- Case Studies

- Free Coaching Session

Production Plan in Business Plan: A Comprehensive Guide to Success

Last Updated:

February 26, 2024

In any business venture, a solid production plan is crucial for success. A production plan serves as a roadmap that outlines the steps, resources, and strategies required to manufacture products or deliver services efficiently. By carefully crafting a production plan within a business plan, entrepreneurs can ensure optimal utilisation of resources, timely delivery, cost efficiency, and customer satisfaction. In this article, we will delve into the intricacies of creating an effective production plan in a business plan , exploring its key components, strategies, and the importance of aligning it with overall business objectives .

Key Takeaways on Production Plans in Business Planning

- A production plan : a detailed outline that guides efficient product manufacturing or service delivery.

- Importance of a production plan : provides a roadmap for operations, optimises resource utilisation, and aligns with customer demand.

- Key components : demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance.

- Strategies : lean manufacturing, JIT inventory, automation and technology integration, supplier relationship management, and continuous improvement.

- Benefits of a well-executed production plan : improved efficiency, reduced costs, enhanced product quality, and increased profitability.

What is a Production Plan?

A production Seamless Searches plan is a detailed outline that specifies the processes, resources, timelines, and strategies required to convert raw materials into finished goods or deliver services. It serves as a blueprint for the entire production cycle, guiding decision-making and resource allocation. The production plan considers factors such as demand forecasting, capacity planning, inventory management, and quality assurance to ensure efficient operations and optimal customer satisfaction.

Why is a Production Plan Important in a Business Plan?

The inclusion of a production plan in a business plan is vital for several reasons. First and foremost, it provides a clear roadmap for business operations, helping entrepreneurs and managers make informed decisions related to production processes. A well-developed production plan ensures that resources are utilised efficiently, minimising wastage and optimising productivity.

Additionally, a production plan allows businesses to align their production capabilities with customer demand. By forecasting market trends and analysing customer needs, businesses can develop a production plan that caters to current and future demands, thus avoiding overstocking or understocking situations.

Furthermore, a production plan helps businesses enhance their competitive advantage. By implementing strategies such as lean manufacturing and automation, companies can streamline their production processes, reduce costs, improve product quality, and ultimately outperform competitors.

Key Components of a Production Plan

To create an effective production plan, it is crucial to consider several key components. These components work together to ensure efficient operations and successful fulfilment of customer demands. Let's explore each component in detail.

Demand Forecasting

Demand forecasting is a critical aspect of production planning. By analysing historical data, market trends, and customer behaviour, businesses can predict future demand for their products or services. Accurate demand forecasting allows companies to optimise inventory levels, plan production capacity, and ensure timely delivery to customers.

One approach to demand forecasting is quantitative analysis, which involves analysing historical sales data to identify patterns and make predictions. Another approach is qualitative analysis, which incorporates market research, customer surveys, and expert opinions to gauge demand fluctuations. By combining both methods, businesses can develop a robust demand forecast, minimising the risk of underproduction or overproduction. Utilising a free notion template for demand forecasting can further streamline this process, allowing businesses to organise and analyse both quantitative and qualitative data efficiently in one centralised location.

Capacity Planning

Capacity planning involves determining the optimal production capacity required to meet projected demand. This includes assessing the production capabilities of existing resources, such as machinery, equipment, and labour, and identifying any gaps that need to be addressed. By conducting a thorough capacity analysis, businesses can ensure that their production capacity aligns with customer demand, avoiding bottlenecks or excess capacity.

An effective capacity plan takes into account factors such as production cycle times, labour availability, equipment maintenance, and production lead times. It helps businesses allocate resources efficiently, minimise production delays, and maintain a consistent level of output to meet customer expectations.

Inventory Management

Efficient inventory management is crucial for a successful production plan. It involves balancing the cost of holding inventory with the risk of stockouts. By maintaining optimal inventory levels, businesses can reduce carrying costs while ensuring that sufficient stock is available to fulfil customer orders.

Inventory management techniques, such as the Economic Order Quantity (EOQ) model and Just-in-Time (JIT) inventory system, help businesses strike the right balance between inventory investment and customer demand. These methods consider factors such as order frequency, lead time, and carrying costs to optimise inventory levels and minimise the risk of excess or insufficient stock.

Resource Allocation

Resource allocation plays a pivotal role in a production plan. It involves assigning available resources, such as labour, materials, and equipment, to specific production tasks or projects. Effective resource allocation ensures that resources are utilised optimally, avoiding underutilisation or overutilisation.

To allocate resources efficiently, businesses must consider factors such as skill requirements, resource availability, project timelines, and cost constraints. By conducting a thorough resource analysis and implementing resource allocation strategies, businesses can streamline production processes, minimise bottlenecks, and maximise productivity.

Quality Assurance

Maintaining high-quality standards is essential for any production plan. Quality assurance involves implementing measures to monitor and control the quality of products or services throughout the production process. By adhering to quality standards and conducting regular inspections, businesses can minimise defects, ensure customer satisfaction, and build a positive brand reputation.

Quality assurance techniques, such as Total Quality Management (TQM) and Six Sigma , help businesses identify and rectify any quality-related issues. These methodologies involve continuous monitoring, process improvement, and employee training to enhance product quality and overall operational efficiency.

In addition to the core components of a production plan, it's also important for businesses to consider the broader aspects of their business strategy, including marketing and advertising. Understanding the costs and returns of different marketing approaches is crucial for comprehensive business planning. For instance, direct response advertising costs can vary significantly, but they offer the advantage of measurable responses from potential customers. This type of advertising can be a valuable strategy for businesses looking to directly engage with their target audience and track the effectiveness of their marketing efforts.

Strategies for Developing an Effective Production Plan

Developing an effective production plan requires implementing various strategies and best practices. By incorporating these strategies into the production planning process, businesses can optimise operations and drive success. Let's explore some key strategies in detail.

Lean Manufacturing

Lean manufacturing is a systematic Seamless Searches approach aimed at eliminating waste and improving efficiency in production processes. It emphasises the concept of continuous improvement and focuses on creating value for the customer while minimising non-value-added activities.

By adopting lean manufacturing principles, such as just-in-time production, standardised work processes, and visual management, businesses can streamline operations, reduce lead times, and eliminate unnecessary costs. Lean manufacturing not only improves productivity but also enhances product quality and customer satisfaction.

Just-in-Time (JIT) Inventory

Just-in-Time (JIT) inventory is a strategy that aims to minimise inventory levels by receiving goods or materials just when they are needed for production. This strategy eliminates the need for excess inventory storage, reducing carrying costs and the risk of obsolete inventory.

By implementing a JIT inventory system, businesses can optimise cash flow, reduce storage space requirements, and improve overall supply chain efficiency. However, it requires robust coordination with suppliers, accurate demand forecasting, and efficient logistics management to ensure timely delivery of materials.

Automation and Technology Integration

Automation and technology integration play a crucial role in modern production planning. By leveraging technology, businesses can streamline processes, enhance productivity, and reduce human error. Automation can be implemented in various aspects of production, including material handling, assembly, testing, and quality control.

Continuous Improvement

Continuous improvement is a fundamental principle of effective production planning. It involves regularly evaluating production processes, identifying areas for improvement, and implementing changes to enhance efficiency and quality.

By fostering a culture of continuous improvement, businesses can drive innovation, optimise resource utilisation, and stay ahead of competitors. Techniques such as Kaizen, Six Sigma, and value stream mapping can help businesses identify inefficiencies, eliminate waste, and streamline production workflows.

Frequently Asked Questions (FAQs)

What is the role of a production plan in business planning.

A1: A production plan plays a crucial role in business planning by providing a roadmap for efficient production processes. It helps align production capabilities with customer demand, optimise resource utilisation, and ensure timely delivery of products or services.

How does a production plan affect overall business profitability?

A2: A well-developed production plan can significantly impact business profitability. By optimising production processes, reducing costs, and enhancing product quality, businesses can improve their profit margins and gain a competitive edge in the market.

What are the common challenges faced in production planning?

A3: Production planning can present various challenges, such as inaccurate demand forecasting, capacity constraints, supply chain disruptions, and quality control issues. Overcoming these challenges requires robust planning, effective communication, and the implementation of appropriate strategies and technologies.

What is the difference between short-term and long-term production planning?

A4: Short-term production planning focuses on immediate production requirements, such as daily or weekly schedules. Long-term production planning, on the other hand, involves strategic decisions related to capacity expansion, technology investments, and market expansion, spanning months or even years.

How can a production plan be adjusted to accommodate changes in demand?

A5: To accommodate changes in demand, businesses can adopt flexible production strategies such as agile manufacturing or dynamic scheduling. These approaches allow for quick adjustments to production levels, resource allocation, and inventory management based on fluctuating customer demand.

In conclusion, a well-crafted production plan is essential for business success. By incorporating a production plan into a comprehensive business plan, entrepreneurs can optimise resource utilisation, meet customer demands, enhance product quality, and drive profitability. Through effective demand forecasting, capacity planning, inventory management, resource allocation, and quality assurance, businesses can streamline production processes and gain a competitive edge in the market.

Related Articles:

Client Success!! Watch THIS >>>

Client Success - Case Study

© 2016 - 2024 Robin Waite. All rights reserved.

- Contact sales

Start free trial

Production Planning 101: Making a Production Plan (Example Included)

As the creation of products and services has become more extensive and varied, the manufacturing industry has become more competitive. There are many things to keep an eye on such as material requirements planning, supply chain management and inventory control. Operations continue to become more complex, meaning manufacturing companies require more thorough production planning.

A production plan is the best way to guarantee you deliver high-quality products or services as efficiently as possible.

What Is Production Planning?

Production planning is the process of deciding how a product or service will be manufactured before the manufacturing process begins. In other words, it’s how you plan to manage your supply chain, raw materials, employees and the physical space where the manufacturing process occurs.

Production planning is important for manufacturers as it affects other important aspects of their business such as:

- Supply chain management

- Production scheduling

- Material requirements planning

- Production lead time

- Capacity planning

ProjectManager is project management software that helps manufacturers cover every aspect of production planning. Plan with Gantt charts, execute with kanban boards and manage resources along the way. No other software offers sophisticated project and resource management features in one intuitive package. Get started today for free.

Why Is Production Planning Important?

If a manufacturing operation wishes to expand, that evolution demands careful production planning and scheduling. Someone must take on the responsibility of managing resources and deciding how they’ll be allocated. This process is a big part of capacity planning —how much can be made in a certain period, with the available resources?

Without production planning, it’s easy to use too much of a resource for one product and not leave enough for another, or fail to schedule your resources properly, which results in delays that affect your overall production management process. It’s just as easy to let resources go to waste. These issues indicate a lack of efficiency in your production planning process.

Production planning is the best way to ensure resources are used appropriately, products and services are high-quality and nothing goes over budget . In most organizations, a production manager manages the production planning process.

What Does a Production Planner Do?

A production planner is a team leader who oversees the production planning process, which defines how an organization will approach major areas of production management such as production scheduling, resource capacity planning, production control and production budgeting to manufacture products.

To better understand what a production planner does and the importance of this role in any manufacturing organization, let’s dive into each of the steps of the production planning process.

10 Steps of the Production Planning Process

The production planning process consists of an organization’s actions to make a production strategy that allows it to manufacture products most efficiently and profitably. Here are 10 key steps you should follow when planning your production process.

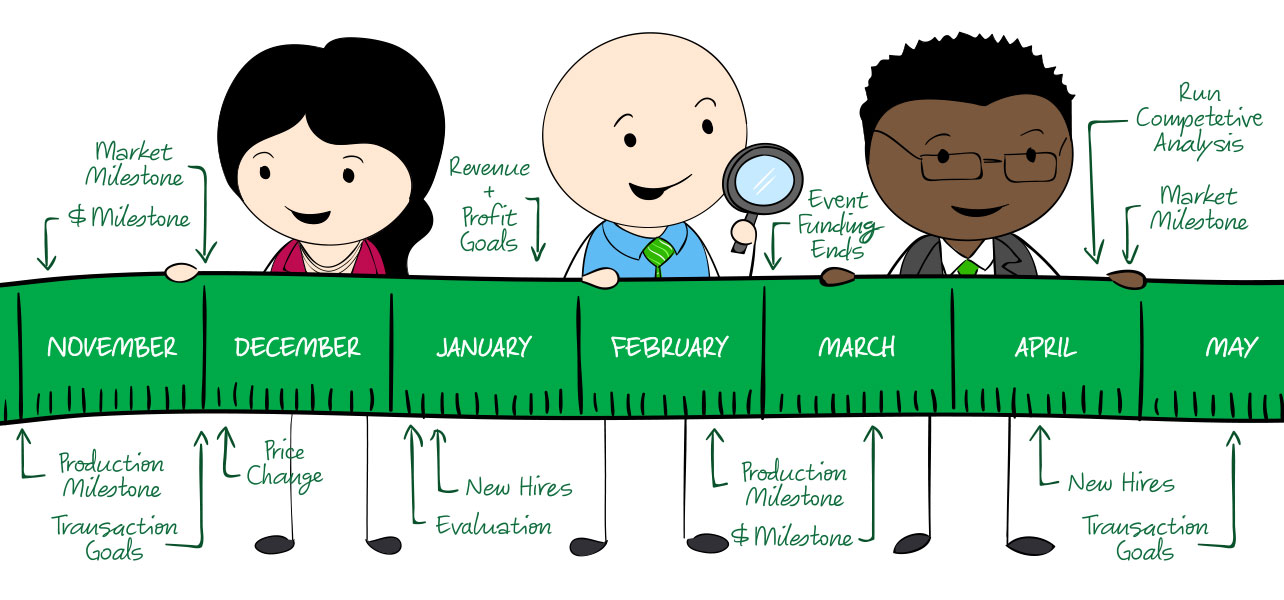

1. Use Production Forecasting Methods for Estimating Customer Demand

The first step of the production planning process is to forecast the customer demand for your product for a future period like a year or a quarter. To do so, manufacturers rely on quantitative and qualitative techniques such as Delphi method, historical analogy method, moving average method and the analysis of business data and sales forecasts.

This process is known as demand planning , which helps manufacturers be better prepared to meet the demand for their products and manufacture the right quantity so they can minimize production and operational costs.

2. Gauge Your Production Capacity

The term production capacity refers to the maximum quantity of product a manufacturing company can produce based on its available production resources such as raw materials, labor, equipment and machinery.

Once you better understand the customer demand for your product, you’ll need to gauge the total quantity of product that needs to be manufactured and then evaluate if your production capacity is sufficient.

3. Map Out the Shop Floor Layout

Now think about the steps of the production process itself. Outline the production tasks that must be executed to transform raw materials, parts and components into a final product and the physical route that those elements will follow to move across the shop floor. This will allow you to pick a production floor layout that minimizes the time and effort required from your employees.

4. Make a Production Budget to Find the Optimal Production Volume

The next challenge in the production planning process is determining the exact number of units to manufacture to keep up with customer demand and maintain your desired stock levels.

This requires a production budget , a document used to calculate the number of units that should be produced by a company to meet the customer demand for a period such as a month, quarter or even a year.

Creating a production budget involves assessing the current product inventory, the production capacity, sales forecasts and the ending inventory that should remain at the end of the period. Once you analyze these variables and use the production budgeting formula, you’ll know the required production level for a given time.

5. Choose a Production Costing Technique

Choose a costing method for your production process such as activity-based costing, process costing, job costing or simply standard costing. Each has its pros and cons depending on your organization’s particular characteristics.

6. Create a Production Schedule

Now it’s time to make a production schedule that allows your organization to create a stock inventory, deliver products to distribution channels, fulfill customer orders and meet the obligations of any manufacturing contracts the organization has in place for the production timeline you’re planning for.

Get your free

- Production Schedule Template

Use this free Production Schedule Template for Excel to manage your projects better.

7. Establish a Production Control System

Next, it’s important to establish standard operating procedures and key performance indicators and use a variety of production control tools to create a system that allows you to track the production process to ensure your products meet quality standards and are manufactured on time and under budget.

8. Set Production Reporting Guidelines

After you’ve decided what KPIs will be used to monitor the efficiency of your production process, you’ll need to determine what types of reports will be used to communicate these metrics with stakeholders and the frequency in which they’ll be produced.

The documentation from each of these production planning stages, such as the production budget and production schedule are gathered in a larger document called the production plan.

What Is a Production Plan?

A production plan is a document that describes how production processes will be executed, and it’s the outcome of the production planning process. It describes the human resources, raw materials and equipment needed and the production schedule that will be followed.

The person responsible for production planning must also be very familiar with the operation’s inner workings, project resources and the products/services they produce. This usually entails collaborating with people on the floor, in the field or in different departments to create products and deliver services.

Production Plan Example

The best way to illustrate this process is through an example. When you set out to create a production plan, make sure to follow these steps to make it as robust as possible.

Sales Forecast

Making a sales forecast greatly helps you decide which product planning method is best for your operation given your production capacity. You’ll need to use diverse sales forecasting techniques to better understand what will be the future demand for your product. From here, you can estimate which resources are required and how they’ll be used in the manufacturing process to begin the production capacity planning process.

Inventory Management Plan

Accessing inventory is about more than simply taking stock: you should make an inventory management plan for your production inventory and work-in-progress inventory so that you don’t experience shortages that might halt production or let things go to waste. For this step, focus on the inventory control and inventory management techniques you can use to handle inventory in the most efficient way possible.

Production Budget

Most manufacturers use the production budgeting formula below to make a production budget that indicates the ideal production volume based on a starting inventory, sales forecasts, production capacity and expected ending inventory levels.

Required Production = Sales Forecast Expected Units + Desired Ending Inventory – Beginning Inventory

Resource Plan

A successful production plan requires you to be familiar with the resource planning details of the manufacturing process, which is why you’ll need to make a resource plan that outlines what resources such as labor, raw materials, equipment and any other capital assets are available for production and when they’re scheduled to be utilized.

Production Cost Estimate

Once you’ve determined what the required level of production is and the resources that will be needed, you’ll need to estimate the cost of production . It’s important to ensure the production process will be profitable before creating a production schedule.

Production Schedule

As stated above, a production schedule is key to making sure your manufacturing team delivers products on time, but also guides efforts in other areas such as supply chain management and logistics management.

Production Control Plan

A production control plan should describe all the metrics, procedures, guidelines and tools that will be utilized to monitor how the results compare to the production schedule and resource management projections. This is something that should continually take place and be documented during the production process.

Types of Production Planning

Every operation is unique, and the same production plan isn’t right for everyone. To get the most from project planning, you decide which method is best for your manufacturing process. Here’s a quick intro to the different types of production planning.

The job method is often used when manufacturing a single product, for which a unique production plan is created. This production planning method is generally used in smaller-scale productions, but it can also be applied to larger manufacturing facilities. The job method is especially advantageous when a production order requires specific customizations.

Batch Production Method

Batch production consists of manufacturing goods in groups, instead of being produced individually or through continuous production . This method is useful when manufacturing products on a large scale.

Flow Method

The flow method is a demand-based manufacturing model that minimizes the production lead time by speeding up the production line. The manufacturing process starts based on work orders, and once it starts, it doesn’t stop until all finished goods are produced. This is called continuous production and it’s achieved by using machinery and little intervention to minimize waiting time.

Process Method

The process method is more or less what most people picture when they think about production—an assembly line. With the process method, there will generally be different types of machinery that complete separate tasks to put together the finished goods.

Mass Production Method

The mass production method primarily focuses on creating a continuous flow of identical products. It’s similar to the flow method, but at a much bigger scale, which cuts production costs. When uniformity is just as critical as efficiency, use “standardized processes” to guarantee all products look the same.

Production Planning Best Practices

No matter what product or service is being manufactured, there are many tried-and-true best practices to increase your operational efficiency . When creating a production plan, keep these two in mind.

Make Accurate Forecasts

When you don’t properly estimate the demand for your product or service, it’s impossible to create a detailed production plan. Demand planning is never static. Consider buying trends from previous years, changes in demographics, changes in resource availability and many other factors. These demand planning forecasts are the foundation of skillful production planning.

Know Your Capacity

Capacity planning means knowing the maximum capacity your operation can manage—the absolute most of a product or service it can offer during a period of time. This is the only way to anticipate how much of each resource you need to create X amount of products.

When you don’t know the production capacity, your production planning is like taking a shot in the dark.

Common Production Planning Mistakes

Stay vigilant of common missteps as you go through the production planning process. Here are three mistakes often made during production planning. Luckily, they can be prevented.

Not Expecting the Unexpected

This means having risk management strategies in place if things go awry. The goal is to never have to employ them, of course, but it’s better to have them and not need them. Production planning is incomplete if it doesn’t anticipate risks, issues and changes. When you plan for them, you’re ready to problem-solve if and when they happen.

Getting Stuck Behind the Desk

You should work with intelligent production planning tools, but that doesn’t mean you should only rely on enterprise resource planning software for production planning and not oversee resources and manufacturing operations in person. When production planning is only done from behind a screen, the result won’t be as informed as it could be. The best production planning is active and collaborative.

Neglecting Equipment

To get the most from your equipment, you need to take care of it. This means tracking usage and keeping up with regular maintenance. This looks different depending on the industry and product or service, but the principle is the same: continually take care of your equipment before it becomes a problem that slows down production.

Use ProjectManager for Production Planning and Scheduling

As the nature of manufacturing goods and services changes, you need modern tools to plan production and make schedules. ProjectManager is award-winning project management software that offers all the tools you need for excellent production planning and scheduling. With it, you can plan projects, create schedules, manage resources and track changes with one tool.

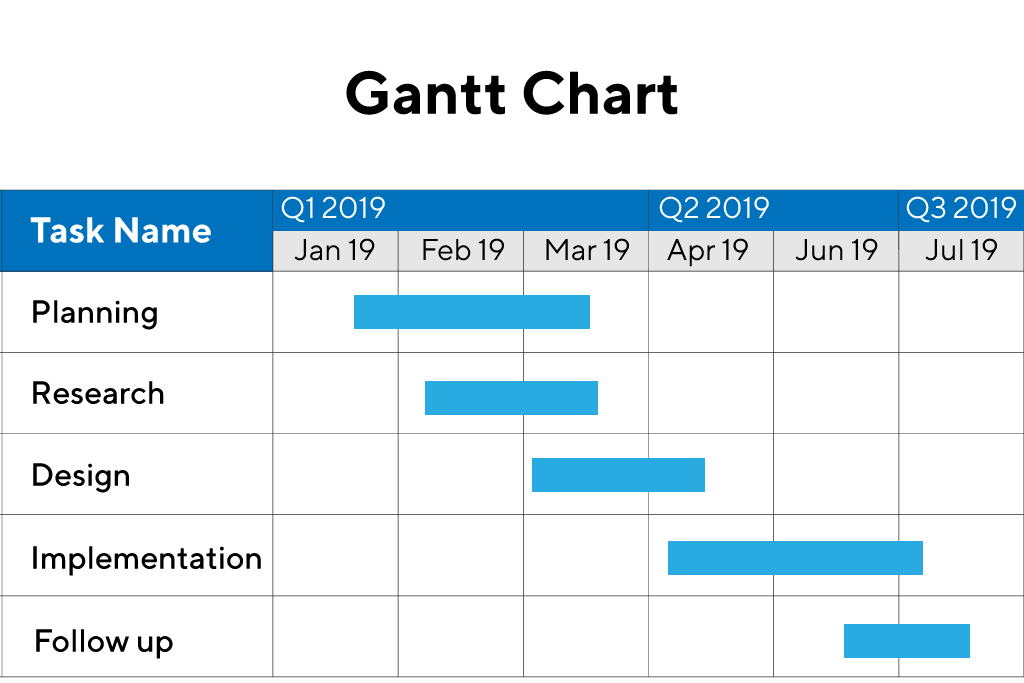

Plan With Gantt Charts

Manage your product manufacturing across a timeline with our Gantt chart view. With it, you can view your resources to help you track your cost of production to ensure you’re never overspending. You can then link any dependent tasks to avoid bottlenecks in your manufacturing.

Get a Bird’s-Eye View

To keep your production plan on track, you need a high-level view to pinpoint setbacks before or as they occur. Our real-time dashboard collects data and converts it into colorful graphs and charts that give you at-a-glance analytics.

Easily Measure and Report Your Progress

Any operation will have stakeholders who want to be kept in the loop. ProjectManager’s project status reports make it easy to share key data points. They can be generated in a single click, making it simple to generate them before important meetings.

Related Production Planning Content

The production planning process involves many different activities such as estimating the quantity of goods to be produced, the resources needed, the production schedule and much more. That’s why we’ve created dozens of blogs, guides and templates on production management topics. Here are some of them.

- Production vs. Manufacturing

- How to Make a Production Flow Chart for Manufacturing

- Best Production Scheduling Software Rankings

- How to Create a Master Production Schedule (MPS)

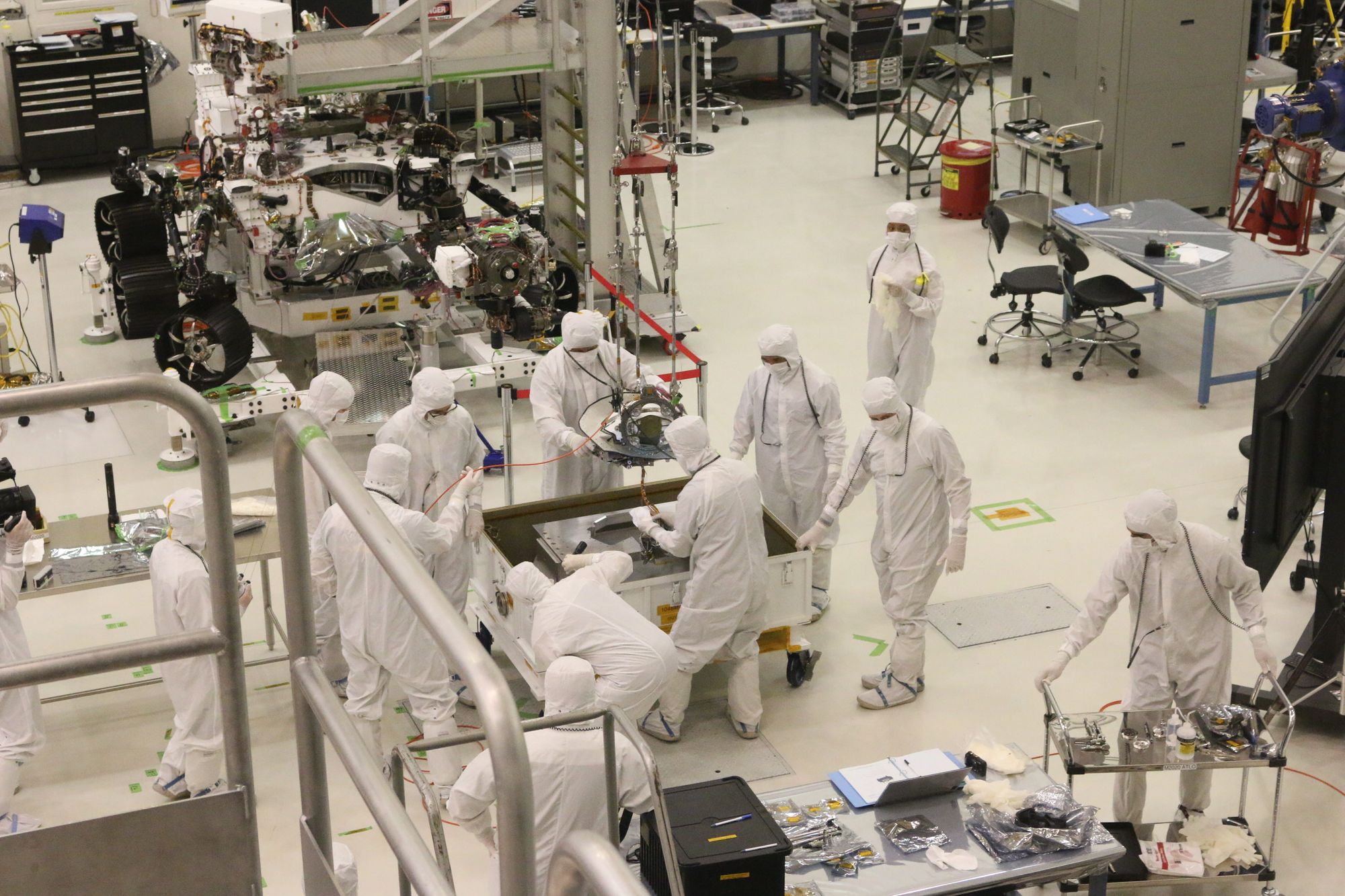

Manage every detail of your operation with ProjectManager’s powerful online project management tools. Our suite of tools is trusted by tens of thousands of teams, from NASA to Volvo, to aid them in the planning, scheduling, tracking and reporting on the progress and performance of their production plans. Our software lets you get out from behind your desk and make adjustments on the go. Try it for yourself for free for 30 days!

Deliver your projects on time and under budget

Start planning your projects.

What Is Production Planning & Why Is It Important?

Business success often hinges on making the products that customers want in a timely and cost-effective way. Production planning helps companies achieve those goals. It maps out all the processes, resources and steps involved in production, from forecasting demand to determining the raw materials, labor and equipment needed. Production planning helps companies build realistic production schedules, ensure production processes run smoothly and efficiently, and adjust operations when problems occur.

What Is a Production Plan?

A production plan describes in detail how a company’s products and services will be manufactured. It spells out the production targets, required resources, processes and overall schedule. The plan also maps all of the operational steps involved and their dependencies. The goal is to design the most efficient way to make and deliver the company’s products at the desired level of quality. A well-designed production plan can help companies increase output and save money by developing a smoother workflow and reducing waste.

What Is Production Planning?

Production planning involves developing a comprehensive strategy for making the company’s products and services. Initially adopted by large manufacturers, production planning has since become more popular among small and midsize businesses in multiple industries — largely because technology has made it easier to plan and track production processes with less effort. Production planning covers many different aspects of production, from forecasting demand to determining the raw materials, workforce, equipment and steps needed to make the company’s products.

Production Planning vs. Production Scheduling

While production planning provides an overview of what the company plans to do, production scheduling creates a more detailed view of exactly how the company will do it. The production schedule describes when each step in the production plan will occur, as well as the workers, machinery and other specific resources assigned to the job. Production scheduling can be extremely complex, especially when there are many interdependent production steps and the company is making multiple products simultaneously. Production scheduling software (opens in new tab) can help businesses create complex schedules, monitor progress in real time and quickly make adjustments when necessary.

Key Takeaways

- Production planning describes in detail how a company’s products and services will be manufactured.

- A production plan defines the production targets, required resources and overall schedule, together with all the steps involved in production and their dependencies.

- A well-designed production plan helps companies deliver products on time, reduce costs and respond to problems.

- Technology has made it easier for small and midsize companies in multiple industries to use production planning to optimize operations.

Product Planning Explained

Production planning is a broad discipline that involves much more than a focus on manufacturing process efficiency. It is intertwined with nearly every other aspect of the business, including finance, sales, inventory and human resources. Production planning activities include demand forecasting to determine the right mix of products to meet customer needs, as well as selecting the optimal approach to building those products. Production planning also assesses the resources needed to meet production goals and lays out in detail all the operations in the production process. Production plans must include the flexibility to make operational adjustments when problems occur — such as machine breakdowns, staffing shortages and supply-chain problems.

Why Is Production Planning Important?

A well-constructed production plan can help to boost revenue, profit and customer satisfaction, while a poorly designed plan can cause production problems and perhaps even sink the company. Specific benefits of production planning include:

- Knowledge. A production plan provides a framework for understanding the resources and production steps required to meet customer needs. It also helps companies understand the potential problems that may occur during production and how to mitigate them.

- Efficiency. Detailed production planning reduces bottlenecks and helps minimize costs. It also helps ensure the high quality of a product, and it keeps expenses on budget.

- Customer satisfaction. Production planning helps ensure that the company can make and deliver products to customers on time, leading to higher customer satisfaction and a greater likelihood of repeat business.

Types of Production Planning

The design of a product plan depends on the production method that the company uses, as well as other factors, such as product type, equipment capabilities and order size. Here are three of the main types of production planning:

Batch production planning.

Refers to manufacturing identical items in groups rather than one at a time or in a continuous process. For some businesses, batch production can greatly increase efficiency. A bakery creating items for sale the next day might first make a batch of chocolate chip cookies, then move on to oatmeal raisin cookies followed by loaves of semolina bread. A clothing manufacturer making goods for the summer might first set up its cutting and sewing machines to make 500 navy-blue T-shirts, then switch to red fabric and thread to make 400 tank tops. A good production plan for batch processing should look out for potential bottlenecks or delays when switching between batches.

Job- or project-based planning.

Used by many small- and medium-sized businesses, job production planning focuses on the creation of a single item by one person or team. Job-based planning is typically used where the specificity of each client’s requirements means it is difficult to make products in bulk. Many construction businesses use this method. Makers of custom jewelry and dresses are other examples of businesses that may use job production planning.

Flow production planning.

In flow production, also known as continuous production, standardized items are continuously mass-produced on an assembly line. Large manufacturers use this method to create a constant stream of finished goods. During production, each item should move seamlessly from one step along the assembly line to the next. Flow production is most effective at reducing costs and delays when there’s steady demand for the company’s products. Manufacturers can then readily determine their needs for equipment, materials and labor at each stage along the assembly line to help streamline production and avoid delays. The automotive industry and makers of canned foods and drinks are among the companies that use this method.

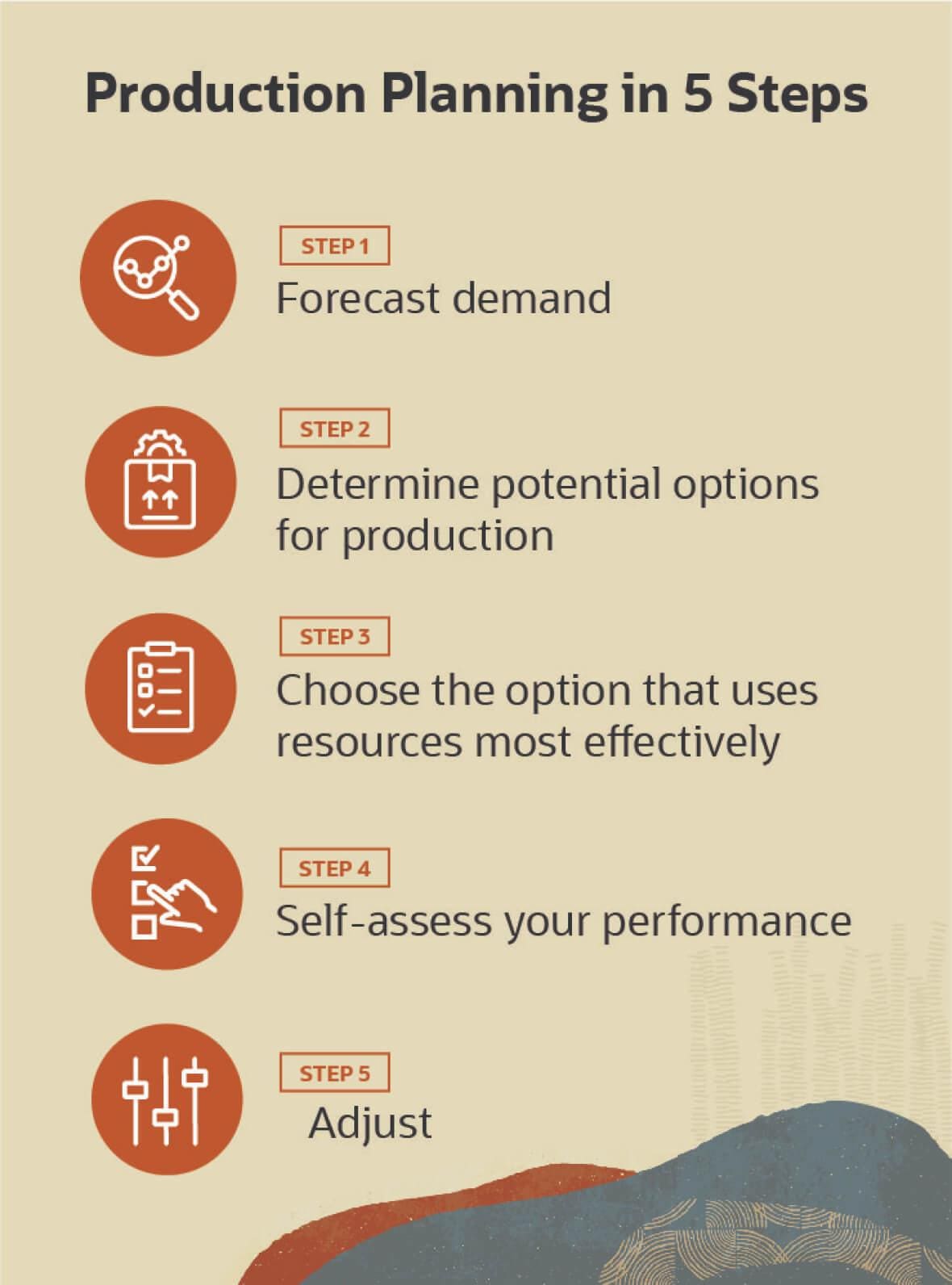

5 Steps to Make a Production Plan

Production planning is a robust undertaking that starts with forecasting and includes process design and monitoring. Here are five typical production planning steps:

Forecast product demand.

Estimate how much of each product you’ll need to produce over a designated period. Historical data can help with forecasting, but you’ll also need to pay attention to other factors that can affect demand, such as market trends and the economic situation for your customer base. Demand planning software can help companies make more informed decisions about the right amount of product needed to meet demand.

Map out production steps and options.

This step determines the processes, steps and resources needed to produce the required output. At this stage, the company may also examine different options for achieving its production goals, such as outsourcing some stages. The production mapping identifies which steps are interdependent and which can be performed simultaneously. Let’s say the job is to produce 1,000 children’s bicycles. Manufacturing the bicycle frames consists of a series of steps that must happen in sequence — cutting metal tubes, welding and painting — while other activities like assembling wheels can occur in parallel. Do you have all the right equipment? What happens if a machine breaks down? Are your suppliers able to meet your demand?

Choose a plan and schedule production.

Select a production plan after comparing the cost, time required and risks for each option. Sharing the selected plan with all necessary stakeholders typically helps assure a smoother production process since all the stakeholders are aware of what’s needed. Create a detailed production schedule that lays out in detail how the company will execute the plan, including the resources and timing for each step.

Monitor and control.

Once production has begun, you’ll need to track performance and continually compare it against the targets described in the production plan. Careful monitoring helps the company to detect any issues as soon as they pop up, so they can be quickly addressed.

Adjust accordingly.

It’s almost inevitable that production will be affected by events that you can’t plan for or predict. Those events can include changes to client specifications, supply chain lags, equipment failures and worker illness. You may also see ways to improve the production plan after seeing it in action for a while. So it’s vital to keep production plans flexible enough to allow for adjustment when needed. Football coaches often make adjustments to their game strategy at halftime — and the same holds true for production planning.

3 Common Product Planning Mistakes

Being aware of potential pitfalls ahead of time can help companies avoid or mitigate problems once production has started. Here are three of the most common production planning mistakes.

Not anticipating hiccups along the way.

In any complex production process, plans can go awry. Production planning should therefore include risk management strategies, including backup plans companies can rely on in the event of problems. Failing to do so can result in serious problems. For example, if a machine breaks on the line and you didn’t budget for repairs and workforce overtime, the issue may strain the company’s financial resources.

Keeping your distance.

Though production management software can provide real-time visibility into a company’s production status, it’s a good idea to supplement that information with in-person visits to the production line. Those visits can provide valuable insights into how production works in practice — insights that you might not gain if you’re stuck behind a desk.

Failing to maintain equipment.

There’s a tradition in football that the quarterback buys presents for his offensive linemen at the end of each season. Why? Because they protect him and enable him to do his job. Your manufacturing equipment is your company’s offensive line, so don’t neglect it. Tracking usage and paying for regular preventive maintenance helps ensure that your machines can keep your business functioning.

Production Planning KPIs

Key performance indicators (KPIs) are important metrics that help companies track the health of their production processes. By monitoring KPIs and comparing them to target values defined in production plans, businesses can determine whether production is on track and pinpoint problems that need to be addressed. Typical production KPIs include:

This key efficiency metric tracks the percentage of time that production is not occurring during scheduled operating hours. Causes include machine breakdowns, tool adjustments and accidents. Some downtime may be necessary for functions such as machine maintenance, but generally, the less downtime the better.

Setup time.

Also referred to as changeover time, this is the amount of time it takes to switch between jobs. Setup time impacts overall productivity because production is halted during these periods. Production schedules should consider how much time and effort it takes to reconfigure production for each job, including changes to the equipment, raw materials and workforce. Designing production schedules to minimize changeover time can increase efficiency.

Production rate.

In a manufacturing environment, this is typically measured as the number of units produced during a specific period. Comparing the actual production rate for each process with the planned rate can help businesses identify strengths and weaknesses and begin to address problems.

Overall equipment effectiveness (OEE).

This is a measure of overall manufacturing productivity that accounts for quality, performance and availability. The formula for OEE is:

OEE = Quality x performance x availability

Quality is typically measured as the percentage of parts that meet quality standards. Performance is how fast a process is running compared to its maximum speed, which is expressed as a percentage. Availability is the percentage of uptime during a company’s scheduled operating hours. Increasing OEE can be achieved by lowering downtime, reducing waste and maintaining a high production rate.

Rejection rate.

This is the number or percentage of products that failed to pass quality checks. Depending on the nature of the product and the problem, it may be possible to salvage some rejected items by reworking them, while others may need to be scrapped.

On-time orders.

Production delays can be costly both in terms of money and reputation. Generating products on schedule means you’re less likely to need costly expedited shipping or other emergency measures to meet deadlines. And delivering orders on time helps keep customers happy, which means they’re more likely to keep doing business with your company.

Production Planning Tools

Businesses rely on a variety of tools to build production plans and track progress, ranging from visualization tools to sophisticated software that automates many of the steps involved. Typical tools include:

Gantt charts.

A Gantt chart is a detailed visual timeline of all the tasks scheduled for a particular job. More than 100 years since its invention by mechanical engineer Henry Laurence Gantt, this chart remains integral to manufacturing and many other industries. Production planning involves coordinating and scheduling many tasks , and the Gantt chart visually represents when each task will take place and how long it will last. Manually creating and updating Gantt charts to reflect complex, ever-changing production schedules can be a time-consuming and error-prone job, however.

Spreadsheets.

Small companies sometimes start out by tracking simple production plans using spreadsheets. However, for most companies, the inherent complexity of production planning quickly outstrips the capabilities of spreadsheet software.

Production planning software.

Production planning involves a wide range of activities, including forecasting, managing the supply chain, tracking inventory and scheduling jobs. Those activities require information from across the company and beyond. Production planning information is integral to business operations and is used by other groups within the company, including finance. That’s a key reason many companies use enterprise resource planning (ERP) application suites that include production planning software and provide a single solution for managing the entire business.

Manage and Optimize Production With NetSuite

NetSuite cloud-based production management software helps companies maximize manufacturing productivity and minimize cost. NetSuite provides real-time visibility into each aspect of the production process, from inventory tracking and monitoring the production floor to fulfilling orders. Production scheduling capabilities let businesses create and update complex real-time production schedules with minimal effort. Because NetSuite production management software is part of an integrated suite of ERP applications , businesses can share production progress with the entire organization and link production processes to financial reports, inventory management and order management.

Production planning is an important function that can boost profitability and customer satisfaction as well as efficiency. It helps companies match output to demand, optimize production processes and determine how to overcome production problems.

Award Winning Cloud Inventory

Production Planning FAQs

What are the 5 steps in production planning.

Here are five typical steps in the production planning process:

- Forecast the short- and long-term demand for your product.

- Map out the various options and processes for manufacturing these goods

- Choose the option that checks as many boxes as possible, and develop a production schedule.

- Monitor production against the plan.

- Adjust the plan where needed. In other words, if it’s broken, fix it.

What are the 3 activities of production planning?

Production planning activities can be divided into three main areas: Develop a production process and strategy; gather the resources needed, from raw materials to machinery and personnel; and select and train the necessary people.

What are the types of production planning?

Three of the main types of production planning are batch planning, job planning and flow or continuous planning . The choice depends on your resources as well as the nature of the product. Batch planning makes the same item in bulk before moving on to another item. Job planning, also called project-based planning, focuses more on custom design and single-item production. Flow production involves a steady stream of mass-produced items moving along the line.

What is the role of production planning?

Production planning is critical to ensure the production process runs smoothly and efficiently and delivers products on time. Planning allows a business to make certain that all necessary preparation is completed before starting production.

Inventory Management

What Is Perishable Inventory? Strategies, Tracking & Free Template

Inventory management is a challenge faced by any business selling a product, but the challenge is particularly acute for businesses dealing in products that expire or quickly lose value over time. By giving special attention…

Trending Articles

Learn How NetSuite Can Streamline Your Business

NetSuite has packaged the experience gained from tens of thousands of worldwide deployments over two decades into a set of leading practices that pave a clear path to success and are proven to deliver rapid business value. With NetSuite, you go live in a predictable timeframe — smart, stepped implementations begin with sales and span the entire customer lifecycle, so there’s continuity from sales to services to support.

Before you go...

Discover the products that 37,000+ customers depend on to fuel their growth.

Before you go. Talk with our team or check out these resources.

Want to set up a chat later? Let us do the lifting.

NetSuite ERP

Explore what NetSuite ERP can do for you.

Business Guide

Complete Guide to Cloud ERP Implementation

- Search Search Please fill out this field.

- Building Your Business

- Becoming an Owner

- Business Plans

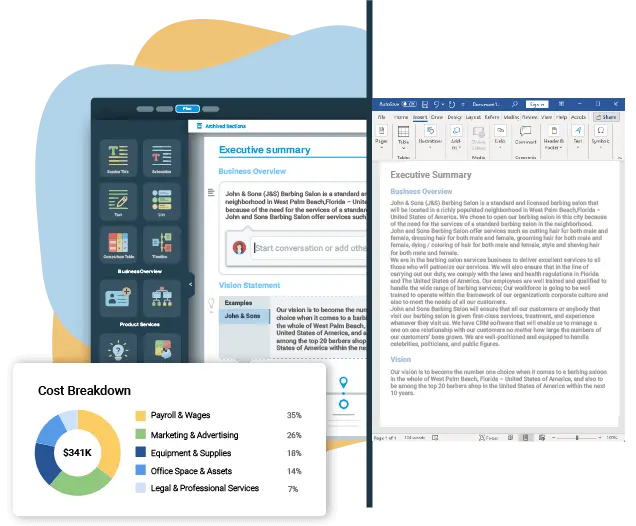

How To Write the Operations Plan Section of the Business Plan

Susan Ward wrote about small businesses for The Balance for 18 years. She has run an IT consulting firm and designed and presented courses on how to promote small businesses.

:max_bytes(150000):strip_icc():format(webp)/SusanWardLaptop2crop1-57aa62eb5f9b58974a12bac9.jpg)

Stage of Development Section

Production process section, the bottom line, frequently asked questions (faqs).

The operations plan is the section of your business plan that gives an overview of your workflow, supply chains, and similar aspects of your business. Any key details of how your business physically produces goods or services will be included in this section.

You need an operations plan to help others understand how you'll deliver on your promise to turn a profit. Keep reading to learn what to include in your operations plan.

Key Takeaways

- The operations plan section should include general operational details that help investors understand the physical details of your vision.

- Details in the operations plan include information about any physical plants, equipment, assets, and more.

- The operations plan can also serve as a checklist for startups; it includes a list of everything that must be done to start turning a profit.

In your business plan , the operations plan section describes the physical necessities of your business's operation, such as your physical location, facilities, and equipment. Depending on what kind of business you'll be operating, it may also include information about inventory requirements, suppliers, and a description of the manufacturing process.

Keeping focused on the bottom line will help you organize this part of the business plan.

Think of the operating plan as an outline of the capital and expense requirements your business will need to operate from day to day.

You need to do two things for the reader of your business plan in the operations section: show what you've done so far to get your business off the ground and demonstrate that you understand the manufacturing or delivery process of producing your product or service.

When you're writing this section of the operations plan, start by explaining what you've done to date to get the business operational, then follow up with an explanation of what still needs to be done. The following should be included:

Production Workflow

A high-level, step-by-step description of how your product or service will be made, identifying the problems that may occur in the production process. Follow this with a subsection titled "Risks," which outlines the potential problems that may interfere with the production process and what you're going to do to negate these risks. If any part of the production process can expose employees to hazards, describe how employees will be trained in dealing with safety issues. If hazardous materials will be used, describe how these will be safely stored, handled, and disposed.

Industry Association Memberships

Show your awareness of your industry's local, regional, or national standards and regulations by telling which industry organizations you are already a member of and which ones you plan to join. This is also an opportunity to outline what steps you've taken to comply with the laws and regulations that apply to your industry.

Supply Chains

An explanation of who your suppliers are and their prices, terms, and conditions. Describe what alternative arrangements you have made or will make if these suppliers let you down.

Quality Control

An explanation of the quality control measures that you've set up or are going to establish. For example, if you intend to pursue some form of quality control certification such as ISO 9000, describe how you will accomplish this.

While you can think of the stage of the development part of the operations plan as an overview, the production process section lays out the details of your business's day-to-day operations. Remember, your goal for writing this business plan section is to demonstrate your understanding of your product or service's manufacturing or delivery process.

When writing this section, you can use the headings below as subheadings and then provide the details in paragraph format. Leave out any topic that does not apply to your particular business.

Do an outline of your business's day-to-day operations, including your hours of operation and the days the business will be open. If the business is seasonal, be sure to say so.

The Physical Plant

Describe the type, site, and location of premises for your business. If applicable, include drawings of the building, copies of lease agreements, and recent real estate appraisals. You need to show how much the land or buildings required for your business operations are worth and tell why they're important to your proposed business.

The same goes for equipment. Besides describing the equipment necessary and how much of it you need, you also need to include its worth and cost and explain any financing arrangements.

Make a list of your assets , such as land, buildings, inventory, furniture, equipment, and vehicles. Include legal descriptions and the worth of each asset.

Special Requirements

If your business has any special requirements, such as water or power needs, ventilation, drainage, etc., provide the details in your operating plan, as well as what you've done to secure the necessary permissions.

State where you're going to get the materials you need to produce your product or service and explain what terms you've negotiated with suppliers.

Explain how long it takes to produce a unit and when you'll be able to start producing your product or service. Include factors that may affect the time frame of production and describe how you'll deal with potential challenges such as rush orders.

Explain how you'll keep track of inventory .

Feasibility

Describe any product testing, price testing, or prototype testing that you've done on your product or service.

Give details of product cost estimates.

Once you've worked through this business plan section, you'll not only have a detailed operations plan to show your readers, but you'll also have a convenient list of what needs to be done next to make your business a reality. Writing this document gives you a chance to crystalize your business ideas into a clear checklist that you can reference. As you check items off the list, use it to explain your vision to investors, partners, and others within your organization.

What is an operations plan?

An operations plan is one section of a company's business plan. This section conveys the physical requirements for your business's operations, including supply chains, workflow , and quality control processes.

What is the main difference between the operations plan and the financial plan?

The operations plan and financial plan tackle similar issues, in that they seek to explain how the business will turn a profit. The operations plan approaches this issue from a physical perspective, such as property, routes, and locations. The financial plan explains how revenue and expenses will ultimately lead to the business's success.

Want to read more content like this? Sign up for The Balance's newsletter for daily insights, analysis, and financial tips, all delivered straight to your inbox every morning!

- HR & Payroll

Production Planning and Scheduling: The Complete Guide

Has your company expanded from a one-person gig to a large team? You may be in-charge of a busy workshop and want to increase productivity there. Whatever the reason, you'll need a solution to make your production planning and scheduling as efficient as possible.

The overall adequate use of resources has always been a focus of production planning and scheduling. Production planning's main objective is to ensure that the supply chain process moves smoothly. The more smoothly your production and supply chains move, the less money you'll spend and the more you make.

One of the most crucial elements and indicators of the health of your supply chain is the flow. You're on the right track if your production process moves smoothly.

Various possibilities are available today for your growing manufacturing company to locate production planning software. These softwares have been created especially for contemporary manufacturers.

You will learn everything you need to know about using production scheduling and planning to organize your resources in this guide. Continue reading to learn how to enhance production scheduling in your expanding manufacturing company.

The following are the topics covered:

What is Production Planning?

What is production scheduling, difference between production planning and scheduling, importance of production planning and scheduling processes, 4 benefits of using a production schedule, how do you optimize production scheduling, the right production plan for you, key takeaways.

Production planning involves scheduling processes, raw materials, and resources to produce goods for consumers within predetermined time frames. Production scheduling specifies who will conduct the operations and when.

- Production planning determines what and how much work needs to be done. Production planning and scheduling help your manufacturing process run as smoothly as possible.

- It is done by combining your production needs with your available resources in the most cost-effective way.

- It ensures that your orders are processed as quickly, smoothly, and stress-free as possible. Do you think that's just a dream? All your production planning flow requires are a few minor adjustments.

In any case, effective production planning and scheduling are essential. For manufacturers, production planning is crucial since it has an impact on other critical parts of their business, such as

- Capacity Planning

- Supply Chain Management

- Production Lead Time

- Production Scheduling

- Material Requirements Planning

Production Planning Process

Production planning is a key process in any manufacturing organization. It helps to ensure that the right products are produced in the right quantities, at the right times, and with the right resources. The following are the five key steps of the production planning process:

- Calculate product demand

It will provide a general idea of how many products need to be produced at a specific time. A combination of analysis of current market trends and historical production trends is used to create this estimate.

This involves estimating the number of products that must be produced to meet customer demand. This step also involves forecasting future demand and understanding customer needs to ensure the right amount of product is produced.

- Evaluate production alternatives

It entails assessing the available resources and determining how to use them best. It is done in light of anticipated demand estimations.

This includes evaluating different production methods, such as batch production, continuous production, and job shop production, as well as different production locations, such as on-site or off-site production. This step helps to identify the most efficient and cost-effective production alternative.

- Select the most effective solution

After evaluating the different production alternatives, the next step is to select the most effective solution. This involves considering factors such as cost, time, quality, and efficiency. It is important to select the solution that will provide the best results for the organization.

- Monitoring and evaluation

As the plan is implemented, businesses keep an eye on what is occurring. They compare it to what should be happening as per the plan. They then assess how well the two line up.

Once the production plan is in place, it is important to monitor and evaluate its progress. This involves tracking the production plan's progress and ensuring that it meets the organization’s objectives. Additionally, it is important to evaluate the effectiveness of the plan in order to identify areas that need to be improved.

- Adjust plan

This may involve making changes to the production process or adjusting the production schedule in order to accommodate changes in demand or other factors. This step helps to ensure that the production plan remains effective.

Types of Production Planning

There are numerous varieties of production planning that concentrate on different aspects of the production process. Here are a few of them:

- Master Production Schedule (MPS)

These are production schedules for specific commodities that must be manufactured one at a time. They are frequently produced by software and subsequently modified by users.

- Material requirements planning (MRP)

MRP is a system for inventory management, production scheduling, and planning. Raw material availability is guaranteed by MRP, which also maintains internal material and product levels as low as feasible.

MRP also schedules manufacturing and purchase activities. Although software frequently partially automates it, it can also be done by hand.

It is the process of figuring out how well-equipped a company is to handle shifting demands.

- Level Production Planning

Level Production Planning is a type of production planning that focuses on the production of a constant rate of output over a given period of time. This means that the same amount of raw materials and resources are used throughout the production period, resulting in consistent and predictable output.

The goal of this type of planning is to achieve high efficiency and reduce costs by ensuring that resources are used in the most efficient way possible.

- Lean Production Planning

Lean Production Planning is a type of production planning that focuses on minimizing waste and optimizing the use of resources. This type of planning emphasizes the use of small batches and the elimination of overproduction. The goal of lean production planning is to reduce costs, increase efficiency, and improve customer satisfaction.

- Kaizen Production Planning

Kaizen Production Planning is a type of production planning that focuses on continuous improvement and process optimization. This type of planning emphasizes the use of data and feedback to identify areas for improvement and to make changes that will increase efficiency and reduce costs.

- Agile Production Planning

Agile Production Planning is a type of production planning that focuses on making quick and effective decisions. This type of planning emphasizes the use of data and feedback to make decisions quickly and to adapt to changing conditions quickly.

Agile production planning is used to reduce costs, improve efficiency, and increase customer satisfaction.

- Workflow Planning

Workflow planning refers to scheduling a series of tasks to be carried out by a single employee or group of employees. Several planning kinds use the logic of production planning in adjacent or unrelated fields to manufacturing.

For instance, optimizing hiring and talent management processes is a component of human resources planning. Other illustrations include:

- Enterprise resource planning (ERP)

Enterprise resource planning (ERP) is a business process combining primary corporate operations into a single, cohesive system. It is often accompanied by software.

- Sales and operations planning (S&OP)

This procedure helps manufacturers more precisely match their supply with market demand.

Types of Production Planning Methods

The same production plan is only appropriate for some operations because every business is different. You must choose the approach that works best for your manufacturing process. It is to maximize the benefits of project planning. Having stated that, here is a brief introduction to the various production planning methods.

When producing a single product for which a particular production plan is made, the task approach is frequently utilized. This method of production planning can be employed in more extensive manufacturing facilities. It is typically used in smaller enterprises. The work technique is beneficial when a good or service needs precise adjustments.

Batch Production Method

In contrast to individual or continuous production, a batch production is a form of production. Batch production involves producing things in groups. When delivering goods on a vast scale, this strategy is helpful.

Flow Method

By accelerating the production line, the flow method is a demand-based manufacturing strategy. It reduces the length of the production lead time. Based on work orders, the production process begins and ends once all finished goods are produced.

Continuous manufacturing is what is accomplished by employing machinery and minimum human intervention. It is done to reduce waiting time.

Process Method

The process method is essentially an assembly line, which is what most people envision when they think of production. The process method often assembles the finished goods with various types of machinery doing different jobs.

Mass Production Method

The main goal of the mass production method is to produce an endless stream of identical goods. Like the flow method, it reduces production costs by operating on a much larger scale.

When efficiency and uniformity are equally important, "standardized processes" must be used. It ensures that all products have the same appearance.

How to Make a Production Plan

Follow these five steps to ensure that your production plan is as robust as it can be when you set out to construct one.

1. Project/Estimate Product Demand The easiest way to choose which product planning strategy is ideal for your operation is to understand product demand planning. The first step is to understand product demand planning.

Then you may determine which resources are necessary and how they will be utilized during the manufacturing process.

2. Access Inventory

Making an inventory management plan will help you avoid experiencing shortages or letting items go to waste. Accessing inventory involves more than just taking stock. To handle inventory as efficiently as possible, concentrate on the inventory control and management strategies you might use in this stage.

3. Resource Planning

Knowing the specifics of resource planning for the manufacturing process is necessary for a successful production plan. Keep in mind the bare minimum of laborers and supplies needed to complete a task (producing a good or providing a service).

Additionally, think about the equipment and systems necessary for your manufacturing plan.

4. Monitor Production

Keep an eye on how the output stacks up against the production schedule and resource allocation forecasts as production progresses. Throughout the production process, this should be ongoing and documented.

5. Modify the Strategy to Improve Production Efficiency in the future

Reflecting on the knowledge, you obtained in step four and making plans for improving the production plan are the final steps in production planning. It is the final step in production planning.

However, production planning aims to manufacture a good or service. It should also serve as a learning opportunity to improve production plans in the future.

Components of Production Planning

Making a proper production plan requires the following inputs:

- Bill of Materials: The Bill of Materials (BOM) is an important document in production planning, as it provides a detailed list of all the components and parts needed to manufacture a product. It is commonly used to track the cost of materials, labor and overhead used to manufacture the product. The BOM also provides a means of tracking the status of each component, from initial procurement to final assembly.

- Stock Levels: Production planning also requires the tracking of stock levels. This is because having too much stock can lead to expensive storage costs, while too little stock can lead to production delays. By monitoring stock levels, production planners can ensure that the right amount of stock is available at the right time.

- Price of Materials: The price of materials is an important factor in production planning. Knowing the cost of materials helps production planners to accurately estimate the cost of producing a product. Additionally, by regularly comparing the current price of materials with the market price, production planners can make sure that they are getting the best value for their money.

- Lot Sizes: Lot sizes are another important factor in production planning. Lot sizes are the number of items produced in a single production run. Lot sizes are determined based on the demand for the product, the cost of production, and the availability of materials.

- Manufacturing Lead Time: Manufacturing lead time is the amount of time that it takes for a product to be manufactured from start to finish. This includes the amount of time required for the procurement of materials, assembly, testing, and packaging. Knowing the lead time can help production planners accurately estimate the time required for production and plan accordingly.

Assigning various raw materials, resources, or production processes to multiple products is the process of product production scheduling. The goal is to produce goods on schedule while making your production process as effective and economical as possible. It is possible in terms of labor and material costs.

All parts of the supply chain depend on the production schedule. In fact, the supply chain as a whole depends on it for some of the most significant key performance indicators (KPIs) . A few typical KPIs for production schedules are listed below:

- Order management

- Daily performance

- Cost reduction

- Production time

- Production service rate

- Inventory turns

Production Scheduling involves planning out how many units need to be produced and when they should be produced. This includes allocating resources (labor, materials, and equipment) to each component of the production process, as well as determining the sequence in which they should be used. To streamline this process and enhance precision in scheduling, consider incorporating a reliable schedule maker for work that caters to your unique production requirements.

Production Scheduling also entails setting deadlines for each step of the process and monitoring the progress of the project to ensure that all tasks are completed on time. It is essential for ensuring that production costs are kept to a minimum, as well as allowing organizations to meet customer demand in a timely manner.

We will need to establish an acceptable timetable and create a plan for accomplishing our objectives. We will need to develop a proper timetable for the KPIs mentioned above.

Types of Schedules

- Master Schedules

The completion dates for significant production items are specified in this timetable. Each product's production requirements were divided into separate columns in this schedule.

Before entering any order into the master schedule, we always consider resource availability when receiving an order. As it includes information on the product's quantities and delivery schedules. The master schedule is beneficial for in-depth planning.

- Manufacturing Schedule

When the master schedule has been created, the manufacturing schedule will be ready. A manufacturing schedule will then be created.

Here, we give a particular store a set amount of time to produce the goods that must be prepared. As well as the deadline, which should be a day or a week from now.

Types of Scheduling

- Forward Scheduling: This scheduling starts on a fixed date. The last operation comes before the first operation, as well. It is made easier to find the date the final product was completed.

The goal of advanced scheduling is to accomplish mass production at a low cost while also maximizing the usage of the plant's capacity.

- Backward Scheduling: To determine the needed start date and ensure that the finished product is produced by the due date, it starts with a due date that has been established. It works backward from there.

- Chase: This type of scheduling is used when the production process is quite simple and does not require a lot of resources. It is used to plan the production order for each stage, starting from the demand for the finished product and moving forward until the production process is completed.

This type of scheduling is mainly used when the production process is quite simple and does not require a lot of resources.

- Infinite Capacity Planning: This type of scheduling is used when the production process has no limitations in terms of resources. It is used to plan the production order for each stage, starting from the demand for the finished product and moving forward until the production process is completed.

This type of scheduling is mainly used when the production process has no limitations in terms of resources.

- Finite Capacity Planning: This type of scheduling is used when the production process has limited resources. It is used to plan the production order for each stage, starting from the demand for the finished product and moving forward until the production process is completed.

This type of scheduling is mainly used when the production process has limited resources.

- Make-To-Stock: This type of scheduling is used when the production process is used to produce a certain number of products in advance, without any specific customer orders. It is used to plan the production order for each stage, starting from the demand for the finished product and moving forward until the production process is completed.

This type of scheduling is mainly used when the production process is used to produce a certain number of products in advance, without any specific customer orders.

- Make-To-Order: This type of scheduling is used when the production process is used to produce a certain number of products based on specific customer orders. It is used to plan the production order for each stage, starting from the demand for the finished product and moving forward until the production process is completed.

This type of scheduling is mainly used when the production process is used to produce a certain number of products based on specific customer orders.

What Is a Production Schedule Used For?

The production schedule is a flexible and significant document for organizing, predicting, and satisfying demand. It helps you maintain the timeliness and affordability of your operations. It supports you in upholding your obligation to your clients. Let's look more closely at its primary functions.

- Planning: Predicting demand and balancing it with available labor, supplies, and equipment.

- Scheduling Resources: A production schedule is used to plan and schedule resources for the production process. This includes personnel, equipment, materials, and other resources. By scheduling resources, producers can ensure that the production process can be completed efficiently and on time.

- Preventing stock-outs: Planning to maintain output even if supplies are delayed or demand surges due to increased orders.

- Improved efficiency: Increased effectiveness in identifying bottlenecks and seeking out areas for development is essential. It leads to shorter lead times and more fluid demand flows. By tracking the progress of production, producers can identify areas where production can be improved and make adjustments accordingly. This helps to ensure that production is as efficient as possible.

- Tracking Progress: A production schedule is also used to track the progress of production. Producers can monitor how the production is progressing, identify problems, and make adjustments as needed. This helps to keep the production on track and ensure that it is completed on time and within budget.

- Improved communication: Communication has been improved because there is now a single document that contains information on every step of the production workflow.

Overall, a production schedule is an important tool used to plan, organize, and track the progress of a production process. It helps to ensure that the production process is completed efficiently and on time, and that all resources are allocated correctly.

Components of Production Scheduling

The following steps are involved in production scheduling:

- Identifying and assigning the correct number of employees;

- Identifying and allocating suitable raw materials;

- Identifying and allocating the right machinery and equipment, and

- Synchronizing all the resources to establish priorities and meet customer needs.