assisting companies with their manufacturing business plans. Additionally, it is a good idea to reach out to trade organisations, industry bodies, and experts in the manufacturing sector for guidance.

Can you write a manufacturing business plan yourself?

Yes, you can write a manufacturing business plan yourself. Depending on the complexity of your plan, you may want to research best practices and consult experts in the field if necessary. When writing a manufacturing business plan, it is important to include a market analysis, competitive analysis, operations plan, financial projections, and strategic plan. Additionally, you should also include key objectives, milestones and management strategies.

Related Business Plans

Home Inventory Business Plan Template & Guidebook

Home Inspection Business Plan Template & Guidebook

Home Decor Business Plan Template & Guidebook

Health And Wellness Business Plan Template & Guidebook

Hauling Business Plan Template & Guidebook

Hardware Business Plan Template & Guidebook

Handyman Business Plan Template & Guidebook

Hair Extension Business Plan Template & Guidebook

Handbag Business Plan Template & Guidebook

I'm Nick, co-founder of newfoundr.com, dedicated to helping aspiring entrepreneurs succeed. As a small business owner with over five years of experience, I have garnered valuable knowledge and insights across a diverse range of industries. My passion for entrepreneurship drives me to share my expertise with aspiring entrepreneurs, empowering them to turn their business dreams into reality.

Through meticulous research and firsthand experience, I uncover the essential steps, software, tools, and costs associated with launching and maintaining a successful business. By demystifying the complexities of entrepreneurship, I provide the guidance and support needed for others to embark on their journey with confidence.

From assessing market viability and formulating business plans to selecting the right technology and navigating the financial landscape, I am dedicated to helping fellow entrepreneurs overcome challenges and unlock their full potential. As a steadfast advocate for small business success, my mission is to pave the way for a new generation of innovative and driven entrepreneurs who are ready to make their mark on the world.

Manufacturing Business Plan Template [Updated 2024]

Manufacturing Business Plan Template

If you want to start a Manufacturing business or expand your current Manufacturing company, you need a business plan.

The following Manufacturing business plan template gives you the key elements to include in a winning Manufacturing business plan.

You can download our business plan template (including a full, customizable financial model) to your computer here.

Below are links to each of the key sections of a sample manufacturing business plan. Once you create your plan, download it to PDF to show banks and investors.

I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

Comments are closed.

Manufacturing Business Plan Home I. Executive Summary II. Company Overview III. Industry Analysis IV. Customer Analysis V. Competitive Analysis VI. Marketing Plan VII. Operations Plan VIII. Management Team IX. Financial Plan

How To Write a Business Plan for Cement Factory in 9 Steps: Checklist

By henry sheykin, resources on cement factory.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

- Marketing Plan

Welcome to our blog post on how to write a business plan for a cement factory in 9 easy steps. The cement industry is thriving in the US, with a market size of $XX billion in [latest year]. With construction projects on the rise and a high demand for cement, now is the perfect time to enter the market and establish your cement factory. In this article, we will guide you through the essential steps to create a comprehensive business plan that will set you up for success in this competitive industry.

First and foremost, it is crucial to identify and research the cement industry in-depth. Understanding the market dynamics, trends, and challenges will help you make informed decisions throughout the business planning process.

Next, conducting a feasibility study is essential to determine the potential profitability of your cement factory. Analyzing the market demand, competition, and assessing the production costs will give you a clear picture of the financial viability of your venture.

Defining your target market and customer base is crucial for tailoring your marketing efforts and business strategies. Understanding the needs, preferences, and purchasing behavior of your target audience will enable you to develop products and services that meet their requirements.

Determining the optimal location for your cement factory is another critical factor for success. Factors such as accessibility to raw materials, proximity to target markets, and transportation infrastructure should be considered when selecting a location.

Assessing the required investment and exploring funding options is necessary to secure the financial resources needed to establish and operate your cement factory. Creating a detailed operational plan that covers production processes, supply chain management, and quality control will help you streamline your operations and maximize efficiency.

Developing a robust marketing strategy is key to reaching your target market and generating sales. Advertising in trade publications, exhibiting at industry conferences, and leveraging digital marketing platforms will help you raise awareness and attract customers.

Establishing strategic partnerships with suppliers for reliable raw material sources, securing necessary permits and licenses, and complying with industry regulations is vital for the smooth operation of your cement factory.

By following these nine steps, you will have a comprehensive business plan that outlines your cement factory's vision, strategies, and potential for success. Stay tuned for our upcoming articles where we will dive deeper into each step, providing you with valuable insights and practical tips to ensure your cement factory prospers in a competitive market.

Identify And Research The Cement Industry

Before starting a cement factory, it is crucial to conduct thorough research and familiarize oneself with the cement industry. This step is essential to gain a comprehensive understanding of the market, potential challenges, and opportunities.

Here are some key aspects to focus on during the identification and research phase:

- Industry Overview: Begin by studying the overall cement industry, including its size, growth rate, and market trends. Look into industry reports and publications to gather information on current and projected market conditions.

- Supply and Demand: Analyze the demand for cement in the target market and identify the factors driving it. Determine the extent of competition and assess the market's capacity for additional cement manufacturers.

- Regulations and Compliance: Familiarize yourself with the regulatory requirements specific to cement production. Understand the environmental regulations, health and safety standards, and any other legal obligations that may apply to such a facility.

- Technological Advancements: Stay updated on the latest advancements in cement production technology. Identify any emerging manufacturing processes or innovative techniques that may improve efficiency and sustainability.

- Key Players and Competitors: Research existing cement manufacturers, distributors, and suppliers in the target market. Determine their market share, pricing strategies, and reputation. Analyze their strengths and weaknesses to identify potential opportunities for differentiation.

- Attend industry conferences and seminars to network with professionals and gain insights into the cement industry.

- Speak to experts in the field or seek advice from industry consultants to deepen your understanding of the market.

- Stay updated on global cement market trends and be aware of any international influences that may impact the domestic industry.

By thoroughly researching the cement industry, you lay a solid foundation for developing an effective business plan tailored to the specific needs and demands of the market. This knowledge will guide you in making informed decisions throughout the entire process of establishing and operating your cement factory.

Understand The Market Demand And Competition

Understanding the market demand and competition is crucial when writing a business plan for a cement factory. This step involves conducting thorough research and analysis to gain insights into the current state of the industry and potential customers.

To begin, it is important to determine the demand for cement in the target market. This can be done by analyzing construction trends, government infrastructure projects, and the growth potential of the local economy. Gathering data on the demand for cement and its projected growth will help to determine the viability of the business and its potential for success.

Next, it is essential to assess the competition in the cement industry. Identify existing cement factories in the area and study their production capacities, pricing strategies, and market share. Analyzing the strengths and weaknesses of competitors will enable the business to develop strategies to differentiate itself and gain a competitive advantage.

- Evaluate the market demand for cement in the target area to determine its potential growth and profitability.

- Research government infrastructure projects and construction trends to identify potential customers and market opportunities.

- Analyze the competition in the cement industry, including their production capacities, pricing strategies, and market share.

- Identify the strengths and weaknesses of competitors to develop strategies for differentiation and gaining a competitive edge.

- Consider conducting surveys or interviews with potential customers to gather insights into their needs, preferences, and satisfaction with existing cement suppliers.

- Stay updated with industry reports and publications to stay informed about the latest trends and developments in the cement market.

- Network with industry professionals and attend industry conferences to gain valuable insights and build relationships within the cement industry.

- Consider utilizing market research services to gather detailed data and analysis on the market demand and competition.

Conduct A Feasibility Study And Analyze Potential Profitability

As you embark on your journey to start a cement factory, it is essential to conduct a feasibility study to assess the viability and potential profitability of your business idea. This study will provide you with valuable insights into the economic and financial aspects of your venture.

1. Market Analysis: Begin by conducting a comprehensive market analysis to gain a deep understanding of the cement industry. Identify key market trends, growth potential, and any potential challenges you may encounter.

2. Demand Assessment: Determine the demand for cement in your target market. Analyze factors such as population growth, construction projects, infrastructure development, and the demand-supply gap. This assessment will help you gauge the potential demand for your product.

3. Competitive Landscape: Evaluate the competitive landscape in the cement industry. Identify existing cement manufacturers, their market share, pricing strategies, and product differentiation. This analysis will help you understand the level of competition you may face and enable you to differentiate your offerings.

4. Financial Projections: Develop detailed financial projections that include revenue forecasts, cost estimates, and cash flow projections. Consider factors such as production costs, raw material procurement, labor expenses, and overhead costs. These projections will help you determine the potential profitability of your cement factory.

5. Risk Assessment: Identify potential risks and challenges that may affect the profitability of your cement factory. Assess factors such as market volatility, regulatory changes, environmental concerns, and supply chain disruptions. This analysis will help you develop contingency plans and risk mitigation strategies.

- Consult industry experts or engage a professional consultant to assist you in conducting a comprehensive feasibility study.

- Consider surveying potential customers and conducting focus groups to gather insights and feedback.

- Utilize reliable sources, such as industry reports and market research, to gather accurate data for your analysis.

- Ensure your financial projections are realistic and based on accurate market research and cost estimates.

By conducting a thorough feasibility study and assessing the potential profitability of your cement factory, you will be equipped with the necessary information to make informed decisions and set realistic goals for your business. This step is crucial in laying a strong foundation for your future success in the cement industry.

Define The Business's Target Market And Customer Base

Defining the target market and customer base is crucial for a cement factory in order to develop a focused marketing strategy and tailor products and services to meet the needs of specific customers. Here are some key steps to define your target market and customer base:

- Conduct market research: Gather information about the construction industry, including current trends, projected growth, and market opportunities. Identify the main customers, such as construction companies, contractors, retailers, and other stakeholders in the supply chain.

- Analyze customer demographics: Determine the specific characteristics of your target market, including location, industry segment, company size, and purchasing power. Consider factors such as average project size, construction volume, and market demand for cement.

- Identify customer needs and preferences: Understand the requirements and preferences of your target customers regarding cement quality, pricing, delivery options, and other ancillary services. This will help you tailor your products and services to meet their specific needs and gain a competitive edge.

- Assess customer behavior and buying patterns: Determine how often your customers purchase cement, their buying habits, and their preferred channels for sourcing materials. This information will help you optimize your distribution strategies and identify potential opportunities for customer loyalty and repeat business.

- Engage with potential customers and industry experts to gain insights into their needs and expectations.

- Segment your target market based on factors such as project types, geographical regions, and customer preferences to develop tailored marketing strategies.

- Consider offering additional services, such as technical support or training, to differentiate your cement factory and attract a wider customer base.

Determine The Optimal Location For The Cement Factory

Choosing the right location for your cement factory is crucial to its success. The location should provide easy access to raw materials, a supportive business environment, and proximity to your target market. Here are some important considerations when determining the optimal location:

- Availability of Raw Materials: Look for a location near abundant sources of limestone, clay, and other necessary minerals. This will help reduce transportation costs and ensure a consistent supply of raw materials for your cement production.

- Transportation Infrastructure: Evaluate the proximity of major transportation routes, such as highways, railways, and ports. A well-connected location will facilitate efficient distribution of your cement to customers.

- Market Accessibility: Analyze the demand for cement in your target market and identify regions with growth potential. Consider locating your factory close to construction hubs or areas with high construction activities.

- Business Environment: Research the local regulations, tax incentives, and government support for the cement industry in different locations. Choose a place that offers a favorable business environment and encourages industrial development.

- Environmental Factors: Assess the impact of your cement factory on the surrounding environment. Consider the availability of water resources, air quality, noise pollution, and potential conflicts with nearby residential or protected areas. Compliance with environmental regulations is crucial for long-term sustainability.

- Contact local authorities and urban planning departments to gather information about zoning regulations and permits required for establishing a cement factory.

- Engage with industry experts, consultants, and real estate professionals to gain insights into the best locations for cement production facilities.

- Consider conducting a cost-benefit analysis to compare potential locations and determine which offers the most advantages in terms of operational efficiency and cost savings.

By carefully evaluating these factors, you can determine the optimal location that aligns with your business goals and maximizes the potential for success in the cement industry.

Assess The Required Investment And Funding Options

Before starting a cement factory, it is crucial to assess the required investment and explore funding options. This step will help determine the financial resources necessary to establish and operate the business successfully. Here are some key considerations:

1. Calculate the startup costs: Begin by calculating the initial investment required for land purchase, construction, machinery, equipment, transportation vehicles, and other necessary infrastructure. Consider obtaining multiple quotes from suppliers and contractors to accurately estimate these costs.

2. Research funding options: Explore various funding options to cover the startup costs. This can include personal savings, loans from financial institutions, venture capital, angel investors, or government grants. Each option has its requirements and implications, so it is essential to carefully evaluate the pros and cons of each.

3. Prepare a detailed financial plan: Create a comprehensive financial plan that includes projected revenue, expenses, and cash flow for the first few years of operation. This plan will help potential investors or lenders assess the viability and profitability of your cement factory.

4. Seek professional advice: Consider consulting with financial experts or hiring a professional business consultant specializing in the cement industry. They can provide valuable insights and guidance on financial matters, assist with preparing financial projections, and help negotiate favorable funding options.

- Include a contingency fund in your financial plan to account for unexpected expenses or market fluctuations.

- Research and compare interest rates and terms offered by different financial institutions to choose the most favorable loan option.

- Consider exploring potential partnerships or joint ventures as additional funding sources.

By thoroughly assessing the required investment and exploring funding options, you can ensure that you have a clear financial roadmap for establishing and operating your cement factory. This step will not only assist in securing necessary funds but also demonstrate to investors or lenders that you have a well-thought-out plan for success.

Create A Detailed Operational Plan

Creating a detailed operational plan is essential for the successful functioning of a cement factory. It outlines the specific tasks, responsibilities, and processes involved in the day-to-day operations of the business. This plan not only helps in streamlining the operations but also serves as a reference point for employees and management to ensure consistency and efficiency.

A well-defined operational plan should include the following key components:

- Production Process: Outline the step-by-step process of cement production, including the sourcing of raw materials, mixing, grinding, and packaging. Clearly define the quality control measures to maintain the highest standards in the manufacturing process.

- Infrastructure and Equipment: Identify the infrastructure requirements such as premises, machinery, and equipment needed for the cement factory. List the specifications and capacities of each equipment to ensure smooth operations and optimal utilization.

- Inventory Management: Detail the procedures for inventory management, including the procurement, storage, and tracking of raw materials, as well as the storage and distribution of finished cement products. Implement robust inventory management systems to minimize wastage and ensure timely availability of materials.

- Workforce Planning: Determine the required workforce and their roles and responsibilities. Define the recruitment and training processes to ensure that the employees possess the necessary skills and knowledge for their specific roles.

- Health and Safety: Prioritize the safety and well-being of employees by incorporating comprehensive health and safety protocols. Establish guidelines for handling and storing hazardous materials, operating machinery, and implementing preventive measures to prevent accidents and protect workers.

- Maintenance and Upkeep: Develop a plan for regular maintenance and servicing of equipment to minimize downtime and ensure optimal performance. Establish protocols for equipment inspections, cleaning, and repairs.

- Quality Assurance: Implement quality assurance measures at every stage of production to uphold the consistency and quality of the cement products. Document quality control procedures, testing methods, and criteria for acceptance or rejection of batches.

Tips for Creating an Operational Plan:

- Collaborate with industry experts or consultants to gain insights into best practices and industry benchmarks for operational efficiency.

- Regularly review and update the operational plan to accommodate changes in the market, technology, or regulations.

- Involve key stakeholders, such as production managers and supervisors, in the development and implementation of the operational plan to ensure ownership and commitment.

- Consider implementing digital tools or software solutions to streamline operations, track inventory, and monitor performance.

- Continuously monitor and analyze key performance indicators to identify areas for improvement and optimization.

Develop A Marketing Strategy

Developing a strong marketing strategy for your cement factory is crucial for attracting customers and generating sales. Here are some important steps to consider:

- Identify your target market: Conduct market research to understand the specific needs, preferences, and demographics of your target customers. This will allow you to tailor your marketing efforts towards their requirements.

- Create a compelling value proposition: Clearly communicate the unique benefits and advantages your cement factory offers to customers. This could include factors such as high-quality cement, timely delivery, competitive pricing, or excellent customer service.

- Establish a strong online presence: Build a professional website and optimize it for search engines to improve your online visibility. Utilize social media platforms to engage with potential customers, share informative content, and showcase your expertise in the cement industry.

- Utilize traditional marketing channels: Consider advertising in trade publications, industry magazines, or local newspapers to reach a wider audience. Participate in industry conferences, trade shows, and exhibitions to network with potential customers and promote your cement factory.

- Offer value-added services: Consider providing additional services such as training programs, technical support, or consultations to differentiate your cement factory from competitors and attract customers.

Tips for Developing a Successful Marketing Strategy:

- Regularly analyze and adapt your marketing strategy based on market trends, customer feedback, and competitor activities.

- Utilize digital marketing tools such as search engine optimization (SEO), pay-per-click advertising, and email marketing to reach a wider audience.

- Create informative and engaging content, such as blog posts or educational videos, to establish your cement factory as a trusted industry resource.

- Collaborate with industry influencers or thought leaders to expand your reach and credibility.

By developing a comprehensive marketing strategy, you can effectively promote your cement factory, attract customers, and drive business growth.

Establish Strategic Partnerships And Secure Necessary Permits And Licenses

Establishing strategic partnerships is crucial for the success of a cement factory. These partnerships can provide valuable resources, expertise, and access to new markets. It is important to identify potential partners who align with the goals and values of the business.

Tip: Look for partners who have experience in the cement industry or related fields. They can offer insights and knowledge that can enhance your operations and help you navigate challenges.

When securing necessary permits and licenses, it is essential to comply with all applicable regulations and legal requirements. These permits and licenses ensure that your cement factory operates within the boundaries set by local, state, and federal authorities.

Tip: Research and understand the specific permits and licenses required for a cement factory in your area. Consult with legal experts or industry associations to ensure compliance and avoid any potential legal issues.

Building strong relationships with regulatory agencies and government bodies is also crucial in securing the permits and licenses. Engage in open and transparent communication with these entities to demonstrate your commitment to operating safely, responsibly, and in compliance with regulations.

Tip: Attend industry conferences and events to connect with regulatory agencies and gain insights into the latest developments in permit requirements and regulations.

Securing the necessary permits and licenses can be a complex process, involving paperwork, inspections, and approvals. It is important to allocate sufficient time and resources to ensure a smooth and timely process.

Tip: Create a comprehensive checklist of all the permits and licenses required, along with the associated deadlines and requirements. This will help you stay organized and avoid any delays or oversights.

Remember that establishing strategic partnerships and securing permits and licenses are ongoing processes. Continuously evaluate and renegotiate existing partnerships and stay updated on any changes in regulations or permit requirements to ensure the long-term success of your cement factory.

In conclusion, writing a business plan for a cement factory requires careful research, analysis, and strategic decision-making. By following the nine steps outlined in this checklist, aspiring cement factory owners can increase their chances of success in this competitive industry.

Identifying and researching the cement industry, understanding market demand and competition, conducting a feasibility study, and analyzing potential profitability are crucial early steps.

Defining the target market and customer base, determining the optimal location for the factory, and assessing the required investment and funding options are essential for establishing a solid foundation.

Creating a detailed operational plan, developing a marketing strategy, and establishing strategic partnerships and securing necessary permits and licenses are key for successful execution.

By following these steps and considering the business model described above, aspiring cement factory owners can position themselves for success in the cement industry.

$169.00 $99.00 Get Template

Related Blogs

- Starting a Business

- KPI Metrics

- Running Expenses

- Startup Costs

- Pitch Deck Example

- Increasing Profitability

- Sales Strategy

- Rising Capital

- Valuing a Business

- How Much Makes

- Sell a Business

- Business Idea

- How To Avoid Mistakes

Leave a comment

Your email address will not be published. Required fields are marked *

Please note, comments must be approved before they are published

Check out everything that is new in the latest version of Visual Components!

December 28, 2021

How to Plan & Design a Manufacturing Plant Layout? (Video Examples Included)

Our experts at Visual Components discuss how to plan and design a manufacturing plant layout with a simulation case. We review the benefits, process, and necessity for a high-quality plant layout in your business organization.

Discover the essentials of factory layout design using advanced simulation and CAD technology. This approach aims to optimize space and efficiency, catering to each factory’s unique needs. Learn about creating lean layouts that streamline production and enhance workflow. Gain insights into how strategic planning can lead to cost savings and increased productivity. Explore the steps from concept to execution, including real-world examples, demonstrating the benefits of effective layout planning for manufacturing success.

Share this article

When it comes to running a manufacturing facility, there are a lot of things to consider. As an owner or manager, you’re probably looking for ways to speed up your process, improve your yield, and increase your profit. Did you know that a simple plant layout can achieve all three of these goals?

Layouts are often overlooked, despite their huge money-saving potential.

In this piece, we’ll discuss what is meant by a plant layout, some benefits of a layout, an example, and our step-by-step process for laying out a plant.

These are the topics we’ll cover. You can also jump to the part that interests you the most 🏃🏻

- What is meant by a plant layout?

- What is a lean plant layout?

- What are the characteristics of a good plant layout?

- Plant layout design benefits

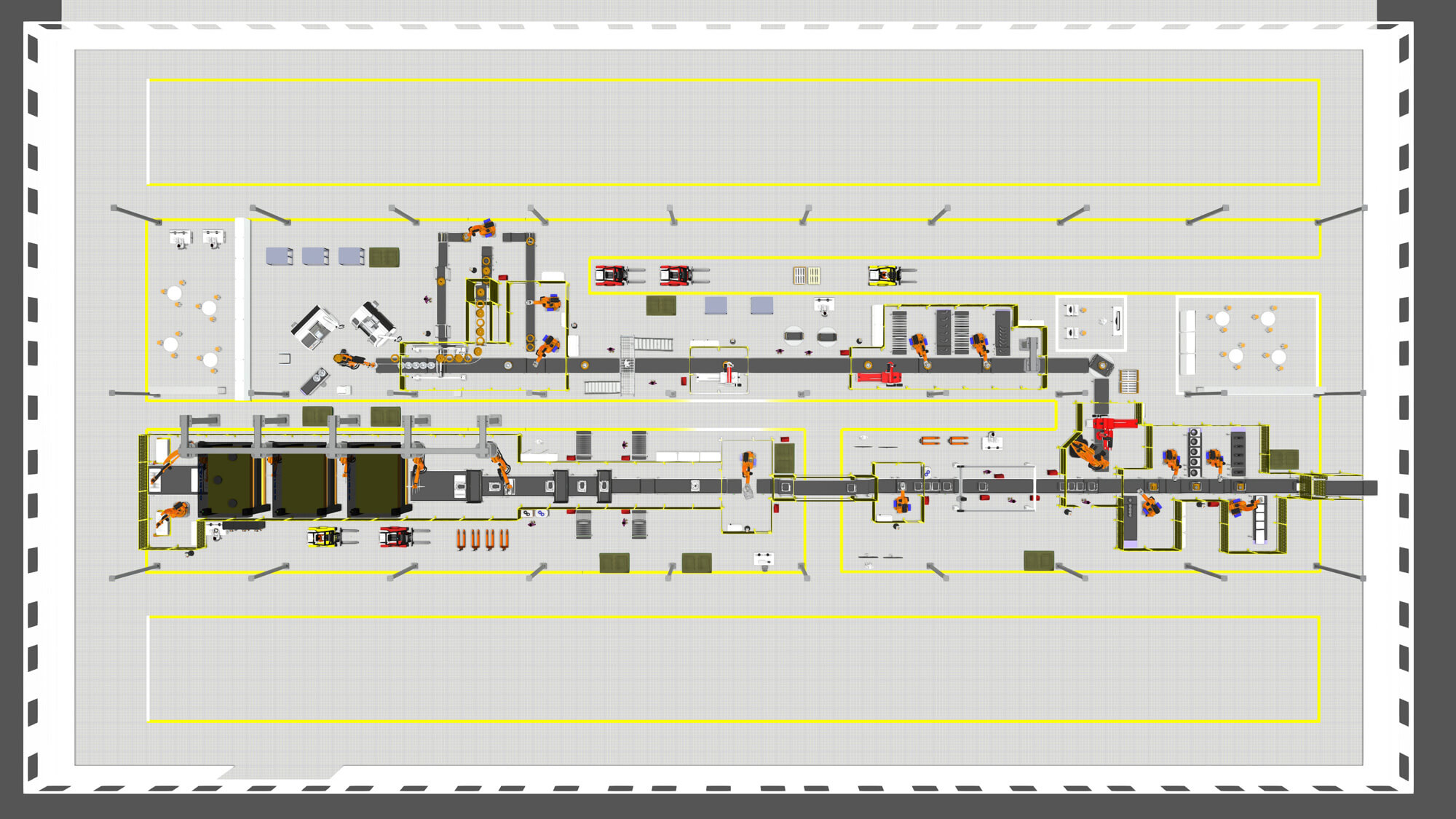

Plant layout example

- Step-by-step plant layout design process

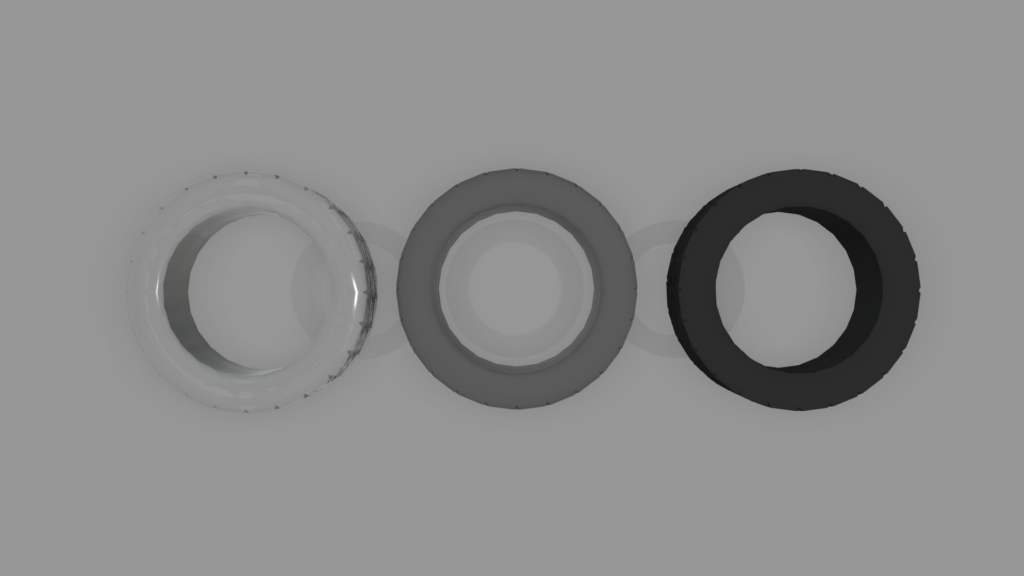

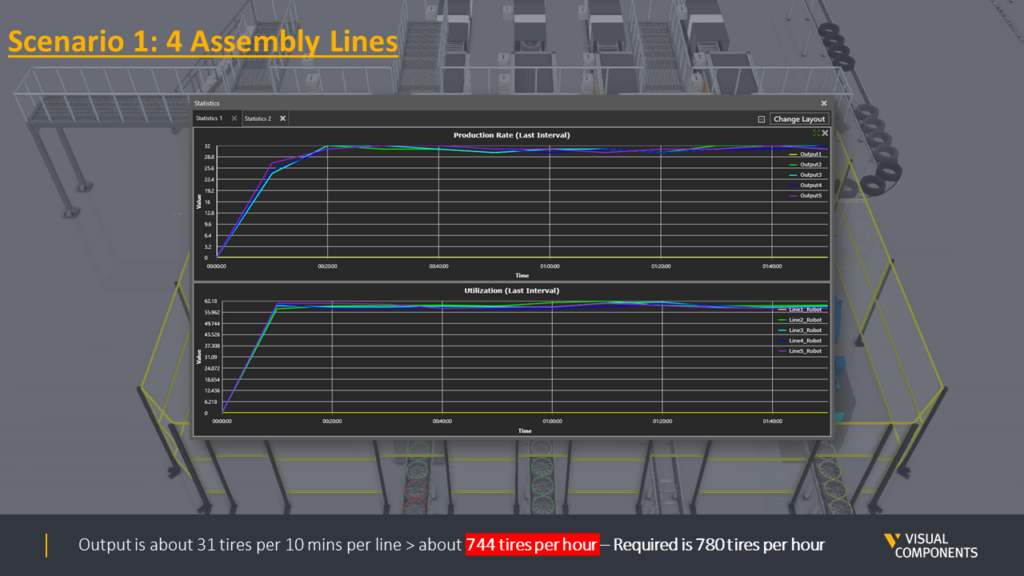

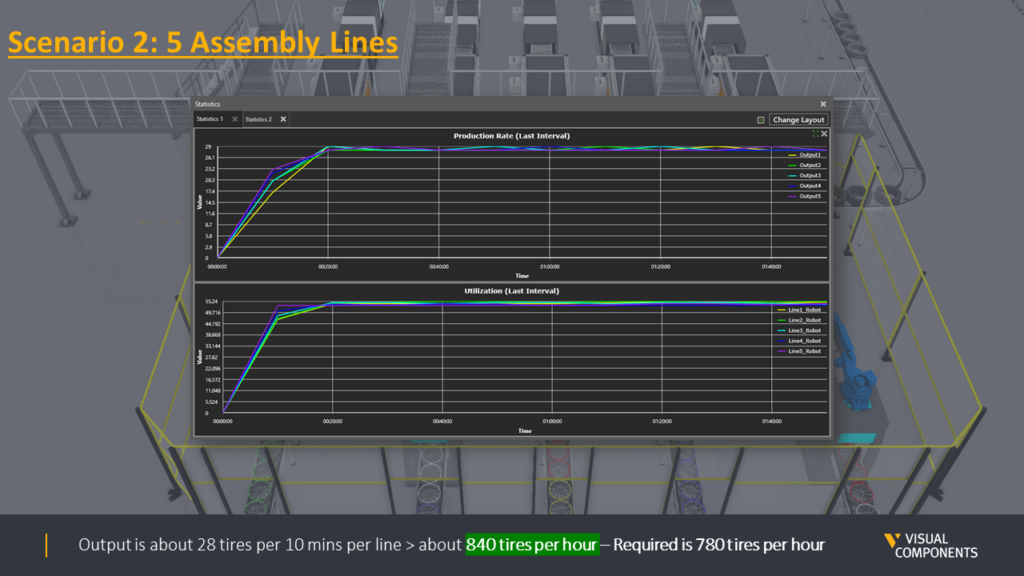

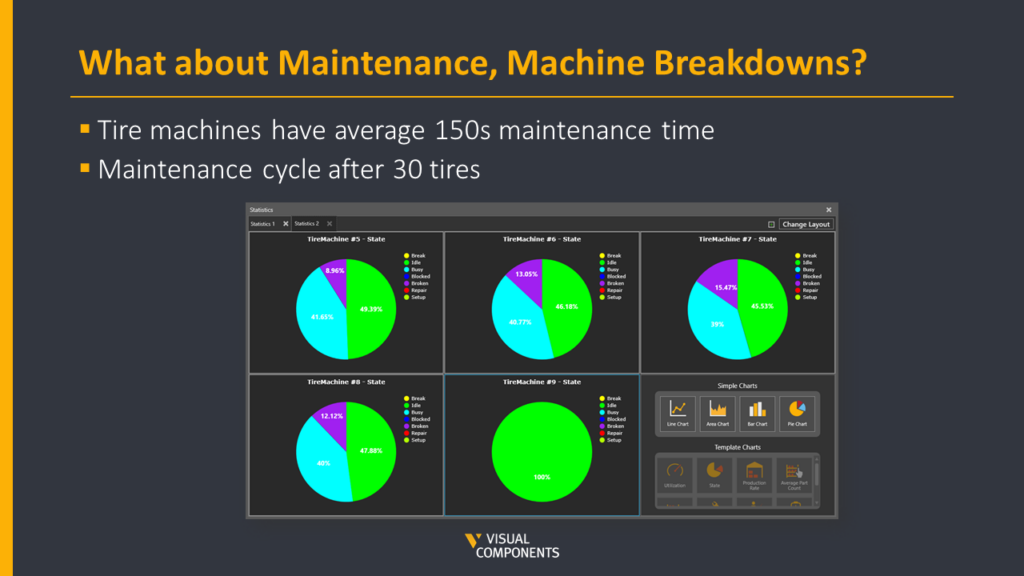

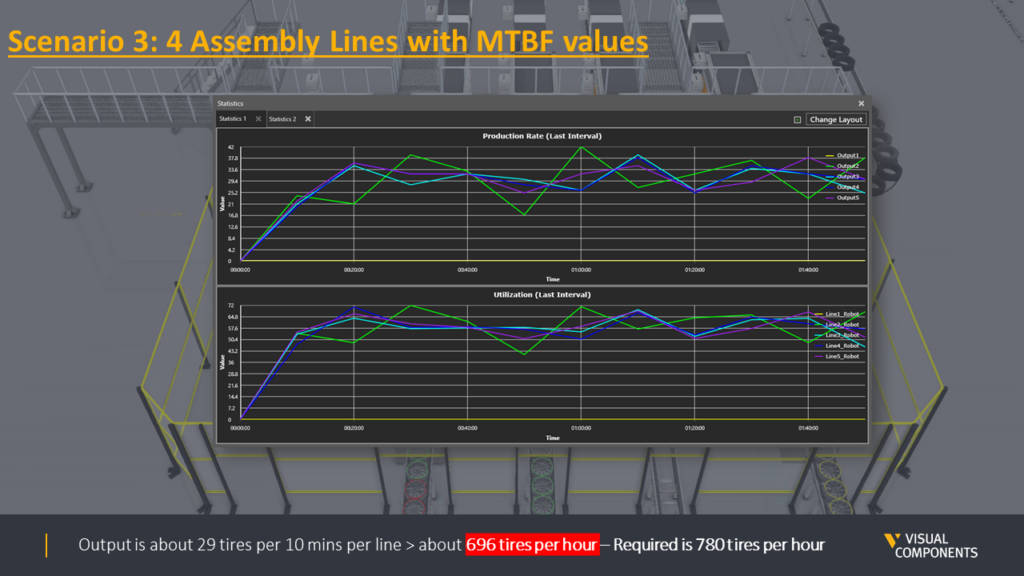

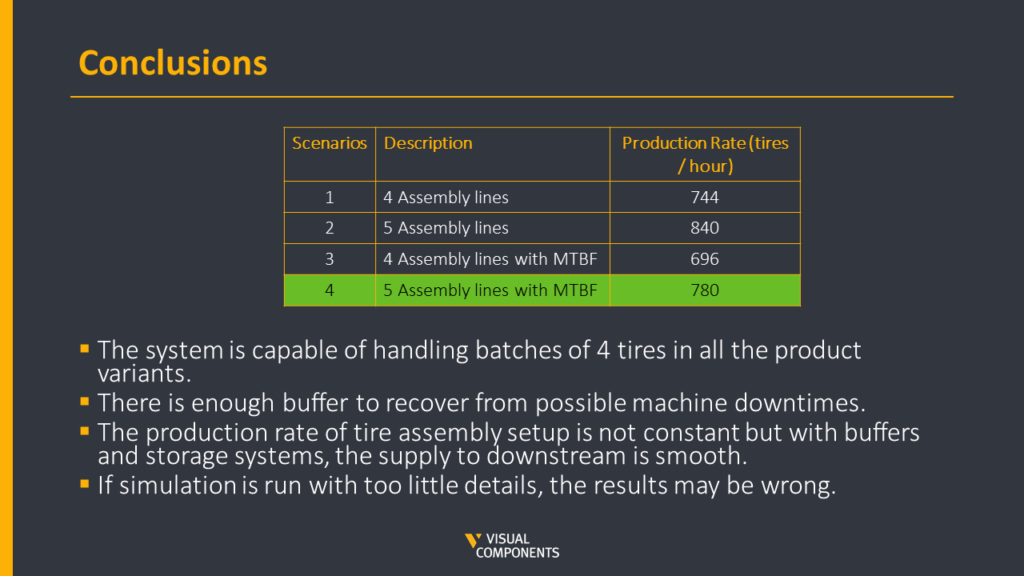

- Case: tire assembly and warehousing layout

Let’s go!

What is meant by a plant layout?

The plant layout definition is simple: it’s a way to draw your facility’s building, equipment, and major components on paper. It’s typically done through 2D CAD (2-dimensional Computer-Aided Drafting and Design) software.

The designer will use real-world dimensions of your equipment and facility and layout a scaled model of your plant. Without using real dimensions, the final layout won’t be as helpful for your plant.

In a lot of cases, the designer will submit a final layout that allows the viewer to fly through the building, seeing the equipment in motion and observing how the process looks. Since everything is a scale model, the viewer can find out how much distance there is between equipment, for walkways, and so on.

Since it’s all done on paper, this can be done before getting equipment or before having a warehouse. It also allows the designer to change the layout as much as they’d like.

The layout includes a lot of different features:

- How product moves through your building

- Equipment

- Building floorplan

- Dimensional distances between everything

- Visualization of your process

What is a lean plant layout?

If you take the concept one step further, you can start optimizing everything. In a lean plant layout, the designer will start incorporating lean principles into the floorplan.

A big principle in lean layouts is adding sections for different operations. If your process has multiple steps, like cutting, organizing, and packing your product, then it will be broken into different physical areas.

Cutting will be done in one zone, organizing in another, and packing in a third. This also groups together the required machinery and personnel to expedite the process.

Why does this work? Material and people travel shorter distances, the layout is more compact, and everything is streamlined.

There are a lot of other concepts that go into lean principles (a lean layout). For the sake of brevity, we’ll leave it there.

What are the characteristics of a good plant layout?