Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Systematic Review on Investment Casting

International Journal for Research in Applied Science and Engineering Technology

Related Papers

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

IJRASET Publication

The aim of this study was to describe systematically the best available evidence of Additive manufacturing (AM) technology for different casting paths and How Rapid Investment casting (RIC) is revolutionizing the field of casting. The objective of this systematic review is to investigate the capabilities and effectiveness of Additive Manufacturing to provide an effective solution for investment casting production. Google Scholar, ResearchGate, Mendeley, ScienceDirect databases are used for research purposes. The conventional method of Investment Casting is less effective in terms of cost and time to develop new hard tooling wax patterns for low volume production and prototypes. To overcome this problem, we introduced additive manufacturing for making patterns for investment casting. This paper reviews the specific applications of Rapid prototyping in the field of casting. After applying the inclusion criteria, we found 40 articles for reviewing. This study concluded that using Additive manufacturing in Investment casting in place of the conventional method is more cost-effective and time-efficient.

Revue des composites et des matériaux avancés

Peter Ikubanni

More reliable and durable parts with high structural integrity are required to meet the increasing advancements in science and technology. This paper reviews five (5) different casting techniques: squeeze casting, sand casting, investment casting, die casting, and continuous casting. Their respective cast products were examined, and their various mechanical properties were discussed. However, these different casting techniques involve a similar fundamental procedure: melting metal, pouring it into a mold, and allowing it to solidify. However, they vary in their physical and mechanical properties, durability, and surface finishing, making one technique more desirable than the other in their application areas. Some techniques were found to be more advantageous and effective than the other, which will aid foundrymen in making the best decision in choosing a technique, considering parameters such as environmental friendliness and cost implications. The appropriate implementation of thes...

Reviews in Chemical Engineering

Tumisang Seodigeng

Conventionally, unfilled wax has been used as a universal pattern material for the investment casting process. With increase in demand for accurate dimensions and complex shapes, various materials have been blended with wax to develop more suitable patterns for investment casting in order to overcome performance limitations exhibited by unfilled wax. The present article initially reviews various investigations on the development of investment casting patterns by exploring pattern materials, type of waxes and their limitations, the effect of filler materials and various additives on unfilled wax, wax blends for pattern materials, plastics and polymers for pattern materials and 3D-printed patterns. The superiority of filled and polymer patterns in terms of dimensional accuracy, pattern strength, surface and flow properties over unfilled wax is also discussed. The present use of 3D patterns following their versatility in the manufacturing sector to revolutionize the investment casting ...

International Journal of Mechanical and Industrial Engineering

Sana Hussain

Investment casting is synonym with producing precision components and investment casters usually take up the order if the volume is huge enough. This is due to high and unjustifiable tooling cost and long lead times associated with the development of metal moulds for producing wax (sacrificial) patterns for customized single casting or small quantity production. One of the feasible solutions is opt rapid tooling. In so- called rapid investment casting the most critical process will be building the investment shell and protecting it from thermal crack. This work investigates the shell crack and counter. In this work pattern are modeled on rapid prototyping machine. During the ceramic shell preparation cracking is reported. Hence a remedy is explored as to control the thermal expansion of the pattern build material-acrylonitrile butadiene styrene (ABS) by using different build styles. Thermal expansion of five distinct styled ABS rapid samples were tested on Dilatometer. The investiga...

adnan sheikh

— Rapid product creation is the buzzword of present market. Prototyping market is thriving today. Conventional manufacturing fails to obey the prototyping marketers 'Faster –Cheaper –Better' dictum. The Prototyping market urges to-days' manufacturers to explore technology integration for compliance. Integration of conventional precision casting process with various rapid prototyping technologies is one of the finest logical options opened to the rapid product development research community, in the realm of precision engineering component development. This paper is made on the same theme. Here, SLS technology, the most popular Rapid Prototyping but the least recommended for the stated purpose is selected for experimentation. Equipments used are 1. Dilatometer,2. SLS Sinterstation,3. Precision casting Lab. The test pieces are modelled in Duraform Polyamide powder on SLS machine. Test pieces are tested for its thermal expansion on Dilatometer. A series of tests are carried out on the dilatometer for exploring the possibility of restricting the thermal expansion of Durafrm artifacts. Duraform expansion is compared with one of the recommended investment casting sacrificial pattern material. Interesting observations are made , thermal expansion restricted considerably ie from 2.2 % to0.3% !!!. It is a success on laboratory scale. Hence authors invite RP research community to commercialise the concept suitably, for the benefit of precision casting industry. Authors are working in their RP lab on technology integration in the area of precision components development.

Procedia CIRP

Michele Di Foggia

Elmy Mohamad

The advancement of the rapid prototyping (RP) technologies evolving toward rapid tooling in producing sacrificial patterns rapidly has profoundly benefits the investment casting (IC) process. Direct expendable pattern fabrication via RP techniques in complex and intricate features significantly reduce the cost when associated with single or low volume production. However inappropriate settings of the RP processes and its variables may cause serious defect in the ceramic shell such as cracking during burning out of the patterns, incomplete collapsibility and poor qualities of end products. By implementing the ANOVA at 95% confidence level to study the relative influence of factors and interactions, result shows that Surface Roughness (SR) and Dimensional Accuracy (DA) drastically affected by input variables within 5 % level of significance. Confirmation runs for all responses were carried out to ensure that the models reliability. The error level for ABS P400 was within reasonable ra...

Rapid Prototyping Journal

Shwe Sin Soe

PurposeThe main objective of this paper is to analyse all stages of the CastForm™ polystyrene (CF) pattern fabrication process, identify the reasons leading to inferior quality, and outline techniques for its improvement and reduction of failures.Design/methodology/approachThis paper describes rapid manufacturing of patterns for shell or flask investment casting using the laser sintering (LS) technique with CF material. The process involves data preparation, LS fabrication of a “green” part, cleaning, and wax infiltration. All process stages are equally important for successful project completion in terms of pattern quality and delivery time. A failure at any stage requires a part or pattern to be produced again, which would incur additional time and cost.FindingsThe conducted experiments show how the CF material strength varies at different process stages and temperatures. Cleaning and wax infiltration are considered the main reasons for part distortion and breakage.Originality/val...

IJSTE - International Journal of Science Technology and Engineering

The objective of this project is to identify defects in investment casting process. A case study has been conducted, involving more than one mechanical part in an investment casting industry. Few of most common defects found in investment cast parts are blowholes, shrinkage cavity, porosity, cold shuts, sand inclusion, misrun, bulging and cracks. Now a days, computational software for investment casting process has begun to complement the design based approach in meeting the demands of higher quality investment cast parts in a cost effective manner. The computations will carry out using Autocast x1 software and the defect will be predicted.

RELATED PAPERS

paul morett

damiena gart

res publication

accounts ziraf

北星学園大学経済学部北星論集

Khaled Bugrara

Mercedes Podestá

Turkish Journal of Medical Sciences

Murat ÖZNUR

Lutfia Mei afia

Neuroscience Letters

Marianna Delussi

AJHSSR Journal

Isabelle Ruin

Nucleic Acid Therapeutics

Nithya Subramanian

Nguyễn Bảo Dân Dụng

ACM Transactions on Multimedia Computing, Communications, and Applications

Ørnulf Jan Rødseth

Journal of the American Medical Directors Association

Muhammad Husen

Gary Comstock

Revista De La Universidad Industrial De Santander Salud

International Journal of Applied Mathematics and Computer Science

Paul Edvige Evans

Macromolecular Rapid Communications

Hans Börner

The Journal of Sexual Medicine

Soraia Coelho

Rahmatullah Agustina

Jeffery Volz

Journal of Occupational Health and Epidemiology

mohammad hassan lotfi

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Architecture and Design

- Asian and Pacific Studies

- Business and Economics

- Classical and Ancient Near Eastern Studies

- Computer Sciences

- Cultural Studies

- Engineering

- General Interest

- Geosciences

- Industrial Chemistry

- Islamic and Middle Eastern Studies

- Jewish Studies

- Library and Information Science, Book Studies

- Life Sciences

- Linguistics and Semiotics

- Literary Studies

- Materials Sciences

- Mathematics

- Social Sciences

- Sports and Recreation

- Theology and Religion

- Publish your article

- The role of authors

- Promoting your article

- Abstracting & indexing

- Publishing Ethics

- Why publish with De Gruyter

- How to publish with De Gruyter

- Our book series

- Our subject areas

- Your digital product at De Gruyter

- Contribute to our reference works

- Product information

- Tools & resources

- Product Information

- Promotional Materials

- Orders and Inquiries

- FAQ for Library Suppliers and Book Sellers

- Repository Policy

- Free access policy

- Open Access agreements

- Database portals

- For Authors

- Customer service

- People + Culture

- Journal Management

- How to join us

- Working at De Gruyter

- Mission & Vision

- De Gruyter Foundation

- De Gruyter Ebound

- Our Responsibility

- Partner publishers

Your purchase has been completed. Your documents are now available to view.

Formulations, development and characterization techniques of investment casting patterns

Conventionally, unfilled wax has been used as a universal pattern material for the investment casting process. With increase in demand for accurate dimensions and complex shapes, various materials have been blended with wax to develop more suitable patterns for investment casting in order to overcome performance limitations exhibited by unfilled wax. The present article initially reviews various investigations on the development of investment casting patterns by exploring pattern materials, type of waxes and their limitations, the effect of filler materials and various additives on unfilled wax, wax blends for pattern materials, plastics and polymers for pattern materials and 3D-printed patterns. The superiority of filled and polymer patterns in terms of dimensional accuracy, pattern strength, surface and flow properties over unfilled wax is also discussed. The present use of 3D patterns following their versatility in the manufacturing sector to revolutionize the investment casting process is also emphasized. Various studies on wax characterization such as physical (surface and dimensions), thermal (thermogravimetric analysis and differential scanning calorimetry), mechanical (thermomechanical analysis, tensile stress testing, dynamic mechanical analysis) and rheological (viscosity and shearing properties) are also discussed.

Acknowledgments

The authors gratefully acknowledge the financial support given by the Technology Innovation Authority, South Africa.

Argueso P. Filler and wax composition for investment casting. US Patent 5,006,583, 1991. Search in Google Scholar

Bemblage O, Karunakar DB. A study on the blended wax patterns in investment casting process. In: Proceeding of the World Congress on Engineering, July 6–8, 2011, London, UK; 1: 1–7. Search in Google Scholar

Biernacki R, Haratym R, Bałkowiec A, Wawulska-Marek P, Matysiak H, Zdunek J, Kurzydłowski KJ. Evaluation of physical properties of wax mixtures obtained from recycling of patterns used in precision casting. Arch Metall Mater 2015; 60: 345–349. 10.1515/amm-2015-0057 Search in Google Scholar

Bihari A, Ramachandran M, Kumar V. Effect of process parameters on roughness and hardness of surface and dimensional accuracy of lost wax process casting. Mater Sci Eng 2015; 4: 1–4. Search in Google Scholar

Borcherding A, Luck T. Application of plant proteins as thermoplastics. Plant Protein from Eur Crops 1998; 4: 313–314. 10.1007/978-3-662-03720-1_52 Search in Google Scholar

Cannell N, Sabau AS. Final technical report – predicting pattern tooling and casting dimensions for investment casting, phase II. Oak Ridge, USA, 2006. 10.2172/923051 Search in Google Scholar

Cao W, Kennedy RL, Willis MP. Differential thermal analysis (DTA) study of the homogenization process in alloy 718. The Minerals, Met & Mater Soc 1991; 1: 147–160. 10.7449/1991/Superalloys_1991_147_160 Search in Google Scholar

Chaudhari BY, Kanoongo N, Sulakhe S, Pathak SD. Shrinkage analysis of wax patterns for aerospace components in investment casting process. IOSR JMCE 2009; 4: 25–29. Search in Google Scholar

Cheah CM, Chua CK, Lee CW, Feng C, Totong K. Rapid prototyping and tooling techniques: A review of applications for rapid investment casting. Int J Adv Manuf Techn 2005; 25: 308–320. 10.1007/s00170-003-1840-6 Search in Google Scholar

Chua C, Feng C, Lee C, Ang G. Rapid investment casting: direct and indirect approaches via model maker II. Int J Adv Manuf Techn 2005; 25: 26–32. 10.1007/s00170-004-1865-5 Search in Google Scholar

Corcione C, Frigione M. Characterization of nanocomposites by thermal analysis. Materials 2012; 5: 2960–2980. 10.3390/ma5122960 Search in Google Scholar

Craig RG, Eick JD, Peyton FA, Green K. Strength properties of waxes at various temperatures and their practical application. J Dent Res 1967; 46: 300–305. 10.1177/00220345670460013101 Search in Google Scholar

Dadhaniya JK. Optimization of investment casting parameters of A443 alluminium alloy with adding trace elements using Taguchi. Int J Adv Res Eng Technol 2015; 6: 1–11. Search in Google Scholar

Everhart W, Lekakh S, Richards V, Chen J, Li H, Chandrashekhara K. Corner strength of investment casting shells. Int J Metalcast 2013; 3: 21–27. 10.1007/BF03355541 Search in Google Scholar

Gebelin J, Jolly MR. Modelling of the investment casting process. J Mater Process Technol 2003; 135: 291–300. 10.1016/S0924-0136(02)00860-9 Search in Google Scholar

Grzeskowiak K, Czarkecka-Komorowska D, Sytek K, Wojciechowski M. Influence of waxes remelting used in investment casting on their thermal properties and linear shrinkage. Metalurgija 2015; 54: 350–352. Search in Google Scholar

Guinn P. Filler material and wax composition for use in investment casting. US Patent 6,485,553 B1, 2002. Search in Google Scholar

Hague R. Stresses created in ceramic shells using QuickCast. University of Nottingham 1995, 242–252. Search in Google Scholar

Harsha AP. An investigation on low stress abrasive wear characteristics of high performance engineering thermoplastic polymers. Wear 2011; 271: 942–951. 10.1016/j.wear.2011.03.019 Search in Google Scholar

Harshit P, Ajay K. Optimization of wax tank parameter to improve the quality of wax pattern in investment casting. IJERD 2013; 8: 49–54. Search in Google Scholar

Hilton PD, Jacobs PF. Rapid tooling: technologies and industrial applications. New York, USA: Marcel-Dekker, 2000. 10.1201/9780203908020 Search in Google Scholar

Horáček M. Accuracy of investment castings. Arch Foundry 2005; 5: 121–137. Search in Google Scholar

Huang C, Leu MC, Richards VL. Investment casting with ice patterns and comparison with other types of rapid protying patterns, in: NSF Design and Manufacturing Grantees Conference, February 25–March 1, 2007, Florida, USA; 2: 1–7. Search in Google Scholar

Idris M, Sharif S, Wan Haron W. Evaluation of ABS patterns produced from FDM for investment casting process evaluation of ABS patterns produced from FDM for investment casting process. In: APIEMS 2008 Proceedings of the 9th Asia Pasific Industrial Engineering & Management Systems Conference Nottingham, United Kingdom; Nottingham, United Kingdom 2009. Search in Google Scholar

Jain P, Kuthe AM. Feasibility study of manufacturing using rapid prototyping: FDM approach. Procedia Eng 2013; 63: 4–11. 10.1016/j.proeng.2013.08.275 Search in Google Scholar

Jang J, Lee DK. Plasticizer effect on the melting and crystallization behavior of polyvinyl alcohol. Polymer 2003; 44: 8139–8146. 10.1016/j.polymer.2003.10.015 Search in Google Scholar

Jones S, Yuan C. Advances in shell moulding for investment casting. J Mater Process Technol 2003; 135: 258–265. 10.1016/S0924-0136(02)00907-X Search in Google Scholar

Kalpakjian S, Schmid S. Manufacturing processes for engineering materials, fifth ed. New Jersey, USA: Prentice Hall Pearson Education Incorporation, 2008. Search in Google Scholar

Karwiński A, Młodnicki S, Pabiś R, Robak I, Kubosz G. New generation of pattern materials for investment casting. Arch Foundry Eng 2011; 11: 53–56. Search in Google Scholar

Khalaji AD, Kazemnejadi M, Mighani H, Das D. Chemical engineering and atomic energy. J Appl Chem 2013; 7: 77–81. Search in Google Scholar

Kocsis J. Recent trends in polymer composites. J Mater 2016; 3: 23–34. Search in Google Scholar

Krupa I, Luyt AS. Mechanical properties of uncrosslinked and crosslinked linear low-density polyethylene/wax blends. J Appl Polym Sci 2000; 4: 973–980. 10.1002/app.1519 Search in Google Scholar

Krupa I, Luyt AS. Thermal and mechanical properties of extruded LLDPE/wax blends. Polym Degrad Stab 2001; 73: 157–161. 10.1016/S0141-3910(01)00082-9 Search in Google Scholar

Krupa I, Mikova G, Luyt AS. Phase change materials based on low-density polyethylene/paraffin wax blends. Eur Polym J 2007; 43: 4695–4705. 10.1016/j.eurpolymj.2007.08.022 Search in Google Scholar

Kumar S. Experimental characterization of physical and thermal behavior of blended wax pattern in investment casting. In: Proceedings of 8th IRF International Conference, 28th December 2014, Goa, India. 2014; pp. 17–21. Search in Google Scholar

Larsson M. Dynamic mechanical analysis of solid polymers and polymer melts. Polym Mater Chem 2010; 2: 1–8. Search in Google Scholar

Lee C, Chua C, Cheah C, Tan L, Feng C. Rapid investment casting: direct and indirect approaches via fused deposition modelling. Int J Adv Manuf Techn 2004; 23: 93–101. 10.1007/s00170-003-1694-y Search in Google Scholar

Li H, Zhang J. A generalized model for predicting non-Newtonian viscosity of waxy crudes as a function of temperature and precipitated wax. Fuel 2003; 82: 1387–1397. 10.1016/S0016-2361(03)00035-8 Search in Google Scholar

Lipatov YS, Shumsky VF, Getmanchuk IP, Gorbatenko AN. Rheology of polymer blends. Rheol Acta 1982; 279: 270–279. 10.1007/BF01515715 Search in Google Scholar

Liu Q, Sui G, Leu MC. Experimental study on the ice pattern fabrication for the investment casting by rapid freeze prototyping (RFP). J Comput Ind 2002; 48: 181–197. 10.1016/S0166-3615(02)00042-8 Search in Google Scholar

Macků M, Horáček M. Applying RP-FDM technology to produce prototype castings using the investment casting method. Arch Foundry Eng 2012; 12: 75–82. 10.2478/v10266-012-0085-y Search in Google Scholar

Manias E, Utracki L. Thermodynamics of polymer blends, 2nd ed., Dordrecht, London: Polymer Blends Handbook Springer Science and Business Media, 2002. 10.1007/0-306-48244-4 Search in Google Scholar

Menard K. Dynamic mechanical analysis: a practical introduction, 2nd ed., New York, USA: CRC Press, 1999. 10.1201/9781420049183 Search in Google Scholar

Merges J, Mills G, Ware R. Investment casting wax. US Patent 3,667,979, 1964. Search in Google Scholar

Mishra T, Mahato M, Aman N, Patel JN, Sahu RK. A mesoporous WN co-doped titania nanomaterial with enhanced photocatalytic aqueous nitrate removal activity under visible light. Catal Sci Technol 2011; 1: 609–615. 10.1039/c1cy00042j Search in Google Scholar

Mohd Nor SZ, Ismail R, Ahmad S, Isa MIN. The effect of dewaxing and burnout temperature in block mold process for copper alloy casting. Int J Eng Technol 2015; 7: 1905–1915. Search in Google Scholar

Muschio HM. Filler and wax composition for investment casting. US Patent 5,518,537, 1996. Search in Google Scholar

Patel B. Evaluation of physical and mechanical properties for various wax blend patterns. IJSRP 2016; 6: 285–288. Search in Google Scholar

Pattnaik S, Karunakar DB, Jha PK. Developments in investment casting process – a review. J Mater Process Technol 2012a; 212: 2332–2348. 10.1016/j.jmatprotec.2012.06.003 Search in Google Scholar

Pattnaik S, Karunakar DB, Jha PK. Parametric optimization of the investment casting process using utility concept and Taguchi method. J of Mater: Design and Applications 2012b; 228: 288–300. 10.1177/1464420713487654 Search in Google Scholar

Pattnaik S, Karunakar DB, Jha PK. Optimization of multiple responses in the lost wax process using Taguchi method and grey relational analysis. J of Mater: Design and Applications 2012c; 227: 156–167. 10.1177/1464420712464711 Search in Google Scholar

Pattnaik S, Karunakar DB, Jha PK. Multi-characteristic optimization of wax patterns in the investment casting process using grey-fuzzy logic. Int J Adv Manuf Techn 2013; 67: 1577–1587. 10.1007/s00170-012-4591-4 Search in Google Scholar

Peleikis K. Natural waxes – properties, compositions and applications. SOFW – J 2011; 137: 1–8. Search in Google Scholar

Pham CB, Leong KF, Lim TC, Chian KS. Rapid freeze prototyping technique in bio-plotters for tissue scaffold fabrication. Rapid Prototyping J 2008; 14: 246–253. 10.1108/13552540810896193 Search in Google Scholar

Piwonka TS, Woodbury KA, Wiest JM. Modeling casting dimensions: effect of wax rheology and interfacial heat transfer. Mater Des 2000; 21: 365–372. 10.1016/S0261-3069(99)00080-1 Search in Google Scholar

Pu G, Wang J, Severtson SJ, Ave F, Paul S, Company N, Naperville WDR. Properties of paraffin wax/montmorillonite nanocomposite coatings department of bioproducts and biosystems engineering. University of Minnesota, 2004. 2007; 2: 112–115. Search in Google Scholar

Queiroz DA, Cunha LG, Duarte JLP, Nevesa CC, da Silva-Concilio LR. Influence of the casting material on the dimensional accuracy of dental dies. Braz Oral Res 2011; 25: 357–361. 10.1590/S1806-83242011005000011 Search in Google Scholar

Quinn JA, Fan N, Lawton J. Investment casting method and pattern material comprising thermally-collapsible expanded microspheres. US Patent 5,176,188, 1993. Search in Google Scholar

Rani D, Karunakar DB. Recycling of pattern wax in the investment casting process using microwave dewaxing. IOSRJEN 2013; 3: 5–10. 10.9790/3021-03520510 Search in Google Scholar

Rao ZH, Zhang GQ. Thermal properties of paraffin wax-based composites containing graphite. Energ Source Part A 2011; 33: 587–593. 10.1080/15567030903117679 Search in Google Scholar

Roschochowski A, Matuszak A. Rapid tooling: the state of the art. J Mater Process Technol 2000; 106: 191–198. 10.1016/S0924-0136(00)00613-0 Search in Google Scholar

Rutto H, Focke WW. Thermo-mechanical properties of urea-based pattern molding compounds for investment casting. Int Polym Process 2009; 25: 15–22. 10.3139/217.2256 Search in Google Scholar

Sabau AS. Numerical simulation of the investment casting process. AFS Trans 2005; 160: 1–11. Search in Google Scholar

Sabau AS, Viswanathan S. Material properties for predicting wax pattern dimensions in investment casting. Mater Sci Eng A 2003; 362: 125–134. 10.1016/S0921-5093(03)00569-0 Search in Google Scholar

Sadiku-Agboola O, Sadiku ER, Adegbola AT, Biotidara OF. Rheological properties of polymers: structure and morphology of molten polymer blends. Mater Sci Appl 2011; 2: 30–41. 10.4236/msa.2011.21005 Search in Google Scholar

Shellhammer T, Rumsey T, Krochta J. Viscoelastic properties of edible lipids. J Food Eng 1997; 33: 305–320. 10.1016/S0260-8774(97)00030-7 Search in Google Scholar

Shivappa DN, Prasad AJK, Harisha K, Manjunath R. Studies on recyclability of investment casting wax formulation – an experimental study. Rec Adv Mech Eng Mechanics 2014; 60: 37–41. Search in Google Scholar

Sirin K, Balcan M, Doğan F. The influence of filler component on mechanical properties and thermal analysis of PP-LDPE and polypropylene. Intechopen J 2012; 4: 500–507. Search in Google Scholar

Speyer F. Polyhydroxy fillers for pattern materials. US Patent 3,854,962, 1974. Search in Google Scholar

Stanco J. The effect of fillers on the physical properties of investment casting waxes. Rochester, England: Remet UK Limited, 1998. Search in Google Scholar

Steinmann W, Walter S, Beckers M, Seide G, Gries T. Thermal analysis of phase transitions and crystallization in polymeric fibers. Applications of calorimetry in a wide context – differential scanning calorimetry, isothermal titration calorimetry and microcalorimetry 2013;12: 279–305. 10.5772/54063 Search in Google Scholar

Straioto FG, Ricomini Filho AP, Fernandes Neto AJ, del Bel Cury AA. Polytetrafluorethylene added to acrylic resins: mechanical properties. Braz Dent J 2010; 21: 55–59. 10.1590/S0103-64402010000100009 Search in Google Scholar

Sturgis D, Yasrebi M, Taft M, Sorbel M. Polymeric organic carbonate materials useful as fillers for investment casting waxes. US Patent 6,326,429 B1, 2001. Search in Google Scholar

Taşcıoğlu S, Akar N. Conversion of an investment casting sprue wax to a pattern wax by chemical agents. Mater Manuf Process 2003; 18: 753–768. 10.1081/AMP-120024973 Search in Google Scholar

Thirugnanam C, Marimuthu P. Experimental analysis of latent heat thermal energy storage using paraffin wax as phase change material. Int J Eng Innov Technol 2013; 3: 372–376. Search in Google Scholar

Ukrainczyk N, Kurajica S, Šipušiæ J. Thermophysical comparison of five commercial paraffin waxes as latent heat storage materials. Chem Biochem Eng Q 2010; 24: 129–137. Search in Google Scholar

Upadhya GK, Das S, Chandra U, Paul AJ. Modelling the investment casting process: a novel approach for view factor calculations and defect prediction. Appl Math Model 1995; 19: 354–362. 10.1016/0307-904X(95)90001-O Search in Google Scholar

Uygunoglu T, Gunes I, Brostow W. Physical and mechanical properties of polymer composites with high content of wastes including boron. Mat Res 2015; 18: 1188–1196. 10.1590/1516-1439.009815 Search in Google Scholar

Vihtelic M, Graham J, McCormick L, Carpenter L. Investment casting with improved AS-Cast surface finish. US Patent 5,983,982, 1986. Search in Google Scholar

Wang T, Mason MS, Hilmas GE, Leu MC. Freeze-form extrusion fabrication of ceramic parts. Virtual Phys Prototyp 2006; 1: 93–100. 10.1080/17452750600649609 Search in Google Scholar

Wang S, Miranda G, Shih C. A study of investment casting with plastic patterns. Mater Manuf Process 2010a; 25: 1482–1488. 10.1080/10426914.2010.529585 Search in Google Scholar

Wang S, Shih C, He X. A study on investment casting directly with plastic rapid prototype patterns. J Mater Sci Eng 2010b; 4: 19–25. Search in Google Scholar

Wolff TM. Investment casting waxes: influences which eliminate wax pattern defects. A report by M. Argueso & Co. Inc, Michigan, USA. 1999. Search in Google Scholar

Xu M. Characterization of investment shell thermal properties. PhD thesis, Missouri University of Science and Technology, USA. 2015. Search in Google Scholar

Yadav N, Singh AK, Bhat MN, Sahu S, Kumar S. Effect of process parameters on the surface roughness of A713 alloy castings produced by investment casting process. IJETAE 2013; 3: 543–548. Search in Google Scholar

Yao WL, Leu M. Shell cracking in investment casting with laser stereolithography patterns. J Rapid Prototyping 1999; 5: 427–434. 10.1108/13552549910251837 Search in Google Scholar

Yodice D. Investment casting process. US Patent 5,072,770, 1991. Search in Google Scholar

Zhang N, Gilchrist MD. Characterization of thermo-rheological behavior of polymer melts during the micro injection moulding process. Polymer Testing 2012; 31: 748–758. 10.1016/j.polymertesting.2012.04.012 Search in Google Scholar

Zych J, Kolczyk J, Snopkiewicz T. Investigations of properties of wax mixtures used in the investment casting technology – new investigation methods. Arch Foundry Eng 2012; 12: 133–138. 10.2478/v10266-012-0096-8 Search in Google Scholar

©2019 Walter de Gruyter GmbH, Berlin/Boston

- X / Twitter

Supplementary Materials

Please login or register with De Gruyter to order this product.

Journal and Issue

Articles in the same issue.

To read this content please select one of the options below:

Please note you do not have access to teaching notes, critical parameters influencing the quality of metal castings: a systematic literature review.

International Journal of Quality & Reliability Management

ISSN : 0265-671X

Article publication date: 26 October 2021

Issue publication date: 17 January 2023

Casting is one of the well-known manufacturing processes to make durable parts of goods and machinery. However, the quality of the casting parts depends on the proper choice of process variables related to properties of the materials used in making a mold and the product itself; hence, variables related to product/process designs are taken into consideration. Understanding casting techniques considering significant process variables is critical to achieving better quality castings and helps to improve the productivity of the casting processes. This study aims to understand the computational models developed for achieving better quality castings using various casting techniques.

Design/methodology/approach

A systematic literature review is conducted in the field of casting considering the period 2000–2020. The keyword co-occurrence network and word cloud from the bibliometric analysis and text mining of the articles reveal that optimization and simulation models are extensively developed for various casting techniques, including sand casting, investment casting, die casting and squeeze casting, to improve quality aspects of the casting's product. This study further investigates the optimization and simulation models and has identified various process variables involved in each casting technique that are significantly affecting the outcomes of the processes in terms of defects, mechanical properties, yield, dimensional accuracy and emissions.

This study has drawn out the need for developing smart casting environments with data-driven modeling that will enable dynamic fine-tuning of the casting processes and help in achieving desired outcomes in today's competitive markets. This study highlights the possible technology interventions across the metal casting processes, which can further enhance the quality of the metal casting products and productivity of the casting processes, which show the future scope of this field.

Research limitations/implications

This paper investigates the body of literature on the contributions of various researchers in producing high-quality casting parts and performs bibliometric analysis on the articles. However, research articles from high-quality journals are considered for the literature analysis in identifying the critical parameters influencing quality of metal castings.

Originality/value

The systematic literature review reveals the analytical models developed using simulation and optimization techniques and the important quality characteristics of the casting products. Further, the study also explores critical influencing parameters involved in every casting process that significantly affects the quality characteristics of the metal castings.

- Optimization

- Bibliometric analysis

Suthar, J. , Persis, J. and Gupta, R. (2023), "Critical parameters influencing the quality of metal castings: a systematic literature review", International Journal of Quality & Reliability Management , Vol. 40 No. 1, pp. 53-82. https://doi.org/10.1108/IJQRM-11-2020-0368

Emerald Publishing Limited

Copyright © 2021, Emerald Publishing Limited

Related articles

We’re listening — tell us what you think, something didn’t work….

Report bugs here

All feedback is valuable

Please share your general feedback

Join us on our journey

Platform update page.

Visit emeraldpublishing.com/platformupdate to discover the latest news and updates

Questions & More Information

Answers to the most commonly asked questions here

Investors’ acceptance and use of investment-based crowdfunding platforms: an integrated perspective

- Original Article

- Published: 02 May 2024

Cite this article

- Felix Friederich ORCID: orcid.org/0000-0002-1113-574X 1 ,

- Ramon Palau-Saumell ORCID: orcid.org/0000-0003-4756-624X 1 ,

- Jorge Matute ORCID: orcid.org/0000-0002-2402-327X 1 &

- José Luis Sánchez-Torelló ORCID: orcid.org/0000-0002-1027-7703 1

Explore all metrics

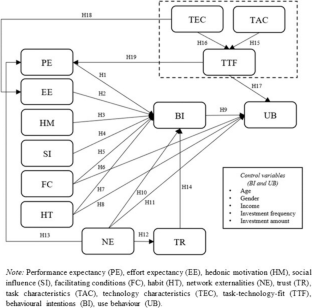

Investment-based crowdfunding platforms (IBCP) have revolutionized the financial landscape by providing viable investment opportunities for non-institutional investors. Nonetheless, only a limited amount of attention has been focused on the factors that shape investors’ adoption of these platforms. Therefore, we primarily explore investors’ adoption of IBCP by employing an integrated model combining the Unified Theory of Acceptance and Use of Technology 2 (UTAUT2) and the Task-technology Fit model (TTF) while incorporating network externalities and trust. Drawing on a sample of current IBCP investors ( n = 303), we found that investors’ behavioural intentions and use behaviour can be explained by performance expectancy, effort expectancy, facilitating conditions, habit, network externalities, trust and the TTF. The integrated model explained a higher variance in the endogenous variables than the two baseline models. We contribute to the emerging literature by delivering a new integrated model and provide platform operators with valuable insights into encouraging investors’ adoption behaviour.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Social media marketing strategy: definition, conceptualization, taxonomy, validation, and future agenda

Online influencer marketing

Social media influencer marketing: foundations, trends, and ways forward

Alalwan, A., Y. K. Dwivedi, N. Rana, N., B. Lal and M. D. Williams. 2015. Consumer adoption of Internet banking in Jordan: Examining the role of hedonic motivation, habit, self-efficacy and trust. Journal of Financial Services Marketing 20: 145-157

Alalwan, A.A., Y.K. Dwivedi, and N.P. Rana. 2017. Factors influencing adoption of mobile banking by Jordanian bank customers: Extending UTAUT2 with trust. International Journal of Information Management 37 (3): 99–110.

Article Google Scholar

Alalwan, A.A., Y.K. Dwivedi, N.P. Rana, and R. Algharabat. 2018. Examining factors influencing Jordanian customers’ intentions and adoption of internet banking: Extending UTAUT2 with risk. Journal of Retailing and Consumer Services 40: 125–138.

Baabdullah, A.M., A. Alalwan, N.P. Rana, H. Kizgin, P. Patil, and P. 2019. Consumer use of mobile banking (M-Banking) in Saudi Arabia: Towards an integrated model. International Journal of Information Management 44: 38–52.

Bajunaied, K., N. Hussin, and S. Kamarudin. 2023. Behavioral intention to adopt FinTech services: An extension of unified theory of acceptance and use of technology. Journal of Open Innovation: Technology, Market, and Complexity 9: 100010.

Bretschneider, U., and J.M. Leimeister. 2017. Not just an ego-trip: Exploring backers’ motivation for funding in incentive-based crowdfunding. Journal of Strategic Information Systems 26 (4): 246–260.

Butticè, V., and S. Vismara. 2022. Inclusive digital finance: The industry of equity crowdfunding. The Journal of Technology Transfer 47: 1224–1241.

Butticè, V., V. Collewaert, S. Stroe, T. Vanacker, S. Vismara, and X. Walthoff-Borm. 2022. Equity Crowdfunders’ Human Capital and Signal Set Formation: Evidence From Eye Tracking. Entrepreneurship Theory and Practice 46 (5): 1317–1343.

Cumming, D., M. Meoli, A. Rossi, and S. Vismara. 2024. ESG and crowdfunding platforms. Journal of Business Venturing 39: 106362.

Cumming, D., M. Meoli, and S. Vismara. 2021. Does equity crowdfunding democratize entrepreneurial finance? Small Business Economics 56: 533–552.

Dang, Y., Y. Zhang, S.A. Brown, and H. Chen. 2020. Examining the impacts of mental workload and task-technology fit on user acceptance of the social media search system. Information Systems Frontiers 22: 697–718.

Daskalakis, N. and Y. Wei. 2017. User's perceptions of motivations and risks in crowdfunding with financial returns. Available at SSRN: https://doi.org/10.2139/ssrn.2968912 . Accessed 6 July 2023.

Davis, F.D. 1989. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Quarterly 13 (3): 319–339.

de Oliveira Santini, F., L. Eberle, W.J. Ladeira, G.S. Milan, A.P. Graciola, and C.H. Sampaio. 2023. Trust in the financial services context: a meta-analysis. International Journal of Bank Marketing 41 (7): 1693–1714.

Fornell, C., and D.F. Larcker. 1981. Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research 18: 39–50.

Fu, J., R. A. Shang, A. Jeyaraj, Y. Sun and F. Hu. 2020. Interaction between task characteristics and technology affordances. Task-technology fit and enterprise social media usage. Journal of Enterprise Information Management 33 (1): 1–22.

Ghazali, E., D.S. Mutum, and M.Y. Woon. 2019. Exploring player behavior and motivations to continue playing Pokémon GO. Information Technology & People 32 (3): 646–667.

Goodhue, D.L., and R.L. Thompson. 1995. Task-technology fit and individual performance. MIS Quarterly 19: 213–236.

Grand View Research. 2022. Crowdfunding market size, share & trends analysis report by type (equity-based, debt-based) by application (food & beverage, technology, media, healthcare, real estate), by Region, and segment forecasts, 2023 – 2030. Market analysis report ID: GVR-4–68040–006–1, https://www.grandviewresearch.com/industry-analysis/crowdfunding-market-report , accessed 2 May 2023.

Gupta, K.P., R. Manrai, and U. Goel. 2019. Factors influencing adoption of payments banks by Indian customers: Extending UTAUT with perceived credibility. Journal of Asia Business Studies 13 (2): 173–195.

Gupta, K., A. Wajid, and G. Gaur. 2023. Determinants of continuous intention to use FinTech services: The moderating role of COVID-19. Journal of Financial Services Marketing . https://doi.org/10.1057/s41264-023-00221-z .

Hair, J.F., G.T.M. Hult, C.M. Ringle, and M. Sarstedt. 2017. A primer on partial least squares structural equation modelling (PLS-SEM) , 2nd ed. Thousand Oaks, CA: Sage.

Google Scholar

Henseler, J., C.M. Ringle, and M. Sarstedt. 2015. A new criterion for assessing discriminant validity in variance-based structural equation modelling. Journal of the Academy of Marketing Science 43 (1): 115–135.

Hu, L., R. Filieri, F. Acikgoz, L. Zollo, and R. Rialti. 2022. The effect of utilitarian and hedonic motivations on mobile shopping outcomes. A cross-cultural analysis. International Journal of Consumer Studies 47: 751–766.

Joa, C.Y., and K. Magsamen-Conrad. 2022. Social influence and UTAUT in predicting digital immigrants’ technology use. Behaviour & Information Technology 41 (8): 1620–1638.

Kang, M., Y. Gao, T. Wang and H. Zheng. 2016. Understanding the determinants of funders' investment intentions on crowdfunding platforms. A trust-based perspective. Industrial Management & Data Systems 116 (8): 1800–1819.

Kock, N. 2015. Common method bias in PLS-SEM: A full collinearity assessment approach. International Journal of e-Collaboration 11 (4): 1–10.

Konhäusner, P., M.M.C. Frias, and D.C. Dabija. 2021a. Monetary Incentivization of Crowds by Platforms. Információs Társadalom XXI 2: 97–118.

Konhäusner, P., M. Thielmann, V. Câmpian, and D.C. Dabija. 2021b. Crowdfunding for Independent Print Media: E-Commerce, Marketing, and Business Development. Sustainability 13: 11100.

Liang, T.P., P.J.S. Wu, and C. Huang. 2019. Why Funders Invest in Crowdfunding Projects: Role of Trust from the Dual-Process Perspective. Information & Management 56: 70–84.

Liebowitz, S., and S.E. Margolis. 1994. Network externality: An uncommon tragedy. Journal of Economic Perspectives 8 (2): 133–150.

Lyu, T., Y. Guo and H. Chen. 2023. Understanding people’s intention to use facial recognition services: the roles of network externality and privacy cynicism. Information Technology & People.

Manrai, R., and K.P. Gupta. 2023. Investor’s perceptions on artificial intelligence (AI) technology adoption in investment services in India. Journal of Financial Services Marketing 28: 1–14.

Meoli, M., A. Rossi, and S. Vismara. 2022. Financial Literacy and Security-based Crowdfunding. Corporate Governance. an International Review 30: 27–54.

Miraz, M. H., Hasan, M. T., Rekabder, M. S. and Akhter, R. 2022. Trust, transaction transparency, volatility, facilitating condition, performance expectancy towards cryptocurrency adoption through intention to use. Journal of Management Information and Decision Sciences 25 (Special issue 1): 1–20.

Molinillo, S., F. Muñoz-Leiva, and F. Pérez-García. 2018. The effects of human-game interaction, network externalities, and motivations on players’ use of mobile casual games. Industrial Management & Data Systems 118 (9): 1766–1786.

Nepal, S., and B. Nepal. 2023. Adoption of Digital Banking: Insights from a UTAUT Model. Journal of Business and Social Sciences Research 8 (1): 1–18.

Oliveira, T., M. Faria, M.A. Thomas, and A. Popovic. 2014. Extending the understanding of mobile banking adoption: When UTAUT meets TTF and ITM. International Journal of Information Management 34 (5): 689–703.

Paas, L.J., and M. Morren. 2018. PLease do not answer if you are reading this: Respondent attention in online panels. Marketing Letters 29: 13–21.

Pae, J.H., and J.S. Hyun. 2002. The impact of technology advancement strategies on consumers’ patronage decisions. Journal of Product Innovation Management 19: 375–383.

Patil, P., K. Tamilmani, N.P. Rana, and V. Raghavan. 2020. Understanding consumer adoption of mobile payment in India: Extending Meta-UTAUT model with personal innovativeness, anxiety, trust, and grievance redressal. International Journal of Information Management 54: 102144.

Podsakoff, P.M., S.B. MacKenzie, J.Y. Lee, and N.P. Podsakoff. 2003. Common method biases in behavioral research: A critical review of the literature and recommended remedies. Journal of Applied Psychology 88 (5): 879–903.

Qasim, H., and E. Abu-Shanab. 2016. Drivers of mobile payment acceptance: The impact of network externalities. Information Systems Frontiers 18: 1021–1034.

Rahi, S., M.M. Khan, and M. Alghizzawi. 2021. Extension of technology continuance theory (TCT) with task technology fit (TTF) in the context of Internet banking user continuance intention. International Journal of Quality & Reliability Management 38 (4): 986–1004.

Reinartz, W., M. Haenlein, and J. Henseler. 2009. An empirical comparison of the efficacy of covariance-based and variance-based SEM. International Journal of Research in Marketing 26 (4): 332–344.

Sharma, S.K., and M. Sharma. 2019. Examining the role of trust and quality dimensions in the actual usage of mobile banking services: An empirical investigation. International Journal of Information Management 44: 65–75.

Shmueli, G., M. Sarstedt, J.F. Hair, J.H. Cheah, H. Ting, S. Vaithilingam, and C.M. Ringle. 2019. Predictive model assessment in PLS-SEM: Guidelines for using PLSpredict. European Journal of Marketing 53 (11): 2322–2347.

Sinha, N., and N. Singh. 2023. Moderating and mediating effect of perceived experience on merchant’s behavioral intention to use mobile payments services. Journal of Financial Services Marketing 28: 448–465.

Song, M., M.E. Parry, and T. Kawakami. 2009. Incorporating network externalities into the technology acceptance model. Journal of Product Innovation Management 26 (3): 291–307.

Song, Y., H. Wu, J. Ma, and N. Naiji Lu. 2020. Exploring the dynamic influences and interaction effects of signals on backers’ investment in the crowdfunding market. Information Technology & People 33 (2): 792–812.

Statista. 2022. Total value of alternative finance market volume in Europe 2020, by country. https://www.statista.com/statistics/1081271/europe-market-volume-alternative-finance-by-country/ Accessed 11 January 2023.

Sultana, N., R.S. Chowdhury, and A. Haque. 2023. Gravitating towards Fintech: A study on Undergraduates using extended UTAUT model. Heliyon 9 (10): e20731.

Tamilmani, K., N.P. Rana, S.F. Wamba, and R. Dwivedi. 2021. The extended unified theory of acceptance and use of technology (UTAUT2): A systematic literature review and theory evaluation. International Journal of Information Management 57: 102269.

Teh, P.L., P. Ahmed, and G.K. Tayi. 2015. Generation-Y shopping: The impact of network externalities and trust on adoption of social commerce. International Journal of Electronic Business 12 (2): 117.

Thies, F., M. Wessel, and A. Benlian. 2018. Network effects on crowdfunding platforms: Exploring the implications of relaxing input control. Information Systems Journal 28 (6): 1239–1262.

Thusi, P., and D.K. Maduku. 2020. South African millennials’ acceptance and use of retail mobile banking apps: An integrated perspective. Computers in Human Behavior 111: 106405.

Toufaily, E., T. Zalan, and D. Ben. 2021. A framework of blockchain technology adoption: An investigation of challenges and expected value. Information & Management 58: 103444.

Valaei, N., S.R. Nikhashemi, G. Bressolles, and H.H. Jin. 2019. A(n) (a)symmetric perspective towards task technology performance fit in mobile app industry. Journal of Enterprise Information 32 (5): 887–912.

Venkatesh, V., J.Y.L. Thong, and X. Xu. 2012. Consumer acceptance and use of information technology: Extending the unified theory of acceptance and use of technology. MIS Quarterly 36 (1): 157–178.

Wattal, S., P. Racherla, and M. Mandviwalla. 2010. Network externalities and technology use: A quantitative analysis of intraorganizational blogs. Journal of Management Information Systems 27 (1): 145–173.

Wu, B., and X. Chen. 2017. Continuance intention to use MOOCs: Integrating the technology acceptance model (TAM) and task technology fit (TTF) model. Computers in Human Behavior 67: 221–232.

Zhao, Y., and F. Bacao. 2020. What factors determining customer continuingly using food delivery apps during 2019 novel coronavirus pandemic period? International Journal of Hospitality Management 91: 102683.

Zhou, T., Y.B. Lu, and B. Wang. 2010. Integrating TTF and UTAUT to explain mobile banking user adoption. Computers in Human Behavior 26 (4): 760–767.

Download references

Author information

Authors and affiliations.

IQS School of Management, Universitat Ramon Llull, Via Augusta, 390, 08017, Barcelona, Catalonia, Spain

Felix Friederich, Ramon Palau-Saumell, Jorge Matute & José Luis Sánchez-Torelló

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Ramon Palau-Saumell .

Ethics declarations

Conflict of interest.

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Measurement instrument

Rights and permissions.

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Friederich, F., Palau-Saumell, R., Matute, J. et al. Investors’ acceptance and use of investment-based crowdfunding platforms: an integrated perspective. J Financ Serv Mark (2024). https://doi.org/10.1057/s41264-024-00278-4

Download citation

Received : 25 October 2023

Revised : 08 April 2024

Accepted : 09 April 2024

Published : 02 May 2024

DOI : https://doi.org/10.1057/s41264-024-00278-4

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Crowdfunding

- Task-technology fit

- Network externalities

- Find a journal

- Publish with us

- Track your research

IMAGES

VIDEO

COMMENTS

Fig. 1. Production of ancient weapon heads by investment casting: (a) making of wax patterns assembled together, (b) pouring of molten metal into clay mold after draining the wax, (c) breaking the clay mold to get the solidified casting, and (d) separated and finished weapons ( Taylor, 1983 ). Kotzin (1981) stated that this process was used for ...

Investment casting process is known to its capability of producing clear net shape, high-dimensional accuracy and intricate design. ... Consistent research effort has been made by various researchers with an objective to explore the world of investment casting. Literature review revealed the effect of processing parameters on output parameters ...

Explore the latest full-text research PDFs, articles, conference papers, preprints and more on INVESTMENT CASTING. Find methods information, sources, references or conduct a literature review on ...

Abstract. Investment casting process is the promising method for manufacturing of complex component with better surface finish and dimensional accuracy. Development of 3D printing or rapid prototyping has given opportunities for the mass customization and production of complex designs having CAD model. In past few years, rapid prototyping has ...

The review throws light on almost all the fields of applications of investment casting and concludes that the process is normally limited by the size and mass of the casting. Kalpakjian and Schmid (2008) beautifully explained the basic steps involved in the production of an investment casting, using a ceramic shell, which are shown in Fig. 4.

Investment casting (also known as 'lost wax casting' or 'precision casting') has been a widely used process for centuries. It is known for its ability to produce components of excellent surface finish, dimensional ... Section 2 presents the literature review on cost estimation methods and cost models for casting processes. Section 3 ...

Investment casting is one of the oldest primary manufacturing processes as man-kind has learnt to use liquid metal around ten millennia [1]. Since about 4000 years, ... Literature review reveals that several researchers and industry personnel have concentrated on simulation-based study for predicting casting defects. Upadhya

Sunpreet Singh Rupinder Singh. Engineering, Materials Science. 2016. Investment casting process is known to its capability of producing clear net shape, high-dimensional accuracy and intricate design. Consistent research effort has been made by various researchers…. Expand.

Some of the applications of investment casting in modern industries are: turbine blades [1,14], jewelry castings, airplane parts, modern weapons [14], and other industrial/scientific components [1 ...

Nonetheless, in literature, only few works presenting parametric cost models for investment casting. ... B.D., Jha, P.K.: Developments in investment casting process—a review. J. Mater. Process. Technol. 212(11), 2332-2348 (2012) Article Google Scholar ASM Handbook, Volume 15: Casting, ASM International (2008) Google Scholar ...

This paper aims to design lattice structures for rapid-investment casting (RIC), and the goal of the design methodology is to minimize casting defects that are related to the lattice topology. ... Literature Review. Investment casting (IC) was described as taking advantage of a fluid's ability to assume the shape of its container . IC design ...

The precision casting process comprises eight main steps ( Figure SM2): (a) making the wax models, (b) assembling the models, (c) coating the refractory sludge and plastering, (d) dewaxing and ...

IJRASET Publication. The aim of this study was to describe systematically the best available evidence of Additive manufacturing (AM) technology for different casting paths and How Rapid Investment casting (RIC) is revolutionizing the field of casting. The objective of this systematic review is to investigate the capabilities and effectiveness ...

Investment casting process is known to its capability of producing clear net shape, high-dimensional accuracy and intricate design. ... Consistent research effort has been made by various researchers with an objective to explore the world of investment casting. Literature review revealed the effect of processing parameters on output parameters ...

Pattnaik S, Karunakar DB, Jha PK. Developments in investment casting process - a review. J Mater Process Technol 2012a; 212: 2332-2348. 10.1016/j.jmatprotec.2012.06.003 Search in Google Scholar. Pattnaik S, Karunakar DB, Jha PK. Parametric optimization of the investment casting process using utility concept and Taguchi method.

This review article focuses on comparative studies of SLM and investment casting at the current technology level. The basis of comparison via systematic approach is mechanical characterization; quality in terms of porosity, microstructure, surface roughness and dimensional accuracy; and residual stress.

The Basic Steps in the Investment Casting Process. Figure-4. 2.Pattern Making. Wax patterns are traditionally[7] moulded in a permanent cavity known as "die", which generally includes the ingates. The wax is injected in the die under 5-35 kg/cm2 pressure, often (but not necessarily) through the ingate.

Some literature research studied and made comparison of mechanical properties (hardness), surface roughness, tensile strength and microstructure of samples produced from AM to samples produced with investment casting process (Table 2).The benefits of investment casting and additive manufacturing are presented in Table 3. Eurocast (Pursuit Aerospace) an investment casting company manufacturing ...

Design/methodology/approach. A systematic literature review is conducted in the field of casting considering the period 2000-2020. The keyword co-occurrence network and word cloud from the bibliometric analysis and text mining of the articles reveal that optimization and simulation models are extensively developed for various casting techniques, including sand casting, investment casting ...

Individual Castings. Once the parts are removed from the sprue, and the gates removed, the surface can be finished via a number of means. Vibratory/Media finishing. Belting or hand grinding. Polishing. Finishing can be done by hand, but in many cases it is automated. Parts are then inspected, marked (if required), packaged and shipped.

This modern book on investment casting fills a substantial gap in the literature of metal founding. The investment casting sector of the foundry industry has seen rapid growth; despite this the literature devoted specially to investment casting and its products has remained relatively sparse. Investment Casting has been produced by drawing upon ...

Investment casting process is known to its capability of producing clear net shape, high-dimensional accuracy and intricate design. Consistent research effort has been made by various researchers with an objective to explore the world of investment casting. Literature review revealed the effect of processing parameters on output parameters of cast specimen.

A systematic literature review process requires a prior procedure or plan. SLR is a well-organized and transparent system in which the search is performed through various reputable databases.

Urban regeneration is a sound, sustainable urban development strategy globally. In China, promoting urban regeneration has become the national sustainable urban strategy. Under the resource constraint, it is necessary to understand what benefits different types of urban regeneration projects can contribute to urban development. Much research has contributed to evaluating the benefits of urban ...

The investment-based crowdfunding market is showing rapid growth. The market was valued at approximately US$ 265 million in 2021 and is forecasted to reach around US$ 900 million by 2030, solely in the USA (Grand View Research 2022).In this line, investment-based crowdfunding platforms (IBCP) have become an essential capital source for ventures and project initiators, representing an emerging ...