You are using an outdated browser. Please upgrade your browser .

- Stay up to date with TXM

Our Top 5 Practical 5S Workplace Organisation Videos

The top 5 txm practical 5s workplace organisation videos.

Over the years, we have helped hundreds of companies implement Practical 5S, our proven approach to 5S deployment. These five 5s videos provide you with practical tips on how to successfully and sustainably deploy Practical 5S in your business.

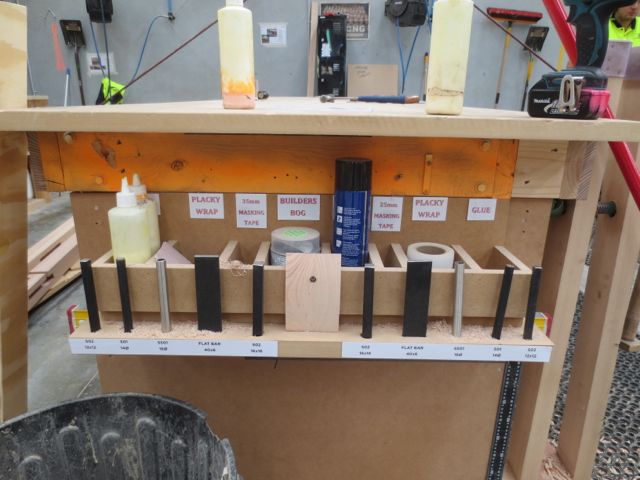

1. TXM Lean Methodology: Why 5S? – The TXM Practical 5S Methodology in a Nutshell

5S is probably the most well known Lean technique and is one of the essential foundations of a successful production system. 5S is easy to start, but many companies struggle to sustain it. This 5s video explains how the TXM Practical 5S (r) approach delivers sustainable results by placing accountability with your front line teams.

2. TXM Lean Minute: Set in Order

5S Set in Order is the second “S” in popular workplace organisaiton method, 5S. In the second of our 5s videos, Anthony Clyne explains what “Set in Order” means and gives you practical hints on how to “Set in Order” your workplace using the TXM Practical 5S approach.

3. TXM Lean Minute: Sustain 5S and Improve with Every 5S Audit

A key question that companies ask us is “how do you sustain 5S”. 5S Training is not the answer . A more practical approach is needed. In this 5s video, Anthony Clyne explains why every 5S audit should look for improvements.

4. TXM Lean Minute: 5S Every Inch of Your Business

In one of my favourite 5S videos, Michelle Brown explains how when you implement 5S often it is the details that can trip you up. Michelle explains how to 5S every inch of your business using a 5S Map.

5. TXM Lean Minute: Creating Standard Workstations with 5S

Featuring the excellent carpentry workstations at Slattery and Acquroff Stairs, Michelle Brown explains how creating standard workstations will help your team increase their productivity. Standard workstations will also save you real money in lost tools and partly used materials.

Author: Timothy McLean

Timothy McLean is the Managing Director of TXM Lean Solutions and is an author of Lean books.

Easy Access: Reaching New Heights

Easyquip Interview: Moving from Batch to Flow Production

Interpod Interview: Building the Production Process for Modular Bathrooms

Unmissable articles.

- The Ultimate Guide To Lean Plant Layout

- Guide To Visual Management for a Lean System

- What is Lean Manufacturing?

- What Is the Fourth Industrial Revolution? Industry 4.0?

LATEST NEWS

- TXM Exhibiting at Australian Manufacturing Week (AMW) 2024

- TXM Lean Solutions Exhibiting at MACH 2024

- Ron Spiteri Departs TXM After 12 Years of Dedication

- TXM Attending Australasian Processing & Packaging Expo 2024

- ISO 18404 Lean Practitioner Online Course 2024

LATEST BLOGS

- Top Five Organisational Structure Mistakes and How to Avoid Them

- A Dream Come True – Luciano’s Japanese Kaizen Study Tour

- How to Manufacture “Manufactured Buildings” Like a Real Manufacturer!

- What is Industry 5.0?

5S Methodology: The Ultimate Guide

What is 5S Methodology

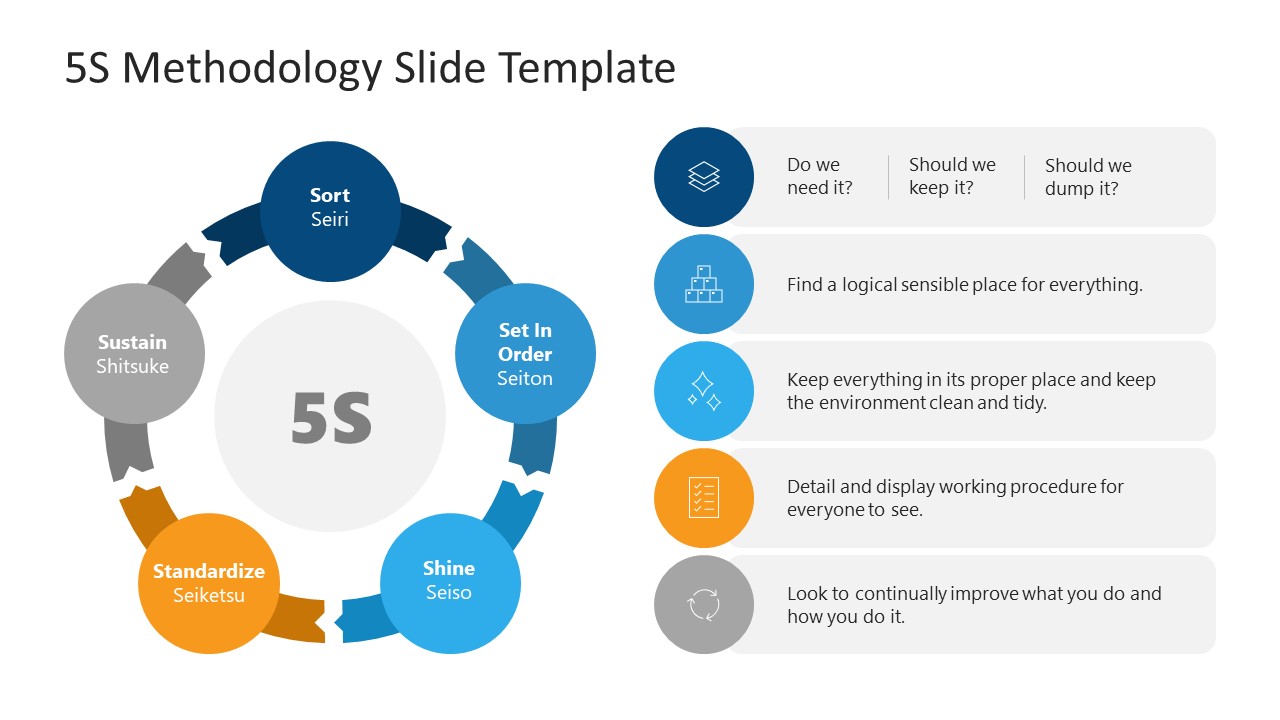

5S Methodology is a workplace organization method that uses a list of five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain) to organize a workspace for efficiency and effectiveness.

By identifying and storing the items used, maintaining the area and items, and sustaining the new organizational system, 5S helps organizations improve efficiency, avoid wastage, reduce delays, and become competitive.

Simply put, 5S is a systematic approach to workplace organization that leads to reduced costs, increased sales, and a more agile workplace.

Origin of 5S

In Post-World War II Japan, Toyota’s President, Kiichiro Toyoda and chief engineer Taiichi Ohno visited the U.S. to study the assembly line at Ford and were dismayed by the wastage in manufacturing process.

In contrast, when Kiichiro visited a Piggly Wiggly Supermarket, he was impressed with their system of reordering and restocking as and when goods were purchased.

This inspired them to develop the Just In Time (JIT) manufacturing system at Toyota, the foundations of which lie in 5S. Largely due to Toyota’s success, companies from a variety of industries have since integrated 5S practices into their own processes.

HP, Boeing, Harley-Davidson, Nike, Caterpillar, and Ford are just a few examples that found success with 5S.

Benefits of 5S

Benefit 1: zero wastage.

5S efficiently minimizes waste by eliminating unnecessary storage spaces and reducing “stand-by waste”, such as inventory waiting for equipment. This approach also tackles waste arising from the improper allocation of space and equipment. It even addresses wasteful motion resulting from activities like searching and sidestepping.

The core of the methodology lies in eliminating actions that do not add value, such as the redundant tasks of picking up, putting down, counting, and carrying. With this approach, 5S optimizes processes and enhances overall efficiency.

Benefit 2: Improved Safety

Organizations practising 5S keep their equipment in spotless condition, making mechanical failures and hazards immediately visible. Places are well-defined, and things are stored in designated places. In an industrial setup, this plays a crucial role in eliminating safety incidents and being better prepared in case of an emergency.

Benefit 3: Zero Breakdowns

5S promotes better maintenance by eliminating trash, dirt, and dust which cause equipment breakdowns and shorten life.

By keeping the workspace sparkling clean and free from filings, oil leakage, etc. it becomes easier to monitor equipment condition. Periodic checks built into the 5S keeps breakdowns to a minimum.

Benefit 4: Zero Defects

Defects are harder to discover when the workplace is unorganized. 5S designates a proper place for everything. A clean and well-organized workplace makes workers more conscious of the way they produce things.

Benefit 5: Zero Changeovers

Most factory workers have simply grown accustomed to “searching” as part of their jobs. The more searching they do, the lower their productivity sinks and the more obsolete their factory becomes.

Implementation of the 5S’s makes workshops simple and transparent enough for observers to understand with ease. Proper arrangement of dies, jigs, and tools eliminates this major form of waste called “searching waste.”

Benefit 6: Zero Delays:

When defects are eliminated, deliveries are on time. Good work environments help increase operational efficiency, leading to waste-free workshops.

Benefit 7: Zero Complaints

Products that come from a neat and clean workshop often have no defects, cost less to make and are delivered on time.

Benefit 8: Positive financial impact

Customers are happy to buy from manufacturers that have rid themselves of waste, injuries, breakdowns, and defects. Companies following 5S at workplaces earn more respect and trust in their community and turn competitive.

Meaning of the five ‘S’ in 5S

Seiri (sort).

The word Seiri (to Sort) means proper arrangement and goes beyond lining things up in rows or piling them into neat stacks. It is required to clearly distinguish between what is needed and kept and what is unneeded and thrown out.

Some questions to ask during this phase include:

- What is the purpose of this item?

- When was this item last used?

- How frequently is it used?

- Who uses it?

- Does it need to be here?

Organizations hold onto excess parts, believing they might be of future use. Inappropriate machines are used simply because they are readily available. Eventually, this starts hindering everyday production activities, leading to a mass buildup of waste that spreads far and wide through the factory.

In Seiri, the following types of waste are identified and eliminated:

- Unwanted inventory

- Warehouse space and shelving that do not contribute to the production

- Stocked items that could become obsolete

- In-process inventory

- Equipment that is no longer needed

Visible methods of proper arrangements, such as red-tagging (discussed later), make it easier to identify and eliminate waste.

Seiton (Set in order)

When everything is properly arranged, the only things that remain are the necessary ones. Hence, the next step is to clarify where these things belong. Seiton means to set things in order and goes hand-in-hand with proper management (Seiri).

In this sense, orderliness means designating a place for every item to be kept such that it becomes easier for anyone to find and use.

Things to consider in Seiton include:

- Which people (or workstations) use which items?

- When are items used?

- Which items are used most frequently?

- Should items be grouped by type?

- Where would it be most logical to place items? Would some placements be more ergonomic for workers than others? Would some placements cut down on unnecessary motion?

- Are more storage containers necessary to keep things organized?

During this phase, everyone should determine what arrangements are most logical. This requires thinking through tasks, the frequency of those tasks, the paths people take through the space, etc.

Businesses may want to stop and think about the relationship between the organization and larger Lean efforts. What arrangement will cause the least amount of waste?

One of the key principles of 5S is that anyone must be able to easily understand the order of things in the workspace. This is different from the usual mindset of having to “learn the ropes” or “become a veteran” before understanding where things go.

Seisō (Shine or Clean)

Seisō promotes the practice that cleanliness does not stop at home and that keeping the workplace clean is closely related to the ability to turn out quality products.

Seisō integrates cleanliness into everyday maintenance tasks. By demolishing the distinction between an operator’s work and a maintenance technician’s work, Seisō requires everyone to get involved in maintaining a clean, orderly workspace.

Activities carried out in Seisō include cleaning up the work area, which means sweeping, mopping, dusting, wiping down surfaces, putting tools and materials away, etc.

Seiketsu (Standardize)

Unlike the first three stages, which are seen as activities, Seiketsu refers to a state. Seiketsu means that the first three S’s (Seiri, Seiton, & Seisō) are being maintained.

When a new company implements 5S, it is easy to clean and get organized but gradually, things slide back to the way they were. Seiketsu systematizes the improvements undertaken in the previous three steps and turns these one-time efforts into habits.

By assigning regular tasks, creating schedules, developing standard operating procedures for 5S activities, and posting instructions, Seiketsu ensures that orderliness doesn’t fall by the wayside.

Initially, people will need reminders, and a small amount of time will have to be set aside for 5S tasks, but over time, these tasks become routine and 5S becomes a habit.

Shitsuke (Sustain or Discipline)

Shitsuke is seen as the most important of the 5S’s and is a pivotal factor for the production system as a whole. It is about making 5S a long-term program.

Shitsuke is top-driven, i.e., the seeds of workspace discipline need to be planted by the organization’s bosses and managers by showing their commitment to 5S.

Some of the strategies to drive this step include:

- Audits: managers can take responsibility for maintaining the routines and send a message about their commitment to 5S. Through a coaching attitude, the audit team discusses problems to find long-term solutions.

- Rewards & recognition: Celebrating success is an important part of 5S implementation. Departments and individuals are recognized for their efforts and their successes are displayed for everyone to see.

The goal of Shitsuke is to make 5S a part of an organization’s culture so that businesses achieve continuous positive results.

Implementing 5S

One of the easiest ways to implement 5S is to make the whole array of waste, abnormal operations, and other problems as explicit and visible as possible. This is also referred to as “Visual Management”.

Vision is our dominant sense, and because 5S uses colors, lines, and labels to organize, following the steps becomes second nature very easily. While 5S stands as the foundation for improvement, “visible 5S” is what every 5S initiative must become in order to be preserved.

Numerous process tools can help make 5S successful. Some of them as shown in the figure:

1. Red Tag Strategy

The red tag strategy is a means of implementing proper arrangement by labeling all unneeded items with conspicuous red tags. It involves six steps as follows:

Step 1: Launching the red tag project

Organizations need to carry out factory-wide red tag campaigns at least once or twice a year. A top manager takes responsibility for such a campaign while project members from every division come together in the identification and disposal of unnecessary stock and equipment.

Step2: Identifying Red Tag target area

The main targets for red tags are inventory, equipment, and space. Inventory can be divided into warehouse inventory and in-process inventory.

It is also important to target inventory that does not have a specified location, such as the ones that get piled up alongside aisles or on shelves in the factory. Unnecessary paperwork, along with superfluous desks, lockers etc., also count as target areas in this step.

Step 3: Setting Red Tag Criteria

Organizations are reluctant to throw familiar things away. Establishing well-defined criteria for deciding what is needed and what is not helps address this challenge.

One of the approaches to setting criteria is to look at the 30-day production schedule. What is needed for that schedule is to be retained while the rest could be classified as red-tag items.

Step 4: Make the Red Tags

While organizations can customize the red tags based on their specific needs, at a minimum, the following information is necessary:

- Category (warehouse item, machine, raw materials, in-process inventory etc).

- Quantity indicating the number of items included under the red tag.

- The reason why a red tag is attached (not needed, defective, etc.)

- Responsibility – Department/individual in charge of managing the red-tagged item.

- Date of tagging.

Step 5: Attach the Red Tags

The red-tagging team must thoroughly understand the criteria for selecting the unneeded items. As a good practice, people attaching red tags must not belong to the area being tagged. This ensures that the team is unhindered by sentimental resistance or regret.

The key to a good red-tagging strategy is to cover the whole workspace in as short a time as possible. It is important to regard red-tagging as a swift and powerful event.

Step 6: Evaluate the Red Tag Targets

Red-tagged inventory items can be treated as per the below workflow:

Red-tagging equipment is just as important as warehouse inventory. All such equipment must be moved away from the production area. In case of large equipment that cannot be moved, a “freeze” red tag must be used to indicate that the equipment should not be used for production activities.

2. Signboard Strategy

A signboard strategy is a tool to make the organizing process of 5S more visible. It should always be preceded by the red tag strategy to avoid efforts in posting signboards over unneeded items.

The below figure gives an overview of visible orderliness using the signboard strategy:

The goal of the signboard strategy is to consolidate what is left after a red-tagging exercise and arrange the equipment layout/production flow pattern in the most efficient and orderly way. It consists of six steps:

Step 1: Determine the locations

To consolidate the equipment layout and the production flow, it is important to determine how things should be placed to best suit the layout. Items that are frequently used must be placed closest to the operator. Ergonomic factors must also be considered in this step.

Step 2. Prepare the Locations

Cabinets, shelving, boxes, pallets, and containers must be used to ensure easy accessibility of storage items (Some of these may be found in red-tagged items and can be repurposed). For better efficiency, First-In First-Out Order [2] , or labor-saving roller conveyors may be used.

Step 3: Indicate Locations

Signboards must indicate the place and the address of items. It is essential to indicate where in the factory the item belongs and what specific address in a particular area.

Step 4: Indicate Item Names

While the placement indicators show where the items belong, item indicators identify each item.

When item indicators include data such as information used to maintain the “pull production” system [3] , operation instructions, and/or delivery instructions, these simple signboards turn into a full-fledged Kanban. [4]

Step 5: Indicate Amount

The purpose of amount indicators is to limit the number of shelves and storage space to be used for inventory items. Unless the amount of inventory items is kept under check, they tend to pile up.

When the exact quantity cannot be indicated, the minimum and maximum must be indicated.

The goal of a good indicator is to help visibly identify abnormalities, waste, and other problems immediately.

Step 6: Maintaining Orderliness

The key to maintaining a successful signboard strategy is to respond to problems as soon as they arise by identifying the causes and making appropriate improvements. Making orderliness easy to maintain, sticking to discipline, and making 5S’s a daily habit is crucial.

3. Organizing by color code

The best way to manage liquids like oil, lubricants, fuel etc. is through color-code. Color-coding the containers and applying the same color-coding to the areas where each type of liquid is stored helps keep the inventory organized.

4. Outlining

Marking outlines around the standardized places for keeping things clearly shows anyone where an object belongs. These can be in the form of tapes/paint strips that mark the locations where equipment or materials are placed or highlight hazards.

They come in a variety of colors and patterns, and can also be used on shelves, workbenches, cabinets, and other surfaces.

5. Checklists

Checklists provide a structured approach to achieving efficiency and organizing the workplace. They serve as a guide to ensure that each of the five steps in 5S is systematically followed and completed.

Checklists enhance communication, facilitate accountability, and serve as a visual reminder of the tasks at hand.

6. Tools for developing discipline in 5S

Badges serve as powerful visual reminders of an organization’s dedication to the principles of 5S. They encourage engagement and foster a sense of pride among employees, promoting a culture of organization, cleanliness, and efficiency at the workplace.

5S mini motto boards

Small signboards can be used to post 5S-related mottoes. Such mottoes can be invented by the company’s own workers to heighten awareness and participation. Mottoes & illustrations must be simple enough to be read and understood in under a minute and must be updated frequently.

5S stickers

Stickers act as visual cues to reinforce the principles of 5S. By labeling tools, equipment, and workstations, they remind employees to maintain organization and cleanliness, promoting discipline and adherence to standardized practices in the workplace.

5S contests

5S contests foster discipline by instilling a sense of competition among employees to maintain the best-organized workspace. They encourage individuals and teams to sustain a disciplined approach to organization, cleanliness, and efficiency, ultimately enhancing productivity and overall workplace discipline.

5S patrols contribute to discipline by assigning designated personnel to regularly inspect work areas. Documenting adherence to 5S standards, identifying areas needing improvement, and prompt timely corrective actions helps improve accountability and feedback mechanism.

5S Photo exhibits

5S photo exhibit shows before-and-after images of workspaces, illustrating the impact of implementing 5S principles. These visual representations motivate employees to maintain order, cleanliness, and standardization, fostering a sense of pride and discipline in upholding improved organizational practices.

Maps showcasing factory layouts enable visitors and passersby to easily refer to and identify areas that require better implementation of the 5S’s. Memo pads must be provided alongside maps for taking notes on potential improvements.

Maps help organizations capitalize on collective insights and contributions, fostering a more organized and efficient environment.

Keys to successful 5S implementation

To ensure the success of any 5S strategy, it is important to organize a “5S Promotion Team”. Such a team is tasked with the responsibility of maintenance and further improvements in 5S.

The following eight points, known as “Eight Keys to 5S Success” are crucial in establishing and maintaining 5S workshops.

Key #1: Getting everyone involved

5S’s cannot be the responsibility of a concerned few. Everyone must get into the act.

All levels of factory management should take part in the decision-making. 5S activities are successful when carried out as a part of the factory’s small-group activities. [7]

Key #2: Get company authorization

Management approval is important in performing 5S activities. A companywide collaborative approach must be followed while avoiding working in isolation.

Key #3: Role of the top management

The 5S’s will not be taken seriously until the CEO/President takes personal responsibility and interest in its implementation. The role of leadership in promoting 5S is crucial.

Key #4: Make everyone understand

Clarity is crucial in 5S. Teams must explain the purpose, method and action plan and address questions from all participants. Using practical examples of successful 5S implementation, including tours of well-maintained workshops, helps bring clarity.

Key #5: Do it all the way

Commitment to 5S is important. Diligent red tag campaigns, clear signboards, well-defined standard operating procedures etc. go a long way in making 5S a success.

Key #6: Top management should drive the initiative

The CEO/president must personally inspect factories and point out their observations. This motivates the group to commit to making the workplace better.

Key #7: Don’t stop halfway in establishing the 5S’s

Once the 5S promotional organization and methods have been established, it is important to follow them all throughout. Developing habits that bring discipline is crucial to keeping the foundation strong.

Key #8: 5S is a continuous improvement process

The act of organizing the workplace, looking for improvements, and optimizing is a continuous process. A successful 5S strategy is one with a shifting goal where there is always room to do better.

Industries using 5s

5S methodology is versatile enough to be used in a variety of industries. Below are some of the industries that have benefited from the 5S methodology.

1. “JIT Implementation Manual — The Complete Guide to Just-In-Time Manufacturing: Volume 2 — Waste and the 5S’s 2nd Edition”. Hiroyuki Hirano, https://www.amazon.com/Implementation-Manual-Complete-Guide-Manufacturing/dp/1420090240 . Accessed 16 Jul 2023

2. “FIFO – First In First Out Warehousing”. Ogiwa, https://www.logiwa.com/blog/first-in-first-out-warehousing . Accessed 18 Sep 2023

3. “Pull Production”. Lean.org, https://www.lean.org/lexicon-terms/pull-production/ . Accessed 19 Jul 2023

4. “What Is the Kanban System?”. Investopedia, https://www.investopedia.com/terms/k/kanban.asp . Accessed 18 Jul 2023

5. “World-class Lubrication Program Transformation”. Machinerylubrication.com, https://www.machinerylubrication.com/Read/881/world-class-lubrication . Accessed 18 Jul 2023

6. “5s Guide”. Creative Safety Supply, https://www.creativesafetysupply.com/content/landing/5S-poster/index.html . Accessed 18 Jul 2023

7. “Small Group Activity – SGA”. Makigami, https://www.makigami.info/continuous-improvement-tools/small-group-activity-sga/ . Accessed 19 Jul 2023

- Six Sigma: The Definitive Guide

Leave a Comment Cancel reply

Save my name and email in this browser for the next time I comment.

Lean Manufacturing Tools

Lean manufacturing tools, techniques and philosophy | lean and related business improvement ideas.

5S Training Presentations

5s pptx and 5s pdf downloads.

If you want to learn all about 5S then the following 5S presentations in ppt (PowerPoint) format and PDF format are available to you for free download. Please note that these 5S Training presentation files are protected by copyright and are to be downloaded for your own personal use only.

- Any commercial use of these 5S presentations and the content therein is prohibited without prior permission. Requests for permission to use can be made through the contact page of http://leanmanufacturingtools.org/contact-page/

- These presentations are for personal use only and cannot be reproduced or circulated by anyone other than www.leanmanufacturingtools.org

- Content may be quoted or reproduced for private and educational assignments as long as a proper citation is given referring to leanmanufacturingtools.org

- The information within these presentations and website are for information purposes only and any action taken is at your own risk.

These lean manufacturing training presentations are organized so that you can tackle the ideas behind 5S one step at a time, for your own education or even to train others within your own organization. Breaking them up into bite sized chunks allows you to learn or teach 5S in manageable and understandable sections even if your available time is limited.

These presentations can be use in conjunction with the following pages here;

Running your own 5S program

How to approach 5S training

Run your own 5S training course in house

5S Training PowerPoint (pptx) Presentations;

Basic introduction to 5s presentations;.

What is 5S – Learn what is 5S.

Benefits of 5S – Learn the benefits of implementing 5S within your organization.

Presentations Detailing Each 5S Stage;

5S Seiri Sort – The first stage of implementing 5S.

5S Seiton Set in Order – The second stage of implementing 5S

5S Seiso Shine – The third stage of implementing 5S

5S Seiketsu Standardize – The forth stage of implementing 5S

5S Shitsuke Sustain – The fifth and final stage of 5S implementation

Lean 6S ppt Training Presentation;

6S – How does 6S differ from 5S and why?

Presentations Supporting Your 5S Training;

5S Red Tag – Learn how to use 5S Red Tags

Runners Repeaters Strangers – Learn how to apply RRS techniques when implementing 5S

Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Program Implementation – Step by step guide to implementing 5S within your operations.

5S Training Exercise Presentation;

Training Exercise – 5S Paper exercise; a quick and simple training exercise designed for 5S which will demonstrate the simplicity and effectiveness of 5S.

5S Training PDF Files for Download;

All of the above 5S presentations are also available as 5S PDF files for download;

What is 5S Presentation

Benefits of 5S

5S Seiri or Sort – First stage of 5S

5S Seiton or Set In Order – Second stage of 5S

5S Seiso or Shine – Third stage of 5S

5S Seiketsu or Standardize – Forth stage of 5S

5S Shitsuke or Sustain – Final stage of 5S

5S Runners Repeaters and Strangers

Implementing 5S Program

5S Training Exercise

Should you require a personalized or editable version of these 5S PowerPoint presentations or 5S PDF files just contact the author through the contact page here; Leanmanufacturingtools.org contact page .

Suggestions for improvements or additions to the above 5S training presentations are welcomed.

Related posts:

- Lean Training, Coaching, and Presentations

- Free Lean Presentations

- 5S Training

Post navigation

13 comments for “ 5s training presentations ”.

i want fully details of 5s

Hi K.P. Feel free to download any of the presentations and PDF files here to provide you with all of the info that you need on 5S.

PLEASE BRIEF ON 5S / 6S , LATEST VERSION. 6 SIGMA.

let me know more about it

5’S means house keeping in our Indian language . each and every letters are starting from “S” letters .so,called 1s,2s 3s,4s&5s . on japan language India language 1) seiri -short out 2)seiton -set in order 3) seiso -shine 4)seiketshu -standardization 5)sitsuke -sustain short out -1)material segregated require /un require.if, unwanted material will be put red tag and remove from our working area 2)if,required material then will be put yellow tag .3)if,not required but,well material then will be through to red zone area . Set in Order – required material will be keep by rack /cup board /shelves etc 3)shine identified material clean daily /weekly/yearly 4)standardization this 1s,2s,3s will be keep regularly. 5)sustain this work will be make habit.

How can I download the course?

Samer, Just click on the links to download each of the 5S presentations.

hi Earley i would like develop on these 5 s principles using my domain knowledge in the Oil and Gas upstream sector and would like to conduct workshops to our fraternity please confirm if you have any objection regards Damodaran M

I would like to use this training for our maintenance department at Westrock Solvay ny.

I have “before” pictures ready and will have “after” pictures as well.

Would you like to see our ,ppt when complete?

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

Give your team the 5S foundation they need to get Lean with this knowledgeable slide show presentation.

In order for 5S programs to have a profound impact on your facility, employees need to be educated on how 5S works and its numerous benefits. This presentation has you covered.

- Information presented in simple, accessible format

- Includes in-depth explanations of the 5S steps

- Demystifies 5S’s unique red tag strategy

- Educates teams about 5S methodology in engaging ways

Other related free guides and resources Browse all free guides

Just one more step...

We respect your information and do not share your details with outside parties in any way.

Researched by Consultants from Top-Tier Management Companies

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Top 10 Templates to 5S Methodology Implementation, Take Your Profits Higher

Lakshya Khurana

The Japanese have been instrumental in inventing new and better management techniques that industries worldwide implement with glee, expecting improved profitability. The 5S Methodology is another such incredible framework that has the business world interested.

What is the 5S Methodology?

5S Methodology is a lean manufacturing tool to eliminate waste and increase efficiency. It is applicable to any work environment, but is highly suited to manufacturing settings; the 5S methodology offers a lot of scope to clean up waste and improve efficiency. The 5S also provides systemic solutions to organize and streamline work environments.

Why Use the 5S Methodology?

At the cost of repetition, please remember that the benefits of implementing the 5S methodology include increased productivity, reduced waste, improved safety, and enhanced quality. The implementation, however, must be done in a systematic and disciplined manner to enjoy these spectacular results, especially on the bottom line of organizations. The use of 5S can also help organizations save money and compete better in today’s global marketplace.

What Does 5S Stand For?

The 5S system originated in Japan as a way to improve efficiency and quality in manufacturing industries. It is derived from the Japanese words Seiri (整理), Seiton (整頓), Seisō (清掃), Shitsuke (躾), and Seiketsu (整備), which respectively mean ‘Sort,’ ‘Set in order,’ 'Shine,’ 'Standardize,’ and ‘Sustain.’

The 5S Methodology is based on five simple principles:

- Sort: Eliminate anything that is not needed at the workplace

- Set in order: Organize everything that remains, making it easy to find and use

- Shine: Keep the workplace clean and free of clutter

- Standardize: Develop procedures and systems, for smoother workplace functioning

- Sustain: Make sure 5S principles are implemented on an ongoing basis.

Templates To Implement the 5S

If you are interested in implementing the 5S methodology at your workplace, the first step is to get everyone on board and train them on the new system and procedures. Planning must also be done to ensure that 5S is made self-sustaining. Finally, flexibility is a key requirement to implementing the system.

Employees need to be made aware of the changes that will take place in the organization and their role in these changes. PowerPoint templates are the best medium to communicate this to a large group of people. We have selected 10 editable and content-ready PPT designs for you. Dig deep into these templates and see which suits you best.

Template 1: 5S Process Management in Finance

The 5S Process is a tool that can help you make your dollar work for longer and harder. This PPT layout helps you manage your finances and make smart financial decisions. It covers the 5S for business process management, financial planning, insurance succession, and more. Click the link below to download.

Download this template

Template 2: 5S Workplace Efficiency Management

For years, 5S has been used as a workplace organization and improvement system in many industries, and it can be just as beneficial for warehouses. This PowerPoint design covers the 5S to improve team efficiency, model lean warehouse management, and maintain organizational procedures, etc. Get it right away!

Grab this template

Template 3: 5S Implementation Plan

The first step in implementing the 5S system is to establish goals. Then, you need to develop a framework for your 5S implementation plan. This PPT deck covers the implementation plan for the goals, workforce, business framework, etc. It also helps you standardize the 5S process. Deploy it now.

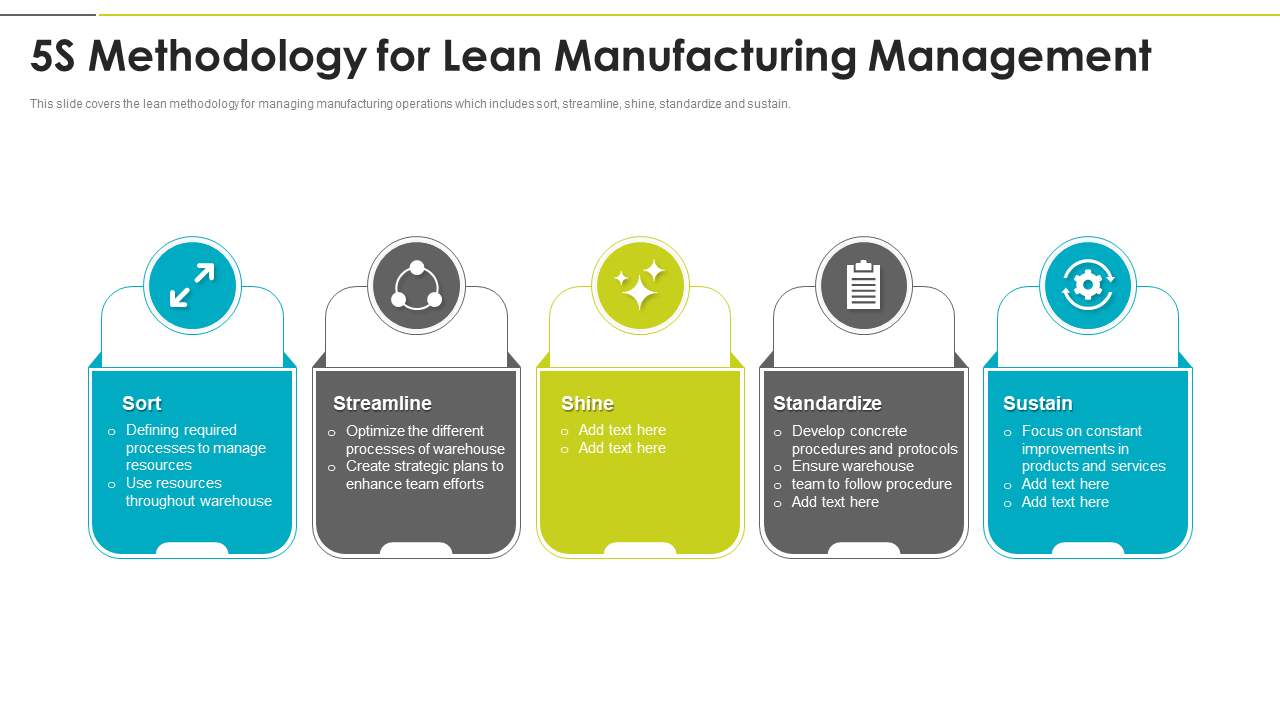

Template 4: 5S Methodology for Lean Manufacturing Management

If you are looking for a lean manufacturing management technique to help business performance, then the 5S methodology is worth considering. This PowerPoint slide helps you showcase these five steps in an attractive color palette to make for a convincing presentation. Download it now.

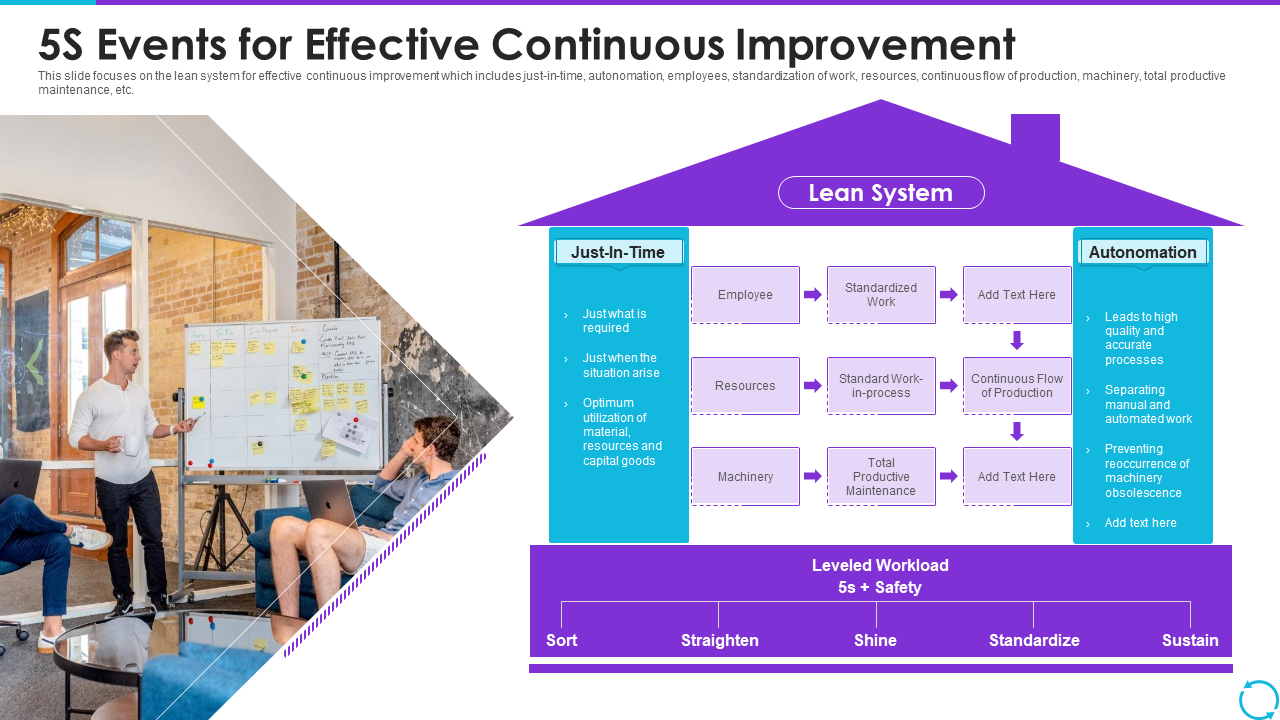

Template 5: 5S Events For Effective Continuous Improvement

This PPT preset helps organizations implement the 5S philosophy in their work environment. It is designed for a team-based setting and includes activities and tools to help organizations improve their work processes. It covers concepts like Just-In-Time, Employees, Automation, etc. Get it now.

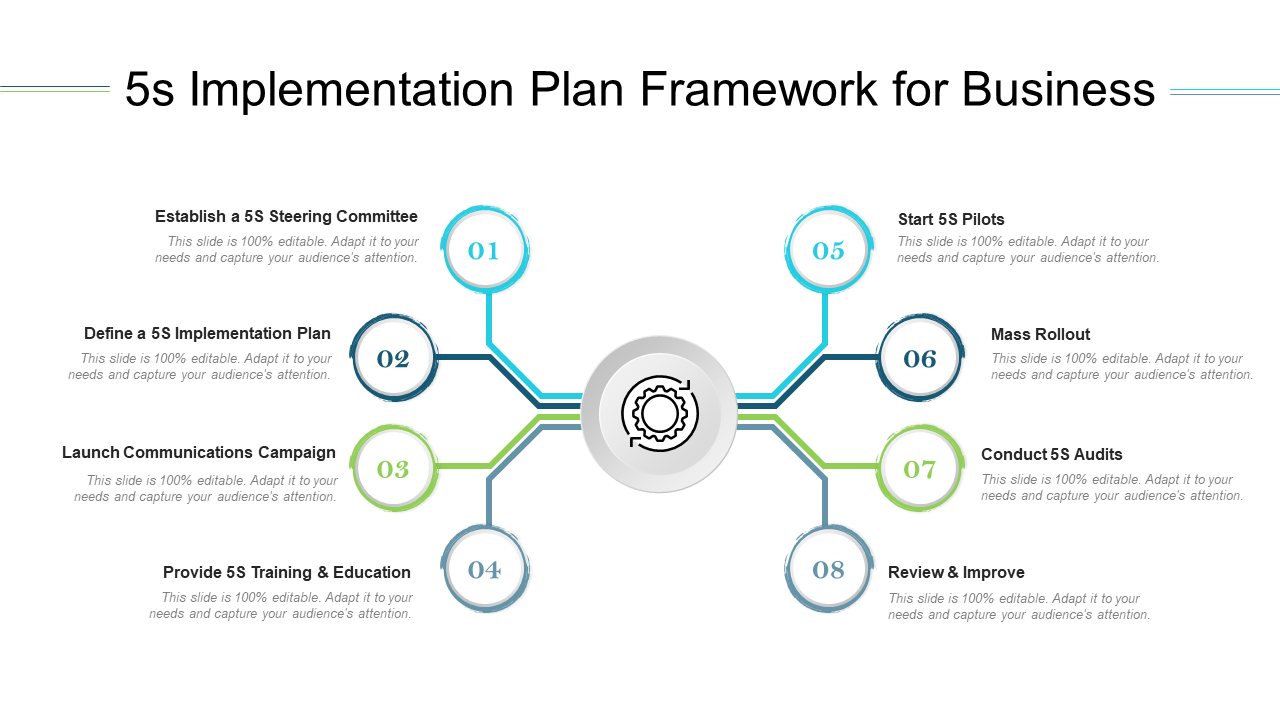

Template 6: 5S Implementation Plan Framework for Business

Our 5S implementation plan framework comes with instructions and explanations, so you can be sure that you are using it correctly. This web-structured 5S framework lists the plan for the implementation of the 5S process with steps such as establishing a committee, defining a plan, launching a communication campaign, and more. Download it right away.

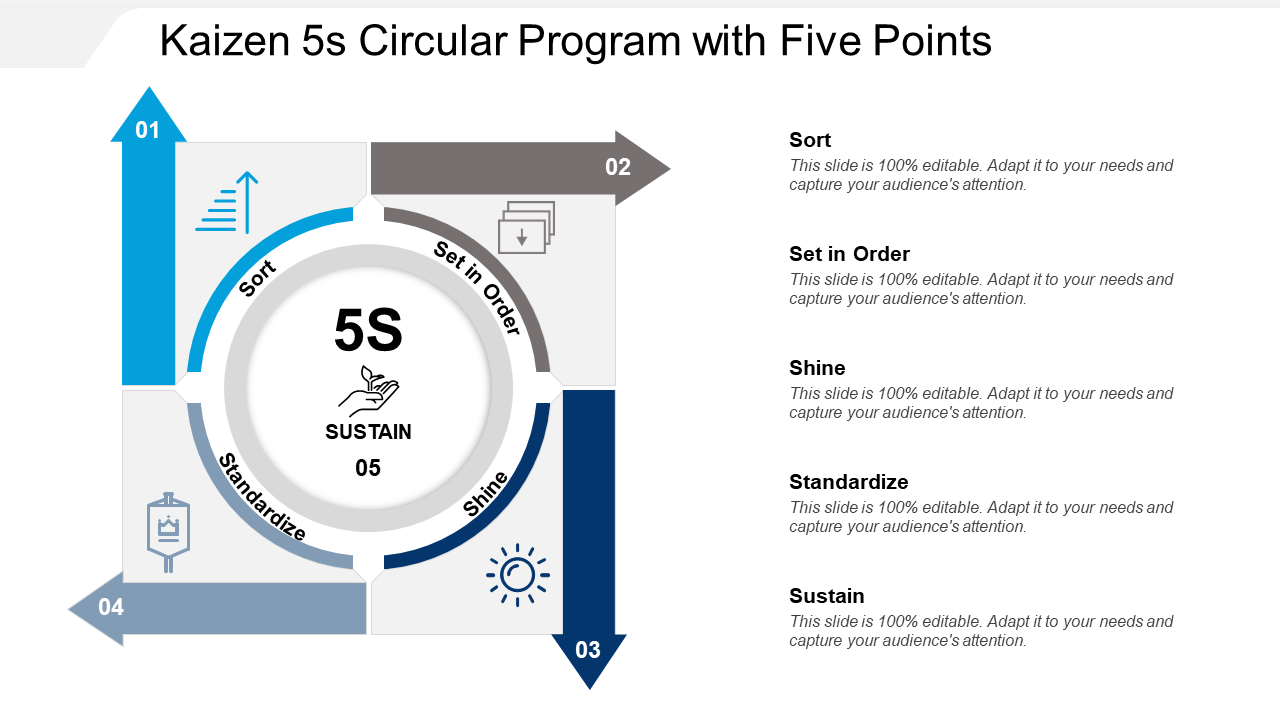

Template 7: Kaizen 5S Circular Program With Five Points

The benefits of the Kaizen 5S circular program are endless. This PPT layout presents the process in a circular layout to improve information retention. It will boost morale among your employees. If you want to take your business to the next level, then get this slide now!

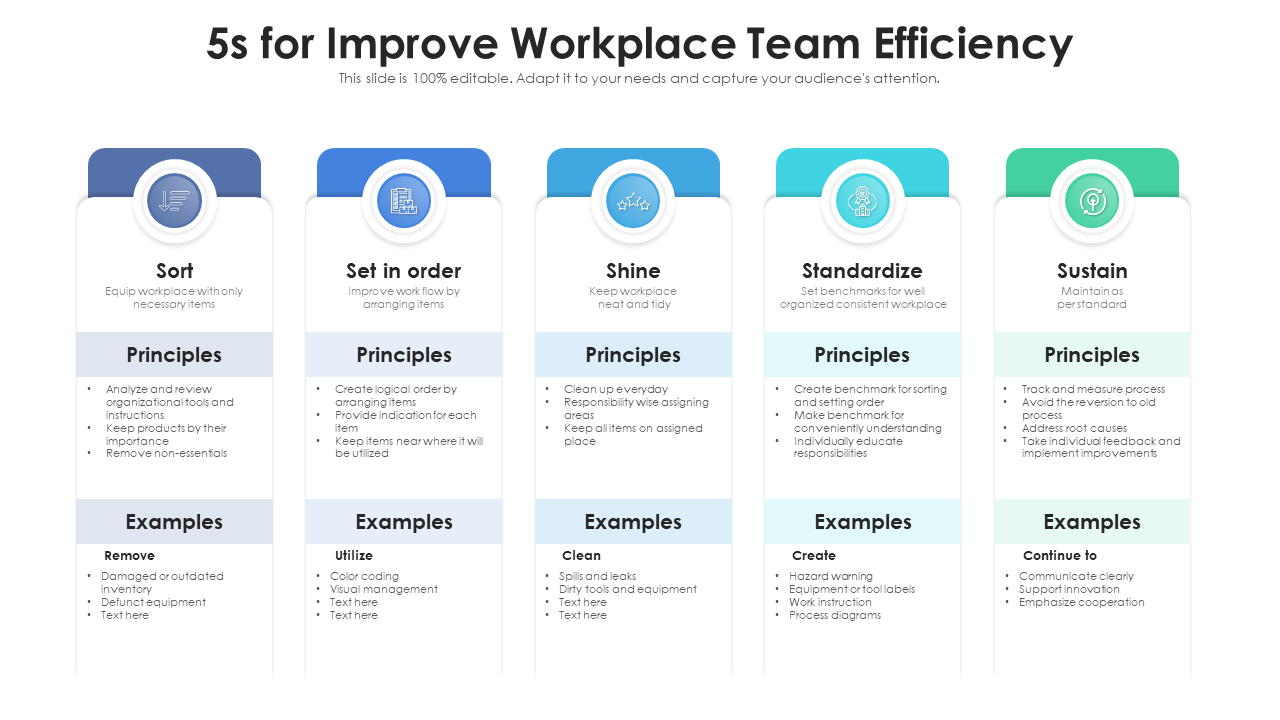

Template 8: 5S to Improve Workplace Team Efficiency

By implementing the 5S system, you can create a system in which everyone knows their roles and responsibilities and has a clear workflow. This PowerPoint theme showcases the principles and examples to execute a 5S strategy. Download this slide now.

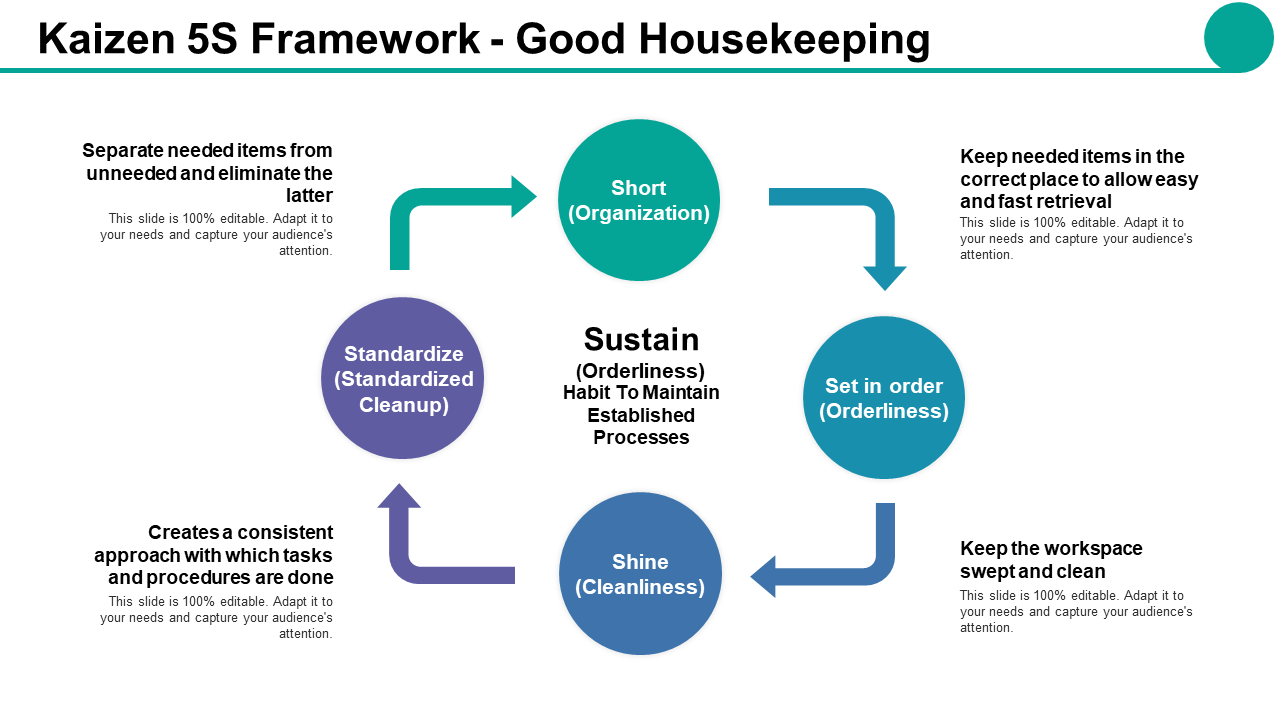

Template 9: Kaizen 5S Framework for Good Housekeeping

Using housekeeping as an example of 5S Methodology, this PPT set showcases steps to needed sustain cleanliness in a process. It is a practical framework that can be used in any business setting and is easy to implement and customize. Click the link below to download it now.

Template 10: Components of 5S Implementation Plan

It is said that successful implementation of any change initiative rests on the involvement and buy-in of those who are expected to enact the said change. This could not be more true regarding 5S or any sort of process improvement, for that matter. Get the 5S and let your employees learn how to implement it in a simple and practical manner with this PowerPoint bundle. Download it now.

Implementing the 5S methodology can be challenging, but the rewards are worth it. To do this, you need everyone to do their part, which is impossible if even a single individual remains unconvinced. Download our 5S Methodology templates and hit the ground running.

P.S: To make your work environment safer for the employees, check out our blog on the Poka-Yoke technique (with templates included), yet another Japanese gift to the business world.

Related posts:

- How to Design the Perfect Service Launch Presentation [Custom Launch Deck Included]

- Quarterly Business Review Presentation: All the Essential Slides You Need in Your Deck

- [Updated 2023] How to Design The Perfect Product Launch Presentation [Best Templates Included]

- 99% of the Pitches Fail! Find Out What Makes Any Startup a Success

Liked this blog? Please recommend us

[Updated 2023] Top 15 Presentation Templates to Showcase Your Management Consulting Services

Top 10 contract management templates to reach an agreement.

This form is protected by reCAPTCHA - the Google Privacy Policy and Terms of Service apply.

Digital revolution powerpoint presentation slides

Sales funnel results presentation layouts

3d men joinning circular jigsaw puzzles ppt graphics icons

Business Strategic Planning Template For Organizations Powerpoint Presentation Slides

Future plan powerpoint template slide

Project Management Team Powerpoint Presentation Slides

Brand marketing powerpoint presentation slides

Launching a new service powerpoint presentation with slides go to market

Agenda powerpoint slide show

Four key metrics donut chart with percentage

Engineering and technology ppt inspiration example introduction continuous process improvement

Meet our team representing in circular format

Home PowerPoint Templates Strategy 5S Methodology PowerPoint Template

5S Methodology PowerPoint Template

Discuss the five points of 5S methodology with our creative 5S Methodology PowerPoint Template with catchy visuals for training and business sessions. The 5S strategy is about creating a well-maintained, standardized workspace to boost operational processes. It is a lean strategy that aims to create an organization of objects or steps that are easy to follow and enhance overall efficiency. The complete forms of the 5S’s are derived from the Japanese words that mean:

- Seiri or Sort, which means to clear out any unnecessary elements that are not strictly required for normal functioning

- Seiton or Set in Order indicates the step to arrange things in an order that is easy to handle every time.

- Seiso or Shine is to make everything neat and arranged for everyone to understand with convenience.

- Seiketsu or Standardize involves mentioning the relevant details for everyone in the team.

- Shitsuke or Sustain is about maintaining and planning the system for better output.

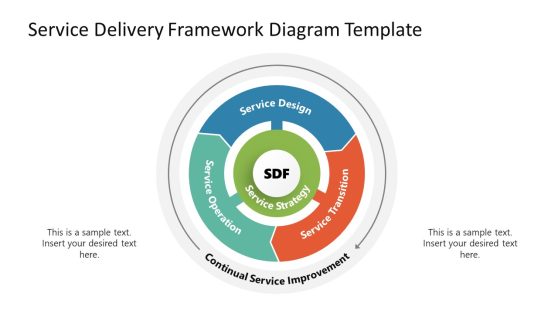

The first slide of this 5S Methodology PowerPoint Template shows a circular diagram in which five small circles are arranged cyclically. Each circular shape has a unique color and the text for the titles. The icons and the descriptive text are in a list with this diagram. The following design is similar, and it is a five-step cyclic process diagram, each component indicating the components of the strategy. Different colors indicate the five cycle elements and carry meaningful graphical icons and titles of the steps. The text boxes around the cyclic diagram have explanatory text according to the methodology steps. Similarly, the third slide has five shapes centered by a circular stripe diagram. Users can mention the additional information using the text boxes around the diagram.

These 5S PPT template slides can be edited using all PowerPoint versions. So, download and customize this presentation template according to your theme and choice. You can also download our other 5S Methodology PowerPoint templates for creating relevant presentations. Try it now!

You must be logged in to download this file.

Favorite Add to Collection

Details (3 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

4-Step Circular Diagram with 2 Levels for PowerPoint

Service Delivery Framework Diagram PowerPoint Template

5-Step PowerPoint List Template

5-Level Pyramid Template for PowerPoint

Get your team up to speed on 5S with this comprehensive slide show presentation.

5S programs can have a profound impact on your facility's organization and production. In order for this change to happen, employees companywide need to be educated on the importance of 5S and its benefits. This presentation will help you accomplish that task.

- Information presented in simple, accessible format

- Includes in-depth explanations of the 5S steps

- Demystifies 5S's unique red tag strategy

- Educates teams about 5S methodology in engaging ways

Other related free guides and resources Browse all free guides ›

Just one more step...

Lean 5S Training Videos | Funny and Free

Lean 5S is a productivity tool that dates back to Henry Ford and Toyota in the early 1900s. It primarily accomplishes two things:

- It makes work “flow” easily due to thoughtful organization, cleanliness, and standardization.

- It makes problems and abnormalities immediately visible.

The five practices of 5S come from five Japanese words that when translated into English all start with the letter “S.” These practices are summarized in the table below.

*The equivalent five Japanese words are seiri, seiton, seiso, seiketsu, and shitsuke.

Note: a variant of lean 5S is 3S, which is often popularized among organizations following the model of Paul Akers and 2 Second Lean . This is discussed at the end.

Our Best 5s Training Videos (Below)

An introduction to lean 5s.

Practicing 5S is not difficult but it does require consistent action and dedication. It’s wasteful and even damaging to run 5S like a project. Instead, it must become a part of everyday life in an organization.

10 Reasons Why You Need 5S Training (Comedy)

In simple terms, we need lean 5S because without it life is frustrating! It’s difficult to get anything done when you can’t find what you need, when something is buried under a bunch of junk, or when things are endlessly getting dirty.

Sort, and Get Rid of the Crap!

Sort is very straight-forward: get rid of all the junk that you don’t need to do your work. It gets in the way, hides problems, and jeopardizes quality and efficiency. Use a red tag system if you need to, or consider implementing a “ question box ” or “junkyard” to aid your ongoing efforts.

Straighten, and Organize Your Stuff!

Straighten is about placing every needed item in the optimal place for work and “flow.” This is why some people call this S “set in order.” You will also hear the saying, “a place for everything, and everything in its place.” When that is the case, work is easy. You can find exactly what you need, when you need it.

Sweep, and Clean Things Up!

The obvious message of sweep is to clean and tidy things up. This serves to promote safety and efficiency in the workplace. But there’s something else about sweep that is equally important: inspecting for problems. One of the major goals of lean 5S is to find problems so that they can be addressed and solved. This only happens when we pay attention to our workplace, ask the question “why,” and focus on improvement.

Standardize, and Make Practices Clear!

Standardization is an underappreciated practice. It is absolutely essential to become lean. People who are just starting off on their lean journey could focus on standardizing practices for months before worrying about trying making things better. The clarity alone is critical and brings tons of benefits. If you want to do well with lean, create the habit of standardizing everything. Make it so simple and easy that a child could do it! And then learn to do it rapidly.

Sustain, and Don’t Give Up!

“Sustain” is exactly what you’d think it’d be—it’s about being consistent and not giving up. Don’t treat the disciplines of 5S as a project or once-a-year activity. Even if you do it every day, don’t get lazy and let it decay. You’ve got to keep it up if you’re going to see results that stick in the long term.

Some organizations sustain their efforts by adding periodic audits of 5S practices. This is commonly done with a simple and flexible checklist. Gemba walks and leader standard work can also assist in sustaining elements of lean culture.

A Simplification of Lean 5S

3S is a simplified version of 5S containing only sort, sweep, and standardize. It is popular among proponents of Paul Akers’ 2 Second Lean . If you’re interested in an introductory video specific to lean 3S, watch it here on YouTube.

Which one is better? 3S or 5S? That’s really up to you and how you use it. However, we have observed that some companies embracing 3S are still doing the remaining two S’s of straighten and sustain–they are just silent. For example, straighten occurs in some companies practicing 2 Second Lean during their daily “lean and clean” or “improvement period.” And sustain occurs via the daily meeting.

To learn more about 2 Second Lean, click here.

You can also view each of these training videos from our YouTube playlist .

Looking For a 5S Training Course?

Visit 5s training videos.

Save time, train on-demand, and engage every employee in simple continuous improvement via Lean Smarts video.

IMAGES

VIDEO

COMMENTS

Learn what 5S methodology is all about in this fun introduction video, which is perfect for teaching lean manufacturing principles. 5S is a housekeeping prac...

What is 5S? 5S is a systematic form of visual management utilizing everything from floor tape to operations manuals. It is not just about cleanliness or orga...

🔥Green Belt Certification Training Course: https://www.simplilearn.com/quality-management/lean-six-sigma-green-belt-training?utm_campaign=SixSigma-UKhGD3UbX...

This 5s video explains how the TXM Practical 5S (r) approach delivers sustainable results by placing accountability with your front line teams. An example of a Workstation that has been given the Practical 5S treatment. 2. TXM Lean Minute: Set in Order. 5S Set in Order is the second "S" in popular workplace organisaiton method, 5S.

The Meaning of Shine. There is a common misconception that 5S methodology is simply about good housekeeping. This is all the more the case when it comes to the third practice shine. Shine (or also known as "sweep") has to do with cleaning all workspaces, equipment, tools, floors, etc. so that they are shiny clean.

Improved safety. Higher equipment availability. Lower defect rates. Reduced costs. Increased production agility and flexibility. Improved employee morale. Better asset utilization. Enhanced enterprise image to customers, suppliers, employees, and management. Five S (5S) Example: Workplace scan diagnostic checklist.

5S is a precursor to many lean manufacturing practices and one of many keys to forming a culture of kaizen (continuous improvement). 5S methodology training resources are easy to find on the internet. However, many of these resources lack quality and creativity. You may do well-enough if you have lots of time on your hands to search through the ...

What is 5S Methodology. 5S Methodology is a workplace organization method that uses a list of five Japanese words: Seiri (Sort), Seiton (Set-in-order), Seisō (Shine), Seiketsu (Standardize), and Shitsuke (Sustain) to organize a workspace for efficiency and effectiveness. By identifying and storing the items used, maintaining the area and items ...

Evaluate your facility with this free 5S audit card. Quality ...

Download your free 5S PowerPoint Presentation. This Powerpoint ...

Best Lean Video Collection: https://www.leanvlog.comLean Video Course in PDFs: https://gum.co/yVgzTelegram Channel: https://t.me/leanvlogThe best slideshow t...

If you can't do 5S, you can't do Lean. Or, as Gemba Academy co-founder Ron Pereira likes to say, " Without 5S, you can forget the rest." 5S is a system for Workplace Management, named for a series of steps that all begin with the letter S: Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain).

All of the above 5S presentations are also available as 5S PDF files for download; What is 5S Presentation. Benefits of 5S. 5S Seiri or Sort - First stage of 5S. 5S Seiton or Set In Order - Second stage of 5S. 5S Seiso or Shine - Third stage of 5S. 5S Seiketsu or Standardize - Forth stage of 5S. 5S Shitsuke or Sustain - Final stage of ...

Give your team the 5S foundation they need to get Lean with this ...

Template 3: 5S Implementation Plan. The first step in implementing the 5S system is to establish goals. Then, you need to develop a framework for your 5S implementation plan. This PPT deck covers the implementation plan for the goals, workforce, business framework, etc. It also helps you standardize the 5S process. Deploy it now.

https://GembaAcademy.com -- In this refreshed 5S Workplace Productivity Course, which now focuses on both manufacturing and office applications, you, and you...

The first slide of this 5S Methodology PowerPoint Template shows a circular diagram in which five small circles are arranged cyclically. Each circular shape has a unique color and the text for the titles. The icons and the descriptive text are in a list with this diagram. The following design is similar, and it is a five-step cyclic process ...

This presentation will help you accomplish that task. Information ...

A 75-slide illustrated 5S PowerPoint presentation by World-Class-Manufacturing.comContent:Five Steps to a better workplace-The 5 words-Why 5S?-A simple quest...

Visit 5S Training Videos. Save time, train on-demand, and engage every employee in simple continuous improvement via Lean Smarts video. Go there now. Make training fun with our free 5s training videos covering the essentials of sort, straighten, sweep, standardize, and sustain.

👉 Optimize your production with our Lean Bulk!Resources, checklists, and templates to excel in Lean Manufacturing.Discover more now! https://www.leanvlog.c...