- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

Safety Data Sheets (SDS)

Published by Janice Robertson Modified over 6 years ago

Similar presentations

Presentation on theme: "Safety Data Sheets (SDS)"— Presentation transcript:

MATERIAL SAFETY DATA SHEET

OSHA’s Revised Hazard Communication Standard

2013 Training Requirements for the Revised OSHA Hazard Communication Standard This presentation (“Employers Hazcom Training Requirements”) summarizes the.

Safety Data Sheet and label Training Prepared by Gary Johnson October 2013.

Reading a Material Safety Data Sheet v An MSDS is written information about the chemicals you are exposed to in shop/work v Every chemical in a shop must.

Hazard Communication: GHS Training Valley City State University | Facilities Services.

PREPARATION SLIDE ONLY. Hazard Communications Training (Includes GHS Elements)

Understanding the Hazard Communication and Laboratory Standards.

Material Safety Data Sheet (MSDS) A Material Safety Data Sheet (MSDS) is designed to provide both workers and emergency personnel with the proper procedures.

/0403 Copyright ©2004 Business and Legal Reports, Inc. BLR’s Safety Training Presentations The MSDS 29 CFR

Material Safety Data Sheets (MSDS)

HAZ COM An employer must assemble information on the hazards of the chemicals they use. (Most will get this data from their chemical suppliers who are.

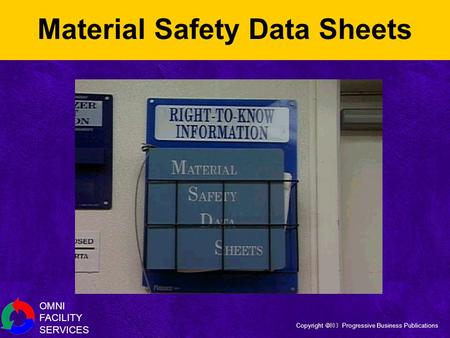

OMNI FACILITY SERVICES Copyright Progressive Business Publications Material Safety Data Sheets.

Hazard Communication Program. l l Any hazardous waste defined by the Solid Waste Disposal Act and the Resource Conservation and Recovery Act and/or regulated.

Material Safety Data Sheets MSDS. What are they used for? A Material Safety Data Sheet (MSDS) is designed to provide both workers and emergency personnel.

WELCOME INSTRUCTOR NAME: Dean Frakes UNDERSTANDING THE MATERIAL SAFETY DATA SHEET SAFETY BY DESIGN TRAINING REGULATORY STANDARD 29 CFR CFR.

Material Safety Data Sheets The MSDS 29 CFR

Material Safety Data Sheets. © Business & Legal Reports, Inc Session Objectives You will be able to: Recognize the importance of the MSDS Access.

Material Safety Data Sheets

Annual Refresher Training. The Federal OSHA Standards, 29 CRF 1910 and 1926, better known as the “Hazard Communications” or “Right-to-Know” standards,

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

What Is Material Safety Data Sheet (MSDS)? Complete Guide

The Material Safety Data Sheet (MSDS) is a crucial reference document that demystifies the complexity of chemical safety in the workplace. Whether you’re an employer, an employee, or a safety officer, understanding the relevance and application of MSDS can significantly enhance safety practices and compliance. This blog will delve into the concept of MSDS, breaking down its components, importance, and how it functions as a critical tool in the broader context of occupational health and safety.

We will explore the diverse facets of MSDS to provide you with a comprehensive understanding of its role in ensuring a safer work environment. So, let’s embark on this informational journey into the world of MSDS.

What is a Material Safety Data Sheet (MSDS)?

A Material Safety Data Sheet (MSDS), also known as a Safety Data Sheet (SDS), is a detailed informational document prepared by the manufacturer or importer of a hazardous chemical. It describes the physical and chemical properties of the product. MSDSs contain useful information such as flash points, toxicity, procedures for spills and leaks, and first aid information.

In simple terms, an MSDS is a paper or electronic document that provides detailed information about the risks of a hazardous chemical and advice about safety precautions. It’s about detailed chemical and physical information, hazards, handling and storage procedures, and what to do in an emergency. MSDSs are used not only in the workplace but also for use by environmental health and safety professionals.

Purpose Of Using Material Safety Data Sheets

The purpose of Material Safety Data Sheets (MSDS), now known as Safety Data Sheets (SDS), is to provide detailed information about a specific hazardous substance. This document is particularly crucial for workplaces where these substances are used or handled. The main objectives of an MSDS are:

- Identifying Hazards: MSDS provides detailed information about the physical and chemical properties of the substance, its hazards, how it can be safely stored, handled, and used, what to do in case of an emergency, and the measures to be taken if someone is exposed to it.

- Protecting Workers: MSDS protects workers from potential harm by providing information about the hazards associated with a chemical or product. They contain detailed first aid measures and recommended personal protective equipment for handling the substance.

- Emergency Preparation: In an emergency involving a substance, such as a spill or fire, the MSDS provides crucial information on handling the situation safely.

- Environmental Safety: MSDS also provides information on the environmental impact of the substance, including details on how to dispose of the substance safely and environmentally friendly.

Benefits of using MSDS

- Worker Safety : When employees know the hazards and understand how to handle a substance safely, the risk of accidents and injuries is significantly reduced.

- Compliance: Providing MSDS helps organizations comply with safety regulations and standards, such as those set by OSHA in the United States. Failure to provide these documents can lead to penalties.

- Efficient Emergency Response: In an accident or emergency, having access to MSDS allows for a quick and efficient response, potentially reducing harm and damage.

- Knowledge and Training: MSDS are valuable resources for training new employees about the potential hazards in the workplace and the safe handling of substances.

In summary, the purpose of MSDS is to inform and protect workers and the environment, and the benefits of using them include increased safety, regulatory compliance, efficient emergency response, and better training.

Components of a Material Safety Data Sheet (MSDS)

A Material Safety Data Sheet (MSDS) typically contains various sections that provide essential information about a chemical substance or product. While the specific format may vary depending on regional regulations and industry practices, the following are the common components found in an MSDS:

- Identification: This section provides the product’s name and the manufacturer’s or distributor’s name, address, and contact information. It may also include an emergency phone number for immediate contact in a crisis. Information on recommended use and restrictions on use can also be found in this section.

- Hazard Identification: Here, you’ll find a description of the physical, health, and environmental hazards associated with the substance. This could include whether the material is flammable, corrosive, toxic, or an irritant. The severity of these hazards is often represented using signal words like “warning” or “danger” and hazard statements that describe the nature of the risk.

- Composition/Information on Ingredients: This section lists the substance’s chemical components and relative concentrations. Not all ingredients may be listed for complex mixtures, but those contributing to the product’s hazard level will be.

- First Aid Measures: This area details the actions to take if a person is exposed to the chemical—inhalation, skin or eye contact, or ingestion. It describes symptoms and required treatment; the information should be specific and practical.

- Fire-Fighting Measures: Here, you will find the best methods to extinguish a fire involving the material, any special protective equipment for firefighters, and potential hazards that may arise when the substance is burned.

- Accidental Release Measures: This portion details the steps to follow if the substance spills or leaks, including emergency procedures, protective equipment, and methods for containment and cleanup to prevent environmental damage.

- Handling and Storage: This section offers guidelines for safely handling the substance to minimize exposure and instructions for properly storing the substance to prevent accidents, like fire or exposure to hazardous fumes.

- Exposure Controls/Personal Protection: This area includes measures to limit workers’ exposure to the substance, such as recommendations on specific types of ventilation, personal protective equipment like gloves or respirators, and what type of eye protection should be worn.

- Physical and Chemical Properties: This section provides technical data about the substance, such as its appearance, odor, boiling and melting points, flash point (the temperature at which it can ignite), solubility in water, and other relevant characteristics.

- Stability and Reactivity: Here, you’ll find information on the substance’s stability under normal conditions, as well as any materials it might react with, creating a hazardous situation. This might include light, heat, or other chemicals.

- Toxicological Information: This part describes the health effects of exposure to the substance, including immediate effects and any long-term health problems it could cause.

- Ecological Information: This section provides information on the substance’s environmental impact, including toxicity to aquatic organisms, persistence and degradability, and its bio-accumulation potential.

- Disposal Considerations: It includes recommendations for appropriate disposal practices, recycling or reclamation of the chemical or its container, and safe handling practices.

- Transport Information: This section provides guidance on how to safely transport the substance, including any special precautions that should be taken.

- Regulatory Information: This area offers additional details about the substance as required by specific regulations. This could include regulations from various jurisdictions, such as international, federal, state or local.

By having an in-depth understanding of these sections, users of these substances can mitigate risks and ensure safe handling and storage, ensuring the safety of individuals and the environment.

Tips For Using Material Safety Data Sheets

Using Material Safety Data Sheets (MSDS), now called Safety Data Sheets (SDS), can be crucial in maintaining a safe working environment. Here are some tips for using these documents:

- Accessibility: Ensure the SDS for each substance in your workplace is readily available and easily accessible to all employees. This could be in a physical binder or a digital database, but the employees must know where to find it.

- Reading and Understanding: All employees who handle hazardous substances should read and understand the SDS for each substance they use. The document should not just be skimmed over but read in detail.

- Training: Employers should provide training to their employees on how to read and understand an SDS. Employees need to know what information is available and how to use that information.

- Stay Updated: SDS should be kept up to date. Manufacturers will update their SDS when new information becomes available, and it’s important to ensure that you’re using the most recent version.

- Emergency Procedures: The SDS contains valuable information about what to do in an emergency, such as a spill or exposure. Make sure that everyone who uses the chemical knows these procedures.

- Personal Protective Equipment (PPE): The SDS specifies what PPE is required when handling the substance. Ensure this equipment is available and everyone knows how to use it correctly.

- First Aid Information: Know where to find the first aid information on the SDS. In case of exposure, it’s important to act quickly, and knowing where to find this information can save precious time.

- Proper Storage and Disposal: The SDS will provide information on properly storing and disposing of the chemical. Ensure these guidelines are followed to prevent accidents .

- Regular Review: Regularly review SDS for all chemicals in your workplace. Regulations and recommended safety measures can evolve even if the chemical composition doesn’t change.

- Communication: Any changes or updates to SDS should be communicated to all employees handling the chemical.

By using these tips, companies and employees can ensure they’re handling, storing, and disposing of hazardous substances safely and prepared in an emergency.

How to Access Material Safety Data Sheets (MSDS)?

Material Safety Data Sheets (MSDS), now known as Safety Data Sheets (SDS), are typically provided by the manufacturer or supplier of a product. Here are a few ways you can access them:

- Directly from the manufacturer or supplier: Manufacturers and suppliers of hazardous chemicals must provide an MSDS with their products. If you can’t find an MSDS that was supposed to come with a product, contact the manufacturer or supplier directly to ask for it.

- Manufacturer or supplier website: Many manufacturers and suppliers provide MSDS for their products on their websites. Look for a link to “MSDS,” “Safety Data Sheets,” or “Product Safety” on the company’s website.

- Online databases: Several online databases collect and provide access to MSDS from various manufacturers and suppliers. These include databases run by private companies, industry associations, and government agencies. Examples include the SIRI MSDS Index, MSDSonline, and the National Library of Medicine’s PubChem database in the United States. While these databases can be useful, they may not always have the most recent version of an MSDS. If possible, always get the most up-to-date information directly from the manufacturer or supplier.

- In the workplace: Employers must keep a copy of the MSDS for every hazardous chemical used and make them readily accessible to employees. They can be kept in a binder in a central location or stored electronically as long as employees know how to access them and there is a backup system in case of computer or power failures.

Remember, it’s important to ensure that the MSDS you are referring to is the most recent version as manufacturers and suppliers must update their MSDS whenever new significant information about a product’s health, safety, or environmental hazards becomes available.

Historical Background And Evolution Of MSDS

The concept of Material Safety Data Sheets (MSDS), now known as Safety Data Sheets (SDS), traces its roots back to the late 20th century when workplace safety emerged as a significant concern. Here’s a brief look at the history and evolution of MSDS:

- 1970s – OSHA Formation and the Hazard Communication Standard: In the United States, the Occupational Safety and Health Administration (OSHA) was established in 1970 to ensure workers’ safe and healthy working conditions. One of the regulations OSHA enforced was the Hazard Communication Standard (HCS), originally promulgated in 1983. This standard required chemical manufacturers and importers to evaluate the hazards of the chemicals they produce or import and provide information about them through labels on shipped containers and more detailed information sheets called MSDS.

- 1994 – Standardization of MSDS: In 1994, OSHA revised the HCS to include a standardized 16-section format for MSDS. This format was voluntary but recommended to help users find pertinent information quickly and easily. It included information such as product and company identification, hazard identification, first-aid measures, fire-fighting measures, accidental release measures, handling and storage, exposure controls/personal protection, physical and chemical properties, stability and reactivity, toxicological information, and ecological information.

- 2002 – Introduction of the Globally Harmonized System (GHS): 2002 the United Nations adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This system aimed to standardize and harmonize hazard classification and communication globally, including standardizing the format and content of safety data sheets.

- 2012 – OSHA Adopts GHS: In 2012, OSHA revised its HCS to align with the GHS . As part of this update, “Material Safety Data Sheets” was replaced with “Safety Data Sheets,” and the standardized 16-section format was made mandatory. Adopting the GHS helped ensure that the same set of labels, pictograms, and safety data sheets could be used for hazardous chemicals worldwide, making it easier for workers to understand the hazards, especially for those who work with chemicals from multiple sources.

Over the years, the MSDS (now SDS) has evolved significantly, with a primary goal of improving workplace safety by providing clear, concise, and standardized information on the hazards of chemicals and how to handle them safely.

An MSDS, or Material Safety Data Sheet, is a document that contains information on the potential hazards (health, fire, reactivity and environmental) of a chemical product and how to work safely with the chemical product.

Any workplace where the workers are potentially exposed to hazardous chemicals should have MSDSs available for the employees. This includes places like factories, laboratories, agricultural settings, and many more. It also extends to emergency responders who may encounter the chemicals during their work.

An MSDS typically includes information such as physical data (melting point, boiling point, flash point, etc.), toxicity, health effects, first aid, reactivity, storage, disposal, protective equipment, and spill-handling procedures.

The manufacturer or importer of a chemical product is responsible for creating the MSDS.

It varies by jurisdiction, but generally, MSDS should be reviewed every three to five years or when new information about the chemical becomes available.

MSDS should be stored in an easily accessible location where the employees can access them in case of emergency.

MSDS and SDS essentially serve the same purpose. The difference is that the SDS format is more consistent and universally applicable, as it follows the globally harmonized system (GHS) for classification and labeling of chemicals.

Yes, in many countries, including the United States, Canada, and member states of the European Union, the availability of MSDS for certain types of products is a legal requirement. This is part of the right-to-know laws which mandate that employees have access to information about the chemicals they are exposed to in their workplace.

Please note that while we strive to provide accurate and timely information, laws and regulations regarding MSDS can change. So, it’s always a good idea to consult with a local authority or expert in your area if you have specific questions.

In conclusion, the Material Safety Data Sheet (MSDS) is a fundamental resource in occupational safety. It’s a comprehensive document that provides vital information about the nature of chemicals used in the workplace, their risks, and the precautions necessary for safe handling and use. Beyond its role in everyday operations, the MSDS is instrumental in training employees, preparing for emergencies, and ensuring regulatory compliance.

This guide provides a complete overview of an MSDS, its components, purpose, and use. By understanding and effectively utilizing MSDS, companies can ensure a safer work environment and foster an informed and alert workforce, which is the bedrock of any successful safety program .

Safety – MSDS

Jul 27, 2014

850 likes | 1.91k Views

Safety – MSDS. Chemical Safety and Storage. Understanding Material Safety Data Sheets. Biotech - Safety. Objectives. Define regulatory acronyms relating to MSDS Identify the key components of MSDS Use MSDS information to identify appropriate PPE and procedures for using a given material.

Share Presentation

- safety data sheet

- readily accessible

- material safety data sheets

- osha hazard communication standard

- cte joint venture

- terminology

Presentation Transcript

Safety – MSDS Chemical Safety and Storage

Understanding Material Safety Data Sheets Biotech - Safety

Objectives • Define regulatory acronyms relating to MSDS • Identify the key components of MSDS • Use MSDS information to identify appropriate PPE and procedures for using a given material. • Locate MSDS in the classroom • Use classroom MSDS information to write appropriate clean up procedures for a given material (including reporting where necessary).

Terminology You need to be familiar with the following safety- related acronyms . • GHS– • HCS - • MSDS (SDS)– • OSHA –

MSDS MSDS- Material Safety Data Sheet(s). -This is a document with all the information on hazardous materials. Why do we have them?

MSDS Material Safety Data Sheets Why do we have them? In 1983 the Occupational Safety and Health Administration adopted rules based on employees “right to know” any hazardous substance they might be working with. OSHA - Occupational Safety and Health Administration. - This is the main agency of the U.S. government responsible for regulating workplace safety.

MSDS Why do we have them? One OSHA requirement is that users of any hazardous material maintain an Hazardous Communications System. This is a written plan explaining what hazardous things are being used, how employees are informed about them, and information for emergency responders about what materials are on site. HCS-Hazardous Communications System. -Establishes the legal requirement to inform users about any hazardous materials they might come in contact with.

MSDS Why do we have them? The law requires an that as part of the HCS, Material Safety Data Sheets for all hazardous materials will be available to employees.

MSDS- What’s on them? MSDS do nothave one required format. • Though the information and format may vary, every MSDS should have key information that will allow you to answer these questions: • What are the hazards of using this material? • What PPE should do I need to safely use this material? • How should I clean up, and dispose of this material? • How should I store this material?

MSDS- What’s on them? MSDS do nothave one required format. Let’s look at two MSDS for the same chemical Property of CTE Joint Venture

Hazards Combustible liquid Body tissue irritant Slightly toxic by ingestion and inhalation

PPE • Splash goggles • Chemical resistant gloves and apron • Proper ventilation • Use respirator in spill or fire situations

Clean Up and Disposal • Remove all ignition sources • Ventilate area • Clean up personnel need PPE • Absorb spills and put cleaning materials in sealed containers.

Storage • Flamables cabinet or can • Store with like chemicals (Organic #2) • Cool, dry place • Absorb spills and put cleaning materials in sealed containers.

MSDS - Looking to the (near) future Since MSDS don’t have a required format, why do so many of them list information in the same 16 sections? • Because many companies are already writing to align with the format of the new INTERNATIONAL system of material safety, the Globally Harmonized System. • GHS– Globally Harmonized System. - This is a voluntary worldwide system for getting all countries to use the same symbols and format for materials information.

OSHA proposed that GHS rules were to take effect in December of 2011… …and required employers to complete employee GHS training by December of 2013

MSDS, hold the "M" Under the GHS system, what OSHA calls a MSDS is called an SDS. What do you think SDS stands for??? SDS = Safety Data Sheet

MSDS – On Site, Or Else… OSHA Hazard Communication Standard, 29 CFR 1910.1200, paragraph(g)(8): • The employer shall maintain in the workplace copies of the required material safety data sheets for each hazardous chemical, and shall ensure that they are readily accessible during each work shift to employees when they are in their work area(s). (Electronic access, microfiche, and other alternatives to maintaining paper copies of the material safety data sheets are permitted as long as no barriers to immediate employee access in each workplace are created by such options.) So, naturally, we have MSDS in our lab for the chemicals we use here.

- More by User

Material Safety Data Sheets (MSDS)

Material Safety Data Sheets (MSDS). By: Jerome Kalo. What is a Material Safety Data Sheet?. Form providing detailed information about hazardous materials present at the worksite. Hazards addressed: Chemical Health hazards Reactivity and fire Environmental . Blue = health Hazard.

4.26k views • 20 slides

Material Safety Data Sheets (MSDS). Material Safety Data Sheets. Are to be provided by Supplier’s with all deliveries MUST be Accessible to EVERYONE in the workplace Must be current Must be made available to attending physician in the event of exposure . DEFINITIONS.

725 views • 11 slides

The Hazardous Materials Emergency, Security and Safety Management Systems

The Hazardous Materials Emergency, Security and Safety Management Systems. Emergency Management and Emergency Plan of HAZMAT. Ludwig Benner’s Definition Hazmat emergency r esponse p rimarily f ocuses o n t he i nteraction o f t he Hazmat a nd i ts c ontainer.

1.25k views • 78 slides

Ladder Safety

Institute for Safety in Powerline Construction. Ladder Safety. Safety Meeting Topics. Session Objectives. By the end of this training session, you will understand: The hazards associated with using ladders The types of ladders in use and the proper use of each

621 views • 24 slides

MSDS. Introduction . This presentation will provide information on the importance, use and responsibilities involved with the MSDS program. As with many other programs, this one also includes all staff to some degree. Agenda. What are MSDS? Who is responsible for MSDS?

821 views • 18 slides

Systems Safety Management

Systems Safety Management. HBR Best Practice Seminar & Texas Gulf Coast Safety Expo. Background and History. “What Initiated the Process?”. Background and History. Safety Manual MSDS Environmental Management Systems Industrial Hygiene Program

322 views • 14 slides

Safety Web Site chemistry.umeche.maine.edu/Safety.html

Safety Web Site chemistry.umeche.maine.edu/Safety.html. Includes: Department Hygiene Plan Links to sites for MSDS Link to NRC “Prudent Practices” Compatibility Tables Chart for choosing gloves ACS Academic Lab Safety Guide. Who Makes the Rules? Federal: OSHA, EPA State: OSHA, DEP

400 views • 25 slides

Ahuja Constructions presents you the best Luxury Apartments in Worli Mumbai

Ahuja Towers Penthouses in Worli, Mumbai. Ahuja Constructions presents you the best Luxury Apartments in Worli Mumbai. http://www.ahujatowers.com/. Marketed By Amura. Overview. 53 storeys above everyday 250 meters above the ordinary Completely Glazed Façade with signature crown

125 views • 4 slides

WHMIS meets GHS: Challenges for MSDS Authors and Users

WHMIS meets GHS: Challenges for MSDS Authors and Users. OHAO March 28, 2007. What is GHS? . GLOBAL approach to defining and classifying hazards, communicating health & safety information on labels and safety data sheets. Today’s presentation:.

651 views • 36 slides

Hazardous Communications & Lab Safety

Hazardous Communications & Lab Safety. Bruce Bradley & Humberto Garcia Sept 11, 2007. Hazardous Communications & Lab Safety. Title 8 CCR, 5194 Smoking Policy Chemical Inventory MSDS’s Hazard Properties Labeling Emergency Response Hazardous Materials & Waste Laboratory Practices.

547 views • 45 slides

An Overview of the MSDS Manager

An Overview of the MSDS Manager. Salient Features. Fully developed in Visual Basic 6.0 Enables storage of Material Safety Data Sheets (MSDS) in an electronic format Documents can be printed out when needed Stores MSDSs on the basis of the material name and CAS number

232 views • 10 slides

Chemical Safety

Chemical Safety. 31.10.2012 Ying-Fen Ran. Contents:. 1. MSDS 2. Use 3. Storage 4. Waste disposal. MSDS (Material safety data sheet). Hazard symbol. European Hazard Symbols (EHS). Globally Harmonised System (GHS). Ref: Hazard Warning Labels

487 views • 19 slides

LABORATORY SAFETY

LABORATORY SAFETY. Chemical Hazard Label. What is a MSDS sheet?. A Material Safety Data Sheet (MSDS) is designed to provide both workers (students and staff at SHS) and emergency personnel with the proper procedures for handling or working with a particular substance (chemical or element).

693 views • 16 slides

SAFETY. what is Osha ? . Occupational Safety and Health Administration Employer guidelines for safe work environment Employer provides hazards training, immunizations, injury prevention etc. MSDS (Material Safety Data Sheets). All inpatient healthcare agencies require:

410 views • 23 slides

Safety Review

Safety Review. Safety Challenge. Look at the picture given to you and list as many unsafe features of the lab as you can. WHMIS. Stands for W __________ H __________ M __________ I __________ S __________ The purpose of WHMIS is. MSDS.

287 views • 7 slides

Best Practices for MSDS & Accountability

Best Practices for MSDS & Accountability. Steps to Success and Timeline for Accountability. The Michigan Student Data System (MSDS). CEPI operates and collects the information by schools statewide.

435 views • 28 slides

Welding Safety

Welding Safety. Material Safety Data Sheets. Material Safety Data Sheets (MSDS) are: Required by law and OSHA Created by the manufacturer of a product per OSHA guidelines Designed to inform users Shipped with every box of Lincoln Electric consumable product Available free online at:

832 views • 13 slides

How to Read a MSDS

How to Read a MSDS. What does MSDS stand for?. Material Safety Data Sheet. MSDS Practice Worksheet. Chemical Name CAS# is an identifying number for each substance Hazards** Very important to read before using!!. MSDS Practice Worksheet. Other topics may include First-aid measures

1.69k views • 10 slides

Material Safety Data Sheets

Material Safety Data Sheets. Interpreting and Understanding Information on a MSDS. Requirements. • MSDS for hazardous chemicals must be in workplace • Employees must be able to interpret MSDS information • MSDS may be in printed form or available electronically

419 views • 12 slides

MSDS Material Safety Data Sheet

MSDS Material Safety Data Sheet. Includes 8 sections: Manufacturer Information Hazard Ingredients/ Identity Information Physical/ Chemical Characteristics Fire and Explosion Hazard Data Reactivity Data Health Hazard Data Precautions for Safe Handling and Use Control Measures.

1.49k views • 10 slides

MSDS Material Safety Data Sheets

MSDS Material Safety Data Sheets. How toxic is that chemical? If a child swallows it, what do I do? A Pakistani woman recently drank household bleach, how much is fatal? MSDS sheets provide many answers, our project for this dry lab experiment. Material Safety Data Sheets.

864 views • 36 slides

- ASME Foundation

- Sections & Divisions

- Sign In/Create Account

- Learning & Development

- Find Courses

- IPPD643 - ASME B31.3 Process Piping Code

- ASME B31.3 Process Piping Code

Credits: CEUs: 3.0 | PDHs: 30.0

Language: EN

Apply the requirements of ASME B31.3 to the design, analysis, materials, fabrication, testing and inspection of process piping systems.

This Standard was last reviewed and reaffirmed in {{activeProduct.ReaffirmationYear}}. Therefore this version remains in effect.

{{activeProduct.DisplayTitle}}

Digital products are restricted to one per purchase.

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} activeProduct.ListPrice"> was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} activeProduct.ListPriceSale"> was {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} activeProduct.ListPriceSale"> was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

0}"> {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPrice) }} activeProduct.MemberPrice"> was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

0"> {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPriceSale) }} activeProduct.MemberPriceSale"> was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

Become a member

*Excluding Lite Members

Final invoices will include applicable sales and use tax.

Print or Share

Product options.

- Location and Date Seats Left Price List Price Member Price

Orlando, FL, USA Oct 28-31st, 2024

Welcome Back!

The ability to interact with ASME instructors who bring real world experience, examples, and best practices to life in our learning experiences is a major reason learners choose face to face training. Networking with peers is also a valuable part of the time spent together Schedule: This course commences at 8:30 AM and ends at 5:30 PM local time, each day, with breaks scheduled throughout. October Venue : This course will be held at the Hilton Orlando Buena Vista Palace in conjunction with ASME Boiler & Pressure Vessel Code Week . Please follow this link for hotel reservations.

This course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems. It explores the rules for various components including fittings, connections, bends, valves and specialty components. Other topics include dimensions and ratings of components, fluid service requirements for joints, piping flexibility and support, welding, heat treatment, bending and forming, brazing and soldering, assembly, erection, examination and inspection.

By participating in this course, you will learn how to successfully:

- Identify the responsibilities of personnel involved in the design, fabrication, assembly, erection, examination, inspection, and testing of process piping

- Describe the scope and technical requirements of the ASME B31.3 Code

- Apply and implement the quality requirements that are defined in the ASME B31.3 Code

Course Materials (included in purchase of course):

- Downloadable version of the course presentation via ASME's learning platform

Special Requirement

Each student must bring his or her own calculator.

Who Should Attend?

This course is designed for engineers, managers and quality personnel who are involved in the design, manufacturing, fabrication and examination of process piping that is being built to the requirements of U.S. Codes & Standards.

A Certificate of Completion will be issued to registrants who successfully attend and complete the course.

Can't make one of these sessions? This course is also available via the ASME Virtual Classroom and On Demand .

- Aims, objectives, and outcomes of the course

- General Statements

- Fluid Service Categories

- Design Conditions

- Design Criteria

- Pressure Design of Components

- Case Study – Pipe Wall Thickness

- Fittings, Bends, Miters, Laps and Branch Connections

- Valves and Specialty Components

- Flanges, Blanks, Flange Facings and Gaskets

- Dimensions and Ratings of Components

- Case Studies – Branch connection & Flanges

- Welded Joints

- Expanded Joints

- Threaded Joints

- Tubing Joints

- Caulked Joints

- Soldered and Brazed Joints

- Special Joints

- Piping Flexibility

- Piping Support

- Case Study – Piping Flexibility

- Case Study – Specification of Spring Support

- Bellows Expansion Joints

- Specific Piping Systems

- Pressure Relieving Systems

- General Requirements

- Materials - Miscellaneous

- Case Study – Selection of Materials for Low Temperature Service

- Heat Treatment

- Bending and Forming

- Brazing and Soldering

- Assembly and Erection

Days Three & Four

- Examination

- Examination Personnel

- Examination Procedures

- Types of Examination

- Case Study – Pressure Testing

- Safeguarding

- Case Study – Development of a Piping System

- Nonmetallic Piping and Piping Lined With Nonmetals

- High Pressure Piping

- High Purity Piping

Jim Meyer, P.E.

Principal/Lead Engineer, CDM Smith

Jim E. Meyer, P.E., has over 45 years of experience in refining petrochemical, chemical, power generation and industrial facilities. He is a principal engineer at CDM Smith, a full-service engineering and architectural firm.

More Information

Buying for your team?

Set up a customized session of this course for your workforce.

- ASME's Terms of Use

- Learning & Development Terms of Use

- Privacy and Security Statement

- Policy Against Discrimination and Harassment

How to Read a Safety Data Sheet (SDS)

Safety data sheets – important terms.

The Safety Data Sheet is the internationally accepted basis for supplying sound written scientific information on hazardous substances. Safety Data Sheets provide essential information that includes How to Read a Safety Data Sheet (SDS) and details on how to use substances safely without harmful effects to people or the environment.

About the course

Safety Data Sheets can be very challenging to read and understand but they do contain a wealth of information. Having an ability to properly interpret them will make it easier to arrive at informed decisions regarding the use of hazardous substances.

This program provides a more in depth explanation of some of the important terms you may come across in Safety Data Sheets (SDS) to help your organisation understand better how to read a safety data sheet, including:

- LD50, & LC50

- PEL & TLV

- Vapor Pressure

- Vapor Density

- Flammability Limits

- Flashpoint and Fire Point, and

Video Running Time: 10 minutes

Course Contents

Safety training video.

On-demand safety video accompanied by supplemental material to form a complete safety video training program.

Facilitator's Guide

Accompanying documentation includes facilitator’s framework, video transcript, exercises and a multiple-choice assessment questionnaire.

Safety Assessment

Course includes a 10-part multiple-choice safety quiz. Participants can take the assessment as is, or the questions can be modified to suit your requirements.

Course Certificate

Participants can print a completion certificate and training progress is stored centrally in Safetyhub to track your participant engagement KPI.

Get access to this video course and all the features of Safetyhub with a subscription.

Share this page

Popular related safety courses:.

Knowing how your workplace affects the environment and how you can prevent environmental damage from your work creates a more eco-friendly workplace. Topics in this program include Climate Change, Emissions, Waste management and Pollution.

This General Waste Management Safety Program examines methods for classifying various kinds of waste and how best to track and ultimately dispose of them. Topics in the program include waste classification, waste disposal and waste manifests.

HAZCOM 1994 is an information and training standard relating to the use of hazardous chemicals in the workplace. This video program covers the how HAZCOM works, hazards associated with chemicals, labelling and material Safety Data Sheets.

The purpose of this training program is to present a clear overview of the subject and address dangerous goods classes, identification of safety marks, how to read the schedules, means of containment, labelling and documentation requirements.

About Safetyhub

Safetyhub helps organisations deliver improved workplace safety training with online safety videos and LMS tools. Safetyhub has been providing safety video learning solutions and high-quality safety video content for over 25 years.

Contact Sales Support

2343 N Hayden Rd Scottsdale, AZ 85257

Toll-Free: 800-414-9811

Connect With Us

Browse course categories, search for a course.

- previous post: Machine Guards

- next post: Warehouse Safety

- Safety Courses

- Microlearning

- LMS Features

- Start Trial

Privacy Overview

IMAGES

VIDEO

COMMENTS

4. PART-A: Definition Of MSDS A Material Safety Data Sheet (MSDS) is a well organized document that contains all information about a given chemical. It includes name, composition, hazards, first aid measures, fire fighting measures, information regarding the proper steps to take with spills, handling and storage, personal protection to be used, physical and chemical properties, and information ...

SDS sheets, formerly known as Material Safety Data Sheets or MSDS, are written informational sheets that are prepared by the manufacturer or importer of a chemical or product that provides specific safety and handling information about that product. The SDS includes information such as the properties of each chemical; the physical, health, and ...

SDS sheets as part of the country's transition to a new global initiative called the Global Harmonize System or GHS. This initiative is part of OSHA's Hazard Communication Program or HAZCOM. •. Part of the change is a transition from using MSDS sheets or Material Safety Data Sheets to the new Global Harmonized System's Safety Data Sheet ...

OSHA Training Toolbox Talk: OSHA's Revised Haz-Com Standard - Safety Data Sheets (SDS's) [Reference 1910.1200(f) / 1926.59(f)] Most of you are probably familiar with Material Safety Data Sheets, called MSDS's, as these documents have been around for almost 30 years. However, MSDS's for products from various

Participants can print a completion certificate and training progress is stored centrally in Safetyhub to track your participant engagement KPI. Get access to this video course and all the features of Safetyhub with a subscription. Safetyhub helps train your Employees in Safety Data Sheets (SDS) with an online SDS Chemical Safety Video Course.

Presentation on theme: "Material Safety Data Sheets"— Presentation transcript: 1 Material Safety Data Sheets Slide Show Notes Welcome to material safety data sheet training. This training is designed for those who work with hazardous chemicals. If there are hazardous chemicals in your workplace, you need to know about the material safety data ...

2014. Number of Slides: 54. Created By: Penn State University. Download Atlantic Training's collection of safety training PowerPoints from around the web to train your team on important EHS Safety topics today. Safety Data Sheets are vital in hazard communication, as they indicate hazardous materials such as dangerous gases, chemicals, waste ...

2013 Training Requirements for the Revised OSHA Hazard Communication Standard This presentation ("Employers Hazcom Training Requirements") summarizes the. ... Safety Data Sheet and label Training Prepared by Gary Johnson October 2013. Reading a Material Safety Data Sheet v An MSDS is written information about the chemicals you are exposed ...

Modernize your msds training presentation and make it accessible anytime, anywhere. Save valuable company time by making your msds training PowerPoint mobile-friendly and completable in 5 minutes. We'll take your PowerPoint courses and automatically turn them into our proven microlearning, mobile format so your team can do their training on the ...

A Material Safety Data Sheet (MSDS), also known as a Safety Data Sheet (SDS), is a detailed informational document prepared by the manufacturer or importer of a hazardous chemical. It describes the physical and chemical properties of the product. MSDSs contain useful information such as flash points, toxicity, procedures for spills and leaks ...

MSDS Training Presentation - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. MSDS

The HCS covers physical hazards (such as flammability) and health hazards (such as irritation, lung damage, and cancer). SDSs - formerly called Material Safety Data Sheets (MSDSs) - are a key requirement of the standard and a primary means for explaining chemical hazards. SDSs include the following information about a chemical:

Material Safety Data Sheets • Are to be provided by Supplier's with all deliveries • MUST be Accessible to EVERYONE in the workplace • Must be current • Must be made available to attending physician in the event of exposure. DEFINITIONS • Flammable: ANY substance easily ignited and quick burning, including liquids with a flash point ...

Presentation Transcript. Objectives • Define regulatory acronyms relating to MSDS • Identify the key components of MSDS • Use MSDS information to identify appropriate PPE and procedures for using a given material. • Locate MSDS in the classroom • Use classroom MSDS information to write appropriate clean up procedures for a given ...

Objective. TO 1.0. Achieve a minimum score of 70% on the final course assessment. LO 1.1.1. Describe general requirements of the Hazard Communication Standard. LO 1.2.1. Discuss the forms of hazardous chemicals, their effects, and routes of entry. LO 1.2.2. Describe the chemical "Hierarchy of Controls" and give examples of control strategies ...

MSDS Training Presentation - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is the world's largest social reading and publishing site.

Instantly convert your PowerPoint training to mobile - for free. Experience the magic of EdApp on your own training content. Upload your PowerPoint file and our powerful conversion tool will instantly make it mobile-friendly. Choose file. Only .pptx files accepted. Maximum file size 100MB.

MSDS AWARENESS - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. MSDS awareness training PPT

Pesticide Environmental Stewardship - Promoting Proper Pesticide Use ...

This course provides an introduction to the ASME B31.3 Process Piping Code. It covers the requirements of B31.3 for design, analysis, materials, fabrication, testing and inspection of process piping systems.

This program provides a more in depth explanation of some of the important terms you may come across in Safety Data Sheets (SDS) to help your organisation understand better how to read a safety data sheet, including: LD50, & LC50. PEL & TLV. Vapor Pressure. Vapor Density.