Wednesday, July 23, 2014

- Take Pride in Continuous Improvement

No comments:

Post a comment.

Search A Lean Journey

Twitter updates.

- Facebook Updates

- Advertising

Subscribe Now

Get new posts by email:

A Lean Journey LinkedIn Group

Recent comments, search this blog, top 10 posts.

- Celebrating my 500th Blog Post

- Visual Management Board

- Guest Post: Reduce, Reuse, Recycle...

- What Do We Mean By True North?

- The Six-Step Problem-Solving Process

- Five Lean Games Every Company Can Benefit From

- 10 Characteristics of a Good Measure and 7 Pitfalls to Avoid

- DOWNTIME and the Eight Wastes

- The 8 Common Wastes in an Office That Cause Downtime

- Lean Leadership: Lessons from Abe Lincoln

Blog Archive

- ► May (1)

- ► April (13)

- ► March (13)

- ► February (12)

- ► January (14)

- ► December (11)

- ► November (13)

- ► October (12)

- ► September (13)

- ► August (13)

- ► July (8)

- ► June (13)

- ► May (14)

- ► April (12)

- ► February (13)

- ► January (13)

- ► December (12)

- ► October (13)

- ► August (14)

- ► July (13)

- ► May (13)

- ► August (10)

- ► March (14)

- ► July (14)

- ► December (10)

- ► June (12)

- ► April (9)

- ► December (13)

- ► October (14)

- ► September (12)

- ► May (12)

- ► January (12)

- ► October (15)

- ► December (14)

- ► November (12)

- Lean Roundup #62 - July, 2014

- Clarity of Vision Sets the Compass Needle to True ...

- Lean Quote: Lean Requires Patience

- Five Essentials of Effective Collaboration

- Lean Quote: Disrespect the Impossible

- Listening is Not the Same as Hearing

- Carrots and Sticks Don’t Motivate in a Thinking En...

- Lean Quote: Success Comes From Perseverance

- Daily Lean Tips Edition #65 (976-990)

- What Lean is Not - 10 Things That Are Not Lean

- Lean Quote: Independence

- Five Simple Ways to Make Your VSM A Valuable Impro...

- ► January (15)

- ► August (17)

- ► July (19)

- ► June (16)

- ► May (19)

- ► April (18)

- ► March (17)

- ► February (16)

- ► January (18)

- ► December (19)

- ► November (18)

- ► October (20)

- ► September (18)

- ► August (22)

- ► July (23)

- ► June (21)

- ► April (17)

- ► February (18)

- ► January (20)

- ► December (18)

- ► November (19)

- ► October (17)

- ► September (22)

- ► July (20)

- ► June (20)

- ► May (21)

- ► April (19)

- ► March (20)

- ► February (17)

- ► January (17)

- ► December (20)

- ► November (15)

- ► August (18)

- ► July (17)

- ► April (14)

- ► November (17)

- ► July (15)

- ► June (9)

- ► May (5)

- A Lean Journey (79)

- A Year Ago (8)

- ASQ's Influential Voices (40)

- Book Review (64)

- Change Management (53)

- Communication (13)

- Conference (10)

- Culture (38)

- Customer Focus (2)

- Daily Management (1)

- Development/Training (13)

- Empowerment (19)

- Engagement (37)

- Exercises/Games (8)

- Facilitation (2)

- Feedback (3)

- Guest Post (167)

- In the News (69)

- Innovation (2)

- L.A.M.E. (5)

- Leadership (218)

- Lean and Green (12)

- Lean Basics (109)

- Lean Definition (24)

- Lean Fun (10)

- Lean in Practice (55)

- Lean Management (152)

- Lean Office (14)

- Lean Products (4)

- Lean Quote (722)

- Lean Resources (44)

- Lean Roundup (198)

- Lean Thinking (5)

- Lean Tips (232)

- Meet-up (25)

- Podcast (5)

- Problem Solving (21)

- Product Review (2)

- Project Management (6)

- Quality (48)

- Respect For People (57)

- Sharing Best Practices (129)

- Soft Skills (3)

- Strategy (6)

- Supply Chain (1)

- Talking Lean (1)

- Teamwork (42)

- Visual Factory (31)

- Webinar (23)

Lean Blogs I Like

- 2 Lean Principles

- 5S Supply Blog

- Avoiding The Corporate Death Spiral

- Be More Careful!

- Curious Cat

- Daily Kaizen

- Evolving Excellence

- Gemba Panta Rei

- Gemba Tales

- Got Boondoggle?

- Gotta Go Lean Blog

- Improve With Me

- Jamie Flinchbaugh

- Kaizen Notebook

- Lean Builder

- Lean Communications

- Lean For Everyone

- Lean Healthcare Exchange

- Lean Homebuilding

- Lean Insider

- Lean Is Good

- Lean Leadership

- Lean Pathways

- Lean Printing

- Lean Reflections

- Lean Simulations

- Lean Six Sigma Academy

- LeanCor Blog

- Learn Lean Manufacturing

- Learning About Lean

- Old Lean Dude Blog

- The A3 Post

- The Lean Edge

- The Lean Library

- The Lean Logistics Blog

- The Lean Thinker

- The Lean Way Consulting

- TimeBack Blog

- To The Gemba

- Training Within Industry

- Visual Management Blog

Other Sites I like

- AME's Target Magazine

- AnythingLean.com

- Art of Lean

- Bosch Rexroth Lean Production

- CIRAS - Theory of Constraints

- Chasing The Rabbit

- Corporate Event Management

- Creative Safety Supply

- Creative Safety Supply 5S Resource Page

- Fuss & O'Neill SPL

- Gemba Academy

- Grassroots Innovation

- IndustryWeek

- Lean Enterprise Institute

- Leanovations

- Learn More McGraw-Hill

- MEP University

- Manufacturers BlogNotions

- Manufacturing Business Technology

- Manufacturing Pulse

- Modern Machine Shop

- Running A Hospital

- Superfactory

- The 5S Store

- Unclutterer

- Visual Workplace

- Xtreme Lean Consulting

- catalyst for change

- freeleansite.com

wibiya widget

A lean journey blog - copyright © 2009-2024 tim mcmahon - all rights reserved.

The PRIDE Model

- About Sheila

PRIDE stands for Purpose, Reputation, Integrity, Direction and Energy. The model is a unique approach to building employee engagement and high performance in the workplace.

Principles of pride.

The PRIDE Model is built on two key principles.

Firstly, recognising the power of the individual to have an impact, to affect change, it looks at life at work from the dual perspective of the organisation and the people that work there. Nothing happens at work unless the employees turn up, physically and mentally, and so the PRIDE Model consciously places them and their interests on a par with those of the organisation.

Secondly, it places equal value on technical skills and emotional intelligence. If you want to build pride in your organisation and to see colleagues taking pride in their roles, you need to appeal to both rational and emotional incentives. People and organisations are successful when they are led by a well-rounded team and so leaders are encouraged to get to know and care about the people who work for them.

“People who apply the PRIDE Model will create an authentic and energetic workplace where people understand and share purpose and direction, where they want and are able to contribute, and also where they have evidence that they are valued.”

The Business Case

There is a compelling business case for pride at work – pride in oneself and pride in one’s organisation lead to better personal and collective performance. People with pride will make more effort, make better decisions, forge better relationships with their customers and become more positive influencers on their colleagues. They will also take more care of their own and their organisation’s reputation. People with pride are generally happier and healthier. They are more confident in their own abilities, are more fulfilled and are less likely to suffer from stress.

Take Pride is for leaders and influencers who want work to be a great place for the majority, not the minority, and who are looking for a fresh approach to make it happen.

Identify Purpose

An authentic statement of purpose creates emotional connections between brands and customers; between institutions and people; and it creates meaning for employees at work.

It may be inherent to your organisation, or it may be a higher ideal that you seek to achieve alongside your business goals. But it is not enough to think that organisational purpose alone creates meaningful work. The motivation of individuals is an interwoven strand that drives people to achieve things for themselves and for others. It impacts how much effort they put in and how they relate to their work. When fulfilled, it can carry them further and deeper into a positive relationship with their work.

Build Reputation

Most companies realise that their reputation can make or break them, and that employees are an integral part in the equation. Fewer companies really consider the impact of their corporate reputation on their existing and potential employees.

The employer brand arena is dominated by a handful of organisations, who recognise the power of the employee voice in employee attraction and reputation management. Most employers are way behind in terms of realising the power of employee advocacy from the inside out and thus creating a brand story that delivers more effective recruitment and retention.

Assure Integrity

The inner truth, or integrity of your brand promise is the central piece of the PRIDE model, and it should at the very least meet the expectations set by your employee brand proposition.

Think employee experience from recruitment through to retirement as a framework, but don’t forget to add the dimension of their every day interaction with colleagues on your premises. Culture, values and behaviours are the real-life demonstrations of policies, standards and processes and every individual person contributes to the whole. The larger your organisation, the longer the chain of interactions, and line managers are key to making work a great place to be. They need to be givers not takers, motivators not judges, and ultimately driven by the success of their teams.

Provide Direction

Clear and visible direction, and a sense of contributing to a future goal, is a huge factor in employee engagement. This is often expressed in terms of vision and strategy, where is an organisation going and how will it get there; but it also needs to articulate what employees need to do to contribute.

Leaders should be well versed in providing the line of sight between a goal and a task, but to truly resonate they need to consider their employees’ direction of travel as well, what life-stage they are at, and where they are in their own skills development. It is vital to set direction but also to know how far and how fast people are able and willing to come with you.

Nourish Energy

While the life expectancy of the average business is falling – companies generally are changing more rapidly, brands are coming and going – and it takes more energy to survive and thrive. Energy encompasses the physical, mental and indeed spiritual health of your company and its people.

Operational health, premises, flexible working and space for creative thought will build longevity, sustainability and stamina. People who are inspired will give their best and be in the flow. At the same time, individual health and wellbeing is a massive economic issue. We are not only living longer but we are working longer too. Organisations need to nourish all their employees, but anticipate the fact they will need to accommodate a more multigenerational workforce than in the past, and that might mean some smarter, more flexible working patterns.

How to get started

So you’ve bought into the philosophy and want to see the pride model come to life in your organisation. although every organisation is in a different starting position, here are the typical steps you will have to think about. if you need help, call sheila to discuss how she can provide support for your internal team., 1. establish a team.

Creating a PRIDE programme and putting it into practice requires leadership, ownership and resource. Typically in smaller companies, this is led by a CEO, and in bigger organisations, it is a strategic partner to the Board, like an HR or Brand Director. The resourcing and structure of the implementation team will depend on the scale and capabilities of the organisation and of your team.

2. Embrace the philosophy

The PRIDE model is built on the core belief that pride in the organisation and pride in one’s role drives performance. So it’s worth giving some time and thought to how that concept may play out in your organisation. It is also essential that the entire programme is explained in clear communications and supported where necessary by skills development and coaching.

HR and Communications professionals are in a great place to represent a PRIDE programme internally, as, in order to function, they are generally tuned in to the different aspects of an organisation’s strategy and its people already, they own or at least manage the communications channels, and are well connected with the decision-makers.

3. Understand your starting point

You then need to determine how all five elements of the PRIDE model are currently working in your organisation, through a combination of fact-finding, qualitative and quantitative investigation.

We recommend following a process of structured interviews and focus groups with representative groups from senor management, functional leads and employee teams. We also supply an employee questionnaire, created with The Centre for Brand Analysis, to gather input from your whole workforce, or a representative portion of it. This can be conducted online or by hard-copy, depending on the working practices of the organisation.

The questionnaire demands up to 100 individual responses to questions and statements in 12 different categories. The number of questions and statements can be tailored according to the target user group, but there is a minimum set of questions that are required before an integrated PRIDE score can be applied.

4. Accept independent analysts

The PRIDE diagnostic will be analysed by The Centre for Brand Analysis and reported by an independent researcher who is experienced in the PRIDE model. The diagnostic report will demonstrate where the strengths and weaknesses of the organisation lie and pinpoint the areas in need of most attention.

The results for each organisation will be unique and the improvement programme will need to be tailored accordingly. We can work with your internal team to present results back to the leadership team and put forward recommendations for improvement.

5. Create action plans

The components of the PRIDE model are influenced and impacted by a wide range of factors and so recommendations for improvement are likely to touch many parts of your organisation. Your implementation team will need to identify the actions that will make the greatest difference to collective and individual performance.

Each aspect of PRIDE can be addressed by introducing and maintaining specific processes and practices at work. They will need to be assigned to the most appropriate lead and work within your existing structures and functions. Previous PRIDE action plans have included new and improved performance management processes, clear communications on future strategies, new energy plans and health and wellbeing communications programmes.

6. Track progress and celebrate achievements

There are several ways of conducting light-touch reviews of your action plans, including informal feedback sessions with employee representatives, and quick pulse surveys on one or two aspects of your programme. In order to track results of the entire programme, the PRIDE Diagnostic should be repeated in its entirety 12-18 months after the initial diagnostic.

Recognition is an important source of motivation for employees. If you already have an employee recognition scheme, you should consider whether to integrate elements of the PRIDE programme into it, or to expand it to celebrate examples of improvements in PRIDE components. Otherwise, you can create a process that will suit the culture of your organisation and encourage people to take celebrate their Moments of Pride in the organisation.

Take Pride includes a chapter called Pride in Practice that provides more details on the PRIDE methodology. The book also contains practical tips and ideas on how to introduce the five factors of Purpose, Reputation, Integrity, Direction and Energy.

How far can you take pride.

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

6.4: Lean Processes

- Last updated

- Save as PDF

- Page ID 50787

- Michael Laverty and Chris Littel et al.

Learning Objectives

By the end of this section, you will be able to:

- Discuss the lean process methodology

- Understand the phases of the lean problem-solving process.

You have learned about different problem-solving approaches that entrepreneurs take to lead their startups and work with others. Most of these approaches have had to do with the entrepreneur’s cognitive or creative mindsets. Now we will learn about an approach that is more rooted in process, called lean process . Lean problem solving has been used as an entrepreneurial methodology in new and emerging ventures, and it’s interesting that it comes from a large corporate, manufacturing background that focuses on efficiencies. The Six Sigma methodology, pioneered at Motorola in the 1970s and 1980s, and adopted by many companies, is a disciplined, data-driven approach that provides companies tools to improve the capability of their business processes. According to the American Society for Quality, “Six Sigma views all work as processes that can be defined, measured, analyzed, improved and controlled. A set of qualitative and quantitative tools is used to drive process improvement. This increase in performance and decrease in process variation helps lead to defect reduction and improvement in profits, employee morale, and quality of products or services.” 26 GE copied it and created the “Process Excellence” programs that millions of managers and others have taken to get certified at various “belts.” Although Six Sigma and Process Excellence do not fit strictly in terms of entrepreneurship, as they are used mainly by large, mature companies, many of the methods fit in the lean model.

Toyota pioneered the lean process in the 1980s. The term “lean manufacturing” is the most common, but it is much more than manufacturing. The lean process is a systematic method for the maximizing of continuous improvement and the minimization of surplus or unused material in the production of a process. The entrepreneur begins the startup with a sense the original product will be the product carrying the organization to success in the long term. In most cases, the good or service will require modification to maintain a process, technology, or up-to-date product offering. Lean problem solving means the entrepreneur’s entire team scans both the company’s internal and external environments for continuous improvement and methods for bringing additional revenue to the startup by cost improvement processes that promote sustainable value. The external environment encompasses customers, industry trends, and competition. The internal environment comprises the factors inside the enterprise, such as employees, and internal practices and processes. In lean manufacturing, for example, improving efficiencies in the internal environment should lead to advantages in the external environment (whether that be cost savings to customers, competitive advantage from more output/superior product, etc.).

For example, every mile saved per day per UPS truck driver results in approximately $50 million in savings per year, according to Juan Perez, the company’s chief information and engineering officer. Using customer data and artificial intelligence, the company created a system dubbed ORION, which is an acronym for On-Road Integrated Optimization and Navigation. 27 To date, the system has resulted in $400 million in savings to UPS. By applying the lean process, everything that UPS saves on the input (by reducing mileage) leads to savings on the output, which leads faster deliveries, lower costs for consumers, and more profit for UPS.

Lean Problem-Solving Process

The lean problem-solving process is a cycle of observation, assessment, and continual evaluation. As shown in Table 6.4.1, this cycle typically involves eight specific steps.

The lean problem-solving, step-wise process allows the business to observe, assess, and continually evaluate.

ARE YOU READY?

Too much too late.

Many entrepreneurs create a startup with an idea that they develop without any feedback from potential customers, relying on their own knowledge or assumptions about the market. Consider the story of Rapid SOS: https://hbr.org/2018/05/do-entrepren...eed-a-strategy . What would most likely happen when they decided to go forward with their product? Will it be a fit to the customer’s needs or solve their problems? How is lean process different from this?

Lean Problem-Solving Phases

Observation is the phase in which the entrepreneur studies the challenge and notes all facets of the challenge requiring solution. In this phase, the entrepreneur asks questions and conducts research about the change needed for a successful product, outcome, or service. The entrepreneurs must determine why the change is needed. What is the purpose of the endeavor? Feedback is extremely important in this phase.

For example, a community asked a group of entrepreneurs to help address the youth obesity problem in a middle school. The entrepreneurs began to study the intake of food by the children and determined that both the content of the school lunch menu and the lifestyle of the majority of the children were affecting the obesity rate in the community. They then defined the purpose of the project as finding a low-cost, low-risk method of changing the lunch menu and agreed that the primary outcome would be a 30 percent reduction in the obesity rate of the children. The entrepreneurs began to assess the cost of changing the lunch menu and observing what else the kids ate. The entrepreneurs discovered that the lunch menu change required to reduce the obesity rate was beyond the financial capability of the school district. Research also showed that many of the children, products of single-parent homes, were eating high-calorie, high-fat, take-out foods for dinner. Further observation revealed that the children did not engage in physical activity after hours because the local surroundings were not safe. The community needed a process to transform the wellness of the children, and the entrepreneurs recommended using a lean process approach to help the children as quickly as possible.

After the observation of the problem comes assessment , the phase in which the entrepreneur experiments and analyzes the potential process and its capabilities. The entrepreneur leverages creative tools and resources to arrive at a solution and assesses each step of a possible solution. Each step must add value to the solution, or that step in the solution is unnecessary. In addition, the step must be capable of solving the issue and add flexibility to the solution. How is the process or product being improved? In this phase, a prototype of the product is developed and delivered. The entrepreneur must ask the customer if all needs and wants are satisfied with the prototype. If the prototype is being developed for mass production, surveying customers about potential sales is essential. In the school lunch example, the school system would have been the customer of the new food menu (prototype) in the assessment phase.

Evaluation is the phase in which behaviors are analyzed to assess success. The entrepreneur continually studies each phase of the solution to observe the effectiveness of outcomes desired by the client. The entrepreneur ensures that transformation is built into the habits of the school to obtain, maintain, and develop the desired outcomes.

In a real-world example of a company applying lean processes, the New Balance Company, which designs and manufactures both athletic and casual shoes, used a batching approach in the early 2000s that organized production by departments, so that all of the cutting took place in one department, all of the stitching took place in another, and so forth. While it seems that batching tasks would improve efficiency, at New Balance, it meant that production of one pair of shoes took nine days. Executives observed piles of inventory sitting between floors and departments, and noticed employees waiting while there were delays in the production line. They also noticed that the pay structure contributed to the piles of works in process because employees were paid by the piece, which encouraged them to produce as much as possible.

The company applied lean principles to rearrange the production floor by value streams, or the making of a product by sharing similar processing steps. On one side was “cut and stitch” products using US materials of leather and mesh, while another side used premade products from overseas for soles, inserts, and kits. This change cut the time to make a pair of shoes down to four hours, meaning that domestic plants could ship some orders in twenty-four hours, while competitors may need as much as 121 days to ship when they outsourced manufacturing to Asia.

An often-used lean problem-solving tool is whiteboarding ( Figure 6.16 ). Whiteboarding is a type of graphing that permits the entrepreneur to plot each step in a process to build comprehension and detailing of the process. The entrepreneur draws each step on the whiteboard using a linking-type diagram, and draws arrows to show how processes affect other processes. Seeing the flow of the process allows the entrepreneur to note where functions in the process are duplicated or inconsistent.

For example, in a community garden, storing tools, such as hoes and hand trowels for weeding, in different sheds wastes time when preparing to begin the process of weeding. These tools should be stored collectively to eliminate multiple trips and wasted time. Seeing the process on a whiteboard or other medium brings awareness to how processes can be improved. After the process is changed, it is graphed again for further scrutiny.

ENTREPRENEUR IN ACTION

The origin of lean.

Would it surprise you to know the origin of lean, in modern times, is considered to be Henry Ford’s production line? Although we don’t necessarily think of the creation of automobiles as an entrepreneurial venture in today’s world, Henry Ford was truly an entrepreneur for his time when the manufacture of automobiles was just beginning. Not only did he recognize the opportunity inherent in the sale of automobiles, he recognized the need to create an efficient process for automobile production that could decrease costs and, consequently, the selling price of the vehicle. As the first entrepreneur to join the use of interchangeable parts with moving conveyance to develop fabrication processes, Ford was able to turn over inventory in a very short time; however, Ford’s process could not deliver variety. In fact, Ford was quoted as saying of the Model T’s color, “You can have any color as long as it's black.” 29 It had the fastest drying time; hence, it was the only color he used for a number of years.

The Ford system was built around one static product. In the 1930s, when the market demanded product variety, the company was not set up to address this challenge. Kiichiro Toyoda (Figure \(\PageIndex{2}\)), the second president of Toyota Motor Corporation, visited the Ford plant in Michigan to learn more about their application of the assembly line concept. After observing, he proposed a new production system that would strive to “right size” equipment to better match tasks and the volume of work, as well as introducing quality assurance steps in each sequence of the work process. Toyoda’s approach shifted the focus from machinery to process, optimizing efficiency while maintaining quality.

LEI's Learning Portal

Intro to problem solving.

Problem solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all your senses to understand what is truly happening.

All too often, people create countermeasures to perceived problems without digging deeper, asking the right questions, and thinking more.

Throughout the entirety of the course, we use a case example to illustrate the problem-solving approach as you are learning. In addition, you will deepen your understanding by applying this new way of thinking to a problem of your choice.

This course breaks down lean problem-solving concepts and techniques into simple, easily understood pieces.

How do you solve problems?

Learning objectives.

This course works for people new to the concepts of lean and continuous improvement, for individuals looking to improve their lean understanding and skills, and for organizations wanting to level set the lean knowledge of their workforce to speed progress.

Build a foundational understanding of problem types and problem solvingIdentify the four types of problems

Resolve business challenges by using scientific method, PDCA-based problem solving

Apply A3 thinking to solve problems

Clearly define problems, beginning with grasping the situation at gemba

Learn to break down vague problems to specific problems that can be solved to root cause

Time Estimates Per Unit*

*Actual times may vary.

Course Units

Expand to view lessons

Course Introduction

0.1 Welcome!

0.2 Platform Tour (optional)

0.3 Copyright Acknowledgment

0.4 Curriculum Concept Map (Visual Syllabus)

0.5 Supplemental Textbook

Unit 1: Lean Problem Solving

1.1.1 | Welcome to Introduction to Problem Solving!

1.1.2 | Lean Transformation Framework

1.1.3 | How We View Problems

1.1.4 | Lead with a Questioning Mindset

1.2.1 | What's a Problem

1.2.2 | Problems Problems Problems

1.2.3 | Four Types of Problems

1.2.4 | Four Types of Problem Solving

1.2.5 | Make the Problem Clear

1.2.6 | Problem Breakdown Analysis

1.2.7 | Unit 1 Personal Reflection

Unit 2: What is an A3?

2.1.0 Helpful information for working on Your A3

2.1.1 | Introduction to A3

2.1.2 | A3 Basics

2.1.3 | Simple A3 Example

2.1.4 | A3 as Good Storytelling

2.1.5 | It's Not a Template

2.1.6 | 5-Step A3 Example

2.1.7 | Your A3: Title and Owner

2.1.8 | Introduction and Chapter 1 (optional)

2.2.1 | Develop Problem Solvers

2.2.2 | Developing Problem Solvers at Herman Miller

2.2.3 | The A3 Process

2.3.1 | Basic Thinking, Mindset, Assumptions

2.3.2 | Porter’s First A3: Rush to a Solution

2.3.3 | Rethinking Thinking by Trevor Maber

2.3.4 | What do I need to know

2.3.5 | Chapter 2: Grasp the Situation—Part 1 (optional)

2.3.6 | Unit 2 Personal Reflection

Unit 3: Your A3

3.1.1 | Grasp the Situation at the Gemba

3.1.2 | Gemba Is More than a Place from Managing to Learn (optional)

3.1.3 | Go See, Ask Why, Show Respect

3.1.4 | Chapter 2: Grasp the Situation—Part 2 (optional)

3.1.5 | Porter’s First Revised A3

3.1.6 | Problem-solving Funnel (Part 1)

3.1.7 | Your A3: Background & Current Condition

3.2.1 | Analysis (part 1)

3.2.2 | Problem-solving Funnel (Part 2)

3.2.3 | Chapter 3: Goals and Analysis—Part 1 (optional)

3.2.4 | Your A3: Background & Current Condition - update

3.2.5 | Analysis (part 2)

3.2.6 | The Five Whys

3.2.8 | The Five Whys Animation

3.2.9 | Problem-solving Funnel (Part 3)

3.2.10 | Your A3: Goal, Target and Analysis

3.3.1 | Choose Countermeasures

3.3.2 | Countermeasures vs. Solutions (optional)

3.3.3 | PICKing Countermeasures

3.3.4 | Your A3: Countermeasures

3.4.1 | Create a Plan

3.4.2 | Nemawashi from Managing to Learn (optional)

3.4.3 | Consensus/Agreement from Managing to Learn (optional)

3.4.4 | From Position Based Authority to Pull-Based Authority (optional)

3.4.5 | Chapter 5: Plan and Followup—Part 1 (optional)

3.4.6 | PDCA from Managing to Learn (optional)

3.4.7 | PDCA Improvement

3.4.8 | Your A3: Plan

3.5.1 | Followup

3.5.2 | Chapter 5: Plan and Followup—Part 2 (optional)

3.5.3 | Detailed A3 Template

3.5.4 | Your A3: Followup

3.5.5 | Conclusion and Getting Started (optional)

3.5.6 | Unit 3 Personal Reflection

3.5.7 | Course Summary

Final Course Survey and Certificate of Completion

Final Course Survey

Certificate of Completion

Continue Your Lean Learning

Extra Resources

More books from the Lean Enterprise Institute

A3 Thinking Questions

More learning experiences from the Lean Enterprise Institute

More on the 'Ladder of Inference'

More on 'Leading with a Questioning Mindset'

About this course

- 0.5 hours of video content

Senior Instructor John Shook

Shook co-authored Learning to See, the book that introduced the world to value-stream mapping. He also co-authored Kaizen Express, a bi-lingual manual of the essential concepts and tools of the Toyota Production System. With Managing to Learn, Shook revealed the deeper workings of the A3 management process that is at the heart of Toyota’s management and leadership.

Worth every minute spent!

Christy leite.

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handlin...

This training covers what other root cause training don’t: The Social-Technical system which is equally important to using problem solving tools when handling a problem. Problem definition is where most teams fall short. This training covers that well with excellent application examples. Definitely worth taking!

Wish i learned this at the beginning of my career

Jonathan fairweather.

would have saved alot of headake on alot of problem solving arguements ect and got to the root problem

Outstanding

William butdorf.

Very organized and professionally delivered.

It's Not Just a Piece of Paper

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should ...

You really have to try and put the simplest problem you think you have and see if you can fix or solve it with a sentence or paragraph about what you should do. Then apply the A3 methodology... I bet you find it isn't one simple problem and you might just discover how complex the problem is, what else is affected that you never realized, or who else might be aware or impacted by it. It's just thinking outside the box and being open to solving the problem. I think to many people don't want to expose a problem because they don't know how to fix it or that it's a failure to have problem at all

Additional Courses

Learning to See Using Value Stream Mapping - with Live Coaching

This workshop shows you how to make and apply this fundamental and critical tool based on the Lean Enterprise Institute's groundbreaking value-stream mapping workbook, Learning to See, which has introduced the mapping tool to thousands of people.

NEW Intro to Lean Thinking & Practice

This online course serves as an introduction to the key concepts, philosophies, and tools associated with lean thinking and practice.

Lean Fundamentals Bundle

Buy all three fundamentals courses at reduced cost. Purchase for yourself or your entire enterprise.

Stay connected on all things lean thinking and practice.

Add your email to LEI's mailing list to get the latest updates.

Please enter a valid email address

Please check this box if you wish to proceed

Oops, something went wrong. Please try again with a different email address.

InfoQ Software Architects' Newsletter

A monthly overview of things you need to know as an architect or aspiring architects.

View an example

We protect your privacy.

Facilitating the Spread of Knowledge and Innovation in Professional Software Development

- English edition

- Chinese edition

- Japanese edition

- French edition

Back to login

Login with:

Don't have an infoq account, helpful links.

- About InfoQ

- InfoQ Editors

- Write for InfoQ

- About C4Media

Choose your language

Discover transformative insights to level up your software development decisions. Use code LIMITEDOFFERIDSBOSTON24 for an exclusive offer.

Get practical advice from senior developers to navigate your current dev challenges. Use code LIMITEDOFFERIDSMUNICH24 for an exclusive offer.

Level up your software skills by uncovering the emerging trends you should focus on. Register now.

Your monthly guide to all the topics, technologies and techniques that every professional needs to know about. Subscribe for free.

InfoQ Homepage News How Lean Has Helped the IT Team Take Pride in Their Work

How Lean Has Helped the IT Team Take Pride in Their Work

This item in japanese

Nov 28, 2019 4 min read

Ben Linders

InfoQ Article Contest

More teamwork, a better vision of daily work, a team that works in a concentrated way, and more pride in doing a job well; these are the benefits that Mélanie Noyel mentioned that their IT team at Acta gained from using Lean. At the Lean Digital Summit 2019 she presented on how they applied Lean to improve the IT team’s daily work.

The IT team is composed of two people for development and three for system and network. The day-to-day work is divided among projects, customer support, development and maintenance for 18 business applications and various IT training.

In early 2018, the situation was disappointing, as Noyel mentioned:

The team was overloaded under support work, customers were not really satisfied, projects dragged on, and the top management pushed for a different way of organizing. Drowned in this situation, we didn’t see how to get out of it.

As Acta was already familiar with Lean, the IT team decided to try the Lean IT Academy, a rendez-vous held once a month in the company to learn how to apply Lean principles to the development and management of IT products and services. "What makes it different is that we see a little of Lean theory and a lot of gemba," Noyel explained.

Before, we just did day-to-day work; from problem-solving to more problem-solving, without a real global vision. Now, we have defined our goals focused on the opinion of our customers. And we made it visual so that the whole team gets it right and pulls in the same direction.

Noyel mentioned that the team members have become proud of their achievements, building self-confidence from success:

The first PDCAs allowed each team member to realize that they were able to tackle big problems and solve them. Later, satisfied customers started to give positive feedback. Then, the other services started wanting to work like us. We regularly present what we are doing, including at this year’s Lean Digital Summit, and it’s a real reward for the pride of the team.

InfoQ interviewed Mélanie Noyel , head of IT at Acta, after her talk at Lean Digital Summit 2019 .

InfoQ: What made you decide to go on a Lean journey?

Mélanie Noyel : The opportunity that we got! The Lean mentality was already familiar within the company. Indeed, Acta is followed by the "Lean Institut France" and benefits from coaching in Lean engineering and Lean manufacturing. Because IT is also a particular domain and because the situation had to be improved, we start talking about another type of coaching for us: the Lean IT Academy. I thought it would help us to take time to start something and to get ideas.

InfoQ: How did the Lean transformation go, can you give some examples of what has changed?

Noyel : A first example is the reliability of our system. One way to measure it is to follow how long we spend on support in a week. We set an objective to reduce it by half in one year. We color a box per 15 minutes spent doing support on a visual graph every evening before leaving work, and we discuss it every morning during the stand up meeting. The goal is to understand what makes us waste time, and trigger PDCA to find the root causes and solve it. We have already met our objective to reduce it by half, but now it becomes harder to continue to reduce the support time. The stand up meeting is the second great change we made. We set up this time for a regular exchange every morning to organize the work of the day and decide things together. It’s a way to align us on priorities. To conclude, I mostly changed my mind! I’m no longer here to decide who does what but to make sure that we maintain the things that make our victories possible, and that the obstacles we encounter are overcome with greater ease.

InfoQ: How has the Lean transformation of Acta Mobilier IT team impacted day-to-day work?

Noyel : I think the day-to-day work has nothing to do with how it was before! Today, other offices in the company are starting to follow our example, simply because our image has changed. The other teams perceive us as more organized, more attentive to them, and as a provider of solutions (in IT but also in the organization of the day-to-day work). We also give the image of a united team, efficient and proud of our work. Our joy of living at work creates envy!

InfoQ: Which benefits have you gained?

Noyel : The IT system is more reliable and applications are faster and more intuitive. Our two types of customers are satisfied. Internal customers (other teams and workshop operators) rely on us to improve their professional lives. And external customers (those who buy the products manufactured by the company) are no longer impacted by problems related to IT. But the biggest benefit is for the people of the team! The team is closer together and ready to face bigger challenges.

InfoQ: What have you learned on your journey?

Noyel : You just have to start! Test something even if you’re not sure if it’s good or not. Test and observe what changes, then adapt and test again. As an example, we tested allocating support to a different person per day. This brought up lots of problems regarding skills, availability, organizing the day, etc… But we learned a lot and we adapted. We did draw many improvements on the management and transfer of skills, on making visual the person assigned to support, etc… Stay in this dynamic of improvement; celebrate your success and do not be afraid to admit your mistakes. For me, the true Lean theory becomes accessible only to those who really try.

Rate this Article

This content is in the culture & methods topic, related topics:.

- Development

- Culture & Methods

- Continuous Improvement

- Agile Conferences

Related Editorial

Related sponsored content, popular across infoq, spring now offers free access for the spring academy pro content, sleeping at scale - delivering 10k timers per second per node with rust, tokio, kafka, and scylla, yelp overhauls its streaming architecture with apache beam and apache flink, allegro reduces kafka producer latency outliers by 82% after switching to xfs, navigating ai, platform engineering, and staff-plus: infoq dev summit boston preview, netflix uses elasticsearch percolate queries to implement reverse searches efficiently, related content, the infoq newsletter.

A round-up of last week’s content on InfoQ sent out every Tuesday. Join a community of over 250,000 senior developers. View an example

- What is Lean?

- Our Approach To Lean

- History & What We’ve Done

- Lean Research

- Lean Capability Development

- Login / Sign up

Sign up and join the community

Email address *

Subscribe to our newsletter

Please select all the ways you would like to hear from us Email

Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy .

Home > Developing Self-Reliant Problem Solving Capability

Developing Self-Reliant Problem Solving Capability

22nd February 2024 - David Brunt

In every organization, problems are an inevitable part of daily operations. Whether it’s a hiccup in the production line, a customer complaint, or an unexpected setback, problems arise constantly, demanding attention and resolution. However, how organizations approach and solve these problems can often make the difference between stagnation and growth. In this blog post, we’ll delve into the art and science of problem solving within organizations, exploring common issues and effective strategies for tackling challenges head-on by developing problem solving capability.

The Problem with Problem Solving

Before delving into solutions, let’s address some common issues that plague the problem-solving process in many organizations:

1. Focusing on Certification over Capability

Many organizations prioritize certifications and formal qualifications over actual problem-solving skills. This emphasis on credentials can lead to a workforce ill-equipped to tackle real-world challenges effectively.

2. Overreliance on Tools

Using the same problem-solving tool for every issue is akin to treating every problem as a nail because you only have a hammer. Organizations often fall into the trap of relying solely on one approach, such as A3, without considering whether it’s the most suitable for the problem at hand.

3. Failure to Address Root Causes

Merely containing problems without digging deeper to identify and address root causes is a recipe for recurring issues. Without addressing underlying issues, organizations find themselves grappling with the same problems repeatedly.

4. Neglecting PDCA (Plan-Do-Check-Act)

Jumping straight to solutions without following a structured problem-solving process like PDCA can lead to ineffective or short-term fixes. Without a systematic approach, organizations risk implementing solutions that fail to address the core issue.

5. Leadership Overload

When leaders attempt to solve every problem themselves, they become overwhelmed and unable to focus on coaching and developing their teams. This reactive approach results in leaders firefighting rather than empowering their teams to tackle challenges autonomously.

6. Lack of Skill and Time

Inadequate problem-solving skills coupled with time constraints can prolong the resolution process, leading to frustration and inefficiency. Understanding problem-solving theory is not enough; individuals must also be able to apply it effectively in real-world situations.

7. Failure to Capture and Visualize Problems

Without a mechanism for capturing and visualizing problems, organizations struggle to prioritize and address issues systematically. This lack of visibility can lead to problems slipping through the cracks and going unresolved.

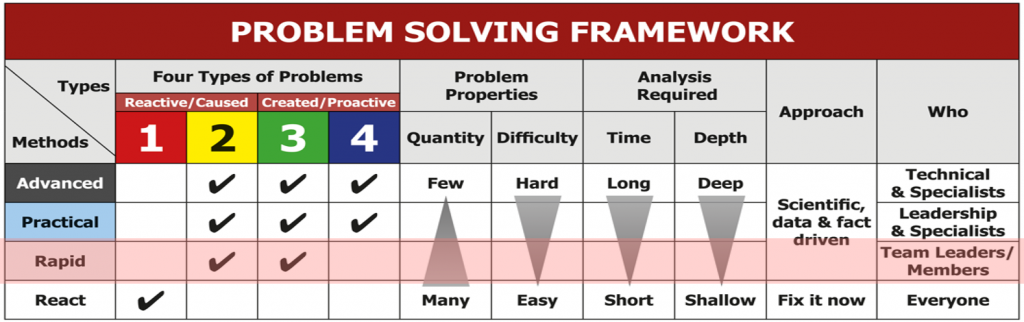

Four Types of Problems

Not all problems are created equal, and organizations must tailor their approach to the specific type of problem at hand. Art Smalley’s framework categorizes problems into four types:

- Type 1 – Troubleshooting: Addressing unexpected or reactive problems.

- Type 2 – Gap from Standard: Dealing with deviations from established norms or standards.

- Type 3 – Target Condition: Pursuing proactive improvements toward predefined objectives.

- Type 4 – Open-Ended: Tackling complex or novel challenges that defy easy categorization.

Each problem type requires a different approach and level of analysis, from rapid problem solving for straightforward issues to practical problem solving for more complex and strategic challenges. Being aware of the differences enhances problem solving capability.

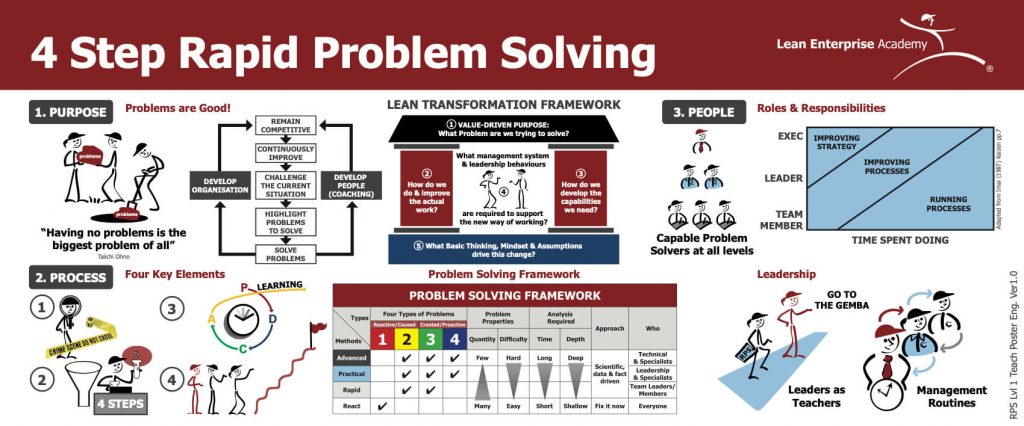

Problem Solving: Purpose, Process and People

At the heart of effective problem solving lies a clear understanding of its purpose and significance within the organization. Rather than viewing problems as obstacles to be avoided, organizations should recognize them as opportunities for growth and development. Taiichi Ohno’s famous quote, “Having no problems is the biggest problem of all,” underscores the importance of embracing challenges as catalysts for improvement.

By addressing problems systematically, organizations not only enhance their operational efficiency but also foster a culture of continuous learning and development. Moreover, problem solving serves as a vehicle for both organizational and individual growth, enabling employees to acquire new skills and competencies while driving business success.

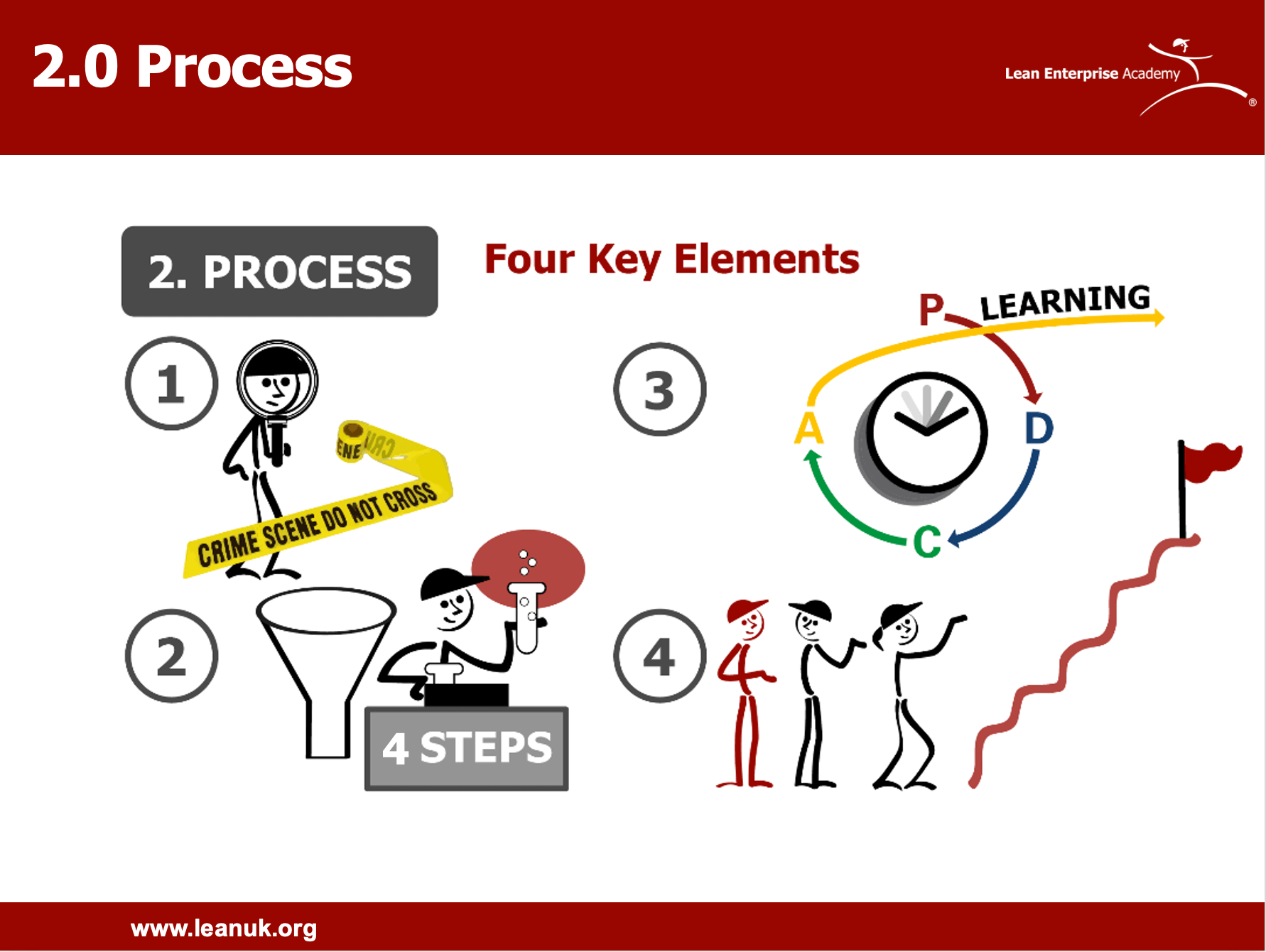

Process: Key Elements of Problem Solving

Effective problem solving entails several key elements, including:

- Go and See: Proactively seeking out problems and gathering firsthand information to inform decision-making.

- Scientific Approach: Applying a structured and data-driven methodology, such as PDCA, to systematically address problems.

- PDCA Thinking: Embracing a mindset of continuous improvement and iteration to drive organizational learning.

- Ultimate Goal: Maintaining a clear focus on the desired outcomes and objectives of problem-solving efforts.

People: Roles and Responsibilities in Problem Solving

Effective lean problem solving is not solely the responsibility of a select few (that’s a key difference between lean and six sigma) but rather a collective effort that engages individuals at all levels of the organization. By fostering a culture of problem solving and empowerment, organizations can unlock the full potential of their workforce and drive sustainable improvement.

Leaders play a critical role in nurturing problem-solving capabilities throughout the organization, from frontline teams to top executives. By allocating time and resources to coaching and development, leaders can cultivate a cadre of skilled problem solvers capable of driving continuous improvement and innovation.

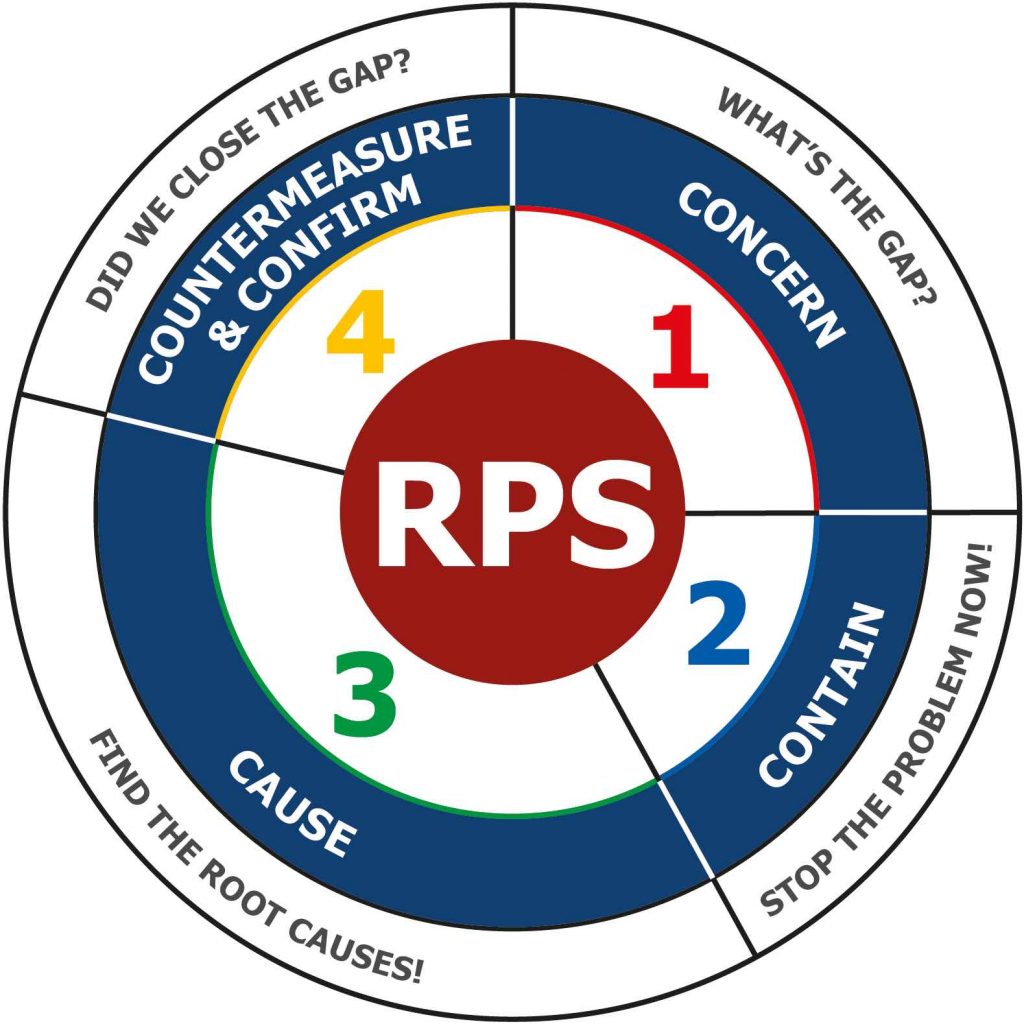

Rapid Problem Solving Method: A Closer Look

The rapid problem-solving method offers a structured approach to addressing challenges quickly and effectively. With its focus on concern, containment, cause, countermeasure, and check, this method provides a simple yet powerful framework for problem solving at all levels of the organization.

Each step of the rapid problem-solving method serves a specific purpose, from clarifying the problem to identifying root causes, developing countermeasures, and evaluating results. By following this systematic approach, organizations can streamline their problem-solving efforts and achieve sustainable improvements in performance and efficiency.

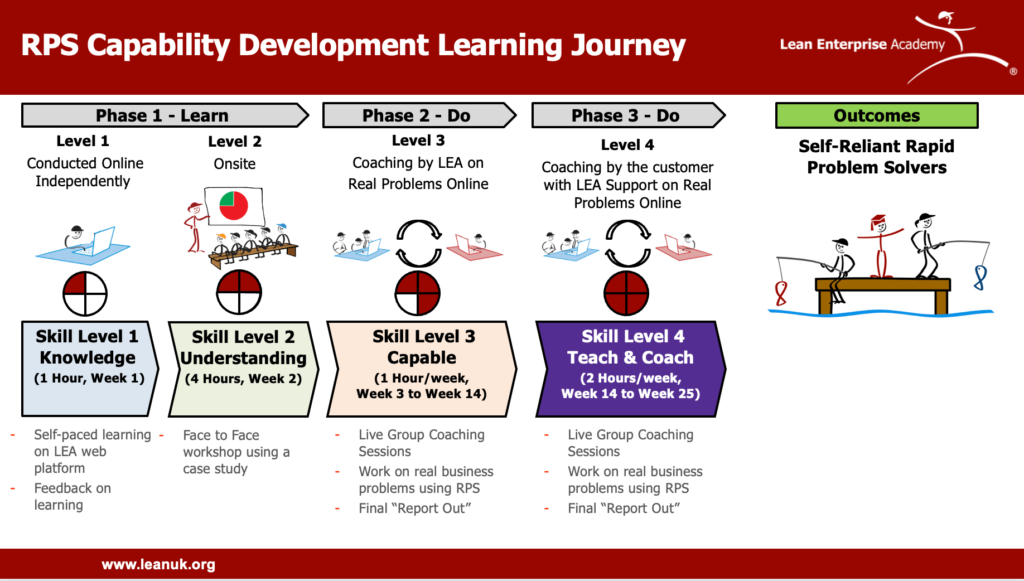

A Learning Journey: Mastering Problem Solving Skills

Mastering problem-solving skills requires a systematic and iterative approach to learning and development. Organizations can facilitate this process through structured training programs, hands-on exercises, and real-world problem-solving projects.

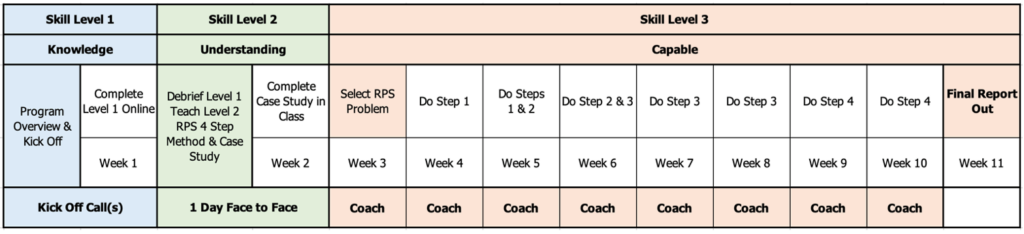

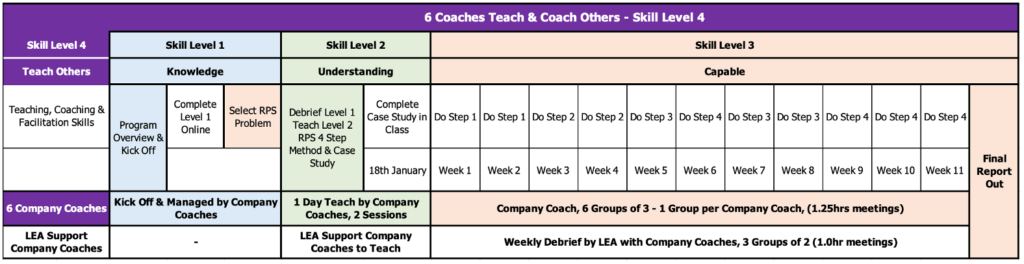

The RPS Capability Learning Journey developed with Hologic provides an illustration of an integrated approach to developing capability and self-reliance. The “Skill Level 1 – Knowledge” part of the learning process is conducted online using LEA’s Lean Learning Journey platform. “Skill Level 2 – Understanding” is a 4 hour session using a case. This can be carried out onsite or broken into 1 hour sessions online as the case is part of our online learning platform. “Skill Level 3 – Capable” uses remote group coaching sessions, working on real business problems. The process used is shown in the table below:

We shared the process during the Lean Global Connection event in November 2023. Here is a level 3 report out showing a real problem that was solved while teaching the RPS process.

Finally a co-hort of the people that progressed through levels 1 to 3 go on to develop the ability to teach and coach their colleagues. This results in the organisation developing self-reliance to use the process internally themselves.

By providing employees with the tools, resources, and support they need to excel in problem solving, organizations can foster a culture of continuous improvement and innovation. From online courses to live coaching sessions and interactive workshops, there are myriad opportunities for individuals to enhance their problem-solving capabilities and drive organizational success.

Effective problem solving is not just a technical skill but a mindset and a culture that permeates every level of an organization. By adopting a structured approach to problem solving capability, nurturing problem-solving capabilities, and providing ongoing support and development, organizations can unlock new opportunities for growth, innovation, and success.

In today’s fast-paced and dynamic business environment, the ability to solve problems quickly and effectively is more critical than ever. By mastering the art and science of problem solving, organizations can navigate challenges with confidence and emerge stronger and more resilient than ever before.

You can learn how several organisations are developing problem solving capability at our UK Lean Summit in April.

- Construction

- Manufacturing

- Public Sector

- Retail & Hospitality

- Supply Chain

- Capability Development

- Lean Leadership

- Lean Principles

- Management System

- Process Improvement

- Product Development

- Tools & Techniques

- Transformation

- Demand Analysis

- Flow Costing

- Lean & Green

- lean certification

- Lean Digital

- lean learning

- Lean Summit

- Lean Thinking

- Lean Transformation Framework

- Managment Routines

- People Capability

- Problem Solving

- product development

- Purpose Process People

- Rapid Problem Solving

- Standardised Work

- Supply Chain Management

- Teach Poster

- Training Within Industry (TWI)

- UK Lean Summit

- Value Stream Analysis

- Value Stream Mapping (VSM)

- Value Streams

- Visual Management

How to Solve Your Problems With Lean Six Sigma (Free DMAIC Checklist)

Elisabeth Swan is the co-author of “The Problem-Solver’s Toolkit” and co-host of “The Just-in-Time Cafe Podcast.” She’s been a process improvement consultant, speaker, and innovator for over 30 years. She’s the Chief Learning Experience Officer for GoLeanSixSigma.com, a former cast member of ImprovBoston, and – if asked – may still be able to ride a unicycle.

Surgeon Atul Gawande made headlines when he told the world that a simple checklist could drastically reduce unnecessary deaths in The Checklist Manifesto .

Yet, checklists conjure images of forklift drivers on loading docks with clipboards counting boxes. How could they transform healthcare?

“ He has… produced a 90-second checklist which reduced deaths and complications by more than one-third in eight hospitals around the world – at virtually no cost and for almost any operation. ” – James Clarke, reviewing The Checklist Manifesto, Ulster Med J. 2011 Jan; 80(1): 54.

Aviation was transformed decades earlier when management and engineers at Boeing Corporation created the pre-flight checklist after the 1935 crash of the prototype Boeing B-17 at Wright Field in Dayton, Ohio. Checklists have become so essential to the airline industry that most crashes can be traced to the misuse or failure to complete a checklist.

A New York Times reviewer noted, “no matter how expert you may be, well-designed checklists can improve outcomes”. Since the purpose of process improvement is improving outcomes, Lean Six Sigma and checklists are natural companions.

To prove that, this Process Street blog post will show the relationship between checklists and lean six sigma, and provide you with a free DMAIC Improvement Project Tollgate Checklist that you can use right now.

Use the links below to jump to that section of the post:

Lean Six Sigma and the role of problem-solving

Lean six sigma & the checklist, introduction phase, define phase, measure phase, analyze phase, improve phase, control phase, checklists and lean six sigma, use process street to reduce error.

Or, if you just want the checklist, check it out below!

Let’s get started.

For those unfamiliar with Lean Six Sigma and process improvement, it is a structured approach for organizations to scrutinize how things are done, poke at data and processes to uncover waste and then cut out things like extra forms, out-dated approvals and other time-wasting steps.

It’s a customer-focused, 5-step problem-solving model that engages entire workforces to constantly seek a better way of doing things.

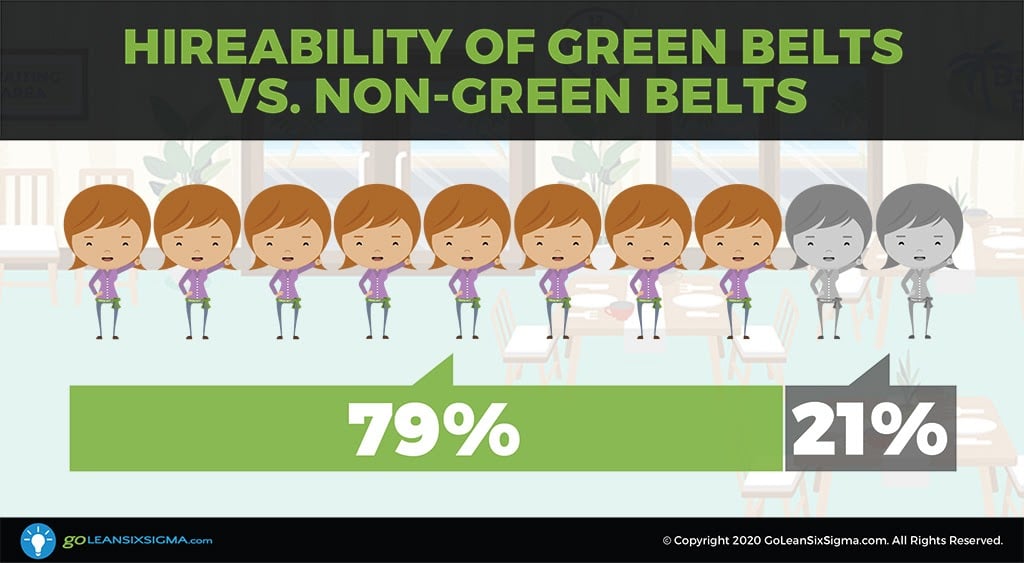

Proof of Lean Six Sigma’s influence is evident in today’s hiring practices. A poll by GoLeanSixSigma highlights that hiring managers prefer a person who is “ Green Belt Certified ” – having substantial Lean Six Sigma skills – by an almost 80% margin. In an interview with the former head of Twitter, problem-solving emerged as the top skill sought by today’s most influential hiring managers.

In other words, problem-solving (especially via Lean Six Sigma) is an absolutely vital skill.

If problem-solving is a must-have skill and checklists are key to good outcomes, then combining the two makes sense.

DMAIC – Define, Measure, Analyze, Improve & Control – is the 5-Step model for Lean Six Sigma and there’s a set of required tollgates at the end of each phase. These tollgates outline what has to be done in order to move the problem-solving process forward.

Using the tollgates as an outline, we created a dynamic Process Street template that you can use for free and run checklists from to track your progress!

Before you can start solving problems, you need a problem to solve.

Picking a process issue – and finding someone in leadership to support you – are two required tasks in this first tollgate. Scoping the project is important (bigger than a “just-do-it” and smaller than “solving world hunger”) but even more critical is finding a Sponsor.

Finding a Sponsor

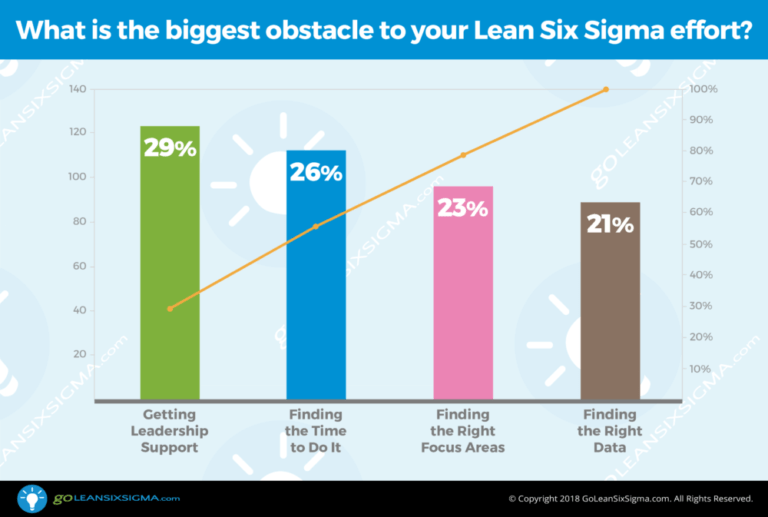

In a poll asking Lean Six Sigma practitioners what they considered the biggest obstacle to process improvement success, “Getting Leadership Support” accounted for almost a third.

When we coach team leads who tell us they can’t find someone to back their project, we let them know, “No Sponsor, no project”. If nobody in charge has any skin in the game, there’s no point in attempting the process fix. Find a different project that leadership supports.

One thing that helps when searching for leadership backing is being able to explain what Lean Six Sigma is and why it makes a difference. Since the checklist template is dynamic we inserted a video in the Define Phase within the checklist item, “Enlist a Project Champion/Sponsor who will support you and the project”. The team lead can share the video with managers or directors who they consider Sponsor candidates.

There’s also a Project Selection Guide Template embedded in the checklist so users can take a project idea and put it through a few screening questions. Is it a repeating problem? Is there a way to measure it? The checklist serves as a reminder, a source of templates, supporting videos and other just-in-time guidance.

The next set of tollgate tasks cover the Define Phase of DMAIC. This is where problem-solvers clarify the problem, the process impacted and customers of the process.

There is a journey of discovery during this phase as everyone agrees on the issue to solve. One of the big challenges is the tendency of ambitious team leads—or equally ambitious Sponsors—to try to “shoot the moon.”

Shooting the moon

They might want to reduce cycle time, reduce defects , improve margins, and increase customer satisfaction all by next Tuesday. But a project that focuses on everything accomplishes nothing. It’s okay to measure the cost reduction that results from reducing defects. But pick one of those to be the goal. Success is more possible if you focus on one goal at a time .

It takes practice and discipline to develop a manageable goal statement. Another moon shot is aiming for perfection out of the starting gate. When we see a goal statement that claims the team will, “reduce defects from 25% to 0%” then we know there is a sizable risk of failure and disappointment.

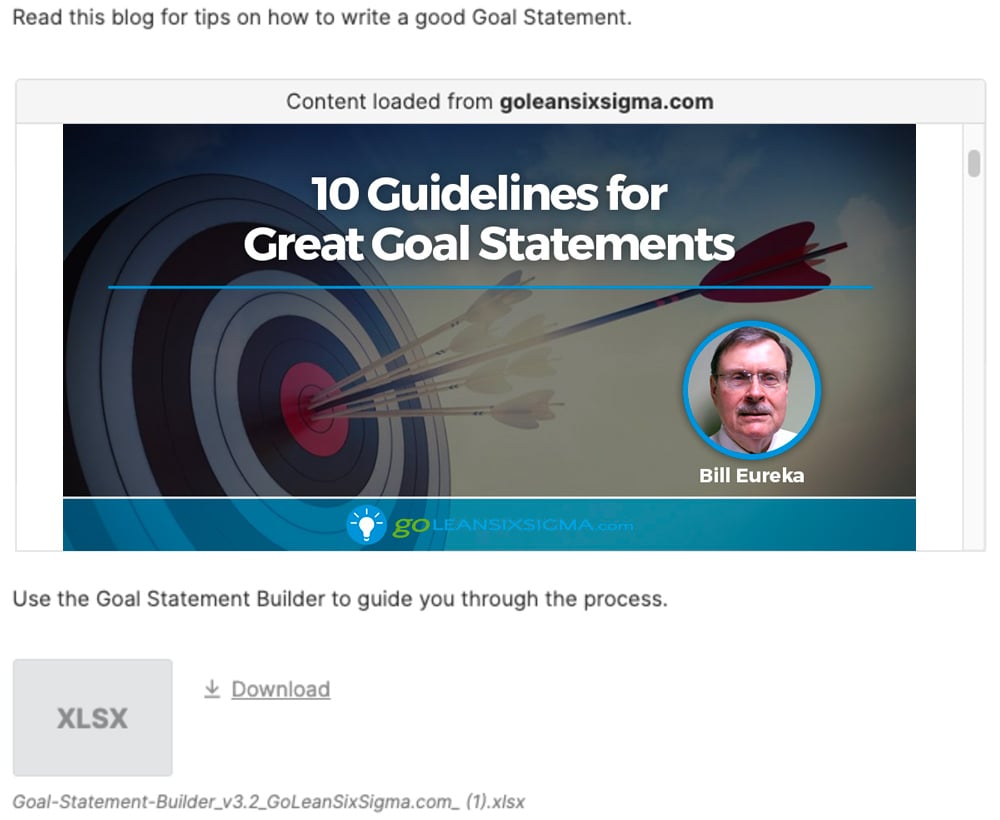

That’s why the Define Phase of the checklist includes a Goal Builder Template along with a blog providing tips on how to create well-crafted goal statements.

The primary focus of the Measure Phase is to baseline the process. If you’re trying to reduce defects, you need to know how you’re doing at that now. What’s your track record? You need to know the baseline of the process in order to measure whether or not you made a difference with your improvement when you get to the Improve Phase.

You need to know the gap, so you can close the gap.

The data’s in the system, somewhere…

One of the issues we run into in this phase is problem solvers assuming that data is sitting in a system somewhere waiting to be accessed. If they simply run a report, they’ll have the baseline. Check that off the list. But that rarely goes according to plan.

Maybe there’s system data, but was it entered with care? Is it reliable? We’ve seen teams struggle to use data that didn’t make sense. They could access cycle time data, but it didn’t take into account that the workday ended at 5:00. I had another team looking at why healthcare invoices had to be manually adjusted. They looked up the defect codes and the biggest category was “Other”. System data existed, but it was useless.

Most of the time, it helps to collect some data manually. In order to think through your approach, you need a Data Collection Plan. That involves listing the data you want and considering things like stratification factors—the “who, what, when, where” of data. If you’re looking at defects, should you collect data on defects by product? Defects by the fields on a form? Defects by customer type?

Within the task: “Develop a Data Collection Plan with Operational Definitions and create Check Sheets as Needed”, we’ve embedded a template (The Data Collection Plan) and a video to guide the process.

You’ll learn a lot by collecting the data firsthand, so if the perfect data set is not magically sitting in the system, it helps to have a plan.

Analyze is the crux of the DMAIC method. This is where learners drill down and discover the root cause of the process problem they’ve been chasing. Once you do that, you can solve the problem for good.

But if you have not determined the root cause then you might be solving a “symptom,” putting a bandaid on the problem or implementing a change based on a hunch. All of this means there’s a high likelihood the problem will remain and the efforts will have been in vain.

Finding the smoking gun

If you’ve always been told, “don’t bring me a problem, bring me a solution,” that’s an encouragement to jump right past this step into the fun of solutions. I’ve seen teams go with their assumptions regardless of what the data says or the process analysis reveals. I’ve seen Sponsors who tell teams what solutions they want to be implemented right from the get-go.

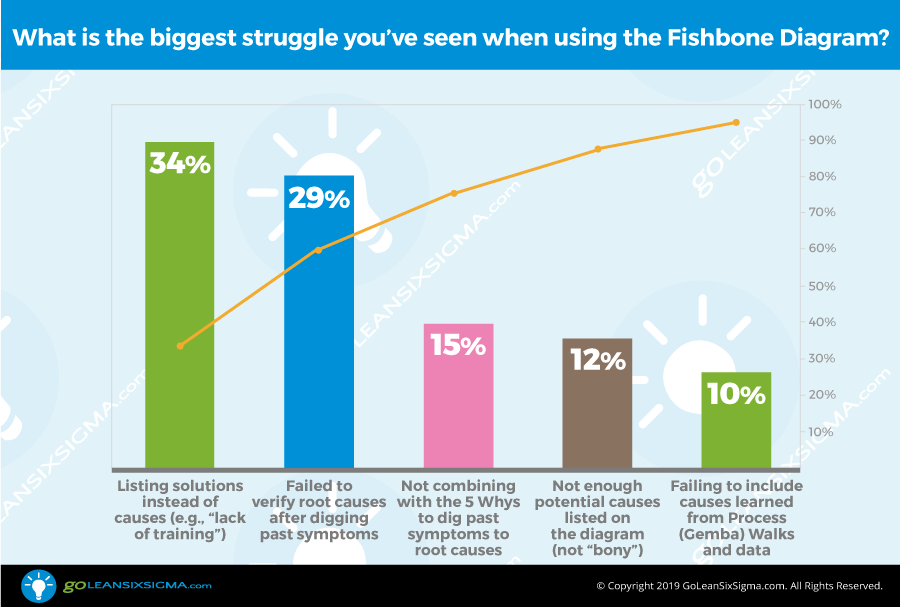

How do you stick with analysis long enough to find the smoking gun? The trick is to keep collecting the clues in the Cause & Effect Diagram , aka The “Fishbone Diagram”. It’s an aptly named tool, popularized by Dr. Ishikawa , which resembles a fish skeleton. Its construction allows teams to develop root cause theories around a problem as they build their knowledge of the process.

Each time they collect data, interview process participants on a Gemba Walk or map the process steps, they uncover potential reasons for defects. Making the most of the Fishbone Diagram is key but, during a poll, users reported where they fell short.

Solutions masquerading as problems

Over a third of respondents reported the issues of “listing solutions” on the Fishbone instead of causes. What we hear are phrases like, “the root cause is a lack of training”.

The problem with “lack of” anything is that it’s a sneaky way of putting a solution on the Fishbone.

The question is, “what is the training addressing?” Is it lack of user knowledge? If that’s the problem, could it be solved with helpful visuals, a simpler process? There are a lot of ways to address user knowledge before jumping to more employee training.

This is when you want to behave like the persistent detective – think Columbo, the classic 70’s TV icon. Every question helps you accumulate clues. People working through the process may have the answer without knowing it. The trick is to keep looking upstream until you find potential culprits. Dig past the symptoms.

To help with this phase, the checklist includes both a Fishbone Diagram Template as well as a video on how to get the most out of the Fishbone.

The Improve Phase is a long-anticipated step in the journey. It’s the step teams generally want to jump to from the start. Testing countermeasures, piloting solutions, watching the problem disappear, that’s the fun of process improvement. If you’ve done a proper job of Define, Measure, and Analyze, this phase falls nicely into place.

The ripple effect

The catch? Unintended consequences.

If you toss a stone into a lake you can see the ripples flow out from the center. The same principle holds true for process change. If you remove a step, change a form, skip an approval , will things fall apart? For that, we look to the Failure Modes & Effects Analysis or FMEA for short.

It’s a methodical way of assessing the potential for things to go wrong. It Involves deciding the potential severity and frequency of future problems and then mistake-proofing the process to prevent them. The technique originated at NASA since they couldn’t risk trial and error when sending men to the moon. By thinking through the risks of change they developed the kind of contingency plans you saw on display in movies like Apollo 13.

That’s why there’s an FMEA Template and a video on how to use it tucked into the main checklist from this post.

It’s okay to make changes. It’s simply key to think through the impact of those changes on other parts of the business.

Process Improvement can happen quickly and have a dramatic impact, but it’s critical to “stick the landing.” The Control Phase exists to see the improvement through to stability.

If teams move on and everyone takes their eyes off the ball, things may start to slip. What they need is the ability to continuously see the performance of the new process.

Sticking the landing

Have you ever tried to watch a game without a scoreboard? How would you know who was winning? Or how much time was left?

It’s the same with process work.

How does your team know how they’re doing? How do you stay aware of how the new process is performing?

By making the data visible.

Keeping an eye on Process Performance can be done with a single metric — you need to focus on one thing. If the goal was to reduce defects, then the single metric would be tracking the daily percentage of defects. A great way to measure success is with a Control Chart.

Control Charts are time charts. You might know them as Line Charts or Run Charts. They include a measure of variation so they are often referred to as “Run Charts that went to college”. They can be created in Excel , but they can also be drawn by hand.

Teams often set up whiteboards in the shared workspace to track things like defects. People can rotate responsibility for updating the chart. If people can see the measure and are responsible for it—they pay attention to it. What gets measured gets managed.

The Control Chart Template is embedded in the checklist for the Control Phase.

Process Improvement is a mainstay of Operational Excellence and checklists are simple but effective ways to make sure you get the outcomes you want. The following quote comes from the interim CEO/President of the Association for Manufacturing Excellence ( AME ).

“ I am a big fan of checklists for ensuring quality at the source. They serve an important purpose in reminding us of all that’s needed in a particular process or project. Without checklists, we risk missing or overlooking something by mistake. Checklists work best when ticking off items as they are completed, not en masse once the entire project is done. The key point is to use and follow them, not “pencil-whip” them from memory after the fact. While not foolproof, checklists can help us cover the details and result in more thorough, successful improvement efforts. ” – Jerry Wright , President, AME

Checklists have transformed healthcare, aviation, and countless other industries. Run this Process Street DMAIC Tollgate Checklist and make sure your next improvement effort gets great results.

Process Street is a powerful piece of workflow software that lets you crush the human error in your organization.

By creating process templates (like the free DMAIC checklist in this post) you can give your whole team a central location for them to see what they have to do, and how exactly they should do it.

No more confusion, no more errors.

Take advantage of our powerful feature set to create superpowered checklists, including:

- Form fields

- Conditional logic

- Variable user permission levels

- Exporting and printing templates

- And much, much more!

Check out our intro webinar to see the app in action!

Stop leaving the success of your processes up to chance. Get started with a free trial of Process Street today!

How do you manage quality control in your business? Let us know in the comments!

Get our posts & product updates earlier by simply subscribing

Ben Mulholland

Ben Mulholland is an Editor at Process Street , and winds down with a casual article or two on Mulholland Writing . Find him on Twitter here .

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Take control of your workflows today

- Lean Philosophy

Effective Lean Problem Solving

Solving problems in a business setting is an important part of the Lean methodology. Using Lean strategies, a company can better identify what problems exist, pinpoint the root causes, and come up with the right solutions to get the best results. Learning about how to effectively use Lean problem-solving techniques can help any business to improve and become more efficient.

Lean Problem-Solving Process

When working to make improvements in any business setting, it is important to start by identifying problems or potential problems. Solving existing issues is a great way to eliminate waste and improve efficiency very quickly. For many businesses, this is the ideal with to create a competitive edge that will help you to succeed.

When using the lean problem-solving techniques , you will go through a series of steps to get the results that are needed. The steps in the Lean problem-solving process are as follows:

- Identify the Problem – The first thing to do is identify what the actual problem is. This should be as specific as possible and include as many details and other information as is available.

- Break it Down – Breaking the problem down into different steps or parts is critical. This will make it possible to develop the right solutions for each aspect of the problem and help get things running as they should.

- Establish Targets – It is difficult to solve a problem if you don’t know what a working system should look like. Establishing target goals for the system you are working on will help guide you through the rest of the process.

- Look for the Root Cause – No problem can be truly solved without knowing what the root cause is. Keep asking questions about the issue at hand until you discover what is truly causing the issues. This can often be done using the ‘Five Whys’ technique , where you keep asking why something is happening until you reach the root cause.

- Propose Countermeasures – Next, come up with ways that you can address the root cause. This could be one or more different actions that are designed specifically to deal with this issue.

- Implement Countermeasures – Take the countermeasures that are proposed in the previous step and begin testing them. Ideally this can be done in a small test segment, but if needed it can be done in a full production environment. If a solution seems to work in a small system, expand it out to make sure the results scale up as expected.

- Test the Results – Analyze the results by comparing the situation where the problem was found against your target results. If you are able to accomplish the goals identified as your target results, the problem-solving countermeasures are successful. If not, move back to proposing additional countermeasures to get the results you need.

- Standardize – Once you have found a proven way to address the problem at hand, it is time to roll it out to the entire environment. Establishing new processes and procedures that will be followed by everyone in the facility is the last step in the problem-solving process.

Include All Impacted Parties

When going through the Lean problem-solving process it is important to consult with all the parties that are impacted by the problem at hand. It is quite rare that one person will be able to find the best possible solution to a problem, especially if they aren’t the ones who are directly impacted by the issue. Part of the Lean methodology is to work with various teams to come up with the best way of doing things. If you are facing a problem that needs a solution, you will want to include people from various groups such as:

- Front Line Employees – These are typically the people who will deal with the problem on a regular basis. Nobody will have greater insights into the root cause, and potential solutions, than these employees. Having one or more people from this level helping to solve a problem is critical.

- Supervisor – A supervisor or department manager will be able to provide additional insights into how the problem is impacting the business. They will also be the ones to help coordinate the implementation of any potential solutions so they should be involved.

- Appropriate Management – If a problem, or the expected solutions, will require upper level management approval, someone from that team should be included in the process. It is easier to have someone from the leadership partnering with you from the beginning than to try to bring them up to speed for approval down the road.

- Customers – When appropriate, having a customer available to discuss the problem can be very helpful. Customers are sometimes the ones who have the most information about the symptoms of the problem, which can make them very helpful.

Solving problems using Lean methodologies is a great way to help improve efficiency and eliminate waste in any workplace. Having an established process in place will allow you to quickly identify and solve a wide-range of problems in any environment.

Additional Resources

- 8D for Problem Solving – creativesafetysupply.com

- Training to Use 8D Problem-Solving Tactics – blog.creativesafetysupply.com

- Design Thinking: Empathy and Iteration for Innovation and Problem-Solving – creativesafetypublishing.com

- The Great Root Cause Problem Solving Debate – realsafety.org

- No Problem is a Problem – jakegoeslean.com

- Lean Six Sigma in small companies, still effective? – lean-news.com

- Lean Manufacturing Implementation – The First 5 Steps – iecieeechallenge.org

- The Lean Method: Go To Gemba and Improve Your Quality Control – blog.5stoday.com

- Applying Hoshin Kanri – 5snews.com

Related posts:

- Total Quality Management And Kaizen Principles In Lean Management

- Why Lean Transformation Fails

- 7 Reasons to Eliminate Waste and Go Lean

- Go Lean – Visual Factory

- Lean Layout Fundamentals

- Why Single Minute Exchange of Die (SMED)?

- Why You Should Use Takt Time Production & How To Do It

- Why Six Sigma Root Cause Analysis is a Great Tool

- Seven Forms of Waste – Lean Six Sigma

Problem Solving

When talking with our partners who worked at Toyota, they will often comment that, “Problem solving was in the air.” To achieve this, organizations need to learn how to both create an environment where problem solving will thrive and a standard approach to how problems are solved. One of these without the other will not work.

The LTG approach to problem solving

- Addresses the cultural transformation required to have problem solving thrive, and

- Addresses the understanding of the Plan Do Check Act (PDCA) cycle as a standard approach

Significantly improving your operational performance.

Problem Solving

In a lean transformation or any process improvement effort, identifying and closing gaps between current and target conditions.