In Vitro Diagnostic Use (IVD) versus Research Use Only (RUO) in the Clinical Laboratory

by Lindsey Drake | Clinical , Molecular

Publish Date: April 3, 2023

Previously, in this series we highlighted the importance of external and third-party quality control products in the clinical laboratory, emphasizing that quality control, by design, should add layers of removal from the assay to ensure the utmost degrees of objectivity. External, third-party quality control materials fulfill this QC requirement by removing bias in the quality control process. However, in addition to adding objectivity to the quality control process, it is critical that clinical laboratories consider the quality and the regulatory status of their quality control products.

The IVD and RUO labels are so commonplace in diagnostic laboratories that they easily go unnoticed. Clinical laboratory professionals may not pause to remember that these labels stand for In Vitro Diagnostics (IVD) and Research Use Only (RUO). Even clinical laboratory professionals who are familiar with these regulatory designations for assays or instruments sometimes do not realize the full significance that these labels have for certain products, including quality controls. Therefore, even though the quality and the regulatory status of quality control products is essential to consider, many clinical laboratories may not know the status of their quality control materials and products. This lack of understanding inadvertently puts both patients and the clinical laboratory at risk.

This blog post will examine the differences between RUO and IVD and the importance of choosing the right quality control products in the clinical laboratory. For additional information on RUO and IVD, check out our webinar highlighting the critical differences between RUO and IVD and the importance of choosing the right clinical diagnostic products. We partnered with CAP Today and industry expert Dr. Sebastian Grömminger to bring you this webinar.

Research Use Only (RUO)

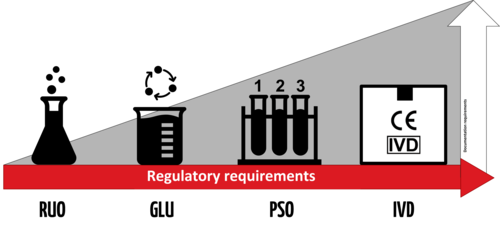

RUO stands for Research Use Only. The RUO label serves as a warning to clinical laboratory professionals that the materials in question are not intended for use with patient diagnostics. RUO products are in the laboratory phase of development and must have no intended medical purpose or objective, as these materials do not require validations or regulatory compliance. 2 RUO materials are not defined in the EU’s In Vitro Diagnostic Medical Devices Regulation (IVDR) and do not have any regulatory requirements. Therefore, RUO materials are to be used only for testing with no direct impact on patient diagnostics.

According to United States Food and Drug Administration (FDA), 3

- Similar to the case in the EU, RUO refers to products in the “laboratory phase of development,” which are “not approved for clinical diagnostic use”

- RUO products are “exempt from most regulatory controls,” so it is therefore “important that they are not distributed for clinical diagnostic uses”

- All product labeling for these products must bear a prominent user notification: “‘For Research Use Only. Not for use in diagnostic procedures.’”

- RUO Labeling is intended to “serve as a warning, to prevent such products” from being used in manners that will impact patient testing and treatment outcomes.

- Companies selling RUO materials are limited in their marketing in some regions. In these regions, manufacturers may be forbidden from providing technical support for RUO materials. Availability of technical support is thus an important advantage of IVD products. Since the clinical diagnostic field is complex, having experts to rely on is an indispensable service exclusive to IVD controls.

Since RUO materials are in the laboratory phase of development, their inappropriate use in clinical diagnostics may pose unnecessary threats to diagnostic precision, laboratory efficiency, operating margins, and risk management systems. Therefore, clinical laboratories should not use these materials for reporting patient results. Thus, the RUO label is a warning to the clinical laboratory professional that this material is not intended for use in clinical diagnostics. Rather than using the RUO material, a clinical laboratory professional should look for the right IVD product for any test that could directly impact patient health outcomes.

In Vitro Diagnostic (IVD)

IVD stands for In Vitro Diagnostic. In contrast to RUO, according to global regulations and standards, IVD products are used for medical applications or purposes. According to the FDA, “In vitro diagnostic products are those reagents, instruments, and systems intended for use in diagnosis of disease or other conditions, including a determination of the state of health, in order to cure, mitigate, treat, or prevent disease or its sequelae. Such products are intended for use in the collection, preparation, and examination of specimens taken from the human body.” 4 According to the IVDR in the European Union and the UK Medicines and Healthcare Products Regulatory Agency (MHRA), IVD medical devices have a medical application or purpose. 4

IVD products must undergo extensive validations to be registered by the FDA, IVDR, and the MHRA. Registrations are required in most countries. Table 1 highlights the regulatory criteria comparison between IVD and RUO products. As shown in the table, IVD products are subject to numerous regulatory requirements, from labeling to post-market surveillance. 6,7 RUO materials do not share these requirements, thus laboratories using RUO materials take on increased risk. 8

Since the manufacturer of the IVD product has invested in extensive studies to validate the performance of IVD product, the clinical laboratory can benefit by reducing the validations required on part of the clinical laboratory. Laboratories choosing to use RUO materials will need to perform more extensive validations than those using IVD products. Thus, clinical laboratories choosing RUO materials take on increased risk and must invest more time into validation and documentation efforts.

Table 1. IVD vs. RUO Regulatory Criteria Comparison. As shown in the table, IVD products are subject to numerous regulatory requirements from labeling to post market surveillance. RUO materials do not share these requirements, thus laboratories using RUO materials take on increased risk.

IVD products also have stringent product development requirements according to IVDR and FDA as shown in Table 2. IVD products have requirements for clinical performance, analytical performance, manufacturing and reproducibility, shipping and stability, failure mode analysis and labeling requirements. RUO materials do not specify requirements for these processes. Again, IVD products are required to demonstrate stringent performance characteristics and regulatory requirements whereas RUO materials do not.

Table 2. IVD: Product Development Requirements. Here we see the product development process requirements under IVDR and FDA for IVD Designation. The IVDR is aligned with FDA here. As shown in the table, IVD products have requirements for clinical performance, analytical performance, manufacturing and reproducibility, shipping and stability, failure mode analysis and labeling requirements. RUO materials do not specify requirements for these processes.

As mentioned above, the unavailability of technical support for RUO materials in certain regions may further limit their ability to fulfill the demands of quality control in clinical settings. Since quality control aims to provide confidence in the laboratory’s analytical processes, QC must bring together the right technical expertise and the right products. Given the complexity of clinical diagnostics, technical support is an indispensable service offered by IVD manufacturers.

Sometimes, IVD products may not be available for a particular assay. In certain cases, non-IVD-labelled products may be permissible in clinical diagnostics, such as when testing materials receive Emergency Use Authorizations because IVD products are not yet available. When used in these extenuating circumstances, non-IVD-labelled products will require the laboratory professional to perform additional steps to satisfy regulatory demands for quality control.

Quality controls help reveal blind spots, biases, material defects, and other causes of inaccurate diagnostic results. By design, quality control allows the clinical laboratory to test their analytical processes in a controlled manner to ensure assays and instruments perform as expected before their use for patient samples. Because approximately 70% of healthcare decisions rely on the results of laboratory testing, accurate diagnostic processes are critical to patient care. Therefore, quality control is foundational to the quality management system of a clinical laboratory, and its role cannot be understated.

Because of this critical role, clinical laboratories must not only use quality control materials with an intended use in clinical diagnostics, but also must choose products meeting the highest standards for quality, precision, and scientific rigor. When clinical laboratories choose an IVD product, they put their confidence not only in the regulatory status of the material for use in clinical diagnostics, but also confidence that manufacturer has invested time and care to ensure the product has been properly validated and subject to stringent quality requirements before its release as a product offering.

Clinical laboratories should keep in mind that, according to global regulations (e.g., European Commission, FDA, etc.), RUO materials have no place in routine clinical diagnostics. Clinical laboratories that choose to use RUO materials are putting their patients and laboratory at risk. In addition to not having an intended use in clinical diagnostics, RUO materials are exempt from most regulatory controls which may impact product quality. Additionally, a lack of technical support may intensify these drawbacks.

Choosing IVD quality control products is essential in the clinical laboratory as these products have undergone extensive validations required to be registered with FDA, European Commission, MHRA, and other regulatory bodies for an intended use in clinical diagnostics. An IVD label signifies exactly what you look for in an external, third-party control: uncompromising quality, according to the highest standards. The IVD label represents product quality and confidence and strengthens the clinical laboratory’s risk management program. The IVD label allows technical support assistance. Reliance on a reputable third-party, IVD quality control manufacturer gives back the clinical laboratory time, money, and peace of mind.

Find IVD controls for your assays at Microbiologics.com .

1. European Commission. (2004, February). Guidance document – In vitro diagnostic medical devices – Research Use Only products – MEDDEV 2.14/2 rev.1. European Commission. https://ec.europa.eu/docsroom/documents/10292/attachments/1/translations

2. Center for Devices and Radiological Health. (2013, November 25). Distribution of In Vitro Diagnostic Products Labeled for Research Use Only or Investigational Use Only. Guidance for Industry and Food and Drug Administration Staff. U.S. Food and Drug Administration. https://www.fda.gov/media/87374/download

3. Center for Devices and Radiological Health. (2013, November 25). Distribution of In Vitro Diagnostic Products Labeled for Research Use Only or Investigational Use Only. Guidance for Industry and Food and Drug Administration Staff. U.S. Food and Drug Administration. https://www.fda.gov/media/87374/download

4. Center for Devices and Radiological Health. Overview of IVD Regulation. U.S. Food and Drug Administration. Retrieved March 6, 2023, from https://www.fda.gov/medical-devices/ivd-regulatory-assistance/overview-ivd-regulation

5. Regulation (EU) 2017/746 In Vitro Diagnostic Medical Devices (IVDR) https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32017R0746&from=EN

6. Center for Devices and Radiological Health. (2021, October 21). Overview of IVD Regulation. U.S. Food and Drug Administration. https://www.fda.gov/medical-devices/ivd-regulatory-assistance/overview-ivd-regulation#1

7. 21CFR809, Subpart B, In Vitro Diagnostic Products for Human Use. https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=809&showFR=1

Written by Lindsey Drake

You may also like.

MLS and MLT Career Opportunities

As a manufacturer of quality controls used in clinical diagnostics, we see firsthand the difficulties that laboratory...

The Challenges of Diagnosing and Treating Secondary Infections

In the past two decades, there have been six major global outbreaks of infectious diseases. While these infections may...

- Pharmaceutical

- Events and Webinars

- Uncategorized

1-800-599-2847 microbiologics.com [email protected]

QUICK LINKS

CATEGORIES RESOURCES ABOUT US CONTACT US SITE MAP PRIVACY POLICY

- Lupe_Grau Cancel

Laboratory Products for “Research Use Only” (RUO) – Often a Dangerous Claim

Manufactures use the “Research Use Only” (RUO) label to declare that their products should not be used in diagnostic procedures. This enables them to avoid the time-consuming and costly documentation required for conformity-assessed in vitro diagnostic medical devices (CE-IVDs). Nevertheless, some medical laboratories, for example, still use RUO products in diagnostic procedures, sometimes even with the knowledge of the manufacturers. This can have consequences – not just for manufacturers and operators, but for patients as well.

In this article, you will learn:

- What the “Research Use Only” label (RUO) means

- What the requirements for RUO products are

- How to avoid legal problems

- What alternatives there are to RUO products

1. “Research Use Only” – what does it mean?

Labeling products for “research use only” has far-reaching consequences. It means the products are barely subject to any regulatory controls under the IVDR. As a result, for a lot of manufacturers and operators, they are desirable alternatives to more costly and time-intensive conformity-assessed in-vitro diagnostic medical devices (CE-IVDs) that must comply with the applicable legal requirements.

a) Institutions affected

The following institutions, in particular, use RUO products:

- Medical laboratories can use RUO products, but this makes them the manufacturer with all the consequences this entails. You can find more information on “lab developed tests” in our article “ The E U Regulates Medical Laboratories. Are Laboratory Developed Tests Still Allowed? ”

- If medical laboratories use RUO products for purposes other than research then, in the worst case, this makes them liable for damages as well as criminally liable.

- Therefore, medical laboratories should inform themselves about the parameters for RUO products and possible alternatives .

- Manufacturers Manufacturers use RUO products as components for their IVDs. They should, therefore, make sure that they know all the requirements in detail before labeling a product as “RUO”.

b) Definition

There is no uniform definition of “research use only” products. In general, they can be understood to be what the name implies, i.e., products to be used for analysis that are intended to be used for scientific research purposes only.

They primarily differ from medical devices in that they cannot be used for medical purposes.

However, the understanding of “research use only” is different in Europe and the USA.

Definition in Europe

In Europe, the MEDDEV 2.14/2 guidance document (IVD Guidance: Research Use Only products – A guide for manufacturers and notified bodies) provides clues as to the definition of RUOs. This guidance was written within the framework of the now obsolete Directive 98/79/EC on in vitro diagnostic medical devices (IVDD) and, in the absence of an up-to-date replacement, it can still be considered the state of the art.

MEDDEV 2.14/2 states:

“for a product to be categorized as an RUO product it must have no intended medical purpose or objective."

Source: MEDDEV 2.14/2 rev.1

This means that an RUO product must not have even a rudimentary medical purpose.

However, in the case of tests developed in-house by a laboratory (LDTs), this restriction does not apply provided that the products are not sold to other companies. The guidance gives the following specific examples of LDTs that may be designated “research use only” under this requirement:

- PCR enzymes

- Gel component agars

The IVDR also addresses RUO products.

“device for performance study’ means a device intended by the manufacturer to be used in a performance study.

A device intended to be used for research purposes, without any medical objective, shall not be deemed to be a device for performance study; ”

Source: IVDR Art. 2(45)

Thus, the IVDR, like MEDDEV 2.14/1 (IVD Medical Device Borderline and Classification issues), draws a distinction between RUO products and “devices for performance studies.”

Again, the key aspect of the definition is the RUO product’s lack of medical purpose.

To be classed an RUO product, it is vital that the product does not serve a medical purpose. Even a suspected medical purpose is enough for a device to be no longer considered an RUO product.

(See MEDDEV 2.14/1 section 1.1 4.)

Definition in the USA

In 2013, the FDA published a guidance document on RUOs entitled “Distribution of In Vitro Diagnostic Products Labeled for Research Use Only or Investigational Use Only.”

This guidance defines RUO products as follows:

“ An RUO product is an IVD product that is in the laboratory research phase of development and is being shipped or delivered for an investigation that is not subject to part 812” [NB: Part 812 concerns the provision of devices for performance evaluation purposes as a preliminary step to IVDs]

Source: FDA guidance “Distribution of In Vitro Diagnostic Products Labeled for Research Use Only or Investigational Use Only”

Some examples of products that the FDA believes fall into this research phase of development are:

- Tests that are in development to identify test kit methodology, necessary components, and analytes to be measured

- Instrumentation, software, or other electrical/mechanical components under development to determine correct settings, subcomponents, subassemblies, basic operational characteristics, and possible use methods

- Reagents under development to determine production methods, purification levels, packaging needs, shelf life, storage conditions, etc.

Therefore, according to the FDA, a clearly visible RUO label must be affixed specifically to products that are in a research phase.

c) What are the consequences of using the “Research Use Only” label?

Normally, IVDs are subject to regulatory requirements (for example, according to the IVDR or FDA) based on their risk class.

However, RUO products do not fall within the definition of “in vitro diagnostic medical devices” given by the IVDR or the relevant FDA regulations . This means that these regulations do not apply to RUO products.

Definition: In vitro diagnostic medical devices (IVDs) in the EU

“‘In vitro diagnostic medical device’ means any medical device which is a reagent, reagent product, calibrator, control material, kit, instrument, apparatus, piece of equipment, software or system, whether used alone or in combination, intended by the manufacturer to be used in vitro for the examination of specimens, including blood and tissue donations, derived from the human body, solely or principally for the purpose of providing information on one or more of the following:

(a) concerning a physiological or pathological process or state;

(b) concerning congenital physical or mental impairments;

(c) concerning the predisposition to a medical condition or a disease;

(d) to determine the safety and compatibility with potential recipients;

(e) to predict treatment response or reactions;

(f) to define or monitoring therapeutic measures.

Specimen receptacles shall also be deemed to be in vitro diagnostic medical devices;”

Source: Article 2 IVDR

Definition: In vitro diagnostic medical devices (IVDs) in the USA

“In vitro diagnostic products are those reagents, instruments, and systems intended for use in diagnosis of disease or other conditions, including a determination of the state of health, in order to cure, mitigate, treat, or prevent disease or its sequelae. Such products are intended for use in the collection, preparation, and examination of specimens taken from the human body.”

Source: 21 CFR 809.3

Therefore, the requirements of the IVDR do not apply to RUO products. In the USA, they are exempt from cGMP and the FDA's quality regulations.

Depending on the product, they may still have to comply with requirements that are not specifically intended for IVDs (such as the REACH regulation for chemicals or the Machinery Directive ).

Since RUO products are thus subject to considerably fewer controls than IVDs, it is necessary to severely restrict their use.

Therefore, in particular they may not be used to:

- Make diagnoses

- Conduct performance studies

2. Use and misuse of “Research Use Only” labels

A) what should ruo products be used for.

As the name “research use only” indicates, products with RUO labeling are intended for research purposes only. RUO products are particularly attractive for the research sector due to the simplified process and lower hurdles for placing them on the market.

MEDDEV. 2.14/2 rev.1 provides a precise list of areas where RUO products may potentially be used:

- Basic research

- Pharmaceutical research

- Better identification and quantification of individual chemical substances or ligands in biological specimens

- In house manufacturing of so called “home brew kits” for research purposes

And of areas where the use of RUOs is expressly not permitted:

- Use of raw materials which are labeled “for “research use only” but which are incorporated into a finished product

- So called “research use” products being tested against a comparator IVD product that bears the CE mark

- Products for market studies/ feasibility studies

b) What RUO products are often used for

However, the low hurdles are also the reason why RUO products are often used for purposes they are not intended for. This poses significant dangers for manufacturers, operators and patients.

Sale of RUO products to medical laboratories

RUO products are sold by manufacturers to medical laboratories. Although doctors sometimes also conduct research, this is not really the main purpose of a medical laboratory. Therefore, when discussing sales with doctors, it should always be assumed that there is a medical reason behind the use of the product.

This means that anyone who knowingly sells RUO products to medical laboratories is potentially under suspicion of using the pretext “for research use only” to ignore an intended medical purpose and thus avoid responsibility for a medical device.

There are certainly laboratory products that clearly have no specific medical purpose, e.g.:

- Nutrient media

- Reaction vessels

- Washing solutions

These products are best labeled as “general laboratory supplies” rather than “RUO”.

Avoid reference to any specific diagnostic procedures in your advertising materials for products that clearly do not have a medical purpose. You should always stay on the technical or purely analytical level.

The issue with analyte specific reagents

Whether an RUO product contains analyte specific reagents, e.g., primary antibodies, FISH probes, PCR primers and probes, and sequencing panels, can be critical. In some cases, a medical purpose can be inferred just from the description of the product's performance.

This would be the case if a manufacturer of a RUO-labeled kit for the detection of viral genes specifies a number of copies per ml of blood that the kit can detect.

ASR in the USA

The FDA abbreviates the term “analyte specific reagents” to “ASR” and defines it as follows:

“Analyte specific reagents (ASR's) are antibodies, both polyclonal and monoclonal, specific receptor proteins, ligands, nucleic acid sequences, and similar reagents which, through specific binding or chemical reaction with substances in a specimen, are intended for use in a diagnostic application for identification and quantification of an individual chemical substance or ligand in biological specimens.”

Source: 21CFR864.4020 a)

In other words, US law says that, by definition, ASRs have a diagnostic purpose.

Exception: The sale of ASRs to IVD manufacturers as components for manufacturing kits or to non-clinical laboratories for research and development without compliance with regulatory requirements is permitted.

ASR in the EU EU law does not contain this exception. Nor does the term “analyte specific reagent” does appear in any of the applicable EU regulations. Therefore, such products may have a general laboratory purpose in the EU, depending on the justification. This means they do not fall under the IVDR if the manufacturer defines the intended purpose accordingly. However, if the manufacturer assigns a medical or diagnostic purpose to these products, the regulatory hurdles will very high once the IVDR comes into full effect (currently scheduled for May 26, 2022).

This means that the crucial factor is whether manufacturers have clearly defined the intended purpose and whether communication with customers (e.g., in advertising materials) is in line with this purpose.

Further information

You can find out more about the intended purpose of medical devices here: Intended purpose and intended use

Use of RUO products in medical laboratories

It is not just manufacturers for whom the sale of RUOs to medical laboratories represents a problem. The laboratories themselves may also not be acting in line with their status as operators and may, as a result, be liable under certain circumstances.

- Medical laboratories are free to develop in-house tests themselves. In such cases, RUO products are often used in diagnostic procedures. Even under the IVDD, MEDDEV 2.14/2 was critical of this. However, with the new In Vitro Diagnostic Medical Device Regulation (IVDR) , the EU is explicitly placing more restrictions on the routine use of such lab developed tests . Read more in our article The EU Is Regulating Medical Laboratories. Are Laboratory Developed Tests Still Allowed? .

- Due to the low regulatory hurdles, purchasing RUO products is very affordable. As a result, medical laboratories prefer them over expensive CE-IVD devices if they can achieve the same level of performance. Nevertheless, the use of RUO products for purposes other than research, even in cases where they provide similar results, is not permitted.

3. Consequences of incorrect classification

Lack of controls can have a negative effect on quality. As a result, the relevant bodies (e.g., authorities during inspections) take a closer look at whether a product is actually intended for “research use only”.

Manufacturers should also be aware that simply sticking an RUO label on a product does not on its own mean that the product no longer has to comply with requirements for IVDs that would otherwise apply.

In its guidance document on RUO , the FDA writes that only the actual intended use qualifies a product as RUO – or doesn’t. The FDA also uses marketing materials or other general factors as evidence of the intended purpose.

"Because these products are exempt from most regulatory controls, it is important that they are not distributed for clinical diagnostic uses. Mere placement of an RUO or IUO label on an IVD product does not render the device exempt from otherwise applicable clearance, approval, or other requirements. FDA may determine that the device is intended for use in clinical diagnosis based on other evidence, including how the device is marketed. ”

Manufacturers and operators who misuse the RUO label could face severe penalties, as such behavior can cause serious harm to patients or even the general public.

a) Consequences for manufacturers and operators

Improperly selling IVDs with an RUO label or using RUO products for purposes other than research is not a trivial offense.

Manufacturers who demonstrably hide or aim to hide a diagnostic purpose behind the RUO label should expect legal consequences in Germany. The same applies for operators who misuse RUO products. There is the possibility of a fine or even prison sentences. In addition, there is potential liability for harm suffered by patients.

b) Consequences in the USA

There are also severe penalties in the USA. If an RUO label is deemed to have been incorrectly used for a product, the product would be considered misbranded under sections 502(a) and 502(o) of 21 US Code, 352(a), 352(o) [A1] and would be considered adulterated under section 501(f) of 21 US Code 351(f).

c) Consequences for patients

However, the consequences can be even worse for patients. After all, the regulatory requirements for IVDs aren’t just plucked out of thin air to annoy manufacturers and operators. The regulations are intended to protect patients against incorrect results and subsequent wrong decisions. False-negative results can lull patients into a false sense of security and an existing disease may worsen undetected. One example would be the metastasis of an undetected cancer due to a test not performing as intended.

Some incorrect diagnoses could even be so severe that they can cause the death of a lot of people: an undetected viral infection can cost many lives in the early stages of an epidemic or pandemic, as the coronavirus pandemic sadly demonstrated.

4. Alternatives to “research use only” products

To avoid legal problems and risks for third parties, manufacturers and users should use alternatives to RUO products in borderline cases.

These alternatives don’t always have to be CE-IVDs. Depending on the specific situation, the following alternatives can be considered based on the intended purpose:

a) Products for general laboratory use

According to the MEDDEV 2.14/1 (IVD Medical Device Borderline and Classification Issues) guidance, it is a product's characteristics that determine whether it can be classified as a product for general laboratory use or not.

- If, based on its characteristics, a product is not specifically intended to be used for in vitro diagnostic examinations, it is not an IVD.

- Manufacturers cannot label products for general laboratory use as IVDs.

RUO products used for a better identification and quantification of individual chemical substances or ligands in biological specimens

Source: MEDDEV 2.14/2

Such products must have a general use. However, use as an IVD does not have to be ruled out, provided the product is not made specifically for a particular test. According to MEDDEV 2.14/2, even the aforementioned analyte specific reagents (ASRs) without a medical purpose fall into this category.

There are several advantages to using products for general laboratory use instead of RUO products:

- The product does not fall under the IVD Directive or the IVDR, which saves you a lot of time and money.

- Laboratories that use these products for in-house procedures are not in danger of being accused of using RUO products in routine diagnostic procedures.

However, the disadvantage is that the medical laboratory is responsible for ensuring that the examination conforms with the IVDR. This can make the product less interesting because the regulatory requirements entail a lot of work.

b) Lab developed tests with class A CE-IVDs Manufacturers may sell general laboratory reagents, which can be authorized as IVDs under the IVDR, to medical laboratories.

In combination with the ASRs developed in-house, laboratories can validate and use these products as lab developed tests (LDTs).

Read our article on lab developed tests to find out what laboratories should be aware of.

c) “For performance evaluation only” as a preliminary stage for certified IVDs

The IVDR defines " device for performance studies ” as follows:

“‘Device for performance study’ means a device intended by the manufacturer to be used in a performance study.”

Source: IVDR 2017/746/EU

These devices must already be safe, as far as possible, and meet the relevant general safety and performance requirements.

5. Ways to protect yourself

Manufacturers, operators and patients can take the following steps to avoid legal and other negative consequences when using RUO products:

a) Manufacturers

In the case of manufacturers, it is particularly important that they narrowly define the intended purpose of their product.

Analyte specific reagents should only be labeled as RUO products for specific non-medical purposes.

Example: SARS-CoV-2 and its mutations: a test kit that uses specific primers and probes to distinguish the variants B.1.1.7 (alpha variant) and B.1.351 (beta variant) from the initial variant following a positive result may be an RUO product if it is only intended to be used to determine the prevalence of the variant in the population. A specific intended purpose in this case would be: “Intended solely for epidemiological research for the purpose of surveying the prevalence of SARS-CoV-2 variants in the general population.” If a medical laboratory subsequently, based on new findings, used this test to provide the best possible treatment for infection by a specific variant, this would be an off-label use. The laboratory would then be responsible for the test's conformity.

Provided the manufacturer did not advertise the product with this clinical benefit, it would be adequately protected.

b) Operators

Operators should record exactly what they use IVDs and RUO products for.

Medical laboratories are operators of medical devices and IVDs and, therefore, are responsible for only using medical devices according to their intended purpose and in accordance with the generally accepted rules of the technology. This is stipulated in Section 4 of the German Medizinprodukte-Betreiberverordnung (MPBetreibV (German)). To be on the safe side, laboratories should keep a record of which medical devices and IVDs are in operation and routine use. This record should include a reference to the applicable test procedure and the intended purpose of the IVD.

This record can also be used to identify investigational procedures for which there are no adequate CE-IVDs available on the market. The lack of alternatives would justify the use of RUOs (as lab developed tests) in validated processes it has developed in-house, provided that the laboratory checks and can demonstrate that the general safety and performance requirements and the additional requirements of Article 5(5) of the IVDR are met.

Read more about the requirements for LDTs in our article on the topic .

c) Patients

Patients lack the knowledge to recognize what is and isn’t an RUO on their own. They are often given little to no information about the test they are undergoing. So, patients should follow this basic rule: ask your doctor or pharmacist!

- Patients can ask for the complete test report from the laboratory so that they can get a second opinion in case of doubt. The report should also indicate which specific test was performed.

- Patients should inform themselves about how “well” or “poorly” a test works, as well as the benefit-risk ratio.

- In the future, patients and doctors will also be able to get information about medical devices from EUDAMED and use this information to decide whether or not the test was performed with certified and thus legally compliant IVDs.

6. Conclusion

In the opinion of the EU Commission and the FDA, products “for research use only" have no place in diagnostics. To be used for diagnostic purposes, products have to go through the necessary controls. But these controls do not apply to RUO products.

Anyone who ignores this prohibition and uses or sells RUO products for purposes other than pure research is playing with fire. Manufacturers and operators run the risk of legal trouble and could even endanger patients’ health. Therefore, RUO products should only be used for research purposes. For other uses, manufacturers and operators should use the alternatives mentioned.

Our tip is: if you, as a manufacturer or medical laboratory, find that an RUO product is particularly well-suited for in vitro diagnostics, consider whether further development and conformity assessment to make it an IVD is worthwhile. We will be happy to help you work out which of the three alternatives to RUOs mentioned above is the best alternative to your product as part of our IVD authorization strategy consultation. If necessary, we can also help you ensure your product development conforms with the regulations.

Dr. Diana Gabriel

A quick overview: Our

Starter-Kit

Always up to date: Our

Back To Top

Privacy settings

We use cookies on our website. Some of them are essential, while others help us improve this website and your experience.

Individual Cookie Settings

Only accept required cookies.

Privacy Notes Imprint

Here is an overview of all cookies use

Required Cookies

These cookies are needed to let the basic page functionallity work correctly.

Show Cookie Informationen

Hide Cookie Information

Provide load balancing functionality.

Provides functions across pages.

Hubspot Forms

Used for the google recaptcha verification for online forms.

Cookies for Statistics

Statistic cookies anonymize your data and use it. These information will help us to learn, how the users are using our website.

Google Analytics

Tracking and analys of traffic on our websites.

Cookies for Marketing

Marketing cookies from thrid parties will be used to show personal advertisment. They use them to track users outside of their own web page.

Keeping track of a visitor's identity. It is passed to HubSpot on form submission and used when deduplicating contacts. It contains an opaque GUID to represent the current visitor. It also introduces cookies from linked in for marketing reasons.

LinkedIn conversion tracking.

Cookies for external Content

Content for Videoplatforms und Social Media Platforms will be disabled automaticly. To see content from external sources, you need to enable it in the cookie settings.

Google Maps

Used to display google maps on our Websites. Google uses cookies to identify and track users.

- Featured News

- Artificial Intelligence

- Bioprocessing

- Drug Discovery

- Genome Editing

- Infectious Diseases

- Translational Medicine

- Browse Issues

- Learning Labs

- eBooks/Perspectives

- GEN Biotechnology

- Re:Gen Open

- New Products

- Conference Calendar

- Get GEN Magazine

- Get GEN eNewsletters

Oversight of Research Use Only Products

March 1, 2010 (Vol. 30, No. 5)

Jeffrey N. N. Gibbs

RUO Assays and Instruments Face Greater Scrutiny

The FDA actively regulates medical devices intended for diagnostic use. Diagnostic kits intended for diagnostic use face the full panoply of FDA regulation. In sharp contrast, research use only (RUO) products are essentially unregulated. In fact, although RUO products are often discussed as though they are a kind of medical device, RUOs are not devices at all.

A commercially important class of products, RUOs are defined very briefly by FDA regulations. RUO products are described as products “in the laboratory research phase of development and not represented as an effective in vitro diagnostic product.” This definition has created some uncertainty as to what products fall into the RUO category.

The same regulation establishing the RUO category requires that RUO products bear the following labeling statement: “For Research Use Only—Not for use in diagnostic procedures.” Although not authorized by the regulation, many companies have shortened the statement to just the first clause. FDA regulations do not prescribe any other restrictions or limitations on RUO products beyond this labeling statement. Thus, FDA regulations define the category and prescribe labeling, and nothing more.

Given that RUO products are not intended to diagnose “a disease or other condition,” it is not clear that they are even subject to FDA’s jurisdiction. The intended use of an RUO product—research, not diagnosis—presumptively removes it from the definition of a device and FDA’s authority.

In any event, aside from bearing the mandated statement, RUO products are not regulated by the agency. For example, they do not need to be listed with FDA or comply with the Quality System Regulation (QSR). They can be sold without any FDA clearance or approval. As a practical matter an RUO is essentially unregulated by FDA.

Over the years, the paramount regulatory issue for products bearing the RUO label has been whether or not they actually do belong within the RUO category. There have been multiple instances in which RUO products have become widely used by laboratories for clinical applications. There have also been a number of occasions where companies have labeled products as RUO but then promoted them for diagnostic use. In some instances, companies have made specific diagnostic claims for their assay or instrument but still labeled the product as RUO.

Biomarker kits are often labeled as RUO because it is not known whether the product has any clinical use or, if so, what that use might be. The assay’s developer may expect that a particular biological substance will be of some clinical value, but not be sure what that value is. Labeling a product RUO, allows it to get into the hands of researchers who can then evaluate whether the product may be potentially valuable for some specific diagnostic purpose.

Often, no clinical use is ever identified. Some assays maintain their true RUO status indefinitely. While the product may be helpful to researchers in understanding basic biological mechanisms, a diagnostic use may never be discovered.

Guidance Documents

FDA has initiated several attempts to try to regulate RUO products more tightly. In the early 1990s, FDA issued a draft Compliance Policy Guide (CPG) document that sought to significantly restrict the availability of RUO products. This guidance document went through several iterations but was never finalized. There is still no guidance document setting out FDA’s policy regarding RUO products, however, reports have recently surfaced that a new RUO policy may finally be released.

One of the elements set forth in the draft CPG was that the distributor of the RUO product should receive a certification from the laboratory customer that the product will be used for research purposes only. Although the CPG was not adopted, some vendors have asked laboratories to sign some type of acknowledgement form. While this will help support a vendor’s position that its product is intended only for research use, it is not currently required. FDA has, however, “encouraged” some instrument suppliers to adopt certification programs.

Concerned by the proliferation of RUO products, in 1997 FDA tried a different tack. That year, FDA promulgated the Analyte Specific Reagent (ASR) regulation. ASRs were broadly defined as the building blocks of diagnostic assays. Unlike RUOs, ASRs were subject to FDA requirements, including QSRs and Medical Device Reporting. This regulation was prompted, in part, by the belief that it would result in the availability of higher quality materials for laboratory tests and displace some of the lower quality RUOs.

To some degree, that plan succeeded. Many different products were offered to laboratories as ASRs. However, while many of these were basic chemical components, more complex products were also sold as ASRs. Ultimately, FDA concluded that the ASR regulation was being used as a vehicle for products that didn’t fit the intent of the regulation.

FDA therefore released a guidance document in 2007 that substantially curbed the availability of ASRs by prohibiting companies from combining more than one active component. With the advent of molecular diagnostics, selling a single component was often impracticable, e.g., a primer and probe pair need to be offered together. This narrow interpretation of ASRs has essentially precluded the sale of ASRs for use in molecular diagnostics. Somewhat predictability, a number of companies responded by relabeling their ASRs as RUOs. This has helped lead to a renewed focus on RUOs by FDA.

For years, the principal regulatory question for products labeled as RUOs has been whether they qualify for this classification and hence are not subject to regulation as devices. While FDA has not issued either a regulation or guidance delineating how companies can promote RUOs, the agency has taken enforcement action against a number of RUO companies.

Even absent regulations or guidance, it is apparent that in FDA’s view a product forfeits its RUO status if certain types of claims are made—claims that the product can diagnose a disease or condition, provide clinical sensitivity or specificity data, or offers a clinical benefit. Correspondingly, the instructions for use (IFU) accompanying the product need to be brief.

While the bulk of RUO products have been assays, the RUO category also encompasses instruments and equipment. This can present its own set of regulatory challenges, particularly when an IVD applicant has used an RUO instrument in conjunction with developing its assay, a situation that is now occurring with greater frequency.

The utilization of RUO instruments in assay development has led to the submission of applications that reference RUO instruments. This may result in naming the RUO instrument in the draft IFU, i.e., the applicant states that the assay is to be performed on an RUO instrument, or the data for the IVD were generated on an RUO instrument.

While FDA had accepted these practices, that has seemingly changed. Therefore, an IVD company that has tested and validated its assay on an RUO instrument or is using RUO assays in its test system should discuss with FDA at an early stage how to address the regulatory implications that may arise from this situation. Simultaneously, companies that are selling RUO-labeled instruments that are being widely used in diagnostics may find that they will be receiving more regulatory scrutiny from FDA.

Over the past few years, RUO products have received relatively little attention from FDA. That regulatory lull seems to be ending.

Jeffrey N. Gibbs ( [email protected] ) is a director at Hyman, Phelps & McNamara. Web: www.hpm.com.

Single-Cell Cloning Remains a Challenge

New approach to nanopore sequencing that is sure to catch your....

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Clin Microbiol Rev

- v.23(3); 2010 Jul

Validation of Laboratory-Developed Molecular Assays for Infectious Diseases

Eileen m. burd.

Emory University Hospital, Atlanta, Georgia

Summary: Molecular technology has changed the way that clinical laboratories diagnose and manage many infectious diseases. Excellent sensitivity, specificity, and speed have made molecular assays an attractive alternative to culture or enzyme immunoassay methods. Many molecular assays are commercially available and FDA approved. Others, especially those that test for less common analytes, are often laboratory developed. Laboratories also often modify FDA-approved assays to include different extraction systems or additional specimen types. The Clinical Laboratory Improvement Amendments (CLIA) federal regulatory standards require clinical laboratories to establish and document their own performance specifications for laboratory-developed tests to ensure accurate and precise results prior to implementation of the test. The performance characteristics that must be established include accuracy, precision, reportable range, reference interval, analytical sensitivity, and analytical specificity. Clinical laboratories are challenged to understand the requirements and determine the types of experiments and analyses necessary to meet the requirements. A variety of protocols and guidelines are available in various texts and documents. Many of the guidelines are general and more appropriate for assays in chemistry sections of the laboratory but are applied in principle to molecular assays. This review presents information that laboratories may consider in their efforts to meet regulatory requirements.

INTRODUCTION

Molecular tests to detect infectious agents are now widely used in many clinical laboratories. The technological advantages of molecular tests make them very powerful diagnostic tools, and they have become particularly valuable for the detection of infectious agents that cannot be grown or are difficult to grow in culture. The field of molecular testing for infectious diseases has expanded greatly and now includes qualitative assays that detect a single target, quantitative assays that are used as a part of monitoring the response to therapy for some viral infections, and multiplexed assays that detect two or more analytes in the same specimen. Most molecular tests used in clinical laboratories are commercially produced, FDA-approved tests. Sometimes, however, tests are developed, evaluated, and validated within one particular laboratory. These “laboratory-developed tests” are used only by the developing laboratory and are not distributed or sold to any other laboratories. Laboratory-developed tests are used in many sections of the laboratory, including chemistry, coagulation, microbiology, hematology, and molecular diagnostics. Molecular assays are often created by a clinical laboratory because a commercial test for the analyte(s) of interest is not currently available. Tests may not be commercially available because the analyte is rare, and the market for such a product would be too small to be profitable. Clinical Laboratory Improvement Amendments (CLIA) regulations recognize that clinical laboratories can run three types of “test systems”: (i) test systems that are cleared or approved by FDA and run by the laboratory without modification, (ii) test systems that are cleared or approved by FDA and run after modification by the laboratory, and (iii) test systems that are not subject to FDA clearance or approval ( 27 ). In spite of the widespread use of molecular tests, there is still confusion surrounding the requirements that need to be met when bringing a molecular test, whether FDA approved/cleared or laboratory developed, into a clinical laboratory. Part of the confusion has arisen because, even with attempts to align terminology, the terms “validation” and “verification” have been used interchangeably to describe the same process.

All laboratories in the United States that perform clinical testing on humans, excluding clinical trials and basic science research, are regulated by the Clinical Laboratory Improvement Amendments (CLIA) of 1988. The CLIA federal regulatory standards (Public Law 100-578) were passed by the 100th Congress in 1988, published in the Federal Register in 1992, and extensively revised in January 2003 ( 71 , 72 ). The regulatory standards are codified in the Code of Federal Regulations (CFR). The main objective of the CLIA regulations is to ensure the accuracy, reliability, and appropriateness of clinical test results, regardless of where the test is performed. As such, CLIA sets the minimum standards that must be met in validating performance of clinical tests. The Centers for Medicare and Medicaid Services (CMS) has the primary responsibility for operation of the CLIA program. Laboratories are recognized as meeting the requirements of CLIA if they are accredited by professional organizations such as the Joint Commission (JC), the College of American Pathologists (CAP), COLA (formerly the Commission on Office Laboratory Accreditation), or another agency officially approved by CMS. Some states (e.g., New York and Washington) also have state health laboratory organizations that are approved by the government and impose specific requirements that are comparable to or more stringent than CLIA regulations. These states are considered to be CLIA exempt, and the state requirements for evaluating a test or test system must be met. Molecular tests are considered to be nonwaived (formerly called moderate and high complexity) and are subject to all CLIA requirements for nonwaived tests. All method validation requirements must be met before results can be used for decisions regarding patient care.

CLIA defines differences between implementation of FDA-approved tests and implementation of laboratory-developed tests (Table (Table1). 1 ). Prior to the 2003 final rule, laboratories could accept the performance characteristics provided by the manufacturer of FDA-approved nonwaived tests instead of performing method validation studies themselves. The 2003 final rule now requires that laboratories do studies for FDA-approved nonwaived tests to verify that the performance specifications established by the manufacturer can be reproduced by the testing laboratory for the population of patients that the laboratory serves. The performance characteristics that must be verified include accuracy, precision, reportable range, and reference interval ( 28 ). Laboratories are not required to verify analytical sensitivity or analytical specificity for FDA-approved tests but should verify limit of detection (LOD) for quantitative assays ( 28 , 33 ). For laboratory-developed tests, however, more extensive studies are required, and the laboratory must establish the performance specifications of the test at the time of test development. The performance characteristics that must be established include accuracy, precision, reportable range, reference interval, analytical sensitivity, and analytical specificity.

Required performance characteristics with suggested studies needed before implementation of FDA-approved/cleared tests and laboratory-developed tests a

Validation and verification studies are not required for tests used by the laboratory before 24 April 2003 but must be done for tests introduced after that date ( 28 ). Documentation of all validation and verification experiments must be kept by the laboratory for as long as the test is in use but for no less than 2 years ( 28 ). Calibration and control procedures must also be determined based on performance characteristics whether the test is cleared/approved by the FDA or laboratory developed. While CLIA requires analytic validation of an assay described here, CLIA does not require clinical validation of an assay prior to its use in a clinical laboratory. Clinical accuracy is not a property of the test per se but is a property of the clinical application of the test. Establishing clinical accuracy requires clinical trials that may go beyond the purview of an individual laboratory ( 18 , 34 ). Studies that document clinical relevance are frequently provided in peer-reviewed literature. CLIA requires laboratories to have a director who is responsible for ensuring, using studies performed by the laboratory or reported in published or other reliable sources, the clinical utility of the tests performed in his or her laboratory ( 32 , 49 ).

The following discussion will be limited to the processes involved in validation of laboratory-developed tests and will also address the ongoing postvalidation calibration and quality control procedures required to ensure that the expected performance is maintained throughout the life of the test ( 29 , 30 ). While CLIA lists the performance specifications that must be established, CLIA does not specify the scientific methodology or data analysis tools to be used. Guidelines to assist in establishing performance specifications have been published by the Clinical and Laboratory Standards Institute (CLSI) and International Organization for Standardization (ISO) in several documents. CLSI consensus documents are developed by subcommittees or working groups with representatives from clinical laboratories, manufacturers of products for medical testing, and regulatory and scientific government agencies. These guidelines are reviewed and approved by an official vote of its members. There are guidelines that address various types of molecular diagnostic assays as well as guidelines that address evaluation of specific assay performance characteristics. Some of the CLSI protocols are intended for test developers, and others are intended for laboratory users of FDA-approved tests. Developers of test methods will generally follow protocols intended for manufacturers, although performance characterization studies will not usually need to include a between-laboratory component unless the test will be performed at multiple sites. Use of CLSI protocols is not mandatory, but they are frequently referred to by accrediting agencies and are regarded as good laboratory practices. ISO is a nongovernmental organization that is similarly structured, with technical committees that draft standards which are then submitted to representatives from the 162 member countries for review and approval by vote.

CLIA regulations stipulate that it is the responsibility of clinical laboratory directors to establish performance characteristics for laboratory-developed tests used in their laboratories. Laboratories face many challenges in trying to accomplish this. Laboratories must determine the type of experiments that are required, include an acceptable number and type of specimens, and choose the statistical methods to evaluate the data. Laboratories may follow relevant guidelines from CLSI, ISO, or other sources. Molecular test methods have advanced rapidly and are continuing to change, making existing guidelines often difficult to apply. Clinical laboratories are subject to inspection from a variety of accrediting agencies (e.g., CMS, COLA, CAP, and JC) that also have standards that must be met. Accrediting agency standards must include the minimum standards set by CLIA, but accrediting agencies may have additional, more stringent requirements. A single set of comprehensive guidelines that would help laboratories manage validation studies and that is acceptable to all accrediting organizations is not available. Laboratories today are also under great pressure to control costs and must carry out method validation studies by performing the minimum necessary to satisfy regulatory requirements and ensure robust performance of an assay. Well-designed experiments are essential to accomplish this. One of the major challenges in validating laboratory-developed infectious disease assays is the absence of standards for many analytes. An additional element that must be considered is that, although not technically research under the U.S. Department of Health and Human Services (DHHS) definition, the use of patient specimens for validation studies may require prior approval by an Institutional Review Board (IRB). DHHS defines research as “a systematic investigation, including research development, testing and evaluation, designed to develop or contribute to generalizable knowledge.” If the activity is not considered research or if patient specimens are used in such a way that subjects cannot be identified either directly or through identifiers linking the specimens to the subject, the activity may be exempt from IRB approval. An IRB, not the investigator, must determine if a project is exempt. If the activity is not considered research under the DHHS definition, it may still meet the FDA definition of research. Some activities involving FDA-regulated products, including in vitro diagnostic tests, will not be exempt, even if specimens are deidentified and the activity seems to fit under the DHHS definition of exempt research. FDA regulations generally require IRB review and approval of activities using FDA-regulated products ( 19 ). Current definitions and the regulatory status of laboratory-developed tests have created uncertainty regarding the need for IRB approval for validation studies. Many IRBs have a specific human subject protection program that governs the use of specimens. Since validation studies may or may not meet the DHHS or FDA definitions of human subjects or research, laboratories should contact their IRB to obtain a written determination.

Definitions

Fda-approved assays..

Clinical laboratory tests are i n vitro diagnostic devices (IVDs) that are defined in the Federal Food, Drug , and Cosmetic Act as an “instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent, or other similar or related article … intended for use in the diagnosis of disease or other conditions, or in the cure, treatment or prevention of disease, in man” ( 41 ). Facilities that manufacture, repackage, relabel, and/or import IVDs sold in the United States are regulated by the FDA's Center for Devices and Radiological Health (CDRH) under authority granted by laws in the Code of Federal Regulations passed by Congress. These facilities undergo periodic inspections by the FDA to ensure that they are in compliance with quality system (QS)/good manufacturing practices (GMP) requirements ( 25 ).

IVDs that are commercially distributed for diagnostic use in the United States require prior approval or clearance by the FDA. A manufacturer can currently place an IVD into the market in two main ways. One way is by premarket notification 510(k), in which a manufacturer provides documentation and data demonstrating that the new device is substantially equivalent to an existing marketed device in terms of both safety and effectiveness under the conditions of intended use. The FDA review of a 510(k) is entirely a scientific evaluation of data. If the FDA assessment indicates that the new device is substantially equivalent to a legally marketed device, the device is cleared and the manufacturer is free to market it in the United States. If there is no similar preexisting marketed device, the manufacturer must submit a premarket approval (PMA) application rather than a 510(k). A PMA may be required if the test is for a novel agent, if it is a new method for which clinical relevance and clinical use must be established, or if the analyte poses a health threat (such as Mycobacterium tuberculosis ) and a false-positive or false-negative result would be of significant risk to the patient or general public. The manufacturer must provide data that demonstrate a reasonable assurance of safety and effectiveness of the device. FDA review of a PMA application includes an in-depth scientific evaluation of the data and a comprehensive good manufacturing practice inspection at the manufacturing facility. Before approval, the PMA may also be reviewed by an FDA advisory panel of outside experts who provide recommendations. If the completed assessment is favorable, the IVD is approved and can be marketed in the United States. An assay that is submitted via the 510K route is listed as “FDA cleared,” since clinical relevance has already been established and predicate devices to which results can be compared are available. An assay that is submitted via the PMA route is listed as “FDA approved” for specific clinical applications such as diagnosis, monitoring, etc.

Assays that have been approved or cleared by the FDA are labeled “for in vitro diagnostic use.” Labeling regulations also require these assays to have a package insert that indicates the intended use of the test; instructions for specimen collection, transport, and preparation for analysis; storage recommendations; a summary and explanation of the test; step-by-step instructions for performing the test; specific performance characteristics such as accuracy, precision, specificity, and sensitivity; cutoff criteria and interpretation of results; limitations of the assay; quality control recommendations; bibliography; and the name and place of business of the manufacturer, packer, or distributor ( 21 ).

Laboratories that use FDA-approved or -cleared assays are required to verify the performance of these assays in their laboratories before reporting patient results.

Laboratory-developed tests.

Laboratory-developed tests are considered to be tests that are used for patient management but have been developed within CLIA-certified laboratories for use by those laboratories. Laboratory-developed tests may be (i) FDA-cleared or -approved tests that have been modified by the laboratory, (ii) tests not subject to FDA clearance or approval, or (iii) test systems in which performance specifications are not provided by the manufacturer ( 28 ).

For FDA-cleared or -approved tests that have been modified by the laboratory, CLIA does define the term “modified,” but modifications are generally considered to include changes in test components (extraction, amplification, and/or detection), procedural parameters, assay cutoff values, specimen types or collection devices, etc. The CAP allows results to be reported with a disclaimer for alternative specimen types while validation studies are in process or if the specimen type is rare and validation studies cannot be done due to insufficient numbers ( 33 ). The disclaimer should state that the specimen type has not been validated.

Tests not subject to FDA clearance or approval include standardized textbook procedures or tests developed in the laboratory that performs the assay and reports the results. FDA has historically taken the position that it has the authority to regulate laboratory-developed tests but has exercised “enforcement discretion” and has chosen not to, in part because CLIA and comparable state laws regulate the practice of clinical laboratory testing.

Laboratory-developed tests are accepted as being scientifically valid and are relied on routinely in the delivery of health care in the United States. Laboratory-developed tests are extensively regulated by CMS under CLIA. Clinical laboratories must determine performance specifications for all laboratory-developed tests as required by CLIA and are responsible for both the quality and interpretation of results generated from those tests. Studies to determine performance specifications for laboratory-developed tests are not transferable to other clinical laboratories, and each laboratory must conduct its own studies. Although laboratory-developed tests are not regulated by FDA, some components, such as reagents (general-purpose reagents and/or analyte-specific reagents [ASRs]), controls, or equipment, used in these tests may be purchased from third-party biological or chemical suppliers and may be FDA approved.

For several years, FDA officials have indicated that, because of the increase in the number and complexity of laboratory-developed tests, they are reconsidering the current enforcement discretion exemption from FDA oversight. Numerous advisory committees have made recommendations for creation of a system of oversight. Some recommendations have suggested that FDA should regulate laboratories as manufacturers of medical devices and that all laboratory-developed tests should be reviewed by the FDA in some manner before being offered clinically. Others suggest that manufacturers and laboratories are different entities and that FDA regulation of all laboratory-developed tests would not allow patients to have access to innovative clinical tests. Any regulatory changes could affect the process of validation.

CAP has proposed a three-tier model for regulatory oversight based on potential risk to patients and the extent to which test results influence diagnosis or treatment decisions. Under the CAP plan, laboratory-developed tests would be classified as low, moderate, or high risk. High-risk tests would require FDA review before being placed into clinical use. Moderate-risk tests would be reviewed by the accrediting agency used by the laboratory. Low-risk tests would be validated in the clinical laboratory, and the accrediting agency would review validation procedures and compliance with accreditation standards during regular inspections. Tests in the proposed low-risk classification include those that may affect diagnosis or treatment but are not used independently or directly. Also considered low risk would be tests for rare diseases as well as FDA-approved/cleared tests that are modified by the laboratory. The distinction between the proposed moderate- and high-risk classifications largely concerns the transparency of the methodology by which the test result is obtained and interpreted. Tests that use a proprietary algorithm or calculation that is not accessible to the end user would be considered high risk. The high-risk category would include in vitro diagnostic multivariate index assays (IVDMIAs), which combine findings from multiple individual analyses into a single, patient-specific test result using an interpretation function that cannot be independently derived or verified by the end user. The CAP plan also calls for stronger CLIA accreditation standards for laboratories using low- and moderate-risk laboratory-developed tests. A requirement for clinical validation of laboratory-developed tests has been included in the CAP proposal to ensure that tests are accurately correlated to a clinical condition. The CAP Laboratory Accreditation Program currently has the requirement that laboratories demonstrate clinical validity as an item in the Molecular Pathology Checklist ( 34 ) but not in the Microbiology Checklist ( 33 ).

The “ASR rule” was published in the Code of Federal Regulations in November 1997 to clarify the role of the FDA in the regulation of laboratory-developed tests and to ensure that the components of those tests were made consistently over time. The “ASR rule” has three major parts: (i) analyte-specific reagents (ASRs) are defined and classified in a rule codified in 21 CFR 864.4020; (ii) restrictions on the sale, distribution, and use of ASRs are imposed in 21 CFR 809.30; and (iii) requirements for ASR labeling are established in 21 CFR 809.10(e) ( 21 , 23 , 26 ). These statutory requirements were enforced by the FDA on 15 September 2008.

ASRs are not diagnostic tests. They are key components of diagnostic tests and are defined as “antibodies, both polyclonal and monoclonal, specific receptor proteins, ligands, nucleic acid sequences, and similar reagents which, through specific binding or chemical reaction with substances in a sample, are intended for use in a diagnostic application for identification and quantification of an individual chemical substance or ligand in biological specimens” ( 26 ). ASRs can be manufactured anywhere in the world. ASRs must be manufactured in compliance with current GMPs to ensure that they are manufactured under controlled conditions that ensure that the devices meet consistent specifications across lots and over time ( 22 ). ASRs are subject to regulation as medical devices when they are purchased by clinical laboratories for use in laboratory-developed tests or certain IVD tests. The FDA classifies medical devices, including ASRs, into class I, II, or III according to the level of risk associated with the device and the regulatory control necessary to provide reasonable assurance of safety and effectiveness. Most ASRs are classified as class I and are exempt from FDA premarket notification requirements in part 807, subpart E, of 21 CFR ( 20 ). ASRs are designated class II and require premarket notification (510k) when they are intended for use in blood banking (e.g., reagents used in cytomegalovirus [CMV] and syphilis serologic tests). Class III ASRs include reagents used in donor screening tests and certain high-risk infectious disease tests (e.g., those for human immunodeficiency virus [HIV] or tuberculosis). FDA regulations require premarket approval (PMA) for all class III ASRs before they can be sold in the United States.

ASRs may be sold only to (i) diagnostic device manufacturers; (ii) clinical laboratories that are CLIA certified to perform high-complexity testing under 42 CFR part 493 or clinical laboratories regulated under the Veteran's Health Administration Directive 1106; or (iii) organizations such as forensic, academic, research and other nonclinical laboratories that use the reagents to make tests for purposes other than diagnostic information for patients and practitioners ( 23 ).

ASR manufacturers must provide on the label the proprietary name, common name, quantity, or concentration of the reagent; the source and measure of its activity; and the name and place of the manufacturer ( 21 ). Class 1 exempt ASRs must be labeled “Analytic Specific Reagent. Analytical and performance characteristics are not established.” Class II or III ASRs must be labeled “Analytic Specific Reagent. Except as a component of the approved/cleared test [name of approved/cleared test], analytical and performance characteristics are not established” ( 21 ). ASR manufacturers are not permitted to include any statements regarding the clinical or analytical performance of the ASR or information on methods or techniques. Manufacturers may not assist with optimization of tests or provide technical support. The responsibility for test development is clearly assigned to the laboratory. ASRs may not be promoted for use on designated instruments or in specific tests. Laboratories may combine individual ASRs and other components in the development of their own tests. ASRs cannot be sold as kits. ASRs cannot be sold with validation information or medical or performance claims.

Federal regulations require laboratories to append the following disclaimer to the laboratory-developed test result report: “This test was developed and its performance characteristics determined by [laboratory name]. It has not been cleared or approved by the U.S. Food and Drug Administration” ( 21 , 26 ). This statement is not required if all of the ASRs used in an assay are created in the laboratory, rather than purchased. The CAP notes that it may be problematic to require clinical laboratories to warn physicians that tests were developed without FDA review and that it would be more accurate to acknowledge that the FDA does not require clearance or approval of laboratory-developed tests ( 34 ). CAP recommends adding language to the required disclaimer such as “The FDA has determined that such clearance or approval is not necessary. This test is used for clinical purposes. It should not be regarded as investigational or for research. This laboratory is certified under the Clinical Laboratory Improvement Amendments of 1988 (CLIA-88) as qualified to perform high complexity clinical laboratory testing” ( 34 ).

Research-use-only (RUO) products are intended solely for research purposes, not for diagnostic purposes. RUO products are often discussed as if they are medical devices, but since the intended use is research only, they do not fit the definition of a device and are essentially unregulated. RUO products are addressed very briefly by FDA regulations. FDA regulations provide only a definition and labeling requirements. RUO products are defined by FDA regulations as “in the laboratory research phase of development and not represented as an effective in vitro diagnostic product” ( 21 ). An RUO product cannot be represented as an effective in vitro diagnostic product, and manufacturers cannot make performance claims or give reference values. RUO products must be labeled “For research use only. Not for use in diagnostic procedures” ( 21 ). Labeling a product RUO allows it to be available to researchers who can then evaluate whether the product may be potentially useful for some specific diagnostic purpose. RUO products may be used in preclinical or nonclinical research settings, and they may be used with either clinical or nonclinical materials; however, the research cannot have intended clinical use. The research is limited to either basic science research unrelated to product development or the investigation of potential clinical utility of a product in the initial phase of development. RUO products cannot be used for investigational purposes (clinical studies) or for research to establish safety and effectiveness of the product. Results cannot be reported to the patient's physician or medical record and cannot be used to assess the patient's condition or for any diagnostic, prognostic, monitoring, or therapeutic purposes. The sale of RUO products is not restricted to high-complexity, CLIA-certified laboratories. Manufacturers and distributors of RUO products are encouraged to have a certification program that documents the researcher's agreement that the product will not be used for clinical purposes. RUO products are not registered with the FDA, and the FDA does not expect these products to be manufactured in compliance with GMP because they cannot be used for clinical purposes ( 21 ). Laboratories should be aware that it is illegal to bill CMS for RUO tests ( 66 ). This may or may not apply to nonfederal payers, depending on their specific coverage policies for RUO tests.