- Information for Faculty

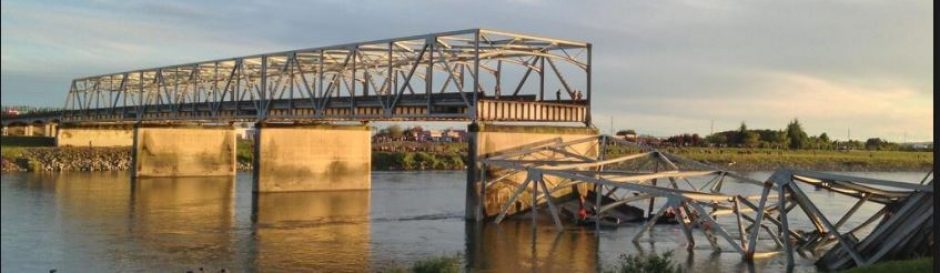

- Bridge Failure Cases

- Dam Failure Cases

- Building Failure Cases

- Other Failure Cases

2000 Commonwealth Avenue, Boston

An investigation into the collapse of a 17-story concrete high-rise under construction at 2000 Commonwealth Avenue disclosed a number of irregularities and deficiencies, including, among others:

- Lack of proper building permit

- Insufficient concrete strength

- Insufficient length of rebars

- Lack of proper field inspection

- Various structural design deficiencies

- Improper formwork

- Premature removal of formwork

- Inadequate placement of rebars

- Lack of construction control (Kaminetzky 1991)

Four workers were killed and twenty injured. Fortunately, the collapse occurred slowly enough for many of the workers to escape. The collapse occurred on January 25, and low temperatures had certainly retarded strength gain. Cores showed concrete compressive strengths as low as 700 psi (Kaminetzky 1991, Feld and Carper 1997).

Complete case study by Suzanne King:

On January 25, 1971, two-thirds of a 16-story apartment building collapsed while under construction at 2000 Commonwealth Avenue, Boston, MA. Four workers died after a failure on the roof instigated a domino-like collapse all the way to the basement, where the men were found. Fortunately, the collapse took a long enough time for most of the workers to run to safety. This paper investigates the numerous causes and lessons learned of this structural failure.

Introduction

Studying structural failure case studies is a way of studying the history of the engineering profession. Typical calculations for design are based on predicting and avoiding failure. The factor of safety is used to avoid failures, but knowledge of past failures will better equip an engineer to steer clear of future failures. It is not only important to know what caused the failure, but also to understand how it occurred and how to avoid the problem in the future.

In the collapse at 2000 Commonwealth Avenue, Boston, Massachusetts on January 25, 1971, punching shear failure is believed to have triggered the collapse of two-thirds of the 16-story concrete building during construction. But an investigation called for by the mayor proved that there were many flaws in the design of the apartment building. It is important to remind engineers of past failures, such as this one so that history does not repeat itself.

Design and Construction

The high-rise apartment building was made of cast-in-place reinforced concrete flat slab construction with a central elevator shaft. This style of construction is popular for multi-story buildings because it requires a minimum slab thickness and reduces the overall height of the building (Feld and Carper 1997). 2000 Commonwealth Ave. was designed to be sixteen stories with a mechanical room above a five-foot crawl space on the roof. The structure also had two levels of underground parking. A swimming pool, ancillary spaces, and one apartment were located on the first floor and one hundred thirty-two apartments were on the second through sixteenth floors. Originally these apartments were to be rented, but the owners later decided to market them as condominiums.

Construction began on the site late in the fall of 1969. Excavation had been partially started a few years earlier. Most of the work was subcontracted to area specialists. Only one representative from the General Contractor was on site during construction. At the time of the collapse, construction was nearing completion. Brickwork was completed up to the sixteenth floor and the building was mostly enclosed from the second to fifteenth floors. Plumbing, heating and ventilating systems were being installed throughout various parts of the building. Work on interior apartment walls had also started on the lower floors. A temporary construction elevator was located at the south edge of the building to aid in transporting equipment to the different floors. It is estimated that one hundred men were working in or around the building at the time of failure (Granger et al. 1971).

After interviewing many eyewitnesses, the mayors investigating commission concluded that the failure took place in three phases. These phases were punching shear failure in the main roof at column E5, a collapse of the roof slab, and, finally, the general collapse.

Phase 1: Punching Shear Failure in the Main Roof at Column E5

At about ten in the morning, concrete was being placed in the mechanical room floor slab, wall, wall beams, and brackets. Placement started at the west edge and proceeded east. Later in the afternoon, at about three o’clock, most of the workers went down to the south side roof for a coffee break. Only two concrete finishers, Mr. Daniel Niro and Mr. Joseph Oliva, remained on the pouring level near line 4-1/2. Shortly after the coffee break, the two men felt a drop in the mechanical room floor of about one inch at first and then another two or three inches a few seconds later. The labor foreman, Mr. Anthony Paolini, was directing the crane carrying the next bucket of concrete. He instructed the operator to “hold the bucket” and went down to the sixteenth floor by way of a ladder in the east stairway. That is when the punching shear was noticed around column E5. The carpenter foreman, Mr. Antonio M. Fantasia, was also in the area and immediately yelled a warning to the men working on the sixteenth floor and roof of a possible roof collapse. The slab had dropped five or six inches around the column and there was a crack in the bottom of the slab extending from column E5 toward column D8. Column E5 is located directly below where the concrete was being placed for the mechanical room floor slab on the east side of the building as shown in the following figure (Granger et al. 1971).

Phase 2: Collapse of the Roof Slab

After hearing Mr. Fantasia’s warning, most of the workers in the area of column E5 managed to run to an east balcony and stay there until after the roof slab collapse. Eyewitness testimony concluded that the collapse happened fairly quickly. The roof slab began to sag in the shape of a belly and reinforcing steel started sticking out from the mechanical room floor slab. Soon everything started to shake and the east half of the roof slab collapsed onto the sixteenth floor. Then it stopped, giving the workers a chance to run down the stairs to the ground. At the time of failure, the Structural Subcontractor was placing reinforcing steel for the stairs on the fourteenth and fifteenth floors on the east side of the building. So when the workers were making their way from the roof and floors above, most of them crossed over to the west side of the building when they reached the fifteenth floor. (Granger et al. 1971)

Phase 3: General Collapse

After the roof collapsed, the roof settled and most of the stranded workers could be rescued using the crane and construction elevator. However, about twenty minutes after the roof failed, the east side of the structure began to collapse. A resident of 1959 Commonwealth Ave. described the collapse as a domino effect (or progressive collapse). The weight of the collapsed roof caused the sixteenth floor to collapse onto the fifteenth floor, which then collapsed on the fourteenth floor, and so on to the ground (Litle 1972). At first, the different floors were distinguishable, but later dust and debris made it difficult to discriminate between the various floors. When the dust finally settled, two-thirds of the building had collapsed. The east side and areas on either side of the elevator shaft were gone. Four workers were killed during the collapse and thirty workers suffered injuries (Granger et al. 1971).

The extent of the collapse is shown in the photographs in APPENDIX B. The first picture is from the February 4, 1971, issue of EngineeringNews-Recordd. This picture shows the floor slabs hanging from individual floors. Only the west side of the building remains standing. The next photograph is a close-up of the collapse. It shows the exposed elevator shaft. The building collapsed around the interior elevator.

Causes of Failure

A week after the collapse, Engineering News Record reported that there were three possible causes of structural failure under investigation: formwork for the penthouse floor slab collapsed onto the roof, a heavy piece of equipment fell from a crane and started the progressive collapse or concrete placed during previous cold days had failed (ENR, February 4, 1971). However, after an extensive investigation, the mayor’s commission concluded that there were many design and construction flaws that attributed to the collapse. The committee determined that punching shear failure at column E5 triggered the initial collapse. This type of failure is caused by unbalanced moments transferred between the column and flat-plate (Megally and Ghali 2000) and was a result of non-conformities to the design documents. The major areas that construction did not follow the design were shoring and concrete strength. Inadequate sharing under the roof slab on the east side of the building made it impossible for the roof to hold the freshly placed concrete for the mechanical room floor slab, construction equipment and two boilers that were stored on that side of the building. Also, the concrete strength of the roof slab was well below three thousand pounds per square inch as specified in the design. However, there were many other factors, design and procedural, that contributed to the collapse (Granger et al. 1971).

Design Concerns

The design concerns that contributed to the collapse include insufficient length and placement of rebar and various structural design deficiencies. All of the reinforcing steel used was designed to be billet steel, however, a large amount of rail steel was found in columns and slabs on the lower floors. The major difference between rail and billet steel (as described in the Commission’s report) is the ultimate elongation. The average ultimate elongation for rail steel used on the project was just over ten and a half inches as opposed to a little over fifteen and a quarter inches for the billet steel. This variance would effect how the floor slabs reacted to tension forces. Also, the steel was delivered by the supplier in bundles with marks on the steel indicating what the steel was intended for. However, some of the marks used were the same as the marks on the design plans, yet meant something different. For example, the supplier gave marks for number four bars at the south edge of the slab which was identical to marks given on the Engineers placing drawings for top slab bars over column E5 (Granger et al. 1971). There were also design errors in the reinforcement. Some of the bars did not extend long enough into the columns as required by code and placement of bars in some of the slabs was not sufficient to meet the American Concrete Institutes (ACI) code at the time. There was also inadequate design around columns. ACI requires that at least twenty-five percent of the negative slab reinforcement in each column strip pass over the column within a distance of “d” on either side of the column face (Granger et al. 1971). This requirement was not fulfilled.

Procedural Concerns

There were many procedural concerns in the construction of 2000 Commonwealth Ave. Nearly every step of construction was flawed (Kaminetzky 1991). Some of the major concerns include lack of proper building permit and field inspection, premature removal of formwork, and lack of construction control.

The investigating committee determined that if the construction had had a proper building permit and followed codes, then the failure could have been avoided. Since there were numerous problems that all aided to the collapse, deciding whom to hold responsible for the collapse became a difficult feat. Ownership changed hands many times and most jobs were subcontracted. Some of the transactions that took place with Bostons Building Department are listed in the table below (Granger et al. 1971). There was confusion surrounding the project from the start.

Construction did not follow the Structural Engineers specifications for shoring or formwork. Before removal of shores and forms, the concrete must first reach seventy percent of its designated twenty-eight-day strength. It was the commission’s opinion that despite seven-day cylinder tests that said otherwise, the average strength of the concrete in the roof slab was only nineteen hundred pounds per square inch after at least forty-seven days, not the required twenty-one hundred pounds per square inch for removal or the specified three thousand pounds per square inch required after twenty-eight days. There was no inspection or cylinder testing done for the east side of the building, so removal of formwork was based on values obtained from the west side of the building. Furthermore, adequate shoring under the roof slab below the freshly place mechanical room floor slab was not used (Granger et al. 1971).

Finally, there was very little construction control on the site. There was no architectural or engineering inspection of the project and the inspection done by the city of Boston was inadequate. The design plans specifically stated that certain aspects of the project needed to be approved by an architect, yet no architect or engineer was consulted. The Affidavit Engineer and Licensed Builder were also nowhere to be found. Instead, construction was based on arrangements made by the subcontractors. As mentioned before, there was only one representative from the General Contractor and this man was not a licensed builder. He did not direct, supervise or inspect any of the work done by the subcontractors (Granger et al. 1971).

Similarities to Other Failures

The progressive collapse of 2000 Commonwealth Ave. was similar to the structural failures of buildings in Bailey’s Crossroads and Harbour Cay . On March 2, 1973, the Skyline Plaza in Baileys Crossroads, Virginia collapsed while under construction. Like 2000 Commonwealth Ave., premature removal of shoring and insufficient concrete strength were the causes of failure (Woodward et al. 1983). The collapse of the flat-plate Harbour Cay condominium building in Cocoa Beach, Florida on March 27, 1981, was caused by punching shear failure triggered a progressive collapse (Lew et al.1983), much like 2000 Commonwealth Ave. Investigations following the three collapses concluded that both design and construction errors contributed to the cause of the collapse. All three failures could have been avoided if better inspections of materials and construction details were conducted.

References:

- Feld, J., and Carper, K. (1997). Construction Failure. 2 nd Ed., John Wiley & Sons, New York, N. Y

- Granger, R. O., Peirce, J. W., Protze, H. G., Tobin, J. J., and Lally, F. J. (1997), The Building Collapse at 2000 Commonwealth Avenue, Boston, Massachusetts, on January 25, 1971 , Report of the Mayor’s Investigating Commission, The City of Boston, Massachusetts.

- Kaminetzky, D. (1991). Design and Construction Failures: Lessons from Forensic Investigations . McGraw-Hill, New York, N. Y.

Illustrations from Chapter 5 of the book Beyond Failure: Forensic Case Studies for Civil Engineers, Delatte, Norbert J., ASCE Press.

- Search for:

- Make a Gift

- Maps / Directions

Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. When you join you get additional benefits.

Confirm Password *

First Name *

Last Name *

Country Select a country… Åland Islands Afghanistan Albania Algeria Andorra Angola Anguilla Antarctica Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belau Belgium Belize Benin Bermuda Bhutan Bolivia Bonaire, Saint Eustatius and Saba Bosnia and Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory British Virgin Islands Brunei Bulgaria Burkina Faso Burundi Cambodia Cameroon Canada Cape Verde Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos (Keeling) Islands Colombia Comoros Congo (Brazzaville) Congo (Kinshasa) Cook Islands Costa Rica Croatia Cuba CuraÇao Cyprus Czech Republic Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Ethiopia Falkland Islands Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guatemala Guernsey Guinea Guinea-Bissau Guyana Haiti Heard Island and McDonald Islands Honduras Hong Kong Hungary Iceland India Indonesia Iran Iraq Isle of Man Israel Italy Ivory Coast Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macao S.A.R., China Macedonia Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Mexico Micronesia Moldova Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar Namibia Nauru Nepal Netherlands Netherlands Antilles New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island North Korea Norway Oman Pakistan Palestinian Territory Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Poland Portugal Qatar Republic of Ireland Reunion Romania Russia Rwanda São Tomé and Príncipe Saint Barthélemy Saint Helena Saint Kitts and Nevis Saint Lucia Saint Martin (Dutch part) Saint Martin (French part) Saint Pierre and Miquelon Saint Vincent and the Grenadines San Marino Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands Somalia South Africa South Georgia/Sandwich Islands South Korea South Sudan Spain Sri Lanka Sudan Suriname Svalbard and Jan Mayen Swaziland Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tokelau Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Turks and Caicos Islands Tuvalu Uganda Ukraine United Arab Emirates United Kingdom (UK) United States (US) Uruguay Uzbekistan Vanuatu Vatican Venezuela Vietnam Wallis and Futuna Western Sahara Western Samoa Yemen Zambia Zimbabwe

By registering, you agree to the Terms of Service and Privacy Policy . *

Log in to TheConstructor to ask questions, answer people’s questions, write articles & connect with other people. When you join you get additional benefits.

Join for free or log in to continue reading...

Username or email *

Forgot Password

Lost your password? Please enter your email address. You will receive a link and will create a new password via email.

Sorry, you do not have permission to ask a question, You must log in to ask a question. Join now!

The Constructor

3 important cases of building collapse due to poor construction management.

Do you need to remove the ads? Join now!

🕑 Reading time: 1 minute

Construction is perhaps the most critical stage in the life cycle of structures, mainly because of the danger of failure and the high chances of underestimating construction loads.

A report developed by the American Society of Civil Engineers, based on their study of around 600 failed structures, found that around 40% of the structures failed during the construction stage, 36% of the structures failed during the pre-construction stage due to flawed designs, and 24% failed during their operational stage.

The failure of a structure is described as the propagation of local collapse from one segment to another segment, eventually resulting in the failure of an entire building or its lopsided part. It could be a product of natural disasters, for example, seismic tremors, floods, or coincidental acts such as an explosion in the service system or terrorist bombings.

Analyzing the reasons for explicit structural failures and proposing measures to relieve their effects is a successful measure to lessen risks and improve the safety of structures. Therefore, this article discusses the failure of some major structures, their root causes, and the lessons learned.

1. The Skyline Plaza Apartment Building, Virginia, US

The design plan of the Skyline Plaza complex included six office buildings, eight apartment buildings, shops, and one hotel. The project was a $200 million residential-commercial complex and was situated in Fairfax County, Virginia. During the construction of the skyline plaza complex, one of the apartment buildings under construction collapsed. A total of 15 labors were killed, and 40 were injured.

Design drawings of the collapsed building included the construction of 26 stories, a penthouse, and a four-story storm basement for parking. The building design was of a reinforced concrete flat plate with a 200 mm thick concrete slab. The height between each story was 2.7 m.

1.1 Investigation Findings

On 2 nd March 1973, some portion of the apartment building collapsed during construction. The collapse began on the 23 rd floor when the slab of the 24 th floor was being cast. On the 23 rd floor, the slab started showing cracks and the failure of the building occurred vertically along the full height of the building, including the basement levels. Also, the adjacent post-tensioned reinforced concrete car parking structure collapsed.

Specialists concurred that the concrete had not acquired sufficient strength to carry the construction loads applied during the construction process. Investigators confirmed that the original design plan had no deficiencies. The most probable reason for the collapse of the building was the punching shear failure on the 23 rd floor of the building.

After the collapse, a team from the Occupational Safety and Health Administration (OSHA) came to the site and started an investigation. Further, a detailed investigation was conducted by the National Bureau of Standards (NBS).

NBS and OSHA mentioned in their reports that the collapse of the building was directly related to poorly managed construction processes. The court found that the contractor and the site engineer were guilty of negligence as the contractor didn't follow the building code requirement and the site engineer didn't inspect the work properly.

1.2 Lessons Learned

After the collapse of the Skyline Plaza apartment building, a series of changes were made in the building code related to the progressive collapse failure. Special inspection procedures were added in the inspection section of the building codes. Design criteria were also changed for effective planning to reduce the possibility of failure due to progressive collapse. The following points describe the violations of specified construction requirements and standard practices:

- Violation of prerequisites to completely shore the two stories underneath the floor being cast.

- Failure to permit legitimate curing time before removing shoring.

- Failure to conduct curing test on the concrete specimen in the field.

- Use of out-of-plumb shoring.

- Improper inspection during casting and formwork removal to check the strength of concrete.

- Improper installation of the climbing crane.

2. Ronan Point Tower, Canning Town , London

The need to give substitution lodging to homes destroyed in World War-II encouraged European engineers to develop innovative pre-assembled construction strategies. One such plan included the construction of high-rise buildings using pre-stressed concrete components made in factories.

The structural framework included the construction of load-bearing walls and each floor was directly stacked onto the walls. Grouted bearing surfaces were used to construct the joint between the wall and the floor. This process of construction was termed as system building. A skyscraper at Ronan Point, Canning Town, UK, was built using this system building technique.

On 16 th May 1968, a blast occurred due to gas leakage in the kitchen of a house on the 18 th floor. Just after the blast, the kitchen walls collapsed, and in-turn, the walls above the 18 th floor caved in. This impacted the floors beneath and obliterated the entire corner of the structure. A total of 14 people were injured and three were killed.

2.1 Investigation Findings

The investigation team revealed that the building collapsed due to the non-availability of an alternative load path when one portion of the external wall collapsed. After the demolition of the building, it was also revealed that the quality of the grouted bearing surface for the joints between floors and the walls was poor.

Because of the unprecedented collapse, the government examined the safety of other buildings constructed using the same concept as the Ronan Point Tower. Many buildings were demolished well ahead of their life span.

The concept of progressive collapse of structures was not much known to the engineers before the failure of the Ronan Point Tower. In such collapses, a local failure is followed by widespread collapse through a chain reaction. What was irregular on account of the failure of the Ronan Point Tower was that a minor gas blast set off the collapse of a huge portion of a finished structure.

2.2 Lessons Learned

The experience due to the failure of Ronan Point Tower re-emphasized the following points:

- Progressive failure can also occur in fully constructed structures.

- A structure should have redundancies to reduce the possibility of progressive failure.

- Quality control should strictly be followed in the construction processes.

3. 2000 Commonwealth Avenue, Boston, US

On 25 th January 1971, a two-third portion of a 16-story residential building known as 2000-Commonwealth Avenue in Boston collapsed during construction, leading to the death of four workers. The building was under construction for more than six years. The collapse of the building generated approximately 8000 tons of debris. Luckily, the failure of the building was gradual, giving the workers some time to escape from the building site.

The building was designed as a reinforced concrete structure and flat slabs were used for the roofing system with an elevator shaft provided in the center. This type of structural design is mainly famous for multi-story construction as it reduces the thickness of the slab and overall height between the floors. The thickness of flat slabs was between 160-190 mm for all the building areas except near the elevator core where it was 230 mm thick. The arrangement of the structural component constituted a height of 2.7 m for all the floors.

The building, situated at 2000 Commonwealth Avenue, was intended to be 16 stories high with a mechanical room of height 1.5 m for the working of the lift at the rooftop. The plan area of the structure was 56 x 21 m 2 . The building additionally had underground parking of two levels. A pool, auxiliary spaces, and one flat were situated on the first floor, and a total of 132 flats were on the second through sixteen floors. At first, these flats were to be leased. However, the proprietors later chose to advertise them as apartment suites.

At the hour of the collapse of the building, construction work was almost completed. The brickwork was finished up to the sixteenth floor, and the structure was generally encased from the second to the fifteenth floor. Heating, plumbing, and ventilation frameworks were introduced all through different floors of the structure. The interior work had also started on the lower floors. A temporary lift was constructed to help in moving equipment to various floors. It was assessed that 100 individuals were working in or around the structure at the hour of the collapse.

The collapse of the building occurred in three stages. These stages were, failure due to punching shear in the rooftop at section E5, the failure of the slab, and in the end, the progressive failure of the structure.

3.1 Investigation Findings

The civic chairman of Boston appointed a commission to inquire about the collapse of the building. The commission discovered the following critical observations:

- There was no signature of an architect or engineer found on a single drawing of the building.

- The design engineer didn't give the computations supporting his structural drawings to the commission. No head or representative of the team of contractors held a building construction license of Boston city.

- Ownership of the venture changed a few times, with changes in planners and architects. This scenario added to the general disarray and contributed to the abnormalities referred above.

- The general contractual worker just had a solitary representative on location. Most subcontracts were given directly by the owner to the subcontractors and bypassed the general contractor. A total of seven subcontractors were involved in the construction.

- The subcontractor, who was assigned to conduct the cold weather protection work on the structural concrete didn't carry out the assigned work. However, the structural engineer had indicated these measures.

- There was no proof of any inspection of the work by a specialist despite the fact that the project particulars needed this.

- The quality of construction material and quality inspections were poor.

- The collapse of the building occurred due to the development of punching shear mechanism around column E5. Punching shear developed the flexural cracks around the roof slab located near the elevator core. Thus, the slab collapsed due to flexural yielding.

- The design manual indicated a 28-day strength of 25 MPa. However, at the failure time, 47 days after casting work, the concrete couldn't seem to attain the necessary 28-day strength.

- The most critical inadequacies were an absence of shoring under the slab at the roof and the quality of the concrete.

3.2 Lessons Learned

The following key factors describe the collapse of the multi-story building situated at 2000 Commonwealth Avenue:

- Authorized design engineers should be chosen for the development of working drawings for construction.

- Engineers and architects should be responsible for all the design-related calculations and their design work must be examined by the experts in that field from a government organization.

- Ownership of a project should not change multiple times to reduce the confusion between the previous engineer and the newly appointed engineer.

- Inspection at the construction site should be conducted regularly by government organizations, especially for cold weather work.

- The quality of concrete work should be monitored throughout the project.

- The construction work should conform to design documents and construction procedures.

The collapse of a building is characterized as the propagation of an initial local collapse from component to component, ultimately resulting in the collapse of a whole structure or a disproportionately large portion of it.

Construction is one of the most critical phases in the life cycle of buildings due to the risk of failure and the possibility of underestimating construction loads.

The structural framework included the construction of load-bearing walls and each floor was directly stacked on the walls. Grouted bearing surfaces were used to construct the joint between the wall and the floor. This process of construction was termed system building.

Top 5 Biggest Dam Failures in the World

5 Disastrous Foundation Failures in New York City

Top 6 Energy-Efficient High-Rise Buildings in the World

Ravi Panwar

Related posts.

16 Types of Pipelines and their Construction Method

Factors Influencing Earthquake Resistant Design of Structures

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Structural Failure of Building's Walkway: Case Study

Related Papers

Falhas em estruturas de fundações

Subramanian Narayanan

With the dwindling natural resources, it is very important for engineers to avoid failures of any nature and build structures which are safe, stable, economic, aesthetic, durable, and environment friendly. However, building and other structural failures are occurring at regular intervals in India. These failures, though well reported in newspapers, the reasons for these collapses are not well documented, even though some committees are appointed in some cases to study the failures. If the causes of failures are well publicized, designers and builders can learn from the mistakes done by others and will not repeat them in their practice. Hence an attempt is made in this paper to describe some important failures that resulted in code clause changes or in changes to professional practice. It is high time that legislation is passed in India, similar to those available in Western Countries, such that only qualified and experienced engineers are allowed to practice, so that failures are minimized.

Procedia Engineering

Yang Miang Goh

Design errors can severely jeopardize safety and contribute to failures in construction and engineering projects. Such failures can have devastating economic, environmental and social consequences. Significant efforts have been made to reduce the incidence of failures through learning from previous disasters and events by modifying building and engineering codes and standards accordingly. Design errors, however, remain an innate feature of construction and engineering projects. Most errors are identified during construction and require rework, but there is always a potential for some to remain undetected and contribute to failure, and as a result potentially contribute to accidents and loss of life. This paper examines the circumstances and issues that contributed to a series of construction and engineering failures, to enable development of a systemic learning framework to contain and reduce design errors and potential failures and accidents.

Forensic Science Medicine and Pathology

Sarah Hainsworth

Gary L Comstock

arjunan chandrasekaran

Yaohua Deng (Jimmy)

The tied arch bridge system provides a unique solution to the several challenges associated with the construction of railroad overpasses and water crossings, such as restricted vertical clearance, undesirable or impractical arrangement for intermediate piers, and extremely limited traffic control during construction. The paper presents the design and construction challenges pertinent to a novel concrete filled steel tubular tied arch system that was first introduced in Ravenna Viaduct (53 m) and applied later to Columbus Viaduct (79 m). The main structural components of Columbus Viaduct are described in detail and the advantages of the system are summarized. The detailed analysis of the system at different construction stages and design checks of main components and connections under various loading conditions are discussed. Experimental investigations conducted on concrete filled steel tubular arch and tie specimens to validate their theoretical capacities are demonstrated. The three‐dimensional nonlinear finite element model developed to analyze the tie‐to‐arch connection and evaluate the lateral stability of arches is presented. Finally, the main construction procedures and challenges of the three tied arches of Columbus Viaduct are highlighted.

Alessandro Lodigiani

Edward Simpson

Ashman Noordin

RELATED PAPERS

Aditya Widya Utama

VISHAL GORE

Javier Mendoza Carranza

AISC 360-16

MIGUEL FRANKLIN

Journal of Structural Engineering

Dawn E Lehman

Juan Pablo Molina Alvarez

Yatniel Bustamante

Journal of Performance of Constructed Facilities

Catherine French

Raul Aliaga Aliaga

Abel Olivas

Ahmed Polra

Tatri Mukherjee

nathan alleyne

Maged Hassan

Toño Camacho

Practice Periodical on Structural Design and Construction

jose tomas euceda

Oscar Gnaedig

Journal of Composites for Construction

Salvatore Russo

Eduardo Buezo

Vaclav Hasik

GISSEL CONDORI GAVILAN

Samir Rabia

Sergio Chacón

2013 ASEE Annual Conference & Exposition Proceedings

Rebecca Atadero

Thomas Scarangello

Eliya Henin, Ph.D., P.E., S.E. PMP , George Morcous

LUIS F. JUAREZ A.

Akwanza Mtenga

wisnu wardhana , Yatniel Bustamante

Jorge Malave

Victor Hugo Belalcazar Uribe

Lucho Montecinos

ISAIAS CORZA GARCIA

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Skip to content

- Skip to search

- Skip to footer

Products, Solutions, and Services

Want some help finding the Cisco products that fit your needs? You're in the right place. If you want troubleshooting help, documentation, other support, or downloads, visit our technical support area .

Contact Cisco

- Get a call from Sales

Call Sales:

- 1-800-553-6387

- US/CAN | 5am-5pm PT

- Product / Technical Support

- Training & Certification

Products by technology

- Software-defined networking

- Cisco Silicon One

- Cloud and network management

- Interfaces and modules

- Optical networking

- See all Networking

Wireless and Mobility

- Access points

- Outdoor and industrial access points

- Controllers

- See all Wireless and Mobility

- Secure Firewall

- Secure Endpoint

- Secure Email

- Secure Access

- Multicloud Defense

- See all Security

Collaboration

- Collaboration endpoints

- Conferencing

- Cisco Contact Center

- Unified communications

- Experience Management

- See all Collaboration

Data Center

- Servers: Cisco Unified Computing System

- Cloud Networking

- Hyperconverged infrastructure

- Storage networking

- See all Data Center

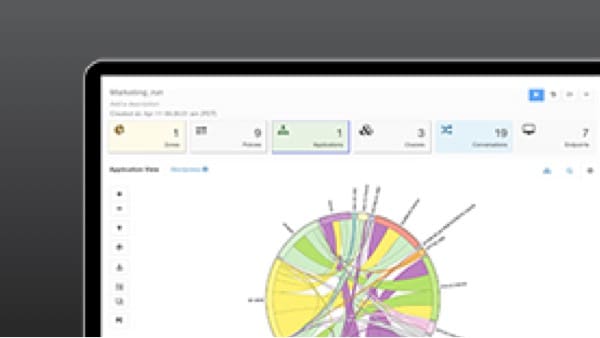

- Nexus Dashboard Insights

- Network analytics

- Cisco Secure Network Analytics (Stealthwatch)

- Video endpoints

- Cisco Vision

- See all Video

Internet of Things (IoT)

- Industrial Networking

- Industrial Routers and Gateways

- Industrial Security

- Industrial Switching

- Industrial Wireless

- Industrial Connectivity Management

- Extended Enterprise

- Data Management

- See all industrial IoT

- Cisco+ (as-a-service)

- Cisco buying programs

- Cisco Nexus Dashboard

- Cisco Networking Software

- Cisco DNA Software for Wireless

- Cisco DNA Software for Switching

- Cisco DNA Software for SD-WAN and Routing

- Cisco Intersight for Compute and Cloud

- Cisco ONE for Data Center Compute and Cloud

- See all Software

- Product index

Products by business type

Service providers

Small business

Midsize business

Cisco can provide your organization with solutions for everything from networking and data center to collaboration and security. Find the options best suited to your business needs.

- By technology

- By industry

- See all solutions

CX Services

Cisco and our partners can help you transform with less risk and effort while making sure your technology delivers tangible business value.

- See all services

Design Zone: Cisco design guides by category

Data center

- See all Cisco design guides

End-of-sale and end-of-life

- End-of-sale and end-of-life products

- End-of-Life Policy

- Cisco Commerce Build & Price

- Cisco Software Central

- Cisco Feature Navigator

- See all product tools

- Cisco Mobile Apps

- Design Zone: Cisco design guides

- Cisco DevNet

- Marketplace Solutions Catalog

- Product approvals

- Product identification standard

- Product warranties

- Cisco Security Advisories

- Security Vulnerability Policy

- Visio stencils

- Local Resellers

- Technical Support

COMMENTS

structural elements, (Car retero-Ayuso et al., 2016) conducted a statistical study based on the. analysis of damages, symptoms and their evolutions, the results of th is study showed 66% of ...

recent facts and trends of building failures. Failure Defined The first study by the writers, cited in the previous section, which became the foundation for this paper, discovered 65 cases of building failures that occurred between 1977 and 1981, while the second study retrieved 46 cases of building failures that took place between 1982 and 1988.

Effects of premature termination: Case studies of Sri Lankan construction projects. Proceeding of the Second World Construction Symposium 2013: Socio-Economic Sustainability in Construction. 14-15 ...

PDF | On Jan 1, 2014, Jackson Musyoka Kioko published Causes of building failures in Africa: A case study on collapsing structures in Kenya | Find, read and cite all the research you need on ...

The case is appearing in existing residential building. The study consists of site investigation to determine the site condition, the types and causes of foundation failure, damaged occurred on site and also the types of remedial works carried out. All the types of failure have very strong connection with the soil, because the soil behaviors ...

Introduction. In the early morning hours of May 16, 1968, the occupant of apartment 90 on the 18 th floor of the Ronan Point apartment tower lit a match for her stove to brew her morning cup of tea. The resulting gas explosion, due to a leak, knocked her unconscious. The pressure of the small gas explosion blew out the walls of her apartment ...

7 Conclusions. On January 2006 a residential building in the southern part of Tel Aviv failed due to large settlements of its foundations. The largest settlement of 35cm occurred at the south-east corner. As a result one of 5 sections of the building has to be demolished.

building: Case study of a building at Oba-Ile, Akure Received (in revised form): 25th January 2011 ... building failure were reported in Lagos State. Between January 2005 and August 2006, over eight cases of building collapse were recorded in the country. Hence, as a matter of

Failure Case Studies in Civil Engineering: ... It also includes new case studies, such as the Alfred P. Murrah Federal Building, the Charles de Gaulle Airport Terminal, and the North Battleford, Saskatchewan, Water Treatment Plant. ... ISBN (PDF): 978--7844-7703-8. Buy E-book

Building Failure Cases. 2000 Commonwealth Avenue, Boston. Agricultural Product Loads. Air Force Warehouses. Bailey's Crossroads, Virginia. Bomber Crash into Empire State Building. Citicorp case study. Cleveland Lift-Slab Parking Garage. Cold-formed Steel Beam Construction Failure.

On January 25, 1971, two-thirds of a 16-story apartment building collapsed while under construction at 2000 Commonwealth Avenue, Boston, MA. Four workers died after a failure on the roof instigated a domino-like collapse all the way to the basement, where the men were found. Fortunately, the collapse took a long enough time for most of the ...

The following case studies show where the building envelope assemblies have fallen below the level of performance expected by the building occupants. The reader can decide for himself if the Standard of Care expected of reasonable and prudent building designers and developers has been breached. CASE STUDIES . Cast-In-Place Concrete Walls

The Education Committee has published several compilations of failure case studies and is currently publishing of a collection of failure case studies of concrete structures. This publication includes the Kobe Viaduct, the Norway Sleipner, the Khobar Towers, the Tropicana Casino parking garage, the Concord Overpass Collapse, the Pipers Row Car ...

1.1 Investigation Findings . On 2 nd March 1973, some portion of the apartment building collapsed during construction. The collapse began on the 23 rd floor when the slab of the 24 th floor was being cast. On the 23 rd floor, the slab started showing cracks and the failure of the building occurred vertically along the full height of the building, including the basement levels.

Building structure failures caused by defects in workmanship. S. Kobielak E. Hutnik Z. Zamiar. Engineering. 2015. The paper describes the failures caused by defects in workmanship, using the following as examples 1) the Hyatt Regency Hotel building in Kansas City, the U.S., 2) the roof over the grandstand at the….

Figure 1: Collapsed part of the building. Figure 2: The reconstructed combined footing with the column reinforcement of the collapsed part of the building. Causes of structural failures of ...

[3] 2012-2013: Concrete technology class-notes on major causes of building failure through various case studies on durability of concrete structure by Prof. Rathish Kumar Pancharathi, National Institute of Technology, Warangal, Department of Civil Engineering, India. Author Jackson M. Kioko Civil Engineering Department,

The causes of the Hyatt Regency walkway collapse was attributed to: 1. Design errors—this includes designing a walkway structure that does not meet the local code requirement, 2. Construction errors—this include verbal communications between the fabricator and the EOR, 3. Lack of design details, 4.

0000000340_Building Failure- Causes and Case Studies - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses causes of building failures and provides examples of structural collapses. It identifies common causes of failures such as cracks and corrosion, thermal changes, foundation failures, fires, and extraordinary loads.

Evidence of explosions include shattered glass, small debris of walls and crushed rubble blown to tens, even hundreds, of meters away. Secondly, the building failed suddenly and vertically. This vertical failure provoked curiosity amongst the engineers, so they investigated all the witnesses.

The publication is also based on the knowledge, mentioned in [17][10][14] and [7]. 3. Conclusion Cavern structures represent a special category of buildings in easily quarried rocks. Their specification is special both in terms of building material, which is composed of rock massif, and in the case of building failures occurring in them.

TIuo case studies illvolvillg the failure of the buildillg ellvelope are presellted ill this paper. Botl' sludies cOllcem rural hospi lals localed ill Ihe cold climale of Ihe 1I0rih celliral area of Ihe province of Alberla, Callada. 111 Ihe first case study the prob lems ellcoulliered were cracks in Ihe brick velleel~ efflorescellce

In book: Handbook of material failure analysis with case studies from the construction industries (pp.157-170) Edition: 1st; Chapter: 8; Publisher: Mathew Deans

Cisco+ (as-a-service) Cisco buying programs. Cisco Nexus Dashboard. Cisco Networking Software. Cisco DNA Software for Wireless. Cisco DNA Software for Switching. Cisco DNA Software for SD-WAN and Routing. Cisco Intersight for Compute and Cloud. Cisco ONE for Data Center Compute and Cloud.