Build my resume

- Resume builder

- Build a better resume in minutes

- Resume examples

- 2,000+ examples that work in 2024

- Resume templates

- 184 free templates for all levels

- Cover letters

- Cover letter generator

- It's like magic, we promise

- Cover letter examples

- Free downloads in Word & Docs

5 Manufacturing Resume Examples Built to Work in 2024

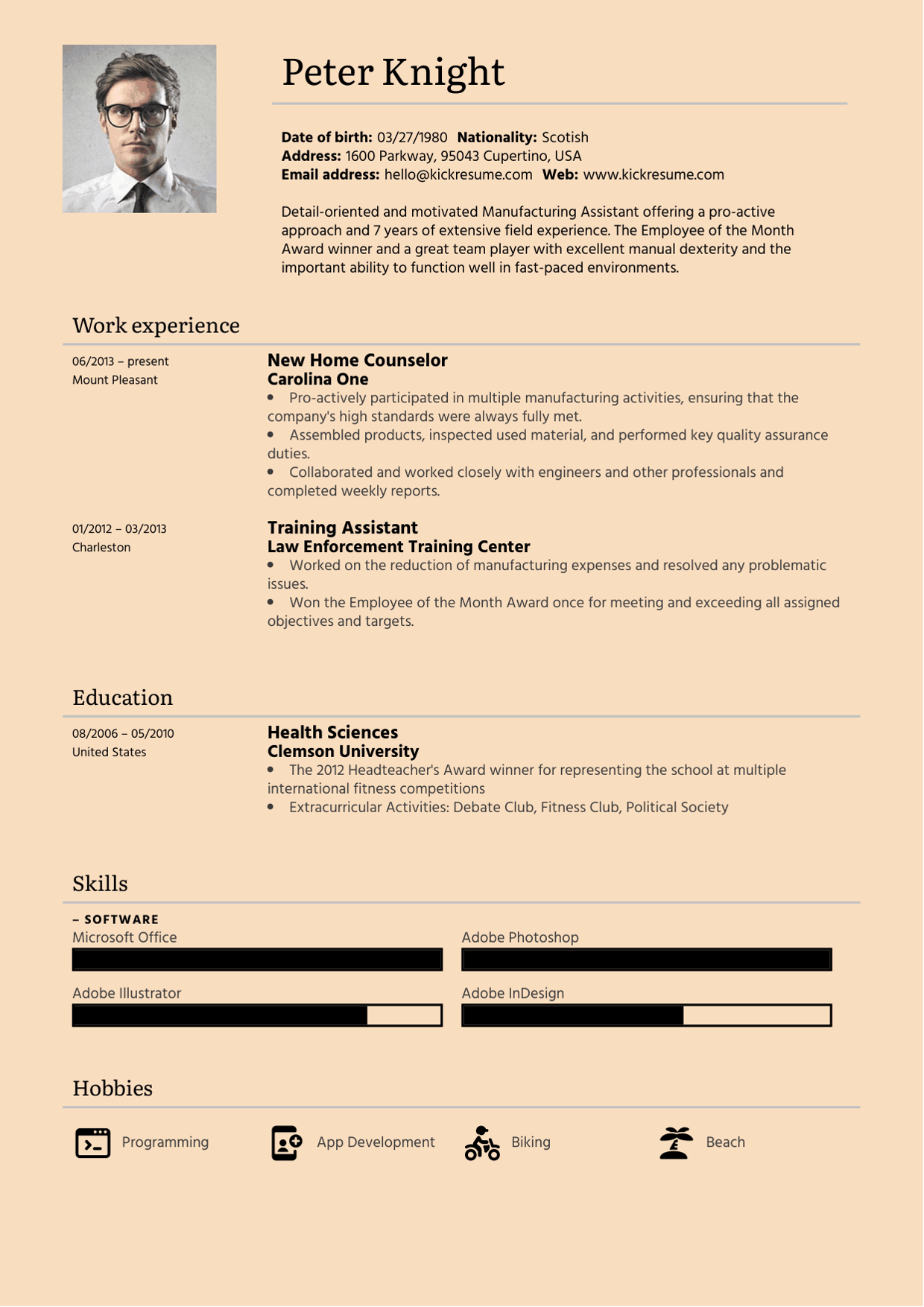

Manufacturing Resume

- Manufacturing Engineer

- Manufacturing Supervisor

- Manufacturing Manager

- Manufacturing Technician

- Write Your Manufacturing Resume

Tons of different components go into manufacturing a product, and you’re ready to handle the job. You could do anything from placing parts in the production line to mentoring new workers on your optimized strategy for improving work environments and ROIs.

But how do you show your packaging prowess or attentive eye on shipments in a resume? What do recruiters really want from you to confirm your excellent fit?

We know you’re already working hard, but don’t sweat. We’ve been helping skilled professionals in manufacturing for years. Try our manufacturing resume examples and handy cover letter writing tips to help launch your career.

or download as PDF

Why this resume works

- Here’s how: Make your manufacturing resume shine with your progress in your career. Even being a general worker is a good start as long as you can highlight that you’ve assisted in production output and lowered misplacement incidents.

Manufacturing Engineer Resume

- Mentioning tools like PLC or CATIA will be more than enough for your expertise in process control and designing. You can even flex your knowledge of statistics by citing key methods such as SPC.

Manufacturing Supervisor Resume

- Any past role in an organization like Kellogg’s is a great addition to your manufacturing supervisor resume. You can keep on adding more great names such as BorgWarner Inc. to gain an upper hand over the other candidates, especially if you’ve got more industry-specific work experience such as automobiles.

Manufacturing Manager Resume

- Having points such as minimizing the average time to complete key production stages by 13% at the main facility in your manufacturing manager resume is a great way to let your employer know that you’re well-equipped to take on this role.

Manufacturing Technician Resume

- You can then move forward with your more recent job roles and go over your responsibilities in handling manufacturing strategies and quality control tools such as InfinityQS ProFicient. Include a couple more such tools that you’re good with and your manufacturing technician resume will be good to go!

Related resume examples

- Production manager

- Production assistant

- Product manager

- Maintenance worker

Build Your Manufacturing Resume For the Job Description

You know well that there are tons of subsets of the manufacturing industry! So, pay attention to what skills each job description actually asks for. Are they seeking skills more like what you learned while pursuing your engineering degree? Or do they need a manager with an excellent work ethic to keep the production line moving?

Review the job description for hints on how you can make your resume into exactly what it needs to be. Where do your job skills overlap with their values? We also recommend browsing the organization’s website to look for any mission statements that hint towards the abilities they value most—and which you happen to have!

Need some starter ideas?

15 popular manufacturing skills

- MasterControl

- InfityQS ProFicient

- Assembly Line

- Visual Inspection

- Quality Assurance

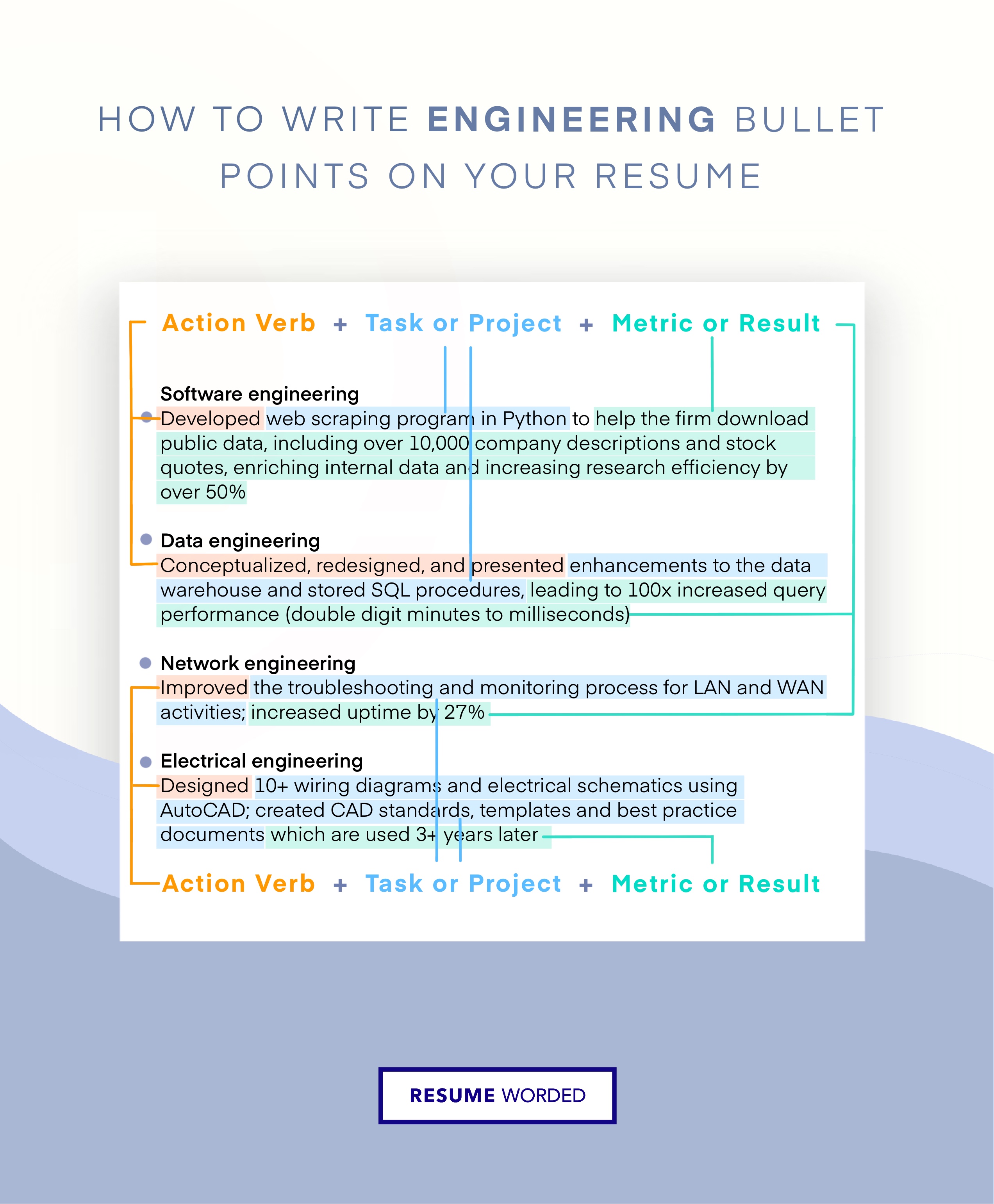

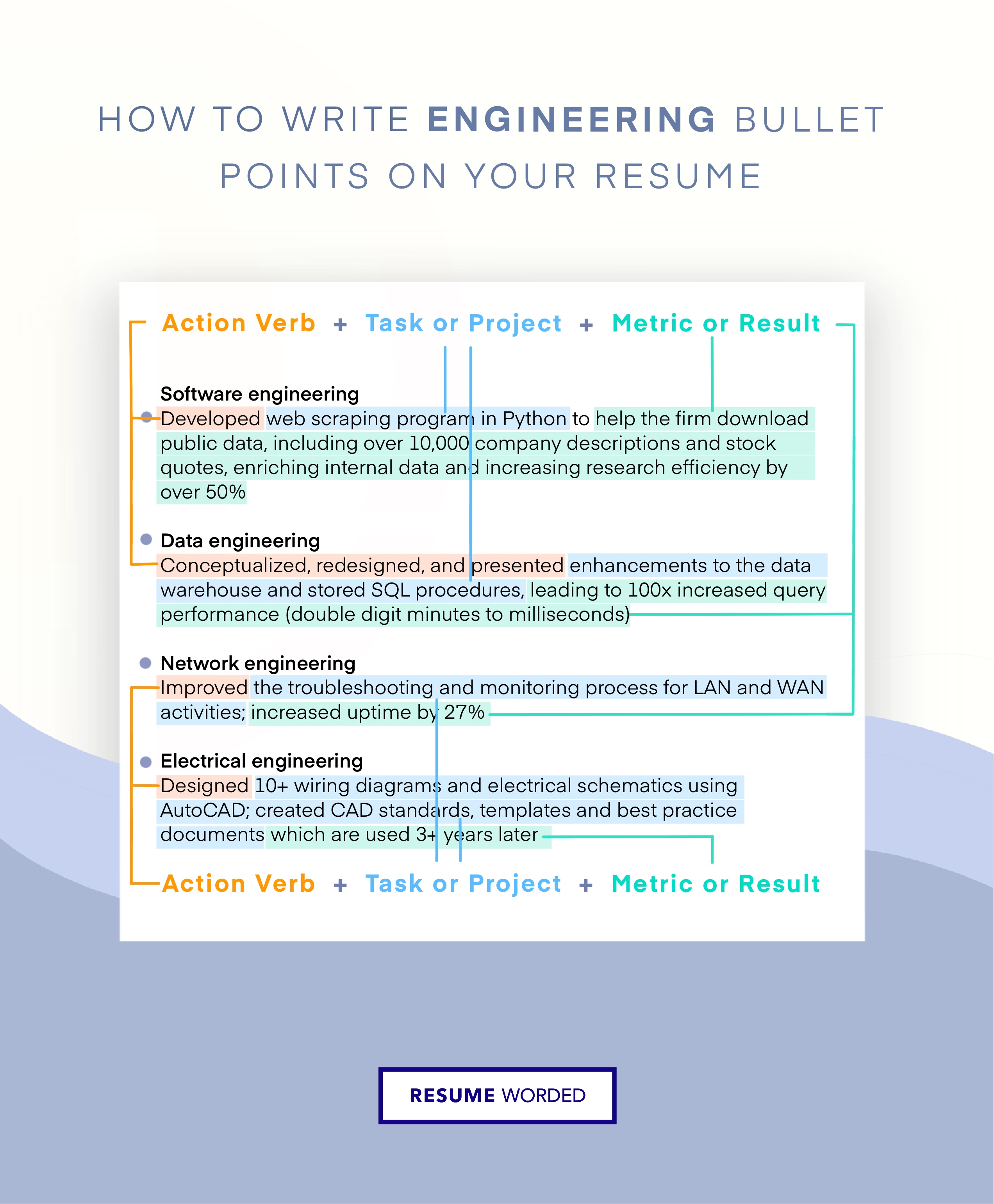

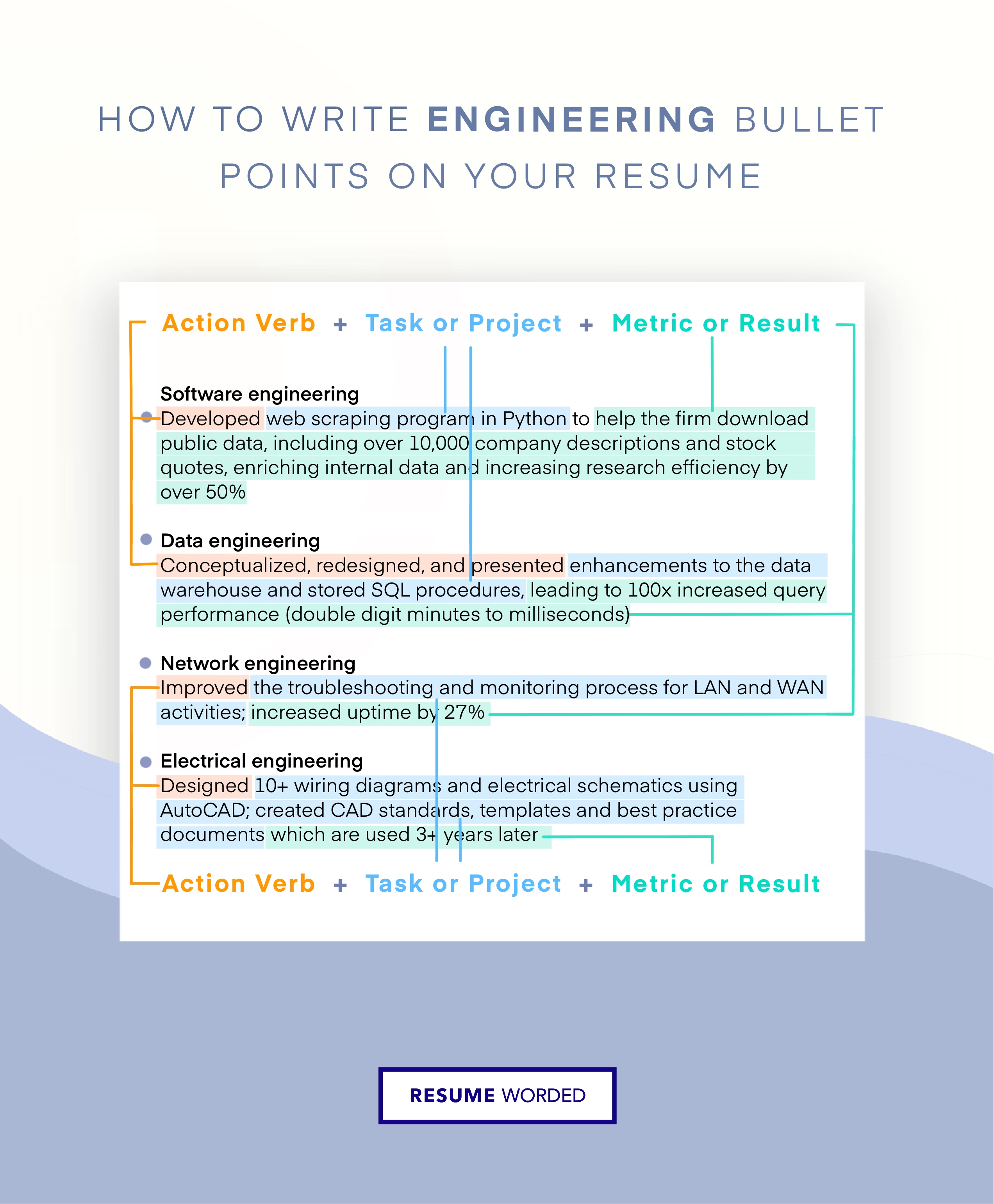

Your manufacturing work experience bullet points

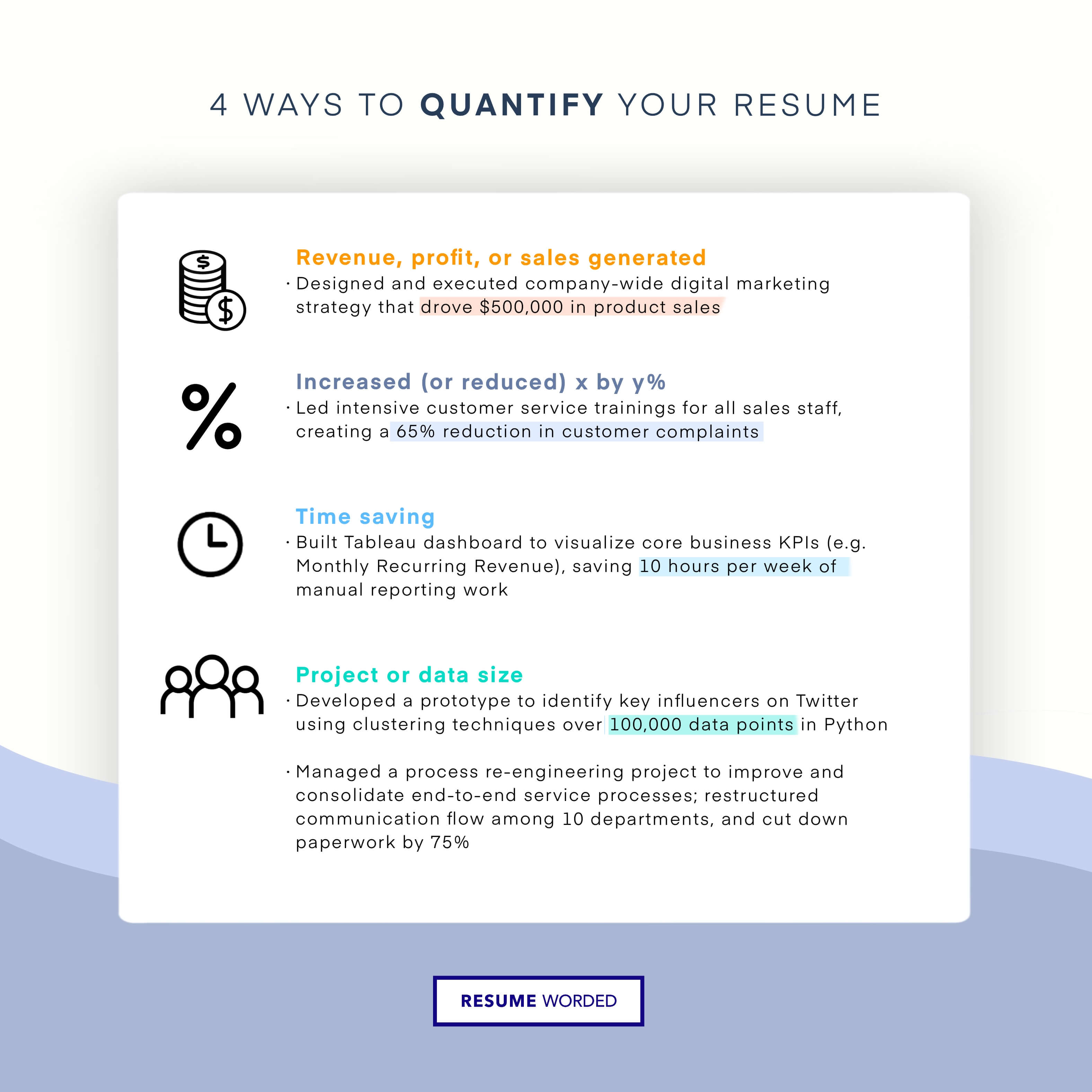

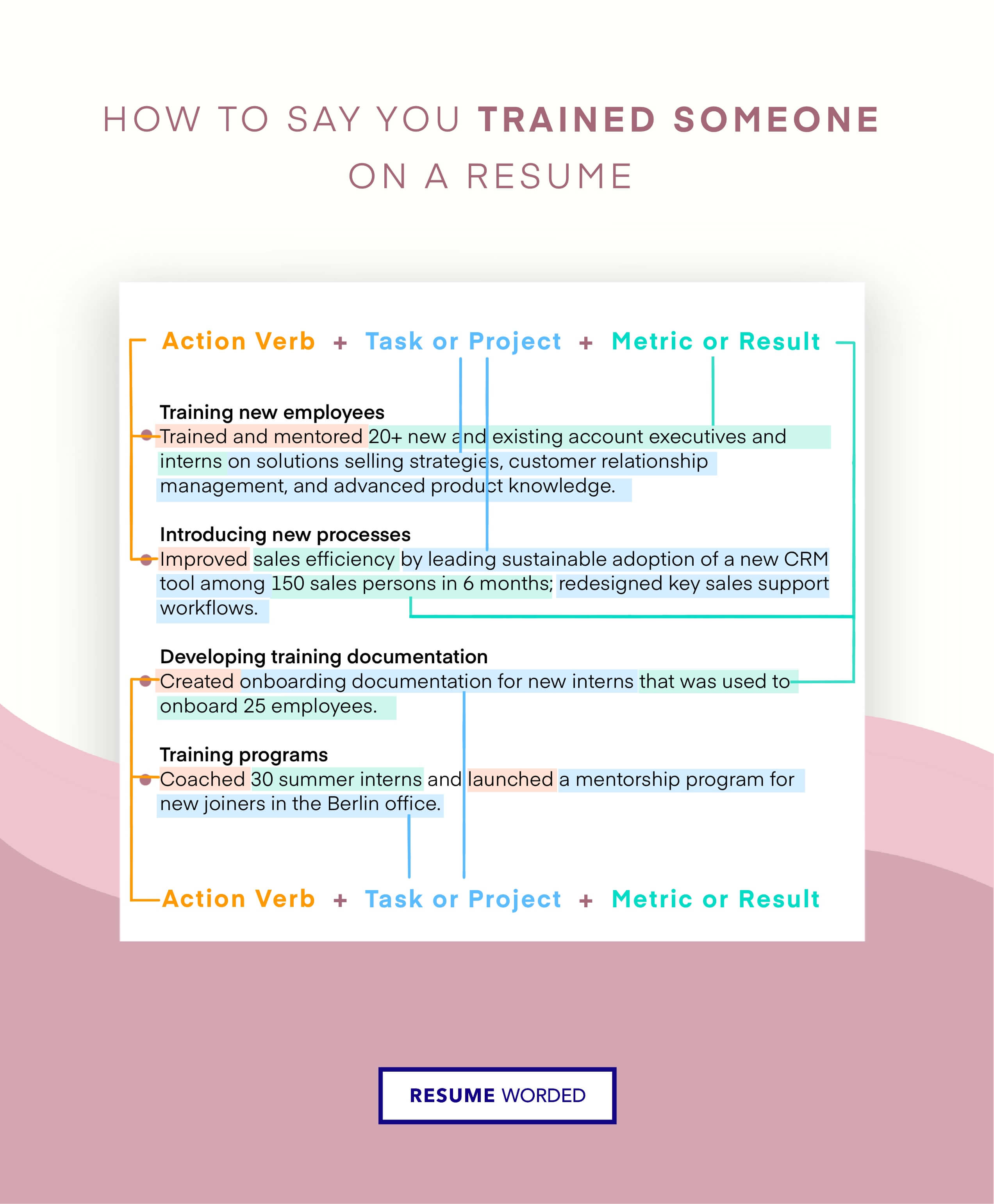

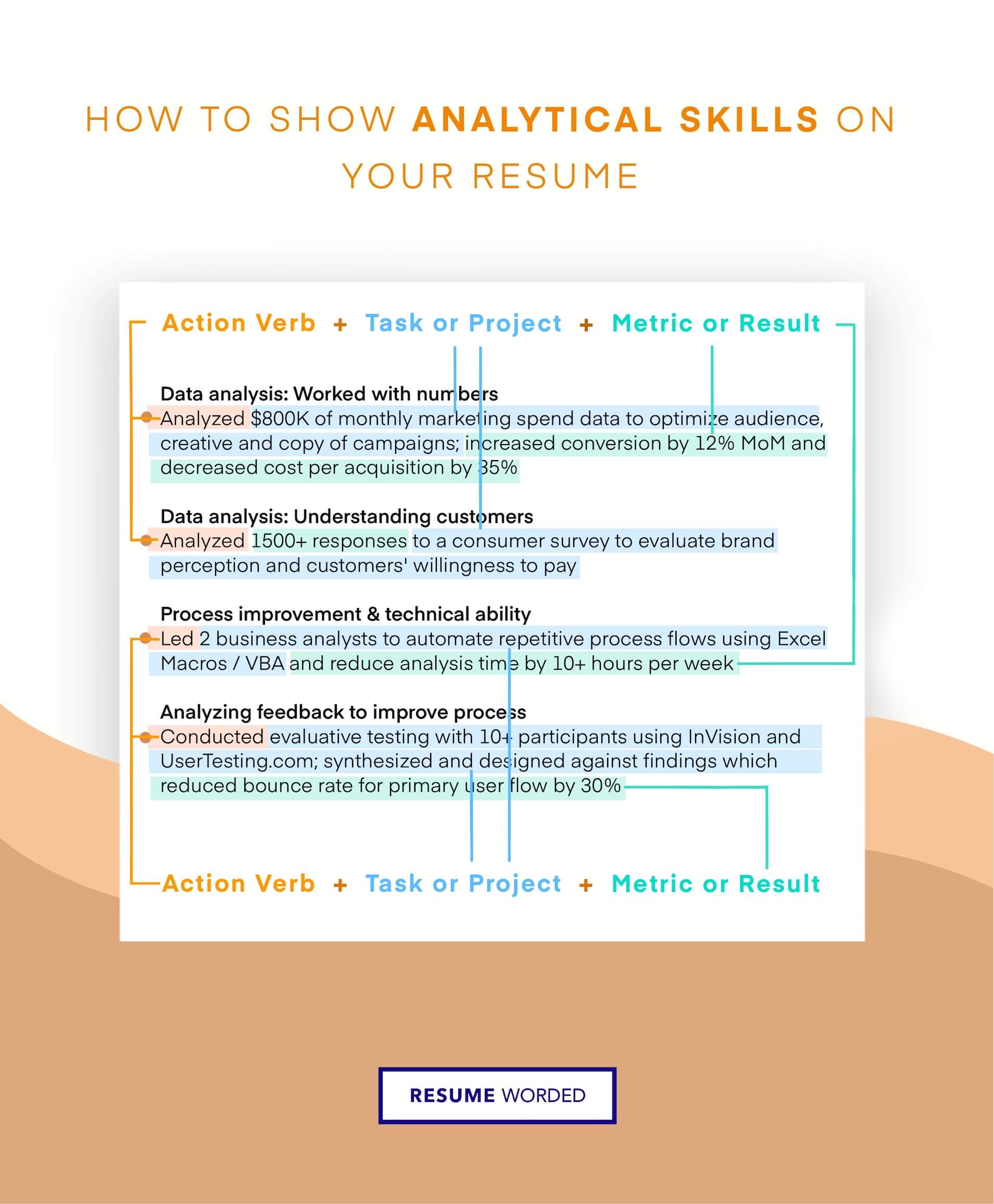

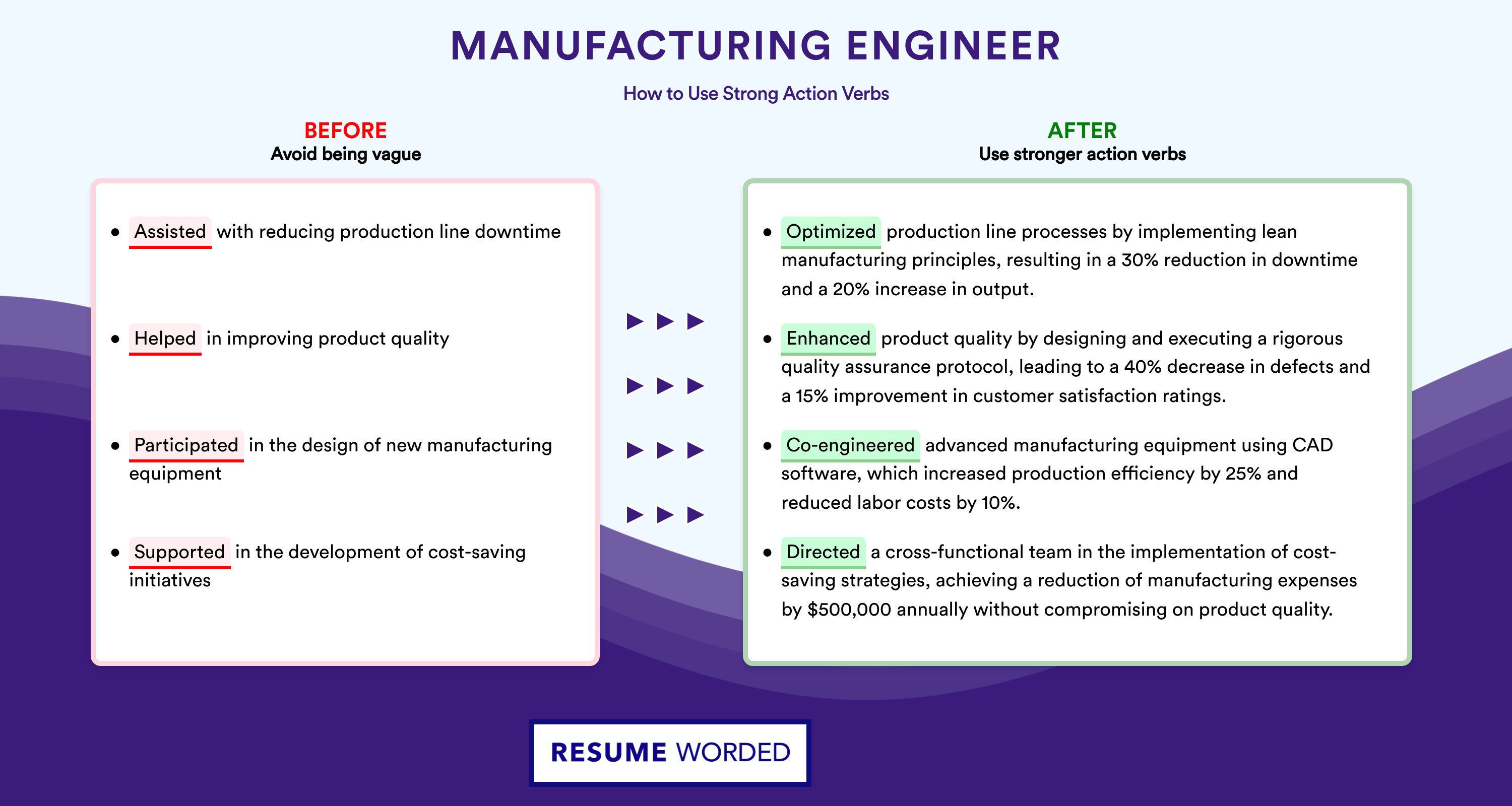

Now, while the ability to convey and follow instructions down to the letter is crucial as a manufacturer, you don’t want to just echo the job requirements. Don’t say you can perform a specialized task if you can show it with experience!

Substantiate your bullet points with quantifiable data, and use metrics that demonstrate problem-solving abilities that will benefit the organization. To really make the recruiter look twice at your experience section, use active verbs and language to display your enthusiasm for the job.

- Decreased production times demonstrate your quick thinking and efficiency

- Increased ROIs show how your hard work and strategies pay off in dollars

- Improved material savings exemplify your ability to negotiate contracts with suppliers

- Reduced turnover rates spotlight your ability to maintain a productive, positive workplace

See what we mean?

- Planned a preventative maintenance overhaul with Fiix, decreasing equipment breakdowns by 42% across high-priority assets

- Developed a lean manufacturing strategy that decreased package handling time by 1.6 hours, enabling the fulfillment of 278 extra orders per day

- Revamped 3M’s audit preparation process through DocuWare, decreasing the time spent on audit preparation by 1.9 hours

- Leveraged 5 Whys Analysis to resolve a recurring defect for Stanley Black & Decker’s flagship products, shrinking rework by 22% and saving approximately $16,741 in annual output

- Updated supplier deliverables and performance metrics into MasterControl, cutting supplier-related defects by 33.8%

9 active verbs to start your manufacturing work experience bullet points

- Strategized

3 Tips for Writing a Manufacturing Resume Without Much Experience

- If you aren’t sure at first glance which of our resume templates to pick, try several on for size! When you have limited work experience and need to strengthen your qualifications with other sections, use a layout with side columns to highlight them.

- If you’ve ever had any internships that relate to manufacturing, inventory, project management, or the many other facets of manufacturing, add ’em! Experience doesn’t have to be paid in order to teach you about your job role and make you a desirable candidate.

- You can also bolster your readiness for your next role in manufacturing with academic awards demonstrating relevant, desirable traits (think stuff like resilience, adaptability, and a strong work ethic).

3 Tips for Writing a Manufacturing Resume if You Have Some Experience

- Consider a resume summary if you have plenty of experience but aren’t sure how to set your resume off as one appealing, cohesive piece! You can provide a quick overview of what’s led you to apply for the role and establish a connection with the company via mutual values.

- You’re a pro at this manufacturing stuff by now! You don’t need to list entry-level jobs or previous roles in other fields of work. Stick with just three to four jobs that best exemplify your alignment with your current goal.

- The idea above also applies to your qualifying degree(s). If you’re operating at a higher-up position in your industry, you don’t need to call upon education or academic accomplishments that aren’t as current as they could be.

Stick with a one-page summary , please! Recruiters don’t have much time to spend skimming your resume, so write as concisely as you can while preserving the key details. Tailor these details to what the job description emphasizes so you’re making the most of your page space.

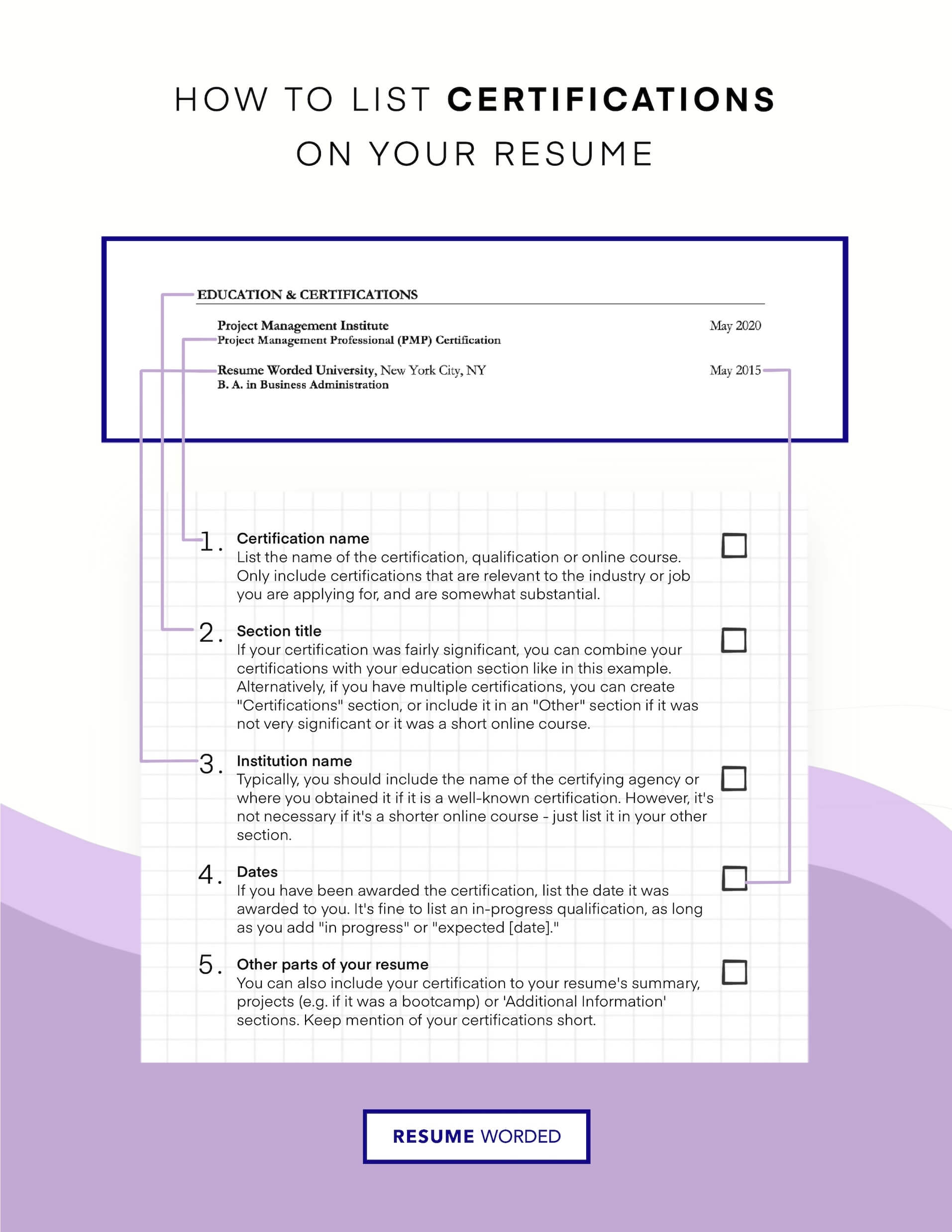

Absolutely! If you have anything like a Certified Production Technician (CPT) or Project Management Professional (PMP) certification, list it. You can even give them their own section if you feel like it works!

Your metrics should strengthen the qualities most clearly required by the job description . Your data should also reinforce your strongest impact point from your experience instead of referring to something random like a headcount.

Privacy preference center

We care about your privacy

When you visit our website, we will use cookies to make sure you enjoy your stay. We respect your privacy and we’ll never share your resumes and cover letters with recruiters or job sites. On the other hand, we’re using several third party tools to help us run our website with all its functionality.

But what exactly are cookies? Cookies are small bits of information which get stored on your computer. This information usually isn’t enough to directly identify you, but it allows us to deliver a page tailored to your particular needs and preferences.

Because we really care about your right to privacy, we give you a lot of control over which cookies we use in your sessions. Click on the different category headings on the left to find out more, and change our default settings.

However, remember that blocking some types of cookies may impact your experience of our website. Finally, note that we’ll need to use a cookie to remember your cookie preferences.

Without these cookies our website wouldn’t function and they cannot be switched off. We need them to provide services that you’ve asked for.

Want an example? We use these cookies when you sign in to Kickresume. We also use them to remember things you’ve already done, like text you’ve entered into a registration form so it’ll be there when you go back to the page in the same session.

Thanks to these cookies, we can count visits and traffic sources to our pages. This allows us to measure and improve the performance of our website and provide you with content you’ll find interesting.

Performance cookies let us see which pages are the most and least popular, and how you and other visitors move around the site.

All information these cookies collect is aggregated (it’s a statistic) and therefore completely anonymous. If you don’t let us use these cookies, you’ll leave us in the dark a bit, as we won’t be able to give you the content you may like.

We use these cookies to uniquely identify your browser and internet device. Thanks to them, we and our partners can build a profile of your interests, and target you with discounts to our service and specialized content.

On the other hand, these cookies allow some companies target you with advertising on other sites. This is to provide you with advertising that you might find interesting, rather than with a series of irrelevant ads you don’t care about.

Manufacturing Resume Examples & Writing Guide for 2024

Powering up your career in the dynamic world of manufacturing? The artfully written manufacturing resume is your blueprint to success.

This guide is packed with practical tips, examples, and useful samples designed to steer your job application to the top of the pile.

We'll cover everything you need to know about writing a job-winning manufacturing resume. Keep reading to how to:

- Choose a resume format that fits your experience level in manufacturing

- Write an eye-catching manufacturing resume summary

- Include technical and interpersonal skills on a manufacturing resume

- Focus on your specialized skills in your work experience section

- Use certifications to enhance your education section

- Access useful job search resources for manufacturing professionals

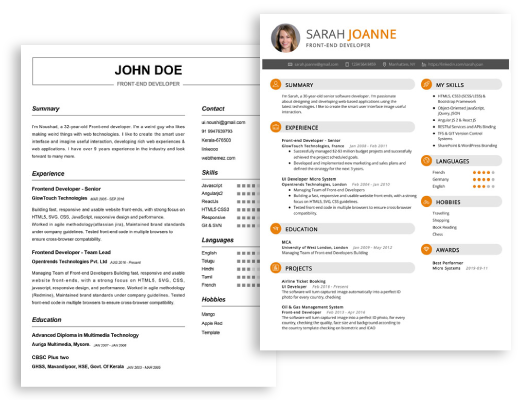

1. Choose a resume format that fits your experience level in manufacturing

Resumes can come in many different shapes and sizes. When it comes to a manufacturing resume, the best format to use is highly dependent on the applicant’s experience level.

Different resume formats serve different purposes – namely in serving applicants with varying levels of work experience. Below we have provided a brief explanation of each main type of resume, as well as how and when to use them:

- Reverse-chronological: This is the most common and standard resume format. It focuses on your work experience the most, listing your most recent position first and then working backward in reverse-chronological order. While this format is what most employers will expect to see, it does not always work well for applicants with limited to no relevant work experience.

- Functional : The functional resume is an alternative format that is commonly used by recent high school or college grads. Rather than focusing on work experience, it places most of its emphasis on education, skills, and unpaid experience. This works well for recent graduates who have many academic and extracurricular experiences, but little to no formal work experience.

- Hybrid : The hybrid resume is exactly as it sounds – a hybrid between the reverse-chronological and functional formats. Rather than placing heavy emphasis on any single section, the hybrid spreads the focus out more evenly amongst all sections. This format works well for applicants with some relevant work experience who have either switched career paths or have large gaps in their work histories .

Try our AI Resume Writer and have your resume ready in minutes!

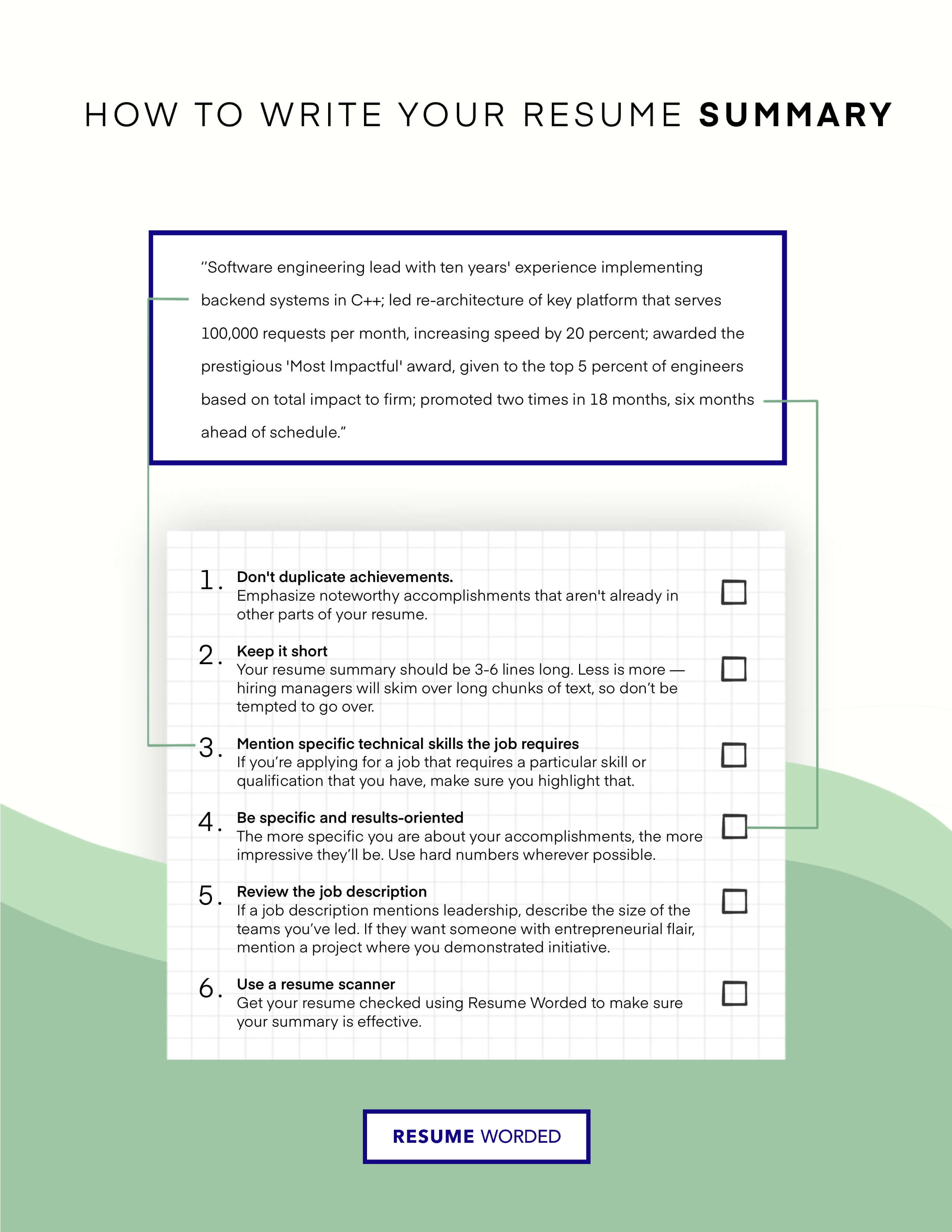

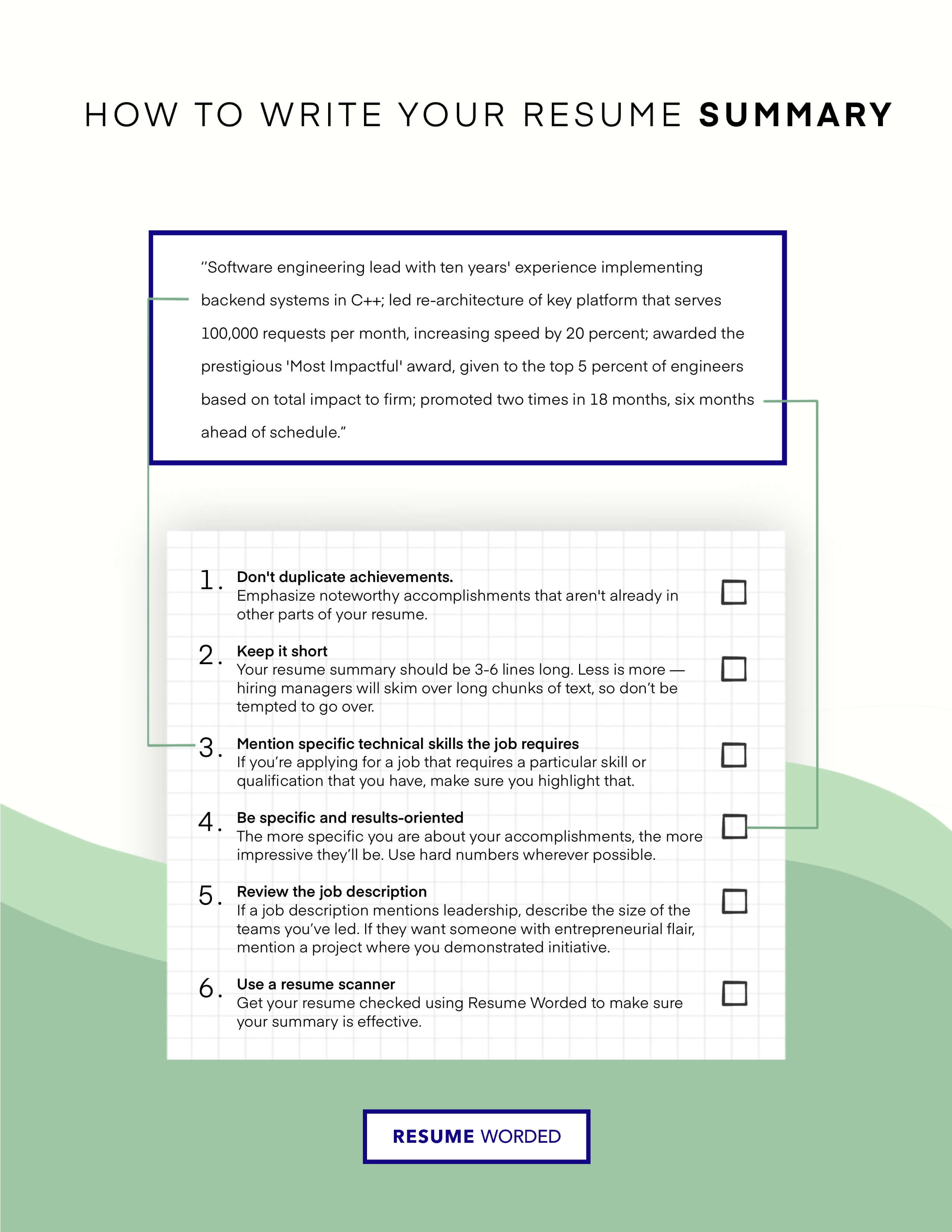

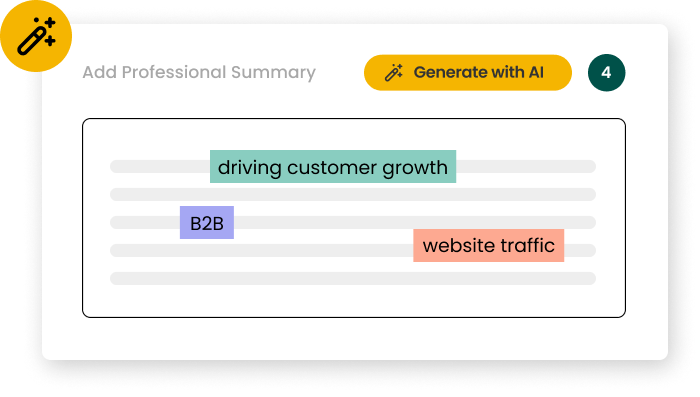

2. write an eye-catching manufacturing resume summary.

A resume summary is a brief statement that serves as the introduction to your resume. In this summary, you should focus on what makes you stand apart as a job applicant, such as your years of experience or significant accomplishments.

Take a look at the following incorrect example of a weak resume summary, followed by a breakdown of how to correct it

Incorrect manufacturing resume summary example.

Experienced manufacturing worker with a background in manufacturing engineering and the related processes. Worked for many years in the plastics industry and helped in the development of new machines designed to reduce waste.

What's wrong with this example? When writing your resume summary, you want to provide as many specific details and contextual information as possible. In this example, the applicant is a bit vague regarding their engineering experience. Additionally, they should talk more about the machinery system they helped to design and develop.

Corrected manufacturing resume summary example

Dedicated Manufacturing Worker with 4+ years of experience working in the plastics industry. Specialized in manufacturing engineering procedures, with an emphasis on sustainability and waste reduction. Assisted in the design and development of a machine system that reduces plastic waste by more than 25%.

Why is this better? In this corrected example, the applicant provides a lot higher quality information in regards to their experience level and accomplishments. They identify their specialization in engineering and then immediately provide a provable example by describing the machine they helped create.

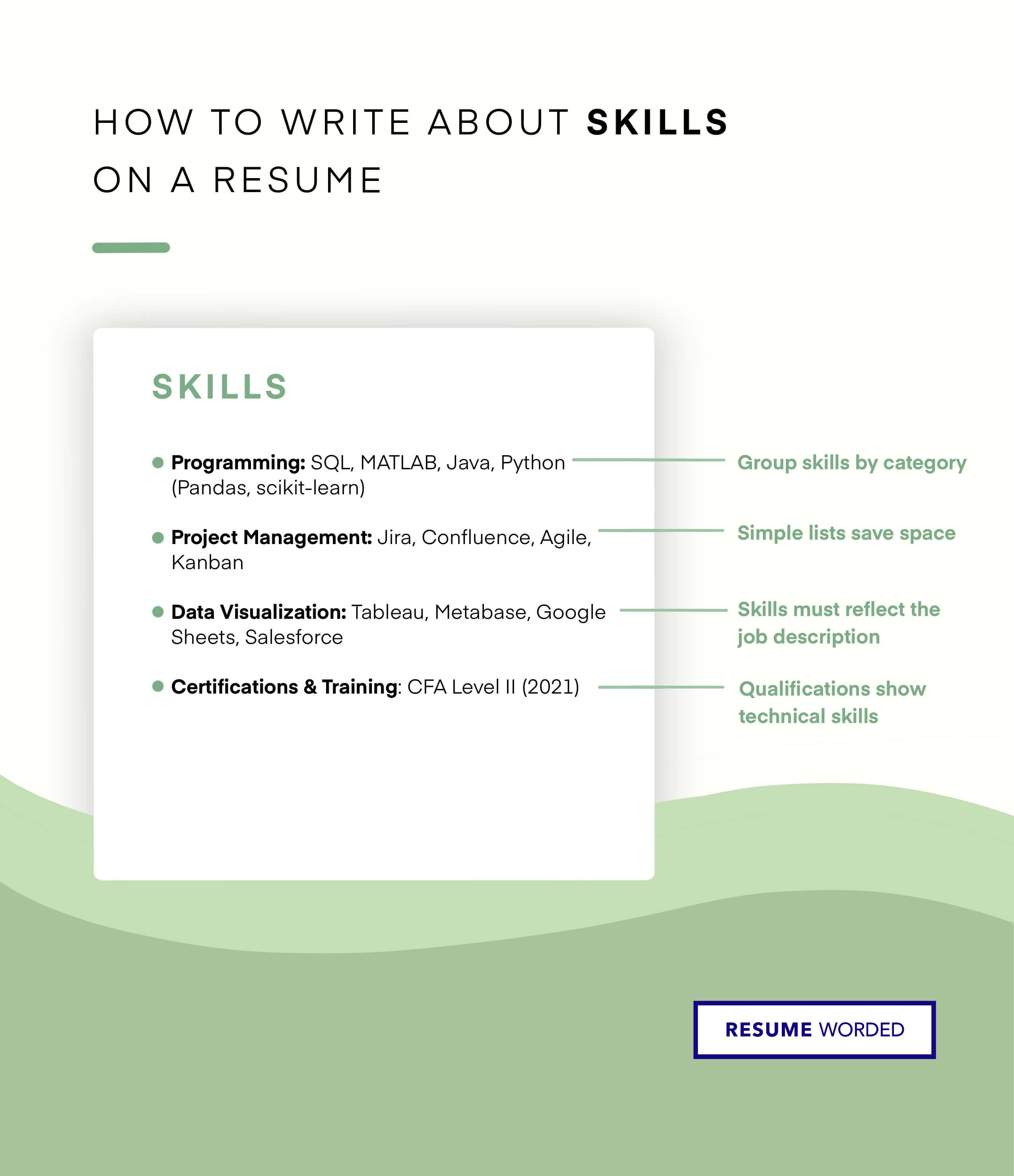

3. Include technical and interpersonal skills on a manufacturing resume

Including both hard and soft skills on your manufacturing resume is crucial for presenting a comprehensive and well-rounded profile to potential employers.

Hard skills are specific technical abilities and knowledge related to the manufacturing industry, such as proficiency in operating machinery, understanding quality control processes, or expertise in Lean Six Sigma methodologies.

These skills demonstrate your technical competencies and make you a valuable asset in executing manufacturing tasks efficiently and effectively.

In addition to hard skills, soft skills are equally important in the manufacturing industry. Soft skills encompass your interpersonal abilities, communication skills, problem-solving aptitude, and teamwork capabilities.

These skills showcase your ability to collaborate effectively with colleagues, adapt to changes in the production environment, and contribute to a positive work culture.

For instance, strong communication skills allow you to effectively convey instructions, provide feedback, and coordinate with cross-functional teams. Meanwhile, problem-solving skills enable you to identify and resolve production issues, minimize downtime, and enhance operational efficiency.

The best hard skills for your manufacturing resume

- Production Machinery

- Mathematical Skills

- Quality Control

- Data Analytics

- Coding/Programming

- Standard Manufacturing Procedures

- Continuous Improvement Process

- Product Design

- Quality Management

Effective soft skills to put on your manufacturing resume

- Problem-Solving

- Verbal Communication

- Organization

- Multi-Tasking

- Supervision

- Attention to Detail

- Critical-Thinking

- Dependability

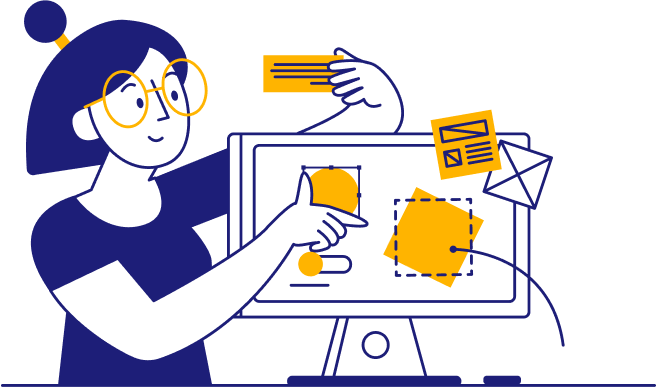

Find out your resume score!

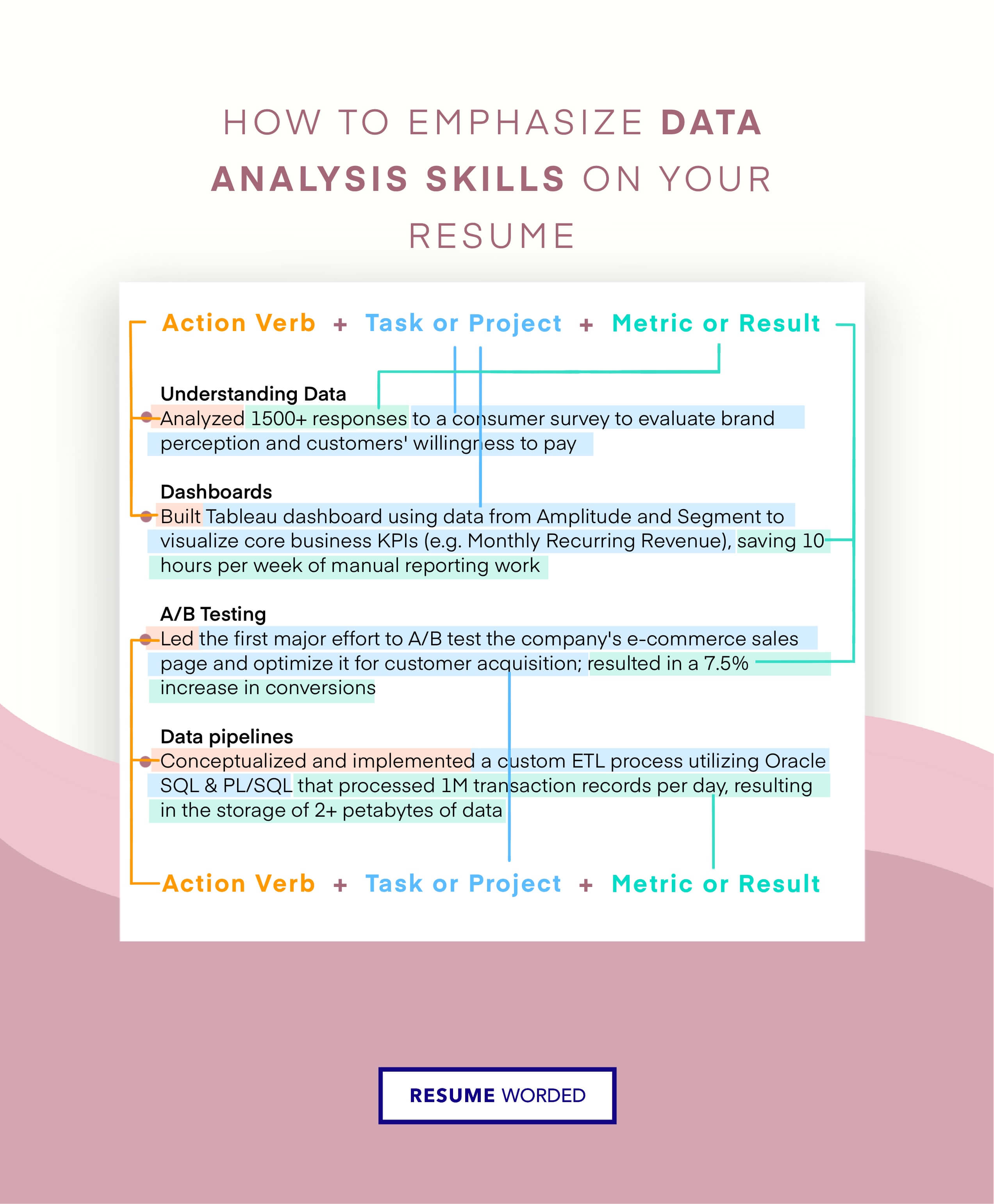

4. Focus on your specialized skills in your work experience section

There are many different positions within the field of manufacturing, each with their own key responsibilities and required skills.

When applying for a job in manufacturing, it is important to be clear about what type of experience you have within the industry and any key accomplishments and goals you helped achieve. You should always strive to provide at least one quantifiable example, such as a percentage of sales you helped to increase.

Additionally, you should work in both technical and interpersonal skills into your job descriptions . This will help you in demonstrating how you apply your abilities within the field.

Here is an example of a work experience entry from a manufacturing resume

Production Line Worker | Empire Manufacturing, Inc.

Boston, MA | February 2019 to January 2021

- Exceeded production targets by 110% weekly while meeting 100% of quality goals.

- Assisted in the installation of energy-efficient machinery and appliances that cut operational expenses by 15% .

- Assembled components of electronic appliances to be packaged and sold together.

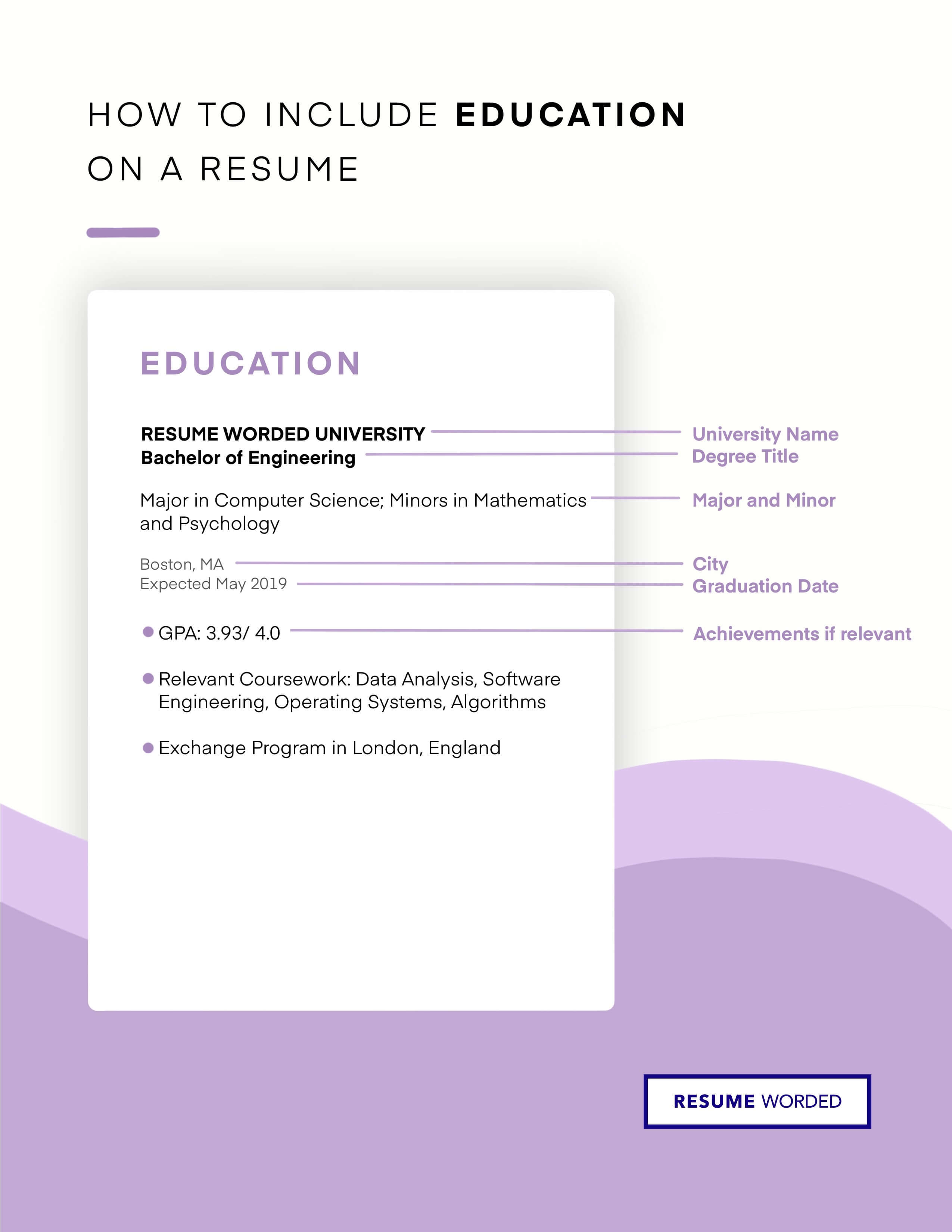

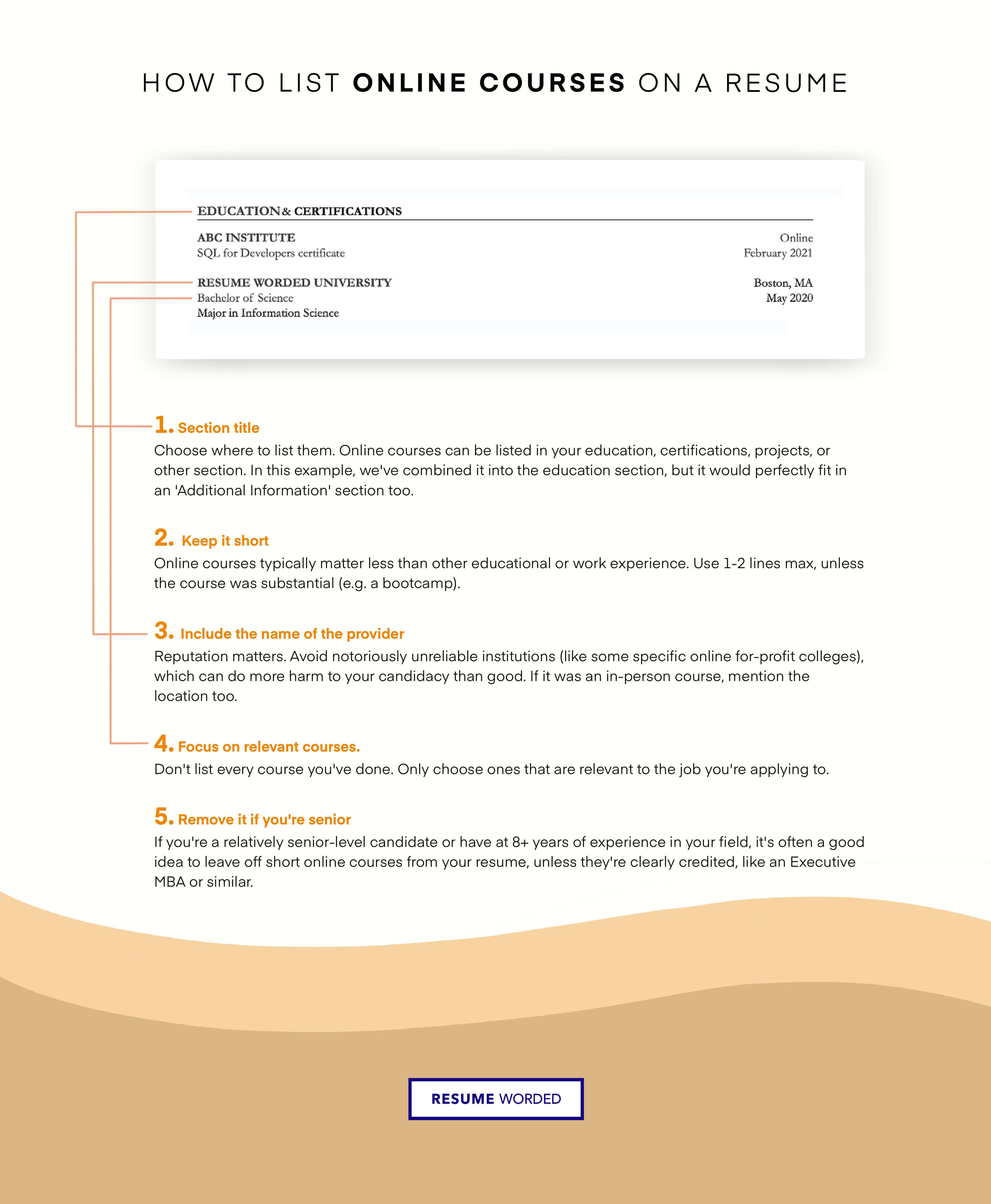

5. Use certifications to enhance your education section

Depending on the manufacturing role you seek, there will be different levels of training and educational credentials expected of you.

In general, the minimum educational requirements for manufacturing workers are either a high school diploma or a GED .

However, having a two- to four-year degree, or having completed additional training and certification programs, can help you maintain a competitive edge on your resume.

Here is an example of a well-crafted education section on a manufacturing resume

- Associate’s Degree in Manufacturing Management | Atlanta Technical College

- Atlanta, GA | 2015-2017

Certifications

- Certified Production Technician | Manufacturing Skill Standards Council

- Project Management Professional | Manufacturing Skill Standards Council

6. Essential job search resources for manufacturing professionals

Crafting your future in manufacturing is a blend of the right skills and the right opportunities. To fine-tune your job search, here's a list of useful resources tailored for the manufacturing maestro:

- Industry-specific job boards: Specialized job sites such as iHireManufacturing and ManufacturingJobs.com focus exclusively on the manufacturing sphere.

- Professional networking sites: LinkedIn remains a go-to platform, abundant with networking chances and diverse job postings in manufacturing.

- Manufacturing association: Organizations such as The Association for Manufacturing Technology (AMT) not only provide resources but often feature job boards and networking events.

- Industry publications: Trade papers and magazines such as Manufacturing Business Technology regularly publish job listings and provide industry insights.

Consider these your tool kit in carving a successful career in manufacturing. Stay connected, stay updated, and let your career take flight.

Manufacturing Resume FAQ

Ideal length depends on your experience. If you're early in your career keep it to one page. Experienced pros can extend to two pages. Keep it concise and impactful.

Balance is key. Use industry-specific terms to display competency, but avoid overloading with jargon that could confuse HR or non-technical readers.

Be open and direct about gaps. Focus on productive activities during these times, such as further education, volunteering, or freelance projects related to manufacturing.

Not mandatory but can be beneficial, especially if changing career paths. Ensure your objective aligns clearly with the specific manufacturing role you're applying for.

Don't underestimate them. While technical skills are crucial, soft skills like communication, teamwork, and problem-solving are highly valued in modern manufacturing environments.

A documentary photographer and writer. Noel has worked for International publications like Deutsche Welle in Germany to News Deeply in New York. He also co-founded the global multimedia project Women Who Stay and collaborated as a journalist fellow with the University of Southern California . He went from traveling around the world to sitting on a couch thanks to the pandemic, but he gets to help other people actually do things (like find jobs) thanks to Kickresume, so he won't complain.

Subcategories

- Assembly Line Worker

- Hair Stylist

- Manufacturing Engineer

- Metal Worker

All manufacturing resume examples

Related manufacturing cover letter examples

Resume guides

How to write a professional resume summary [+examples], how to put your education on a resume [+examples], how to describe your work experience on a resume [+examples], let your resume do the work..

Join 5,000,000 job seekers worldwide and get hired faster with your best resume yet.

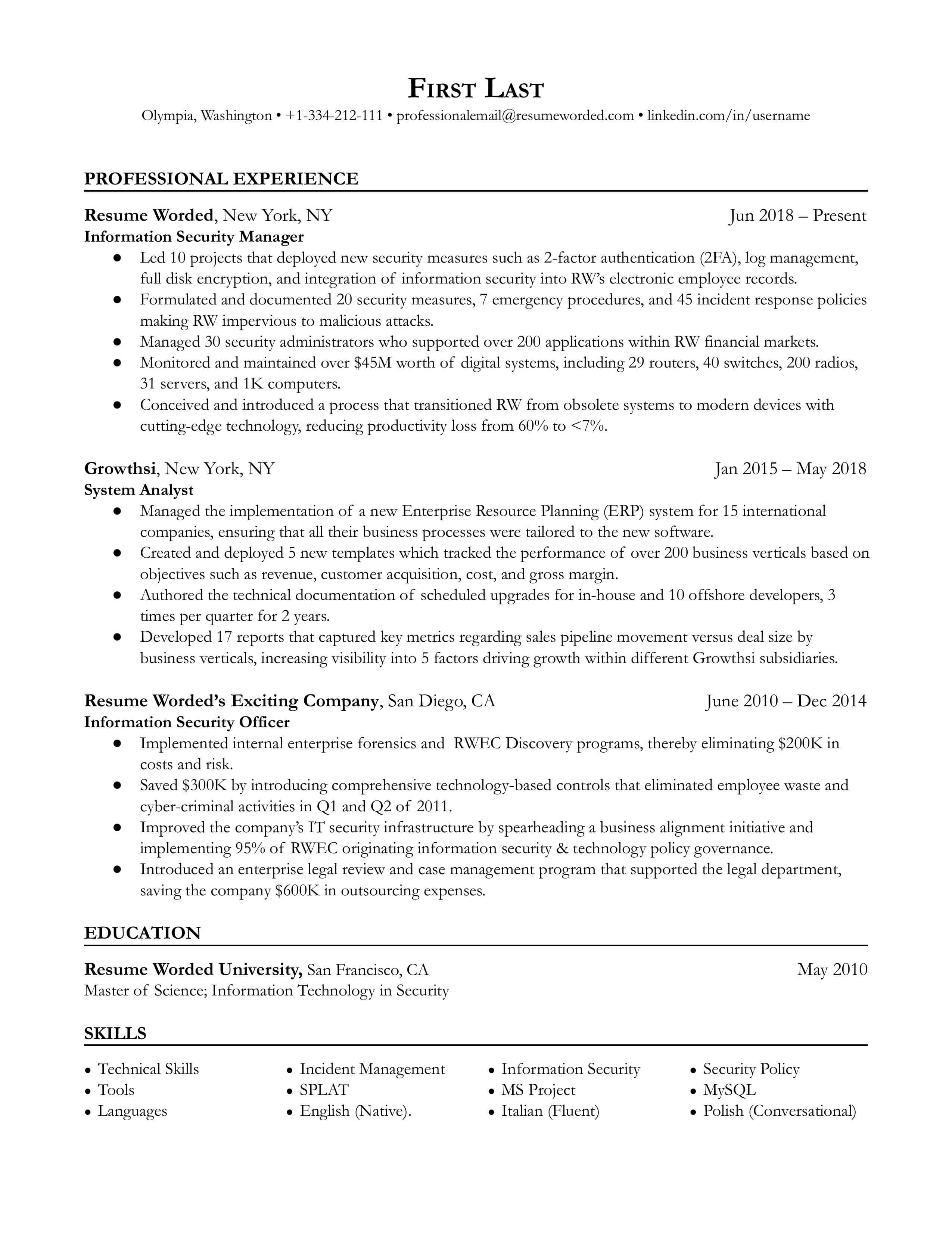

Resume Worded | Proven Resume Examples

- Resume Examples

- Engineering Resumes

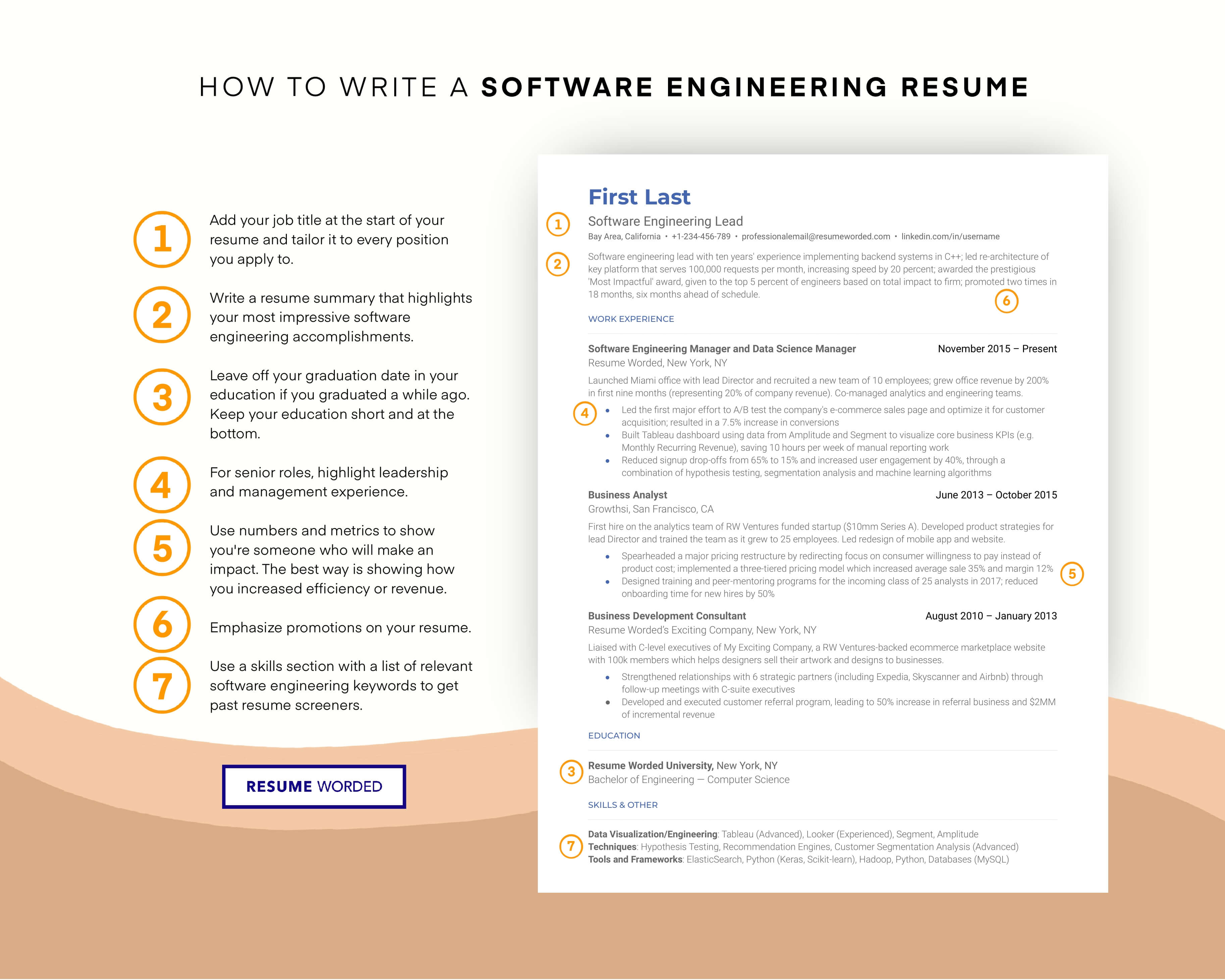

10 Manufacturing Engineer Resume Examples - Here's What Works In 2024

Manufacturing engineers are one of the most in-demand experts due to the rapid changes the field undergoes as new materials and processes are developed. if you have an analytical mind and enjoy planning a product’s production from start to finish, this guide will help you build an eye-catching manufacturing engineer resume by reviewing five templates and key skills..

With the number of consumer and industrial products in development continuing to increase, the role of manufacturing engineers is more important than ever. Being able to plan and layout the manufacturing process of new products or optimize existing products is a critical function employers are looking for. Per the Bureau of Labor Statistics, the average manufacturing engineer makes around $89,000, and demand is projected to grow 10 percent a year through 2029 (or more than double the average job growth rate). To be a manufacturing engineer, you’ll need analytical, technical, and communication skills, paired with a familiarity of manufacturing processes and quality assurance and control techniques. The specific skills and proficiencies you’ll want to include in your resume will vary based on your experience and the position you’re applying for. This guide will look at five manufacturing engineer resume templates to help provide an outline you can base your own resume on. At the bottom, we’ll review particular skills and strong action verbs you should emphasize to convey your capabilities to hiring managers.

Manufacturing Engineer Resume Templates

Jump to a template:

- Manufacturing Engineer

- Senior Manufacturing Engineer

- Manufacturing Quality Engineer

- Entry Level Manufacturing Engineer

Jump to a resource:

- Keywords for Manufacturing Engineer Resumes

Manufacturing Engineer Resume Tips

- Action Verbs to Use

- Related Engineering Resumes

Get advice on each section of your resume:

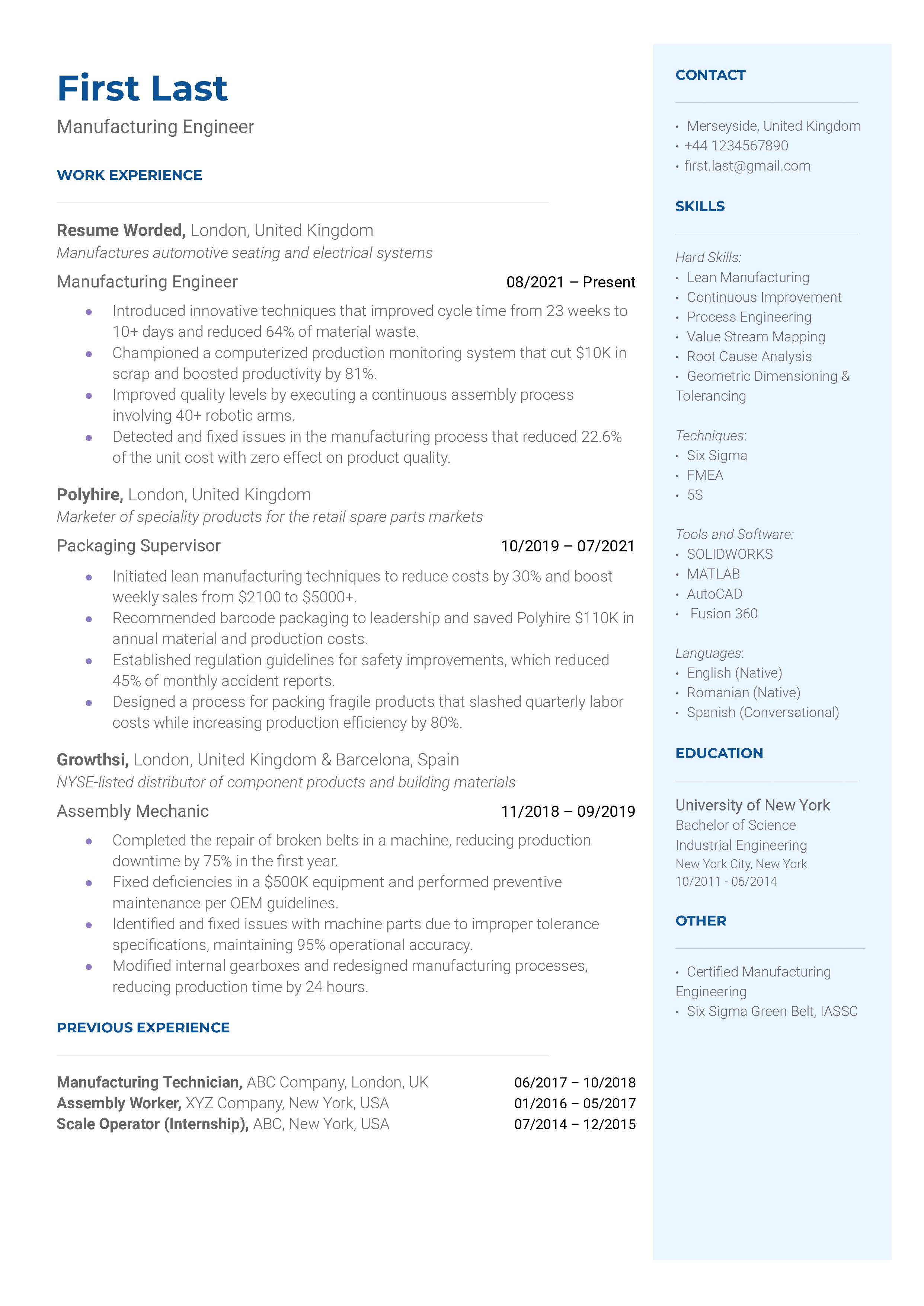

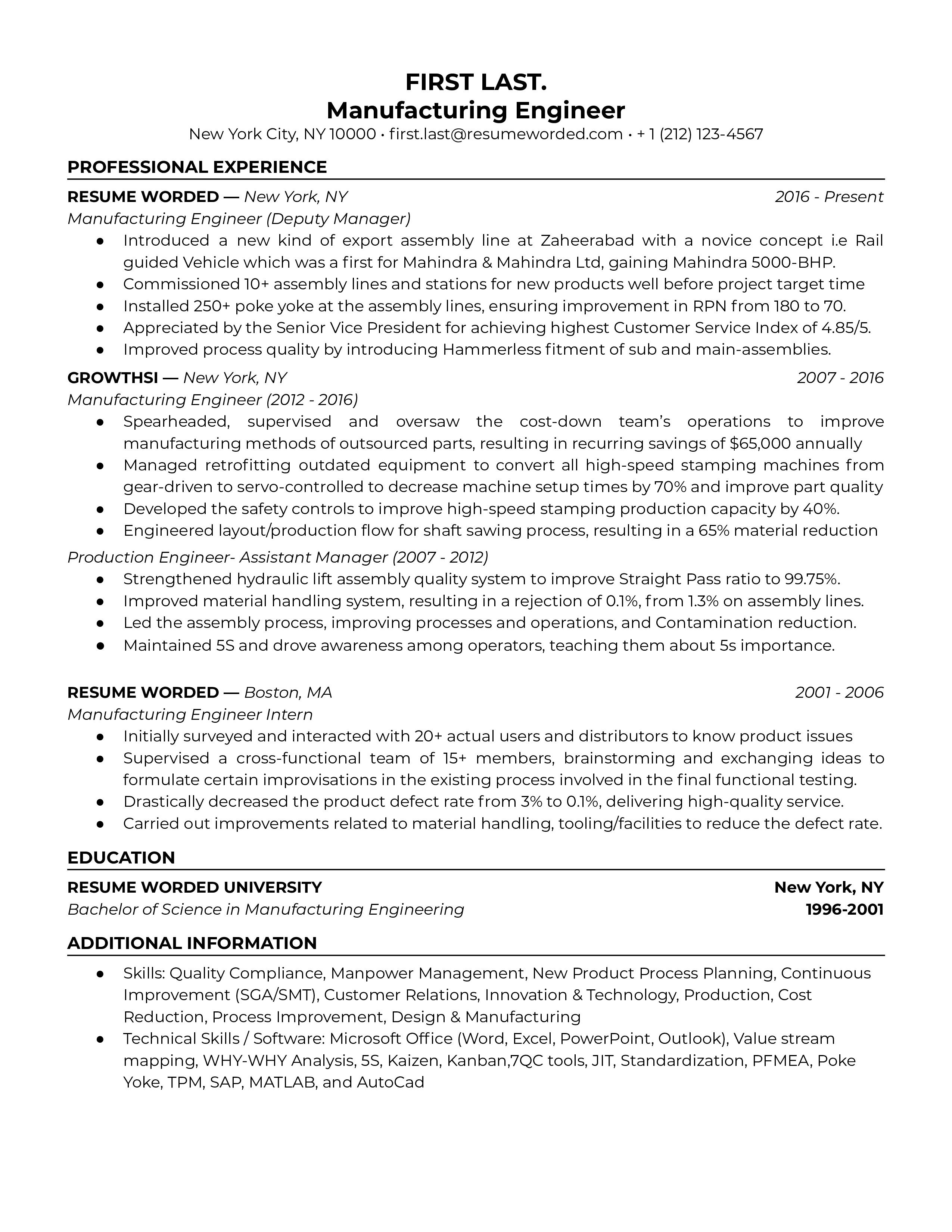

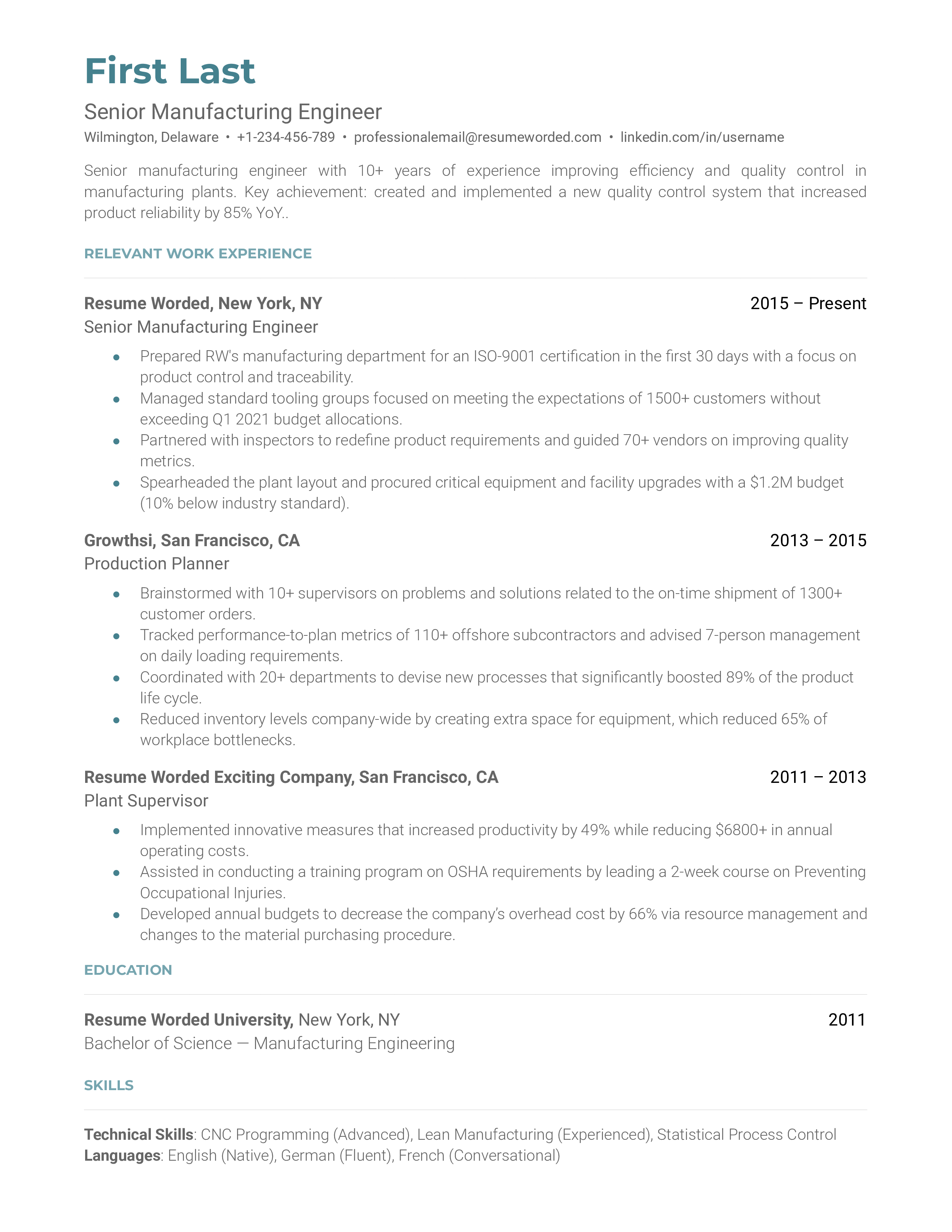

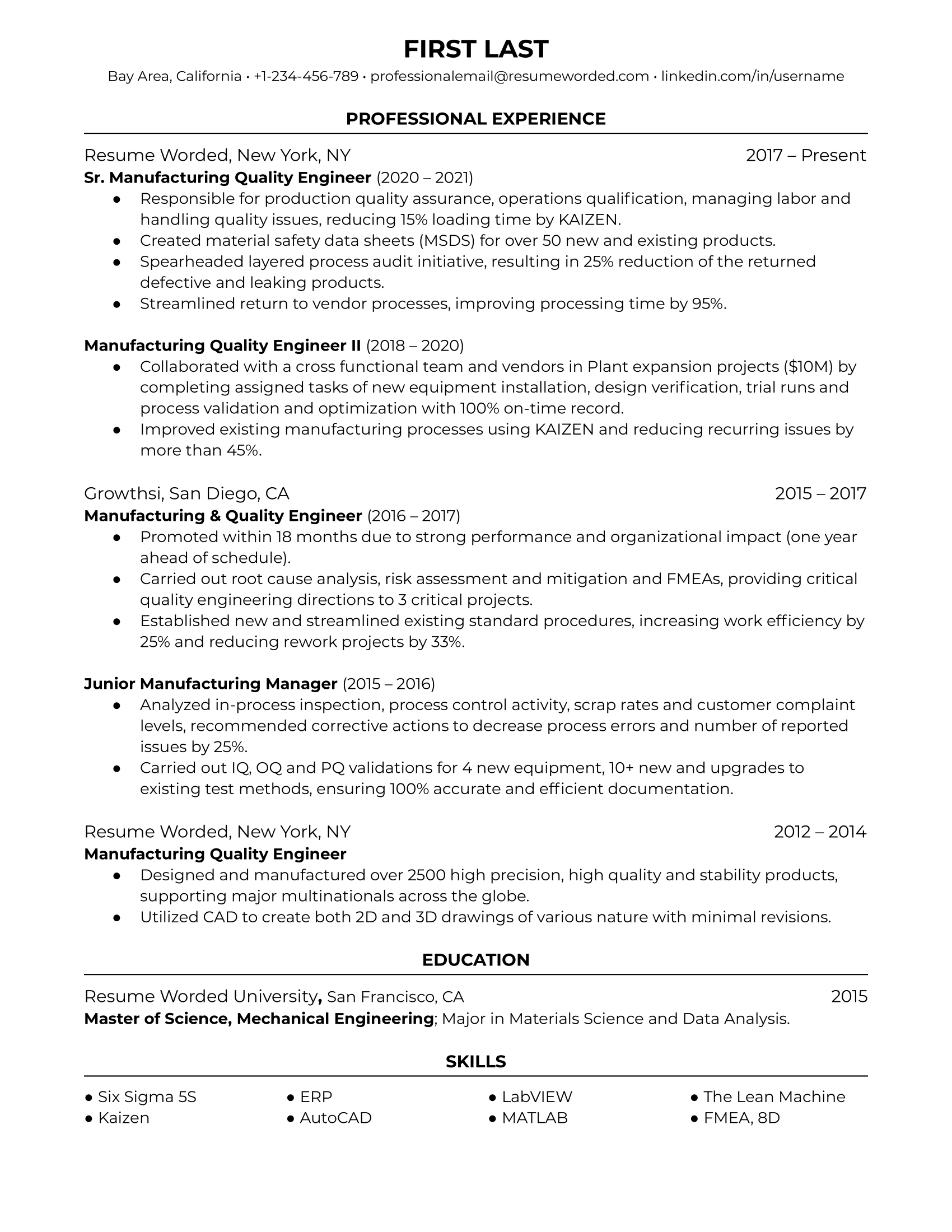

Template 1 of 10: Manufacturing Engineer Resume Example

As a manufacturing engineer, your primary role is to design and improve manufacturing processes that optimize productivity, quality, and cost efficiency. In recent years, the industry has seen a shift towards automation, lean manufacturing, and sustainable practices. Companies searching for manufacturing engineers typically look for expertise in process improvement, problem-solving, and familiarity with relevant manufacturing technologies. Your resume is crucial in conveying your skills and experience to potential employers, as it serves as your primary marketing tool in this highly technical field. In the manufacturing engineering industry, a well-crafted resume can help you stand out from the competition. Showcasing your achievements related to process optimization, waste reduction, and cost savings can demonstrate your commitment to efficiency and effectiveness. Quantifiable results can give employers a clear sense of your value and potential impact on their organization.

We're just getting the template ready for you, just a second left.

Tips to help you write your Manufacturing Engineer resume in 2024

highlight relevant technical skills.

Be sure to emphasize specific technical skills relevant to the manufacturing engineering field, such as CAD/CAM software, process simulation tools, lean manufacturing principles, and automation technologies. Tailor your resume to each job application by matching the desired skills listed in the job posting.

Showcase project experience and results

Use your resume to provide concrete examples of projects you've worked on, emphasizing your role in improving manufacturing processes and achieving positive outcomes. Quantify your achievements with numbers, such as percentage reductions in defect rates or time saved in process cycle times, to demonstrate your impact on efficiency and productivity.

Skills you can include on your Manufacturing Engineer resume

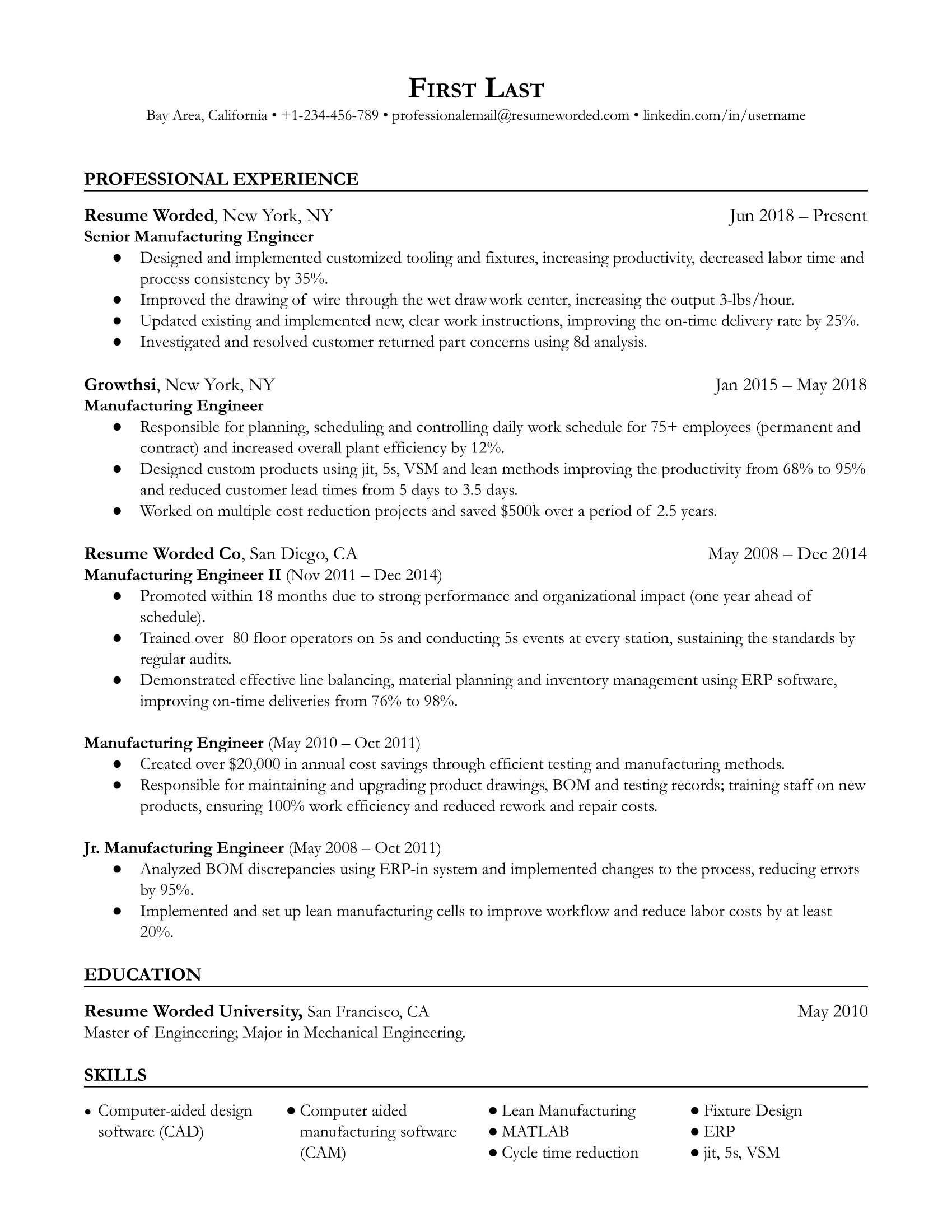

Template 2 of 10: manufacturing engineer resume example.

Being able to demonstrate your aptitude for a job can be difficult in a single piece of paper, but as a manufacturing engineer, you should use it as an opportunity to showcase your efficiency. Incorporate a skills bank to highlight your particular proficiencies and show your hard work by indicating relevant internal promotions.

Lists skills and technical skills related to manufacturing engineering

Manufacturing engineers walk a balance between requiring a mastery of technical skills and manufacturing techniques. Regardless of the specific type of manufacturing engineer position you're applying for, you should include a separate skill bank that outlines your expertise with both.

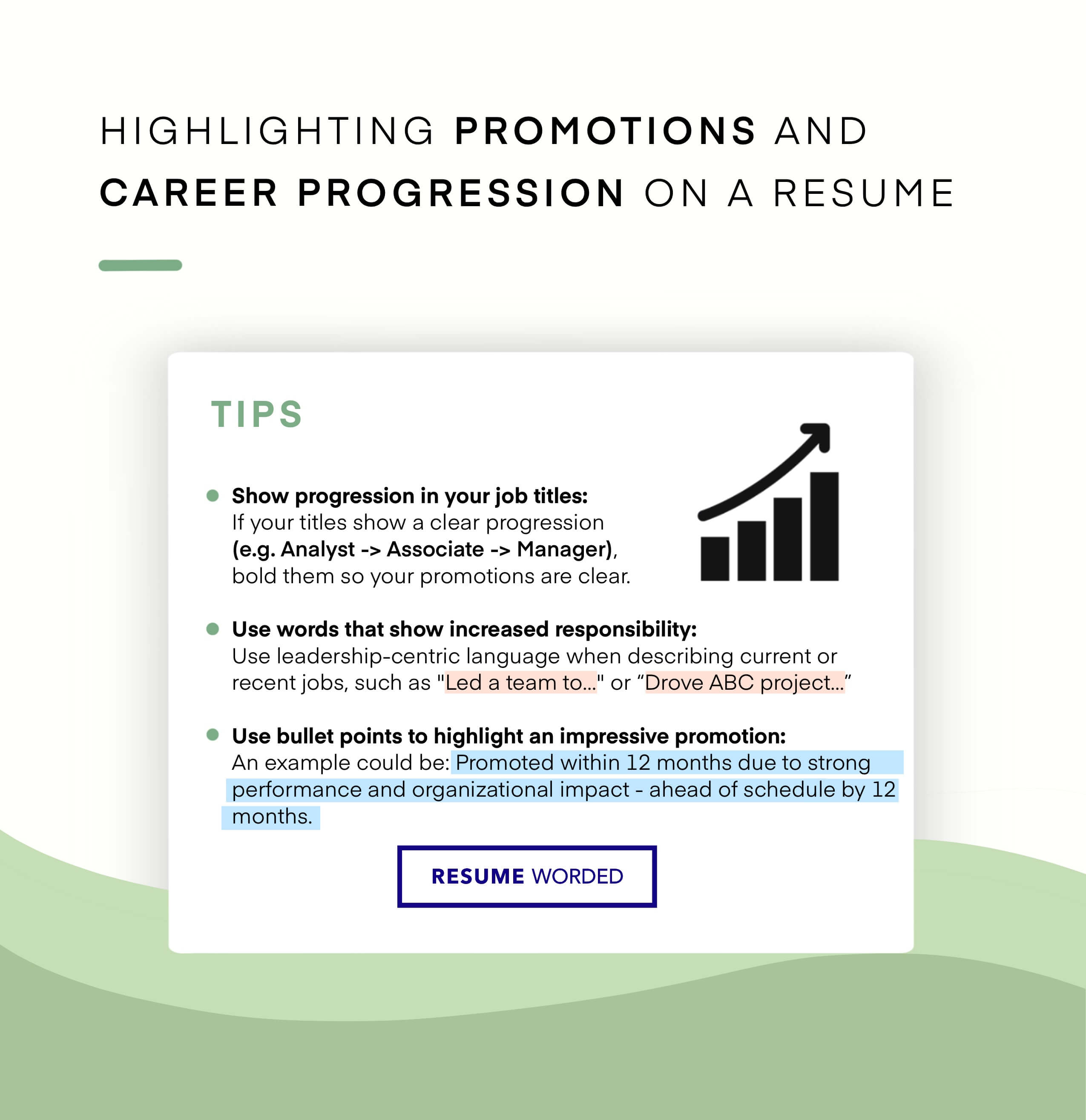

Shows internal promotions within companies

All manufacturing engineers who have had successful field experience to the point of being internally promoted with past employers should indicate that promotion on their resume. This shows to hiring managers that you are dedicated to performing at a high level and have demonstrated this in the past.

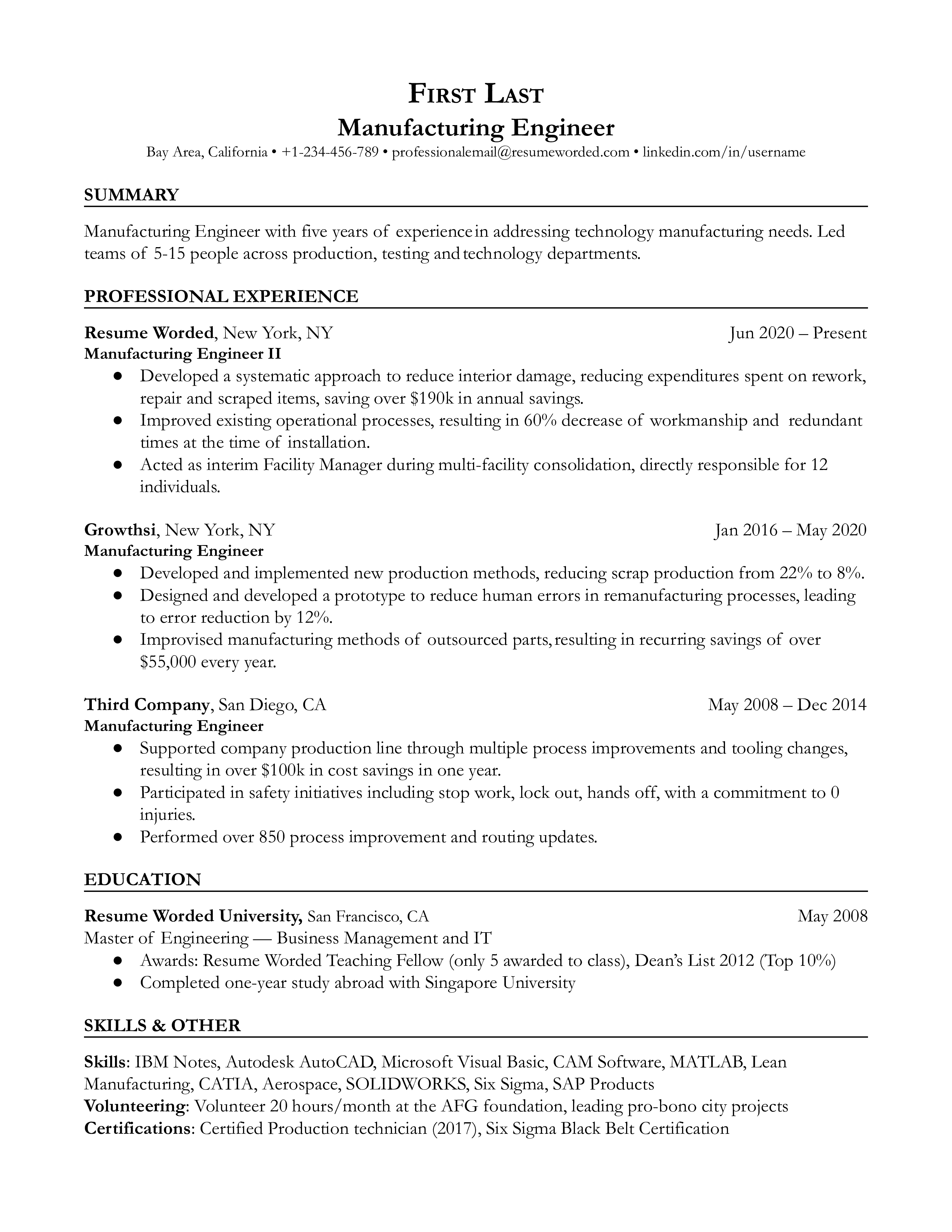

Template 3 of 10: Manufacturing Engineer Resume Example

Manufacturing engineers will generally want to demonstrate their level of comfort in working with numbers and efficient communication techniques. Incorporate quantitative values into your resume, including in an opening summary, to give that impression.

Utilize numbers to indicate scope and scale of manufacturing projects

Being meticulous about details is a key skill for manufacturing engineers. Highlight each of your bullet pointed accomplishments by including a numerical data point that helps hiring managers understand your impact as efficiently as possible.

Includes succinct summary to highlight manufacturing engineering experience

As a manufacturing engineer, a major portion of your role is to conduct assessments and provide direct, accurate reports. Demonstrate your familiarity with the position by opening your resume with a short summary that boils down your relevant experience to a few sentences (and includes quantitative values for impact).

Template 4 of 10: Senior Manufacturing Engineer Resume Example

As a Senior Manufacturing Engineer, you'll be expected to have strong expertise in manufacturing processes and industry-specific knowledge. Recently, companies have been focusing on automation and lean manufacturing, so it's essential to highlight your experience in these areas on your resume. Additionally, ensure you showcase your problem-solving skills, as well as your ability to lead and manage cross-functional teams. In the ever-evolving manufacturing industry, staying on top of the latest trends and technologies is crucial. As a result, be sure to emphasize your adaptability and continuous learning on your resume, as this will demonstrate to potential employers that you can successfully navigate changes in the sector.

Tips to help you write your Senior Manufacturing Engineer resume in 2024

highlight automation expertise.

In today's manufacturing industry, knowledge of automation technologies is highly valued. Showcase your experience in implementing and optimizing automated systems, as well as any relevant certifications or training in this area, to make your resume stand out.

Emphasize lean manufacturing and process improvement

Lean manufacturing is a crucial skill for a Senior Manufacturing Engineer. Highlight your experience in implementing lean methodologies, driving process improvements, and reducing waste within manufacturing environments to demonstrate your value to potential employers.

Skills you can include on your Senior Manufacturing Engineer resume

Template 5 of 10: senior manufacturing engineer resume example.

Senior manufacturing engineers are expected to have a broader understanding of the manufacturing process, including being able to analyze larger scale changes and supervising teams of other engineers. You should aim to indicate your past accomplishments as a leader, and use strong action verbs to impart your familiarity with the work.

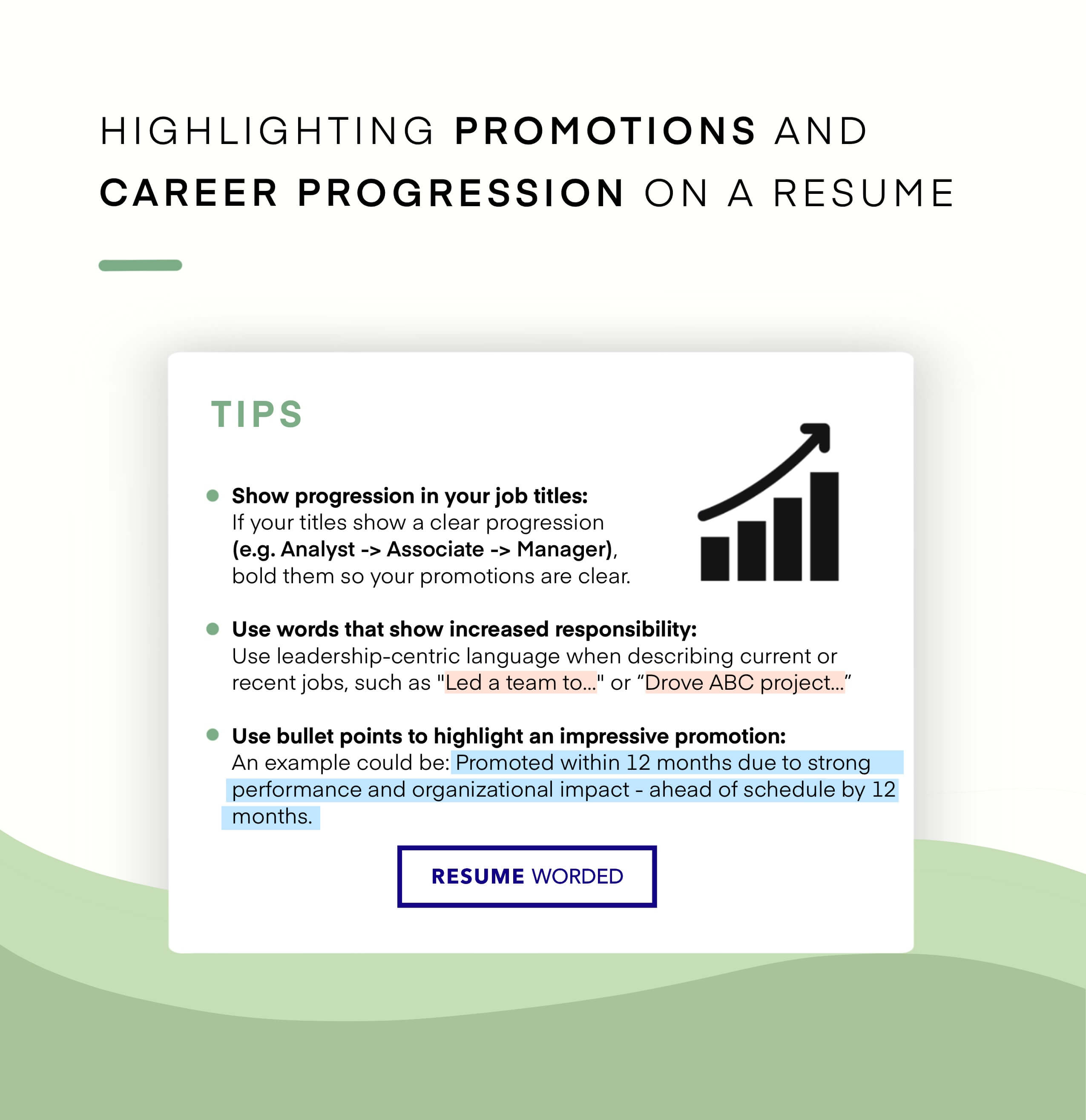

Show promotions and increasing levels of responsibility as an engineer

As a senior manufacturing engineer, hiring managers will be looking for you to have experience with managing teams and taking on higher levels of responsibility over time. Indicate this on your resume by making sure to include leadership roles or accomplishments, ideally growing in scale through to present day.

Use strong action verbs to highlight your technical manufacturing engineering accomplishments When you start each of your bullet pointed accomplishments with a strong action verb, you are grabbing the attention of the hiring manager and conveying that you know the position. Indicate your experience by opening with "Investigated", "Updated", "Designed", and "Trained" and your work as a senior manufacturing engineer will be well illustrated.

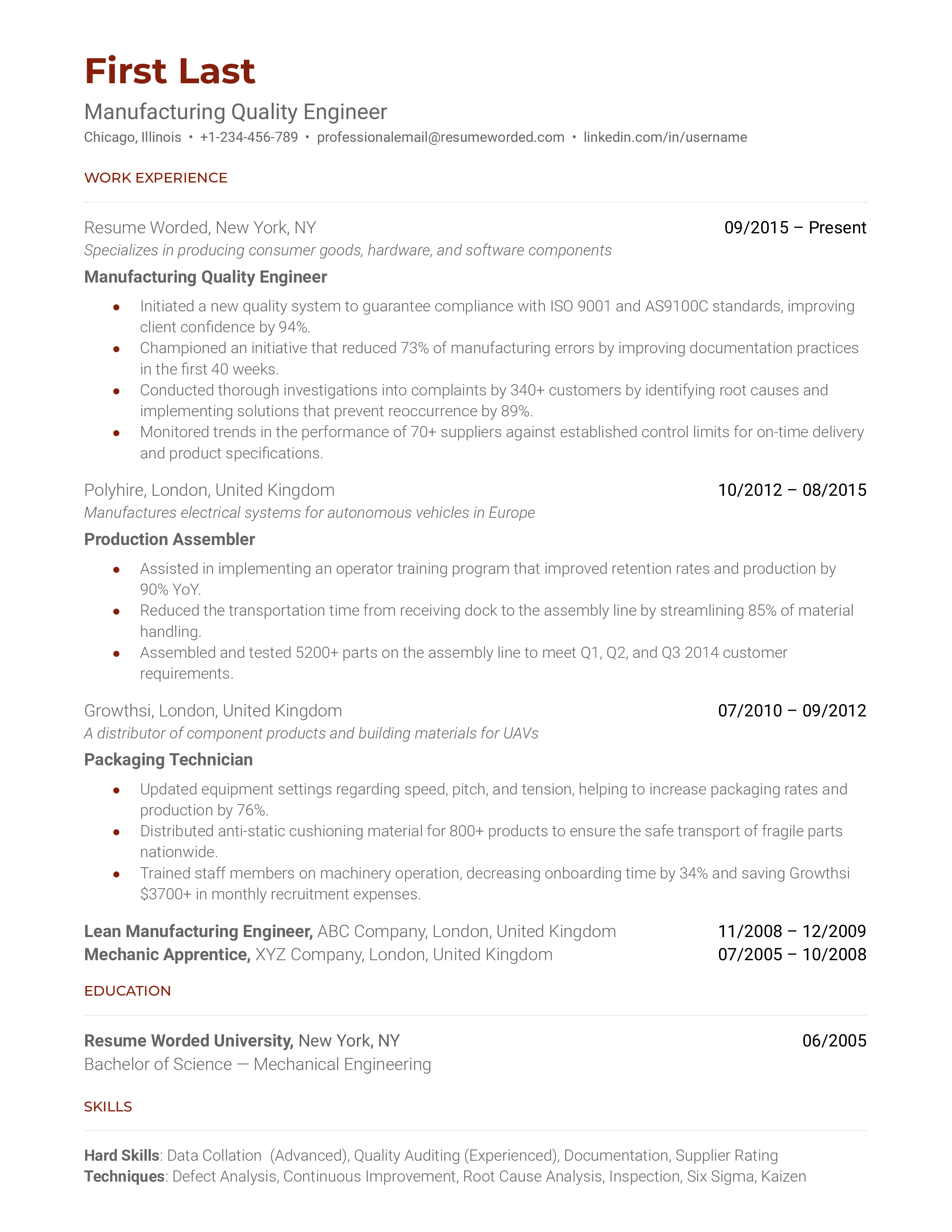

Template 6 of 10: Manufacturing Quality Engineer Resume Example

As a Manufacturing Quality Engineer, you're responsible for ensuring products adhere to strict quality standards and continuous improvement initiatives. In this competitive field, it's important to create a resume that stands out by highlighting your technical expertise and industry knowledge. A trend in manufacturing is the increasing use of advanced technologies and automation, so demonstrating your familiarity with these innovations can be beneficial. Furthermore, showcase your ability to collaborate with cross-functional teams, as communication and teamwork are critical skills to drive quality efforts. When crafting your resume for a Manufacturing Quality Engineer role, focus on your experience with quality control methodologies and lean manufacturing principles. Emphasize your ability to identify and solve quality issues using data-driven approaches, as this is key to driving improvements in a fast-paced manufacturing environment.

Tips to help you write your Manufacturing Quality Engineer resume in 2024

highlight relevant certifications.

In the manufacturing industry, certifications such as Six Sigma, Lean Manufacturing, and ISO 9001 are crucial for demonstrating your commitment to quality. Include these credentials in your education or professional development section, as they validate your expertise in quality engineering principles.

Showcase your analytical skills

Strong analytical skills are essential for a Manufacturing Quality Engineer. On your resume, detail your experience using statistical analysis tools, such as Minitab or JMP, to identify trends, implement improvements, and monitor their effectiveness in improving product quality and reducing defects.

Skills you can include on your Manufacturing Quality Engineer resume

Template 7 of 10: manufacturing quality engineer resume example.

As a Manufacturing Quality Engineer, you'll be focusing on ensuring the quality and efficiency of manufacturing processes. In recent years, the industry has been adopting lean manufacturing and Six Sigma methodologies to minimize waste and variability in production. When writing your resume, keep in mind that hiring managers are looking for candidates who can demonstrate their expertise in these areas, as well as their ability to analyze and improve manufacturing processes. In addition, it's important to showcase your experience working with cross-functional teams, as collaboration is a key aspect of this role. Emphasize your skills in problem-solving, data analysis, and continuous improvement, as these are highly sought-after attributes in Manufacturing Quality Engineers.

Highlight Six Sigma or Lean certifications

In your resume, make sure to mention any Six Sigma or Lean certifications you've earned, as well as any relevant training you’ve completed. These certifications are highly valued in the industry and can set you apart from other candidates.

Showcase data analysis skills

As a Manufacturing Quality Engineer, you'll be using data to identify trends, patterns, and areas for improvement. Include specific examples of how you've utilized data analysis tools and techniques in your previous roles to drive improvements in the manufacturing process.

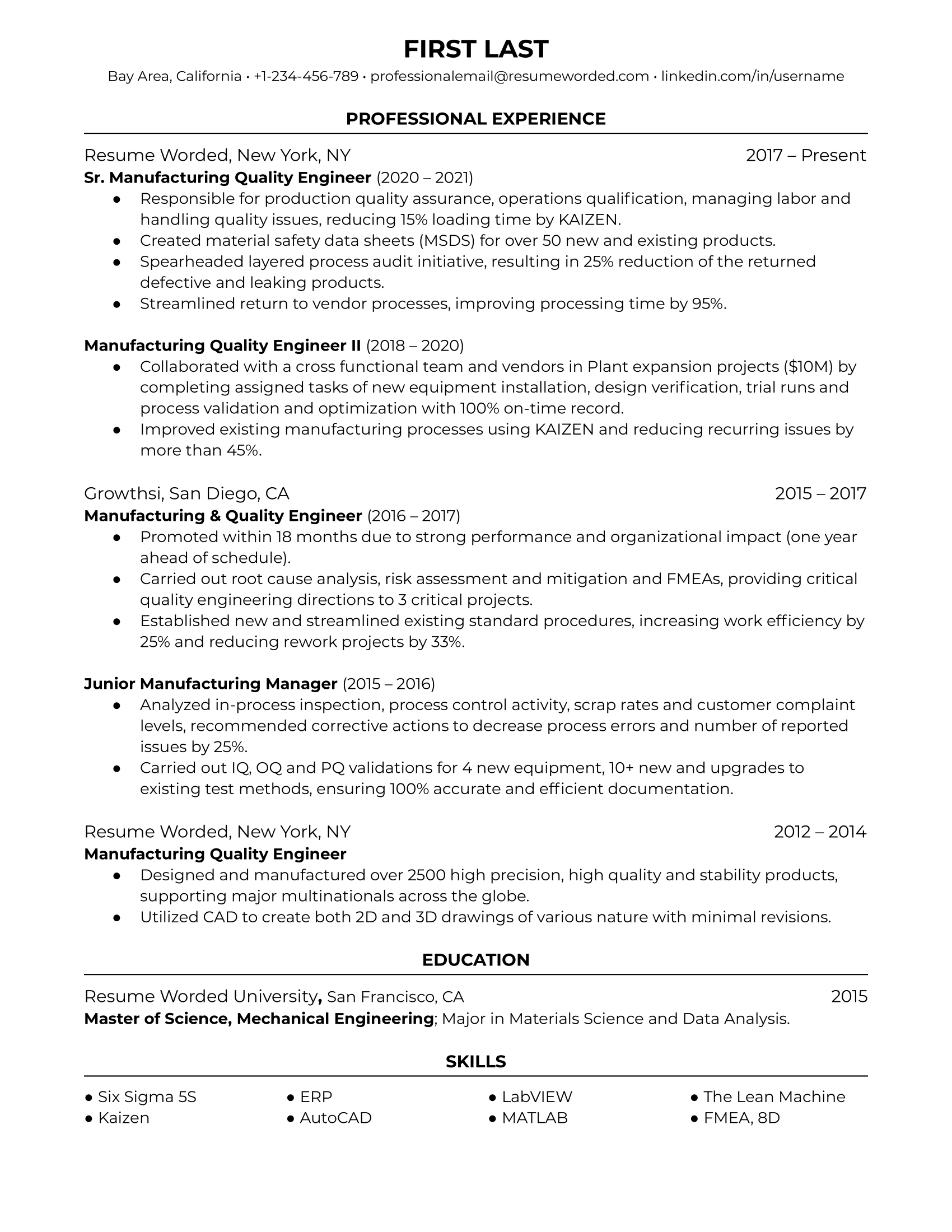

Template 8 of 10: Manufacturing Quality Engineer Resume Example

Manufacturing quality engineers are expected to have an understanding of the overall manufacturing process with a specific focus on being able to assess the quality of the final product. Efficiency is everything to manufacturing engineers, but weighing that against quality is a specific ability. Indicate your experience by emphasizing quality-related skills and techniques.

Emphasis on quality engineering skills

As a manufacturing quality engineer, it's in your best interest to highlight your quality assurance and control work in particular. Each of your accomplishments should relate to data points such as reducing load times, reducing the number of returns, or improving processing times.

Incorporates technical skills and techniques relating to manufacturing engineering

Along with listing your technical skills and quality control techniques in a separate skill bank, you should incorporate them into the body of your resume to lend credibility to your expertise with them. Reference using software such as CAD or IQ, OQ, and PQ validations, as examples, to impart your successful hands-on utilization of them.

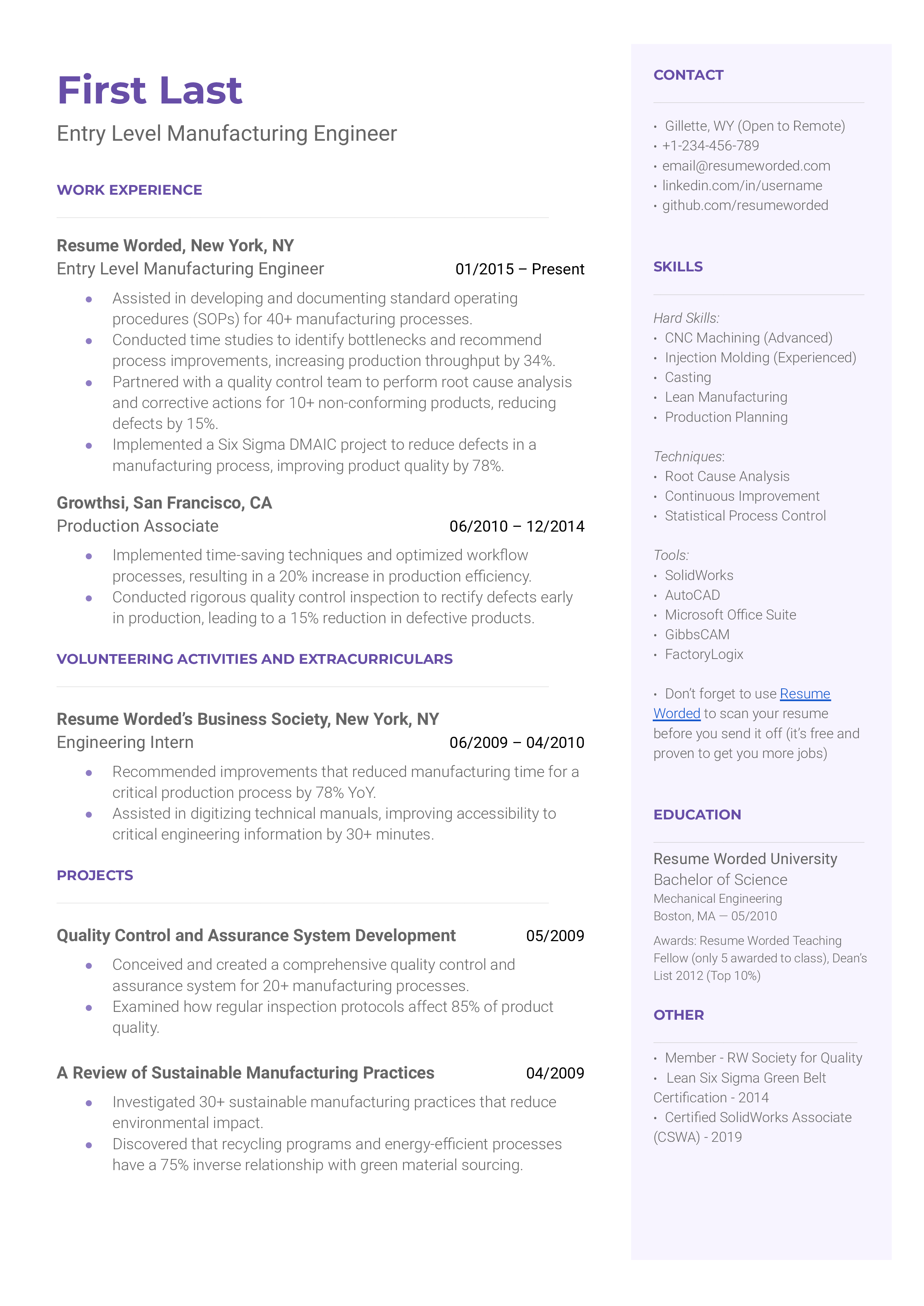

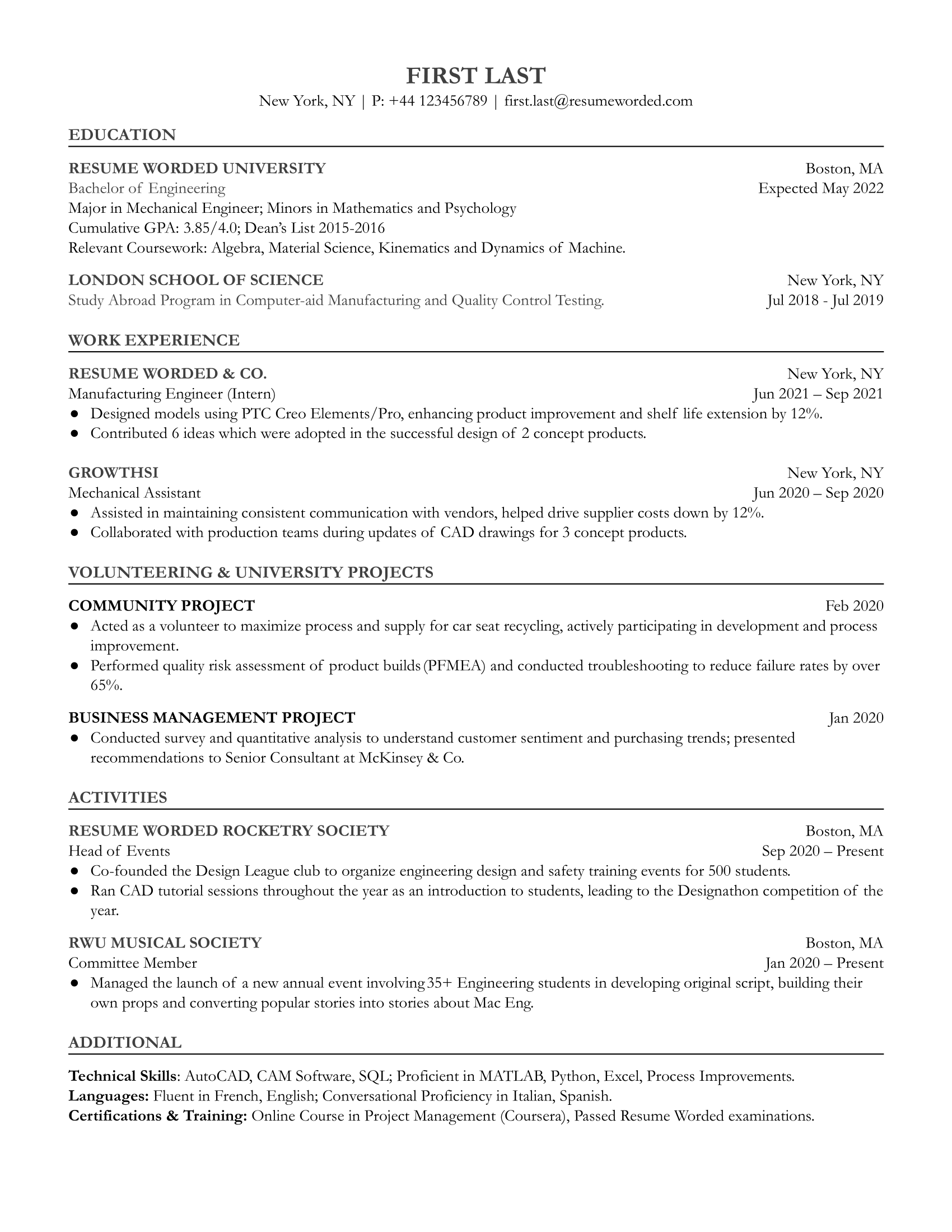

Template 9 of 10: Entry Level Manufacturing Engineer Resume Example

Manufacturing Engineering is quite a competitive field, especially at the entry level. You'll want your resume to demonstrate both your concrete skills and your ability to adapt in a fast-paced environment. Manufacturing companies have been increasingly leveraging automation and data-driven processes, so showing that you're comfortable with this trend is important. When putting your resume together, remember that hiring managers are not just looking for technical skills, but also for problem-solving abilities, communication skills, and efficiency. Your resume should reflect your understanding of manufacturing processes and principles, but equally important is the ability to work in a team. Manufacturing is a highly collaborative field where different departments work closely together. Having some practical experience, even from internships or school projects, can significantly boost your chances. A well-structured resume will also indicate your attention to detail - a crucial trait for any successful manufacturing engineer.

Tips to help you write your Entry Level Manufacturing Engineer resume in 2024

show proficiency in relevant software and technology..

As a Manufacturing Engineer, you'll frequently be working with computer-aided design (CAD) software, manufacturing execution systems (MES), and other process optimization tools. Your resume should clearly indicate your proficiency in these technologies and any others relevant to the role.

Highlight practical experience in manufacturing environments.

Practical experience is incredibly valuable in manufacturing engineering. Even if you've only worked in a manufacturing environment during internships or school projects, make sure to list these on your resume. Include specific tasks you've performed and any results achieved.

Skills you can include on your Entry Level Manufacturing Engineer resume

Template 10 of 10: entry level manufacturing engineer resume example.

Entry level manufacturing engineers may be fresh out of college, meaning they may not have direct experience on the job. If this describes you, bolster your resume by detailing your coursework and including any relevant special projects or activities you’ve been a part of.

Includes relevant technical coursework relevant to engineering Along with naming the program you attained your degree in, it helps to list the courses that you took that most apply to the position you're interested in. The courses taught within programs vary by university, so by outlining them you're indicating to the hiring manager exactly what you have academic training in.

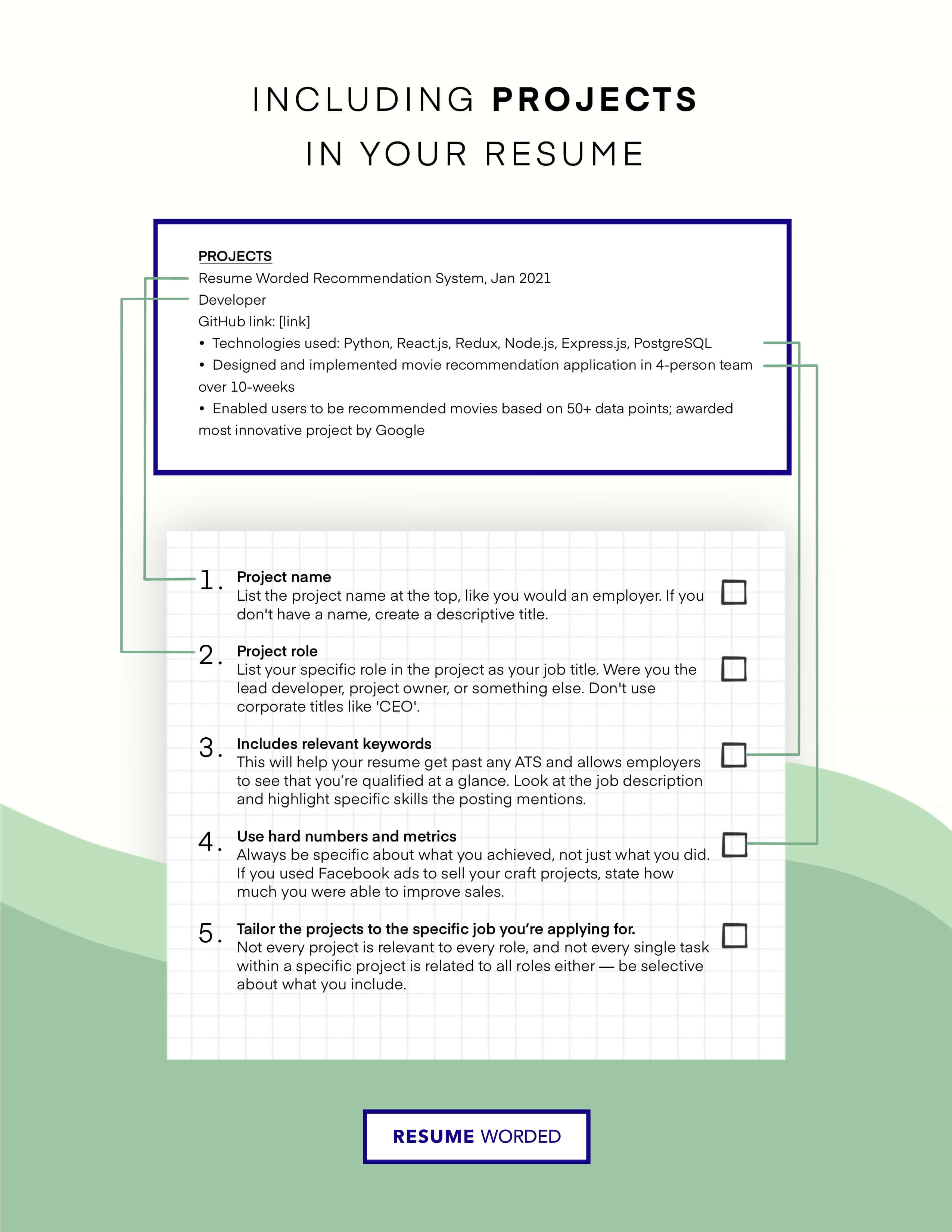

Highlights projects and activities that use technical skills

Even without field experience with an employer, you can demonstrate your familiarity with engineering responsibilities by including a list of community projects, volunteer work, and university activities to which you've dedicated your time. For each project listed, highlight your contributions that are most relevant to a manufacturing engineer's duties.

We spoke with hiring managers at top manufacturing companies like Tesla, General Motors, and Honeywell to gather their best advice for creating a Manufacturing Engineer resume. They shared valuable insights on what they look for when hiring for this role. In this guide, we'll cover specific tips and examples to help you showcase your skills and experience in a way that will catch the attention of recruiters and hiring managers.

Highlight your technical expertise

Hiring managers want to see that you have the technical skills needed for the job. Focus on showcasing your expertise in areas like:

- CAD software such as SolidWorks, AutoCAD, or CATIA

- Manufacturing processes like injection molding, CNC machining, or 3D printing

- Quality control methods such as Six Sigma or Lean Manufacturing

- Automation and robotics systems

Don't just list the skills, but provide specific examples of how you've used them. For instance:

- Designed and implemented a new assembly line using CATIA, increasing production efficiency by 20%

- Led a Six Sigma project that reduced defect rates by 15% and saved the company $500K annually

Quantify your accomplishments

When describing your work experience, use numbers and metrics to quantify your achievements whenever possible. This helps hiring managers understand the impact you've made. Compare these two examples:

- Improved manufacturing processes to increase efficiency

Instead, write:

- Implemented Lean Manufacturing principles, reducing cycle times by 30% and increasing OEE from 70% to 85%

Other examples of quantifiable accomplishments for a Manufacturing Engineer could include:

- Reduced scrap rates from 5% to 2%, saving $250K in material costs

- Developed a new testing protocol that decreased product returns by 20%

Tailor your resume to the job description

Customize your resume for each job you apply to by highlighting the skills and experience that match what the employer is looking for. Carefully review the job description and incorporate relevant keywords.

For example, if a job description emphasizes experience with a specific manufacturing process like injection molding, make sure to call out your expertise in that area:

- 5+ years of experience optimizing injection molding processes for automotive parts manufacturing

- Designed and implemented a new injection molding tool that reduced cycle times by 25%

By tailoring your resume to the job, you show the hiring manager that you're a strong match for the role.

Include relevant projects and certifications

In addition to your work experience, highlight any relevant projects, certifications, or training that showcase your manufacturing engineering skills. This could include:

- Capstone projects from your engineering degree program

- Certifications like Certified Manufacturing Engineer (CMfgE) or Lean Six Sigma Green Belt

- Courses or workshops you've completed on topics like Industrial IoT or Advanced Materials

For example:

- Capstone Project: Designed and built a custom machine vision system to inspect electronic components, resulting in a 50% reduction in false rejects

- Certified Manufacturing Engineer (CMfgE), Society of Manufacturing Engineers, 2020

Demonstrate your problem-solving skills

Manufacturing Engineers are constantly tasked with solving problems and improving processes. Use your resume to highlight specific examples of how you've used your problem-solving skills to overcome challenges and drive results.

For instance:

- Led a cross-functional team to troubleshoot and resolve a persistent issue with a packaging line, reducing downtime by 80% and increasing throughput by 15%

- Developed and implemented a new system for tracking and analyzing production data, enabling real-time decision-making and driving a 10% improvement in overall equipment effectiveness (OEE)

By showcasing your problem-solving abilities, you demonstrate to hiring managers that you have the skills to tackle the challenges of the role.

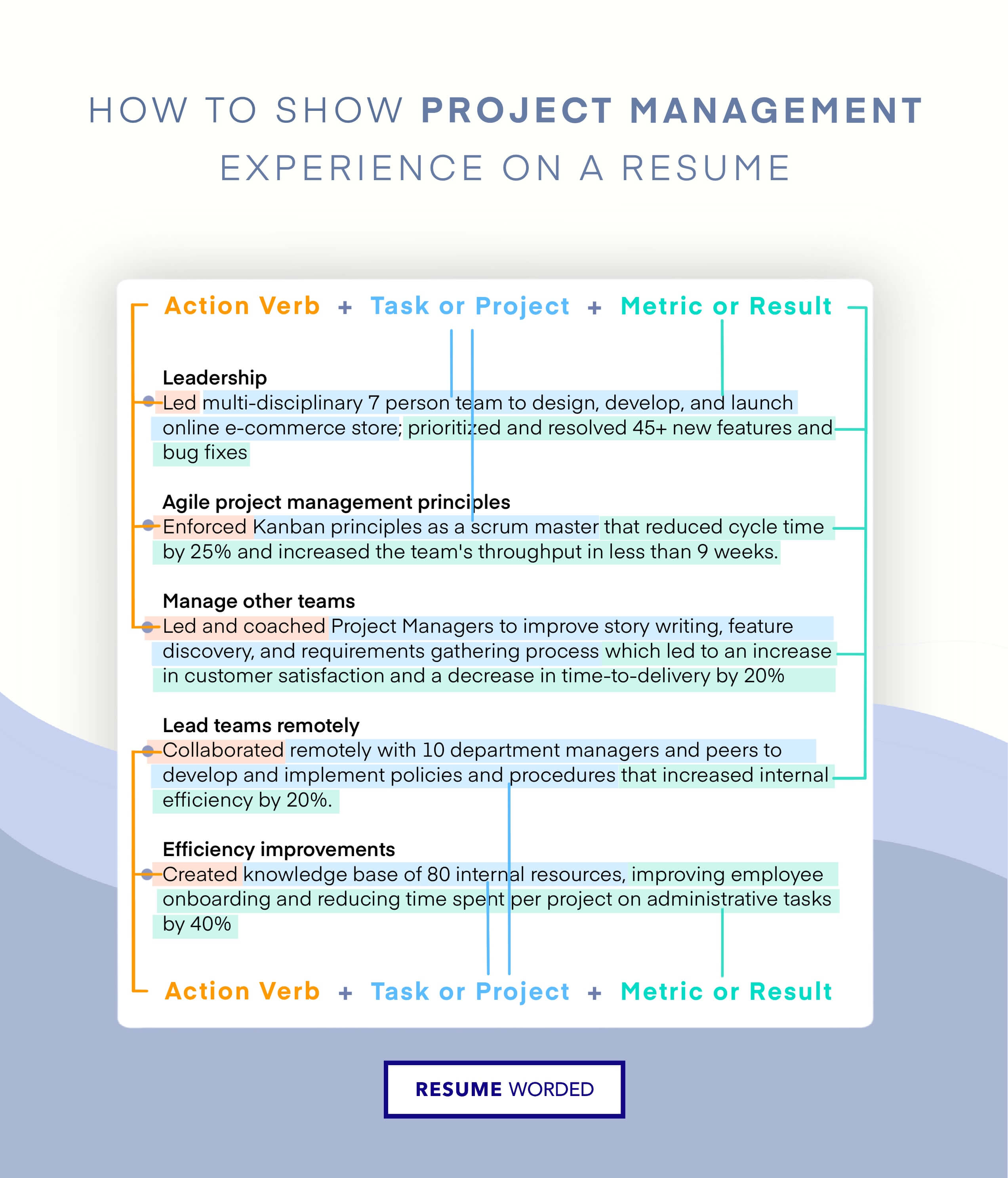

Show your leadership and collaboration skills

While technical skills are crucial for Manufacturing Engineers, hiring managers also look for candidates with strong leadership and collaboration abilities. Highlight any experience you have leading projects, teams, or initiatives.

- Led a team of 5 engineers and 20 production staff to successfully launch a new product line, delivering the project on time and under budget

- Collaborated with cross-functional teams from R&D, Quality, and Operations to develop and implement a new supplier qualification process, resulting in a 25% reduction in supplier-related quality issues

Also, emphasize your communication and interpersonal skills, as Manufacturing Engineers often need to work closely with people from different departments and backgrounds.

Skilled in collaborating with diverse teams, from shop floor operators to executive leadership, to drive continuous improvement and achieve manufacturing excellence.

Writing Your Manufacturing Engineer Resume: Section By Section

header, 1. put your name on its own line.

Your name should be the most prominent element in your header, so it's important to put it on its own line. This makes it easy for recruiters to quickly identify who you are.

Here's an example of what to do:

- 123-456-7890 | [email protected] | linkedin.com/in/johnsmith

And here's what to avoid:

- John Smith | 123-456-7890 | [email protected] | linkedin.com/in/johnsmith

2. Include essential contact details

In addition to your name, your header should include your phone number, email address, and a link to your LinkedIn profile (if you have one). These are the essential details that recruiters need to get in touch with you.

You can include these details on one line, separated by vertical bars or bullet points. For example:

Avoid including your full mailing address, as it's not necessary at this stage and takes up valuable space. A city and state are sufficient if you want to include a location.

3. Tailor your job title

If you're applying for a specific manufacturing engineer position, consider including a tailored job title in your header. This can help show the recruiter that you're a good fit for the role at a glance.

John Smith Mechanical Design Engineer 123-456-7890 | [email protected] | linkedin.com/in/johnsmith

However, avoid stuffing your header with keywords or listing multiple job titles, as this can look cluttered and desperate. Stick to one targeted job title at most.

Summary

A resume summary is an optional section that provides a brief overview of your professional background and key qualifications. While a summary isn't required, it can be useful for manufacturing engineers to provide context and highlight their most relevant skills and experience. Avoid using an objective statement, as it focuses on your goals rather than what you can offer an employer.

When writing your summary, tailor it to the specific manufacturing engineer position you're targeting. Emphasize your technical expertise, problem-solving abilities, and any notable achievements or projects. Keep your summary concise, typically no more than 3-4 sentences or bullet points.

To learn how to write an effective resume summary for your Manufacturing Engineer resume, or figure out if you need one, please read Manufacturing Engineer Resume Summary Examples , or Manufacturing Engineer Resume Objective Examples .

1. Highlight your manufacturing expertise

When writing your manufacturing engineer resume summary, showcase your specific expertise within the field. Consider the following examples:

- Experienced manufacturing engineer with a strong background in various industries

- Skilled manufacturing engineer with a proven track record of success

Instead, focus on the specific areas of manufacturing you specialize in and the impact you've made:

- Manufacturing engineer with expertise in lean manufacturing and Six Sigma methodologies, resulting in a 15% increase in production efficiency

- Experienced manufacturing engineer specializing in automotive components, with a history of implementing cost-saving measures and improving product quality

Results-driven manufacturing engineer with 5+ years of experience optimizing production processes for medical devices. Skilled in CAD/CAM software, lean manufacturing, and quality control. Led a team that reduced manufacturing costs by 20% while improving product reliability.

2. Tailor your summary to the job description

To create a compelling manufacturing engineer resume summary, align your qualifications with the requirements of the specific job you're applying for. Read through the job description carefully and identify the key skills and experience the employer is seeking.

For example, if the job description emphasizes experience with a particular manufacturing process or software, make sure to highlight your proficiency in those areas:

- Manufacturing engineer with expertise in injection molding and proficiency in Autodesk Moldflow, seeking to leverage skills to optimize production processes at XYZ Company

- Experienced manufacturing engineer with a strong background in welding and fabrication, aiming to contribute to ABC Company's production of heavy machinery components

By tailoring your summary to the job description, you demonstrate to the employer that you're a strong fit for the specific role and increase your chances of getting noticed.

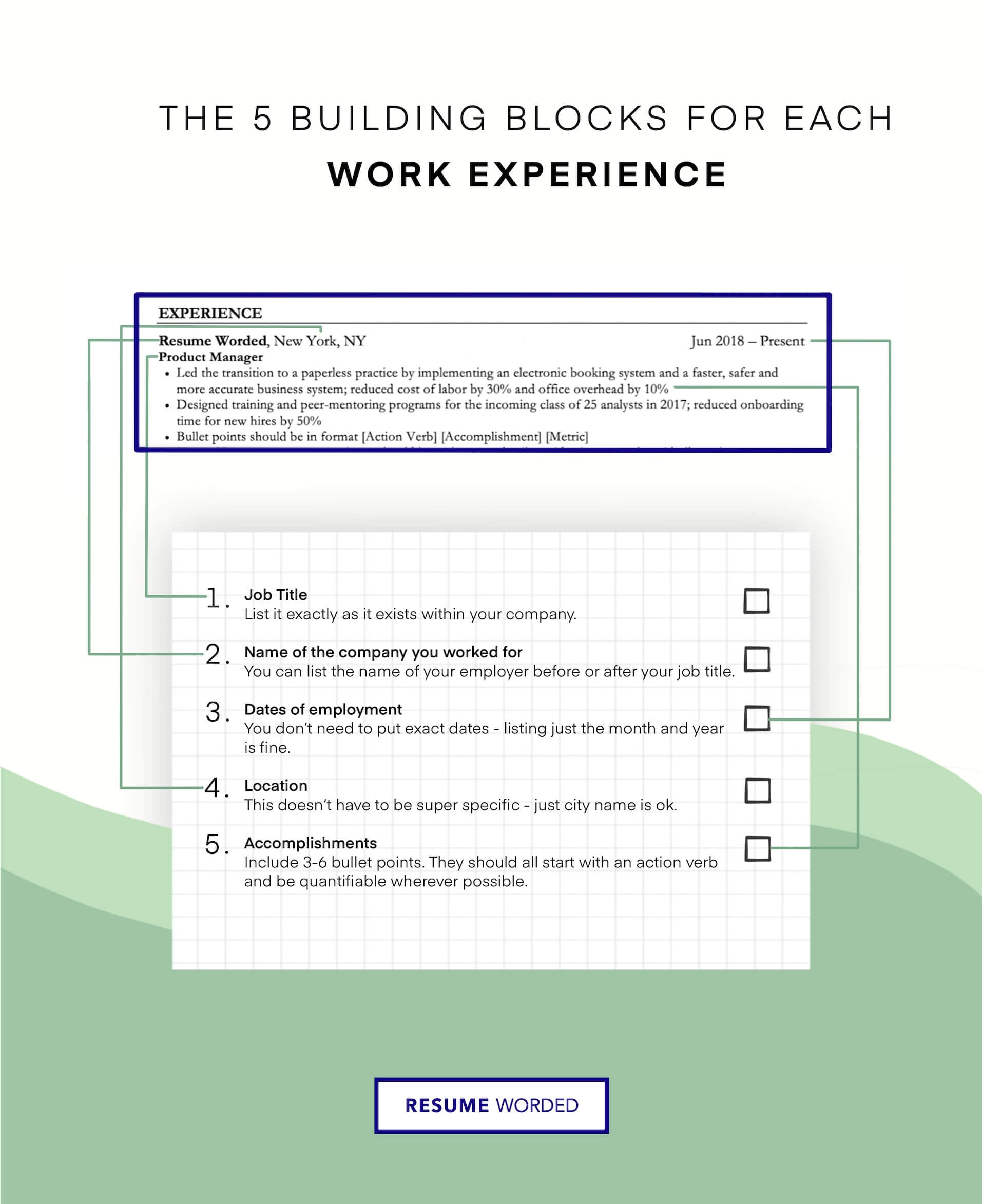

Experience

Your work experience section is the heart of your resume as a manufacturing engineer. It's where you show hiring managers how you've applied your skills to real-world problems and delivered results. Let's break down how to write an effective work experience section step-by-step.

1. Focus on your engineering achievements

Instead of listing your daily responsibilities, highlight your top accomplishments in each role. Emphasize the engineering problems you solved, processes you improved, and results you delivered.

Compare these two examples:

- Responsible for optimizing production lines and reducing waste

This is too vague and reads like a generic job description. Instead, try:

- Implemented Lean manufacturing principles to streamline production lines, resulting in a 15% increase in output and $50K annual cost savings from waste reduction

Quantify your impact whenever possible. Use metrics like cost savings, efficiency gains, and quality improvements to make your achievements concrete and show the value you brought to each role.

2. Showcase your technical expertise

Manufacturing engineering roles require specialized knowledge. Highlight the specific technical skills, tools, and methodologies you've used to show you have the expertise for the job. For example:

- Designed and implemented PLC programs using Allen Bradley RS Logix 5000 to automate key process steps

- Utilized CAD software including AutoCAD and SolidWorks to create detailed product schematics and assembly drawings

- Applied Six Sigma DMAIC methodology to identify and eliminate sources of quality defects

Avoid just listing tools and buzzwords, though. Always tie your technical skills to how you applied them to drive projects and results.

Tailor the skills you highlight to the job you want. Look at the job description for the technical qualifications required, and mirror that language in your bullet points. Our Targeted Resume tool can help you check if your resume has the right skills and keywords for a specific job.

3. Demonstrate your cross-functional leadership

Effective manufacturing engineers don't just have technical chops. They also coordinate across teams to bring new products to life and drive continuous improvement. Use your experience section to showcase your leadership and collaboration skills.

Spearheaded cross-functional Kaizen event with engineering, production, and quality teams to overhaul tablet coating process, resulting in 25% output gain and $1.2M cost savings

In this example, the bullet point showcases the engineer's ability to lead teams, apply Lean methodology, and deliver major results – all in one concise statement.

As you draft your experience bullet points, think beyond just your individual role. How did you partner with other functions like R&D, production, and quality? What initiatives did you lead? Weaving in these examples will paint a fuller picture of your capabilities.

4. Show your career progression

Hiring managers love to see candidates who've grown in their careers and taken on increasing responsibility. If you've earned promotions or expanded your scope, make that clear in your experience section.

One way to do this is by grouping multiple roles at the same company together, with your most recent position first:

ABC Manufacturing Senior Manufacturing Engineer (2018-Present) Manufacturing Engineer II (2016-2018) Manufacturing Engineer I (2014-2016)

Then use your bullet points to show how you advanced and took on higher-level projects over time. This makes your trajectory clear at a glance.

If you're unsure how your experience section stacks up, our free Score My Resume tool can help. It checks your resume on 30+ key criteria hiring managers look for, including experience and career progression, so you can see where you stand and where to improve.

Education

The education section of your resume is important for showing hiring managers your credentials. When writing the education section for a manufacturing engineer position, focus on your engineering degree and any specialized coursework or training you've completed. Here are some key tips to make your education section stand out.

1. Put your highest degree first

List your degrees in reverse chronological order, with your most recent degree at the top. For each degree, include:

- Name of the degree (e.g. Bachelor of Science in Mechanical Engineering)

- Name of the university

- Location of the university

- Graduation year

Here's an example:

Bachelor of Science in Mechanical Engineering Purdue University, West Lafayette, IN Graduated: May 2020

2. Highlight relevant coursework

If you're a recent graduate or have limited work experience, you can include relevant coursework to show your knowledge and skills. Choose courses that relate directly to manufacturing engineering, such as:

- Manufacturing Processes

- Quality Control

Avoid listing basic or introductory courses that don't showcase specialized knowledge. For example:

- Introduction to Engineering

- College Algebra

- English Composition

3. Include certifications and training

In addition to your degree, list any relevant certifications or training you've completed. This can include:

- Six Sigma certifications (e.g. Green Belt, Black Belt)

- Lean manufacturing certifications

- PLC programming certifications

- CAD software certifications (e.g. SolidWorks, AutoCAD)

Here's an example of how to list a certification:

Certified Six Sigma Green Belt (CSSGB) American Society for Quality (ASQ) Issued: June 2021

4. Keep it concise for senior-level positions

If you're a senior-level manufacturing engineer with many years of experience, you can keep your education section brief. Hiring managers will be more interested in your work history and accomplishments. For example:

M.S. in Industrial Engineering, Stanford University B.S. in Mechanical Engineering, University of Michigan

Avoid listing graduation years if you've been out of school for a long time, as it can lead to age discrimination. For example:

B.S. in Mechanical Engineering, Georgia Tech (1985)

Action Verbs For Manufacturing Engineer Resumes

Once you've selected a basic template to work with based on your experiences and the position you're applying for, think about past employers where you performed responsibilities that are most relevant to being a manufacturing engineer. Use the skills list above to outline those responsibilities, and then select a strong action verb to pair with it. The action verb should lead the bullet point to provide an impactful impression to the hiring manager.

- Contributed

- Collaborated

- Established

- Manufactured

- Streamlined

For more related action verbs, visit Engineering Action Verbs .

For a full list of effective resume action verbs, visit Resume Action Verbs .

Action Verbs for Manufacturing Engineer Resumes

Skills for manufacturing engineer resumes.

Being able to improve a company’s manufacturing operations is the goal of manufacturing engineers, and the skills that you highlight on your resume should reflect that. Use the list on the left to get an idea of the types of accomplishments you should be focusing on (along with the templates above), and tailor your resume appropriately for your background. Having the ability to determine when something is out of place - using either technical tools or a hands-on assessment - is what you should aim to demonstrate as a manufacturing engineer. Pick out the skills that match your experience and work them into the body of your resume (including in the summary, if you choose to include one). Make sure to list your technical skills and techniques in a separate skill bank.

- Manufacturing Engineering

- Lean Manufacturing

- Root Cause Analysis

- Engineering Management

- Failure Mode and Effects Analysis (FMEA)

- Manufacturing

- Continuous Improvement

- Process Engineering

- Engineering

- Product Development

- Manufacturing Operations

- Cross-functional Team Leadership

- Design for Manufacturing

- Statistical Process Control (SPC)

- Manufacturing Operations Management

- Value Stream Mapping

Skills Word Cloud For Manufacturing Engineer Resumes

This word cloud highlights the important keywords that appear on Manufacturing Engineer job descriptions and resumes. The bigger the word, the more frequently it appears on job postings, and the more 'important' it is.

How to use these skills?

Other engineering resumes.

Materials Engineer

Security Manager

- Software Engineer Resume Guide

- Software Developer Resume Guide

- Web Developer Resume Guide

- Programmer Resume Guide

- Front End Developer Resume Guide

- DevOps Resume Guide

- Full Stack Developer Resume Guide

- Java Developer Resume Guide

- Python Developer Resume Guide

- IT Manager Resume Guide

- Cyber Security Resume Guide

- Salesforce Resume Guide

- Quality Assurance Resume Guide

- Quality Engineer Resume Guide

- Electrical Engineer Resume Guide

- System Administrator Resume Guide

- Scrum Master Resume Guide

- Civil Engineer Resume Guide

- Network Administrator Resume Guide

- Mechanical Engineer Resume Guide

Manufacturing Engineer Resume Guide

- Network Engineer Resume Guide

- Node.js Resume Guide

- SQL Developer Resume Guide

- Integration Architect Resume Guide

- Engineering Manager Resume Guide

- Software Tester Resume Guide

- Service Technician Resume Guide

- Platform Engineer Resume Guide

- Automation Engineer Resume Guide

- C, C++, and C# Developer Resume Guide

- Technical Support Resume Guide

- Project Engineer Resume Guide

- Security Manager Resume Guide

- Electronic Technician Resume Guide

- System Engineer Resume Guide

- IT Specialist Resume Guide

- Packaging Engineer Resume Guide

- Oracle Resume Guide

- Planning Engineer Resume Guide

- Blockchain Resume Guide

- Cloud Developer Resume Guide

- ETL Developer Resume Guide

- SharePoint Developer Resume Guide

- Kafka Resume Guide

- Audio Engineer Resume Guide

- HVAC Resume Guide

- Industrial Engineer Resume Guide

- Maintenance Technician Resume Guide

- Solutions Architect Resume Guide

- Implementation Specialist Resume Guide

- Software Architect Resume Guide

- PHP Developer Resume Guide

- Biomedical Engineer Resume Guide

- Robotics Resume Guide

- Chief Digital Officer Resume Guide

- Innovation Resume Guide

- Security Analyst Resume Guide

- IT Auditor Resume Guide

- Director of Software Engineering Resume Guide

- Environmental Engineer Resume Guide

- Technology Director Resume Guide

- Director of Information Technology Resume Guide

- AWS Resume Guide

- Director of Engineering Resume Guide

- Materials Engineer Resume Guide

- UAT Tester Resume Guide

- Manufacturing Engineer Resume Example

- Senior Manufacturing Engineer Resume Example

- Manufacturing Quality Engineer Resume Example

- Entry Level Manufacturing Engineer Resume Example

- Tips for Manufacturing Engineer Resumes

- Skills and Keywords to Add

- All Resume Examples

- Manufacturing Engineer CV Examples

- Manufacturing Engineer Cover Letter

- Manufacturing Engineer Interview Guide

- Explore Alternative and Similar Careers

Download this PDF template.

Creating an account is free and takes five seconds. you'll get access to the pdf version of this resume template., choose an option..

- Have an account? Sign in

E-mail Please enter a valid email address This email address hasn't been signed up yet, or it has already been signed up with Facebook or Google login.

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number. It looks like your password is incorrect.

Remember me

Forgot your password?

Sign up to get access to Resume Worded's Career Coaching platform in less than 2 minutes

Name Please enter your name correctly

E-mail Remember to use a real email address that you have access to. You will need to confirm your email address before you get access to our features, so please enter it correctly. Please enter a valid email address, or another email address to sign up. We unfortunately can't accept that email domain right now. This email address has already been taken, or you've already signed up via Google or Facebook login. We currently are experiencing a very high server load so Email signup is currently disabled for the next 24 hours. Please sign up with Google or Facebook to continue! We apologize for the inconvenience!

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number.

Receive resume templates, real resume samples, and updates monthly via email

By continuing, you agree to our Terms and Conditions and Privacy Policy .

Lost your password? Please enter the email address you used when you signed up. We'll send you a link to create a new password.

E-mail This email address either hasn't been signed up yet, or you signed up with Facebook or Google. This email address doesn't look valid.

Back to log-in

These professional templates are optimized to beat resume screeners (i.e. the Applicant Tracking System). You can download the templates in Word, Google Docs, or PDF. For free (limited time).

access samples from top resumes, get inspired by real bullet points that helped candidates get into top companies., get a resume score., find out how effective your resume really is. you'll get access to our confidential resume review tool which will tell you how recruiters see your resume..

Writing an effective resume has never been easier .

Upgrade to resume worded pro to unlock your full resume review., get this resume template (+ 9 others), plus proven bullet points., for a small one-time fee, you'll get everything you need to write a winning resume in your industry., here's what you'll get:.

- 📄 Get the editable resume template in Google Docs + Word . Plus, you'll also get all 9 other templates .

- ✍️ Get sample bullet points that worked for others in your industry . Copy proven lines and tailor them to your resume.

- 🎯 Optimized to pass all resume screeners (i.e. ATS) . All templates have been professionally designed by recruiters and 100% readable by ATS.

Buy now. Instant delivery via email.

instant access. one-time only., what's your email address.

I had a clear uptick in responses after using your template. I got many compliments on it from senior hiring staff, and my resume scored way higher when I ran it through ATS resume scanners because it was more readable. Thank you!

Thank you for the checklist! I realized I was making so many mistakes on my resume that I've now fixed. I'm much more confident in my resume now.

- Career Blog

Manufacturing Production Resume: Winning Examples

When it comes to securing a job in manufacturing production, having a winning resume can be the difference between getting the job or getting overlooked. Employers receive numerous resumes for each position they advertise, so it’s crucial to make sure yours stands out. A well-crafted manufacturing production resume should highlight your skills and experience, reflect your career goals and achievements, and demonstrate your value to potential employers.

Importance of a winning manufacturing production resume

A winning resume is essential for getting noticed by potential employers in any job market, but it’s especially important in the manufacturing production industry. Employers in this industry are looking for candidates who possess specific technical skills, experience with machinery and equipment, and a keen eye for detail. With a carefully constructed manufacturing production resume, you can showcase your qualifications and experience effectively and demonstrate that you have what it takes to excel in the role.

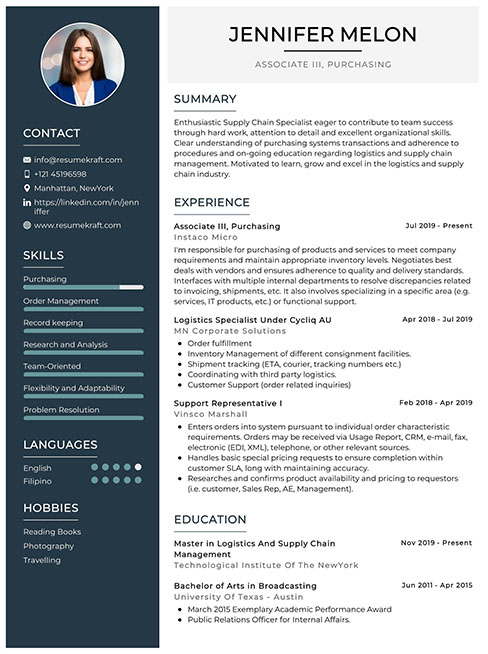

Key elements of a manufacturing production resume

A successful manufacturing production resume should include the following key elements:

- A clear and concise summary statement that highlights your experience and skills.

- A detailed section on your manufacturing production experience, including specific accomplishments and projects you’ve completed.

- Education and training related to manufacturing production, including any certifications or licenses.

- Technical skills related to machinery and equipment used in manufacturing production.

- Related soft skills, including attention to detail, problem-solving abilities, and teamwork.

By highlighting these elements in your resume, you can make a positive impression on potential employers and demonstrate your qualifications for the role. With the right combination of technical expertise, experience, and essential skills, you can create a winning manufacturing production resume that will help you land your dream job.

Understanding the Manufacturing Production Industry

The Manufacturing Production Industry is a massive sector that encompasses the production of goods for both consumers and industrial use. It involves a variety of processes and technologies that are used to create products, from raw materials to finished goods.

Overview of the Manufacturing Production Industry

The Manufacturing Production Industry plays a significant role in the economy, contributing significantly to job creation, GDP growth, and exports. Domestic manufacturers create goods at every level and supply chain, from inputs to final products, and are involved in a range of industries, including automotive, aerospace, electronics, food, and textiles, among others.

Current Trends in Manufacturing Production Industry

The Manufacturing Production Industry is an ever-changing field, with constant advances in technology, regulations, and market integration, leading to several industry changes. Recent trends impacting manufacturing production roles include the growing use of automation and machine learning, the incorporation of Industry 4.0 technologies, green manufacturing, and additive manufacturing.

Key Skills Required for Manufacturing Production Roles

Manufacturing production roles require a combination of technical and non-technical skills. Besides the technical knowledge required to operate different types of equipment, some of the most crucial skills needed to succeed in these roles include:

- Attention to detail: Manufacturing production roles require individuals who can pay attention to details to ensure accuracy in every process.

- Computer skills: Manufacturing production roles today require computer skills that will allow for effective use of technology in production.

- Communication skills: Effective communication skills are essential in manufacturing production roles, from reporting machine issues to collaborating with teams.

- Problem-solving skills: Manufacturing production roles require critical thinking and problem-solving skills during unexpected breakdowns, process inefficiencies, and malfunctions.

- Time management: Time management is vital to meet production targets and schedules in line with quality and safety standards.

The Manufacturing Production Industry demands well-trained individuals with exceptional problem-solving, time management, communication, and attention to detail skills. Demonstrating these key skills in a resume with concise examples tailored to specific manufacturing production roles will help showcase the applicant’s expertise and increase their chances of landing an interview.

Resume Structure and Formatting

When it comes to crafting a winning manufacturing production resume, paying attention to structure and formatting can make all the difference. In this section, we’ll explore the purpose of a manufacturing production resume, how to understand and apply ATS, choosing the right layout and format, and tips for effective formatting.

The Purpose of a Manufacturing Production Resume

A manufacturing production resume serves as a marketing tool to showcase your skills, experience, and accomplishments to potential employers. It should communicate your ability to produce high-quality products, work efficiently in a team, and meet production goals.

Understanding and Applying ATS

Many companies use ATS (Applicant Tracking Systems) to help filter through a large number of resumes quickly. ATS software scans resumes for specific keywords and phrases related to the job description. To optimize your resume for ATS, make sure to include relevant industry-specific keywords, job titles, and experience. Avoid using unusual fonts or formatting that could confuse the software.

Choosing the Right Layout and Format

When choosing the layout and format for your manufacturing production resume, consider your industry and target audience. A traditional chronological format is suitable for most industries, but if you’re applying for a job in the creative sector, a more visually appealing layout may be more appropriate.

Tips for Effective Formatting

To make sure your manufacturing production resume stands out from the competition, here are some formatting tips:

- Use a clean, easy-to-read font such as Arial or Calibri.

- Consider adding bullet points to highlight key achievements and skills.

- Keep your resume concise, ideally under two pages.

- Use industry-specific terminology to showcase your expertise.

- Avoid using passive language and focus on proactive action verbs.

- Proofread your resume for spelling and grammar errors.

By carefully considering the purpose of your resume, applying ATS best practices, choosing the right layout and format, and using effective formatting tips, you can create a manufacturing production resume that stands out in a sea of applicants.

Writing Your Manufacturing Production Resume

Your manufacturing production resume needs to be crafted carefully in order to showcase your relevant experience, skills and accomplishments. In this section, we will discuss some essential tips for writing a strong manufacturing production resume that stands out.

1. Crafting a strong summary statement

Your summary statement should be a brief and powerful statement that communicates who you are, what you can offer and your career goals. Your statement should be tailored to the job you are applying for and highlight your key strengths and achievements.

2. Showcasing relevant experience and skills

Your manufacturing production resume should showcase your relevant experience and skills. Focus on highlighting the experience and skills that are most relevant to the job you are applying for. This could include experience with specific machinery or equipment, quality control, lean manufacturing, project management, or leadership skills.

3. Highlighting accomplishments and achievements

Your manufacturing production resume should also highlight your accomplishments and successes. Include any notable achievements such as improvements to production times, streamlining of processes, cost savings, or quality improvements. Be specific and use numbers to quantify your accomplishments.

4. Including relevant keywords

Finally, make sure to include relevant keywords in your manufacturing production resume. This will help your resume get noticed by hiring managers and recruiters. Use keywords that are specific to the job you are applying for, such as industry-specific jargon or technical skills.

Crafting a strong manufacturing production resume involves creating a strong summary statement, showcasing relevant experience and skills, highlighting accomplishments and achievements, and including relevant keywords. By following these tips, you can create a winning manufacturing production resume that will help you stand out in a competitive job market.

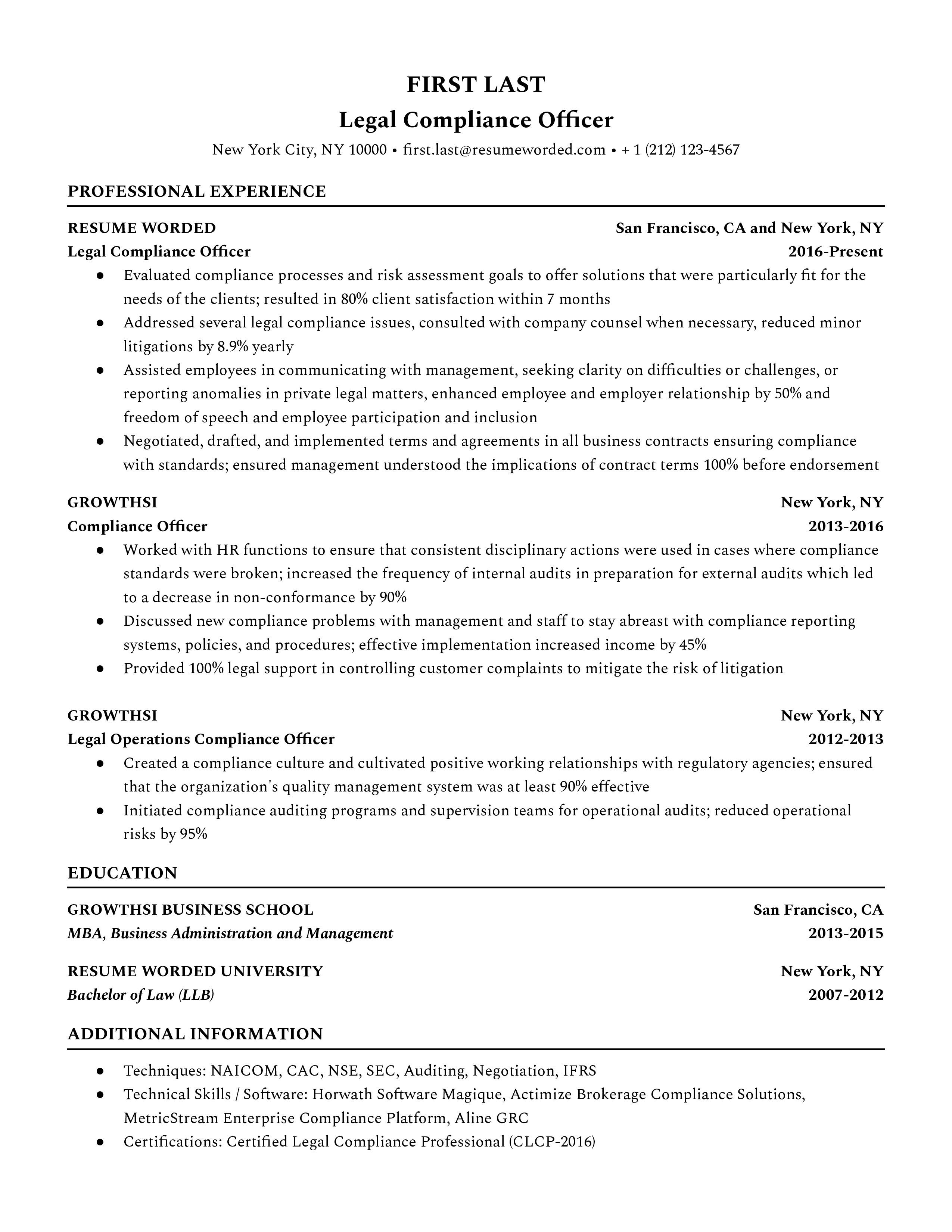

Essential Sections of a Manufacturing Production Resume

When writing a Manufacturing Production Resume, there are essential sections that need to be included. These sections help the hiring manager or recruiter quickly identify your skills, experiences, education, and qualifications. In this section, we will discuss the five essential sections of a Manufacturing Production Resume.

Contact Information

The Contact Information section is the first and most important section of your resume. This section should include your full name, address, phone number, and email address. It is essential to ensure that your contact information is up-to-date and accurate. You don’t want to miss out on a job opportunity just because the recruiter couldn’t contact you.

Summary Statement

The Summary Statement is a brief overview of your most significant achievements, relevant experiences or skills, and what you can contribute to the manufacturing company. It should be tailored to the position you are applying for, and it should cover no more than three to five bullet points. The Summary Statement should be attention-grabbing and convey your unique value proposition.

Professional Experience

The Professional Experience section is where you highlight your relevant work experience related to manufacturing production. It is essential to include your job title, company name, employment dates, and your primary responsibilities and achievements. Use bullet points to make it easy for the recruiter to scan your work experience. Be sure to focus on results and quantify whenever possible.

The Skills section is where you list all your relevant skills that match the job requirements. You can include skills such as equipment operation, production line management, quality control, safety protocols, and others. Be sure to include both hard and soft skills, technical and interpersonal skills, and any areas of expertise you possess.

The Education section is where you list your academic credentials, such as your degree, major, and the institution where you graduated. If you have relevant coursework, you can include that as well. List any honours, awards, or scholarships you received. The Education section is an essential element for entry-level applicants or those with limited work experience.

Certifications and Licenses

The Certifications and Licenses section is where you list your industry-specific certifications, licences, and professional memberships. If you have Lean Manufacturing, Six Sigma, OSHA, or other certifications, make sure to list them here. This can give you an edge over other applicants and demonstrate your commitment to continuous learning and improvement.

A Manufacturing Production Resume must contain all essential sections discussed above. Ensure that each section is relevant, clear, and concise. This way, you increase your chances of getting noticed, getting invited to an interview and eventually getting hired.

The Importance of Tailoring Your Manufacturing Production Resume

Crafting an exceptional resume takes time, effort, and a deep understanding of the job you are applying for. When it comes to manufacturing production, tailoring your resume to fit the job description is essential for standing out in a competitive job market. Here’s why:

Understanding the Job Description

Before you begin crafting your resume, it’s crucial to have a solid understanding of the job description. Start by reading it carefully and taking note of the key responsibilities, required skills, and qualifications mentioned. This will help you identify the most important information you’ll need to include in your resume.

Analyzing Key Skills and Requirements

Once you’ve thoroughly read and analyzed the job description, the next step is to identify the key skills and requirements the employer is looking for. Make a list of the most important hard and soft skills, educational and professional requirements, and any specific certifications or experience that are mentioned.

By understanding the key skills and requirements of the job, you can tailor your resume to highlight your strengths in these areas. Doing so will not only make it easier for the hiring manager to identify your qualifications, but it will also demonstrate that you have taken the time to understand the company’s needs and have the skills necessary to meet them.

Matching Skills and Experience to Job Requirements

The final step in tailoring your manufacturing production resume is to match your skills and experience to the job requirements. This means highlighting your past experiences that directly relate to the job at hand and showcasing your strongest qualifications in a clear and concise way.

Be sure to use specific examples and metrics whenever possible to demonstrate your success in previous roles. For example, if you are applying for a position that requires experience in lean manufacturing, highlighting a specific project where you implemented lean principles and reduced manufacturing waste by XX% can be an excellent way to demonstrate your expertise.

Tailoring your manufacturing production resume to fit the job description is crucial for standing out in a crowded job market. By understanding the job description, analyzing key skills and requirements, and matching your skills and experience to the job requirements, you can create a winning resume that showcases your qualifications and lands you your dream job.

Common Mistakes to Avoid When Writing a Manufacturing Production Resume

When applying for a manufacturing production job, it is important to stand out among the competition. Many applicants, however, make common mistakes that hurt their chances of getting hired. Here are some of the mistakes to avoid when crafting your manufacturing production resume:

Failing to tailor the resume to the job

One of the biggest mistakes job seekers make is failing to customize their resume to the specific job they are applying for. When writing your manufacturing production resume, take the time to review the job posting and tailor your resume to highlight the qualities and experience the employer is looking for.

Using irrelevant or outdated information