Accessibility Links

- Skip to content

- Skip to search IOPscience

- Skip to Journals list

- Accessibility help

- Accessibility Help

Click here to close this panel.

Purpose-led Publishing is a coalition of three not-for-profit publishers in the field of physical sciences: AIP Publishing, the American Physical Society and IOP Publishing.

Together, as publishers that will always put purpose above profit, we have defined a set of industry standards that underpin high-quality, ethical scholarly communications.

We are proudly declaring that science is our only shareholder.

The Taguchi Method Application to Improve the Quality of a Sustainable Process

A M Titu 1 , A V Sandu 2 , A B Pop 3 , S Titu 4 and T C Ciungu 5

Published under licence by IOP Publishing Ltd IOP Conference Series: Materials Science and Engineering , Volume 374 , Euroinvent ICIR 2018 17–18 May 2018, Iasi, Romania Citation A M Titu et al 2018 IOP Conf. Ser.: Mater. Sci. Eng. 374 012054 DOI 10.1088/1757-899X/374/1/012054

Article metrics

1261 Total downloads

Share this article

Author e-mails.

Author affiliations

1 Lucian Blaga University of Sibiu, 10, Victoriei Street, Sibiu, România

2 Gheorghe Asachi Technical University, 67, Dimitrie Manjeron, Iasi, România

3 SC TEHNOCAD SA, 72, Vasile Alecsandri Street, Baia Mare, România

4 The Oncology Institute "Prof. Dr. Ion Chiricuță", 34-36, Republicii Street, Cluj Napoca, România

5 SC Construcții SA, 51, Morilor Street, Sibiu, România

Buy this article in print

Taguchi's method has always been a method used to improve the quality of the analyzed processes and products. This research shows an unusual situation, namely the modeling of some parameters, considered technical parameters, in a process that is wanted to be durable by improving the quality process and by ensuring quality using an experimental research method. Modern experimental techniques can be applied in any field and this study reflects the benefits of interacting between the agriculture sustainability principles and the Taguchi's Method application. The experimental method used in this practical study consists of combining engineering techniques with experimental statistical modeling to achieve rapid improvement of quality costs, in fact seeking optimization at the level of existing processes and the main technical parameters. The paper is actually a purely technical research that promotes a technical experiment using the Taguchi method, considered to be an effective method since it allows for rapid achievement of 70 to 90% of the desired optimization of the technical parameters. The missing 10 to 30 percent can be obtained with one or two complementary experiments, limited to 2 to 4 technical parameters that are considered to be the most influential. Applying the Taguchi's Method in the technique and not only, allowed the simultaneous study in the same experiment of the influence factors considered to be the most important in different combinations and, at the same time, determining each factor contribution.

Export citation and abstract BibTeX RIS

Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence . Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

14.1: Design of Experiments via Taguchi Methods - Orthogonal Arrays

- Last updated

- Save as PDF

- Page ID 22674

- Stephanie Fraley, John Zalewski, Mike Oom, & Ben Terrien

- University of Michigan

The Taguchi method involves reducing the variation in a process through robust design of experiments. The overall objective of the method is to produce high quality product at low cost to the manufacturer. The Taguchi method was developed by Dr. Genichi Taguchi of Japan who maintained that variation. Taguchi developed a method for designing experiments to investigate how different parameters affect the mean and variance of a process performance characteristic that defines how well the process is functioning. The experimental design proposed by Taguchi involves using orthogonal arrays to organize the parameters affecting the process and the levels at which they should be varies. Instead of having to test all possible combinations like the factorial design, the Taguchi method tests pairs of combinations. This allows for the collection of the necessary data to determine which factors most affect product quality with a minimum amount of experimentation, thus saving time and resources. The Taguchi method is best used when there is an intermediate number of variables (3 to 50), few interactions between variables, and when only a few variables contribute significantly.

The Taguchi arrays can be derived or looked up. Small arrays can be drawn out manually; large arrays can be derived from deterministic algorithms. Generally, arrays can be found online. The arrays are selected by the number of parameters (variables) and the number of levels (states). This is further explained later in this article. Analysis of variance on the collected data from the Taguchi design of experiments can be used to select new parameter values to optimize the performance characteristic. The data from the arrays can be analyzed by plotting the data and performing a visual analysis, ANOVA, bin yield and Fisher's exact test, or Chi-squared test to test significance.

In this article, the specific steps involved in the application of the Taguchi method will be described and examples of using the Taguchi method to design experiments will be given.

Summary of Taguchi Method

Philosophy of the taguchi method.

- Quality should be designed into a product, not inspected into it. Quality is designed into a process through system design, parameter design, and tolerance design. Parameter design, which will be the focus of this article, is performed by determining what process parameters most affect the product and then designing them to give a specified target quality of product. Quality "inspected into" a product means that the product is produced at random quality levels and those too far from the mean are simply thrown out.

- Quality is best achieved by minimizing the deviation from a target. The product should be designed so that it is immune to uncontrollable environmental factors. In other words, the signal (product quality) to noise (uncontrollable factors) ratio should be high.

- The cost of quality should be measured as a function of deviation from the standard and the losses should be measured system wide. This is the concept of the loss function, or the overall loss incurred upon the customer and society from a product of poor quality. Because the producer is also a member of society and because customer dissatisfaction will discourage future patronage, this cost to customer and society will come back to the producer.

Taguchi Method Design of Experiments

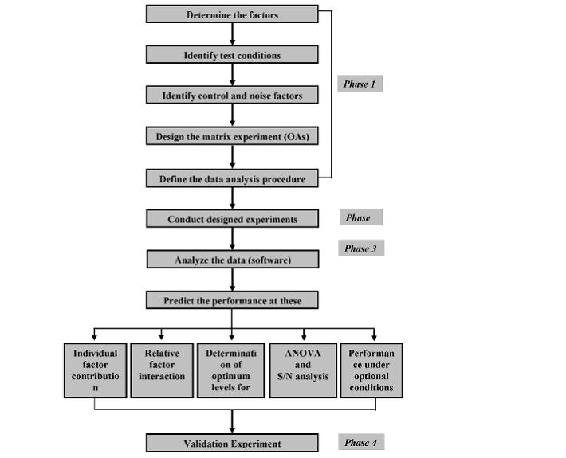

The general steps involved in the Taguchi Method are as follows:

- Define the process objective, or more specifically, a target value for a performance measure of the process. This may be a flow rate, temperature, etc. The target of a process may also be a minimum or maximum; for example, the goal may be to maximize the output flow rate. The deviation in the performance characteristic from the target value is used to define the loss function for the process.

- Determine the design parameters affecting the process. Parameters are variables within the process that affect the performance measure such as temperatures, pressures, etc. that can be easily controlled. The number of levels that the parameters should be varied at must be specified. For example, a temperature might be varied to a low and high value of 40 C and 80 C. Increasing the number of levels to vary a parameter at increases the number of experiments to be conducted.

- Create orthogonal arrays for the parameter design indicating the number of and conditions for each experiment. The selection of orthogonal arrays is based on the number of parameters and the levels of variation for each parameter, and will be expounded below.

- Conduct the experiments indicated in the completed array to collect data on the effect on the performance measure.

- Complete data analysis to determine the effect of the different parameters on the performance measure.

See below for a pictorial depiction of these and additional possible steps, depending on the complexity of the analysis.

A detailed description of the execution of these steps will be discussed next.

Taguchi Loss Function

The goal of the Taguchi method is to reduce costs to the manufacturer and to society from variability in manufacturing processes. Taguchi defines the difference between the target value of the performance characteristic of a process, τ, and the measured value, y, as a loss function as shown below.

\[l(y)=k_{c}(y-\tau)^{2} \nonumber \]

The constant, k c , in the loss function can be determined by considering the specification limits or the acceptable interval, delta.

\[k_{c}=\frac{C}{\Delta^{2}} \nonumber \]

The difficulty in determining k c is that τ and C are sometimes difficult to define.

If the goal is for the performance characteristic value to be minimized, the loss function is defined as follows:

\[l(y)=k_{c} y^{2} \nonumber \]

where \(\tau=0\).

If the goal is for the performance characteristic value to maximized, the loss function is defined as follows:

\[l(y)=\frac{k_{c}}{y^{2}} \nonumber \]

The loss functions described here are the loss to a customer from one product. By computing these loss functions, the overall loss to society can also be calculated.

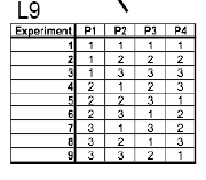

Determining Parameter Design Orthogonal Array

The effect of many different parameters on the performance characteristic in a condensed set of experiments can be examined by using the orthogonal array experimental design proposed by Taguchi. Once the parameters affecting a process that can be controlled have been determined, the levels at which these parameters should be varied must be determined. Determining what levels of a variable to test requires an in-depth understanding of the process, including the minimum, maximum, and current value of the parameter. If the difference between the minimum and maximum value of a parameter is large, the values being tested can be further apart or more values can be tested. If the range of a parameter is small, then less values can be tested or the values tested can be closer together. For example, if the temperature of a reactor jacket can be varied between 20 and 80 degrees C and it is known that the current operating jacket temperature is 50 degrees C, three levels might be chosen at 20, 50, and 80 degrees C. Also, the cost of conducting experiments must be considered when determining the number of levels of a parameter to include in the experimental design. In the previous example of jacket temperature, it would be cost prohibitive to do 60 levels at 1 degree intervals. Typically, the number of levels for all parameters in the experimental design is chosen to be the same to aid in the selection of the proper orthogonal array.

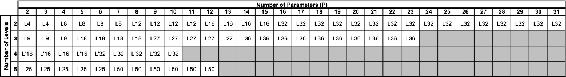

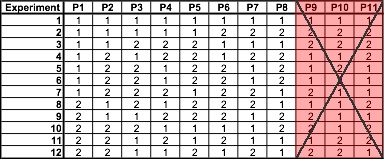

Knowing the number of parameters and the number of levels, the proper orthogonal array can be selected. Using the array selector table shown below, the name of the appropriate array can be found by looking at the column and row corresponding to the number of parameters and number of levels. Once the name has been determined (the subscript represents the number of experiments that must be completed), the predefined array can be looked up. Links are provided to many of the predefined arrays given in the array selector table. These arrays were created using an algorithm Taguchi developed, and allows for each variable and setting to be tested equally. For example, if we have three parameters (voltage, temperature, pressure) and two levels (high, low), it can be seen the proper array is L4. Clicking on the link L4 to view the L4 array, it can be seen four different experiments are given in the array. The levels designated as 1, 2, 3 etc. should be replaced in the array with the actual level values to be varied and P1, P2, P3 should be replaced with the actual parameters (i.e. voltage, temperature, etc.)

Array Selector

Links to Orthogonal Arrays

The following links are connected to images of the orthogonal array named in the link title:

Important Notes Regarding Selection + Use of Orthogonal Arrays

The array selector assumes that each parameter has the same number of levels. Sometimes this is not the case. Generally, the highest value will be taken or the difference will be split.

The following examples offer insight on choosing and properly using an orthogonal array. Examples 1 and 2 focus on array choice, while Example 3 will demonstrate how to use an orthogonal array in one of these situations.

# parameter: A, B, C, D = 4 # levels: 3, 3, 3, 2 = ~3 array: L9

# parameter: A, B, C, D, E, F = 6 # levels: 4, 5, 3, 2, 2, 2 = ~3 array: modified L16

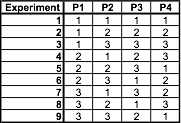

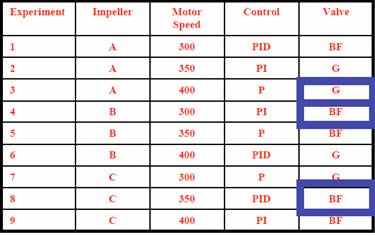

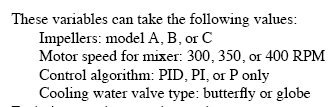

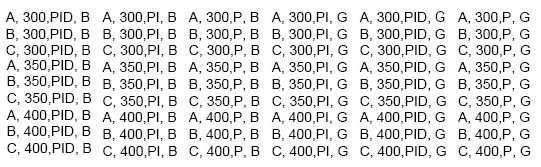

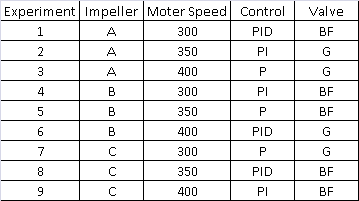

A reactor's behavior is dependent upon impeller model, mixer speed, the control algorithm employed, and the cooling water valve type. The possible values for each are as follows:

Impeller model: A, B, or C

Mixer speed: 300, 350, or 400 RPM

Control algorithm: PID, PI, or P

Valve type: butterfly or globe

There are 4 parameters, and each one has 3 levels with the exception of valve type. The highest number of levels is 3, so we will use a value of 3 when choosing our orthogonal array.

Using the array selector above, we find that the appropriate orthogonal array is L9:

When we replace P1, P2, P3, and P4 with our parameters and begin filling in the parameter values, we find that the L9 array includes 3 levels for valve type, while our system only has 2. The appropriate strategy is to fill in the entries for P4=3 with 1 or 2 in a random, balanced way. For example:

Here, the third value was chosen twice as butterfly and once as global.

If the array selected based on the number of parameters and levels includes more parameters than are used in the experimental design, ignore the additional parameter columns. For example, if a process has 8 parameters with 2 levels each, the L12 array should be selected according to the array selector. As can be seen below, the L12 Array has columns for 11 parameters (P1-P11). The right 3 columns should be ignored.

Analyzing Experimental Data

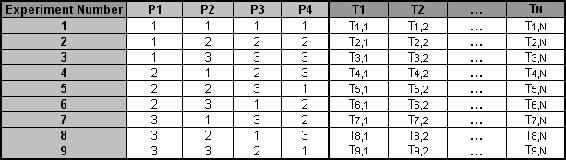

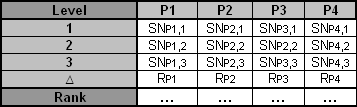

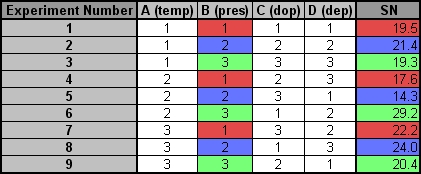

Once the experimental design has been determined and the trials have been carried out, the measured performance characteristic from each trial can be used to analyze the relative effect of the different parameters. To demonstrate the data analysis procedure, the following L9 array will be used, but the principles can be transferred to any type of array.

In this array, it can be seen that any number of repeated observations (trials) may be used. Ti,j represents the different trials with i = experiment number and j = trial number. It should be noted that the Taguchi method allows for the use of a noise matrix including external factors affecting the process outcome rather than repeated trials, but this is outside of the scope of this article.

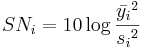

To determine the effect each variable has on the output, the signal-to-noise ratio, or the SN number, needs to be calculated for each experiment conducted. The calculation of the SN for the first experiment in the array above is shown below for the case of a specific target value of the performance characteristic. In the equations below, yi is the mean value and si is the variance. yi is the value of the performance characteristic for a given experiment.

\[S N_{i}=10 \log \frac{\bar{y}_{i}^{2}}{s_{i}^{2}} \nonumber \]

\[\bar{y}_{i}=\frac{1}{N_{i}} \sum_{u=1}^{N_{i}} y_{i, u} \nonumber \]

\[s_{i}^{2}=\frac{1}{N_{i}-1} \sum_{u=1}^{N_{i}}\left(y_{i, u}-\bar{y}_{i}\right) \nonumber \]

- \(i\) is the experimental number,

- \(u\) is the trial number, and

- \(N_i\) is the numb er of trials for experiment \(i\)

For the case of minimizing the performance characteristic, the following definition of the SN ratio should be calculated:

\[S N_{i}=-10 \log \left(\sum_{u=1}^{N_{i}} \frac{y_{u}^{2}}{N_{i}}\right) \nonumber \]

For the case of maximizing the performance characteristic, the following definition of the SN ratio should be calculated:

\[S N_{i}=-10 \log \left[\frac{1}{N_{i}} \sum_{u=1}^{N_{i}} \frac{1}{y_{u}^{2}}\right] \nonumber \]

After calculating the SN ratio for each experiment, the average SN value is calculated for each factor and level. This is done as shown below for Parameter 3 (P3) in the array:

Once these SN ratio values are calculated for each factor and level, they are tabulated as shown below and the range R (R = high SN - low SN)of the SN for each parameter is calculated and entered into the table. The larger the R value for a parameter, the larger the effect the variable has on the process. This is because the same change in signal causes a larger effect on the output variable being measured.

Please refer to the Worked Out Example for a numeric example of how the data analysis procedure described here is applied.

Advantages and Disadvantages

An advantage of the Taguchi method is that it emphasizes a mean performance characteristic value close to the target value rather than a value within certain specification limits, thus improving the product quality. Additionally, Taguchi's method for experimental design is straightforward and easy to apply to many engineering situations, making it a powerful yet simple tool. It can be used to quickly narrow down the scope of a research project or to identify problems in a manufacturing process from data already in existence. Also, the Taguchi method allows for the analysis of many different parameters without a prohibitively high amount of experimentation. For example, a process with 8 variables, each with 3 states, would require 6561 (3 8 ) experiments to test all variables. However using Taguchi's orthogonal arrays, only 18 experiments are necessary, or less than .3% of the original number of experiments. In this way, it allows for the identification of key parameters that have the most effect on the performance characteristic value so that further experimentation on these parameters can be performed and the parameters that have little effect can be ignored.

The main disadvantage of the Taguchi method is that the results obtained are only relative and do not exactly indicate what parameter has the highest effect on the performance characteristic value. Also, since orthogonal arrays do not test all variable combinations, this method should not be used with all relationships between all variables are needed. The Taguchi method has been criticized in the literature for difficulty in accounting for interactions between parameters. Another limitation is that the Taguchi methods are offline, and therefore inappropriate for a dynamically changing process such as a simulation study. Furthermore, since Taguchi methods deal with designing quality in rather than correcting for poor quality, they are applied most effectively at early stages of process development. After design variables are specified, use of experimental design may be less cost effective.

Other Methods of Experimental Design

Two other methods for determining experimental design are factorial design and random design. For scenarios with a small number of parameters and levels (1-3) and where each variable contributes significantly, factorial design can work well to determine the specific interactions between variables. However, factorial design gets increasingly complex with an increase in the number of variables. For large systems with many variables (50+) where there are few interactions between variables, random design can be used. Random design assigns each variable a state based on a uniform sample (ex: 3 states = 0.33 probability) for the selected number of experiments. When used properly (in a large system), random design usually produces an experimental design that is desired. However, random design works poorly for systems with a small number of variables.

To obtain a even better understanding of these three different methods, it's good to get a visual of these three methods. It will illustrate the degree of efficiency for each experimental design depending on the number of variables and the number of states for each variable. The following will have the three experimental designs for the same scenario.

Scenario. You have a CSTR that has four(4) variables and each variable has three or two states. You are to design an experiment to systematically test the effect of each of the variables in the current CSTR.

Experimental Design #1: Factorial Design By looking at the # variables and # states, there should be a total of 54 experiments because (3impellers)(3speeds)(3controllers)(2valves)=54. Here's a list of these 54 experiments:

Experimental Design #2: Taguchi Method Since you know the # of states and variables, you can refer to the table above in this wiki and obtain the correct Taguchi array. It turns out to be a L9 array.

With the actual variables and states, the L9 array should look like the following:

Experimental Design #3: Random Design

Since we do not know the number of signal recoveries we want and we don't know the probabilities of each state to happen, it will be difficult to construct a random design table. It will mostly be used for extreme large experiments. Refer to the link below to help you obtain a better grasp on the random design concept.

http://groups.csail.mit.edu/drl/journal_club/papers/CS2-Candes-Romberg-05.pdf

Example \(\PageIndex{1}\)

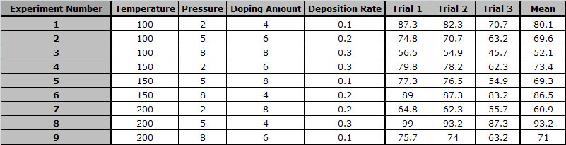

A microprocessor company is having difficulty with its current yields. Silicon processors are made on a large die, cut into pieces, and each one is tested to match specifications. The company has requested that you run experiments to increase processor yield. The factors that affect processor yields are temperature, pressure, doping amount, and deposition rate.

Determine the Taguchi experimental design orthogonal array. The operating conditions for each parameter and level are listed below:

- A: Temperature

- A1 = 100ºC

- A2 = 150ºC (current)

- A3 = 200ºC

- B: Pressure

- B2 = 5 psi (current)

- C: Doping Amount

- C2 = 6% (current)

- D: Deposition Rate

- D1 = 0.1 mg/s

- D2 = 0.2 mg/s (current)

- D3 = 0.3 mg/s

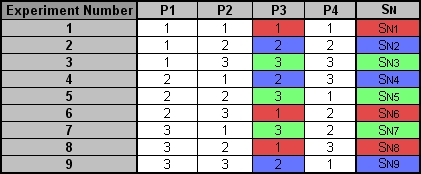

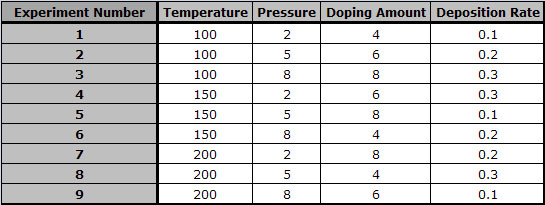

Conducting three trials for each experiment, the data below was collected. Compute the SN ratio for each experiment for the target value case, create a response chart, and determine the parameters that have the highest and lowest effect on the processor yield.

The L9 orthogonal array should be used. The filled in orthogonal array should look like this:

This setup allows the testing of all four variables without having to run 81 [=3 4 =(3 Temperatures)(3 Pressures)(3 Doping Amounts)(3 Deposition rates)] separate trials.b) Question:

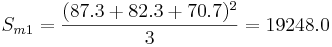

b) Shown below is the calculation and tabulation of the SN ratio.

Shown below is the response table. This table was created by calculating an average SN value for each factor. A sample calculation is shown for Factor B (pressure):

The effect of this factor is then calculated by determining the range:

It can be seen that deposition rate has the largest effect on the processor yield and that temperature has the smallest effect on the processor yield.

NOTE: The data for the following example is not real, and details pertaining to microprocessor fabrication may not be completely accurate.

a) Solution:

Example \(\PageIndex{2}\): Sesame Seed Suffering

You have just produced one thousand 55 gallon drums of sesame oil for sale to your distributors. However, just before you are to ship oil, one of your employees remembers that one of the oil barrels was temporarily used to store insecticide and is almost surely contaminated. Unfortunately, all of the barrels look the same.

One barrel of sesame oil sells for $1000, while each assay for insecticide in food oil costs $1200 and takes 3 days. Tests for insecticide are extremely expensive. What do you do?

Extreme multiplexing. This is similar to using a Taguchi method but optimized for very sparse systems and specific cases. For example, instead of 1000 barrels, let us consider 8 barrels for now, one of which is contaminated. We could test each one, but that would be highly expensive. Another solution is to mix samples from each barrel and test the mixtures.

- Mix barrels 1,2,3,4 ---> Sample A

- Mix barrels 1,2,5,6 ---> Sample B

- Mix barrels 1,3,5,7 ---> Sample C

We claim that from testing only these three mixtures, we can determine which of the 8 barrels was contaminated. Let us consider some possible results of these tests. We will use the following label scheme: +/-,+/-,+/- in order of A, B, C. Thus, +,-,+ indicates A and C showed contamination but not B.

- Possible Result 1: -,-,- The only barrel not mixed in was #8, so it is contaminated.

- Possible Result 2: +,-,- Barrel #4 appears in A, but not in B and C. Since only A returned positive, barrel #4 was contaiminated.

- Possible Result 3: -,+,- Barrel #6 appears in B, but not in A and C. Since only B returned positive, barrel #6 was contaminated.

We can see that we have 2 3 = 8 possible results, each of which corresponds to a particular barrel being contaminated. We leave the rest of the cases for the reader to figure out.

Solution with 1,000 barrels: Mix samples from each barrel and test mixtures. Each mixture will consist of samples from a unique combination of 500 barrels. Experiments required = log 2 (1000)=~10.

Solution with 1,000,000 barrels: Experiments required = log 2 (1000000)=~20.

Thus, by using extreme multiplexing, we can greatly reduce the # of experiments needed, since the # of experiments scales with log 2 (# of barrels) instead of # of barrels.

Exercise \(\PageIndex{1}\)

You are producing decaffeinated coffee using supercritical carbon dioxide as a solvent. To optimize the effectiveness of caffeine removal, you would like to test 2 different possible pressures of CO2, 3 possible temperatures, 3 ratios of CO2 to coffee beans, 3 residence times of supercritical CO2 with beans, and 2 different procedures for preroasting the beans prior to caffeine extraction. What is the most appropriate method to design your optimization experiments?

- Factorial design

- Taguchi methods

- Random design

- None of the above. Coffee should never be decaffeinated

To perform a full factorial experiment, you’d need to account for: (2 pressures)(3 temperatures)(3 ratios)(3 times)(2 roasts) = 108 experiments! Thus, factorial design is not a practical choice: a good rule of thumb is 1-3 variables with few states for a manageable factorial analysis. However, selecting 3 for the number of levels and consulting the array selector, we see that an L18 array will suffice for a Taguchi analysis. 18 is a much more feasible number of experiments than 108. Finally, random design is only practical when >50 variables are involved and few will have significant impact on the system, which is not the case here. Thus, although the author is of the opinion that choice ‘D’ has significant merit, the correct answer is ‘B’.

Exercise \(\PageIndex{2}\)

Which of the following is inconsistent with the Taguchi philosophy of quality control?

- Variation is the opposite of quality

- Interactions between parameters affecting product quality are unimportant and should never be considered

- Customer dissatisfaction is the most important measure for process variation, and should be minimized

- A high signal to noise ratio (SN) should be present in a process to make it robust against uncontrollable factors that would cause variation

Choice ‘A’ is another way of expressing point 3 of the Taguchi philosophy above. Similarly, choice ‘C’ is another way of expressing the cost function, and choice ‘D’ is consistent with philosophy 2. Although it is true that the Taguchi methods do not account well for interactions between variables, choice ‘B’ is incorrect for two reasons. 1) Pair-wise interactions between variables are accounted for in Taguchi orthogonal arrays. 2) Negligibility of interactions between parameters is not so much a central tenet of Taguchi philosophy as a necessary simplifying assumption. An analog is decoupling of MIMO systems. Since applying this assumption yields good results, it is consistent with Taguchi thinking to say that makes it valid.

- Vuchkov, I.N. and Boyadjieva, L.N. Quality Improvement with Design of Experiments: A Response Surface Approach. Kluwer Academic Publishers. Dordrecht, 2001.

- http://www.ee.iitb.ac.in/~apte/CV_PRA_TAGUCHI_INTRO.htm

- http://www.york.ac.uk/depts/maths/tables/orthogonal.htm

- www.freequality.org/sites/www_freequality_org/documents/tools/Tagarray_files/tamatrix.htm

- Roy, R. K., A Primer on the Taguchi Method, Van Nostrand Reinhold, New York 1990.

- Ravella Sreenivas Rao, C. Ganesh Kumar, R. Shetty Prakasham, Phil J. Hobbs (2008) The Taguchi methodology as a statistical tool for biotechnological applications: A critical appraisal Biotechnology Journal 3:510–523.

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 06 August 2021

Application of Taguchi method and response surface methodology into the removal of malachite green and auramine-O by NaX nanozeolites

- Siroos Shojaei 1 ,

- Saeed Shojaei 2 ,

- Shahab S. Band 3 ,

- Amir Abbas Kazemzadeh Farizhandi 4 ,

- Milad Ghoroqi 5 &

- Amir Mosavi 6

Scientific Reports volume 11 , Article number: 16054 ( 2021 ) Cite this article

6437 Accesses

48 Citations

8 Altmetric

Metrics details

- Environmental sciences

- Natural hazards

In the present study, the simultaneous removal of malachite green (MG) and auramine-O (AO) dyes from the aqueous solution by NaX nanozeolites in a batch system is investigated. Taguchi method and response surface methodology (RSM) were used to optimize and model dye removal conditions. In order to do so, the effect of various factors (dyes concentration, sonication time, ionic strength, adsorbent dosage, temperature, and pH of the solution) on the amount of dye removal was evaluated by the Taguchi method. Then, the most important factors were chosen and modeled by the RSM method so as to reach the highest percentage of dye removal. The proposed quadratic models to remove both dyes were in good accordance with the actual experimental data. The maximum removal efficiencies of MG and AO dyes in optimal operating conditions were 99.07% and 99.61%, respectively. Also, the coefficients of determination (R 2 ) for test data were 0.9983 and 0.9988 for MG and AO dyes, respectively. The reusability of NaX nanozeolites was evaluated during the adsorption process of MG and AO. The results showed that the adsorption efficiency decreases very little up to five cycles. Moreover, NaX nanozeolites were also applied as adsorbents to remove MG and AO from environmental water samples, and more than 98.1% of both dyes were removed from the solution in optimal conditions.

Similar content being viewed by others

RETRACTED ARTICLE: Optimization of dyes and toxic metals removal from environmental water samples by clinoptilolite zeolite using response surface methodology approach

Preparation and characterization of low-cost adsorbents for the efficient removal of malachite green using response surface modeling and reusability studies

Adsorptive removal of acid red 18 dye from aqueous solution using hexadecyl-trimethyl ammonium chloride modified nano-pumice

Introduction.

Pollution of water resources has become an economic problem since industrial factories have been increasing and water resources are limited 1 , 2 . Numerous industries, such as textiles, pharmaceuticals, and papermaking, produce large volumes of dye effluents. It is reported that about 10,000 types of commercial dyes with a volume of more than 700,000 tons are produced worldwide. In fact, about 20% of these dyes enter the aqueous medium due to the lack of proper stabilization of dye molecules on the fibers and the inefficiency of dyeing factories in wastewater treatment. Studies have shown that most of these dyes are toxic, allergenic, carcinogenic, and mutagenic to humans and various organisms 3 , 4 .

Malachite green (MG) is a toxic cationic dye originally used in the dyeing industry for materials such as silk, leather, and paper. This dye was first used in the fisheries industry in 1933 5 . Because it was too inexpensive and effective in eradicating aquatic infections. This dye was used too much in many countries. On the other hand, as a result of using this dye, many destructive effects such as carcinogenicity and mutagenicity have been reported in various organisms, especially mammals 6 , 7 , 8 .

Auramine-O (AO) is a water-soluble cationic dye. AO dye is one of the dyes used in the textile, carpet, and leather industries. Studies have shown that this dye is converted to biotransformation in human organs and increases the risk of bladder cancer 9 , 10 . Accordingly, efforts should be made to improve methods that reduce or eliminate these dyes from the aqueous environment.

There are different ways to remove the dye, such as reverse osmosis, ultra-filtration, ion exchange, and adsorption 11 , 12 , 13 , 14 , 15 , 16 , 17 . Adsorption is one of the acceptable techniques to reduce the concentration of dissolved dyes in aqueous solutions. The advantages of this technique include simplicity in operation, cheapness, and flexibility compared to other separation techniques 18 , 19 .

Various adsorbents such as eggshell 20 , activated carbon 21 , bentonite 22 , shrimp shell 23 , and zeolite 24 have been used to remove dye effluents. Recently, researchers have applied inexpensive adsorbents with high adsorption potential with high adsorption power and do not harm the environment. Thus, economic problems and the recovery of adsorbents have made researchers focus on inexpensive adsorbents such as zeolites.

Zeolites are generally divided into natural and synthetic. Natural zeolites are mostly found in volcanic rocks, but they are not produced a lot because they are not economical to extract. Synthetic zeolites are far better than their natural counterparts due to a special type, high purity, easy commercial-scale access, and fixed and controllable pore sizes. The most popular synthetic zeolites include A, X, Y, and ZSM-5 25 , 26 . In synthetic zeolites, there are fundamental changes in the properties of these materials as the particle size is reduced from micrometers to nanometers, which is very effective on the function of zeolites in catalytic applications and separation. As the particle size decreases, the ratio of the number of outer atoms to the material increases rapidly, resulting in an increase in the outer surface area and significant surface activity 27 , 28 . Nowadays, the use of zeolites as adsorbents in the adsorption process has received much attention.

Arabkhani et al. (2021) have recently used magnetic GO/ZIF-8/γ-AlOOH-NC as a novel and effective adsorbent to remove diclofenac from hospital effluents. Optimal conditions of diclofenac removal were evaluated by the RSM method. The reusability results revealed that the reuse of the adsorbent up to 5 times caused no significant reduction in its adsorption capacity. They also investigated the magnetic efficiency of GO/ZIF-8/γ-AlOOH-NC in diclofenac removal from simulated hospital effluents containing various drugs and organic and inorganic substances. They reported that the magnetic GO/ZIF-8/γ-AlOOH-NC could be promising as an efficient adsorbent for diclofenac removal from wastewater 29 .

A research was conducted on the application of ZSM-5 zeolite to remove malachite green from aqueous solutions. Optimum condition zeolite dosage 5 wt%, pH 10, initial dye concentration of 10 mg L −1 , and temperature 25 °C was obtained. Also, 99.12% dye removal was achieved in optimal conditions 30 .

In another study, nano ZSM-5 zeolite (nZSM-5) synthesized from rice husk ash to remove crystal violet from aqueous solutions was carried out by Sivalingam and Sen (2020) effectiveness of nZSM-5 in removing crystal violet from aqueous solutions was investigated. Maximum dye removal (99.99%) in conditions adsorbent dosage of 100 mg, pH of 8, initial CV dye concentration of 100 mg L −1 , and sonication time of 30 min were obtained 31 .

Sivalingam and Sen used nanozeolite X to remove ions such as Cu 2+ , Zn 2+ , Pb 2+ , Cd 2+ , Ca 2+ , Ni 2+ , Mg 2+ , and various dyes such as crystal violet methylene blue, Congo red, and indigo carmine. The results showed that the maximum adsorption capacity of metals was obtained for Pb 2+ 196.24 mg g −1 and methylene blue 193.45 mg g −1 . Therefore, nanozeolite X can be used as a highly efficient adsorbent to remove various dyes and ions 32 .

The ultrasonic process has been considered as an efficient and advanced technology in various fields of science to help eliminate contaminants in water 33 . Theory to explain how ultrasound breaks chemical bonds involves the formation, growth, and eventual destruction of a bubble that forms within a liquid. This phenomenon, known as acoustic cavitation, creates an environment with a pressure of up to 10 pascals. The phenomenon of acoustic cavitation increases mass transfer, increases the adsorption permeability into the adsorbent, increases process efficiency, and reduces time 34 , 35 .

Generally, experiments and factors affecting the process are carried out in the form of one-factor-at-a-time. Different factors in this method are done by changing the effective factor studied in a range of levels and keeping other factors constant. To achieve optimal conditions by this method, the tests must be repeated for all factors, which leads to a substantial increase in the number of tests. In order to cope with the limitations, various experimental design methods based on mathematical and statistical techniques have been developed, including the Taguchi method and response surface methodology (RSM) 36 , 37 . Taguchi method includes experimental design method to determine the effect of factors on the response and to obtain the optimal process conditions. One of the main advantages of this method is providing optimal conditions with the minimum number of experiments using orthogonal arrays, leading to cost reduction 38 , 39 . RSM is very useful to design experiments and analyze data to lead to a purposeful and reliable conclusion. RSM is a particular set of mathematical and statistical methods used to design experiments, construct models, evaluate optimal conditions, effect independent variables on dependent variables, and obtain optimal conditions for multiple responses simultaneously. Also, the graphs presented in the RSM method are three-dimensional, which allows showing the change of all factors in one graph 40 , 41 . This study aimed to remove toxic dyes by NaX nanozeolites as well as. The variables were first examined based on the Taguchi method, and the most important ones were selected. In the next step, these variables were modeled using the RSM method to determine the optimal conditions.

Experimental section

Materials and instruments.

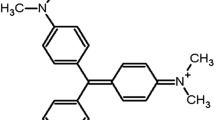

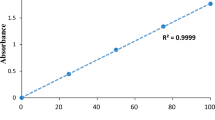

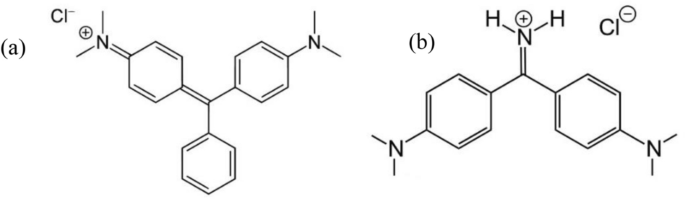

All materials used, such as sodium aluminate, sodium hydroxide, tetraethylorthosilicate, hydrochloric acid, and other chemicals, were used without further refining and were supplied from Aldrich or Merck companies. The stock solution of the dyes was prepared by dissolving the solid substance of each dye in distilled water. Other solutions in this study were prepared by diluting the stock solution and used immediately in adsorption experiments. UV/Vis spectrophotometer (2120 UV plus, Optizen) was used to detect dyes at maximum wavelength of malachite green (MG) (λ max = 620 nm) and auramine-O (AO) (λ max = 430 nm). Sodium hydroxide (1 M) and hydrochloric acid (1 M) solutions were used to adjust the pH. The chemical structures and descriptions of the dyes are shown in Fig. 1 and Table 1 , respectively.

The chemical structure of (a) MG, and (b) AO.

Preparation of NaX nanozeolites

In order to synthesize NaX nanozeolites, molecular composition (5.5 Na 2 O: 1.0 Al 2 O 3 : 4.0 SiO 2 : 190 H 2 O) was used. Also, 7.22 g of sodium hydroxide was calculated according to the molar composition and dissolved in a plastic bottle (250 ml) with distilled water. Then, the solution was divided into two equal parts, and in the first part, 0.16 g of sodium aluminate and the second part 5.22 g of Tetraethyl orthosilicate were added. The two solutions, including aluminate and silicate solutions, were then mixed and placed in an ice-water bath. Hydrothermal crystallization was done by shaking with a shaker for 3 days. Furthermore, the obtained powder was recovered by centrifugation for 5 min at 3500 rpm. The synthesized NaX nanozeolites were washed several times with distilled water to bring the pH below 8 and finally dried at room temperature for 1 day 42 , 43 . The synthesized NaX nanozeolites have been characterized by X-ray diffraction (XRD) using Cu K a as the radiation source, scanning electron microscopy (SEM), and Brunauer Emmett Teller (BET) adsorption/desorption isotherms for surface area analysis.

Experimental design

Taguchi method.

Taguchi is a method that reduces the number of experiments by minimizing the interference of uncontrolled factors, which is used as a mathematical technique. By creating orthogonal arrays and matching many factors, Taguchi identifies minor variables in the shortest amount of time. The orthogonal arrays are shown in Table 2 . Factors studied include temperature (25–35 °C), solution pH (3–9), adsorbent (100–300 mg), ionic strength (0–6 w/v%), dye concentration (6–10 mg L -1 ) and sonication time (3–9 min). Applying the Taguchi method, only 27 experiments are required to obtain the optimal levels of the variables (Table 2 ), while the most accurate optimization method for a complete study of seven variables at three levels requires 2187 experiments (3 7 = 2187), which is practically time-consuming. Therefore, the Taguchi method can reduce the number of tests, reduce time, decrease costs, and determine important factors in a short time. Taguchi uses the signal-to-noise ratio in measurable amounts of qualitative characteristics according to the purpose of the experiments. The signal-to-noise ratio (S/N) is obtained by Eq. ( 1 ):

In this equation, n is the number of experiments, and y is the response of the variables 44 .

Response surface methodology (RSM)

RSM is a set of mathematical and statistical methods determining the relationship between one or more responses to several variables. In chemistry, many phenomena are modeled based on their theories. However, many phenomena do not have a satisfactory mathematical model due to their dependence on many controlling factors, unknown mechanisms, and mathematical complexity. In such cases, the use of experimental modeling methods such as the response level method is effective. In the central composite design (CCD)-based RSM, variables are examined at five levels. Low levels (-α) and high levels (+ α) are entered into the software by the operator, and the software provides other levels. According to the results obtained in the Taguchi method in “Taguchi method”. Taguchi method, in this step, five factors that were of great importance were examined. These factors were the amount of adsorbent, dye concentration, sonication time, and pH solution (Table 3 ). The percentage of dye removal was considered as the response variable. The equation that can be used in the response surface method is the polynomial quadratic equation. The responses must conform to Eq. ( 2 ) in order to use it.

Where k is the number of variables, β 0 is the model constant, β i are the coefficients of linear factors, β ij and β ii are the coefficients of the factors that interact with each other, ɛ the remaining values are related to random error, X i and X j are the variables 45 .

Analytical methods

In order to study the efficiency of NaX nanozeolites to remove MG and AO dyes, batch experiments were performed. The experiments were designed by the CCD method. For this reason, at room temperature, in a centrifuge tube, 25 mL of a solution containing both dyes (4 mg L −1 ) was added. Then, 347 mg of NaX nanozeolites were added to the sample solution. The pH of the solution was adjusted to 8. The solution was placed in an ultrasonic bath for 11.5 min and centrifuged at 3000 rpm for 5 min. Finally, the supernatant was removed and transferred to UV/Vis cells to determine the amount of residual concentration and to calculate the percentage of dye removal of MG and AO, and the adsorption of solutions for MG and AO was read at 620 nm and 430 nm, respectively. In these experiments, Eq. ( 3 ) was used to determine the percentage of dye removal.

C 0 and C are the initial and final concentrations of the desired dye in terms of mg L −1 , respectively 46 .

Results and discussion

Characterization of the nax nanozeolites.

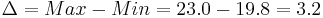

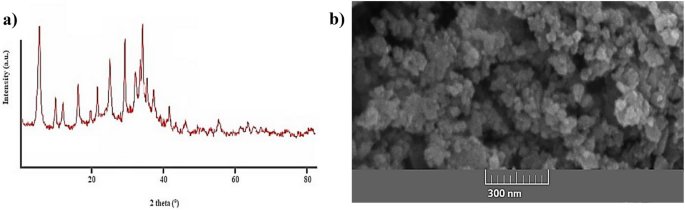

Figure 2 a shows the XRD pattern of the sample, and XRD analysis shows that high purity NaX zeolite phase without phase interference has been synthesized in the above phase method (JCPDS no. 39-0218) 47 , 48 . The average size of the crystals synthesized using the Scherer equation was in the range of 40–70 nm. The crystal size indicates that the synthesis of NaX zeolite in nanometer dimensions has been successful. Morphological analysis of NaX nanozeolites was performed using SEM. The SEM image of the synthesized zeolite sample (Fig. 2 b) shows that the particle sizes are in the range between 50 and 150 nm. Also, the adsorption and desorption porosity was measured by the BET analysis. The BET surface area, calculated average particle size, and total pore volume of synthesized NaX nanozeolites were found as 852.5 m 2 /g, 69.42 nm, 0.304 cm 3 /g, respectively.

(a) XRD pattern of nanozeolite-X, (b) SEM image of the corresponding sample.

Determination of pH PZC

pH PZC is the point at which the adsorbent surface charge is neutral. Thus, at a pH above this point, the adsorbent surface has a negative charge, and at a lower pH, the surface charges become positive. In order to determine pH PZC , 10 mL of NaCl solution (0.1 M) was poured into separate test tubes, and the solutions were adjusted to different pH (2–12). Hydrochloric acid (1 M) and sodium hydroxide (1 M) were used to adjust the pH. Then, 0.3 g of adsorbent was added to the solutions, and the samples were placed in a shaker at 150 rpm. After 24 h, the adsorbents were separated from the solution, and the solutions' pH was measured again. The pH PZC was found to be 6.5 (Fig. S1 ).

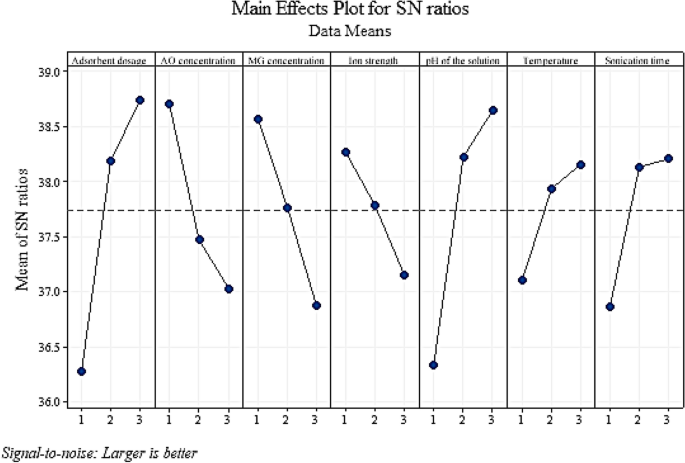

Response factors based on the Taguchi

The experimental design was performed by the Taguchi method in Minitab software version 19. In order to estimate the most important factors in the removal of MG and AO dyes by NaX nanozeolites by the Taguchi method, 7 factors were investigated at 3 levels. These levels were initially obtained by trial and error. The software proposed the orthogonal table L27 (7 factors in 3 levels) to design the above experiment, which includes 27 experiments. Taguchi test design table for removing MG and AO dyes is given in Table S1 .

The change in each of the factors indicates the importance of the factor in the process. In Table 4 , the effect of each factor at each level was calculated independently by the software, and finally, according to the differences created in each factor, the importance of each was investigated. In MG and AO dye removal experiments, the amount of adsorbent has the first effect on the adsorption process, pH comes as the second factor, MG dye concentration the third, AO dye concentration the fourth, sonication time the, ionic strength the sixth, and finally the temperature is the seventh factor. Based on the results of Table 4 , the variables of adsorbent amount, solution pH, dye concentration, and sonication time were selected as effective variables for optimization and modeling by the RSM method. Therefore, the variables of temperature and ionic strength were omitted. Because as shown in Fig. 3 and Table 4 , the temperature has little effect on the process compared to other factors and was maintained at 25 °C in subsequent optimal experiments. Increasing ionic strength also reduces the adsorption of dyes by NaX nanozeolites. This can be attributed to preventing dye molecules from approaching the active sites of adsorption 49 . The same effect has been reported in the literature for some cationic dyes, such as the adsorption of methylene blue by sludge ash, methylene blue, and crystal violet by palm kernel fiber 50 , 51 .

Signal to noise ratios for removal MG and AO.

Significant variable optimization by RSM

In this section, Design Expert statistical software version 10 was used to execute the CCD design and analyze the resulting data. Software output includes main effects, their interactions, quadratic equation, and statistical graphs. To perform experiments by the CCD method, the software designed 32 experiments. Table 5 shows the order of these 32 experiments. Method of analysis in “Analytical methods”. Analytical methods are provided. The answer to each row of the experiment is also given.

A reliable method for evaluating the quality of a matched model is the analysis of variance (ANOVA). In ANOVA, the share of variance of each factor is compared with the variance caused by random errors in measurement. In fact, the significance of regression can be examined through this comparison. Significance of regression is performed by comparing the regression variance to the variance of the residuals with the Fisher distribution (F-test). If this ratio is greater than the critical value of F, the mathematical model is consistent with the experimental data. If the calculated p-value for each of the factors is less than 0.05, it indicates the effectiveness of that factor, and if it is more than 0.05, it means that the change of that factor does not affect the values. The parameters for MG and AO dyes are given in Table 6 . The correlation coefficients (R 2 ) were 0.9983 and 0.9988, and adj-R 2 were 0.9953 and 0.9967 for MG and AO, respectively. High values of R 2 and adj-R 2 confirm the model's ability to make a convincing estimate of the response.

As can be seen in Table 6 , the value of p for linear and interaction factors is less than 0.05. From the value of p related to nonconformity, it can be deduced that the equation obtained is consistent with the experimental data. The mathematical model was presented as a second-order polynomial relation in coded form (A, B, etc.) to describe each deletion efficiency response (%R) for each of the dyes in Eqs. ( 4 ) and ( 5 ).

In Eqs. ( 4 ) and ( 5 ), the parameters of adsorbent amount (A), pH of solution (B), MG concentration (C), AO concentration (D), and sonication time (E).

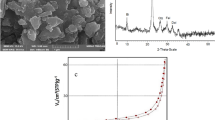

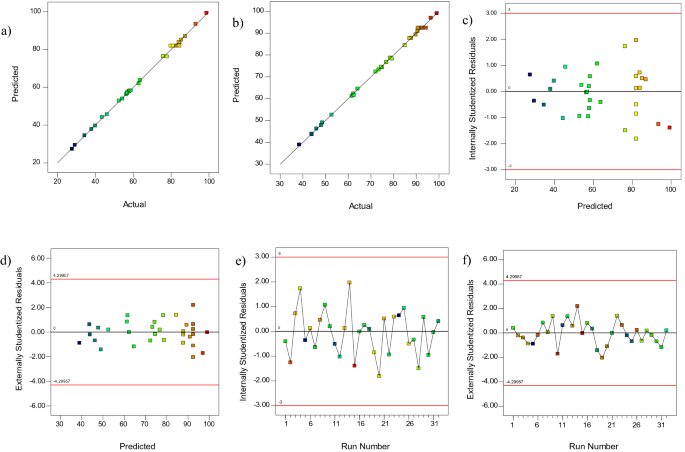

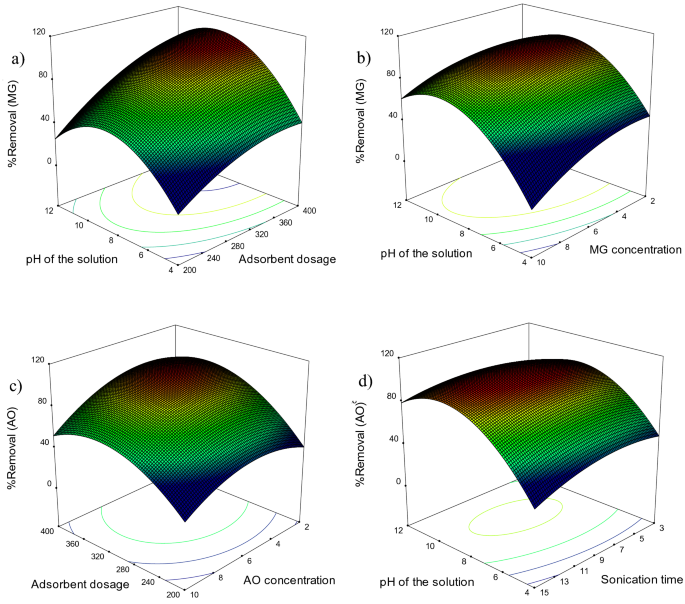

Residual diagrams help to interpret the results accurately. Assuming that the errors are normally distributed and independent of each other, residual probability diagrams (Fig. 4 a,b) are an essential diagnostic tool to identify and explain systematic deviations. Also, the residual probability graph also shows that the error variance is homogeneous 28 . In this diagram, the closer the points are to the line, the less error there is. As shown in Fig. 4 a,b are points close to the line. In Fig. 4 c–f, the better the distribution of points at the top and bottom of the axis is the same (i.e., the probability of positive and negative error is the same, and the test error is not a systematic error). As shown in Fig. 4 c–f, there is no systematic error. Figure 5 shows the three-dimensional diagrams of the interaction effect. Three-dimensional diagrams of surface response are a function of two independent parameters that keep all other parameters at constant levels. These diagrams can provide information about the relationship between the two parameters and are useful in understanding the main effects and interaction effects of the two parameters. Figure 5 a shows the interaction of the two parameters of solution pH and the amount of adsorbent on MG dye removal. The MG dye removal goes up with increasing pH of the solution and increasing the amount of adsorbent. At pHs higher than pH PZC , which is 6.5 for NaX nanozeolites, the surface charge of the nanoparticles is negative. Thus, the adsorption of positively charged dye molecules due to electrostatic attraction increases. On the other hand, increasing the amount of adsorbent provides more adsorption sites for dye molecules to be adsorbed on the adsorbent surface. Therefore, the interaction of these two parameters, which causes the positive surface of nanoparticles and increases the adsorption sites, increases the adsorption. Similar results about an increase in the removal percentage with increasing pH (alkaline conditions or natural pH) and increasing the amount of adsorbent have also been reported for MG and AO dyes 33 , 52 . As shown in Fig. 5 b,c, the amount of dye removal decreases with an increasing dye concentration of MG and AO. Decreasing the removal percentage at higher concentrations is due to the increase in dye concentration relative to the number of initial moles of dye available to the surface area. For a given amount of adsorbent, the total number of active sites available is constant, and as a result, the same amount of site absorbs the analyte, so as the initial dye concentration increases, the removal percentage decreases. Arabkhani and Asfaram (2020) used a novel three-dimensional magnetic polymer aerogel for the removal of MG dye and achieved similar results to this stage of this study, stating that the removal efficiency decreases with increasing the initial dye concentration 6 . Figure 5 d shows the effect of sonication time on the amount of AO dye removal. As it is known, with increasing sonication time, the amount of dye removal should increase. This is because with increasing time, there is more opportunity for the dye and adsorbent molecules to be exposed. In a study entitled "Rapid removal of Auramine-O (AO) and Methylene blue (MB) dyes from aqueous solutions using ZnS:Cu nanoparticles as the adsorbent, Asfaram et al. (2015) found similar results to the present study and showed that the removal efficiency increased with increasing sonication time 10 .

Plot of predicted value versus actual value (a) MG and (b) AO, plots of residuals for removal of (c,e) MG and (d,f) AO.

Response surface plots of removal of (a,b) MG and (c,d) AO.

Optimization

Optimization in chemistry is used effectively and economically to reduce cost and time in multi-response methods. For this reason, following investigating the factors affecting the removal of MG and AO dyes by the Taguchi method, the conditions for removing the dye from the solution by RSM were optimized. According to the experiments performed in Taguchi design, the most important factors affecting the removal of MG and AO dyes in the method are solution pH, adsorbent mass, sonication time, the concentration of MG and AO dyes. These items were evaluated as the main factors (independent variables) in the RSM statistical design. The software presented the optimal values of each parameter and the relevant tests were performed. All stages of the experiment were carried out according to the Analytical methods section. Optimal values and test results are shown in Table S2 . It is observed that more than 99% of both dyes are removed from the solution by NaX nanozeolites in optimal conditions.

Application to real samples

In order to study the efficiency of the method for the analysis of real samples, NaX nanozeolites were used as adsorbents to remove MG and AO from fish farms, tap water, and drinking water samples. For this reason, tests were performed in optimal conditions, in accordance with the method mentioned in “Analytical methods”. Environmental water samples were used instead of distilled water. After spectrophotometric determination of the remaining amount of dye, the percentage of simultaneous removal for MG and AO dyes was more than 98.1% in environmental water samples (Table S3 ). This means that NaX nanozeolites can remove significant amounts of MG and AO from environmental water samples.

Interference studies

After obtaining the optimal conditions of effective parameters for removing the synchrony of MG and AO dyes, interference studies were carried out to evaluate the method's selectivity. In order to investigate the disturbance effect of different ions, different concentrations of disturbing ions were added to the solution and the steps were taken according to the method described in “Analytical methods”. Also, Analytical methods were applied (Removal conditions: 347 mg of NaX nanozeolites, pH: 8, the concentration of both dyes 4 mg L −1 , centrifuge rate: 3500 rpm). The results are shown in Table S4 . If the signal obtained in the presence of the disturbing ion differs by ± 5% from the signal in the absence of the disturbing ion, it indicates the degree of disturbance of the species on the decomposition signal. To determine the tolerance limit of the disturbing ion, a lower concentration of that species is examined to give an error value of ± 5%. According to the results, by adding almost high amounts of ions, no interference was observed on the decomposition signal. In this study and optimal conditions, the rate of dye removal in the presence of other ions was above 95%, which indicates the proper selectivity of NaX nanozeolites to both dyes despite the competitive effect of other ions.

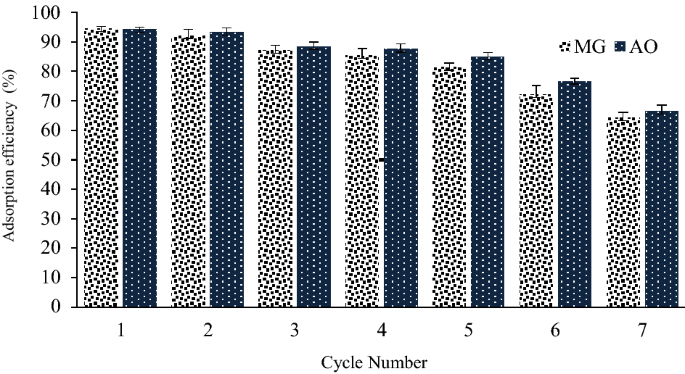

Desorption and reusability studies

The reuse of adsorbent could be considered as one of the important economic parameters. Therefore, the recyclability of NaX nanozeolites during the MG and AO adsorption process was evaluated. In this study, the NaX nanozeolites used were washed with 10 ml of methanol (0.01 M) and placed in an ultrasonic bath for 5 min. Finally, the amount of adsorption in each cycle was measured by spectrophotometry. The results in Fig. 6 show that up to 5 cycles, the adsorption efficiency decreases slightly. In general, this reduction can be due to adsorption degradation during adsorption–desorption cycles 53 , 54 .

Effect of regeneration cycles on adsorption of dyes onto NaX nanozeolites.

Comparison of adsorbents

The efficiency of the proposed method was evaluated with other methods for removing MG and AO dyes. The results are given in Table 7 . This study showed that the developed method, compared to other methods, provides high removal of contamination (dye) in a short time from water samples. This method also has other advantages, such as the low number of tests, low operating costs, and optimization in the best possible way to achieve the highest efficiency (percentage of paint removal).

The efficiency of NaX nanozeolites for simultaneous removal of malachite green (MG) and auramine-O (AO) dyes from aqueous solutions was investigated. The synthesized nanosorbents were characterized using SEM and XRD. The most important variables affecting the dye removal process were determined by the Taguchi method. These effective variables included solution pH, adsorbent mass, sonication time, MG, and AO dye concentrations and were optimized and modeled by CCD based on the RSM method. The optimal conditions obtained by RSM modeling included pH 8, ultrasound time of 11.5 min, an absorbent dose of 347 mg, and concentration of both dyes 4 mg L −1 , and the highest dye removal (more than %99) was obtained for both dyes. Quadratic models for dye determination were statistically compared with values of R 2 ˃ 0.99 and p < 0.0001, and the results showed that both models have reasonable accuracy. The results obtained for adsorption–desorption experiments showed that the adsorbent could be reused up to five times without a significant reduction in the percentage of dye removal. The methodmethod's efficiency for analyzing real samples containing MG and AO dyes also showed that the developed methodcould remove high amounts of dye contamination (%98.1) from complex samples.

Data availability

The authors declare that (the/all other) data supporting the findings of this study are available within the paper (and its supplementary information files).

Lakkaboyana, S. et al. Synthesis and characterization of Cu(OH)2-NWs-PVA-AC nano-composite and its use as an efficient adsorbent for removal of methylene blue. Sci. Rep. 11 , 5686 (2021).

Article ADS CAS PubMed PubMed Central Google Scholar

Shojaei, S. et al. Application of chemometrics for modeling and optimization of ultrasound-assisted dispersive liquid–liquid microextraction for the simultaneous determination of dyes. npj Clean Water 4 , 23 (2021).

Article CAS Google Scholar

Moattari, R. M., & Mohammadi, T. Hybrid adsorbents for dye removal from wastewater. in Green Adsorbents to Remove Metals, Dyes and Boron from Polluted Water . 405–451. (Springer, 2021).

Ismail, M. et al. Pollution, toxicity and carcinogenicity of organic dyes and their catalytic bio-remediation. Curr. Pharm. Des. 25 (34), 3645–3663 (2019).

Article CAS PubMed Google Scholar

Rahman, I. A., Saad, B., Shaidan, S. & Rizal, E. S. Adsorption characteristics of malachite green on activated carbon derived from rice husks produced by chemical–thermal process. Biores. Technol. 96 (14), 1578–1583 (2005).

Arabkhani, P. & Asfaram, A. Development of a novel three-dimensional magnetic polymer aerogel as an efficient adsorbent for malachite green removal. J. Hazard. Mater. 384 , 121394 (2020).

Sadat, S. A. et al. Rapid room-temperature synthesis of cadmium zeolitic imidazolate framework nanoparticles based on 1, 1′-carbonyldiimidazole as ultra-high-efficiency adsorbent for ultrasound-assisted removal of malachite green dye. Appl. Surf. Sci. 467 , 1204–1212 (2019).

Article ADS CAS Google Scholar

Sreekanth, T. V. M. et al. Urea assisted ceria nanocubes for efficient removal of malachite green organic dye from aqueous system. Sci. Rep. 9 , 14477 (2019).

Article ADS PubMed PubMed Central CAS Google Scholar

de Jesus Azevedo, C. C. et al. Auramine dyes induce toxic effects to aquatic organisms from different trophic levels: An application of predicted non-effect concentration (PNEC). Environ. Sci. Pollut. Res. 28 (2), 1866–1877 (2021).

Asfaram, A., Ghaedi, M., Agarwal, S., Tyagi, I. & Gupta, V. K. Removal of basic dye Auramine-O by ZnS: Cu nanoparticles loaded on activated carbon: Optimization of parameters using response surface methodology with central composite design. RSC Adv. 5 (24), 18438–18450 (2015).

Shindhal, T. et al. A critical review on advances in the practices and perspectives for the treatment of dye industry wastewater. Bioengineered 12 (1), 70–87 (2021).

Arabkhani, P., Asfaram, A. & Ateia, M. Easy-to-prepare graphene oxide/sodium montmorillonite polymer nanocomposite with enhanced adsorption performance. J. Water Process Eng. 38 , 101651 (2020).

Article Google Scholar

Hasanzadeh, M., Simchi, A. & Far, H. S. Nanoporous composites of activated carbon-metal organic frameworks for organic dye adsorption: Synthesis, adsorption mechanism and kinetics studies. J. Ind. Eng. Chem. 81 , 405–414 (2020).

Liu, Y., Zhu, W., Guan, K., Peng, C. & Wu, J. Freeze-casting of alumina ultra-filtration membranes with good performance for anionic dye separation. Ceram. Int. 44 (10), 11901–11904 (2018).

Wang, J., Zhang, T., Mei, Y. & Pan, B. Treatment of reverse-osmosis concentrate of printing and dyeing wastewater by electro-oxidation process with controlled oxidation-reduction potential (ORP). Chemosphere 201 , 621–626 (2018).

Article ADS CAS PubMed Google Scholar

Tan, Y. J. et al. Fouling characteristics and fouling control of reverse osmosis membranes for desalination of dyeing wastewater with high chemical oxygen demand. Desalination 419 , 1–7 (2017).

Hajati, S. et al. Application of high order derivative spectrophotometry to resolve the spectra overlap between BG and MB for the simultaneous determination of them: Ruthenium nanoparticle loaded activated carbon as adsorbent. J. Ind. Eng. Chem. 20 (4), 2421–2427 (2014).

El-Sayed, M. E. Nanoadsorbents for water and wastewater remediation. Sci. Total Environ. 739 , 139903 (2020).

Soliman, N. K. & Moustafa, A. F. Industrial solid waste for heavy metals adsorption features and challenges; A review. J. Market. Res. 9 (5), 10235–10253 (2020).

CAS Google Scholar

Rápó, E. et al. Adsorption of remazol brilliant violet-5R textile dye from aqueous solutions by using eggshell waste biosorbent. Sci. Rep. 10 (1), 1–12 (2020).

Tang, S. H. & Zaini, M. A. A. Development of activated carbon pellets using a facile low-cost binder for effective malachite green dye removal. J. Clean. Prod. 253 , 119970 (2020).

Saja, S. et al. Fabrication of low-cost ceramic ultrafiltration membrane made from bentonite clay and its application for soluble dyes removal. J. Eur. Ceram. Soc. 40 (6), 2453–2462 (2020).

Bouhadjra, K., Lemlikchi, W., Ferhati, A. & Mignard, S. Enhancing removal efficiency of anionic dye (Cibacron blue) using waste potato peels powder. Sci. Rep. 11 (1), 1–10 (2021).

Mittal, H., Babu, R., Dabbawala, A. A., Stephen, S. & Alhassan, S. M. Zeolite-Y incorporated karaya gum hydrogel composites for highly effective removal of cationic dyes. Colloids Surf. A Physicochem. Eng. Asp. 586 , 124161 (2020).

Song, I. et al. Simple physical mixing of zeolite prevents sulfur deactivation of vanadia catalysts for NO x removal. Nat. Commun. 12 (1), 1–9 (2021).

Radoor, S., Karayil, J., Parameswaranpillai, J. & Siengchin, S. Removal of anionic dye Congo red from aqueous environment using polyvinyl alcohol/sodium alginate/ZSM-5 zeolite membrane. Sci. Rep. 10 (1), 1–15 (2020).

Article ADS Google Scholar

Santillán, J. M., Arboleda, D. M., Muraca, D., Schinca, D. C. & Scaffardi, L. B. Highly fluorescent few atoms silver nanoclusters with strong photocatalytic activity synthesized by ultrashort light pulses. Sci. Rep. 10 (1), 1–13 (2020).

Oenema, J. et al. Influence of nanoscale intimacy and zeolite micropore size on the performance of bifunctional catalysts for n-heptane hydroisomerization. ACS Catal. 10 (23), 14245–14257 (2020).

Article CAS PubMed PubMed Central Google Scholar

Arabkhani, P., Javadian, H., Asfaram, A. & Ateia, M. Decorating graphene oxide with zeolitic imidazolate framework (ZIF-8) and pseudo-boehmite offers ultra-high adsorption capacity of diclofenac in hospital effluents. Chemosphere 271 , 129610 (2021).

Radoor, S., Karayil, J., Jayakumar, A., Parameswaranpillai, J. & Siengchin, S. An efficient removal of malachite green dye from aqueous environment using ZSM-5 zeolite/polyvinyl alcohol/carboxymethyl cellulose/sodium alginate bio composite. J. Polymers Environ. 29 , 1–14 (2021).

Sivalingam, S. & Sen, S. Rice husk ash derived nanocrystalline ZSM-5 for highly efficient removal of a toxic textile dye. J. Market. Res. 9 (6), 14853–14864 (2020).

Sivalingam, S. & Sen, S. Rapid ultrasound assisted hydrothermal synthesis of highly pure nanozeolite X from fly ash for efficient treatment of industrial effluent. Chemosphere 210 , 816–823 (2018).

Asfaram, A., Ghaedi, M., Azqhandi, M. H. A., Goudarzi, A. & Hajati, S. Ultrasound-assisted binary adsorption of dyes onto Mn@ CuS/ZnS-NC-AC as a novel adsorbent: Application of chemometrics for optimization and modeling. J. Ind. Eng. Chem. 54 , 377–388 (2017).

Sricharoen, P. et al. Ultrasound-irradiated synthesis of 3-mercaptopropyl trimethoxysilane-modified hydroxyapatite derived from fish-scale residues followed by ultrasound-assisted organic dyes removal. Sci. Rep. 11 , 5560 (2021).

Bazrafshan, A. A., Hajati, S. & Ghaedi, M. Synthesis of regenerable Zn (OH) 2 nanoparticle-loaded activated carbon for the ultrasound-assisted removal of malachite green: Optimization, isotherm and kinetics. RSC Adv. 5 (96), 79119–79128 (2015).

Shojaei, S., Ardakani, M. A. H. & Sodaiezadeh, H. Simultaneous optimization of parameters influencing organic mulch test using response surface methodology. Sci. Rep. 10 (1), 1–11 (2020).

Ghaedi, M., Hajati, S., Zare, M. & Jaberi, S. S. Experimental design for simultaneous analysis of malachite green and methylene blue; derivative spectrophotometry and principal component-artificial neural network. RSC Adv. 5 (49), 38939–38947 (2015).

Park, R., Sridhar, V. & Park, H. Taguchi method for optimization of reaction conditions in microwave glycolysis of waste PET. J. Mater. Cycles Waste Manage. 22 (3), 664–672 (2020).

Tan, Y. H., Abdullah, M. O., Nolasco-Hipolito, C. & Zauzi, N. S. A. Application of RSM and Taguchi methods for optimizing the transesterification of waste cooking oil catalyzed by solid ostrich and chicken-eggshell derived CaO. Renewable Energy 114 , 437–447 (2017).

Shojaei, S., Kalantari, Z. & Rodrigo-Comino, J. Prediction of factors affecting activation of soil erosion by mathematical modeling at pedon scale under laboratory conditions. Sci. Rep. 10 (1), 1–12 (2020).

Bagheri, R., Ghaedi, M., Asfaram, A., Dil, E. A. & Javadian, H. RSM-CCD design of malachite green adsorption onto activated carbon with multimodal pore size distribution prepared from Amygdalus scoparia : Kinetic and isotherm studies. Polyhedron 171 , 464–472 (2019).

Shojaei, S., Nouri, A., Baharinikoo, L., Farahani, M. D. & Shojaei, S. Removal of the hazardous dyes through adsorption over nanozeolite-X: Simultaneous model, design and analysis of experiments. Polyhedron 196 , 114995 (2021).

Matavos-Aramyan, S., Bagheri, G. & Jazebizadeh, M. H. Pervaporation separation of toluene from aqueous solutions using nano-based PEBA/NaX mixed matrix membrane. SILICON 11 (4), 1725–1730 (2019).

Shojaei, S. & Shojaei, S. Experimental design and modeling of removal of Acid Green 25 dye by nanoscale zero-valent iron. Euro-Mediterr. J. Environ. Integr. 2 (1), 1–7 (2017).

Shojaei, S. Optimization of process variables by the application of response surface methodology for dye removal using nanoscale zero-valent iron. Int. J. Environ. Sci. Technol. 16 (8), 4601–4610 (2019).

Mehr, H. V., Saffari, J., Mohammadi, S. Z. & Shojaei, S. The removal of methyl violet 2B dye using palm kernel activated carbon: Thermodynamic and kinetics model. Int. J. Environ. Sci. Technol. 17 (3), 1773–1782 (2020).

Azizi, S. N., Ghasemi, S. & Kavian, S. Synthesis and characterization of NaX nanozeolite using stem sweep as silica source and application of Ag-modified nanozeolite in electrocatalytic reduction of H2O2. Biosens. Bioelectron. 62 , 1–7 (2014).

Ghasemi, Z. & Younesi, H. Preparation of free-template nanometer-sized Na–A and–X zeolites from rice husk ash. Waste Biomass Valorization 3 (1), 61–74 (2012).

Ging, R. et al. Utilization of powdered peanut hull as biosorbent for removal of anionic dyes from aqueous solutions. Dyes Pigments 64 (3), 187–192 (2005).

Weng, C. H. & Pan, Y. F. Adsorption characteristics of methylene blue from aqueous solution by sludge ash. Colloids Surf. A 274 (1–3), 154–162 (2006).

El-Sayed, G. O. Removal of methylene blue and crystal violet from aqueous solutions by palm kernel fiber. Desalination 272 (1–3), 225–232 (2011).

Ghasemi, S. M., Ghaderpoori, M., Moradi, M., Taghavi, M. & Karimyan, K. Application of Box-Behnken design for optimization of malachite green removal from aqueous solutions by modified barley straw. Global NEST J. 22 (3), 390–399 (2020).

Google Scholar

Boukhalfa, N., Boutahala, M., Djebri, N. & Idris, A. Maghemite/alginate/functionalized multiwalled carbon nanotubes beads for methylene blue removal: Adsorption and desorption studies. J. Mol. Liq. 275 , 431–440 (2019).

Liu, Y. et al. Graphene oxides cross-linked with hyperbranched polyethylenimines: Preparation, characterization and their potential as recyclable and highly efficient adsorption materials for lead (II) ions. Chem. Eng. J. 285 , 698–708 (2016).

Wang, D., Liu, L., Jiang, X., Yu, J. & Chen, X. Adsorption and removal of malachite green from aqueous solution using magnetic β-cyclodextrin-graphene oxide nanocomposites as adsorbents. Colloids Surf. A 466 , 166–173 (2015).

Iqbal, M. & Datta, D. Competitive removal of malachite green and Rhodamine-B using Amberlite-XAD-4 impregnated with Aliquat 336: Experimental and modelling studies. Sep. Sci. Technol. 55 (3), 537–553 (2020).

Mohammadi, A., Daemi, H. & Barikani, M. Fast removal of malachite green dye using novel superparamagnetic sodium alginate-coated Fe3O4 nanoparticles. Int. J. Biol. Macromol. 69 , 447–455 (2014).

Hasan, I., Bhatia, D., Walia, S. & Singh, P. Removal of malachite green by polyacrylamide-g-chitosan γ-Fe2O3 nanocomposite-an application of central composite design. Groundw. Sustain. Dev. 11 , 100378 (2020).

Altintig, E., Onaran, M., Sarı, A., Altundag, H. & Tuzen, M. Preparation, characterization and evaluation of bio-based magnetic activated carbon for effective adsorption of malachite green from aqueous solution. Mater. Chem. Phys. 220 , 313–321 (2018).

Shakeri, S., Rafiee, Z. & Dashtian, K. Fe3O4-based melamine-rich covalent organic polymer for simultaneous removal of auramine O and rhodamine B. J. Chem. Eng. Data 65 (2), 696–705 (2020).

Shabaan, O. A., Jahin, H. S. & Mohamed, G. G. Removal of anionic and cationic dyes from wastewater by adsorption using multiwall carbon nanotubes. Arab. J. Chem. 13 (3), 4797–4810 (2020).

Firoozi, M., Rafiee, Z. & Dashtian, K. New MOF/COF hybrid as a robust adsorbent for simultaneous removal of auramine O and rhodamine B dyes. ACS Omega 5 (16), 9420–9428 (2020).

Mahmud, T. Biosorption of Auramine O and Drimarene dyes from aqueous solutions using seed powder of Diospyros lotus. Int. J. Environ. Sustain. 6 (3), 1 (2018).

Martins, L. R. et al. Optimization of cellulose and sugarcane bagasse oxidation: Application for adsorptive removal of crystal violet and auramine-O from aqueous solution. J. Colloid Interface Sci. 494 , 223–241 (2017).

Sharma, A. K. et al. Selective removal of cationic dyes using response surface methodology optimized gum acacia-sodium alginate blended superadsorbent. Int. J. Biol. Macromol. 124 , 331–345 (2019).

Muthukumaran, C., Sivakumar, V. M., Sumathi, S. & Thirumarimurugan, M. Adsorptive removal of recalcitrant Auramine-O dye by sodium dodecyl sulfate functionalized magnetite nanoparticles: isotherm, kinetics, and fixed-bed column studies. Int. J. Nanosci. 19 (01), 1950004 (2020).

Download references

Acknowledgements

University of Tehran supported this research.

Author information

Authors and affiliations.

Department of Chemistry, Faculty of Sciences, University of Sistan and Baluchestan, Zahedan, 98135-674, Iran

Siroos Shojaei

Department of Arid and Mountainous Regions Reclamation, Faculty of Natural Resources, University of Tehran, Tehran, Iran

Saeed Shojaei

Future Technology Research Center, National Yunlin University of Science and Technology, 123 University Road, Section 3, Douliou, 64002, Yunlin, Taiwan

Shahab S. Band

Computer Science Department, Boise State University, 777 W Main St, Boise, ID, 83702, USA

Amir Abbas Kazemzadeh Farizhandi

Department of Civil Engineering, Islamic Azad University, Central Tehran Branch, Tehran, P.O. Box 13185, Iran

Milad Ghoroqi

John von Neumann Faculty of Informatics, Obuda University, 1034, Budapest, Hungary

Amir Mosavi

You can also search for this author in PubMed Google Scholar

Contributions

Si.S. conceived and planned the experiments. Si.S. and Sa.S. carried out the experiments. S.S.B. and M.G. contributed to the interpretation of the results. A.M. and A.K. had a significant contribution for technical checking, validation and programming language checking and revision the manuscript in terms of grammar checking and writing. All authors discussed the results and contributed to the final manuscript.

Corresponding authors

Correspondence to Siroos Shojaei or Shahab S. Band .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary information., rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions