MBA Knowledge Base

Business • Management • Technology

Home » Management Case Studies » Case Study: Inventory Management Practices at Walmart

Case Study: Inventory Management Practices at Walmart

About walmart.

Wal-Mart Stores, Inc. is the largest retailer in the world, the world’s second-largest company and the nation’s largest nongovernmental employer. Wal-Mart Stores, Inc. operates retail stores in various retailing formats in all 50 states in the United States. The Company’s mass merchandising operations serve its customers primarily through the operation of three segments. The Wal-Mart Stores segment includes its discount stores, Supercenters, and Neighborhood Markets in the United States. The Sam’s club segment includes the warehouse membership clubs in the United States. The Company’s subsidiary, McLane Company, Inc. provides products and distribution services to retail industry and institutional foodservice customers. Wal-Mart serves customers and members more than 200 million times per week at more than 8,416 retail units under 53 different banners in 15 countries. With fiscal year 2010 sales of $405 billion, Wal-Mart employs more than 2.1 million associates worldwide. Nearly 75% of its stores are in the United States (“Wal-Mart International Operations”, 2004), but Wal-Mart is expanding internationally. The Group is engaged in the operations of retail stores located in all 50 states of the United States, Argentina, Brazil, Canada, Japan, Puerto Rico and the United Kingdom, Central America, Chile, Mexico,India and China.

Walmart Inventory Management

Wal-Mart had developed an ability to cater to the individual needs of its stores. Stores could choose from a number of delivery plans. For instance, there was an accelerated delivery system by which stores located within a certain distance of a geographical center could receive replenishment within a day. Wal-Mart invested heavily in IT and communications systems to effectively track sales and merchandise inventories in stores across the country. With the rapid expansion of Wal-Mart stores in the US, it was essential to have a good communication system. Hence, Wal-Mart set up its own satellite communication system in 1983. Explaining the benefits of the system Walton said, “I can walk in the satellite room, where our technicians sit in front of the computer screens talking on the phone to any stores that might be having a problem with the system, and just looking over their shoulders for a minute or two will tell me a lot about how a particular day is going. On the screen, I can see the total of the day’s bank credit sales adding up as they occur. If we have something really important or urgent to communicate to the stores and distribution centers, I, or any other Wal-Mart executive can walk back to our TV studio and get on that satellite transmission and get it right out there. I can also go every Saturday morning around three, look over these printouts and know precisely what kind of work we have had.”

Wal-Mart was able to reduce unproductive inventory by allowing stores to manage their own stocks, reducing pack sizes across many product categories, and timely price markdowns. Instead of cutting inventory across the board, Wal-Mart made full use of its IT capabilities to make more inventories available in the case of items that customers wanted most, while reducing the overall inventory levels. Wal-Mart also networked its suppliers through computers. The company entered into collaboration with P&G for maintaining the inventory in its stores and built an automated reordering system, which linked all computers between P&G and its stores and other distribution centers. The computer system at Wal-Mart stores identified an item which was low in stock and sent a signal to P&G. The system then sent a re-supply order to the nearest P&G factory through a satellite communication system. P&G then delivered the item either to the Wal-Mart distribution center or directly to the concerned stores. This collaboration between Wal-Mart and P&G was a win-win proposition for both because Wal-Mart could monitor its stock levels in the stores constantly and also identify the items that were moving fast. P&G could also lower its costs and pass on some of the savings to Wal-Mart due to better coordination.

Employees at the stores had the ‘Magic Wand,’ a hand-held computer which was linked to in-store terminals through a radio frequency network. These helped them to keep track of the inventory in stores, deliveries and backup merchandise in stock at the distribution centers. The order management and store replenishment of goods were entirely executed with the help of computers through the Point-of-Sales (POS) system. Through this system, it was possible to monitor and track the sales and merchandise stock levels on the store shelves. Wal-Mart also made use of the sophisticated algorithm system which enabled it to forecast the exact quantities of each item to be delivered, based on the inventories in each store. Since the data was accurate, even bulk items could be broken and supplied to the stores. Wal-Mart also used a centralized inventory data system using which the personnel at the stores could find out the level of inventories and the location of each product at any given time. It also showed whether a product was being loaded in the distribution center or was in transit on a truck. Once the goods were unloaded at the store, the store was furnished with full stocks of inventories of a particular item and the inventory data system was immediately updated.

Wal-Mart also made use of bar coding and radio frequency technology to manage its inventories. Using bar codes and fixed optical readers, the goods could be directed to the appropriate dock, from where they were loaded on to the trucks for shipment. Bar coding devices enabled efficient picking, receiving and proper inventory control of the appropriate goods. It also enabled easy order packing and physical counting of the inventories. In 1991, Wal-Mart had invested approximately $4 billion to build a retail link system. More than 10,000 Wal-Mart retail suppliers used the retail link system to monitor the sales of their goods at stores and replenish inventories. The details of daily transactions, which approximately amounted to more than 10 million per day, were processed through this integrated system and were furnished to every Wal-Mart store by 4 a.m., the next day. In October 2001, Wal-Mart tied-up with Atlas Commerce for upgrading the system through the Internet enabled technologies. Wal-Mart owned the largest and most sophisticated computer system in the private sector. The company used Massively Parallel Processor (MPP) computer system to track the movement of goods and stock levels. All information related to sales and inventories was passed on through an advanced satellite communication system. To provide back-up in case of a major breakdown or service interruption, the company had an extensive contingency plan. By making effective use of computers in all its company’s operations, Wal-Mart was successful in providing uninterrupted service to its customers, suppliers, stockholders and trading partners.

Related posts:

- Case Study: Supply Chain Management of Walmart

- Case Study: How Walmart Enhances Supply Chain Management with ERP Initiatives?

- Case Study: Why Walmart Failed in Germany?

- Inventory Management Practices in Multinational Corporations

- Case Study of Walmart: Procurement and Distribution

- Case Study: Analysis of Performance Management at British Petroleum

- Case Study: Quality Management System at Coca Cola Company

- Case Study of Burger King: Achieving Competitive Advantage through Quality Management

- Inventory Management Concepts in Supply Chain Management

- Inventory Management

One thought on “ Case Study: Inventory Management Practices at Walmart ”

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Already on SCMDOJO? Log in

I accept SCMDOJO'S Terms of Use and Privacy Notice .

Walmart Supply Chain: Building a Successful Integrated Supply Chain for Sustainable Competitive Advantage

- Case Studies

Introduction

The global business landscape has witnessed an increasingly fierce competition, pushing companies to seek effective strategies to maintain and enhance their competitiveness. Among these strategies, the role of supply chain capability stands out as a key factor in driving success. A well-optimized supply chain not only ensures efficient delivery and cost-effectiveness but also provides companies with a competitive advantage in the market. In this context, Walmart, the world’s largest retailer, has demonstrated a highly successful and integrated Walmart supply chain, propelling its growth and dominance in the retail industry.

This case study aims to delve into the significance of supply chain capability for enhancing a company’s competitiveness and how it serves as a competitive advantage for companies. Additionally, we will explore the imperative need for supply chain redesign in the global economy to adapt to the challenges of the modern era of globalization. Focusing on Walmart’s exemplary supply chain practices, the purpose of this case study is to analyze the features of its successful integrated supply chain while identifying relevant issues in the context of the current globalized market.

[Read More: Rivian: Navigating Supply Chain and Operational Challenges and Embracing Growth ]

Walmart’s Supply Chain: Integrated Supply Chain Success

Data-driven success factors.

In the realm of modern supply chain management, data-driven strategies play a pivotal role in enhancing a company’s competitiveness. Walmart’s remarkable success as the world’s largest retailer can be attributed to its astute utilization of data analysis and advanced technologies within its integrated supply chain. This section delves into the key data-driven success factors that have propelled Walmart’s supply chain to the forefront of the retail industry.

[Read More: ERP Master Data: A Guide to Improve Quality & Governance ]

Role of Data Analysis through Barcode Scanning and Point-of-Sale Systems

Data analysis is at the core of Walmart’s supply chain prowess. The company has implemented sophisticated barcode scanning and point-of-sale systems to collect real-time data from its stores. By employing these technologies, Walmart gains valuable insights into customer buying behavior, sales trends, and inventory levels. The ability to analyze this data enables the retail giant to make informed decisions on product procurement, inventory management, and demand forecasting.

Efficient Supply Chain Practices: Automated Distribution Centers and Computerized Inventory Systems

Automation is a key component of Walmart’s efficient supply chain practices. The company has strategically invested in automated distribution centers, streamlining the flow of products from manufacturers to stores. These automated facilities not only optimize the handling and movement of goods but also enable faster order fulfillment and replenishment. Additionally, computerized inventory systems provide Walmart with accurate and up-to-date information about stock levels, allowing for precise inventory control and reducing the risk of stockouts or excess inventory.

Utilizing Walmart’s Own Trucking System and Cross-Docking Logistics

Another critical factor contributing to Walmart’s supply chain success is the utilization of its private trucking system and cross-docking logistics. By maintaining its own trucking fleet, Walmart gains greater control over transportation and delivery schedules, leading to improved efficiency and timely product replenishment. Furthermore, the adoption of cross-docking logistics techniques has enabled Walmart to minimize the need for intermediate storage, leading to reduced handling costs and faster product movement through the supply chain.

[Read More: The Ultimate Guide to Contract Logistics: What You Need to Know ]

Information Technologies Driving Efficiency

In Walmart’s journey towards becoming a global leader, information technologies have played a pivotal role in driving efficiency within the integrated Walmart supply chain. The retail giant has strategically adopted various IT initiatives to optimize its operations, enhance collaboration with suppliers, and achieve real-time inventory targeting. These technologies have contributed significantly to Walmart’s supply chain success, allowing them to maintain a competitive edge in the retail industry.

Collaborative Planning, Forecasting, and Replenishment (CPFR)

One of the key information technologies that have bolstered Walmart’s supply chain efficiency is the implementation of Collaborative Planning, Forecasting, and Replenishment (CPFR). This system facilitates seamless communication and coordination between Walmart and its supply chain partners, including suppliers and distributors. By sharing real-time sales data and demand information, CPFR enables accurate forecasting and demand planning, minimizing information distortion, and promoting synchronized inventory replenishment. The CPFR program has been instrumental in enhancing overall supply chain visibility and efficiency, allowing Walmart to respond promptly to fluctuations in demand and supply, reducing stockouts, and optimizing inventory levels.

Vendor-Managed Inventory (VMI) and Its Benefits

Walmart’s adoption of Vendor-Managed Inventory (VMI) has been another critical information technology-driven initiative. Through VMI, Walmart empowers its suppliers to take on the responsibility of managing their inventory stored in Walmart’s warehouses. By granting suppliers access to real-time inventory data and sales information, Walmart facilitates efficient inventory tracking and replenishment. This hands-on approach by suppliers results in streamlined inventory management, reduced delays in replenishment, and lower stockouts. The VMI model has proved particularly advantageous for Walmart due to its vast product range and numerous suppliers, making inventory management complex and costly if managed solely by the retailer.

[Read More: Vendor Managed Inventory: A Comprehensive Guide ]

Leveraging RFID Technology for Real-Time Inventory Targeting

RFID (Radio Frequency Identification) technology has been a game-changer in Walmart’s pursuit of real-time inventory targeting and enhanced supply chain visibility. By employing RFID tags on products, Walmart can track the movement of inventory throughout the supply chain in real-time. RFID enables accurate and automated inventory tracking, reducing the need for manual counting and minimizing errors in inventory management. The technology also provides crucial details, such as production time, location, and expiry dates of goods, allowing for efficient inventory targeting and better control over inventory turnover. RFID technology has been instrumental in Walmart’s cost reduction efforts, ensuring optimal stock levels while avoiding overstocking and unnecessary inventory holding costs.

Achieving Competitive Advantage through Strategy

Walmart’s competitive strategy: “everyday low prices” (edlp).

Walmart’s competitive advantage is deeply rooted in its strategic focus on offering “Everyday Low Prices” (EDLP) to its customers. The EDLP strategy revolves around providing high-quality products and services at the lowest possible prices, ensuring that customers can benefit from affordable prices every day. This approach sets Walmart apart from its competitors and has been instrumental in establishing the company as a dominant force in the retail industry.

Implementing the “Everyday Low Costs” (EDLC) Policy through Direct Procurement

To support its EDLP strategy, Walmart follows an “Everyday Low Costs” (EDLC) policy in its supply chain management. One of the key elements of the EDLC policy is the direct procurement of items from suppliers, eliminating intermediaries in the process. By procuring directly from manufacturers, Walmart can negotiate and understand their cost structure, enabling them to make informed purchasing decisions and obtain the best prices for their products.

Walmart’s emphasis on direct procurement is further bolstered by the use of technology and information systems. The company has implemented a central database, store-level point-of-sale systems, and a satellite network, along with barcodes and RFID technology as previously mentioned. These technologies allow Walmart to gather and analyze real-time store-level information, including sales data and external factors like weather forecasts, to enhance the accuracy of purchasing predictions. This integration of information technology helps Walmart optimize its procurement process and maintain low costs throughout the supply chain.

Utilizing Information Systems for Better Inventory Management

Effective inventory management is critical for Walmart to sustain its competitive advantage through the EDLP strategy. The company relies on information systems and information technology (IT) capabilities to control inventory levels efficiently. By capturing customers’ demand information, Walmart can identify popular products and stock them adequately, leading to an overall reduction in inventory.

One notable example of Walmart’s successful utilization of information systems is its collaboration with Procter & Gamble (P&G) through the Collaborative Planning, Forecasting, and Replenishment (CPFR) program. This program links all computers of P&G to Walmart’s stores and warehouses, allowing for efficient replenishment orders based on real-time inventory needs. Additionally, Walmart’s Retail Link , developed in the early 1990s, serves as another vital IT application for storing data, sharing it with vendors, and aiding in shipment routing assignments.

Challenges and Opportunities

Supplier cooperation and collaboration.

Walmart’s supply chain success can be attributed to its strong relationships with suppliers, but achieving and maintaining supplier cooperation and collaboration is not without challenges. Let’s explore the challenges and opportunities in this area:

Challenges in Obtaining Suppliers’ Cooperation

- Supplier Resistance to Direct Procurement: Walmart follows an “Everyday Low Costs” (EDLC) policy by directly procuring items from suppliers, eliminating intermediaries. However, some suppliers may be reluctant to cooperate with this approach as it can disrupt existing distribution channels and potentially reduce their bargaining power.

- Complex Supplier Networks: With thousands of suppliers across various product categories, managing diverse supplier networks can be challenging. Each supplier may have different production and delivery schedules, making coordination difficult.

- Balancing Profit Margins: As Walmart emphasizes low prices, maintaining a balance between cost savings and ensuring suppliers’ profitability can be a delicate task. Suppliers may resist pressure to reduce prices further to maintain their margins.

Opportunities for Enhanced Supplier Cooperation and Collaboration

- Establishing Transparent Communication Channels: Walmart can create transparent and open communication channels with its suppliers to foster better cooperation. Clear communication regarding demand forecasts, inventory levels, and potential disruptions can help suppliers plan their production and deliveries more efficiently.

- Supplier Incentive Programs: Introducing incentive programs that reward suppliers for meeting certain performance metrics, such as on-time delivery or cost reduction, can motivate suppliers to actively collaborate and improve their supply chain capabilities.

- Collaborative Planning, Forecasting, and Replenishment (CPFR): Walmart can leverage technology, such as CPFR, to share real-time sales data and demand forecasts with its suppliers. This collaborative approach allows suppliers to align their production and inventory management with actual market demand, reducing the bullwhip effect and optimizing the supply chain.

- Sharing Inventory Visibility: Providing suppliers with access to inventory data, including stock levels and sales information, can help them plan production and deliveries more effectively. This visibility can prevent stockouts and overstocking issues.

- Long-term Partnerships: Building long-term strategic partnerships with key suppliers can create a sense of mutual commitment and trust. By assuring consistent business over an extended period, Walmart can foster stronger relationships and supplier loyalty.

[Read More: 3 Types of Supplier Segmentation Matrix You Can Use to Classify Suppliers ]

Importance of Collaboration to Enhance Supply Chain Efficiency

- Reducing Lead Times: Effective collaboration with suppliers can help shorten lead times by streamlining production and transportation processes. Faster lead times enables Walmart to respond quickly to changes in demand, reducing the risk of stockouts.

- Efficient Inventory Management: Collaborative efforts with suppliers enable better inventory planning and management. Suppliers can adjust production based on actual demand, reducing excess inventory and associated costs.

- Supply Chain Flexibility: Collaboration fosters agility and adaptability in the supply chain. When Walmart and its suppliers work together closely, they can quickly adjust to market changes, supply disruptions, or new opportunities.

- Cost Reduction: Improved supplier collaboration can lead to cost-saving opportunities. By eliminating unnecessary intermediaries and optimizing production and transportation, overall supply chain costs can be minimized.

The Incentives Alignment Issue

In any supply chain, maintaining a balance of profit margins among different parties is essential for efficient collaboration and sustained success. However, achieving incentives alignment can be challenging, and this issue is particularly relevant in the case of Walmart supply chain. Addressing misalignment of interests between Walmart and its suppliers is crucial for optimizing the overall performance of the supply chain and ensuring long-term success. The following points highlight the incentives alignment issue faced by Walmart:

1. Balancing Profit Margins Among Different Supply Chain Parties:

Walmart’s success is attributed to its ability to offer high-quality products and services at the lowest affordable prices. To achieve this, Walmart employs various cost-cutting strategies, such as direct procurement from suppliers and streamlined distribution practices. While these strategies help Walmart maintain competitive prices, they can create challenges for suppliers who may face pressure to lower their own profit margins to meet Walmart’s demands. This misalignment of profit margins can lead to strained relationships and potentially impact the overall efficiency of the supply chain.

2. Misalignment of Interests Between Walmart and Suppliers:

Walmart’s size and market dominance can lead to power imbalances in supplier relationships. Suppliers may feel compelled to comply with Walmart’s demands to maintain access to its large customer base. However, this can lead to situations where suppliers may not have enough leverage to negotiate favorable terms, impacting their own profitability. As a result, suppliers may be less inclined to invest in innovations or improvements that would benefit the supply chain as a whole.

3. Conflict Between Inventory Growth and Sales Growth:

Walmart faced inventory growth issues in the past, with the inventory growth rate outpacing the sales growth rate. This can be indicative of conflicting incentives between Walmart and its suppliers. Suppliers may prioritize producing and delivering more inventory to ensure they meet Walmart’s demands, even if the sales growth does not keep up with the increased inventory. This misalignment can lead to excess inventory, increased carrying costs, and potential stockouts.

4. The Need for a New Triple-A Supply Chain:

Addressing the incentives alignment issue requires a fundamental shift in the supply chain strategy. Lee (2004) proposed the concept of a new Triple-A supply chain for Walmart and other companies in the 21st century. The Triple-A supply chain emphasizes agility, adaptability, and alignment to create a sustainable competitive advantage. Achieving alignment among all participating parties is crucial to optimize supply chain performance and ensure that risks and rewards are distributed fairly.

The Triple-A Supply Chain Approach

In today’s competitive business landscape, companies like Walmart recognize that a successful supply chain is not just about having a fast and cost-effective system. To maintain a sustainable competitive advantage and address the challenges of the global economy, it is essential to redesign supply chains that incorporate agility, adaptability, and alignment. This section explores the concept of the Triple-A Supply Chain Approach, which emphasizes these three key qualities that an ideal supply chain should possess: agility, adaptability, and alignment of interests among all participating parties.

The Three Qualities of an Ideal Supply Chain

Agility for quick and cost-effective responses:.

Agility refers to a supply chain’s ability to respond quickly and cost-effectively to sudden changes in demand, supply, and external disruptions. In the fast-paced business environment, companies must be able to adapt swiftly to fluctuations in customer preferences, market conditions, and unforeseen events. For Walmart, agility has been a critical factor in maintaining its leadership position in the retail industry. The company’s investments in technology and supply chain optimization strategies have allowed them to optimize inventory levels and respond rapidly to changing customer demands, ensuring the availability of products while minimizing inventory costs.

Adaptability to Handle Changes in Demand and Supply:

Supply chains should be adaptable and flexible enough to handle variations in demand and supply patterns. Demand forecasts can be uncertain, and unexpected supply chain disruptions may occur, making adaptability a vital quality. Walmart’s focus on omnichannel and various fulfillment options, such as in-store pickup and ship from store, demonstrates their commitment to adaptability. By utilizing multiple channels, Walmart can cater to diverse customer preferences, ensuring an uninterrupted flow of products to meet demand.

Alignment of Interests among All Participating Parties:

One of the significant challenges in supply chain management is ensuring alignment of interests among all parties involved, including suppliers, manufacturers, distributors, and retailers. Walmart’s scale and dominance in the retail market have allowed them to establish strong relationships with vendors, enabling strategic partnerships with vendors who can meet their high-volume demands. Additionally, Walmart’s adoption of Vendor Managed Inventory (VMI) allows suppliers to manage their own inventory stored in Walmart’s warehouses. This collaboration aligns the incentives of suppliers and Walmart, streamlining inventory management and ensuring timely replenishment.

In conclusion, Walmart’s integrated supply chain has been a crucial factor in the company’s global dominance and sustained competitive advantage. By strategically investing in technology and optimizing its supply chain, Walmart has managed to maintain its position as the world’s largest retailer with over $572 billion in revenue in 2022.

Walmart’s success serves as a compelling example of the importance of a well-integrated supply chain in achieving and sustaining competitive advantage in the global market. As businesses continue to navigate the complexities of the 21st-century economy, building and enhancing supply chain capabilities will remain a critical aspect of ensuring sustainable growth and profitability. By prioritizing agility, adaptability, and alignment, companies can follow in Walmart’s footsteps and position themselves for continued success in the dynamic and ever-evolving global marketplace.

References:

- Lee H.L. (2004): The triple A supply chain. “Harvard Business Review”, Vol. 82, No. 10, pp. 102-112.

- Nguyen T.T.H. (2017): Wal-Mart’s successfully integrated supply chain and the necessity of establishing the Triple-A supply chain in the 21st century. “Journal of Economics and Management”, Vol. 29(3), pp. 102-117

About the Author – Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker , vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn , Facebook , Twitter or Instagram .

- Walmart Walmart Supply Chain

Download Indirect Procurement Assessment

An Indirect Procurement Best Practices Assessment is a valuable process for organisations to evaluate and optimise their indirect procurement functions.

What makes Walmart Inventory Management unique from other e-commerce platforms

Jeniffer Alexander

If you’re an e-commerce business owner, you are likely familiar with Walmart, the world’s largest retailer. With its massive reach and influence in the market, chances are that your business may have had some dealings with this retail giant.

However, you might not be aware that Walmart operates on a distinctive inventory system, setting it apart from the practices commonly employed by most marketplace giants.

In this blog post, we aim to offer a comprehensive overview of Walmart’s distinctive inventory system, providing you with valuable insights.

Here’s a sneak peek into the article

What is inventory management in e-commerce?

Importance of walmart inventory management, how does walmart’s inventory system work, walmart’s vendor-managed inventory model, different types of inventory at walmart and their functions.

- How Walmart measures inventory performance

- Walmart inventory management strategies for an effective supply chain

- Benefits of Walmart’s inventory management system

Inventory management is the biggest asset of any retail business , and you should treat it like one.

encompassing storage, sourcing , and selling of products. It serves as the backbone of efficient operations and plays a crucial role in preventing wastage and saving both time and money.

Whether your business is small or large, understanding how to effectively manage your inventory is essential. Implementing a robust inventory management system can significantly increase efficiency and reduce operational costs , providing your business with a valuable source of leverage.

Inventory management is a crucial aspect of any business, yet many companies, even major ones, still face challenges in this area. These struggles can sometimes lead to disastrous consequences and even the collapse of a firm. To avoid such pitfalls, you should invest in a proper inventory management system to ensure your products consistently remain at the forefront of the supply chain .

There’s no one size fits all approach in inventory management. Depending on your business model and requirements, you can use ABC analysis, JIT (Just-in-time) inventory, Dropshipping , or First in First out (FIFO) approaches to manage your inventory. Strategies such help you avoid overstocking and understocking issues, plan for unexpected demand surges, and effectively manage the supply chain.

Walmart’s inventory management holds immense significance in the retail giant’s operations and overall success. As one of the world’s largest retailers, Walmart deals with a vast array of products and serves a massive customer base. Efficient inventory management is the backbone of its supply chain, enabling the company to oversee and control various aspects, including raw materials, finished goods, warehousing , and storage.

One of the primary goals of Walmart’s inventory management is to ensure that products reach distributors and stores promptly and efficiently.

By carefully tracking inventory levels and demand patterns, the company can minimize the risk of stockouts, where products are unavailable when customers want to purchase them. This proactive approach to inventory management ensures that customers find the products they need when they walk into a Walmart store or shop online, enhancing customer satisfaction and loyalty.

Moreover, Walmart’s inventory management is geared towards striking a delicate balance in stock levels. Excessive stock ties up valuable capital and storage space, while insufficient stock can lead to lost sales opportunities and dissatisfied customers. By avoiding both overstocking and understocking, Walmart can optimize costs, improve profitability, and maintain a healthy inventory turnover ratio. This careful balance allows the company to stay agile and responsive to changing market demands.

Accurate inventory records are essential for any retailer, and Walmart is no exception. By maintaining precise inventory data, Walmart can optimize its operational efficiency. This includes planning staffing levels to meet customer demand, managing storage space effectively, and ensuring that the supply chain runs smoothly.

Real-time visibility into inventory levels across Walmart’s vast network of stores and distribution centers empowers the company to make data-driven decisions, optimizing product offerings, pricing strategies , and stock allocations.

Recommended read:

What is the registration process for Walmart plus

How to Sell Refurbished Products on Walmart’s Restored Program

Walmart’s inventory system is a sophisticated and highly efficient platform that plays a crucial role in the company’s supply chain management. The system is designed to facilitate seamless coordination between Walmart and its suppliers, ensuring a constant flow of products to meet customer demands.

Here’s how Walmart’s inventory system works:

Real-Time Updates:

The system constantly updates information about how much of each product is available. So, when you buy something from Walmart, the system immediately knows and adjusts the inventory accordingly.

Supplier Collaboration:

Walmart works closely with the companies that supply them with products. These suppliers use the system to know when their products are running low in Walmart’s stores. They then send more of those products to Walmart to keep the shelves stocked.

Avoiding Stockouts:

The system helps Walmart avoid running out of popular products . When the inventory of a product gets low, the system alerts the supplier, who quickly sends more to Walmart. This way, you’re more likely to find what you need when you go shopping.

Cost Savings:

By using this smart system, Walmart can reduce unnecessary costs. Suppliers take care of managing their products’ inventory levels, which means Walmart doesn’t have to keep too much stock on hand.

Happy Customers:

Because the system keeps products available and reduces stockouts, customers have a better shopping experience. You can find the things you want, and Walmart can offer competitive prices.

Thus, Walmart’s inventory system helps them and their suppliers work together smoothly, making sure products are available when you need them, keeping costs down, and ensuring happy customers.

One of the key factors behind Walmart’s successful inventory management is its vendor-managed inventory model. In this system, suppliers play a proactive role in managing their products’ stock levels at Walmart stores. They use Walmart’s information systems to access real-time data on inventory levels and decide when to send more goods to the company.

With this approach, some of the inventory control responsibilities are transferred to the suppliers. They have direct access to Walmart’s inventory data, allowing them to better monitor and manage their products’ availability in stores. This collaboration between Walmart and its suppliers helps minimize delays in the supply chain, ensuring products reach the stores efficiently.

The vendor-managed inventory model benefits both Walmart and its suppliers. For Walmart, it leads to reduced inventory management costs as suppliers take on the responsibility of managing their goods. This means Walmart doesn’t need to hire additional staff to handle each supplier’s inventory. Instead, the costs are directly borne by the suppliers.

Recommended read: Amazon Review Software Tools to Increase Sales .

Walmart employs a diverse range of inventory types to efficiently manage its vast retail operations. Among the most important inventory categories are:

Finished Good Inventory

This is the backbone of Walmart’s business . It comprises the finished products that arrive at Walmart’s retail locations, where they are stored and regularly replenished. The main purpose of this inventory is to support the smooth operation of Walmart’s stores, ensuring that products are readily available for customers. These finished goods are moved from Walmart’s merchandise distribution centers to the store shelves for sale to retail buyers.

Transit Inventory

As Walmart’s supply chain spans globally, transit inventory plays a significant role in supporting its retail operations. This inventory category refers to goods that are in transit, often for days or weeks, as they move through the supply chain. The purpose of transit inventory is to aid in replenishing finished goods inventory at merchandise distribution centers and Walmart stores, ensuring a steady flow of products to meet customer demand.

Buffer Inventory

Walmart utilizes buffer inventory at its stores, maintaining a small surplus of goods on hand. This extra stock serves as a safeguard against unexpected fluctuations in demand. The purpose of buffer inventory is to ensure business continuity and accommodate sudden increases in customer demand, as retail market prediction models may not always perfectly anticipate such fluctuations.

Anticipation Inventory

Based on seasonal changes and market data, anticipation inventory is employed by Walmart to meet specific periods of heightened demand. For instance, Walmart significantly increases its inventory size before and during events like Black Friday , Christmas, and long holiday weekends. This inventory type allows the company to proactively address expected seasonal spikes in customer demand and ensure sufficient stock availability during these special shopping periods .

Through strategic management of these various inventory types, Walmart maintains a responsive and efficient supply chain. That also guarantees well-stocked stores to meet customer demands consistently.

How does Walmart measure inventory performance?

Given the vast scale and diverse product range of Walmart’s business, the company employs several key variables to gauge inventory performance.

Some of the most important measures used by Walmart are:

Inventory Turnover

The turnover of inventories, also known as inventory turnover rate, is a crucial metric used by Walmart to assess how quickly its product inventory is sold out and replenished. It measures the frequency with which items are sold and replaced within a specific period, typically a year. A higher turnover rate indicates that products are moving off the shelves swiftly, reducing the time items spend in inventory.

Walmart aims for a high inventory turnover rate as it signifies efficient sales and restocking processes. This approach aligns with the company’s cost leadership strategy, which emphasizes cost minimization and operational efficiency. By turning over inventory rapidly, Walmart reduces holding costs, such as storage and carrying expenses and can pass on cost savings to customers through competitive pricing.

Stock-out Rate

The rate of stock-outs is another vital variable Walmart closely monitors. A stock-out occurs when the available inventory is insufficient to meet customer demand for a particular product. For a retailer like Walmart, avoiding stock-outs is essential to provide a positive customer experience and maintain customer loyalty.

Walmart strives to minimize stock-outs to ensure that customers can find the products they need when visiting their stores. Through effective inventory management and close collaboration with suppliers, Walmart endeavors to maintain optimal inventory levels and respond promptly to changes in demand. By minimizing stock-outs, Walmart can enhance customer satisfaction and retention.

Inventory Size

The size of the inventory refers to the total quantity of products held by Walmart at any given time. Walmart carefully manages the size of its inventory to strike a balance between meeting customer demand and minimizing holding costs. A larger inventory may provide a wider selection for customers, but it can lead to higher storage and handling expenses.

With the help of inventory size, Walmart can maintain a responsive supply chain, ensure product availability, and uphold its commitment to offering customers a broad range of products at competitive prices.

Walmart inventory management strategies for an effective supply chain

Walmart employs effective strategies to manage its inventory across its extensive supply chain.

Here are the key approaches they use:

ABC Analysis

Walmart categorizes its inventory into three groups based on its significance. Category A items include finished goods and operational equipment, which are closely monitored and recorded. Category B items consist of supplies and materials used for operations, receiving moderate monitoring and recording. On the other hand, Category C involves the least monitored and recorded inventory items, like janitorial and office supplies, with minimal impact on daily retail operations. This categorization helps Walmart prioritize and efficiently manage its inventory based on its importance.

Integrated Information Systems

Walmart’s integrated information systems support its global retail operations and e-commerce. These systems are utilized throughout the organization and play a vital role in inventory management. Walmart provides its suppliers with access to their product inventory data through these systems, supporting its vendor-managed inventory model. This enables a collaborative approach where suppliers actively manage their products’ stock levels in Walmart’s stores and distribution centers.

Bullwhip Effect Management

The bullwhip effect, where errors amplify throughout the supply chain, can harm Walmart’s operations and increase costs. To minimize this effect, Walmart employs a vendor-managed inventory model. By allowing suppliers direct access to their data, Walmart reduces the involvement of company personnel in errors associated with moving goods from suppliers to stores. This fosters a more efficient and error-resistant supply chain.

Recommended Guide: Why should you advertise on Walmart ?

Benefits of Walmart Inventory Management System – Benefits

In addition to providing excellent services for eCommerce businesses, Walmart and other 3PLs primarily focus on their interests.

As a business owner, the return on investment (ROI) of your business investments is crucial, and tracking inventory costs and supply chain requirements are a must.

To efficiently manage inventory and streamline operations, businesses often need an external system that complements the Walmart ecosystem. The Walmart inventory management software is designed to track all aspects of a business’s inventory, from supplier management to product shipping .

This system offers several tangible features and benefits:

Utilizing Multiple Data Aggregation Channels

A successful business strategy involves selling products through various channels, not limited to just Walmart. Retailers can leverage physical locations, customizable storefronts like Shopify, and reputable marketplaces like Etsy and eBay. Relying solely on Walmart may not be ideal due to higher fees for slow-moving items and seasonal storage. An efficient inventory management system can consolidate all inventory data into a single dashboard, simplifying operations and eliminating the need for multiple logins.

Recommended read: 13 Best SEO Tips for Etsy Sellers

Implementing a Robust SKU System

Maintaining an organized product tracking system is crucial for a multichannel strategy . With a Walmart inventory management app, businesses can easily create unique SKUs for each product, incorporating essential details like attributes, manufacturing dates, locations, and lot numbers. The ability to generate and print barcodes further streamlines replenishing Walmart’s inventory.

Generating Comprehensive Reports

As businesses diversify their sales channels, reconciling reports from various storefronts becomes essential but time-consuming. To ensure a positive return on investment (ROI), having access to comprehensive reports is crucial. Walmart’s fulfillment services (WFS) offer helpful reports, such as the Replenishment Report, aiding in effective inventory management. These reports facilitate sales forecasting , reorder point establishment, and determining optimal order quantities.

By embracing these strategies, businesses can efficiently manage inventory across multiple channels, optimize their operations, and make informed decisions to enhance overall performance and customer satisfaction.

Walmart’s inventory management practices play a pivotal role in the success of the retail giant. Through a combination of strategic approaches, advanced information systems, and efficient supply chain management, Walmart has set a high standard for inventory control and optimization.

As a beacon of effective inventory management, Walmart’s practices serve as a valuable example for businesses aspiring to optimize their inventory control and achieve long-term success in the dynamic world of retail.

Additional read:

How does AmazonAI review summaries work?

What are the criteria to get the Pro Seller badge?

11 actionable Walmart advertising strategies.

Eligibility Criteria for Walmart Restored Program

Walmart Connect Ad Types

Surprising Walmart Facts and Statistics That Will Blow Your Mind

Was this post helpful?

Related posts:.

- The Ultimate Guide to Create Amazon Removal Orders FBA

Understanding Amazon Seller KPIs – Measure Your Marketplace Success

- Walmart Marketplace Pro Seller Badge: A Detailed Guide

- 11 Walmart Advertising Strategies You Should Know For Better Conversions

Post Written by:

4 comments on “what makes walmart inventory management unique from other e-commerce platforms”.

Thank you, SellerApp, for being a valuable resource in my journey as an Amazon seller!

Clare Thomas

Glad to hear that SellerApp has been instrumental in your Amazon seller journey.

Kudos to the team at SellerApp for consistently delivering top-notch content!

Glad you’re enjoying the content, appreciate the recognition!

Leave a comment Cancel Reply

Your email address will not be published. Required fields are marked *

Related posts

A Complete Guide on Amazon Retail Arbitrage

Amazon Long-term Storage Fees: Everything you Need to Know

Mastering Amazon FBA Reimbursement: Essential Tips for Sellers

Essential Guide to Amazon Inventory Performance Index

Amazon FNSKU Label 101 – What You Should Know

How to liquidate excess inventory on Amazon?

How to Leverage Amazon Inventory Reports – Step-By-Step Guide

Streamlining Amazon Order Management: Best Practices for Success

Recent posts.

- About / Contact

- Privacy Policy

- Alphabetical List of Companies

- Business Analysis Topics

Walmart’s Operations Management: 10 Strategic Decisions & Productivity

Walmart Inc.’s operations management involves a variety of approaches that are focused on managing the supply chain and inventory, as well as sales performance. The company’s success is significantly based on effective performance in retail operations management. Specifically, Walmart’s management covers all the 10 decision areas of operations management. These strategic decision areas pertain to the issues managers deal with on a daily basis as they optimize the e-commerce company’s operations. Walmart’s application of the 10 decisions of operations management reflects managers’ prioritization of business objectives. In turn, this prioritization shows the strategic significance of the different decision areas of operations management in the retail company’s business. This approach to operations aligns with Walmart’s corporate mission statement and corporate vision statement . The retail enterprise is a business case of how to achieve high efficiency in operations to ensure long-term growth and success in the global market.

The 10 decisions of operations management are effectively addressed in Walmart’s business through a combination of approaches that emphasize supply chain management, inventory management, and sales and marketing. This approach leads to strategies that strengthen the business against competitors, like Amazon and its subsidiary, Whole Foods , as well as Home Depot , eBay, Costco , Best Buy, Macy’s, Kroger, Alibaba, IKEA, Target, and Lowe’s.

The 10 Strategic Decision Areas of Operations Management at Walmart

1. Design of Goods and Services . This decision area of operations management involves the strategic characterization of the retail company’s products. In this case, the decision area covers Walmart’s goods and services. As a retailer, the company offers retail services. However, Walmart also has its own brands of goods, such as Great Value and Sam’s Choice. The company’s operations management addresses the design of retail service by emphasizing the variables of efficiency and cost-effectiveness. Walmart’s generic strategy for competitive advantage, and intensive growth strategies emphasize low costs and low selling prices. To fulfill these strategies, the firm focuses on maximum efficiency of its retail service operations. To address the design of goods in this decision area of operations management, Walmart emphasizes minimal production costs, especially for the Great Value brand. The firm’s consumer goods are designed in a way that they are easy to mass-produce. The strategic approach in this operations management area affects Walmart’s marketing mix or 4Ps and the corporation’s strategic planning for product development and retail service expansion.

2. Quality Management . Walmart approaches this decision area of operations management through three tiers of quality standards. The lowest tier specifies the minimum quality expectations of the majority of buyers. Walmart keeps this tier for most of its brands, such as Great Value. The middle tier specifies market average quality for low-cost retailers. This tier is used for some products, as well as for the job performance targets of Walmart employees, especially sales personnel. The highest tier specifies quality levels that exceed market averages in the retail industry. This tier is applied to only a minority of Walmart’s outputs, such as goods under the Sam’s Choice brand. This three-tier approach satisfies quality management objectives in the strategic decision areas of operations management throughout the retail business organization. Appropriate quality measures also contribute to the strengths identified in the SWOT analysis of Walmart Inc .

3. Process and Capacity Design . In this strategic decision area, Walmart’s operations management utilizes behavioral analysis, forecasting, and continuous monitoring. Behavioral analysis of customers and employees, such as in the brick-and-mortar stores and e-commerce operations, serves as basis for the company’s process and capacity design for optimizing space, personnel, and equipment. Forecasting is the basis for Walmart’s ever-changing capacity design for human resources. The company’s HR process and capacity design evolves as the retail business grows. Also, to satisfy concerns in this decision area of operations management, Walmart uses continuous monitoring of store capacities to inform corporate managers in keeping or changing current capacity designs.

4. Location Strategy . This decision area of operations management emphasizes efficiency of movement of materials, human resources, and business information throughout the retail organization. In this regard, Walmart’s location strategy includes stores located in or near urban centers and consumer population clusters. The company aims to maximize market reach and accessibility for consumers. Materials and goods are made available to Walmart’s employees and target customers through strategic warehouse locations. On the other hand, to address the business information aspect of this decision area of operations management, Walmart uses Internet technology and related computing systems and networks. The company has a comprehensive set of online information systems for real-time reports and monitoring that support managing individual retail stores as well as regional market operations.

5. Layout Design and Strategy . Walmart addresses this decision area of operations management by assessing shoppers’ and employees’ behaviors for the layout design of its brick-and-mortar stores, e-commerce websites, and warehouses or storage facilities. The layout design of the stores is based on consumer behavioral analysis and corporate standards. For example, Walmart’s placement of some goods in certain areas of its stores, such as near the entrance/exit, maximizes purchase likelihood. On the other hand, the layout design and strategy for the company’s warehouses are based on the need to rapidly move goods across the supply chain to the stores. Walmart’s warehouses maximize utilization and efficiency of space for the company’s trucks, suppliers’ trucks, and goods. With efficiency, cost-effectiveness, and cost-minimization, the retail company satisfies the needs in this strategic decision area of operations management.

6. Human Resources and Job Design . Walmart’s human resource management strategies involve continuous recruitment. The retail business suffers from relatively high turnover partly because of low wages, which relate to the cost-leadership generic strategy. Nonetheless, continuous recruitment addresses this strategic decision area of operations management, while maintaining Walmart’s organizational structure and corporate culture . Also, the company maintains standardized job processes, especially for positions in its stores. Walmart’s training programs support the need for standardization for the service quality standards of the business. Thus, the company satisfies concerns in this decision area of operations management despite high turnover.

7. Supply Chain Management . Walmart’s bargaining power over suppliers successfully addresses this decision area of operations management. The retailer’s supply chain is comprehensively integrated with advanced information technology, which enhances such bargaining power. For example, supply chain management information systems are directly linked to Walmart’s ability to minimize costs of operations. These systems enable managers and vendors to collaborate in deciding when to move certain amounts of merchandise across the supply chain. This condition utilizes business competitiveness with regard to competitive advantage, as shown in the Porter’s Five Forces analysis of Walmart Inc . As one of the biggest retailers in the world, the company wields its strong bargaining power to impose its demands on suppliers, as a way to address supply chain management issues in this strategic decision area of operations management. Nonetheless, considering Walmart’s stakeholders and corporate social responsibility strategy , the company balances business needs and the needs of suppliers, who are a major stakeholder group.

8. Inventory Management . In this decision area of operations management, Walmart focuses on the vendor-managed inventory model and just-in-time cross-docking. In the vendor-managed inventory model, suppliers access the company’s information systems to decide when to deliver goods based on real-time data on inventory levels. In this way, Walmart minimizes the problem of stockouts. On the other hand, in just-in-time cross-docking, the retail company minimizes the size of its inventory, thereby supporting cost-minimization efforts. These approaches help maximize the operational efficiency and performance of the retail business in this strategic decision area of operations management (See more: Walmart: Inventory Management ).

9. Scheduling . Walmart uses conventional shifts and flexible scheduling. In this decision area of operations management, the emphasis is on optimizing internal business process schedules to achieve higher efficiencies in the retail enterprise. Through optimized schedules, Walmart minimizes losses linked to overcapacity and related issues. Scheduling in the retailer’s warehouses is flexible and based on current trends. For example, based on Walmart’s approaches to inventory management and supply chain management, suppliers readily respond to changes in inventory levels. As a result, most of the company’s warehouse schedules are not fixed. On the other hand, Walmart store processes and human resources in sales and marketing use fixed conventional shifts for scheduling. Such fixed scheduling optimizes the retailer’s expenditure on human resources. However, to fully address scheduling as a strategic decision area of operations management, Walmart occasionally changes store and personnel schedules to address anticipated changes in demand, such as during Black Friday. This flexibility supports optimal retail revenues, especially during special shopping occasions.

10. Maintenance . With regard to maintenance needs, Walmart addresses this decision area of operations management through training programs to maintain human resources, dedicated personnel to maintain facilities, and dedicated personnel to maintain equipment. The retail company’s human resource management involves training programs to ensure that employees are effective and efficient. On the other hand, dedicated personnel for facility maintenance keep all of Walmart’s buildings in shape and up to corporate and regulatory standards. In relation, the company has dedicated personnel as well as third-party service providers for fixing and repairing equipment like cash registers and computers. Walmart also has personnel for maintaining its e-commerce websites and social media accounts. This combination of maintenance approaches contributes to the retail company’s effectiveness in satisfying the concerns in this strategic decision area of operations management. Effective and efficient maintenance supports business resilience against threats in the industry environment, such as the ones evaluated in the PESTEL/PESTLE Analysis of Walmart Inc .

Determining Productivity at Walmart Inc.

One of the goals of Walmart’s operations management is to maximize productivity to support the minimization of costs under the cost leadership generic strategy. There are various quantitative and qualitative criteria or measures of productivity that pertain to human resources and related internal business processes in the retail organization. Some of the most notable of these productivity measures/criteria at Walmart are:

- Revenues per sales unit

- Stockout rate

- Duration of order filling

The revenues per sales unit refers to the sales revenues per store, average sales revenues per store, and sales revenues per sales team. Walmart’s operations managers are interested in maximizing revenues per sales unit. On the other hand, the stockout rate is the frequency of stockout, which is the condition where inventories for certain products are empty or inadequate despite positive demand. Walmart’s operations management objective is to minimize stockout rates. Also, the duration of order filling is the amount of time consumed to fill inventory requests at the company’s stores. The operations management objective in this regard is to minimize the duration of order filling, as a way to enhance Walmart’s business performance.

- Reid, R. D., & Sanders, N. R. (2023). Operations Management: An Integrated Approach . John Wiley & Sons.

- Szwarc, E., Bocewicz, G., Golińska-Dawson, P., & Banaszak, Z. (2023). Proactive operations management: Staff allocation with competence maintenance constraints. Sustainability, 15 (3), 1949.

- Walmart Inc. – Form 10-K .

- Walmart Inc. – History .

- Walmart Inc. – Location Facts .

- Walmart’s E-commerce Website .

- Copyright by Panmore Institute - All rights reserved.

- This article may not be reproduced, distributed, or mirrored without written permission from Panmore Institute and its author/s.

- Educators, Researchers, and Students: You are permitted to quote or paraphrase parts of this article (not the entire article) for educational or research purposes, as long as the article is properly cited and referenced together with its URL/link.

- Skip to main

- Skip to footer

You're off the clock!

- Flagship Conferences

Decking the aisles with data: How Walmart's AI-powered inventory system brightens the holidays

Parvez Musani

Sr. Vice President, E2E Fulfillment

Oct. 25, 2023

Empowered by our artificial intelligence (AI)-and-machine learning (ML)-driven inventory management systems, Walmart is primed to deliver one of the most seamless and gratifying holiday shopping experiences for our customers. From sought-after gifts and festive decor to delectable treats, our customers and members can be confident in finding the perfect items to make their holiday season merry and bright.

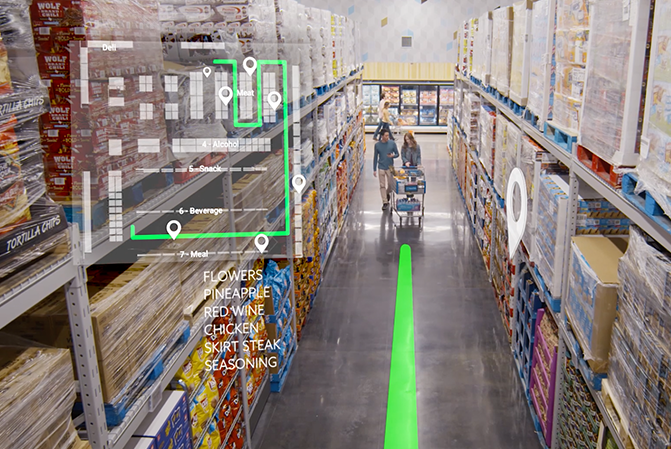

Our AI-powered inventory management system is essential for supplying customers with what they need, when they need it, and at the low costs they expect from Walmart. By leveraging historical data and pairing it with predictive analytics, we’re able to strategically place holiday items across distribution and fulfillment centers, and stores, optimizing the entire shopping experience. This data management system, along with investments in our supply chain—including automated facilities, department-ready freight, Next-Gen fulfillment centers, and store-based fulfillment—combined with in-store technology used by our associates and our massive last-mile delivery network, also ensures the efficient delivery of items. Our system is more powerful because it integrates insights from all the channels we use to serve customers. As an omni-channel retailer, we analyze both physical and digital sales to deliver our customers with an easy shopping experience over the holidays and beyond.

Combining decades of customer service and holiday inventory management with AI insights

Walmart has helped customers and members celebrate the holidays for more than 60 years by continually advancing our inventory management processes to ensure customers can find everything from coveted gifts to festive treats. In recent years, we have tested and integrated AI/ML models into our systems, complementing our use of historical data to guide the flow of holiday items through our supply chain. Today, our AI/ML engines are primed to offer even deeper insights and we expect our performance will be stronger than ever.

When building AI/ML frameworks for holidays, we start with a foundation of data and business constraints to create a possible universe of Machine Learning models. During model training, we fine-tune machine-learning models using historical data like past sales, as well as online searches and page views.

We also consider ‘future data’ such as macroweather patterns, macroeconomic trends and local demographics to anticipate demand and potential fulfillment disruptions. With this combined data, our engines identify and correct discrepancies, inefficiencies, or inaccuracies in supply chain models. By the time our customers are ready to shop, our AI/ML data has already completed the heavy lifting to improve inventory flow.

Leveraging a patent-pending capability

While predicting consumer behavior is possible, unforeseen events and their impact on typical purchasing patterns can create added challenges.

However, we do not always want to apply anomalies like a once-in-a-lifetime snowstorm in Florida to our future inventory management process. Instead, our software aims to display demand as closely as possible to historical consumer tendencies and adjustments.

What makes our AI/ML engines so powerful is that they can ‘forget’ such anomalies so that we are not carrying over one-time deviations into future inventory management practices. This will be the first year this capability has been used to help deliver for our customers during the holiday season.

AI is ‘always on’ and ready to distribute, supply and deliver

Whether customers are shopping in stores, online or using the app, Walmart is able to provide them with the holiday supplies they need, within their reach. Our inventory management systems connect to our 4,700 stores, fulfillment centers, distribution centers and our suppliers. Every interaction and step of the way is measured, captured and used to further train our AI models and machine learning engines.

Our AI-driven systems leverage a variety of factors to determine both quantity and timing of inventory flow, as well as more precisely identify where we distribute. With greater accuracy in our geographic distribution zones, we can understand our customers’ demands down to differentiations by zip codes. For customers enjoying at-home delivery, our systems are optimizing Spark delivery routes to save time from the moment of purchase to their front door.

With state-of-the-art learning systems, we are also adding inputs to help adjust for regional differences in needs, cultures, and buying habits. For example, we will always make sure that pool toys are available in the sunny states, and warmer sweaters are stocked in colder states. Our engines are always learning, so we can optimize, increase demand or reposition inventory to higher selling regions. For instance, if a toy isn’t selling well on the East Coast but is hot in the Midwest, we can reposition inventory or divert the demand.

Empowering our associates with industry-leading analytics

At Walmart, we are people-led and tech-powered. While our AI-driven inventory systems can offer recommendations, the associate is ultimately in charge. Nobody, and no robot, can replicate the intuition of our associates gained over their careers. Our associates’ feedback is a critical part of the tuning and training process that drives our continued innovation.

As we embrace another holiday season, our associates nationwide have been working tirelessly to deliver exceptional holiday shopping experiences. With our powerful AI-driven inventory system, customers can rely on us to deliver great experiences and savings all season long.

- Ask Walmart

- Privacy & Security

- California Privacy Rights

- California Supply Chain Act

- Terms of Use

- Do Not Sell My Personal Information

- Request My Personal Information

Optimizing Walmart Inventory Management: Strategies for Effective Control and Efficiency

Inventory management, the delicate art of balancing supply and demand, lies at the heart of retail operations. In the complex ecosystem of retailing, efficiency is key, and the effectiveness of inventory control can make or break a company's profitability. This is especially true for giants like Walmart, which handles millions of products across thousands of stores and online platforms. In this blog, we will explore strategies for optimizing Walmart's inventory management to create control, increase efficiency, and drive the bottom line. Inventory control is not merely about having products on the shelves. It's about having the right products, in the right quantity, at the right time, in the right place, and at the right cost. It involves complex decision-making, timely data analysis, and strategic planning. The purpose of this blog is to provide a comprehensive guide to retailers on strategies for optimizing inventory management at Walmart. We will delve into a deeper understanding of Walmart's inventory system, the significance of inventory turnover, and effective strategies to streamline inventory management for maximum profitability.

Understanding Walmart's Inventory Management System Before we can begin to optimize inventory, it is critical to understand how Walmart's inventory management system functions and what its specific requirements are. Walmart has a sophisticated, data-driven inventory management system that ensures products are replenished on shelves as quickly as they're sold, preventing stockouts and overstocking. Walmart uses two main types of inventory systems: the perpetual inventory system and the cross-docking inventory system. The perpetual inventory system allows real-time tracking of inventory levels, with adjustments made for every sale, return, and restocking. Cross-docking, on the other hand, is a logistics practice where products from suppliers are directly transferred to stores or customers, with minimal to no storage at distribution centers. This minimizes storage time and costs, while ensuring fresh inventory for customers. The terminology used in Walmart's inventory management includes Stock Keeping Units (SKUs), which is a distinct item for sale, such as a product or a service. Walmart uses an electronic product code or a universal product code to track each SKU. On-Hand Inventory refers to the stock available for sale, while Shelf-Cap is the maximum quantity of a product that can fit on a store shelf. To effectively manage inventory at Walmart, one needs to familiarize themselves with Walmart's inventory management tools and resources. Walmart’s Retail Link system is an invaluable tool for suppliers, providing a portal into their inventory levels, sales data, and other key metrics at Walmart. By leveraging Retail Link, suppliers can gain a clear view of their performance, enabling them to make data-driven decisions about replenishment, sales strategies, and marketing. An understanding of these systems and terminologies is the first step towards successful inventory management at Walmart. In the next sections, we will explore strategies to improve your inventory turnover rate and effective tactics for streamlining inventory management at Walmart.

Analyze and Forecast Demand Inventory management is akin to walking a tightrope, balancing the need to satisfy customer demand while minimizing holding costs. Thus, an essential aspect of optimizing Walmart inventory management lies in accurate demand analysis and forecasting. By understanding how demand varies, retailers can optimize inventory levels, minimizing stockouts and overstocks, thereby increasing turnover and profitability. Analyzing historical sales data provides invaluable insights into product performance, seasonal trends, and customer behavior. This data serves as a foundation to forecast future demand accurately. It allows you to identify patterns, such as peak sales periods and slower months, aiding in strategic planning and preparation for inventory fluctuations. Market trends also play a crucial role in demand forecasting. Retailers should stay abreast of current events, industry developments, consumer behavior changes, and competitors' activities. All these factors can impact product demand, and keeping an eye on them helps to adjust forecasts accurately. Several tools and techniques can be employed for demand forecasting. Machine learning algorithms can analyze large data sets to predict future trends. Regression analysis can identify relationships between variables impacting demand. Time series analysis can reveal seasonal fluctuations and long-term trends. Walmart's Retail Link system is an invaluable tool here, providing insights into sales data and other key metrics. It also offers demand forecasting features that retailers can leverage to ensure optimal inventory levels. Moreover, investing in specialized inventory management software that incorporates AI for demand forecasting can be a game-changer, allowing for more accurate predictions and automated processes.

Implement Just-in-Time (JIT) Inventory Management Just-in-Time (JIT) inventory management, a strategy where stock is received precisely when needed for sale, can be incredibly beneficial for Walmart suppliers. This approach can lead to cost savings by reducing the amount of inventory held in storage, thereby minimizing holding costs and the risk of obsolete inventory. The success of JIT inventory management largely depends on the reliability of your suppliers. It's vital to identify and build strong relationships with suppliers who can consistently meet your delivery timelines. This ensures you always have stock available to meet demand without the need for excessive inventory. Automating the reorder process is another crucial aspect of JIT. By setting up automated reorder points based on your demand forecast, you ensure inventory is replenished before it runs out. This involves tracking your inventory levels in real-time, analyzing your sales velocity, and understanding lead times. Walmart’s Retail Link system can be instrumental in this regard, providing real-time data to set up accurate reorder points. Additionally, suppliers can invest in inventory management software with features for automatic reordering and real-time inventory tracking. Implementing a JIT inventory management approach requires strategic planning, reliable suppliers, and efficient use of technology. However, the benefits of reduced storage costs, improved cash flow, and increased efficiency can significantly outweigh the efforts.

Utilize Inventory Management Software One of the primary advantages of inventory management software is the elimination of manual tracking and recording. Manual processes are prone to errors and can lead to inaccurate inventory counts, stockouts, or excess stock. By automating these processes, you not only reduce the risk of human error but also free up time for more strategic tasks. When selecting the right inventory management software for your business, consider factors such as the size of your business, the number of SKUs you manage, the complexity of your supply chain, and your budget. The software should be scalable to accommodate your business growth and flexible to adapt to your operational changes. Furthermore, it should seamlessly integrate with Walmart’s Retail Link system and other platforms you use. Once the software is in place, leverage its features to optimize your inventory management. Use the real-time tracking feature to keep an eye on your stock levels. Utilize reporting capabilities to analyze sales trends, inventory turnover, and holding costs. The predictive analytics feature can aid in more accurate demand forecasting, allowing you to maintain optimal stock levels. Optimize Inventory Placement and Fulfillment Optimizing inventory placement and fulfillment is another critical aspect of efficient inventory management at Walmart. Proper inventory placement ensures faster delivery times, lower shipping costs, and increased customer satisfaction. For businesses selling on Walmart's online platform, strategically placing inventory in Walmart's fulfillment centers can enhance efficiency. Walmart's fulfillment centers are strategically located across the country, and storing your products closer to your customers reduces delivery times and costs. Another viable strategy is to leverage third-party logistics (3PL) providers. These companies specialize in handling inventory management and order fulfillment, allowing you to focus on core business areas. 3PLs often have a network of warehouses, enabling you to store your products in multiple locations for faster fulfillment. Regardless of whether you use Walmart's fulfillment centers or a 3PL, it's crucial to monitor and optimize your fulfillment processes regularly. Track metrics like order accuracy, fulfillment speed, and return rates to gauge your performance. Identify bottlenecks in your fulfillment process and implement strategies to overcome them. Regular audits of your fulfillment process can help ensure timely and accurate order fulfillment, leading to higher customer satisfaction and increased sales.

Implement Effective Inventory Tracking and Auditing Inventory tracking and auditing form the backbone of efficient inventory management. They ensure the accuracy of inventory records, help identify discrepancies early, and prevent stockouts or overstock situations. Implementing robust inventory tracking and auditing practices is crucial for suppliers in Walmart’s supply chain to maintain seamless operations. An effective way to track inventory is by implementing barcode scanning systems. Every product or SKU should have a unique barcode, which can be scanned each time a product enters or leaves your inventory. This allows for real-time tracking of inventory levels and quick identification of products, making inventory management significantly more efficient. Inventory management software, such as the tools we discussed in section V, often come with built-in inventory tracking tools. These systems update inventory levels in real-time as sales occur or new stock is received, providing accurate visibility into your stock levels at all times. Regular inventory audits are crucial to ensure the accuracy of your inventory records. Depending on the size of your inventory, these audits can be daily, weekly, monthly, or annually. The aim is to physically count your inventory and compare it against your inventory records. This helps identify discrepancies, potential theft, or loss, and you can make necessary adjustments to prevent stockouts or overstock situations.