Understanding whole-wheat flour and its effect in breads: A review

Affiliations.

- 1 Food Technology Area, College of Agricultural Engineering, University of Valladolid, Palencia, Spain.

- 2 Programa de Pós-Graduação em Ciência e Tecnologia de Alimentos, Universidade de Passo Fundo, Passo Fundo, RS, Brazil.

- PMID: 33337058

- DOI: 10.1111/1541-4337.12625

Although the consumption of whole grains, including bread made with whole-wheat flour, is promoted for health benefits and reduced risk for disease and mortality, consumer acceptance, and consumption of some whole-wheat products is low compared to that of white breads. This review focuses on the understanding of whole-wheat flours, both their positive and negative aspects, and how to improve those flours for the production of whole-wheat breads. The review addresses genetic aspects, various milling systems, and pretreatment of bran and germ. The baking process and use of additives and enzymes may also improve product quality to help consumers meet dietary recommendations for daily whole-wheat consumption.

Keywords: bakery products; bran; nutrition; rheology; whole wheat.

© 2020 Institute of Food Technologists®.

Publication types

- Research Support, Non-U.S. Gov't

- Bread / standards*

- Flour / standards*

- Food Handling / methods

- Food Preferences

- Food Quality

- Nutritive Value

- Triticum / genetics

Advertisement

Sensory attributes of wheat bread: a review of influential factors

- Review Paper

- Published: 23 December 2022

- Volume 17 , pages 2172–2181, ( 2023 )

Cite this article

- Neda Mollakhalili-meybodi 1 , 2 ,

- Zhaleh Sheidaei 3 ,

- Nasim khorshidian 4 ,

- Amene Nematollahi ORCID: orcid.org/0000-0001-8643-7745 5 &

- Elham khanniri 3

778 Accesses

4 Citations

Explore all metrics

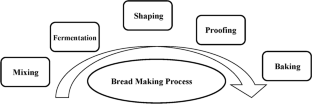

Bread is one of the main bakery products which is consumed all over the world in large amounts. It has specific role in nutrition and providing energy to human, due to possessing macronutrients like carbohydrates and proteins as well as micronutrients including iron, calcium and group B’ vitamins. In spite of high global production of bread, there is extensive extent of wheat bread waste (due to adverse organoleptic properties resulted from microbial activities and physical changes) in most of countries during production and consumption stages. Bread staling and unpleasant taste (flavor and odor) are opposes with consumer preferences, which cause to bread waste. Actually, consumers are considered as the most suitable tool to determine ending time of bread shelf life. Descriptive analysis and hedonic scale methods are commonly used in evaluation of sensory properties of bread including texture and flavor and its overall liking, respectively. In this regard, this article aims to review the influential factors on sensory attributes of wheat bread considering both the formulation and processing steps. Some attributes like flavor, freshness, volume, texture and color considerably influence the total perception of wheat bread. The formulation and processing steps (mixing, kneading, fermentation and baking) are dramatically influence the sensory properties of final wheat bread.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Effect of pseudo cereal flours on some physical, chemical and sensory properties of bread

Nermin Bilgiçli & Şenol İbanoğlu

Functional characterization of whole wheat flours for chapatti quality and acceptability

Manju Kundu, Bhupendar Singh Khatkar, … Rajesh Kumar

Influence of adding rice bran on physio-chemical and sensory properties of bread

Ngoc Thuc Trinh Doan, Quoc Dat Lai, … Hoang Dzung Nguyen

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

D. Sarica, V. Demircan, A. Erturk, N. Arslantas, Br. Food J. (2020)

B. Demirtaş, A. Kaya, E. Dağıstan, Turk. J. Agric. Food Sci. Technol. 6 (11), 1653–1661 (2018)

Google Scholar

D.N. Mtelisi, F. Xu, R. Zhao, Grain Oil Sci. Technol. (2020)

Y. Dong, S. Karboune, Compr. Rev. Food Sci. Food Saf. 20 (2), 1937–1981 (2021)

Article CAS PubMed Google Scholar

C. Chairy, C. Raharja, J. Syahrivar, M. Ekananda, Int. Rev. Public. Nonprofit Mark. 17 (4), 391–407 (2020)

Article Google Scholar

P. Brancoli, M. Lundin, K. Bolton, M. Eriksson, Resour. Conserv. Recy 147 , 128–136 (2019)

E. Goryńska-Goldmann, M. Gazdecki, K. Rejman, J. Kobus-Cisowska, S. Łaba, and R. Łaba, Agric. 11 (1), 19 (2021)

H. Lai, T. Lin, Bakery Products. In “Handbook of food Science, Technology and Engineering,” ed. By YH Hui (CRC press, 2006)

M. Salehifar, M. Ardebili, M. Azizi, Food Sci. Technol. (Campinas) 30 , 833–837 (2010)

S.M. Asim, A. Ahmed, R.M. Amir, M. Nadeem, J. Food Process Preserv. 42 (7), 13670 (2018)

G. Mueen-ud-Din, F.M. Anjum, H. Nawaz, M.A. Murtaza, Int. J. Nutr. Food Eng. 4 (8), 668–674 (2010)

H. Boz, M.M. Karaoğlu, Czech J. Food Sci. 31 (5), 457–466 (2013)

A. Benayad, M. Taghouti, A. Benali, Y. Aboussaleh, N. Benbrahim, Saudi J. Biol. Sci. 28 (1), 635–642 (2021)

D. Guardado-Félix, M.A. Lazo-Vélez, E. Pérez-Carrillo, D.E. Panata-Saquicili, S.O. Serna-Saldívar, LWT 129 , 109517 (2020)

M. Mashayekh, M.R. Mahmoodi, M.H. Entezari, Int. J. Food Sci. Technol. 43 (9), 1693–1698 (2008)

Article CAS Google Scholar

M. Beck, M. Jekle, T. Becker, J. Sci. Food Agric. 92 (3), 585–592 (2012)

M.C. Belz, L.A. Ryan, E.K. Arendt, Crit. Rev. Food Sci. Nutr. 52 (6), 514–524 (2012)

M. Hernandez-Lopez, J. Prieto, F. Randez-Gil, Antonie van Leeuwenhoek. 84 (2), 125–134 (2003)

A. Pasqualone, F. Caponio, M.A. Pagani, C. Summo, V.M. Paradiso, Food Chem. 289 , 575–581 (2019)

E. Lynch, F. Dal Bello, E. Sheehan, K. Cashman, E. Arendt, Food Res. Int. 42 (7), 885–891 (2009)

C.J. Wyatt, K. Ronan, J. Food Sci. 47 (2), 672–673 (1982)

A. Raffo, M. Carcea, E. Moneta, V. Narducci, S. Nicoli, M. Peparaio, F. Sinesio, V. Turfani, J. Cereal Sci. 79 , 518–526 (2018)

R. Spies, Application of rheology in the bread industry, Dough Rheology and Baked Product Texture. 1990, Springer. pp. 343–361

G. Roudaut, C. Dacremont, M. Le Meste, J. Texture Stud. 29 (2), 199–213 (1998)

M. Mastromatteo, M. Guida, A. Danza, J. Laverse, P. Frisullo, V. Lampignano, M.A. Del Nobile, Food Res. Int. 51 (2), 458–466 (2013)

N. Avramenko, R. Tyler, M. Scanlon, P. Hucl, M. Nickerson, Food Rev. Int. 34 (3), 204–225 (2018)

S.M. Mohsen, M.H. Aly, A.A. Attia, D.B. Osman, J. Appl. Environ. Microbiol. 4 (2), 39–45 (2016)

CAS Google Scholar

C.G. Rizzello, A. Lorusso, M. Montemurro, M. Gobbetti, Food Microbiol. 56 , 1–13 (2016)

K. Katina, Sourdough: a tool for the improved flavour, texture and shelf-life of wheat bread, vol. 569 (VTT Publications, 2005)

L. Sun, X. Li, Y. Zhang, W. Yang, G. Ma, N. Ma, Q. Hu, F. Pei, Food Control. 109 , 106914 (2020)

E. Stribiţcaia, E.M. Krop, R. Lewin, M. Holmes, A. Sarkar, Food Hydrocoll. 104 , 105692 (2020)

C.W. Bamforth, D.J. Cook, Food, Fermentation, and micro-organisms, John Wiley & Sons, 2019

A. Cappelli, L. Bettaccini, E. Cini, Trends Food Sci. Technol. 104 , 91–101 (2020)

T. C.I.S.S, H.C.F. Sleep, W.U. Loss, G.H.N. Lean, H.N. More, G.R.V.V. More, F.S. Naturally, M.M.P. Cure, C.S.F. Cream, Forever, B.R.S. Kit, Energy (kcal). 329 (216.0), 216.0

N.M. Almoraie, Int. J. Food Sci. 2019, 5676205 (2019)

G. Zehentbauer, W. Grosch, J. Cereal Sci. 28 (1), 81–92 (1998)

J.D. Kouassi-Koffi, A. Sturza, A. Paucean, S. Man, A.E. Muresan, G. Petrut, V. Muresan, S. Muste, Food Sci. Technol. 39 , 127–133 (2018)

A.M. Miguel, T.S. Martins-Meyer, E. Figueiredo, B.W.P. Lobo, and G.M. Dellamora-Ortiz, Food Indust. 278–321 (2013)

K. Pourmohammadi, E. Abedi, Food Chem. 356 , 129679–129679 (2021)

H. Xiang, D. Sun-Waterhouse, G.I. Waterhouse, C. Cui, Z. Ruan, Food Sci. Human Well 8 (3), 203–243 (2019)

R.S. Chavan, S.R. Chavan, Compr. Rev. Food Sci. Food Saf. 10 (3), 169–182 (2011)

L.A. Hazelwood, J.-M. Daran, A.J. Van Maris, J.T. Pronk, J.R. Dickinson, Appl. Environ. Microbiol. 74 (8), 2259–2266 (2008)

Article CAS PubMed PubMed Central Google Scholar

W. da Silva Cotrim, V.P.R. Minim, L.B. Felix, L.A. Minim, J. Food Eng. 277 , 109916 (2020)

S.P. Cauvain, Breadmaking: An overview, in Breadmaking: Improving quality, Second Edition. 2012. p. 9–31

L.A.D. Aguiar, D.B. Rodrigues, V.A.V. Queiroz, L. Melo, L.D.L.D.O. Pineli, Food Res. Int. 131 (2020)

P. Bandara, P. Arampath, Trop. Agric. Res. 31 (3), 25–36 (2020)

S. Nawaratne, Trop. Agric. Res. Extension. 10 (2010)

M.J. Callejo, M.E. Vargas-Kostiuk, M. Rodríguez-Quijano, J. Cereal Sci. 61 , 55–62 (2015)

G.V. Civille, B.T. Carr, Sensory Evaluation Techniques (CRC Press, Boca Raton, 2015)

Book Google Scholar

S. Protonotariou, P. Stergiou, M. Christaki, I.G. Mandala, Food Chem. 318 , (2020)

H.S. Kwak, M.J. Kim, S.S. Kim, J. Sens. Stud. 34 (2), e12487 (2019)

A. Hoehnel, J. Bez, I.L. Petersen, R. Amarowicz, J. Juśkiewicz, E.K. Arendt, E. Zannini, Food Func. 11 (5), 4732–4751 (2020)

K.L. Zook, J.H. Pearce, Quantitative descriptive analysis, Applied sensory analysis of foods (Routledge, Abingdon, 2018), pp.43–71

B.S. Kamel, C.E. Stauffer, Advances in Baking Technology (Springer, 2013)

C. Gonzalez Viejo, S. Fuentes, K. Howell, D.D. Torrico, F.R. Dunshea, Physiol. Behav. 200 , 139–147 (2019)

D.D. Torrico, S.C. Hutchings, M. Ha, E.P. Bittner, S. Fuentes, R.D. Warner, F.R. Dunshea, Meat Sci. 144 , 30–42 (2018)

Article PubMed Google Scholar

E.A. Esmerino, J.A. Paixão, A.G. Cruz, L. Garitta, G. Hough, H.M.A. Bolini, J. Dairy. Sci. 98 (11), 7544–7551 (2015)

S. Nasir, F.M. Allai, M. Gani, S. Ganaie, K. Gul, A. Jabeen, D. Majeed, J. Food Sci. (2020). https://doi.org/10.1155/2020/8874872

S. Kowalski, A. Mikulec, H. Pustkowiak, Pol. J. Food Nutr. Sci. 70 (4), 387–397 (2020)

N.O. Eddy, P.G. Udofia, D. Eyo, Afr. J. Biotechnol. 6 (20), 2415–2418 (2007)

Download references

Acknowledgements

The authors would like to thank the Fasa University of Medical Sciences supported this study (IR.FUMS.REC.1400.055).

This study was supported by Fasa University of Medical Sciences, grant No. 400064.

Author information

Authors and affiliations.

Department of Food Sciences and Technology, School of Public Health, Shahid Sadoughi University of Medical Sciences, Yazd, Iran

Neda Mollakhalili-meybodi

Research Center for Food Hygiene and Safety, Shahid Sadoughi University of Medical Sciences, Yazd, Iran

Department of Food Technology, Faculty of Nutrition Sciences and Food Technology/National Nutrition and Food Technology Research Institute, Shahid Beheshti University of Medical Sciences, Tehran, Iran

Zhaleh Sheidaei & Elham khanniri

Department of Food Technology Research, National Nutrition and Food Technology Research Institute, Shahid Beheshti University of Medical Sciences, Tehran, Iran

Nasim khorshidian

Department of Food Safety and Hygiene, School of Health, Fasa University of Medical Sciences, Fasa, Iran

Amene Nematollahi

You can also search for this author in PubMed Google Scholar

Corresponding authors

Correspondence to Amene Nematollahi or Elham khanniri .

Ethics declarations

Conflict of interest.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to participate:

Not applicable.

Consent for publication

Additional information, publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Mollakhalili-meybodi, N., Sheidaei, Z., khorshidian, N. et al. Sensory attributes of wheat bread: a review of influential factors. Food Measure 17 , 2172–2181 (2023). https://doi.org/10.1007/s11694-022-01765-9

Download citation

Received : 30 August 2021

Accepted : 09 December 2022

Published : 23 December 2022

Issue Date : June 2023

DOI : https://doi.org/10.1007/s11694-022-01765-9

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Find a journal

- Publish with us

- Track your research

- Search Menu

- Advance articles

- Darwin Reviews

- Special Issues

- Expert View

- Flowering Newsletter Reviews

- Technical Innovations

- Editor's Choice

- Virtual Issues

- Community Resources

- Reasons to submit

- Author Guidelines

- Peer Reviewers

- Submission Site

- Open Access

- About Journal of Experimental Botany

- About the Society for Experimental Biology

- Editorial Board

- Advertising and Corporate Services

- Journals Career Network

- Permissions

- Self-Archiving Policy

- Dispatch Dates

- Journal metrics

- Journals on Oxford Academic

- Books on Oxford Academic

Article Contents

Introduction, origin and evolution of wheat, cultivated wheats today, why has wheat been so successful, wheat gluten proteins and processing properties, wheat in nutrition and health, adverse reactions to wheat, the future for wheat.

- < Previous

- Article contents

- Figures & tables

- Supplementary Data

P. R. Shewry, Wheat, Journal of Experimental Botany , Volume 60, Issue 6, April 2009, Pages 1537–1553, https://doi.org/10.1093/jxb/erp058

- Permissions Icon Permissions

Wheat is the dominant crop in temperate countries being used for human food and livestock feed. Its success depends partly on its adaptability and high yield potential but also on the gluten protein fraction which confers the viscoelastic properties that allow dough to be processed into bread, pasta, noodles, and other food products. Wheat also contributes essential amino acids, minerals, and vitamins, and beneficial phytochemicals and dietary fibre components to the human diet, and these are particularly enriched in whole-grain products. However, wheat products are also known or suggested to be responsible for a number of adverse reactions in humans, including intolerances (notably coeliac disease) and allergies (respiratory and food). Current and future concerns include sustaining wheat production and quality with reduced inputs of agrochemicals and developing lines with enhanced quality for specific end-uses, notably for biofuels and human nutrition.

Wheat is counted among the ‘big three’ cereal crops, with over 600 million tonnes being harvested annually. For example, in 2007, the total world harvest was about 607 m tonnes compared with 652 m tonnes of rice and 785 m tonnes of maize ( http://faostat.fao.org/ ). However, wheat is unrivalled in its range of cultivation, from 67º N in Scandinavia and Russia to 45º S in Argentina, including elevated regions in the tropics and sub-tropics ( Feldman, 1995 ). It is also unrivalled in its range of diversity and the extent to which it has become embedded in the culture and even the religion of diverse societies.

Most readers will be aware of the significance of bread in the Judaeo-Christian tradition including the use of matzo (hard flat bread) at the Jewish Passover and of bread to represent the ‘host’ at the Christian Eucharist (Holy Communion). The latter may be a thin unleavened wafer, similar to the Jewish matzo, in the Roman Catholic Church and some Protestant denominations, or leavened in other Protestant denominations and the Eastern Orthodox Church. But how many readers are aware that bread is treated as sacred in everyday life in the largely Muslim communities of Central Asia, such as Uzbekistan and Kyrgyzstan? In this culture, the leavened round breads (nan) are stamped before baking and must be treated with respect, including being kept upright and never left on the ground or thrown away in public. These customs almost certainly originate from earlier indigenous religions in the Middle East in which wheat played a similar role and was sometimes equated with the sun and its god.

Although such cultural and religious traditions are fascinating and will certainly reward further study, they are essentially outside the scope of this article which will examine why wheat has developed and continues to be so successful as a crop and food source.

The first cultivation of wheat occurred about 10 000 years ago, as part of the ‘Neolithic Revolution’, which saw a transition from hunting and gathering of food to settled agriculture. These earliest cultivated forms were diploid (genome AA) (einkorn) and tetraploid (genome AABB) (emmer) wheats and their genetic relationships indicate that they originated from the south-eastern part of Turkey ( Heun et al. , 1997 ; Nesbitt, 1998 ; Dubcovsky and Dvorak, 2007 ). Cultivation spread to the Near East by about 9000 years ago when hexaploid bread wheat made its first appearance ( Feldman, 2001 ).

The earliest cultivated forms of wheat were essentially landraces selected by farmers from wild populations, presumably because of their superior yield and other characteristics, an early and clearly non-scientific form of plant breeding! However, domestication was also associated with the selection of genetic traits that separated them from their wild relatives. This domestication syndrome has been discussed in detail by others, but two traits are of sufficient importance to mention here. The first is the loss of shattering of the spike at maturity, which results in seed loss at harvesting. This is clearly an important trait for ensuring seed dispersal in natural populations and the non-shattering trait is determined by mutations at the Br ( brittle rachis ) locus ( Nalam et al. , 2006 ).

The second important trait is the change from hulled forms, in which the glumes adhere tightly to the grain, to free-threshing naked forms. The free forms arose by a dominant mutant at the Q locus which modified the effects of recessive mutations at the Tg ( tenacious glume ) locus ( Jantasuriyarat et al. , 2004 ; Simons et al. , 2006 ; Dubkovsky and Dvorak, 2007 ).

Cultivated forms of diploid, tetraploid, and hexaploid wheat all have a tough rachis apart from the spelt form of bread wheat. Similarly, the early domesticated forms of einkorn, emmer, and spelt are all hulled, whereas modern forms of tetraploid and hexaploid wheat are free-threshing.

Whereas einkorn and emmer clearly developed from the domestication of natural populations, bread wheat has only existed in cultivation, having arisen by hybridization of cultivated emmer with the unrelated wild grass Triticum tauschii (also called Aegilops tauschii and Ae . squarosa ). This hybridization probably occurred several times independently with the novel hexaploid (genome AABBDD) being selected by farmers for its superior properties. The evolution of modern wheats is illustrated in Fig. 1 which also shows examples of spikes and grain.

The evolutionary and genome relationships between cultivated bread and durum wheats and related wild diploid grasses, showing examples of spikes and grain. Modified from Snape and Pánková (2006) , and reproduced by kind permission of Wiley-Blackwell.

The genetic changes during domestication mean that modern wheats are unable to survive wild in competition with better adapted species. This was elegantly demonstrated by John Bennet Lawes in the 1880s when he decided to allow part of the famous long-term Broadbalk experiment at Rothamsted to return to its natural state ( Dyke, 1993 ). He therefore left part of the wheat crop unharvested in 1882 and monitored the growth in successive years. After a good crop in 1883 the weeds dominated and in 1885 the few remaining wheat plants (which were spindly with small ears) were collected and photographed.

The A genomes of tetraploid and hexaploid wheats are clearly related to the A genomes of wild and cultivated einkorn, while the D genome of hexaploid wheat is clearly derived from that of T . tauschii . In fact, the formation of hexaploid wheat occurred so recently that little divergence has occurred between the D genomes present in the hexaploid and diploid species. By contrast, the B genome of tetraploid and hexaploid wheats is probably derived from the S genome present in the Sitopsis section of Aegilops , with Ae . speltoides being the closest extant species. The S genome of Ae . speltoides is also closest to the G genome of T . timopheevi , a tetraploid species with the A and G genomes ( Feldman, 2001 ).

The spread of wheat from its site of origin across the world has been elegantly described by Feldman (2001) and is only summarized here. The main route into Europe was via Anatolia to Greece (8000 BP) and then both northwards through the Balkans to the Danube (7000 BP) and across to Italy, France and Spain (7000 BP), finally reaching the UK and Scandanavia by about 5000 BP. Similarly, wheat spread via Iran into central Asia reaching China by about 3000 BP and to Africa, initially via Egypt. It was introduced by the Spaniards to Mexico in 1529 and to Australia in 1788.

Currently, about 95% of the wheat grown worldwide is hexaploid bread wheat, with most of the remaining 5% being tetraploid durum wheat. The latter is more adapted to the dry Mediterranean climate than bread wheat and is often called pasta wheat to reflect its major end-use. However, it may also be used to bake bread and is used to make regional foods such as couscous and bulgar in North Africa. Small amounts of other wheat species (einkorn, emmer, spelt) are still grown in some regions including Spain, Turkey, the Balkans, and the Indian subcontinent. In Italy, these hulled wheats are together called faro ( Szabó and Hammer, 1996 ) while spelt continues to be grown in Europe, particularly in Alpine areas ( Fossati and Ingold, 2001 ).

The recent interest in spelt and other ancient wheats (including kamut, a tetraploid wheat of uncertain taxonomy, related to durum wheat) as healthy alternatives to bread wheat ( Abdel-Aal et al. , 1998 ) may also lead to wider growth for high value niche markets in the future.

Despite its relatively recent origin, bread wheat shows sufficient genetic diversity to allow the development of over 25 000 types ( Feldman et al. , 1995 ) which are adapted to a wide range of temperate environments. Provided sufficient water and mineral nutrients are available and effective control of pests and pathogens is ensured, yields can exceed 10 tonnes ha −1 , comparing well with other temperate crops. However, deficiencies in water and nutrients and the effects of pests and pathogens cause the global average yield to be low, at about 2.8 tonnes ha −1 . Wheat is also readily harvested using mechanical combine harvesters or traditional methods and can be stored effectively indefinitely before consumption, provided the water content is below about 15% dry weight and pests are controlled.

There is no doubt that the adaptability and high yields of wheat have contributed to its success, but these alone are not sufficient to account for its current dominance over much of the temperate world. The key characteristic which has given it an advantage over other temperate crops is the unique properties of doughs formed from wheat flours, which allow it to be processed into a range of breads and other baked products (including cakes and biscuits), pasta and noodles, and other processed foods. These properties depend on the structures and interactions of the grain storage proteins, which together form the ‘gluten’ protein fraction.

Transcriptomic studies have shown that over 30 000 genes are expressed in the developing wheat grain ( Wan et al. , 2008 ) while proteomic analysis of mature grain has revealed the presence of about 1125 individual components ( Skylas et al. , 2000 ). However, many of these components are present in small amounts and have little or no impact on the utilization of the grain, with one protein fraction being dominant in terms of amount and impact. This fraction is the prolamin storage proteins, which correspond to the gluten proteins. The precise number of individual gluten protein components has not been determined, but 2D gel analyses suggest that about 100 is a reasonable estimate. Together they have been estimated to account for about 80% of the total grain protein in European wheats ( Seilmeier et al. , 1991 ).

Gluten was one of the earliest protein fractions to be described by chemists, being first described by Beccari in 1728 (see translation by Bailey, 1941 ). It is traditionally prepared by gently washing wheat dough in water or dilute salt solution, leaving a cohesive mass which comprises about 80% protein, the remainder being mainly starch granules which are trapped in the protein matrix.

The ability to prepare the gluten proteins in an essentially pure state by such a simple procedure depends on their unusual properties. Firstly, they are insoluble in water or dilute salt solutions but are soluble in alcohol/water mixtures (as discussed below) and were hence defined as ‘prolamins’ by TB Osborne in his classic studies of plant proteins carried out at the end of the 19th century and the start of the 20th century ( Osborne, 1924 ). Secondly, the individual gluten proteins are associated by strong covalent and non-covalent forces which allow the whole fraction to be isolated as a cohesive mass.

What is the origin of gluten?

In common with other seed storage proteins, the gluten proteins are secretory proteins, being synthesized on the rough endoplasmic reticulum and co-translationally transported into the lumen of the ER. Once within the ER lumen, cereal seed storage proteins may follow two routes: a Golgi-dependent route leading to deposition within protein bodies of vacuolar origin or a Golgi-independent route in which protein deposits formed within the ER lumen may ultimately fuse with protein bodies of vacuolar origin (see Kumamaru et al. , 2007 , for a review).

Work carried out by Galili and colleagues ( Levanany et al. , 1992 ; Galili et al. , 1995 ; Galili, 1997 ) indicated that wheat gluten proteins may follow both routes, and this has recently been confirmed using epitope tags and specific antibodies to follow individual proteins and groups of proteins in cells of developing grain ( Tosi et al. , 2009 ). It is also clear that the protein deposits fuse to form a continuous matrix as the cells of the starchy endosperm dry and die during the later stages of grain maturation ( Fig. 2A ). Thus a proteinaceous network is present in each endosperm cell ( Fig. 2B ) and these networks are brought together when flour is mixed with water to form a continuous network in the dough. Washing the dough to remove non-gluten components therefore allows the network to be recovered as the cohesive mass which is called gluten ( Fig. 2C ).

The origin of wheat gluten. (A) Transmission electron microscopy of the developing starchy endosperm cells at 46 d after anthesis shows that the individual protein bodies have fused to form a continuous proteinaceous matrix. Taken from Shewry et al. , 1995 , ( Biotechnology 13, 1185–1190) and provided by Dr M Parker (IFR, Norwich, UK). (B) Digestion of a flour particle with amylases to remove starch reveals a continuous proteinaceous network. Taken from Amend and Beauvais (1995) and reproduced by kind permission of Getreidetechnologie. (C) After kneading, dough can be washed to recover the gluten network as a cohesive mass which is stretched in the photograph to demonstrate its viscoelastic properties.

The biochemical and molecular basis for gluten functionality

Humankind has been aware for many centuries that wheat dough has unusual properties which are shared to a limited extent by doughs made from rye flour but not by those from other cereal flours. These properties, which are usually described as ‘viscoelasticity’, are particularly important in making leavened bread, as they allow the entrapment of carbon dioxide released during leavening. However, they also underpin a range of other uses including making unleavened breads, cakes, and biscuits, pasta (from durum wheat), and noodles (from bread wheat). They are also exploited in the food industry where gluten proteins may be used as a binder in processed foods.

The volume of research carried out on wheat gluten is vast, with a simple search of the Web of Science database showing almost 20 000 papers since 1945. This volume not only reflects the commercial importance of wheat processing, but also the complexity of the system which remains incompletely understood. They include studies at the genetic, biochemical, biophysical, and functional (ie processing) levels.

Genetic studies have exploited the extensive polymorphism which exists between the gluten protein fractions present in different genotypes to establish genetic linkages between either groups of gluten proteins, or allelic forms of these, and aspects of processing quality. Similarly, studies at the biochemical and biophysical levels have demonstrated a relationship between dough strength and the ability of the gluten proteins to form polymeric complexes (called glutenins). Combining results from these two approaches highlighted the importance of a specific group of gluten proteins, called the high molecular weight (HMW) subunits of glutenin.

Cultivars of bread wheat express between three and five HMW subunit genes, with the encoded proteins accounting for up to about 12% of the total grain protein ( Seilmeier et al. , 1991 ; Halford et al. , 1992 ). The HMW subunits are only present in high molecular mass polymers and allelic variation in both the number of expressed genes and the properties of the encoded proteins results in effects on the amount and size of the polymers and hence dough strength (reviewed by Payne, 1987 ; Shewry et al. , 2003 b ). These glutenin polymers are known to be stabilized by inter-chain disulphide bonds, but it is apparent that non-covalent hydrogen bonds are also important in stabilizing the interactions between glutenin polymers and monomeric gluten proteins (called gliadins) ( Belton, 2005 ). Hence, the individual gliadins and glutenin polymers can be separated using solvents which disrupt hydrogen bonding (such as urea) but reducing agents (such as 2-mercaptoethanol or dithiothreitol) are required to break down the glutenin polymers to release the individual subunits.

Although the HMW subunits are the main determinants of glutenin elasticity relationships between other gluten proteins and functional properties have also been reported (reviewed by Shewry et al. , 2003 a ).

The relationship between the HMW subunits and dough strength was first established over 25 years ago ( Payne et al. , 1979 ) and allelic forms associated with good processing quality have been selected by plant breeders for over two decades, using simple SDS-PAGE separations. The established relationships between the number of expressed HMW subunit genes, the total amount of HMW subunit protein and dough strength have also resulted in the HMW subunit genes being an attractive target for genetic transformation, in order to increase their gene copy number and hence dough strength.

The first studies of this type were reported over 10 years ago ( Altpeter et al. , 1996 ; Blechl and Anderson, 1996 ; Barro et al. , 1997 ) and many studies have since been reported (reviewed by Shewry and Jones, 2005 ; Jones et al. , 2009 ). It is perhaps not surprizing that the results have been ‘mixed’, but some conclusions can be drawn. Firstly, expression of an additional HMW subunit gene can lead to increased dough strength, even when a modern good quality wheat cultivar is used as the recipient (see Field et al. , 2008 ; Rakszegi et al. , 2008 , as recent examples, and reviews of earlier work cited above). However, the effect depends on the precise HMW subunit gene which is used and on the expression level, with the transgenes resulting in over-strong (ie too elastic) gluten properties in some studies. Thus, although transgenesis is a realistic strategy to increase dough strength in wheat, it is also necessary to have an understanding of the underlying mechanisms in order to optimize the experimental design.

Wheat is widely consumed by humans, in the countries of primary production (which number over 100 in the FAO production statistics for 2004) and in other countries where wheat cannot be grown. For example, imported wheat is used to meet consumer demands for bread and other food products in the humid tropics, particularly those with a culinary tradition dating back to colonial occupation. Statistics are not available for the total volume of wheat which is consumed directly by humans as opposed to feeding livestock, although figures for the UK indicate about one-third of the total production (approximately 5.7 m tonnes per annum are milled with home production being 15–16 m tonnes). Globally there is no doubt that the number of people who rely on wheat for a substantial part of their diet amounts to several billions.

The high content of starch, about 60–70% of the whole grain and 65–75% of white flour, means that wheat is often considered to be little more than a source of calories, and this is certainly true for animal feed production, with high-yielding, low-protein feed varieties being supplemented by other protein-rich crops (notably soybeans and oilseed residues).

However, despite its relatively low protein content (usually 8–15%) wheat still provides as much protein for human and livestock nutrition as the total soybean crop, estimated at about 60 m tonnes per annum (calculated by Shewry, 2000 ). Therefore, the nutritional importance of wheat proteins should not be underestimated, particularly in less developed countries where bread, noodles and other products (eg bulgar, couscous) may provide a substantial proportion of the diet.

Protein content

Although wheat breeders routinely select for protein content in their breeding programmes (high protein for breadmaking and low protein for feed and other uses), the current range of variation in this parameter in commercial cultivars is limited. For example, Snape et al. (1993) estimated that typical UK breadmaking and feed wheats differed in their protein content by about 2% dry weight (eg from about 12–14% protein) when grown under the same conditions, which is significantly less than the 2-fold differences which can result from high and low levels of nitrogen fertilizer application. This limited variation in conventional wheat lines has led to searches for ‘high protein genes’ in more exotic germplasm.

Early studies of the USDA World Wheat Collection showed approximately 3-fold variation in protein content (from 7–22%), with about one-third of this being under genetic control ( Vogel et al. , 1978 ). However, the strong environmental impact on protein content (accounting for two-thirds of the variation) underpins the difficulty of breeding for this trait. Nevertheless, some success has been achieved by incorporating sources of variation from exotic bread wheat lines or related wild species.

The former include Atlas 50 and Atlas 66, derived from the South American line Frandoso, and Nap Hal from India. These lines appear to have different ‘high protein genes’ and both were extensively used in breeding programmes in Nebraska with the Atlas 66 gene being successfully incorporated into the commercial variety Lancota ( Johnson et al. , 1985 ). Frandoso and related Brazilian lines have also been successfully exploited in other breeding programmes in the USA ( Busch and Rauch, 2001 ). The Kansas variety, Plainsman V, also contained a high protein gene(s) from a related Aegilops species ( Finney, 1978 ).

The most widely studied source of ‘high protein’ is wild emmer (tetraploid Tr . turgidum var. dicoccoides ) wheats from Israel. One accession, FA15-3, accumulates over 40% of protein when grown with sufficient nitrogen ( Avivi, 1978 ). The gene in this line was mapped to a locus on chromosome 6B (called Gpc-B1 ), which accounted for about 70% of the variation in protein content in crosses ( Chee et al. , 2001 ; Distelfeld et al. , 2004, 2006 ). More recent studies have shown that the gene Gpc-B1 encodes a transcription factor which accelerates senescence in the vegetative parts of the plant, resulting in increased mobilization and transfer to the grain of both nitrogen and minerals (notably iron and zinc) ( Uauy et al. , 2006 ). However, it remains to be shown whether this gene can be incorporated into high-yielding and commercially viable lines.

Protein composition

Of the 20 amino acids commonly present in proteins, 10 can be considered to be essential in that they cannot be synthesized by animals and must be provided in the diet. Furthermore, if only one of these is limiting the others will be broken down and excreted. There has been much debate about which amino acids are essential and the amounts that are required, with the most recent values for adult humans being shown in Table 1 . This table includes a combined value for the two aromatic amino acids, tyrosine and phenylalanine, which are biosynthetically related, and both single and combined values for the two sulphur-containing amino acids: methionine, which is truly essential, and cysteine which can be synthesized from methionine. Comparison with the values for whole wheat grain and flour shows that only lysine is deficient, with some essential amino acids being present in considerably higher amounts than the requirements. However, the lysine content of wheat also varies significantly with the values shown in Table 1 being typical of grain of high protein content and the proportion increasing to over 30 mg g −1 protein in low protein grain ( Mossé and Huet, 1990 ). This decrease in the relative lysine content of high protein grain results from proportional increases in the lysine-poor gluten proteins when excess N is available (for example, when fertilizer is applied to increase grain yield and protein content) and also accounts for the lower lysine content of the white flour (the gluten proteins being located in the starchy endosperm tissue).

Recommended levels of essential amino acids for adult humans compared with those in wheat grain and flour (expressed as mg g −1 protein)

FAO/WHO/UNU (2007) .

Calculated from literature values as described in Shewry (2007) .

The amino acid requirements for infants and children vary depending on their growth rate, being particularly high in the first year of life. Similarly, higher levels of essential amino acids are required for rapidly growing livestock such as pigs and poultry.

Wheat as a source of minerals

Iron deficiency is the most widespread nutrient deficiency in the world, estimated to affect over 2 billion people ( Stoltzfus and Dreyfuss, 1998 ). Although many of these people live in less developed countries, it is also a significant problem in the developed world. Zinc deficiency is also widespread, particularly in Sub-Saharan Africa and South Asia, and has been estimated to account for 800 000 child deaths a year (Micronutrient Initiative, 2006 ), in addition to non-lethal effects on children and adults. Wheat and other cereals are significant sources of both of these minerals, contributing 44% of the daily intake of iron (15% in bread) and 25% of the daily intake of zinc (11% in bread) in the UK ( Henderson et al. , 2007 ). There has therefore been considerable concern over the suggestion that the mineral content of modern wheat varieties is lower than that of older varieties.

This was initially suggested by Garvin et al. (2006) who grew 14 red winter wheat cultivars bred between 1873 and 2000 in replicate field experiments and determined their mineral contents. Plants were grown at two locations in Kansas and significant negative correlations were found between grain yield, variety release date, and the concentrations of zinc in material from both of these sites and of iron in materials from only one site. Similar trends were reported by Fan et al. (2008 a , b ) who took a different approach. Rather than carrying out direct comparisons of varieties in field trials, they analysed grain grown on the Rothamsted Broadbalk long-term wheat experiment. This experiment was established in 1843 and uses a single variety which is replaced by a more modern variety at regular intervals. Analysis of archived grain showed significant decreases in the contents of minerals (Zn, Fe, Cu, Mg) since semi-dwarf cultivars were introduced in 1968. A similar difference was observed between the cultivars Brimstone (semi-dwarf) and Squareheads Master (long straw) which were grown side by side in 1988–1990, the concentrations of Zn, Cu, Fe, and Mg being 18–29% lower in Brimstone. A more recent comparison of 25 lines grown also showed a decline in the concentrations of Fe and Zn since semi-dwarf wheats were introduced ( Zhao et al. , 2009 ) ( Fig. 3 ). Although the decrease in the mineral content of modern wheats is partly due to dilution, resulting from increased yield (which was negatively correlated with mineral content), it has been suggested that short-strawed varieties may be intrinsically less efficient at partitioning minerals to the grain compared with the translocation of photosynthate.

The relationship between the iron content of wholemeal flours from 25 wheat cultivars grown on six trial sites/seasons and their release dates. Taken from Zhao et al. (2009) and reproduced by kind permission of Elsevier.

Such genetic differences in mineral content are clearly relevant to international efforts to increase the mineral content of wheat to improve health in less developed countries. Thus, increasing iron, zinc, and vitamin A contents are a major focus of the HarvestPlus initiative of the Consultative Group on International Agricultural Research (CGIAR) which is using conventional plant breeding ( Ortiz-Monasterio et al. , 2007 ) while other laboratories are using genetic engineering approaches (reviewed by Brinch-Pedersen et al. , 2007 ).

These initiatives are focusing not only on contents of minerals but also on their bioavailability. Iron is predominantly located in the aleurone and as complexes with phytate ( myo -inositolphosphate 1,2,3,4,5,6-hexa-kisphosphate). These complexes are largely insoluble, restricting mineral availability to humans and livestock. The use of transgenesis to express phytase in the developing grain can result in increased mineral availability, particularly when a heat-stable form of the enzyme is used to allow hydrolysis to occur during food processing (reviewed by Brinch-Pedersen et al. , 2007 ).

Guttieri et al. (2004) also reported an EMS-induced low phytate mutant of wheat. This mutation resulted in 43% less phytic acid in the aleurone, but has not so far been incorporated into commercial cultivars. However, previous experience with low phytic acid mutants of maize, barley, and soy bean has shown that they may also have significant effects on yield and germination rates (reviewed by Brinch-Pedersen et al. , 2007 ).

Wheat as a source of selenium

Selenium is an essential micronutrient for mammals (but not plants), being present as selenocysteine in a number of enzymes. However, it is also toxic when present in excess (above about 600 μg d −1 ; Yang and Xia, 1995 ). Cereals are major dietary sources of selenium in many parts of the world, including China ( FAO/WHO, 2001 ), Russia ( Golubkina and Alfthan, 1999 ), and the UK (MAFF, 1997). However, the content of selenium in wheat varies widely from about 10 μg kg −1 to over 2000 μg kg −1 ( FAO/ WHO, 2001 ; Combs, 2001 ).

The concentration of selenium in wheat is largely determined by the availability of the element in the soil. Consequently, wheat produced in Western Europe may contain only one-tenth of the selenium that is present in wheat grown in North America. Thus, a survey of 452 grain samples grown in the UK in 1982 and 1992 showed a mean value of 27 μg Se kg −1 fresh weight ( Adams et al. , 2002 ) compared with 370 μg SE kg −1 fresh weight for 290 samples from the USA ( Wolnik et al. , 1983 ).

Because the import of wheat from North America into Europe has declined over the last 25 years, the intake of selenium in the diet has also decreased, which has resulted in concern in some European countries. One response to this is to apply selenium to the crops in fertilizer (called biofortification), which is practised in Finland ( Eurola et al. , 1991 ).

Unlike iron, selenium is not concentrated in the aleurone, being present wherever sulphur is present. The concentration of selenium in grain from the Broadbalk continuous wheat experiment also appeared to be determined principally by the sulphur availability in the soil (which competes to prevent selenium uptake), with no evidence of decreased levels over time ( Fan et al. , 2008 b ). However, sulphur fertilizer is often applied to wheat to improve the grain quality ( Zhao et al. , 1997 ) and this could clearly have negative impacts on selenium in grain.

The reader is referred to a recent review article by Hawkesford and Zhao (2007) for a detailed review of selenium in wheat.

Wholegrain wheat and health

The consumption of white flour and bread have historically been associated with prosperity and the development of sophisticated roller mills in Austro-Hungary during the second part of the 19th century allowed the production of higher volumes of whiter flour than it was possible to produce by traditional milling based on grinding between stones and sieving (see Jones, 2007 , for a fascinating account of the history of roller milling). However, the increased consumption of bread made from highly refined white flour was not accepted universally, leading to what we would today recognize as a movement to increase the consumption of wholegrain products.

In 1880, May Yates founded the Bread Reform League in London to promote a return to wholemeal bread, particularly to improve the nutrition of the children of the poor, and suggested in 1909 that an official minimum standard of 80% flour extraction rate should be adopted. This was called ‘Standard Bread’. Although we now appreciate the nutritional advantages of wholegrain products, this was not supported by the science of the time and clearly conflicted with the tastes of consumers as well as the economics of bread production. Nevertheless, the League continued to campaign and received scientific support in 1911 when Gowland Hopkins agreed that ‘Standard Bread’ may contain ‘unrecognized food substances’ which were vital for health: these were subsequently called vitamins ( Burnett, 2005 ).

By contrast, Thomas Allinson (1858–1918) had a much greater impact by marketing and vigorously promoting his own range of wholemeal products. He can therefore be regarded as the father of the wholegrain movement and remains a household name to this day in the UK ( Pepper, 1992 ).

We now know that wholegrain wheat products contain a range of components with established or proposed health benefits which are concentrated or solely located in the bran. Hence they are either present in lower amounts or absent from white flour which is derived almost exclusively from starchy endosperm cells. They vary widely in their concentrations. For example, lignans, a group of polyphenols with phytoestrogen activity, are present at levels up to about 10 μg g −1 in wholemeal wheat and twice this level in bran ( Nagy-Scholz and Ercsey, 2009 ), while total phenolic acids in wholemeal range up to almost 1200 μg g −1 ( Li et al. , 2008 ).

The most detailed study of wheat phytochemicals which has so far been reported was carried out as part of the EU Framework 6 HEALTHGRAIN programme ( Poutanen et al. , 2008 ; Ward et al. , 2008 ). This study determined a range of phytochemicals in 150 wheat lines grown on a single site in one year, meaning that the levels of the components may have been influenced by environmental as well as genetic effects. The lines were selected to represent a broad range of dates and places of origin. The choice of phytochemicals focused on those which have putative health benefits and for which cereals are recognized dietary sources. For example, cereals are considered to account for about 22% of the daily intake of folate (vitamin B12) in the UK ( Goldberg, 2003 ) and 36% and 43% of the daily intake in Finnish women and men, respectively ( Findiet Study Group, 2003 ). In the HEALTHGRAIN study the contents of folates in wholemeal varied from 364 to 774 ng g −1 dry weight in 130 winter wheats and from 323 to 741 ng g −1 dry weight in 20 spring wheats, with the content in the former being positively correlated with bran yield and negatively correlated with seed weight (indicating concentration in the bran) ( Piironen et al. , 2008 ).

The quantitatively major group of phytochemicals in the wheat grain is phenolic acids, derivatives of either hydroxybenzoic acid or hydroxycinnamic acid. Epidemiological studies indicate that phenolic acids have a number of health benefits which may relate to their antioxidant activity; the total antioxidant activities of grain extracts and their phenolic acid contents being highly correlated ( Drankham et al. , 2003 ; Beta et al. , 2005 ; Wende et al. , 2005 ).

Cereals are also significant sources of tocols (which include vitamin E) (27.6–79.7 μg g −1 in the HEALTHGRAIN study) ( Lampi et al. , 2008 ) and sterols (670–959 μg g −1 ) ( Nurmi et al. , 2008 ).

The HEALTHGRAIN study also determined the levels of dietary fibre. In wheat, this mainly derives from cell wall polymers: arabinoxylans (approximately 70%) with lower amounts of (1-3)(1-4)β- D -glucans (approximately 20%) and other components. The arabinoxylans also occur in soluble and insoluble forms, with the latter being rich in bound phenolic acids which form oxidative cross-links. These bound phenolic acids account, on average, for 77% of the total phenolic acid fraction and are predominantly ferulic acid. Soluble fibre is considered to have health benefits ( Moore et al. , 1998 ; Lewis and Heaton, 1999 ) which are not shared by insoluble fibre and these may therefore be reduced by the phenolic acid cross-linking. However, insoluble fibre may also have benefits in delivering phenolic antioxidants into the colon: these benefits may include reduction in colo-rectal cancer ( Vitaglione et al. , 2008 ).

The HEALTHGRAIN study showed wide variation in the contents of total and water-extractable arabinoxylans in both white flour and bran fractions ( Gebruers et al. , 2008 ) ( Fig. 4 ). Similarly, Ordaz-Ortiz et al. (2005) showed variation from 0.26% to 0.75% dry weight in the content of water-extractable arabinoxylan in 20 French wheat lines and from 1.66% to 2.87% dry weight in total arabinoxylans. A high proportion of the variation in water-extractable arabinoxylans is also heritable ( Martinant et al. , 1999 ).

Contents of arabinoxylan (AX) fibre in flour and bran of 150 wheat cultivars grown on a single site as part of the EU FP6 HEALTHGRAIN project. (A) Total AX in flour (mg g −1 ); (B) water-extractable AX in flour (%); (C) total AX in bran (mg g −1 ), and (D) water-extractable AX in bran. Prepared from data reported by Gebruers et al. (2008) with permission of the authors.

It is clear from these and other studies that there is sufficient genetically determined variation in the phytochemical and fibre contents of wheat to be exploited in breeding for varieties with increased nutritional benefits.

Allergy to wheat

Both respiratory and food allergies to wheat have been reported.

Respiratory allergy (bakers' asthma) has been known since Roman times (when slaves handling flour and dough were required to wear masks) and is currently one of the most important forms of occupational allergy. For example, it is the second most widespread occupational allergy in the UK and has been reported to affect over 8% of apprentice bakers in Poland after only 2 years exposure ( Walusiak et al. , 2004 ). A wide range of wheat grain proteins have been shown to react with immunoglobulin (Ig)E in sera of patients with bakers' asthma, including gliadins, glutenins, serpins (serine proteinase inhibitors), thioredoxin, agglutinin, and a number of enzymes (α- and β-amylases, peroxidase, acyl CoA oxidase, glycerinaldehyde-3-phosphate dehydrogenase and triosephosphate isomerase) (reviewed by Tatham and Shewry, 2008 ). However, it is clear that the predominant wheat proteins responsible for bakers' asthma are a class of α-amylase inhibitors, also known as CM proteins due to their solubility in chloroform:methanol mixtures ( Salcedo et al. , 2004 ). Furthermore, their activity has been demonstrated by a range of approaches including skin pricks and RAST (radioallergosorbent test) as well as immunoblotting, ELISA, and screening expression libraries with IgE fractions.

The CM proteins comprise monomeric, dimeric, and tetrameric forms, with subunit masses ranging between about 10 000 and 16 000. They differ in their spectrum of activity but all inhibit mammalian and insect α-amylases (including those in some pest organisms) rather than endogenous wheat enzymes. Hence, they are considered to be protective rather than regulatory in function. Eleven individual subunits have been shown to play a role in bakers' asthma (using one or more of the assays listed above) but they differ in their activity, with a glycosylated form of CM16 being particularly active.

Wheat is listed among the ‘big eight’ food allergens which together account for about 90% of all allergic responses. However, the incidence of true (ie IgE-mediated) food allergy is, in fact, fairly infrequent in adults, although it may affect up to 1% of children ( Poole et al. , 2006 ). A number of wheat proteins have been reported to be responsible for allergic responses to the ingestion of wheat products but only one syndrome has been studied in detail. Wheat-dependent exercise-induced anaphylaxis (WDEIA) is a well-defined syndrome in which the ingestion of a product containing wheat followed by physical exercise can result in an anaphylactic response. Work carried out by several groups has clearly established that this condition is associated with a group of ω-gliadins (called ω5-gliadins) which are encoded by genes on chromosome 1B ( Palosuo et al. , 2001 ; Morita et al. , 2003 ; Battais et al. , 2005 ). Mutational analysis has also identified immunodominant epitopes in the ω5-gliadins: short glutamine-rich and proline-rich sequences present in the repetitive domains of the proteins ( Matsuo et al. , 2004 , 2005 ; Battais et al. , 2005 ). However, a number of other proteins have also been shown to react with IgE from patients with WDEIA, including gliadins, glutenin subunits, and related proteins from barley and rye (reviewed by Tatham and Shewry, 2008 ).

Other allergic responses to wheat proteins include atopic dermatitis, urticaria, and anaphylaxis. Not surprizingly, these symptoms have been associated with a number of wheat proteins, most notably gluten proteins but also CM proteins, enzymes, and lipid transfer protein (LTP) (reviewed by Tatham and Shewry, 2008 ).

Comparison of the proteins identified as responsible for the respiratory and food allergy shows significant overlap in their functions (most being storage or protective) and identities (notably gluten proteins and CM proteins).

Intolerance to wheat

Dietary intolerance to wheat is almost certainly more widespread than allergy, notably coeliac disease (CD) which is estimated to affect 1% of the population of Western Europe ( Feighery, 1999 ), and dermatitis herpetiformis which has an incidence between about 2-fold and 5-fold lower than CD ( Fry, 1992 ).

CD is a chronic inflammation of the bowel which leads to malabsorption of nutrients. Like bakers' asthma, CD has been known since classical times but it was only defined in detail in 1887 and its relationship to wheat established by Dicke in the late 1940s ( Losowsky, 2008 ).

A series of elegant studies carried out over the past decade, particularly by Sollid, Koning and co-workers, have established that CD results from an autoimmune response which is triggered by the binding of gluten peptides to T cells of the immune system in some (but not all) individuals with the human leucocyte antigens (HLAs) DQ2 or DQ8, expressed by specialized antigen-presenting cells. The presented peptides are then recognized by specific CD4+ T cells which release inflammatory cytokines which lead to the flattening of the intestinal epithelium. It has also been demonstrated that tissue transglutaminase enzyme present in the epithelium of the intestine plays an important role, generating toxic peptides by deamidation of glutamine residues to give glutamate.

The HLA-DQ2 antigen is present in about 95% of coeliac patients ( Karell et al. , 2003 ) and detailed studies have identified the peptide sequences which are recognized by intestinal T cell lines, using either peptide fractions produced from gluten proteins or synthetic peptides. This has led to the definition of two overlapping immunodominant epitopes corresponding to residues 57–68 (α-9) and 62–75 (α-2) of A gliadin (a form of α-gliadin) ( Arentz-Hansen et al. , 2000 , 2002 ; Anderson et al. , 2000 ; Ellis et al. , 2003 ). Related epitopes were similarly defined in γ-gliadins, corresponding to residues 60–79, 102–113, 115–123, and 228–236 ( Sjöström et al. , 1998 ; Arentz-Hansen et al. , 2002 ; Vader et al. , 2002 a ). Furthermore, Vader et al. (2002 b ) showed that the spacing between glutamine and proline residues determined the specificity of glutamine deamidation and hence peptide activation, and developed algorithms to predict the presence of novel T cell stimulatory peptides in gluten proteins and in related proteins from other cereals.

Less work has been carried out on the determinants of the HLA8-DQ8 associated coeliac disease, which affects only about 6% of patients without HLA-DQ2 and 10% of patients with HLA-DQ2 ( Karell et al. , 2003 ). This has again allowed immunodominant epitopes to be identified in gliadins and glutenin subunits ( van der Wal et al. , 1998 , 1999 ; Mazzarella et al. , 2003 ; Tollefsen et al. , 2006 ) although detailed structural studies indicate that the HLA-DQ2 and HLA-DQ8-mediated forms of the disease may differ in their molecular mechanisms ( Henderson et al. , 2007 ).

The possibility of producing wheat which lacks the coeliac toxic peptides has been discussed for many years but interest in the strategy tended to decline as it became clear that most, if not all, gluten proteins are toxic to at least some susceptible individuals, rather than only the α-gliadins as initially thought. However, Spaenij-Dekking et al. (2005) and van Herpen et al. (2006) have shown that it is possible to identify natural forms of gliadin which have few or no coeliac toxic epitopes, raising the possibility of selecting for less toxic lines of wheat by classical plant breeding. RNA interference (RNAi) technology has also been used to silence the α-gliadin ( Becker et al. , 2006 ; Wieser et al. , 2006 ) and γ-gliadin ( Gil-Humanes et al. , 2008 ) gene families, although some effects on grain-processing properties were observed.

The combination of these two approaches may therefore allow the production of less toxic, if not non-toxic, wheat for coeliac patients without significant loss of the processing properties conferred by the gluten proteins.

Dermatitis herpetiformis is a skin eruption resulting from ingestion of gluten, and is associated with the deposition of IgA antibodies in dermal papillae. These include IgA antibodies to epidermal transglutaminase which is considered to be an important autoantigen in disease development ( Hull et al. , 2008 ).

Other medical conditions related to gluten proteins

There are many reports of the association of wheat, and particularly wheat proteins, with medical conditions, ranging from improbable reports in the popular press to scientific studies in the medical literature. Not surprisingly, they include autoimmune diseases such as rheumatoid arthritis which may be more prevalent in coeliac patients and relatives ( Neuhausen et al. , 2008 ). It is perhaps easier to envisage mechanisms for relationships between such diseases which have a common immunological basis ( Hvatum et al. , 2006 ) than to explain a well-established association between wheat, coeliac disease, and schizophrenia ( Singh and Roy, 1975 ; Kalaydiian et al. , 2006 ) Other reported associations include ones with sporadic idiopathic ataxia (gluten ataxia) ( Hadjivassiliou et al. , 2003 ), migraines ( Grant, 1979 ), acute psychoses ( Rix et al. , 1985 ), and a range of neurological illnesses ( Hadjivassiliou et al. , 2002 ). An association with autism has also been reported ( Lucarelli et al. , 1995 ) with some physicians recommending a gluten-free, casein-free diet ( Elder, 2008 ).

Some of these effects may be mediated via the immune system but effects which are not immune-mediated are notoriously difficult to define and diagnose. However, they could result from the release within the body of bioactive peptides, derived particularly from gluten protein. Thus, gluten has been reported to be a source of a range of such peptides including opioid peptides (exorphins) ( Takahashi et al. , 2000 ; Yoshikawa et al. , 2003 ) and an inhibitor of angiotensin I-converting enzyme ( Motoi and Kodama, 2003 ) (see also reviews by Dziuba et al. , 1999 ; Yamamoto et al. , 2003 ). However, these activities were demonstrated in vitro and their in vivo significance has not been established.

There is little doubt that wheat will retain its dominant position in UK and European agriculture due to its adaptability and consumer acceptance. However, it may also need to adapt to face changing requirements from farmers, food processors, governments, and consumers.

Reducing inputs

Currently grown wheat cultivars require high inputs of nitrogen fertilizer and agrochemicals to achieve high yields combined with the protein content required for breadmaking. For example, UK farmers currently apply 250–300 kg N ha −1 in order to achieve the 13% protein content required for the Chorleywood Breadmaking Process, which is the major process used for breadmaking in the UK. Since a 10 tonnes ha −1 crop containing 13% protein equates to about 230 kg N ha −1 , this means that 50–70 kg N ha −1 may be lost. As fertilizer N currently costs about £1 kg −1 this represents a significant financial loss as well as a loss of the energy required for fertilizer production and may also have environmental consequences.

A number of projects worldwide are therefore focusing on understanding the processes that determine the efficiency of uptake, assimilation, and utilization of nitrogen in order to improve the efficiency of nitrogen recovery in the grain (reviewed by Foulkes et al. , 2009 ).

Reducing the nitrogen requirement of wheat does not only relate to the grain protein content, as an adequate supply of nitrogen is also essential for high wheat yields in order to build a canopy and fix carbon dioxide by photosynthesis. Furthermore, a substantial proportion of this nitrogen is remobilized and redistributed to the developing grain during canopy senescence ( Dalling, 1985 ). Hawkesford and colleagues at Rothamsted Research have targeted this process in order to develop a strategy for improving the recovery of N in the grain, using a combination of biochemical analysis and metabolite and transcript profiling to identify differences in metabolites and gene expression which are associated with efficient mobilization and redistribution ( Howarth et al. , 2008 ). Some of the genes identified in these and similar studies are suitable candidates for manipulation to increase the proportion of the total nitrogen recovered in the grain.

Stability of quality

The increases in temperature and carbon dioxide concentration associated with climate change are expected to have effects on crop development and yield, although the magnitude of these is difficult to predict due to interactions with other factors which may also be affected, notably water availability and populations of pests and pathogens ( Coakley et al. , 1999 ; Semenov, 2008 ). Similarly, although it is generally accepted that higher growth temperatures result in greater dough strength, the precise effects are not clearly understood (see review by Dupont and Altenbach, 2003 ) with heat stress (ie above 30–33 °C) actually resulting in dough weakening and reduced quality ( Blumenthal et al. , 1993 ). A recent review of the effects of CO 2 concentration on grain quality also failed to draw clear conclusions ( Högy and Fangmeier, 2008 ).

Of more immediate interest to wheat breeders and grain-utilizing industries are year-to-year fluctuations in growth conditions, and the frequency and magnitude of such fluctuations are also predicted to increase in the future ( Porter and Semenov, 2005 ). Although some cultivars are generally considered to be more consistent in quality than others, this is largely anecdotal with no detailed scientific comparisons.

Given the recent advances in ‘omics’ technologies it should now be possible to dissect the effects of G×E on grain development and quality, and to establish markers suitable for use in plant breeding. However, this will require substantial resources and a multi-disciplinary approach: by growing mapped populations and lines in multi-site/multi-year trials and determining aspects of composition and quality from gene expression profiling to pilot scale breadmaking.

Wan et al. (2009) have reported the application of this approach using a limited set of seven doubled haploid lines to identify a number of transcripts whose expression profile was associated with quality traits independently of environmental conditions. Millar et al. (2008) also reported a larger study in which three doubled haploid populations of wheat were used to map novel QTLs (quantitative trait loci) for breadmaking and pastry making which were stable over two years field trials, but did not relate quality traits to gene expression profiles.

Wheat is an attractive option as a ‘first generation biofuel’ as the high content of starch is readily converted into sugars (saccharification) which can then be fermented into ethanol. Murphy and Power (2008) recently reported that the gross energy recovered in ethanol using wheat was 66 GJ ha −1 a −1 , but that this only corresponds to 50% energy conversion and that the net energy production is as low as 25 GJ ha −1 a −1 . The same authors also calculated that the net energy production could be increased to 72 GJ ha −1 a −1 if the straw was combusted and the residue after distillation, called stillage or distillers grain and solubles (DGS), was converted to biogas (biomethane).

A major concern about using wheat grain for biofuel production is the high energy requirement for crop production, including that required to produce nitrogenous fertilizer. It is therefore necessary to develop new crop management strategies to reduce inputs ( Loyce et al. , 2002 ) as well as exploiting wheats with low N input requirements combined with high starch contents ( Kindred et al. , 2008 ).

The second major concern is, of course, the impact on international grain prices which may exacerbate problems of grain supply to less affluent populations.

New benefits to consumers

The increasing awareness of the important role of wheat-based products in a healthy diet has been discussed above, focusing on the identification and exploitation of natural variation in bioactive components. However, in some cases the natural variation in a trait may be limited in extent or difficult to exploit and, in this case, other approaches may be required. Currently, the most important target of this type of approach is resistant starch.

Most of the starch consumed in the human diet, including wheat starch, is readily digested in the small intestine, resulting in a rapid increase in blood glucose which may contribute to the development of type 2 diabetes and obesity ( Sobal, 2007 ). However, a fraction of the starch may resist digestion and pass through the small intestine to the colon, where it is fermented to short chain fatty acids, notably butyrate, which may have health benefits including reduction of colo-rectal cancer (as discussed by Topping, 2007 ).

Although the proportion of resistant starch (RS) depends on a number of factors including the effects of food processing, the most widely studied form is high amylose starch. In most species, amylose accounts for 20–30% of starch and amylopectin for 70–80%. However, mutant lines have been identified in a number of species in which the proportion of amylose is increased up to about 40% (e.g. Glacier barley; Yoshimoto et al. , 2000 ).

Selection for high amylose mutants is relatively easy in a diploid species such as barley, but more painstaking approaches are required in hexaploid wheat as mutations in homoeologous genes on all three genomes may be required to have a significant effect on the phenotype. This has been demonstrated very elegantly by Yamamori et al. (2000) who combined mutations in the gene encoding the starch synthase II enzyme (also called starch granule protein 1) that catalyses the synthesis of amylopectin. The resulting triple mutant line contained about 37% amylose.

However, the complexity of starch biosynthesis means that similar high amylose phenotypes can result from changes in other enzymes, with a notable example being the use of RNA interference technology to down-regulate the gene encoding starch-branching enzyme IIa ( Regina et al. , 2006 ). The resulting transgenic lines had up to 80% amylose and increased RS as measured in rat feeding trials. This study demonstrates the power of GM technology, although it remains to be shown that lines with such high levels of amylose will have acceptable yields and properties for milling and processing.

It also remains to be shown that consumers will be prepared to eat bread and other foods produced from GM wheat. The wheat grain and its products have been treated with reverence by humans for millennia and GM wheat may just be regarded as a step too far, even in countries in which other GM crops are currently accepted.

I wish to thank all of my colleagues and collaborators who have contributed to the work discussed in this article, Professor John Snape and the John Innes Institute for providing Fig. 1 and Dr Jane Ward (Rothamsted) for preparing Fig. 4 . Rothamsted Research receives grant-aided support from the Biotechnology and Biological Sciences Research Council of the UK.

Google Scholar

Google Preview

Email alerts

Citing articles via.

- Recommend to your Library

Affiliations

- Online ISSN 1460-2431

- Print ISSN 0022-0957

- Copyright © 2024 Society for Experimental Biology

- About Oxford Academic

- Publish journals with us

- University press partners

- What we publish

- New features

- Open access

- Institutional account management

- Rights and permissions

- Get help with access

- Accessibility

- Advertising

- Media enquiries

- Oxford University Press

- Oxford Languages

- University of Oxford

Oxford University Press is a department of the University of Oxford. It furthers the University's objective of excellence in research, scholarship, and education by publishing worldwide

- Copyright © 2024 Oxford University Press

- Cookie settings

- Cookie policy

- Privacy policy

- Legal notice

This Feature Is Available To Subscribers Only

Sign In or Create an Account

This PDF is available to Subscribers Only

For full access to this pdf, sign in to an existing account, or purchase an annual subscription.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Review article on wheat flour/wheat bran/wheat husk based bio composites

In recent years, extensive studies have been carried out on natural fiber reinforced thermoplastics due to their low cost, high specific properties, simple fabrication methods, biodegradable nature and diverse applications touching all commercial sectors. The challenge is to make composites with properties that are not overly compromised by the use of low technology. In this work, we review the performances of these resources, that is, wheat flour/wheat husk/wheat grain. By adding natural fibers, composites are also obtained by extrusion process. These composites exhibit performances which allow their use only for short duration. The mechanical, morphological, chemical, water absorption and thermal properties of biocomposites were studied.

Related Papers

Composites Part A: Applied Science and Manufacturing

Nathalie Leblanc

Polymer International

narendra kumar reddy

Meysam Mehdinia

The use of renewable and natural fibers instead of synthetic fibers, as reinforcement additives in thermoplastics, due to environmental friendly, low costs, etc are growing. However the present paper is concerned with the physical and mechanical properties (Flexural resistance, tensile, impacted absorbed energy, water uptake and thickness swelling) of Soy Stalk Flour/Polyethylene composite. Various composites using of different percentage of Polyethylene (PE) and Soy Stalk Flour (SSF), 50/50 and 60/40 by weight, have been made, and their mechanical and physical properties are measured. The statistical analysis of result shows that, the best mechanical properties (includes flexural, tensile, notch and unnotched absorbed impact energy) were obtained when we used the 60/40 mixture ratio of soy stalk flour and HDPE, and 4% MAPE. But the best physical properties (includes water uptake and thickness swelling) related to 50/50 mixture ratio of HDPE and soy stalk flour, and 4% MAPE. In summ...

Abdullah Al Mamun

Polymer Composites

Fatih Mengeloglu

Volume 3: Design, Materials and Manufacturing, Parts A, B, and C

Mahmoud Farag

Maria-Beatrice Coltelli

The present work aims to enhance the use of agricultural byproducts for the production of bio-composites by melt extrusion. It is well known that in the production of such bio-composites, the weak point is the filler-matrix interface, for this reason the adhesion between a polylactic acid (PLA)/poly(butylene succinate)(PBSA) blend and rice and wheat bran platelets was enhanced by a treatment method applied on the fillers using a suitable beeswax. Moreover, the coupling action of beeswax and inorganic fillers (such as talc and calcium carbonate) were investigated to improve the thermo-mechanical properties of the final composites. Through rheological (MFI), morphological (SEM), thermal (TGA, DSC), mechanical (Tensile, Impact), thermomechanical (HDT) characterizations and the application of analytical models, the optimum among the tested formulations was then selected.

Fibers and Polymers

Jakub Wiener

Composites Science and Technology

RELATED PAPERS

Matija Zorn

Jurnal Mercumatika : Jurnal Penelitian Matematika dan Pendidikan Matematika

titin masfingatin

Luis Sgarbossa

https://newztech.in/ Kumar

Nadila Nurahma Ramadhein

Proceedings of the 23rd Florida Artificial …

Natalie Person

Turizmus Bulletin

János Csapó

Equatorial – Revista do Programa de Pós-Graduação em Antropologia Social

Ana Manoela Primo dos Santos Soares

Aloysius Saputra

Anwar Hasan

Revue d'Épidémiologie et de Santé Publique

emilien jeannot

Luiz Mors Cabral

Stefano Boni

Journal of the American Statistical Association

David Zucker

On walking Conference

Clarissa Gonzalez

siti fatimah

HortScience

Rufus Chaney

English Education:Journal of English Teaching and Research

Arina H Husna

Vetus Testamentum

Richard J Clifford

The Electricity Journal

Nguyen Minh Quan

Helminthologia

Gabriela Hrčkova

BIOPENDIX: Jurnal Biologi, Pendidikan dan Terapan

Nurmiati Asmar Suneth

Zenodo (CERN European Organization for Nuclear Research)

MANUELA A B A T H VALENCA

Journal of Fourier Analysis and Applications

António Caetano , Abel Carvalho

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- J Food Sci Technol

- v.52(7); 2015 Jul

Development and analysis of composite flour bread

Lakshmi menon.

Department of Food Process Engineering, School of Bioengineering, S.R.M. University, Kattankulathur, Kancheepuram District, Tamil Nadu, India