Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 13 June 2017

Sol-gel Autocombustion Synthesis of Nanocrystalline High-entropy Alloys

- Fan Zhang 1 ,

- Hang Ping 1 ,

- Jieyang Zhou 1 ,

- Liwen Lei 1 ,

- Jingjing Xie 1 ,

- Jinyong Zhang 1 ,

- Weimin Wang 1 &

- Zhengyi Fu 1

Scientific Reports volume 7 , Article number: 3421 ( 2017 ) Cite this article

12k Accesses

92 Citations

Metrics details

- Nanoparticle synthesis

- Synthesis and processing

A reduction in the particle size is expected to improve the properties and increase the application potential of high-entropy alloys. Therefore, in this study, a novel sol–gel autocombustion technique was first used to synthesize high-entropy alloys. The average grain size of the prepared nanocrystalline CoCrCuNiAl high-entropy alloys showed was 14 nm with an excellent and uniform dispersion, exhibiting a distinct magnetic behavior similar to the superparamagnetic behavior. We show that the metal nitrates first form (Co,Cu,Mg,Ni,Zn)O high-entropy oxides, and then in situ reduce to CoCrCuNiAl high-entropy alloys by the reducing gases, and the chelation between citric acid and the metal ions and the in situ chemical reactions are the dominant reaction mechanisms. We demonstrate that the sol–gel autocombustion process is an efficient way to synthesize solid solution alloys eluding the restriction of a high mixing entropy.

Similar content being viewed by others

Partial liquid metal dealloying to synthesize nickel-containing porous and composite ferrous and high-entropy alloys

Retrosynthetic design of core–shell nanoparticles for thermal conversion to monodisperse high-entropy alloy nanoparticles

Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy

Introduction.

Over the past years, high-entropy alloys (HEAs) have received more and more attention owing to their unique compositions, microstructures and adjustable properties 1 . In contrast to traditional alloys based on only one or two principal elements, HEAs were originally defined as multicomponent alloys composed of five or more principal elements in an equal or near-equal ratio 2 , 3 . The resulting high mixing entropy was demonstrated to facilitate the formation of simple solid solutions rather than complex phases 4 . HEAs typically exhibit excellent physicochemical properties such as special electrical and magnetic properties 5 , 6 , a high strength as well as promising resistances to wear, oxidation and corrosion 7 , 8 , 9 , making them promising candidates for future engineering applications.

A variety of synthesis techniques have aided the development of HEAs such as arc melting 10 , laser cladding 11 and thin-film sputtering 12 . However, these fabrication routes are sometimes unsuitable for industrial manufacturing, because they might prove uneconomic or impose restrictions on the shape (bulk or film) or the size of the final product. Metallic nanoparticles have attracted significant attention from both the academia and the industry because of their unique physicochemical properties (e.g., their magnetic, catalytic and biomedical properties) arising from their much smaller size compared to their bulk counterparts 13 , 14 . To date, HEA nanoparticles are generally synthesized via mechanical alloying (MA). However, when using this method, the grains are usually larger than 30 nm and the nanograins tend to agglomerate and form particles larger than 3 μm 15 , 16 . A size reduction of the particles is expected to improve the properties and increase the application potential of HEAs. This, however, requires the development of a new synthesis method to prepare nanocrystalline HEAs.

Sol–gel autocombustion is a rapid and economical synthesis technique for the fabrication of particulate products and has been widely used for the synthesis of a variety of metal and alloy nanoparticles, forming nano-sized, homogeneous, and highly reactive powders through mixing different elements at the atomic level 17 . For instance, Yang et al . successfully synthesized pure Co, Ni, Cu, Ag, and Bi metals with a grain size of several nanometers via sol–gel autocombustion 18 . Pure metal atoms can be used as building blocks in the construction of different types of alloys. In previous studies, CoNi, NiFe, and even immiscible NiAg nanoalloys have been successfully prepared by the sol–gel autocombustion method 19 , 20 , 21 , indicating a great potential for the synthesis of nanocrystalline HEAs.

In this study, the feasibility of this approach was demonstrated using the CoCrCuNiAl HEA as an example. As one of the first identified HEAs 22 , CoCrCuNiAl contains five metals with different crystal structures (Cu, Ni and Al crystallize in the face-centered cubic (FCC) structure, Cr in the body-centered cubic (BCC), and Co in the hexagonal close-packed (HCP) structure) and consists of simple solid solutions of the FCC and BCC structure. In this study, CoCrCuNiAl HEA was synthesized via sol-gel autocombustion, and the effect of the fuel-oxidant ratio on the combustion process and the final products was investigated. In addition, the microstructure and the magnetic properties of the prepared CoCrCuNiAl HEA were studied.

Results and Discussion

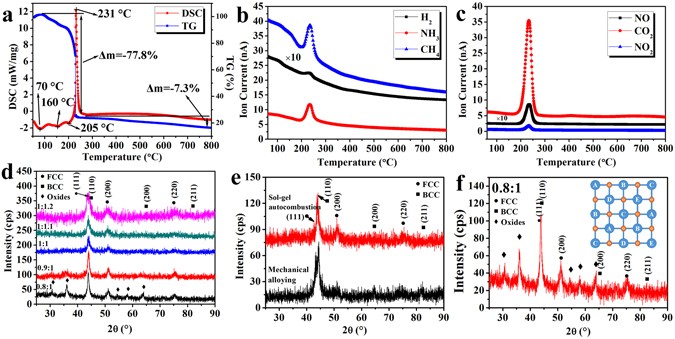

The sol–gel autocombustion technique is primarily used to synthesize nanosized oxides via an exothermic reaction between oxidants (typically metal nitrates) and fuel (such as organic amines, urea and acids) 23 . In this study, a nitrate–citric acid system was used, with the nitrate ions acting as the oxidants and the citric acid as the fuel. To further understand the reaction process, a thermogravimetric–differential scanning calorimetry–mass spectrometry (TG–DSC–MS) analysis was performed to analyze the combustion reaction, and the gas composition of the dried gel with a fuel-oxidant ratio of 1:1. As shown in Fig. 1 , the endothermic peaks appeared at ∼ 70 and 130 °C. They correspond to the evaporation of the free and the bound water in the dried gels, respectively. Another endothermic peak was observed at a temperature of 205 °C and may be ascribed to the decomposition of NH 4 NO 3 formed during the adjustment of the pH value. A strong exothermal peak associated with a sharp decrease in the weight was observed at 231 °C, related to the combustion reaction. No additional peaks but only a small reduction in weight were observed after the combustion process, indicating the formation of a stable phase. As shown in Fig. 1b and c , during the combustion process, gases such as CO 2 , NO 2 , and NO are released, and the metal oxides will be formed simultaneously through the decomposition of the nitrates. Meanwhile, reduction gases such as H 2 , CH 4 , and NH 3 are released as well and play an important role in the reduction of the metal oxides according to a previous study 24 . The combustion reaction can be simply described as follows (where M denotes the metal atom/ions and n is the metal valence):

( a – c ) TG–DSC–MA results obtained for the dried gel prepared from the sol with a fuel–oxidant ratio of 1:1; ( d ) XRD patterns revealing the crystal structures of the combustion products of the dried gels for different fuel-oxidant ratios; ( e ) comparison of XRD patterns of CoCrCuNiAl HEAs synthesized by sol–gel autocombustion and MA; ( f ) XRD patterns of the combustion product of the gels with a fuel–oxidant ratio of 0.8:1 and the schematic illustration of HEOs.

The TG–DSC–MS results show that the gas phases play an important role in the mechanism behind the sol–gel autocombustion process. Different fuel-oxidant ratios will promote the formation of different gas components, which will significantly affect the composition and structure of the final product. To optimize the fuel–oxidant ratio, reagents with different fuel-oxidant ratios (0.8:1, 0.9:1, 1:1, 1.1:1, and 1.2:1) were dissolved in deionized water to obtain the sols. The dried gels were then activated by combustion at a temperature of 300 °C based on the TG–DSC–MS results.

The XRD patterns obtained for the synthesized CoCrCuNiAl HEAs powders are shown in Fig. 1d . Oxide phase was detected in the combustion product of the gels with a fuel–oxidant ratio of 0.8:1, so the volume of reducing gases created by the fuel was not enough to completely reduce the metal oxides to pure alloys. When the fuel–oxidant ratio was increased to 0.9:1, only weak oxide peaks were detected, and when the fuel-oxidant ratio was increased to 1:1, only peaks corresponding to an FCC structure ((111), (200), and (220)) and a BCC structure ((110), (200) and (211)) could be identified. Further increasing the fuel–oxidant ratio to 1.1:1 and 1.2:1 did not result in an obvious change in the XRD patterns. Combustion product of the gel with fuel-oxidant ratio of 1:1 was annealed at 1,000 °C in a flowing argon atmosphere with a soaking time of 1 h and cooled naturally to the room temperature. A Comparison of the XRD results before and after annealing is shown in Supplementary Figure S1 . No oxide peak is detected after annealing, indicating no amorphous oxide in the sol–gel combustion product. In consequence, simple solid solutions rather than complex phases were formed, indicating successful synthesis of HEAs via the sol–gel autocombustion method, and the lowest fuel-oxidant ratio to synthesize pure CoCrCuNiAl HEAs was determined to be a 1:1 ratio. For comparison, a CoCrCuNiAl HEA was also prepared by conventional mechanical alloying (MA). More detailed information on the prepared CoCrCuNiAl HEA via MA is provided in Supplementary Figure S2 . As shown in Fig. 1e , both of the XRD patterns of the CoCrCuNiAl HEAs synthesized by MA and sol–gel autocombustion show the same phases, further confirming the successful synthesis of HEAs by the sol–gel autocombustion.

There are two possible routes of the synthesis of CoCrCuNiAl HEAs in the autocombustion process. (i) different metal oxides are reduced to metals by the reducing gases and then form HEAs as the building blocks. (ii) different metal oxides form complex multicomponent oxides, followed by in situ reduction to HEAs by the reducing gases. According to thermodynamics, it is impossible to obtain metallic aluminum and chromium in the autocombustion process because Al 2 O 3 and Cr 2 O 3 cannot be reduced to metals by any type of the gases formed in the combustion. Therefore, the synthesis of CoCrCuNiAl HEAs is through the second route. Recently, (Co,Cu,Mg,Ni,Zn)O high-entropy oxides (HEOs) were synthesized by pyrolyzing nitrates of the individual metals according to the report of Sarkar et al . 25 . Similar with HEAs, HEOs containing five or more metals in equiatomic amounts will be formed because of the high mixing entropy. Hence, the oxide phase in the XRD patterns of the combustion product with fuel–oxidant ratios less than 1:1 is likely to be (Co,Cr,Cu,Ni,Al)O HEO. In the HEOs, the metallic elements are bonded together and ordered in thermodynamics to form the structure of A–B–C–D–E–O (where A, B, C, D, and E denote the metallic elements and O represents oxygen), as shown in Fig. 1f . There is always an intermediate anion separating neighboring cation lattice sites, and no single component metal oxide phases exist in the (Co,Cr,Cu,Ni,Al)O HEOs, so that the reduction of Al 3+ and Cr 3+ can be realized. The dried gels with fuel–oxidant ratios of 0.8:1 and 0.9:1 were also activated through combustion in a tube furnace under a flowing hydrogen atmosphere. The XRD patterns of the combustion products are shown in Supplementary Figure S3 . No oxide phase was detected in the combustion product, so the external H 2 can further reduce the oxide phases, validating the above hypothesis.

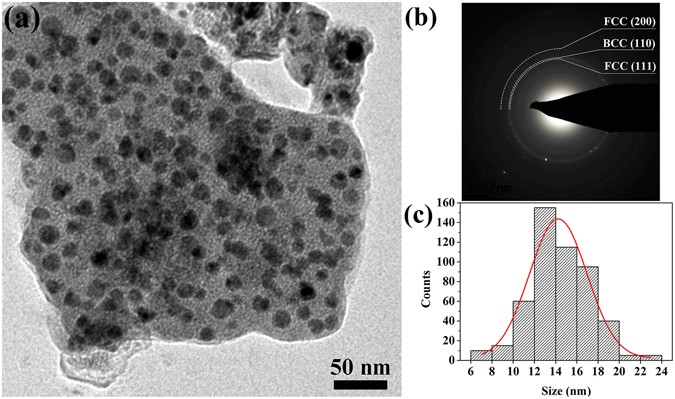

Transmission electron microscopy (TEM) was used to study the microstructure of the prepared CoCrCuNiAl HEAs. The TEM micrograph revealing the detailed microstructure of the CoCrCuNiAl HEA prepared from a sol with a fuel–oxidant ratio of 1:1 is shown in Fig. 2a , and the TEM images of the combustion products obtained from sols with fuel–oxidant ratios of 0.8:1, 0.9:1, 1.1:1, and 1.2:1 are shown in Supplementary Figure S4 , indicating unifromly dispersed HEA nanoparticles. The average grain size of the nanoparticles was calculated to be 14 nm based on a statistical analysis of the size of the particles shown in Fig. 2b . It is worth noting that the grain size of the CoCrCuNiAl HEA synthesized in this study via the sol–gel autocombustion is smaller than the sizes of all HEA nanoparticles so far reported in literature. Furthermore, the nanoparticles show an excellent uniform dispersion. The rings in the SAED pattern reveal that the nanocrystalline CoCrCuNiAl HEA powder prepared via the sol–gel autocombustion consists of a BCC phase and a FCC phase and is in agreement with the XRD results.

( a ) TEM image of the prepared CoCrCuNiAl HEA; ( b ) corresponding SAED pattern; ( c ) histogram plot of the particle size distribution.

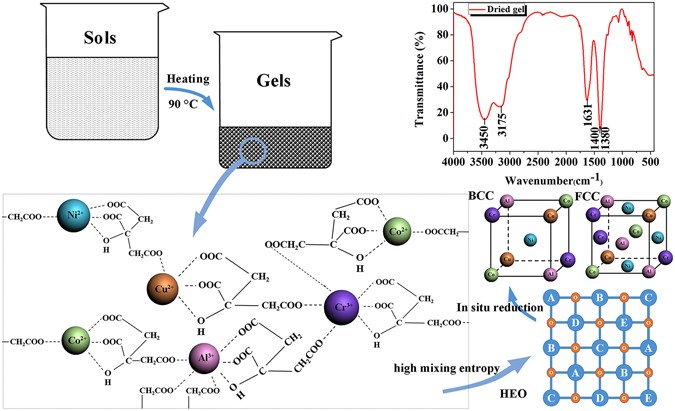

Based on the above results, it can be claimed that nanocrystalline CoCrCuNiAl HEA with an average grain size of 14 nm was synthesized via the sol–gel autocombustion. According to the knowledge about HEAs, the different metals should homogeneously share a common lattice to form simple solid solutions. Herein, we suggest that the formation of nanocrystalline HEAs is attibuted to the chelation between citric acid and metal ions. Citric acid has three carboxyl (-COOH) groups and one hydroxyl group (-OH), providing four lone pair electrons to form a tetradentate ligand. However, one metal ion cannot be chelated with more than two of the carboxyl groups, and another carboxyl group can only chelate with other metal ions 25 . The dried gels with a fuel–oxidant ratio of 1:1 were studied by Fourier Transform infrared spectroscopy (FTIR) in the wavelength range from 440 to 4000 cm −1 , and the resulting spectra are shown in Fig. 3 . The band at 1380 cm −1 is commonly assigned to the NO − ions, whereas the bands at 1400 and 1631 cm −1 are because of the symmetric vibrations, ν s (COO − ), and antisymmetric stretching vibrations, ν as (COO − ), of the citrate molecules, respectively. The band at 3175 cm −1 is linked to the hydroxyl group (-OH), and the broad bands ∼ 3500 cm −1 can be assigned to water molecules. The distance between the antisymmetric and symmetric stretching vibration peaks, Δ( ν as (COO − )- ν s (COO − )), was larger than 200 cm −1 , indicating that some carboxylate groups in the citrate molecules are coordinated to metal ions in a monodentate configuration 26 . Therefore, in the sols, Co 2+ , Cu 2+ , and Ni 2+ will form tetradentate complexes with an α-hydroxyl group, an α-carboxyl group, and a β-carboxyl group of the citric acid, as well as one of the β-carboxyl groups of another citric acid molecule; Cr 3+ and Al 3+ will form hexadentate complexes with an α-hydroxyl group, an α-carboxyl group, and a β-carboxyl group of the citric acid, as well as three β-carboxyl groups of three other citric acid molecules. Because of the chelation of the citric acid and the metal ions, a 3D network will form in the sols, which remains intact during the transformation of the sols into gels, as indicated by the spectra shown in Fig. 3 . As a result, the Co 2+ , Cr 3+ , Cu 2+ , Ni 2+ , and Al 3+ ions will be homogeneously distributed in the dried gels, and no interface will exist between the metal ions. Compared to traditional HEAs synthesis techniques requiring long periods of time for the diffusion of the atoms to form solid solutions, the in situ chemical reactions described in Eq. ( 1 ) groups (4) only require a short-range diffusion of the atoms to form solid solutions.

Schematic illustration of the sol–gel combustion process and the FTIR pattern for the dried gel.

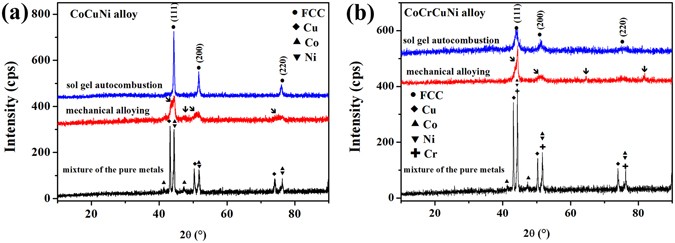

To better understand the results, an equiatomic CoCuNi alloy and an equiatomic CoCrCuNi alloy were also synthesized via the sol–gel autocombustion. As shown in Fig. 4 , both of these alloys feature an FCC structure. More information on the CoCuNi and CoCrCuNi alloys can be found in Supplementary Figure S5 . A comparison of the XRD patterns of equiatomic CoCuNi alloy and equiatomic CoCrCuNi alloy synthesized by the sol–gel autocombustion and MA are shown in Fig. 4 . Some additional peaks still can be detected after mechanical alloying for 60 h; however, there are no additional peaks, and the background is low and flat, and peak widths are narrow in 2θ space in the XRD patterns of equiatomic CoCuNi alloy and CoCrCuNi alloy synthesized by the sol–gel autocombustion, indicating the successful synthesis of ternary and quaternary equiatomic solid solution alloys. According to Boltzmann’s hypothesis regarding the relationship between the entropy of a system and the system complexity, for a random solid solution, the configurational entropy of mixing is represented by the following Eq.

where R is the gas constant (8.314 J/K mol) and \({c}_{i}\) is the molar content of the i th component 27 . Thus, for an equiatomic alloy with n components, the configurational entropy of mixing is:

XRD patterns obtained for the equiatomic CoCuNi and CoCrCuNi alloys prepared via sol-gel autocombustion and mechanical alloying, respectively.

For an equiatomic alloy with 3, 4, and 5 principal components, Δ S mix is 1.10 R , 1.39 R , and 1.61 R , respectively. In fact, complex phases or intermetallics easily form in alloy systems with multiple principal components according to traditional metallurgical knowledge 28 , and simple solid solutions will be formed when the alloys contain more than five principal elements because of the high mixing entropy (>1.61 R ) according to the knowledge about HEAs. However, CoCuNi (ternary, \({\rm{\Delta }}{S}_{mix}=1.10R\) ) and CoCrCuNi (quaternary, \({\rm{\Delta }}{S}_{mix}=1.39R\) ) equiatomic solid solution alloys without a high mixing entropy were synthesized in this study. Therefore, according to the above discussion, some equiatomic solid solution alloys can be synthesized eluding the restriction of a high mixing entropy, which further indicates the superiority of the sol–gel autocombustion technique for the preparation of solid solution HEAs.

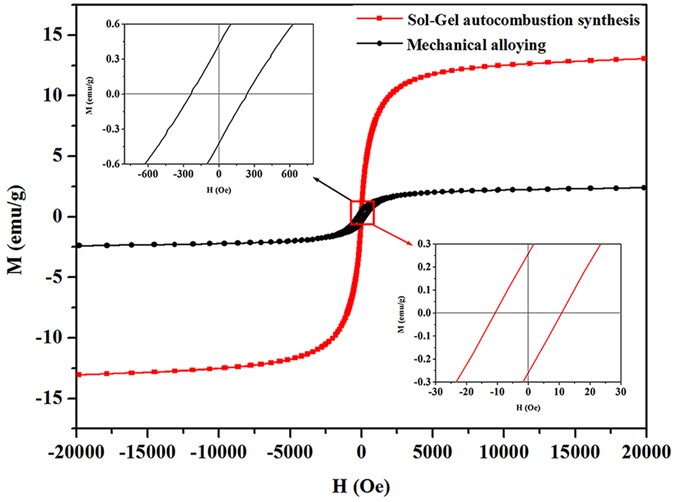

The magnetic properties of the CoCrCuNiAl HEAs synthesized via the sol–gel autocombustion and mechanical alloying were measured at room temperature. The obtained magnetic hysteresis loops are shown in Fig. 5 . The HEA powder prepared via MA showed a ferromagnetic behavior, and the saturated magnetizations ( M S ), remanence ratio ( M R / M S ) and coercivity force ( H C ) were measured to be 2.521 emu/g, 17.3%, and 238.867 Oe, respectively. However, compared to the magnetic properties of the CoCrCuNiAl HEA synthesized via MA, the corresponding HEA synthesized via the sol–gel autocombustion showed a distinctive soft magnetic behavior and higher saturated magnetizations (13.372 emu/g), a lower remanence ratio (1.93%), and a lower coercivity force (10.528 Oe). Furthermore, the HEA powder synthesized via the sol–gel autocombustion showed a behavior similar to a superparamagnetic behavior because of the low remanence ratio. In general, magnetic nanoparticles with diameters <10 nm exhibited a superparamagnetic behavior 29 . The CoCrCuNiAl HEA synthesized via the sol–gel autocombustion had an average grain size of 14 nm, and can easily lead to the observed magnetic behavior similar to a superparamagnetic behavior. This makes HEAs prepared via the sol–gel autocombustion promising candidates for future applications in some special conditions.

Comparison of the magnetic hysteresis curves obtained for the CoCrCuNiAl HEAs prepared via the sol–gel autocombustion and mechanical alloying, respectively.

Conclusions

In summary, CoCrCuNiAl HEAs were successfully synthesized via the sol–gel autocombustion. The optimal fuel–oxidant ratio for the synthesis of CoCrCuNiAl HEAs using nitrate ions as the oxidants and citric acid as the fuel was determined to be 1:1. Solid solutions with an FCC and BCC structure and an average grain size of 14 nm were obtained after the combustion process, and the HEA nanoparticles showed an excellent uniform dispersion. The synthesis of the nanocrystalline HEAs was associated with the chelation between citric acid and metal ions and the in situ chemical reactions. The nanopowders exhibited a distinctive magnetic behavior similar to a superparamagnetic behavior, demonstrating the great application potential of HEAs synthesized via the sol–gel autocombustion.

Preparation of the HEAs by sol–gel autocombustion

Analytical grade Co(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 ·9H 2 O, Cu(NO 3 ) 2 ·3H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 ·9H 2 O, citric acid, ethanol, and ammonia (all procured from Sinopharm, China) were used as the starting materials in this study. The metal nitrates were first dissolved in distilled water at an equiatomic ratio and stirred thoroughly at room temperature for 1 h. Then, citric acid was added to the solution as coordinating agent with the molar ratio of citric acid to the total amount of metal ions selected to 0.8:1, 0.9:1, 1:1, 1.1:1, or 1.2:1. After homogenizing the solution through magnetic stirring, the pH value was adjusted to 7 by adding ammonia, and finally the sols were annealed at 90 °C for 48 h to form the dried gels. The dried gels were activated by combustion at 300 °C in a tube furnace under a protective argon atmosphere or under a flowing hydrogen atmosphere.

Preparation of the HEAs by mechanical alloying

For comparison, CoCuNi, CoCrCuNi, and CoCrCuNiAl HEAs were also prepared via mechanical alloying (MA). Co, Cr, Cu, Ni, and Al metal powders were used as the starting materials in this case. The powders were milled in a high-energy planetary ball mill (QM-BP, Nanjing Nan-Da Instrument Plant) at 250 rev/min with a ball-to-powder weight ratio of 15:1 for 60 h, and n-heptane was used as the process-controlling agent.

Characterization of alloys

X-ray diffraction (XRD, Rigaku Ultima III) measurements were performed using Cu Kα radiation in the 2θ range from 10 to 90° at a scanning rate of 4°/min to analyze the crystal structure of the obtained HEAs powders. A thermogravimetric analysis combined with differential scanning calorimetry and dynamic mass spectrometry (TG–DSC–MS, Netzsch STA449F3, Germany) was used to perform an in situ thermogravimetric and gas-phase analysis of the reactive gels under a high-purity argon atmosphere using a heating rate of 10 K/min. Transmission electron microscopy (TEM, Philips M12) was used in conjunction with selected area electron diffraction (SAED) to analyze the microstructure of the powders. The gels were evaluated by Fourier Transform infrared spectroscopy (FTIR, Thermo Scientific Nicolet 6700) from 4000 to 400 cm −1 , at a resolution of 4 cm −1 with 32 scans. The magnetic properties of the HEAs at room temperature were measured using a Physical Property Measurement System (PPMS, Quantum Design PPMS-9T), and the magnetic field was varied from −20000 to 20000 Oe.

Zhang, Y. et al . Microstructures and properties of high-entropy alloys. Prog. Mater Sci. 61 , 1–93 (2014).

Article Google Scholar

Cantor, B., Chang, I. T. H., Knight, P. & Vincent, A. J. B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377 , 213–218 (2004).

Yeh, J. W. et al . Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6 , 299–303 (2004).

Article CAS Google Scholar

Zhang, Y., Zhou, Y. J., Lin, J. P., Chen, G. L. & Liaw, P. K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 10 , 534–538 (2008).

Koželj, P. et al . Discovery of a Superconducting High-Entropy Alloy. Phys. Rev. Lett. 113 , 107001 (2014).

Article ADS PubMed Google Scholar

Zhang, Y., Zuo, T. T., Cheng, Y. Q. & Liaw, P. K. High-entropy Alloys with High Saturation Magnetization, Electrical Resistivity, and Malleability. Sci. Rep. 3 , 1455 (2013).

Article ADS PubMed PubMed Central Google Scholar

Gludovatz, B. et al . Fracture-resistant high-entropy alloy for cryogenic applications. Science 345 , 1153–1158 (2014).

Article ADS CAS PubMed Google Scholar

Lim, X. Z. Mixed-up metals make for stronger, tougher, stretchier alloys. Nature 533 , 306–307 (2016).

Li, Z. M., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 534 , 227–230 (2016).

Santodonato, L. J. et al . Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat. Commun 6 , 5964 (2015).

Article PubMed Google Scholar

Qiu, X. W. & Liu, C. G. Microstructure and properties of Al 2 CrFeCoCuTiNi x high-entropy alloys prepared by laser cladding. J. Alloys Compd. 553 , 216–220 (2013).

Zou, Y., Ma, H. & Spolenak, R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 6 , 7748 (2015).

Alivisatos, A. P. Semiconductor Clusters, Nanocrystals, and Quantum Dots. Science 271 , 933–937 (1996).

Article ADS CAS Google Scholar

Guo, T. & Tan, Y. W. Formation of one-dimensional Ag-Au solid solution colloids with Au nanorods as seeds, their alloying mechanisms, and surface plasmon resonances. Nanoscale 5 , 561–569 (2013).

Zhang, K. B. et al . Nanocrystalline CoCrFeNiCuAl high-entropy solid solution synthesized by mechanical alloying. J. Alloys Compd 485 , 31–34 (2009).

Zhang, K. B. et al . Characterization of nanocrystalline CoCrFeNiTiAl high-entropy solid solution processed by mechanical alloying. J. Alloys Compd. 495 , 33–38 (2010).

Kessler, V. G., Seisenbaeva, G. A., Unell, M. & Hakansson, S. Chemically Triggered Biodelivery Using Metal-Organic Sol-Gel Synthesis. Angew. Chem. Int. Ed. 47 , 8506–8509 (2008).

Jiang, Y. W., Yang, S. G., Hua, Z. H. & Huang, H. B. Sol-Gel Autocombustion Synthesis of Metals and Metal Alloys. Angew. Chem. Int. Ed. 48 , 8529–8531 (2009).

Hua, Z. H., Cao, Z. W., Deng, Y., Jiang, Y. W. & Yang, S. G. Sol-gel autocombustion synthesis of Co-Ni alloy powder. Mater. Chem. Phys. 126 , 542–545 (2011).

Li, P. Y., Syed, J. A. & Meng, X. K. Sol-gel preparation and characterization of NiCo and Ni 3 Fe nanoalloys. J. Alloys Compd. 512 , 47–51 (2012).

Jiang, Y. W., Yang, S. G., Hua, Z. H., Gong, J. F. & Zhao, X. N. Sol-gel auto-combustion synthesis of totally immiscible NiAg alloy. Mater. Res. Bull. 46 , 2531–2536 (2011).

Yeh, J. W., Chang, S. Y., Hong, Y. D., Chen, S. K. & Lin, S. J. Anomalous decrease in X-ray diffraction intensities of Cu-Ni-Al-Co-Cr-Fe-Si alloy systems with multi-principal elements. Mater. Chem. Phys. 103 , 41–46 (2007).

Yue, Z., Zhou, J., Li, L., Zhang, H. & Gui, Z. Synthesis of nanocrystalline NiCuZn ferrite powders by sol-gel combustion method. J. Magn. Magn. Mater. 208 , 55–60 (2000).

Manukyan, K. V. et al . Solution Combustion Synthesis of Nano-Crystalline Metallic Materials: Mechanistic Studies. J. Phys. Chem. C 117 , 24417–24427 (2013).

Sarkar, A. et al . Nanocrystalline multicomponent entropy stabilised transition metaloxides. J. Eur. Ceram. Soc 37 , 747–754 (2017).

Francis, A. J., Dodge, C. J. & Gillow, J. B. Biodegradation of metal citrate complexes and implications for toxic-metal mobility. Nature 356 , 140–142 (1992).

Kaliva, M. et al . A Unique Dinuclear Mixed V(V) Oxo-peroxo Complex in the Structural Speciation of the Ternary V(V)-Peroxo-citrate System. Potential Mechanistic and Structural Insight into the Aqueous Synthetic Chemistry of Dinuclear V(V)-Citrate Species with H 2 O 2 . Inorg. Chem. 50 , 11423–11436 (2011).

Article CAS PubMed Google Scholar

Greer, A. L. Confusion by design. Nature 366 , 303–304 (1993).

Article ADS Google Scholar

Shinde, S. R. et al . Co-occurrence of superparamagnetism and anomalous Hall effect in highly reduced cobalt-doped rutile TiO 2−δ films. Phys. Rev. Lett. 92 , 166601 (2004).

Download references

Acknowledgements

This work was financially supported by the Ministry of Science and Technology of the People’s Republic of China (2015DFR50650), the National Natural Science Foundation of China (51502220, 51521001, 51672197), and the Self-determined and Innovative Research Funds of WUT(2017II17XZ), and the Open Project Program of Key Laboratory of Inorganic Functional Materials and Devices, Chinese Academy of Sciences (Grant No.: KLIFMD201606).

Author information

Authors and affiliations.

State Key Laboratory of Advanced Technology for Materials Synthesis and Processing, Wuhan University of Technology, Wuhan, 430070, China

Bo Niu, Fan Zhang, Hang Ping, Na Li, Jieyang Zhou, Liwen Lei, Jingjing Xie, Jinyong Zhang, Weimin Wang & Zhengyi Fu

You can also search for this author in PubMed Google Scholar

Contributions

B. Niu and F. Zhang designed the research, carried out most experiments, analyzed data and wrote the manuscript. H. Ping, N. Li, and J.Y. Zhou performed the characterization. L.W. Lie, J.J. Xie and J.Y. Zhang supervised the research and analyzed the data. W.M.W. and Z.Y. Fu developed the theoretical model. F. Zhang and Z.Y. Fu proposed the idea and initiated the project. All authors discussed the results and revised the manuscript.

Corresponding authors

Correspondence to Fan Zhang or Zhengyi Fu .

Ethics declarations

Competing interests.

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Supporting information, rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Niu, B., Zhang, F., Ping, H. et al. Sol-gel Autocombustion Synthesis of Nanocrystalline High-entropy Alloys. Sci Rep 7 , 3421 (2017). https://doi.org/10.1038/s41598-017-03644-6

Download citation

Received : 10 March 2017

Accepted : 02 May 2017

Published : 13 June 2017

DOI : https://doi.org/10.1038/s41598-017-03644-6

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

This article is cited by

Preparation of high-entropy alloy bifunctional catalysts with rare earth ce coordination and efficient water splitting research.

- Zhang Wenyu

Ionics (2024)

Functional two-dimensional high-entropy materials

- Srinivasa Kartik Nemani

- Mohammad Torkamanzadeh

- Babak Anasori

Communications Materials (2023)

High entropy materials based electrocatalysts for water splitting: Synthesis strategies, catalytic mechanisms, and prospects

- Guoqing Guan

Nano Research (2023)

High-entropy catalysts for electrochemical water-electrolysis of hydrogen evolution and oxygen evolution reactions

Frontiers in Energy (2023)

Review of electrodeposition methods for the preparation of high-entropy alloys

- Zahra Shojaei

- Gholam Reza Khayati

- Esmaeel Darezereshki

International Journal of Minerals, Metallurgy and Materials (2022)

By submitting a comment you agree to abide by our Terms and Community Guidelines . If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

- school Campus Bookshelves

- menu_book Bookshelves

- perm_media Learning Objects

- login Login

- how_to_reg Request Instructor Account

- hub Instructor Commons

Margin Size

- Download Page (PDF)

- Download Full Book (PDF)

- Periodic Table

- Physics Constants

- Scientific Calculator

- Reference & Cite

- Tools expand_more

- Readability

selected template will load here

This action is not available.

11.6: Combustion Reactions

- Last updated

- Save as PDF

- Page ID 53784

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

How do you cook the perfect marshmallow?

Roasting marshmallows over an open fire is a favorite past-time for campers, outdoor cook-outs, and just gathering around a fire in the back yard. The trick is to get the marshmallow a nice golden brown without catching it on fire. Too often we are not successful and we see the marshmallow burning on the stick – a combustion reaction taking place right in front of us.

Combustion Reactions

A combustion reaction is a reaction in which a substance reacts with oxygen gas, releasing energy in the form of light and heat. Combustion reactions must involve \(\ce{O_2}\) as one reactant. The combustion of hydrogen gas produces water vapor:

\[2 \ce{H_2} \left( g \right) + \ce{O_2} \left( g \right) \rightarrow 2 \ce{H_2O} \left( g \right)\nonumber \]

Notice that this reaction also qualifies as a combination reaction.

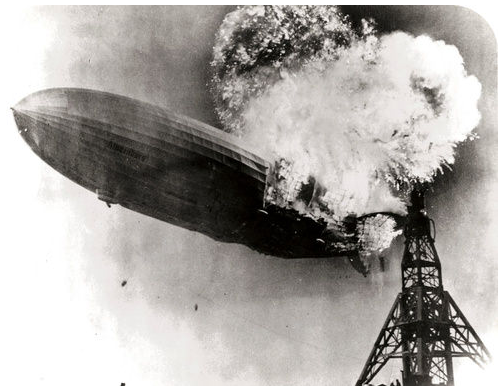

The Hindenberg was a hydrogen-filled airship that suffered an accident upon its attempted landing in New Jersey in 1937. The hydrogen immediately combusted in a huge fireball, destroying the airship and killing 36 people. The chemical reaction was a simple one: hydrogen combining with oxygen to produce water.

Many combustion reactions occur with a hydrocarbon, a compound made up solely of carbon and hydrogen. The products of the combustion of hydrocarbons are carbon dioxide and water. Many hydrocarbons are used as fuel because their combustion releases very large amounts of heat energy. Propane \(\left( \ce{C_3H_8} \right)\) is a gaseous hydrocarbon that is commonly used as the fuel source in gas grills.

\[\ce{C_3H_8} \left( g \right) + 5 \ce{O_2} \left( g \right) \rightarrow 3 \ce{CO_2} \left( g \right) + 4 \ce{H_2O} \left( g \right)\nonumber \]

Example \(\PageIndex{1}\): Combustion Reactions

Ethanol can be used as a fuel source in an alcohol lamp. The formula for ethanol is \(\ce{C_2H_5OH}\). Write the balanced equation for the combustion of ethanol.

Step 1: Plan the problem .

Ethanol and oxygen are the reactants. As with a hydrocarbon, the products of the combustion of an alcohol are carbon dioxide and water.

Step 2: Solve .

Write the skeleton equation:

\[\ce{C_2H_5OH} \left( l \right) + \ce{O_2} \left( g \right) \rightarrow \ce{CO_2} \left( g \right) + \ce{H_2O} \left( g \right)\nonumber \]

Balance the equation.

\[\ce{C_2H_5OH} \left( l \right) + 3 \ce{O_2} \left( g \right) \rightarrow 2 \ce{CO_2} \left( g \right) + 3 \ce{H_2O} \left( g \right)\nonumber \]

Step 3: Think about your result.

Combustion reactions must have oxygen as a reactant. Note that the water produced is in the gas state, rather than the liquid state, because of the high temperatures that accompany a combustion reaction.

- Combustion reaction is defined and examples are given.

- What is needed for a combustion reaction to take place?

- What is formed in any combustion reaction?

- Mercury reacts with oxygen to form mercuric oxide. Is this a combustion reaction?

- What are the products of any combustion reaction involving a hydrocarbon?

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers.

We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too.

Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective

Want to get in touch? Contact our London head office or media team here

Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing.

Home > Books > Developments in Combustion Technology

Solution Combustion Synthesis: Applications in Oxide Electronics

Reviewed: 30 June 2016 Published: 05 October 2016

DOI: 10.5772/64761

Cite this chapter

There are two ways to cite this chapter:

From the Edited Volume

Developments in Combustion Technology

Edited by Konstantinos G. Kyprianidis and Jan Skvaril

To purchase hard copies of this book, please contact the representative in India: CBS Publishers & Distributors Pvt. Ltd. www.cbspd.com | [email protected]

Chapter metrics overview

2,757 Chapter Downloads

Impact of this chapter

Total Chapter Downloads on intechopen.com

Total Chapter Views on intechopen.com

Oxide-based electronics have been well established as an alternative to silicon technology; however, typical processing requires complex, high-vacuum equipment, which is a major drawback, particularly when targeting low-cost applications. The possibility to deposit the materials by low-cost techniques such as inkjet printing has drawn tremendous interest in solution processible materials for electronic applications; however, high processing temperatures still required. To overcome this issue, solution combustion synthesis has been recently pursued. Taking advantage of the exothermic nature of the reaction as a source of energy for localized heating, the precursor solutions can be converted into oxides at lower process temperatures. Theoretically, this can be applied to any metal ions to produce the desired oxide, opening unlimited possibilities to materials’ composition and combinations. Solution combustion synthesis has been applied for the production of semiconductor thin films based on ZnO, In2O3, SnO2 and combinations of these oxides, and also for high κ dielectrics (Al2O3). All of which are required for numerous electronic devices and applications such as fully oxide-based thin-film transistors (TFTs). The properties of produced thin films are highly dependent on the precursor solution characteristics; hence, the influence of several processing parameters; organic fuel, solvent and annealing temperature was studied. Although precursor solution degradation/oxide formation mechanisms are not yet fully understood, particularly for thin films, we demonstrate that high-performance devices are obtained with combustion solution-based metal oxide thin films. The results clearly show that solution combustion synthesis is becoming one of the most promising methods for low-temperature flexible electronics.

- solution processing

- combustion synthesis

- environmentally friendly

- metal oxide materials

- thin-film transistors

- semiconductor oxides

- dielectric oxides

Author Information

Rita branquinho *.

- i3N/CENIMAT, Department of Materials Science, Faculty of Science and Technology, NOVA University of Lisbon and CEMOP/UNINOVA, Caparica, Portugal

Emanuel Carlos

Daniela salgueiro, pedro barquinha, rodrigo martins, elvira fortunato.

*Address all correspondence to: [email protected]

1. Introduction

1.1. solution combustion synthesis.

Solution combustion synthesis (SCS) is a popular method for the preparation of a wide variety of materials due to its simplicity, broad range of applicability and the possibility of easily obtaining products in the desired composition. This method has been widely used for the development of oxide powder materials; including perovskites, spinels, ferrites; for diverse applications, such as catalysis and solid oxide fuel cells [ 1 – 3 ] and is becoming one of the most convenient methods for the preparation of simple and multicomponent oxides for electronic applications [ 4 ].

SCS is based on a redox system that requires a solution that upon heating to moderate temperatures leads to the development of a strongly exothermic redox reaction, which generally provides the energy for the metal oxide formation. The ignition temperature of the exothermic reaction is significantly lower than the final combustion temperature which results in the material formation; thus allowing the conversion of solution precursors into oxides at lower process temperatures [ 1 – 3 ].

The precursor solution for combustion synthesis is typically constituted by metal nitrates, which are employed simultaneously as metal source and oxidizing agents, and an organic fuel that acts as a reducing agent. However when using metal chlorides, as a metal ion source, a combustion aid is required to provide the oxidizing nitrate ions; in this case, ammonium nitrate is typically used. The most frequently applied fuels are urea, acetylacetone and glycine, amongst others, since these can form stable complexes with metal ions to increase solubility and prevent selective precipitation of the metal ions in solution. This process produces oxide materials of good compositional homogeneity, which is especially important in the synthesis of multicomponent oxides. Historically, water is the most widely used solvent for the combustion synthesis of powder materials [ 1 – 3 ]. Recently, the pursuit of environmental friendly solvents for electronic applications, such as ethanol and water, is growing [ 5 – 7 ]; however, organic solvents, including 2-methoxyethanol and acetonitrile, are currently the most widely used for the production of oxide thin films for electronic applications purposes [ 5 ].

The resulting solution is then heated to evaporate the solvent and when ignition temperature is reached the exothermic reaction takes place. During the combustion reaction, the fuel is oxidized by the nitrate ions. The precursor materials are converted into the metal oxide, and gaseous H 2 O, CO 2 and N 2 are the remaining products formed in the combustion reaction. This process can in theory be applied to any desired metal ion.

The solution combustion synthesis of a metal oxide can be represented by the combination of metal nitrate decomposition reaction and fuel oxidation reaction. As an example, respective equations for the combustion synthesis of Al 2 O 3 from aluminium nitrate and using urea as fuel are given as follows [Eq. ( 1 ) and ( 2 )] [ 6 ].

The overall combustion reaction can thus be written as Eq. ( 3 )

Note that these are theoretical reaction equations that do not consider possible secondary reactions such as nitrates decomposition, urea hydrolysis, thermal decomposition and also fuel-oxidizer adducts; however, the overall reaction allows the calculation of a stoichiometric condition that can be used as a reference [ 3 , 6 ].

There are many essential variables in solution combustion synthesis, including metal ion, metal precursor type and concentration, content of organic fuel, combustion aid and oxidizer/fuel proportion; which is determinant for the thermodynamics of the oxide formation [ 2 ].

A concept for determining the stoichiometric proportion of oxidizer and fuel for SCS was adopted from the Jain method [ 8 ], which is based on propellant chemistry and allows the calculation of the reducing/oxidizing valences (OV/RV) of a redox mixture. In this method, oxygen and nitrogen are considered oxidizers with the respective valence of −2 and 0. On the other hand, carbon, hydrogen and metal ions are considered as reducing elements with their final valences of +4 and +1 and the corresponding metal valence, respectively. Consequently, urea has a reducing valence of +6 (RV = 4 + 4 × 1 + 2 × 0 − 2) whilst aluminium nitrate has an oxidizing valence of −15 (OV = 3 + 2 × 0 − 3 × 6), resulting in a 15/6 (or 5/2) reducing/oxidizing valences for an optimal stoichiometric redox mixture of urea-aluminium nitrate.

The relation between the redox stoichiometry and the molar ratio of reagents can be determined by the reducing/oxidizing valences (RV/OV) of the reagents and is given by Eq. ( 4 )

The oxygen consumption or production is controlled by the fuel/oxidizer ratio ( Ф ) which also depends on n; the number of moles of fuel per mole of oxidizer [ 1 – 3 ]. The optimal stoichiometry composition of the redox mixture is obtained for Ф = 1 that corresponds to a condition in which the reaction does not require any molecular oxygen to occur. For the given example of urea-aluminium nitrate redox mixture, 5 moles of urea are required per 2 moles of aluminium nitrate to assure redox stoichiometry of the aluminium oxide formation reaction, as depicted in Eq. ( 3 ) [ 6 ].

A fuel-lean condition is obtained when Ф < 1 and upon reaction molecular oxygen is produced; whereas when Ф > 1 molecular oxygen is required to fully convert the fuel and the redox mixture is in a fuel-rich regime [ 3 ].

1.2. Solution-based oxide electronics

The evolution from rigid silicon-based electronics to flexible electronics requires the use of new materials with novel functionalities that allow non-conventional, low-cost and environmental friendly processing technologies [ 9 , 10 ]. Metal oxide-based electronics have been well established as an alternative to silicon technology, demonstrating exceptional electronic performance as active semiconductor components, which can be tuned for the applications, where high transparency/electrical conductivity is demanded [ 11 , 12 ]. The major investment of several high-profile companies: SHARP, SAMSUNG, LG, BOE has led to the commercialization of oxide-based display backplanes in a very short period of time, and the global market is expected to increase [ 9 , 10 ]. The current typical processing techniques require complex high-vacuum equipment which is a major drawback, particularly when targeting low-cost applications.

Recently, the demands for low-cost flexible electronics has led to a remarkable development of solution-based production methods and solution-processed inorganic metal oxide semiconductor materials for high-performance thin-film transistors (TFTs), and such devices have demonstrated competitive results when compared with materials obtained by physical techniques [ 4 , 13 ].

Several solution-based chemical synthetic routes have been exploited for the preparation of these oxides because of their simplicity, versatility, and scale-up capability; however, the application of solution combustion synthesis to the production of thin films for TFT applications was first reported in 2011 [ 4 ]. Since then, significant research efforts have been put on the development of semiconductor materials such as indium oxide and indium, zinc tin and gallium-based multicomponent oxides [ 13 – 16 ] and more recently of dielectric materials [ 5 , 6 , 17 ]. However, most of the research as focussed on the use of toxic solvents (2-methoxyethanol) and scarce materials (indium), which can be a major drawback in the upscaling of this technology. Consequently, the challenge remains to unveil the combination of solution combustion synthesis processing parameters that allow an environmentally friendly production of high-quality insulator and semiconductor thin films at low temperature and their combination in fully combustion solution-processed TFTs.

In this work, we focus on the environmentally friendly solution combustion synthesis of oxide-based materials for electronic applications, including insulator and semiconductor thin films by studying the influence of synthetic and processing parameters, such as fuel type; solvent and annealing temperature, on their electrical properties. Fully combustion solution-processed indium-free AlO x /ZTO TFTs using ethanol as solvent were successfully produced demonstrating extremely promising performance for electronic applications.

2. Experimental details

2.1. precursor solution preparation and characterization.

The preparation of all precursor solutions was performed in a similar manner. Typically, the metal salts were dissolved in 25 mL of solvent, either 2-methoxyethanol (2-ME, C 3 H 8 O 2 , Fluka, 99%), ethanol (C 2 H 6 O, Merck, 99.5%) or deionized water, to yield solutions with the desired metal ion concentration. Then, the fuel (urea; CO(NH 2 ) 2 , Sigma, 98%) and ,if required, the combustion aid (ammonium nitrate; NH 4 NO 3 , Roth, 98%) were added to the prepared solutions which were maintained under constant stirring until complete dissolution. The urea to metal nitrate molar proportion was determined by the Jain method, as described in Section 1.1, to guarantee the redox stoichiometry of the reaction for each material; namely 1.6:1 for Zn 2+ metal ions and 2.5:1 for In 3+ and Al 3+ metal ions. In the case of metal chloride precursors, a combustion aid is required and the molar proportion of metal ion:NH 4 NO 3 :urea used was 1:1:1 for tin chloride solutions.

Semiconductor ZTO precursor solutions were prepared by mixing zinc oxide and tin oxide precursor solutions in a 2:1 proportion. Zinc oxide precursor solution was prepared as described earlier in 2-methoxyethanol or ethanol to yield solutions with 0.05 M concentration. Tin oxide precursor solutions were prepared by mixing tin chloride (SnCl 2 ⋅2H 2 O, Sigma, 98%), urea and ammonium nitrate to yield solutions with 0.05 M concentration. Individual solutions were magnetically stirred for 12 h before ZTO solution preparation.

Dielectric aluminium oxide precursor solutions were prepared by dissolving aluminium nitrate nonahydrate (Al(NO 3 ) 3 ⋅9H 2 O, Fluka, 98%) and urea in 2-methoxyethanol, ethanol or water, to yield solutions with 0.1 M concentration. Prior to their use, all solutions where magnetically stirred for at least 15 min and filtrated through a 0.45 µm hydrophilic filter. All reagents were used without further purification.

Thermal characterization of precursor solutions was performed by thermogravimetry and differential scanning calorimetry (TG-DSC). TG-DSC analyses were performed on precursors dried for 12 h at 80°C under air atmosphere up to 550°C with a 10°C/min heating rate in an aluminium crucible using a Simultaneous Thermal Analyzer, Netzsch (TGA-DSC—STA 449 F3 Jupiter).

2.2. Thin-film deposition and characterization

Prior to deposition all substrates (silicon wafer and soda-lime glass) were cleaned in an ultrasonic bath at 60°C in acetone for 15 min, then in 2-isopropanol for 15 min. and dried under N 2 ; followed by a 30 min. UV/Ozone surface activation step using a PSD-UV Novascan system. Thin films were deposited by spin coating the precursor solutions at 2000 rpm for 35 s (Laurell Technologies) followed by an immediate hotplate annealing in ambient conditions; this procedure was repeated to obtain the desired thickness.

The films’ structure was assessed by glancing angle X-ray diffraction (GAXRD) performed by an X’Pert PRO PANalytical powder diffractometer using with Cu Kα line radiation (λ = 1.540598 Å) with angle of incidence of the X-ray beam fixed at 0.9°. The surface morphology was investigated by atomic force microscopy (AFM, Asylum MFP3D) and scanning electron microscopy (SEM-FIB, Zeiss Auriga Crossbeam microscope). Cross section of produced films and devices was performed by focussed ion beam (FIB). In FIB milling experiments, Ga + ions were accelerated to 30 kV at 5 pA and the etching depth was around 250 nm. Spectroscopic ellipsometry measurements of thin films deposited on silicon substrates were made over an energy range of 1.5–6.0 eV with an incident angle of 70° using a Jobin Yvon Uvisel system to determine film thickness.

2.3. Electronic device fabrication and characterization

Metal-insulator-semiconductor (MIS) capacitors were produced by AlO x thin-film deposition onto p-type silicon substrates (1–10 Ω cm) as described earlier (see section 2.2). Aluminium gate electrodes (100 nm thick) with an area of 8.7 × 10 −3 cm 2 were deposited by thermal evaporation via shadow mask. A 100-nm-thick aluminium film was also deposited on the back of the silicon wafer to improve electrical contact. Electrical characterization was performed measuring both the capacitance-voltage and capacitance-frequency characteristics in the range off 10 kHz to 1 MHz of the devices using a semiconductor characterization system (Keithley 4200SCS).

Thin-film transistors (TFTs) were produced in a staggered bottom-gate, top-contact structure by depositing AlO x thin films onto p-type silicon substrates (1–10 Ω cm) as described earlier. The semiconductor layer was deposited by sequentially spin coating four layers of semiconductor precursor solution 0.05 M onto the AlO x thin films and annealed in air at 350°C for 30 min after each layer deposition. For comparison, AlO x /IGZO TFTs were also produced with sputtered IGZO thin films. IGZO thin films were fabricated in a AJA ATC-1300F sputtering system using a IGZO target with 2:1:1 composition (in In 2 O 3 :Ga 2 O 3 :ZnO molar ratio). Deposition was carried out in Ar+O 2 atmosphere at a pressure of 2.3 mTorr and r.f. power of 100 W, to obtain a 30 nm thick film. Post-processing annealing was performed in air on a hotplate at 180°C for 1 h. Finally, source and drain aluminium electrodes (100 nm thick) were deposited by e-beam evaporation via shadow mask onto annealed films, defining a channel width ( W ) and length ( L ) of 1400 µm and 10 µm, respectively ( W / L = 14). Electrical characterization was performed by the measurement of current-voltage characteristics of the devices using a semiconductor parameter analyser (Agilent 4155C) attached to a microprobe station (Cascade M150) inside a dark box, at room temperature. The saturation mobility (µ SAT ) was determined from the following equation: [ 18 ]

where C i is the gate dielectric capacitance per unit area, W and L are the channel width and length, V G is the gate voltage and V T is the threshold voltage, which was determined in the saturation region by linear fitting of a I D 1/2 vs. V G plot.

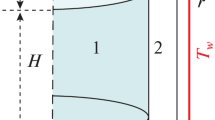

The core of oxide-based electronics for displays applications are thin-film transistors (TFTs). Figure 1 shows a schematic representation of a TFT structure and respective transfer plot. TFTs are three terminal field-effect devices, whose working principle relies on the modulation of the current flowing in a semiconductor placed between two electrodes (source and drain). A dielectric layer is inserted between the semiconductor and a transversal electrode (gate), being the current modulation achieved by the capacitive injection of carriers close to the dielectric/semiconductor interface, known as field effect [ 12 ].

Schematic representation of a bottom-gate TFT structure and typical field effect electrical characteristics plot.

The semiconductor and gate insulator are equally important material components in field-effect transistors; consequently, the development of both materials by solution techniques is essential [ 6 ].

3.1. Amorphous semiconductor oxides

Amorphous oxide semiconductors (AOSs) have drawn significant attention in the field of flat panel displays during the last decade, due to their high carrier mobility when compared to amorphous silicon (a-Si). Indium-gallium-zinc oxide (IGZO) is the most explored semiconductor due to its superior field effect mobility and enhanced electrical performance [ 11 , 12 ]. However, alternative semiconductor materials that rely on abundant and non-toxic elements are required due to environmental demands. Zinc-tin-oxide (ZTO) is a promising indium and gallium-free alternative and impressive results have already been obtained in TFTs applications [ 19 , 20 ].

Several solution-processed ZTO-based TFTs have been reported; however, processing temperature above 400°C and a toxic organic solvent, such as acetonitrile, 2-ethoxyethanol or 2-methoxyethanol are usually required [ 5 ]. The use of non-toxic solvents has been pursued and ethanol [ 5 ] and water [ 7 ] based ZTO TFTs have already been reported.

The decomposition of urea [Eq. ( 2 )] and zinc nitrate [Eq. ( 6 )] is represented as follows.

The overall ZnO formation reaction can thus be written as follows Eq. ( 7 ).

Using the Jain method, the reducing valence of urea is +6 and the oxidizing valence of zinc nitrate is –10. In order to assure the redox stoichiometry 5/3 (or 1.6), moles of urea are required per mole of zinc nitrate.

The tin oxide formation can be represented by the following equation:

In the combustion synthesis of tin oxide, a combustion aid, ammonium nitrate, was added to the precursor solution as commonly performed for chlorine-based metal salts. According to Jain’s method, the oxidizer valence of ammonium nitrate (NH 4 NO 3 ) is −2 and to achieve Ф = 1 0.3 mol of urea per mole of ammonium nitrate are required. In this case, a fuel-rich condition, Ф > 1, was used to ensure the full oxidation of the metal precursor.

ZTO precursor solution was prepared after mixing individual of zinc and tin oxide precursor solutions of 0.05 M concentration in a 2:1 proportion, respectively. Thermal analysis of ZTO precursor solutions was performed to investigate the influence of solvent on their decomposition behaviour. TG-DSC measurements were performed on precursors dried for 12 h at 80°C. Figure 2 shows the DSC results for ZTO precursors up to 350°C as above this temperature no further events were observed.

The combustion reaction of the organic fuel with the metal nitrates typically leads to an intense exothermic peak with corresponding abrupt mass loss. For ZTO precursors, these were observed at 125°C and 108°C for 2-ME and ethanol-based solutions, respectively. A smaller peak is observed at 275°C which can be related to secondary reactions [ 3 , 4 ] that can occur during thermal decomposition of the reagents.

TG-DSC analysis of ZTO-based precursor solutions using 2-methoxyethanol (2-ME) and ethanol as solvent. Adapted from [ 5 ].

The precursor solution degradation mechanism is expected to be different in bulk and thin-film form which explains the need for higher thin-film processing temperature than the one determined by thermal analysis. Devices annealed at temperatures below 350°C did not show effective gate modulation as such, the processing temperature was fixed at this temperature although the minimum temperature required for full degradation of the precursors is 275°C.

Structural characterization of the films ( Figure 3a ) indicates that amorphous films are obtained up to 350°C for both precursor solution solvents, as no diffraction peaks were observed. Morphological surface analysis show that smooth and uniform films are obtained regardless of solvent; however, 2-ME-based ZTO films demonstrate a lower surface roughness, 0.2 nm, when compared to ethanol-based films; 5 nm.

Structural and morphological analysis of 2-methoxyethanol (2-ME) and ethanol-based ZTO thin films produced at 350°C: a) XRD, b) AFM, c) SEM.

Combustion solution-based ZTO TFTs were produced by spin-coating precursor solutions onto commercial Si/SiO 2 substrates. Electrical characterization of TFTs was performed by measuring the transfer and output characteristics of the devices in ambient conditions in the dark. Figure 4 shows a cross section SEM image of ZTO TFTs produced on Si/SiO 2 , with Al source-drain electrodes, obtained after FIB milling and electrical characterization of 2-ME and ethanol-based ZTO TFTs.

Electrical and morphological characterization of ZTO/SiO 2 TFTs produced at 350°C: transfer and output characteristics of a) 2-methoxyethanol (2-ME) and b) ethanol-based ZTO/SiO 2 TFTs. c) SEM-FIB cross section of a ZTO/SiO 2 TFT.

The analysis of the electrical characteristics reveals that ZTO TFTs show an I on / I off above 10 6 , saturation mobility of 2 cm 2 /V⋅s, low subthreshold swing and low hysteresis. Output characteristics exhibit saturation suggesting a low background carrier concentration and anticipate the absence of transconductance degradation as V GS increases, revealing good dielectric/semiconductor interface properties and no significant carrier injection problems. These devices exhibit high operational stability under positive gate bias stress [ 21 ]. Combustion synthesis-based ZTO thin films thus demonstrate high potential for alternative and environmental friendly solution-based electronic applications, allowing their use as reliable switching elements in active matrices.

3.2. Dielectric oxides

Insulator materials suitable for TFT gate dielectric applications must fulfil some criteria, namely i) high bang gap, with favourable conduction band offset to avoid high gate leakage; ii) high dielectric constant (high-κ) the added capacitance can compensate interface traps, thus improving the transistor performance and allow low operating voltage; iii) good interface properties, which can be achieved using amorphous dielectrics [ 11 , 22 , 23 ].

Solution-based high-κ dielectrics, such as Al 2 O 3 , HfO 2 , ZrO 2 , have demonstrated high performance and suitability for the application in metal oxide semiconductor-based TFTs [ 5 , 6 , 17 , 24 – 28 ]. Amongst these, aluminium oxide is one of the most developed materials from solution synthesis since several aluminium precursors salts are readily availability at low cost. The influence of processing parameters on the solution combustion synthesis of aluminium oxide was studied.

The decomposition reactions for aluminium, urea and the overall aluminium oxide formation reaction are already represented by Eq. ( 1 ), ( 2 ) and ( 3 ), respectively. According to Jain’s method and to ensure redox stoichiometry, 2.5 mol of urea per mole of aluminium nitrate were used to prepare aluminium oxide precursor solutions with 0.1 M concentration. The influence of several processing parameters such as fuel, solvent and annealing temperature on the properties of dielectric AlO x thin films was studied.

Thermal analysis of AlO x precursor solutions was performed to investigate the influence of solvent on their decomposition behaviour. Figure 5 shows the DSC results for AlO x precursors prepared with 2-methoxethanol, ethanol and water.

TG-DSC analysis of AlO x -based precursor solutions: a) non-combustion AlO x precursor using 2-methoxyethanol (2-ME) and b) combustion AlO x precursor using 2-ME, ethanol and water as solvent.

Thermal behaviour of AlO x precursor solutions is strongly affected by the presence of urea, which acts as fuel; when no fuel is added only endothermic peaks corresponding to solvent evaporation (water at 95°C and 2-methoxyethanol at 125°C) which is the main component of the solution with a corresponding 60% mass loss and subsequent organics decomposition (235°C) are observed, meaning that additional energy must be supplied to promote oxide formation. On the other hand, when urea is added in a stoichiometric proportion an intense exothermic peak with corresponding abrupt mass loss at about 180°C is observed. This exothermic event is attributed to the combustion reaction of the organic fuel with the metal nitrates; a smaller peak at 250°C is also observed and can be related to the degradation of residual organics. Thermal behaviour of combustion AlO x precursor solutions does not shown significant variations when using different solvents. The influence of solvent in the oxide formation reaction is apparently more significant for multicomponent oxides, such as ZTO ( Figure 2 ).

Thin films of AlO x were produced by spin-coating precursor solution onto a substrate (either soda-lime glass or Si) and annealing on a hotplate for 30 min. The influence of several processing parameters on the structural and morphological properties of dielectric AlO x thin films obtained from 0.1 M concentration solutions was studied. XRD, SEM and AFM characterization of the AlO x thin films was performed and Figure 6 shows typical data obtained for AlO x thin films produced at 350°C from 2-methoxyethanol, ethanol and water-based precursor solutions.

Structural and morphological analysis of combustion solution AlO x thin films produced at 350°C: a) XRD, b) SEM and c) AFM of water-based films. Inset show gate current density.

Generally, structural and morphological properties of AlO x thin films did not vary significantly regardless of processing parameters within the studied range. The variation of precursor solution’s solvent does not influence the structural properties of the films, which is in agreement with that observed for DSC measurements. Morphological properties are slightly influenced by the solvent used with rms film roughness increasing from 0.3 nm when using 2ME or ethanol to 0.9 nm for water-based films. Fuel content and annealing temperature also do not affect structural and morphological properties as amorphous, highly uniform and smooth AlO x thin films with rms roughness of below 1 nm were consistently obtained at 350°C. The properties demonstrated by these aluminium oxide thin films produced from solution synthesis are highly desirable for electronic applications as low surface roughness leads to enhanced interface properties.

The effect of processing parameters on the electrical properties of these films was studied by assessing the electrical performance of capacitors and thin-film transistors comprising the solution-based AlO x films.

Solution-based AlO x capacitors were produced by spin-coating AlO x precursor solutions onto commercial Si substrates followed by aluminium gate contact deposition by thermal evaporation. The effect of processing parameters on the electrical performance of these devices was studied and Figure 7 shows capacitance-voltage measurements for different fuel, using either urea, citric acid or no fuel; and annealing temperature, 350, 250 and 200°C. The effect of precursor solution solvent variation has already been reported elsewhere [ 6 ].

Electrical characterization of AlO x capacitors produced with different parameters: a) fuel variation in 2-ME; b) temperature variation for 2-methoxyethanol-based films. Inset show gate current density.

The electrical characteristics of AlO x capacitors produced with no fuel show a non-uniform capacitance variation at −3 to −2 V indicating the presence of organic residues within the film such as nitrate groups; these ions favour water adsorption leading to higher capacitance due to the high dielectric constant of water, as previously observed [ 6 , 29 ]. To improve film properties, when a non-combustion synthesis route is applied, either higher temperature or UV-assisted annealing is currently being used [ 26 , 30 ]. When citric acid is added as fuel low capacitance and high current density is observed, this is consistent with more porous AlO x films and in fact their application as gate dielectric in TFTs was not successful as only short-circuited devices were obtained. Urea leads to consistent one domain capacitance characteristics and low current density within TFT operating voltage range as required for gate dielectric applications. The film properties are highly affected by processing temperature due to inefficient organics removal; at 250°C a two domain system is obtained, similar to that observed for non-combustion synthesis route, and at 200°C large hysteresis indicates an increase in charge defects concentration consistent with organic impurities within the film. Although from DSC analysis, the ignition temperature of AlO x combustion reaction was determined to be 180°C, still higher temperature is required to obtain thin films with desirable dielectric properties. This inconsistency between thermal analysis and electrical properties obtained at low temperature is attributed to the difference between bulk and film decomposition processes.

IGZO TFTs comprising combustion solution-based AlO x gate dielectric were produced by sputtering IGZO semiconductor layer onto annealed AlO x thin films and finally evaporating aluminium source/drain contacts. The use of a standard sputtered semiconductor allowed the assessment of the TFTs performance variation solely due to the dielectric layer’s processing parameters influence. Electrical characterization of TFTs was performed by measuring the electrical characteristics of the devices in ambient conditions in the dark ( Figure 8 ).

Electrical characterization of IGZO/AlO x TFTs produced at different temperatures using a) 2-methoxyethanol and b) water as solvent.

TFT performance is assessed trough the analysis of the turn-on voltage ( V ON ), the threshold voltage ( V T ), drain current on-off ratio ( I ON /I OFF ), subthreshold slope ( S ) and saturation mobility ( µ SAT ), which was calculated using AlO x capacitance at the 10 kHz in order to minimize overestimation. Electrical characteristics of these devices are presented in Table 1 .

Electrical characteristics of solution-based IGZO/AlO x TFTs.

Despite the non-ideal capacitance-voltage characteristics obtained for low-temperature AlO x thin films, IGZO/AlO x TFTs were successfully produced. Similarly to what is obtained for capacitors the TFTs performance is highly dependent on annealing temperature. For both solvents used, 2-methoxyethanol and water, enhanced properties are obtained for 350°C and similar trend with temperature variation is observed which is in agreement with DSC-TG analysis. For lower temperatures, a hysteresis increase and on/off current ratio decrease is observed, being more significant for 200°C, due to oxide charge defects within the dielectric as a consequence of incomplete organic residues removal. Nevertheless, successful gate modulation at low operation voltage, due to the higher capacitance achieved with very thin AlO x films, was obtained for all devices which demonstrated close to zero V ON , high I ON , high saturation mobility and low subthreshold swing as required for electronic applications.

3.3. Fully solution-based oxide TFTs

The realization of printed electronics requires all solution-based devices; consequently, semiconductor and dielectric materials must be combined in TFTs. Fully combustion-solution-based TFTs comprising the developed dielectric and semiconductor materials have been successfully fabricated. Figure 9 shows transfer characteristics of these devices [ 5 , 6 ].

Transfer characteristics of fully combustion solution-based bottom gate TFTs produced at 350°C on highly doped p-Si (gate) with a) 2ME-based ZTO and AlO x , b) ethanol-based ZTO and AlO x , and c) 2ME-based GZTO and water-based AlO x . Adapted from [ 5 , 6 ].

The combination of solution-processed dielectric and semiconductors yielded TFTs with a good overall performance, demonstrating very low clockwise hysteresis, close to zero V ON and I ON /I OFF above 10 4 . Generally, 2ME-based devices show better performance when compared to more environmental friendly ethanol; saturation mobility increases from 0.8 cm 2 /V⋅s to 2.3 cm 2 /V⋅s for ZTO/AlO x TFTs, also 2ME GZTO shows µ SAT of 1.3 cm 2 /V⋅s when combined with water-based AlO x . These differences in device performance are attributed to trapped charges at the semiconductor-insulator interface as consequence of the semiconductor films’ composition and rougher morphology of ethanol-based films [ 5 , 6 ]. The high I OFF observed mainly arises from the use of non-patterned semiconductor layers which can be improved by implementing patterning techniques. The combination of AlO x dielectrics and ZTO-based semiconductors yielded very promising results for application in fully solution-processed electronics; however, the processing temperature required for good TFT performance was 350°C which is still too high for flexible substrates. Nevertheless, these results are within the state-of-the-art for solution-processed ZTO TFTs using different solvents ( Table 2 ).

Selected processing details for reported solution-based ZTO TFTs.

Transfer characteristics of fully combustion-solution-based InO x /AlO x TFTs produced from 2ME precursors using a maximum processing temperature of 200°C.

The use of indium-free semiconductor materials, such as ZTO and GZTO, although environmentally relevant somehow lead to a compromise of solution-processed TFTs performance both in saturation mobility and processing temperature.

Fully solution-based TFTs were obtained at maximum processing temperature of 200°C when combining the developed 2-methoxyethanol-based AlO x dielectric with solution-based indium oxide semiconductor produced using UV-assisted low-temperature annealing as reported in [ 36 ]. Transfer characteristics of low-temperature InO x /AlO x TFTs are depicted in Figure 10 .

In O x /AlO x TFTs showed higher saturation mobility (µ SAT = 5.6 cm 2 V −1 s −1 ) when compared to indium-free devices processed at higher temperatures and otherwise similar electrical performance whilst at the same time being compatible with polymeric substrates for flexible electronics applications.

4. Conclusions

The application of solution combustion synthesis to prepare oxide materials for electronic devices was successfully achieved for dielectric and semiconductor thin films using varied processing parameters. We have clearly demonstrated that dielectric AlO x thin films can be obtained using green solvents such as ethanol and water and successfully combined with ethanol-based ZTO semiconductor layers to yield fully combustion solution-based TFTs. Although electrical properties of these solution-processed TFTs are still far for what is required in AMTFT displays applications, successful preparation and combination of dielectric and semiconductor oxides films by a relatively low-temperature solution process represents a significant achievement and an advancement towards environmentally friendly production process. The facile applicability of SCS to other metal precursors opens numerous possibilities for low temperature synthesis of oxides materials and thin films required for the development of all solution-based devices. The mechanisms behind precursor degradation/oxide formation process are not yet fully understood so the challenge remains to unravel the ideal combination of solvent, oxidizer and organic fuel to obtain high-quality materials and properties. Nevertheless, this versatile synthesis method combined with innovative low-temperature annealing processes will continue to play a major role in the future development flexible electronics.

Acknowledgments

This work was partly funded by FEDER funds through the COMPETE 2020 Programme and National Funds through FCT—Portuguese Foundation for Science and Technology under the projects POCI-01-0145-FEDER-007688, Reference UID/CTM/50025 and EXCL/CTM-NAN/0201/2012; European Community FP7 2007-2013 project i-FLEXIS Grant Agreement n. 611070. D. Salgueiro acknowledges FCT-MEC for doctoral grant SFRH/BD/110427/2015. Authors would like to acknowledge J. V. Pinto for XRD, D. Nunes for SEM-FIB and T. Sequeira for AFM measurements.

- 1. M. Epifani, E. Melissano, G. Pace, and M. Schioppa, “Precursors for the combustion synthesis of metal oxides from the sol-gel processing of metal complexes,” J. Eur. Ceram. Soc., vol. 27, no. 1, pp. 115–123, 2007.

- 2. Z. Shao, W. Zhou, and Z. Zhu, “Advanced synthesis of materials for intermediate-temperature solid oxide fuel cells,” Prog. Mater. Sci., vol. 57, no. 4, pp. 804–874, 2012.

- 3. S. L. Gonzalez-Cortes and F. E. Imbert, “Fundamentals, properties and applications of solid catalysts prepared by solution combustion synthesis (SCS),” Appl. Catal. A Gen., vol. 452, pp. 117–131, 2013.