Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- My Account Login

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Open access

- Published: 26 May 2024

Simulation and optimization of 30.17% high performance N-type TCO-free inverted perovskite solar cell using inorganic transport materials

- Emmanuel A. Nyiekaa 1 , 4 ,

- Timothy A. Aika 1 ,

- Eli Danladi 2 ,

- Christopher E. Akhabue 3 &

- Patience E. Orukpe 1

Scientific Reports volume 14 , Article number: 12024 ( 2024 ) Cite this article

589 Accesses

10 Altmetric

Metrics details

- Materials science

- Nanoscience and technology

Perovskite solar cells (PSCs) have gained much attention in recent years because of their improved energy conversion efficiency, simple fabrication process, low processing temperature, flexibility, light weight, and low cost of constituent materials when compared with their counterpart silicon based solar cells. Besides, stability and toxicity of PSCs and low power conversion efficiency have been an obstacle towards commercialization of PSCs which has attracted intense research attention. In this research paper, a Glass/Cu 2 O/CH 3 NH 3 SnI 3 /ZnO/Al inverted device structure which is made of cheap inorganic materials, n-type transparent conducting oxide (TCO)-free, stable, photoexcited toxic-free perovskite have been carefully designed, simulated and optimized using a one-dimensional solar cell capacitance simulator (SCAPS-1D) software. The effects of layers’ thickness, perovskite’s doping concentration and back contact electrodes have been investigated, and the optimized structure produced an open circuit voltage (V oc ) of 1.0867 V, short circuit current density (J SC ) of 33.4942 mA/cm 2 , fill factor (FF) of 82.88% and power conversion efficiency (PCE) of 30.17%. This paper presents a model that is first of its kind where the highest PCE performance and eco-friendly n-type TCO-free inverted CH 3 NH 3 SnI 3 based perovskite solar cell is achieved using all-inorganic transport materials.

Similar content being viewed by others

All-inorganic perovskite photovoltaics for power conversion efficiency of 31%

An extensive study on multiple ETL and HTL layers to design and simulation of high-performance lead-free CsSnCl3-based perovskite solar cells

Device simulation of highly efficient eco-friendly CH3NH3SnI3 perovskite solar cell

Introduction.

Due to the enormous energy demand brought on by the growing world population, energy consumption is increasing at fast rate every day. Fossil fuels provide about 80% of the world’s energy requirements 1 , which have negative environmental effects and have forced the development of renewable energy sources 2 . Because of its abundant, clean, and limitless nature, solar energy is regarded as the most major and significant source of renewable energy 3 , making it the most promising contender because of its affordability and sustainability 4 . The generations of solar cells is recently categorized into four; the crystalline silicon (c-Si) and gallium arsenide (GaAs) constitute the first generation, while the thin films such as copper indium gallium selenide (CIGS), amorphous silicon (a-Si) and cadmium telluride (CdTe), formed the second generation. The evolving class of solar cells such as dye-sensitized solar cells (DSSC), copper zinc tin sulfide (CZTS) and quantum dot (QD) belongs to the third generation while the novel solar cells recognized as “inorganics-in-organics” such as hybrid perovskites represents one of the candidates of fourth-generation solar cells 5 . The monocrystalline and polycrystalline silicon-based are the known two kinds of solar cells 6 . Solar cells based on CdTe 7 , 8 , quantum dot sensitized-based solar cells 9 , CIGS 10 , 11 , organic photo cells 12 and perovskite-based solar cells 13 have also been explored by researchers.

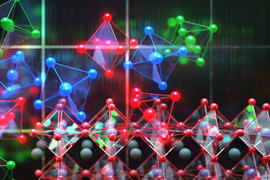

The metal halide perovskites are represented by ABX 3 , where A refers to an organic cation, B refers to a metal cation, and X refers to a halogen anion. The cation embraces individual or mixed compositions of methylammonium (MA), cesium (Cs), and formamidinium (FA), whereas the halogen anion embraces individual or mixed compositions of Cl, Br, and I 14 . Recent researches have focused on perovskite solar cells (PSCs), due to their increased efficiencies 15 , low processing temperatures, high absorption, long diffusion length, high charge mobility, low trap density, low exciton binding energy, tunable bandgap and low-cost of fabrication 14 , 15 . PSCs have been the subject of numerous studies, which have improved energy power conversion efficiencies (PCEs) from 3.8% in 2009 to about 25% after 13 years of development 16 , while 15 reported PCE of 25.6%, and 26.1% have recently been attained 17 . The impressive characteristics of perovskite materials include good charge carrier mobility, high coefficient of absorption, high diffusion charge carrier and low binding energy 18 , 19 . Because of their excellent photovoltaic performance, methyl ammonium lead halides, both pure and modified, have been the subject of several studies 20 , 21 . However, lead-based electronics posed hindrance to commercialization due to its harmful nature 14 , 22 , 23 , 24 . Recent reports revealed stern circumscribe of lead-based electronics devices by many countries, notably the European Union because of its toxic nature to human and environment irrespective of their high-power conversion efficiency 25 , 26 , 27 , 28 .

Some of the major challenges affecting the large-scale production of PSCs is the high cost of electron and hole transport materials, toxicity of the perovskite materials and degradability of the solar cells. Despite significant improvements made thus far, high temperature and humidity as well as the presence of moisture results to reduced lifespan of some perovskite materials such as Spiro-OMeTAD, the popular hole transport material. The difficulty in processing, and the expensive nature of Spiro-OMeTAD is a possible impediment to commercialization of PSCs going forward 29 , 30 , 31 , 32 . Additionally, the Spiro-OMeTAD layer aids polarisation of the electrode and plays a significant part in the current density–voltage (J–V) hysteresis phenomenon, which ultimately influence the device’s instability 33 . Conventional structures of PSCs using organic-based materials as hole transport medium and the metallic electrodes constitute the major reasons for the PSCs’ shorter life span 34 . Pin-holes in the HTM have been a challenge of interest in recent studies as it leads to poor PSC’s stability owing to penetration of oxygen and ambient moisture which deteriorates the perovskite absorbent layer. Numerous attempts have been made to address the detrimental effects of pinholes in HTMs and perovskites. One of such efforts is the significant improvement of stability in perovskite solar cells through the use of doping engineering to create a hole transport layer free of pinholes 35 . Investigations by other scientists have concentrated on creating effective PSCs employing novel kinds of hole-transport materials as replacement to Spiro-OMeTAD 36 , 37 , or PSCs without HTL that are suitable for streamlining the device’s ideal process, and further reduce manufacturing cost and as well prevents perovskite’s degradation 38 , 39 , 40 . There is no doubt that the absence of pinholes in HTM layer considerably increases the PSC’s device stability under operating environments 41 .

Regardless of tremendous research progresses in PCSs, planar inverted PSCs have received lesser interest, hence limited research work is conducted in this area of study despites their easy fabrication, cost-effectiveness, and suppressed hysteresis characteristics 42 . Therefore, intense study is required in this field of study to improve and maximize their performances as compared to their conventional counterparts’ structures. Most of the available researches on inverted planar PSCs have focused on the use of gold as contact electrode, spiro-OMeTAD as HTM with a maximum achievable PCE of approximately 30% through simulations 43 , 44 , 45 , 46 , 47 .

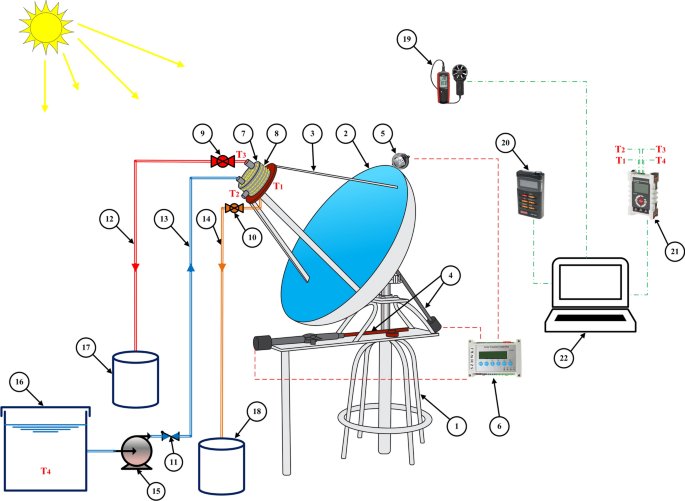

This research sought to streamline production innovations in PSCs, lower production costs, and maximise performance. The use of eco-friendly perovskite material, cheap and suitable all-inorganic transport materials and the use of the appropriate back contact electrode will increase efficiency, stability, and significantly reduce the production costs. The possibility of attaining high efficiency by utilising the inverted planar technique without using silicon composites and organic HTMs can lead to a greater variety of benefits in the sector. This paper presents a simulation of an inverted planar and n-type transparent conducting oxide-free structure using inorganic transport materials. The selection of appropriate back contact electrode, variation of system’s parameters such as thickness of HTM, absorber material, ETM, absorber doping concentration and determination of optimal values of series and shunt resistances is carried out to achieve optimal performance of the device.

Materials and methods

Device structure and simulation.

There are different types of software used for simulation of solar cells such as PC1D, ASA, Amps-1D, WxAMPS, SCAPS-1D, SETFOS, Gpvdm, AFORS-het, Aspin-2D, PECSIM, Adept, TCAD, Atlas, Silvaco etc. However, SCAPS-1D software is used in this work to simulate an inverted tin-based perovskite solar cell with planar heterojunction because of its best accurate non-commercial tool that is straightforward in operation, with friendly dialog box and extremely quick in simulations at no additional expense and support for multi-junction solar cells 48 . Three related differential equations were solved to determine the energy bands, quantum efficiency of the device, current density–voltage (J–V) curve, and recombination rate curve. The Poisson Eq. ( 1 ), the electron continuity Eq. ( 2 ), and the hole Eq. ( 3 ) are built in the SCAPS-1D software. These curves are used to compute the solar cell device’s open circuit voltage (V oc ), short circuit current density (J SC ), fill factor (FF), and power conversion efficiency (PCE).

where \(G\) , \({\tau }_{n}\) , \({\tau }_{p},\) \(D\) , \(q\) , \(\varepsilon\) \(\psi,\) \({\mu }_{n}\) , \({\mu }_{p}\) , \(n\left(x\right), p\left(x\right),\) \({n}_{t}(x)\) , \({p}_{t}\left(x\right),\) \({N}_{A}^{-}(x),\) \({N}_{D}^{+}\left(x\right)\) and \(E\) represent the rate of generation, life time of electron, life time of hole, diffusion coefficient, electron charge, permittivity, electrostatic potential, electron mobility, hole mobility, concentration of free electrons, concentration of free holes, concentration of trapped electrons, concentration of trapped holes, ionized acceptor concentrations, ionized donor concentrations, and electric field respectively. Meanwhile, x represents the direction along the thickness of the solar cell 49 .

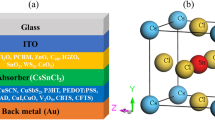

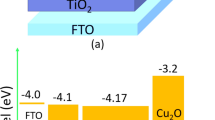

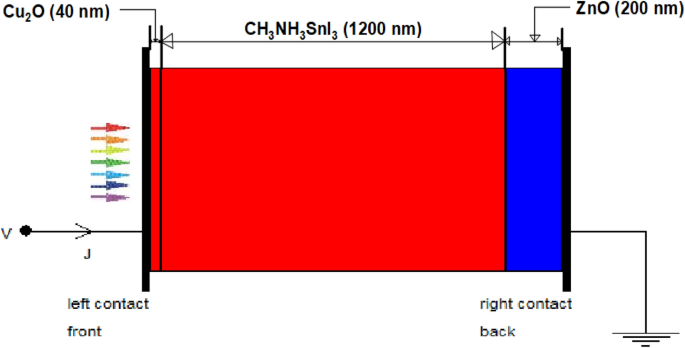

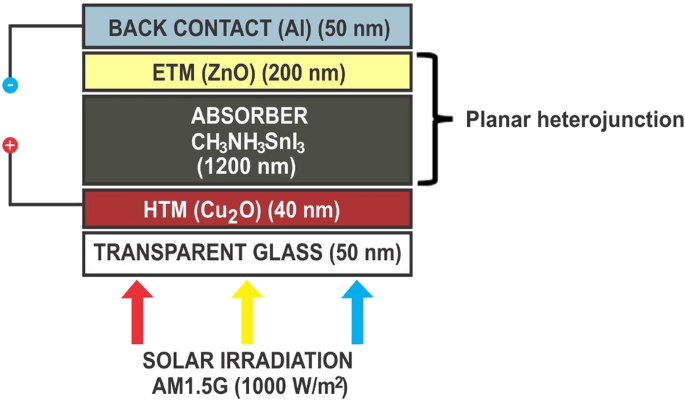

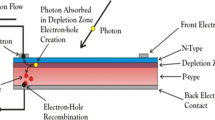

The device’s structure is composed of Cu 2 O as HTM layer, CH 3 NH 3 SnI 3 as absorber layer and ZnO as ETM layer. The choice of Cu 2 O as HTM in this work over other HTMs is based on the fact that it is relatively cheap when compared to organic based HTMs, high absorption coefficient, high intrinsic hole mobility, and acceptable energy levels that are aligned with the absorber layer (MASnI 3 ), high photochemical and thermal stability as well as long-term stability in air 50 . Similarly, CH 3 NH 3 SnI 3 is also adopted as the absorber layer because of its eco-friendliness with potentials for commercialization 51 , 52 and superior optoelectronic properties with 1.3 eV direct band gap, which is an appropriate range for the absorber layer 21 , 49 , 53 , 54 . Meanwhile, ZnO is used as ETM because of its high absorption coefficient, higher electron mobility 2 , 51 and aligned energy bandgap with the chosen perovskite (MASnI 3 ) when compared to the SnO 2 36 .

Background and selection of device parameters

Light generates electron–hole pairs within the absorber layer. The junction field draws holes to the HTM layers and electrons to the ETM layers, respectively. The thickness, coefficient of absorption, and mobility of the active material all affect the device’s J SC . The photocurrent will increase as the absorption coefficient increases 49 , 54 , 55 . Another important consideration is the absorber’s thickness, which must be sufficient to absorb the maximum cutoff wavelength of the incident solar light 49 , 53 . Aside from that, mobility is essential to achieving the high J SC which is ideally equal to the current in the solar cell. For the sample of CH 3 NH 3 SnI 3 produced using the open tube approach, a very high mobility of electrons (2000 cm 2 /Vs) and holes (300 cm 2 /Vs) was discovered by Ma et al. and Stoumpos et al. 56 , 57 . Lazemi et al. reported a high value of J SC using similar values of carrier mobility 53 . Devi et al. 58 and Khattak et al. 59 have taken into account the equal and noticeably lesser values of the electron and hole mobility, which are 1.6 cm 2 /Vs and 0.16 cm 2 /Vs respectively. In line with experimental work done by 60 , the electron (2000 cm 2 /Vs) and hole (300 cm 2 /Vs) mobility values for CH 3 NH 3 SnI 3 is adopted for use in this study. It is important to note that diffusion length also has a proportionality relationship to the square root of mobility 58 .

The device simulation was conducted under the 1000 W/m 2 light illumination at 300 K temperature and 1.5G air mass. The proposed device’s series resistance was adjusted to 1 Ωcm 2 while the shunt resistance at 10 4 Ωcm 2 during simulation. The value of work function for front electrode (Cu 2 O) is 5.0 eV while the surface recombination velocity for electrons and holes as 10 5 cm/s and 10 7 cm/s respectively. Moreover, the work function for the back contact electrode ticked as flat band with surface recombination velocity for electrons and holes as 10 7 cm/s and 10 5 cm/s respectively at the beginning of the simulation until an optimized back contact electrode work function was determined as discussed in section " Effect of back contact electrode on the proposed inverted perovskite solar cell ". The characteristics of the device’s material parameters adopted were carefully selected from theories, experiments and research reviews is presented in Table 1 , while the interface parameters are presented in Table 2 . Scientifically, the neutral defect type adopted in the simulation means non-reactive, which can further be explained as a situation where there is no donor nor acceptor of charges within the films of a layer or interface. The bulk defect densities of the materials were chosen above ideal values to demonstrate ideal experimental conditions.

Various decisive parameters like electron mobility, hole mobility, carrier diffusion length, interfacial resistance, etc., have been considered constant and taken from the literature. These parameters are extremely dependent on experimental processes and can hugely alter practical performance of the device. The relative humidity, temperature, the type of instruments used, procedural and human expertise, control of crystallization and grain growth rates are some of the factors behind the real-life performance and their variations from theoretical values.

Results and discussions

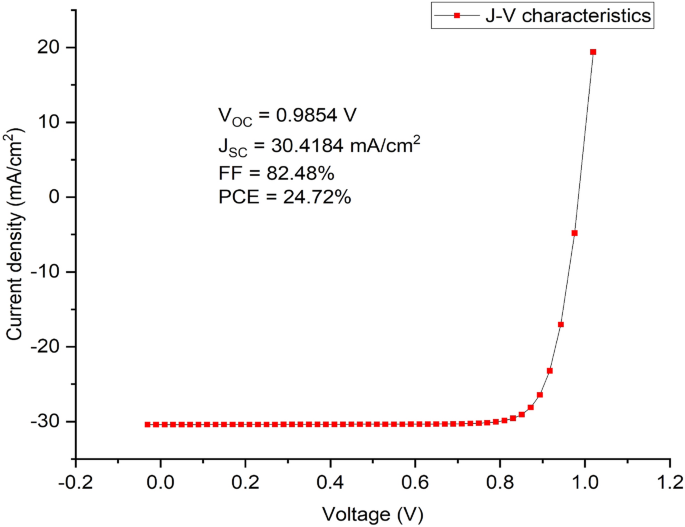

In general, the electron and hole pairs are produced within the absorber layer after illumination. The junction field causes holes and electrons to travel in the directions of HTM and ETM layers, respectively. A voltage is created when these holes and electrons are collected at the anode and cathode, respectively. The simulation results of the proposed inverted device structure Cu 2 O/CH 3 NH 3 SnI 3 /ZnO using the available initial device parameters as contained in Tables 1 and 2 shows the J–V characteristics of the proposed device as shown in Fig. 1 produced a Voc of 0.9854 V, J SC of 30.4185 mA/cm 2 , an FF of 82.48% and PCE of 24.72%. The proposed device structure Cu 2 O/MASnI 3 /ZnO underwent further simulation and optimization so as to obtain optimized thickness of the constituent layers.

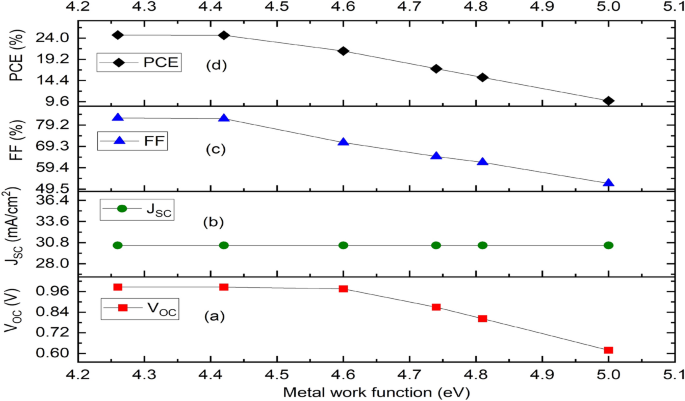

Effect of different back metal contact electrodes on parameters of the proposed IPSC. ( a ) Plot of V OC against metal work function, ( b ) Plot of J SC against metal work function, ( c ) Plot of FF against metal work function, ( d ) Plot of PCE against metal work function.

Effect of back contact electrode on the proposed inverted perovskite solar cell

Various metal back contact electrodes such as aluminium (4.26 eV), tin (4.42 eV) graphene (4.60 eV), silver (4.74 eV), iron (4.81 eV) and copper (5.00 eV) have been tested on the proposed inverted structure so as to determine the most appropriate one to be used for enhanced optimal performance. Figure 1 shows the work function of various metals used as back contact electrodes and their associated photovoltaic parameters on the proposed IPSC based device simulated using initial given parameters presented in Tables 1 and 2 . The results in Fig. 1 clearly show that the choice of aluminum (Al) for back electrode maintained the most optimal device performance, as the V oc , J SC , FF and PCE of 0.9854 V, 30.4185 mA/cm 2 , 82.48% and 24.72% respectively is produced. It is interesting to note in this model that the J SC (Fig. 1 b) remains constant as the work function of the back contact varies while the V OC , FF and PCE declines as the work function increases from 4.26 to 5.00 eV (Fig. 1 a,c,d). For p–n configuration, the current is negative because of the uphill diffusion of the minority charge carriers in terms of concentration gradient arising from reverse bias during solar illumination. The current growth from the negative quadrant towards the positive quadrant signifies power generation up to zero value of current where an open circuit voltage (V OC ) of 0.9854 V is achieved. The J–V characteristics of the device having used aluminum as the back contact electrode is shown as Fig. 2 .

J–V Characteristics of the proposed inverted perovskite solar cell with initial parameters using MASnI 3 as absorber material, Cu 2 O as HTM, ZnO as ETM and Al as back contact respectively.

Effect of n-type TCO-free on inverted perovskite solar cell architecture.

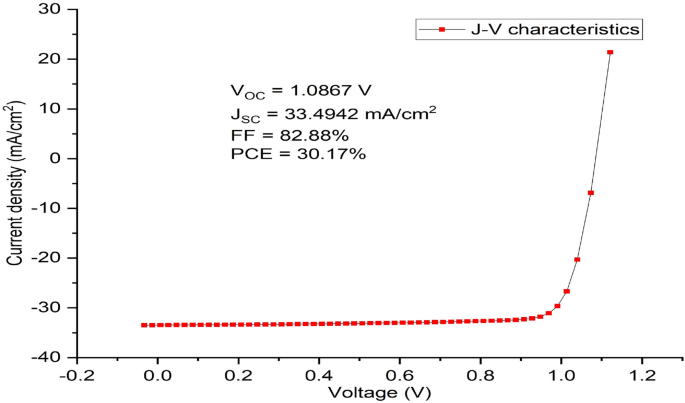

There is no experimental result for this exact structure (Cu 2 O/CH 3 NH 3 SnI 3 /ZnO/Al) known to us, which makes this research novel and interesting. There is no clear reasons why the lack of experimental works to support this study, but this could be due to lack of good conductivity of all-inorganic transport materials in nano electronics compared to organic transport materials and high processing temperature required. However, there are few simulation results of exact combination in n–i–p structure reported in 63 , 64 . The PCEs of 26.55% and 9.27% respectively were obtained in 63 and 64 , while our designed n-type TCO-free p-i-n device produced a superior PCE of 30.17% as shown in Fig. 8 .

The proposed inverted model will not simulate when the conventional n-type TCO (ITO/FTO) of donor concentration ND is used with the acceptor concentration NA being zero, except an organic p-type TCO is used which is outside the scope of this study. It’s worth noting that the top transparent glass used as presented in Fig. 16 is an n-type TCO-free substrate in order to avoid non-convergence of voltage between the front and back electrodes when a conventional n-type TCOs are used. The carefully chosen transparent glass substrate size of 50 nm is not included in the simulation model, hence it is undoped and may not have significant impact on the device in real experimental situation. In this work, it is difficult to drive an output from the device if a TCO of an n-type material (FTO/ITO) is used as front electrode in the inverted structure when the same n-type material of same polarity is used as back hole blocker (ZnO) because of non-voltage convergence arising from non-compatible work function between the layers. The non-voltage convergence experienced when ITO with metal function of 4.7 eV is used is as a result of non-ideal band gap between the adjacent semiconductors layers (ITO/Cu 2 O) which makes the proposed n-type TCO-free model feasible. However, a back contact electrode of low metal function lower than ZnO like aluminium (4.26 eV) is required for optimal performance.

The use of Cu 2 O as front contact electrode may suffer setback due its high sheet resistance and poor conductivity when compared to n-type TCOs. However, the sheet resistance of most metal oxides depends on the method of deposition, temperature, oxygen flow rate and thickness of the films. The control of power and oxygen flow rates during deposition of copper oxide thin films at a thickness of less than 100 nm prepared by reactive magnetron sputtering can reduce the sheet resistance and enhance performance of the device in practical sense 65 . The provision of a high density of low energy sputtered copper radicals/ions, and when combined with a controlled amount of oxygen, can produce good quality p-type transparent Cu 2 O films with electrical resistivity ranging from 10 2 to 10 4 Ω-cm 66 which makes Cu 2 O a potential transparent front conducting oxide for photovoltaic applications. Also, the doping of Cu 2 O with nickel can improve its p–type conductivity via extrinsic doping and post–growth processing 67 . Therefore, the Cu 2 O may not be as conductive as other n-type TCOs in experimental sense but runs conveniently in the simulation model without challenge which means the proposed n-type TCO–free model is novel and less complex, providing good direction in the design and modeling of simple inverted perovskite solar cells as shown in Figs. 13 and 16 . Cu 2 O can act as a front electrode efficiently provided its thickness is thin enough to ensure adequate clarity and transparency to enhance admittance of photons into the absorber (perovskite) layer.

Effect of thickness of the HTM (Cu 2 O), absorber (CH 3 NH 3 SnI 3 ) and ETM (ZnO) layers

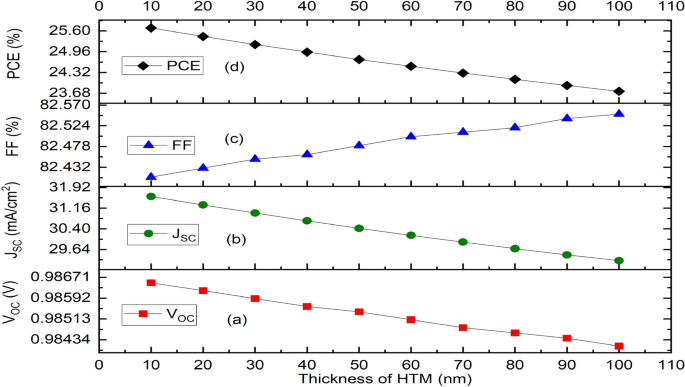

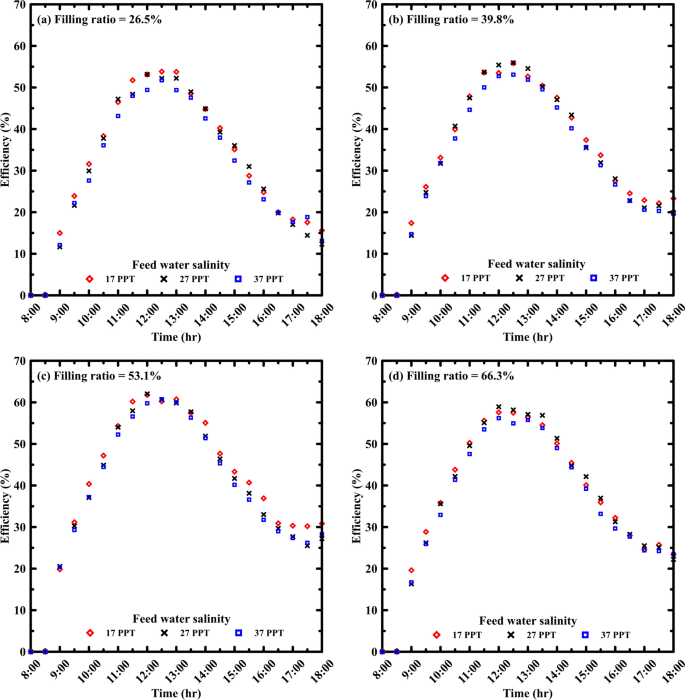

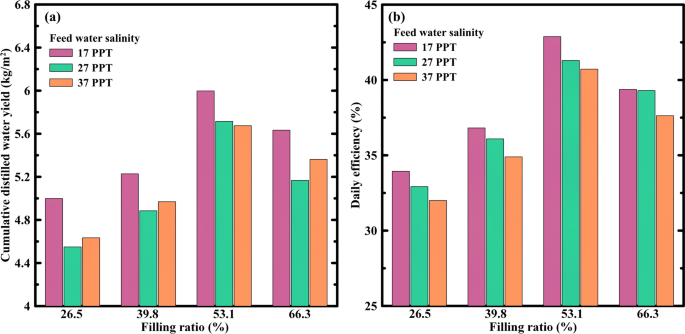

In this study, the variation of HTM’s layer thickness from 10 to 100 nm results to a slight increase in FF (Fig. 3 c) while a decline in device parameters such as V OC , J SC and PCE is experienced as presented in Fig. 3 a,b,d respectively.

Effect of variation of thickness of the HTM layer (Cu 2 O) on solar cell parameters. ( a ) Plot of V OC against thickness, ( b ) Plot of J SC against thickness, ( c ) Plot of FF against thickness, ( d ) Plot of PCE against thickness.

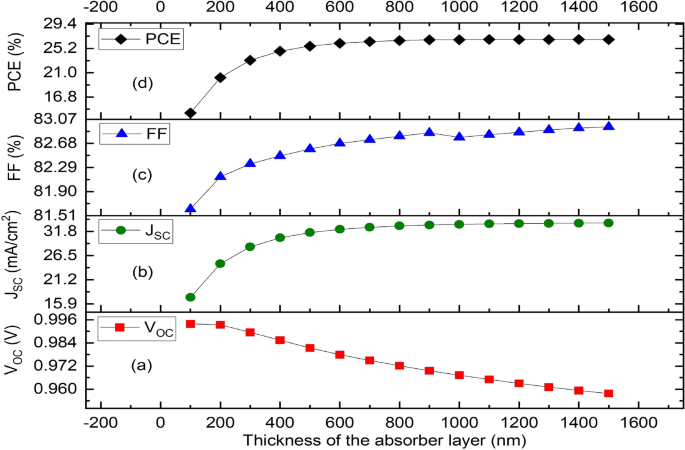

The thickness of the absorber layer considerably affects the solar cell’s overall performance. The increase in absorber’s thickness decreases the V OC due to increase in series resistance. Meanwhile, the increase in absorber’s thickness increases the J SC, FF and PCE to the maximum after which it decreases with further increase in thickness. In this study, the thickness of CH 3 NH 3 SnI 3 has been adjusted in this simulation from 100 to 1500 nm. The fluctuation of photovoltaic characteristics with thickness of absorber layer is shown in Fig. 4 . The V OC declines as a result of faster recombination due to increased thickness (Fig. 4 a). A thicker absorber layer absorbs more photons, which increases short circuit current density (J CS ) and the fill factor (FF) and as seen in Fig. 4 b,c, respectively. The solar cell efficiency is increased as the thickness of absorber layer increases up to an ideal thickness for the solar cell after which efficiency declines (Fig. 4 d). However, as diffusion necessitates a longer charge travel distance, recombination is more common in larger absorber layers; hence, efficiency decreases after a certain thickness value. Our results concur with experimental findings in 62 , 68 . As shown in Fig. 4 d, the ideal absorber layer thickness for this inverted PSC is achieved between 1200 and 1300 nm.

Effect of variation of thickness of the absorber layer (MASnI 3 ) on solar cell parameters. ( a ) Plot of V OC against thickness, ( b ) Plot of J SC against thickness, ( c ) Plot of FF against thickness, ( d ) Plot of PCE against thickness.

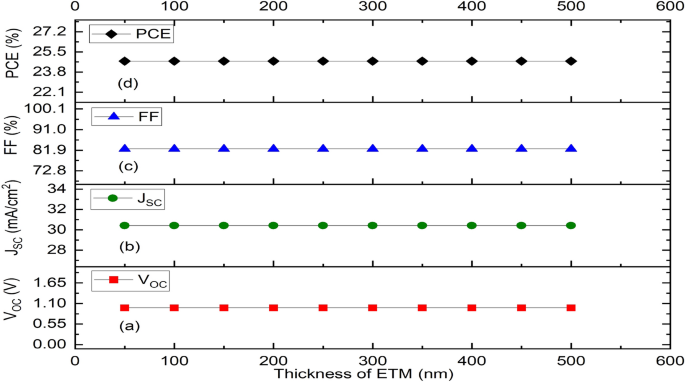

Nevertheless, the increase in ETM’s thickness leads to a non-noticeable change in V OC , J SC , FF and PCE (Fig. 5 a–d) respectively. Therefore, it can be inferred that while device performance is mostly determined by absorber thickness, IPSC device performance is not influenced by the ETM layer’s thickness but rather varies slightly with the HTM’s thickness, which is designed to be small enough to guarantee optical transparency and ensure easy photon penetration to the absorber layer. The selection of optimal thickness is important to regulate series and shunt resistance and ensure improved device performance in terms of short circuit current, open circuit voltage, fill factor and power conversion efficiency.

Effect of variation of thickness of the ETM layer (ZnO) on solar cell parameters. ( a ) Plot of V OC against thickness, ( b ) Plot of J SC against thickness, ( c ) Plot of FF against thickness, ( d ) Plot of PCE against thickness.

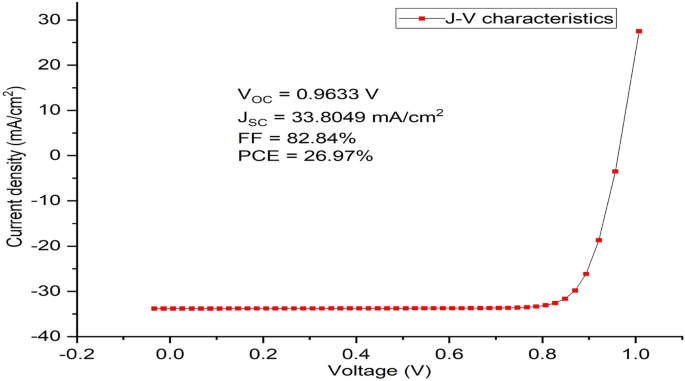

Simulation and thickness optimization of the proposed device structure

Simulation and optimization of the proposed device shows that the HTM (Cu 2 O) layer, the absorber (MASnI 3 ) layer and ETM layer (ZnO) have been optimized to the thickness of 40 nm, 1200 nm and 200 nm respectively. The simulation of these optimized dimensions led to an improvement in the solar cell parameters as it produced a Voc of 0.9633 V, J SC of 33.8049 mA/cm 2 , FF of 82.84% and PCE of 26.97% as shown in the J–V characteristics curve (Fig. 6 ).

J–V characteristics of the optimized device’s thickness using MASnI 3 as absorber material, Cu 2 O as HTM, ZnO as ETM and Al as back contact respectively.

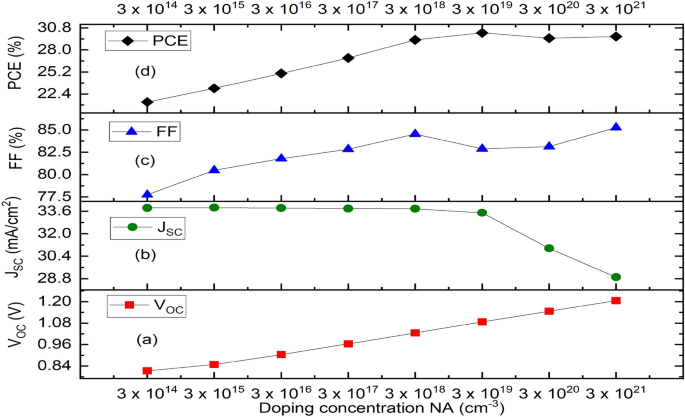

Effect of absorber’s doping concentration (NA)

The holes’ acceptor density of the absorber layer has a major impact on the photovoltaic cell’s device performance in addition to its thickness. As demonstrated in Fig. 7 , the Fermi energy level of the hole falls with increasing doping concentration of the acceptor, and as a result, V OC increases (Fig. 7 a). Also, an increase in the doping concentration of the acceptor leads to a built-in potential that increases charge separation, which in turn causes a rise in V OC . In this work, the acceptor concentration NA (1/cm 3 ) of the absorber layer is varied within a range of 3 × 10 14 cm −3 to 3 × 10 21 cm −3 to ascertain the most optimal value that can produce an optimal performance of the proposed device. Nevertheless, J SC maintains a steady decline marginally up to NA’s value of 3 × 10 19 cm −3 before falling off sharply. At the same NA’s value, the value of FF drops suddenly which might be caused by a rise in the rate at which charge carriers within the absorber layer recombine or an increase in series resistance 55 . The absorber layer’s doping concentration value of 3 × 10 19 cm −3 produced the best cell performance having V oc of 1.0867 V, J SC of 33.4942 mA/cm 2 , FF of 82.88% and PCE of 30.17% as shown in Fig. 7 a–d respectively, while its J–V characteristics is shown as Fig. 8 .

Effect of variation of doping concentration of the absorber (CH 3 NH 3 SnI 3 ) on solar cell parameters. ( a ) Plot of V OC against doping concentration (NA), ( b ) Plot of J SC against doping concentration (NA), ( c ) Plot of FF against doping concentration (NA), ( d ) Plot of PCE against doping concentration (NA).

J–V Characteristics of the final optimized inverted simulated solar cell device using MASnI 3 as absorber material, Cu 2 O as HTM, ZnO as ETM and Al as back contact respectively.

The complex nature of an organic molecule in the A site of the perovskite structure (ABX 3 ) may be the cause of degradation, as evidenced by the absorber’s bandgap of 1.3 eV and the measured Voc of 1.0867 V. Using varying ratios of the precursors causes an intrinsic fault when the perovskite structure is distorted. Higher degrees of crystallization and a slower rate of breakdown are the results of vacancies in the structure caused by the excess CH 3 NH 3 I (MAI). The crystalline lattice’s anomalies emphasize the role MAI plays in the deterioration process. Excess MAI may potentially release halide ions, depending on the concentration. Afterwards, these halide ions function as dopants, altering the perovskite semiconductors' bandgap 69 . When exposed to air, the Sn 2+ in CH 3 NH 3 SnI 3 is changed to Sn 4+ (a process known as self-doping), converting the device into a p-type semiconductor. Sadly, this procedure deteriorates the device performance, such as the output power and the power conversion efficiency 56 , 70 .

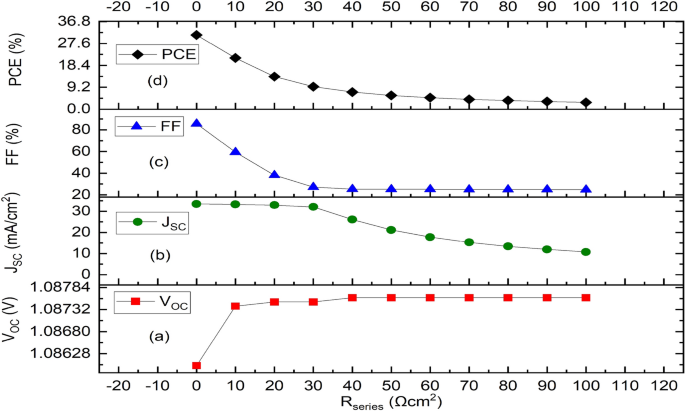

Effect of series resistance R series and shunt resistance R shunt

The resistance in series and shunt (R series and R shunt ) affects the J–V curve’s form and slope, which in turn affects the solar cell’s efficiency. The connections electrodes, electrical dissipation in the perovskite, and layers of hole and electron transport materials (HTM and ETM) are primarily linked to the cause of the R series . However, different recombination pathways, device design, and defects induced during the layer deposition process are linked to the cause of the R shunt . According to the literature, a high shunt resistance and a low series resistance are necessary for a solar cell to have a high efficiency. Electrons cannot flow freely across a circuit if the series resistance is large, and leakage current will occur if the shunt resistance is low, producing PSCs with low stability and efficiency. When there’s a low shunt resistance or a high series resistance, the PSC’s maximum output and FF would both drop 71 , 72 . The ideal diode model’s Eq. ( 4 ) was applied in order to comprehend the impact of R series and R shunt on the perovskite solar cell’s performance 73 .

When \(J\approx\) 0 mA/cm 2 for open circuit state, the variables V OC and R shunt relationship is presented in Eq. ( 5 )

where J is the current flowing via the external circuit, V is the output voltage, A is the ideality factor, k is the Boltzmann constant, T is the temperature, q is the electron charge, J O is the saturation current density and J L is the light-induced current density. As a result, low R shunt reduces photovoltaic voltage and may also have an impact on the photocurrent that is collected, whereas high R series values primarily influence the FF and Jsc values 72 .

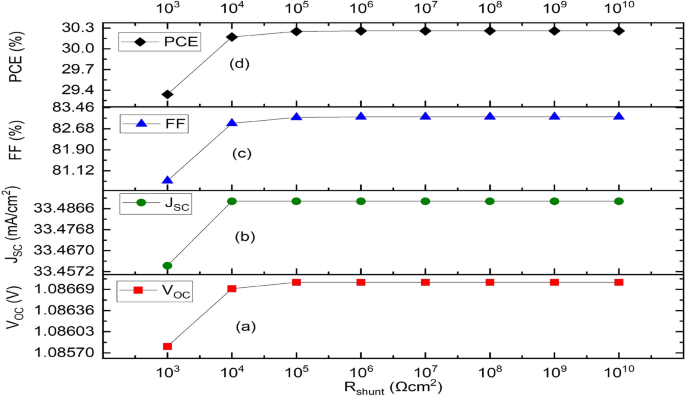

While keeping the other simulation parameters same, R series and R shunt were changed from 0 to 100 Ωcm 2 and 10 3 Ωcm 2 to 10 10 Ωcm 2 respectively, to better understand their influence on the J–V curves. The responses of V OC , J SC FF and PCE as a function of R series are presented in Fig. 9 . V OC stays fairly constant, J SC falls from 33.51 to 10.77 mA/cm 2 , and FF drops from 85.63 to 24.88% while R series grows from 0 to 100 Ωcm 2 . As a result, as Fig. 9 d illustrates, PCE’s behavior is precisely proportional to J SC and FF, decreasing from 31.16 to 2.91% for the same range. Alternatively, as Fig. 10 illustrates, when R shunt rises from 10 3 to 10 10 Ωcm 2 , V OC rises from 1.0858 to 1.0868 V, J SC maintains a constant 33.49 mA/cm 2 from 10 4 Ωcm 2 , FF rises from 80.75 to 83.12%, and the PCE rises from 29.34 to 30.26% respectively (Fig. 10 a–d). For R series and R shunt , the optimal values are therefore 1 Ωcm 2 and 10 6 Ωcm 2 respectively, which is in conformity with literature.

Effect of series resistance variation on the optimized IPSC based device parameters. ( a ) Plot of V OC against series resistance. ( b ) Plot of J SC against series resistance. ( c ) Plot of FF against series resistance, ( d ) Plot of PCE against series resistance.

Effect of shunt resistance variation on parameters of the optimized IPSC device. ( a ) Plot of V OC against shunt resistance, ( b ) Plot of J SC against shunt resistance, ( c ) Plot of FF against shunt resistance, ( d ) Plot of PCE against shunt resistance.

Effect of the defect state of bulk and interface layers

The impact of the absorber’s defect density is an important factor that needs to be examined. In the absorber layer, defects are inevitable. Both at surfaces and in the bulk, they are present. Point defects in the perovskite absorber layer include lattice vacancies, interstitial, Schottky, and Frenkel defects. In addition, there may be higher order defects like grain boundaries and dislocations 74 . The self-doping process in the absorber layer creates the p-type semiconductor that results in an impurity defect 54 , 56 , 75 , 76 . These defects cause the energy bandgap to appear at shallow or deep levels 74 . Charge carriers have the ability to capture and promote nonradiative recombination of electron–hole as a result of these defects 53 , 55 . Noteworthy, the simulated interface defect density for both electron and hole recombination velocities was 1 × 10 -2 cm/s for both HTM/MASnI 3 and ETM/MASnI 3 interface. In the Sn-based perovskite absorber layer, the electron and hole diffusion lengths were 16 µm and 6.2 µm, respectively. The optimized device’s absorber defect density (Nt) of 2 × 10 15 cm −3 achieved a V OC of 1.0867 V, a J SC of 33.4942 mA/cm 2 , FF of 82.88%, and a PCE of 30.17%. Nevertheless, synthesizing a material with a low defect density value is a challenging task in an experiment 55 .

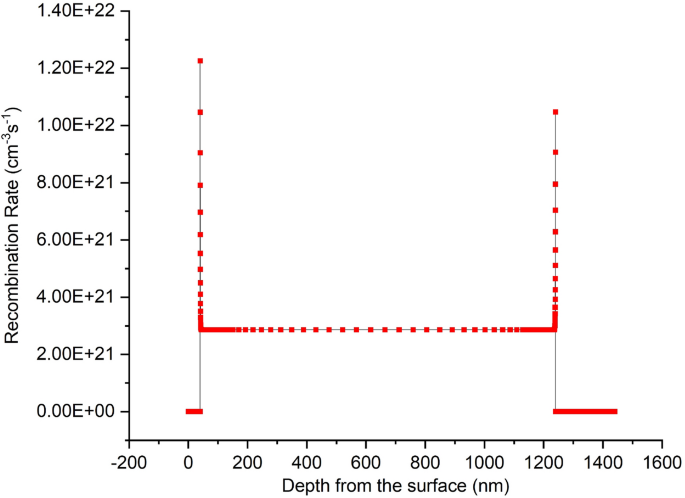

The Shockley–Read–Hall (SRH) recombination model has been applied to provide understanding regarding the impact of defect density in the absorber layer on device performance 49 , 53 , 77 . The effect of defect density on the recombination rate based on the SRH recombination model is essential to determining the critical influence of Nt on the device performance. The plot of recombination rate with depth from the optimized device’s surface is depicted in Fig. 11 .

Recombination rate of the optimized device with depth from the surface.

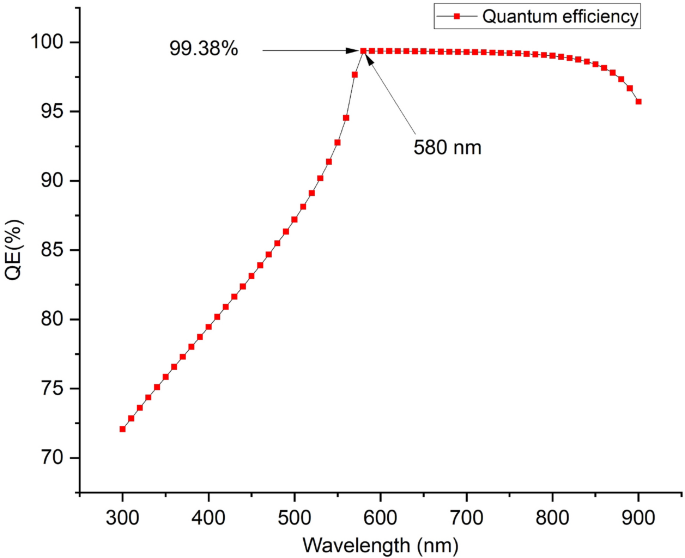

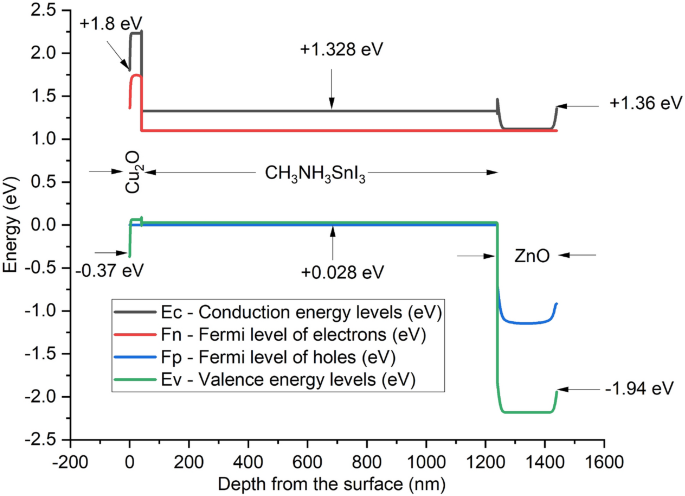

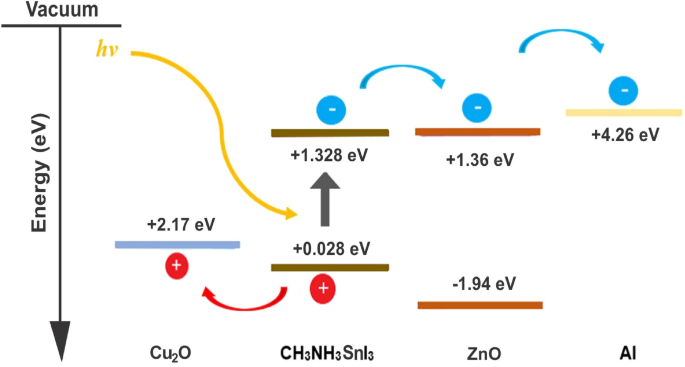

The proposed device produced quantum efficiency curve covering the entire visible spectrum (300–900 nm) achieving an optimum quantum efficiency (QE) of 99.38% at 580 nm wavelength, which is in agreement with other works 15 , 43 , 54 , 61 , 78 , 79 is presented as Fig. 12 . The simulated inverted structure, energy band diagram, energy band alignment and complete device structure of the optimized inverted planar perovskite solar cells are presented as Figs. 13 , 14 , 15 and 16 , respectively. It’s very clear that the photovoltaic performance of the proposed device as shown in Table 3 is superior to other related works reported in the literature.

Quantum efficiency of the proposed inverted perovskite solar cell.

The simulated inverted device structure.

Energy band diagram of the proposed inverted perovskite solar cell.

Energy band alignment profile of the proposed inverted perovskite solar cell.

The complete optimized structure of the proposed n-type TCO-free inverted perovskite solar cell.

The toxic-free CH 3 NH 3 SnI 3 as light harvesting material is explored in this study. A heterojunction planar perovskite solar cell with an inverted structure Glass/Cu 2 O/CH 3 NH 3 SnI 3 /ZnO/Al was simulated, optimized and analyzed in this paper. In relation to various photovoltaic parameters such as the work function of the back contact electrodes, thickness of the HTM layer, absorber and the ETM layers, and the absorber’s doping concentration were optimized. The thickness of the HTM, absorber layer and ETM were optimized to 40 nm, 1200 nm and 200 nm respectively. The optimized structure produced an enhanced Voc of 1.0867 V, J SC of 33.4942 mA/cm 2 , FF of 82.88% and PCE of 30.17% respectively. The results indicate that an increase in doping concentration of the absorber increased the Voc, FF and PCE but decreased the J SC of the solar cell. The interface between the ETM/back-electrode requires a cheap and low work function metal for enhanced performance. The n-type TCO-free inverted CH 3 NH 3 SnI 3 -based PSC provides a potential path to attaining simple, eco-friendly, cheap and highly efficient perovskite solar cell device using all-inorganic transport materials.

Data availability

The data that support the findings can be made available upon reasonable request from the corresponding author on [email protected].

Danladi, E. et al. Impact of transport material on perovskite solar cells with different metal electrode: A SCAPS-1D Simulation insight. Heliyon. https://doi.org/10.1016/j.heliyon.2023.e16838 (2023).

Article PubMed PubMed Central Google Scholar

Saha, P., Singh, S. & Bhattacharya, S. Efficient and lead-free perovskite solar cells based on defect-ordered methyl ammonium antimony iodide. IEEE Trans. Electron. Devices 70 (3), 1095–1101. https://doi.org/10.1109/TED.2023.3235870 (2023).

Article ADS CAS Google Scholar

Bhattarai, S. et al. Carrier transport layer free perovskite solar cell for enhancing the efficiency: A simulation study. Opt. Int. J. Light Electron. Opt. 243 , 167492. https://doi.org/10.1016/j.ijleo.2021.167492 (2021).

Article CAS Google Scholar

Celik, I. et al. Environmental analysis of perovskites and other relevant solar cell technologies in a tandem configuration. Energy Environ. Sci. 10 , 1874–1184. https://doi.org/10.1039/c7ee01650f (2017).

Lhoussayne, E. et al. Numerical analysis of earth-abundant Cu 2 ZnSn(S x Se 1 − x ) 4 solar cells based on Spectroscopic Ellipsometry results by using SCAPS-1D. Solar Energy. 201 , 827–835. https://doi.org/10.1016/j.solener.2020.03.070 (2020).

Battaglia, C., Cuevas, A. & Wolf, S. D. High-efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 9 , 1552–1576. https://doi.org/10.1039/C5EE03380B (2016).

Major, J. D. Grain boundaries in CdTe thin film solar cells: A review. Semicond. Sci. Technol. 31 , 093001. https://doi.org/10.1088/0268-1242/31/9/093001 (2016).

Basol, B. M. & McCandless, B. Brief review of cadmium telluride-based photovoltaic technologies. J. Photon. Energy. 4 (1), 040996. https://doi.org/10.1117/1.JPE.4.040996 (2016).

Article Google Scholar

Carey, G. H. et al. Colloidal quantum dot solar cells. Chem. Rev. 115 (23), 12732–12763. https://doi.org/10.1021/acs.chemrev.5b00063 (2015).

Article ADS CAS PubMed Google Scholar

Ramanujam, J. & Singh, U. P. Copper indium gallium selenide based solar cells—A review. Energy Environ. Sci. 10 , 1306–1319. https://doi.org/10.1039/C7EE00826K (2017).

Feurer, T. et al. Progress in thin film CIGS photovoltaics—Research and development, manufacturing, and applications. Progress Photovolt. Res. Appl. 25 (7), 645–667. https://doi.org/10.1002/pip.2811 (2017).

Lu, L. Y. et al. Recent advances in bulk heterojunction polymer solar cells. Chem. Rev. 115 (23), 12666–12731. https://doi.org/10.1021/acs.chemrev.5b00098 (2015).

Saparov, B. & Mitzi, D. B. Organic–inorganic perovskites: Structural versatility for functional materials design. Chem. Rev. 116 (7), 4558–4596. https://doi.org/10.1021/acs.chemrev.5b00715 (2016).

Article CAS PubMed Google Scholar

Pandey, R. et al. Halide composition engineered a non-toxic perovskite−silicon tandem solar cell with 30.7% conversion efficiency. ACS Appl. Electron. Mater. 5 , 5303–5315. https://doi.org/10.1021/acsaelm.2c01574 (2023).

Bhattarai, S. et al. Comparative study of distinct halide composites for highly efficient cesium-based perovskite solar cells. Energy Fuels. 37 , 16035–16049. https://doi.org/10.1021/acs.energyfuels.3c02610 (2023).

Durodola, O. M., Ugwu, C. & Danladi, E. Highly efficient lead-free perovskite solar cell based on Magnesium-doped copper delafossite hole transport layer: A SCAPS-1D framework prospect. Emerg. Mater. 100 , 101001. https://doi.org/10.1016/j.jics.2023.101001 (2023).

Hartono, N. T. P. et al. Stability follows efficiency based on the analysis of a large perovskite solar cells ageing dataset. Nat. Commun. 14 , 4869. https://doi.org/10.1038/s41467-023-40585-3 (2023).

Article ADS CAS PubMed PubMed Central Google Scholar

Kim, H. S., Im, S. H. & Park, N. G. Organolead halide perovskite: New horizons in solar cell research. J. Phys. Chem. C 118 , 5615–5625. https://doi.org/10.1021/jp409025w (2014).

Lyu, M. et al. Addressing toxicity of lead: Progress and applications of low-toxic metal halide perovskites and their derivatives. Adv. Energy Mater. 7 , 1602512–1602537. https://doi.org/10.1002/aenm.201602512 (2017).

Burschka, J. et al. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature 499 , 316–319. https://doi.org/10.1038/nature12340 (2013).

Lee, M. M. et al. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 338 (6107), 643–647. https://doi.org/10.1126/science.1228604 (2012).

Bhattarai, S. et al. Performance improvement approach of all inorganic perovskite solar cell with numerical simulation. Mater. Today Commun. 33 , 104364. https://doi.org/10.1016/j.mtcomm.2022.104364 (2022).

Saha, P. et al. Optimization and formulation of different hole-transporting materials (HTMs) for the performance of eco-friendly Cs 2 TiBr 6 —Based perovskite solar cells. Energy Technol. https://doi.org/10.1002/ente.202300991 (2024).

Saha, P., Singh, S. & Bhattacharya, S. Eco-friendly methyl-ammonium tin-based planar p–n homojunction Perovskite solar cells: Design and performance estimation. Int. J. Modern Phys. B 37 (17), 22350169. https://doi.org/10.1142/S0217979223501692 (2023).

Huang, H. H. et al. Boosting the ultra-stable unencapsulated perovskite solar cells by using montmorillonite/CH 3 NH 3 PbI 3 nanocomposite as photoactive layer. Energy Environ. Sci. 12 , 1265–1273. https://doi.org/10.1039/C8EE02958J (2019).

Liu, D. et al. Predicted photovoltaic performance of lead-based hybrid perovskites under the influence of a mixed-cation approach: Theoretical insights. J. Mater. Chem. C 7 , 371–379. https://doi.org/10.1039/C8TC04065F (2019).

Santosa, I. M. D. L. et al. Optimization of CH 3 NH 3 PbI 3 perovskite solar cells: A theoretical and experimental study. Solar Energy 199 , 198–205. https://doi.org/10.1016/j.solener.2020.02.026 (2020).

Li, X. et al. Low-temperature solution processed ZnSe electron transport layer for efficient planar perovskite solar cells with negligible hysteresis and improved photostability. ACS Nano 12 (6), 5605–5614. https://doi.org/10.1021/acsnano.8b01351 (2018).

Article MathSciNet CAS PubMed Google Scholar

El-Mellouhi, F. et al. Hydrogen bonding and stability of hybrid organic–inorganic perovskites. ChemSusChem 9 , 2648–2655. https://doi.org/10.1002/cssc.201600864 (2016).

El-Mellouhi, F. et al. Enhancing intrinsic stability of hybrid perovskite solar cell by strong, yet balanced, electronic coupling. Sci. Rep. 6 , 30305. https://doi.org/10.1038/srep30305 (2016).

Wang, Q. et al. Enhancement in lifespan of halide perovskite solar cells. Energy Environ. Sci. 12 , 865–886. https://doi.org/10.1039/C8EE02852D (2019).

Zhao, Z. et al. Metal halide perovskite materials for solar cells with long-term stability. Adv. Energy Mater. 9 , 1802671. https://doi.org/10.1002/aenm.201802671 (2019).

Chen, B. et al. Origin of J–V hysteresis in perovskite solar cells. J. Phys. Chem. Lett. 7 , 905–917. https://doi.org/10.1021/acs.jpclett.6b00215 (2016).

Chen, H. & Yang, S. Carbon-based perovskite solar cells without hole transport materials: The front runner to the market. Adv. Mater. 29 (24), 1603994. https://doi.org/10.1002/adma.201603994 (2017).

Jung, M. C. et al. Substantial improvement of perovskite solar cells stability by pinhole-free hole transport layer with doping engineering. Sci. Rep. 5 , 9863. https://doi.org/10.1038/srep09863 (2015).

Article CAS PubMed PubMed Central Google Scholar

Rahman, S., et al . Simulation based investigation of inverted planar perovskite solar cell with all metal oxide inorganic transport layers. In Proceedings of the 2019 International Conference on Electrical, Computer and Communication Engineering (ECCE) , Cox’s Bazar, Bangladesh, 7–9 February 2019. document/8679283.

Shubhranshu, B. et al. Performance of WO 3 -incorporated carbon electrodes for ambient mesoscopic perovskite solar cells. ACS Omega 5 (1), 422–429. https://doi.org/10.1021/acsomega.9b02934 (2020).

Asad, J. et al. Perovskite solar cells free of hole transport layer. J. Sol–Gel Sci. Technol. 90 , 443–449. https://doi.org/10.1007/s10971-019-04957-w (2019).

Wang, T. et al. Optimal design of efficient hole transporting layer free planar perovskite solar cell. Sci. China Mater. 59 , 703–709. https://doi.org/10.1007/s40843-016-5108-4 (2016).

Xiaonan, H. et al. Preparation of high-efficiency (>14%) HTL-free carbon-based all-inorganic perovskite solar cells by passivation with PABr derivatives. ACS Appl. Mater. Interfaces 15 (7), 9382–9391. https://doi.org/10.1021/acsami.2c21226 (2023).

Ono, L. K. et al. The absence of pinholes in HTM significantly improves the stability of perovskite solar cells under operating conditions. J. Mater. Chem. A 3 , 15451–15456. https://doi.org/10.1039/C5TA03443D (2015).

Príncipe, J., Duarte, V. C. M. & Andrade, L. Inverted perovskite solar cells: The emergence highly stable and efficient architecture. Energy Technol. 10 , 2100952. https://doi.org/10.1002/ente.202100952 (2022).

Fakhri, N. et al. Simulation of perovskite solar cells optimized by the inverse planar method in SILVACO: 3D electrical and optical models. Energies 14 , 5944. https://doi.org/10.3390/en14185944 (2021).

Liu, J. et al. HClO 4 -assisted fabrication of SnO 2 /C 60 bilayer electron-transport materials for all air-processed efficient and stable inverted planar perovskite solar cells. J. Power Sources. 476 , 228648. https://doi.org/10.1016/j.jpowsour.2020.228648 (2020).

Li, T. et al. Multiple functional groups synergistically improve the performance of inverted planar perovskite solar cells. J. Nano Energy. 82 , 105742. https://doi.org/10.1016/j.nanoen.2021.105742 (2021).

He, Y. et al. Enhanced efficiency and stability of inverted planar perovskite solar cells with piperazine as an efficient dopant into PCBM. IEEE J. Photovolt. 10 , 811–817. https://doi.org/10.1109/JPHOTOV.2020.2974803 (2020).

Lan, F., Jiang, M., Tao, Q. & Li, G. Revealing the working mechanisms of planar perovskite solar cells with cross-sectional surface potential profiling. IEEE J. Photovolt. 8 , 125–131. https://doi.org/10.1109/JPHOTOV.2017.2762525 (2017).

Abdul, S., et al . Performance Evaluation of Solar Cells by Different Simulating Softwares . Vol. 7, pp. 1–21 (2023). https://doi.org/10.5772/intechopen.111639 .

Lin, L. et al. A modelled perovskite solar cell structure with a Cu 2 O hole-transporting layer enabling over 20% efficiency by low-cost low-temperature processing. J. Phys. Chem. Solids. 14 , 205–211. https://doi.org/10.1016/j.jpcs.2018.09.024 (2019).

Song, L., Yong-Li, C., Wen-Hua, L. & Zhi-Shan, B. A brief review of hole transporting materials commonly used in perovskite solar cells. Rare Met. 40 (10), 2712–2729. https://doi.org/10.1007/s12598-020-01691-z (2021).

Bhattarai, S. & Das, T. D. Optimization of carrier transport materials for the performance enhancement of the MAGeI 3 based perovskite solar cell. Solar Energy. 217 , 200–207. https://doi.org/10.1016/j.solener.2021.02.002 (2021).

Saha, P., Singh, S. & Bhattacharya, S. FASnI 3 -based eco-friendly heterojunction perovskite solar cell with high efficiency. Micro Nanostruct. 186 , 207739. https://doi.org/10.1016/j.micrna.2023.207739 (2024).

Lazemi, M., Asgharizadeh, S. & Bellucci, S. A computational approach to interface engineering of lead-free CH 3 NH 3 SnI 3 highly-efficient perovskite solar cells. Phys. Chem. Chem. Phys. 20 (40), 25683–25692. https://doi.org/10.1039/C8CP03660H (2018).

Hao, F. et al. Lead-free solid-state organic–inorganic halide perovskite solar cells. Nature Photon. 8 , 489–494. https://doi.org/10.1038/nphoton.2014.82 (2014).

Du, H. J., Wang, W. C. & Zhu, J. Z. Device simulation of lead-free CH 3 NH 3 SnI 3 perovskite solar cells with high efficiency. Chin. Phys. B. 25 , 108802–188809. https://doi.org/10.1088/1674-1056/25/10/108802 (2016).

Ma, L. et al. Carrier diffusion lengths of over 500 nm in lead-free perovskite CH 3 NH 3 SnI 3 films. J. Am. Chem. Soc. 138 , 14750–14755. https://doi.org/10.1021/jacs.6b09257 (2016).

Stoumpos, C. C., Malliakas, C. D. & Kanatzidis, M. G. Semiconducting tin and lead iodide perovskites with organic cations: Phase transitions, high mobilities, and near-infrared photoluminescent properties. Inorg. Chem. 52 , 9019–9038. https://doi.org/10.1021/ic401215x (2013).

Devi, C. & Mehra, R. Device simulation of lead-free MASnI3 solar cell with CuSbS 2 (copper antimony sulfide). J. Mater. Sci. 54 , 5615–5624. https://doi.org/10.1007/s10853-018-03265-y (2019).

Khattak, Y. H., Baig, F., Toura, H., Beg, S. & Soucase, B. M. CZTSe kesterite as an alternative hole transport layer for MASnI 3 perovskite solar cells. J. Electron. Mater. 48 , 5723–5733. https://doi.org/10.1007/s11664-019-07374-5 (2019).

Constantinos, C. et al. Semiconducting tin and lead iodide perovskites with organic cations: Phase Transitions, high mobilities, and near-infrared photoluminescent properties. Org. Chem. 52 , 9019–9038. https://doi.org/10.1021/ic401215x (2013).

Patel, P. K. Device simulation of highly efficient eco-friendly CH 3 NH 3 SnI 3 perovskite solar cell. Sci. Rep. 11 , 3082. https://doi.org/10.1038/s41598-021-82817-w (2021).

Shamna, M. S., Nithya, K. S. & Sudheer, K. S. Simulation and optimization of CH 3 NH 3 SnI 3 based inverted perovskite solar cell with NiO as hole transport material. Mater. Today Proc. 33 (2), 1246–1251. https://doi.org/10.1016/j.matpr.2020.03.488 (2020).

Manisha Ahamad, A. K. M. & Hossain, A. Design and optimization of non-toxic and highly efficient tin-based organic perovskite solar cells by device simulation. Heliyon 9 , e19389. https://doi.org/10.1016/j.heliyon.2023.e19389 (2023).

Tareq, D.E., et al . Perovskite solar cells based on CH 3 NH 3 SnI 3 structure. In 2nd International Scientific Conference of Al-Ayen University (ISCAU-2020), IOP Conf. Series: Materials Science and Engineering vol. 928, 072148 (2020). https://doi.org/10.1088/1757-899X/928/7/072148 .

Ogwu, A. A. et al. Electrical resistivity of copper oxide thin films prepared by reactive magnetron. J. Ach. Mater. Manuf. Eng. 24 , 171–177 (2007).

Google Scholar

Li, F. M. et al. Low temperature (b100 °C) deposited P-type cuprous oxide thin films: Importance of controlled oxygen and deposition energy. Thin Solid Films 520 , 1278–1284. https://doi.org/10.1016/j.tsf.2011.04.192 (2011).

Wang, Y. et al. Improving the P-type conductivity of Cu 2 O thin films by Ni doping and their heterojunction with N–Zno. Appl. Surf. Sci. 590 , 153047. https://doi.org/10.1016/j.apsusc.2022.153047 (2022).

Correa-Baena, J. P. et al. Unbroken perovskite: Interplay of morphology, electro-optical properties, and ionic movement. Adv. Mater. 28 , 5031–5037. https://doi.org/10.1002/adma.201600624 (2016).

Rahimi, F. et al. Methylammonium iodide and its effect as an intrinsic defect in perovskite structure and device performance. Org. Electron. 62 , 304–310. https://doi.org/10.1016/j.orgel.2018.08.025 (2018).

Cao, H. et al. The effect of defects in tin-based perovskites and their photovoltaic devices. Mater. Today Phys. 21 , 100513. https://doi.org/10.1016/j.mtphys.2021.100513 (2021).

Kim, D. I. et al. A high-efficiency and stable perovskite solar cell fabricated in ambient air using a polyaniline passivation layer. Sci. Rep. 12 , 697. https://doi.org/10.1038/s41598-021-04547-3 (2022).

Karthick, S., Velumani, S. & Bouclé, J. Experimental and SCAPS simulated formamidinium perovskite solar cells: A comparison of device performance. Solar Energy. 205 , 349–357. https://doi.org/10.1016/j.solener.2020.05.041 (2020).

Li, Y. et al. Ultra-high open-circuit voltage of perovskite solar cells induced by nucleation thermodynamics on rough substrates. Sci. Rep. 7 , 46141. https://doi.org/10.1038/srep46141 (2017).

Lee, Y. M. et al. Comprehensive understanding and controlling the defect structures: An effective approach for organic–inorganic hybrid perovskite-based solar-cell application. Front. Energy Res. 6 , 1–9. https://doi.org/10.3389/fenrg.2018.00128 (2018).

Noel, N. K. et al. Lead-free organic–inorganic tin halide perovskites for photovoltaic applications. Energy Environ. Sci. 7 , 3061–3068. https://doi.org/10.1039/C4EE01076K (2014).

Hao, F. et al. Solvent-mediated crystallization of CH 3 NH 3 SnI 3 films for heterojunction depleted perovskite solar cells. J. Am. Chem. Soc. 137 , 11445–11452. https://doi.org/10.1021/jacs.5b06658 (2015).

Haider, S. Z., Anwar, H. & Wang, M. A. comprehensive device modelling of perovskite solar cell with inorganic copper iodide as hole transport material. Semicond. Sci. Technol. 33 (3), 035001–035012. https://doi.org/10.1088/1361-6641/aaa596 (2018).

Odari, V. et al. Device simulation of SB2S3 solar cells by SCAPS-1D software. Africa J. Phys. Sci. 3 , 39–54 (2019).

Totohua, E. P. Numerical simulation of an inverted perovskite solar cell using a SiOx layer as down-conversion energy material to improve efficiency and stability. Materials 16 , 7445. https://doi.org/10.3390/ma16237445 (2023).

Farhana, A., Rafee, M., Sakin, S. S. & Saeed, M. U. Effects of different HTM layers and electrical parameters on ZnO nanorod-based lead-free perovskite solar cell for high-efficiency performance. Int. J. Photoenergy. https://doi.org/10.1155/2017/9846310 (2017).

Danladi, E. et al. Optimization of absorber and ETM layer thickness for enhanced tin based perovskite solar cell performance using SCAPS-1D software. Phys. Access. 2 (1), 1–11. https://doi.org/10.47514/phyaccess.2022.2.1.001 (2022).

Hao, L. et al. A tin-based perovskite solar cell with an inverted hole-free transport layer to achieve high energy conversion efficiency by SCAPS device simulation. Opt. Quantum Electron. 53 , 524. https://doi.org/10.1007/s11082-021-03175-5 (2021).

Banihashemi, M. Simulation of an inverted perovskite solar cell with inorganic electron and hole transfer layers. J. Photon. Energy 2 , 022001. https://doi.org/10.1117/1.JPE.7.022001 (2017).

Gong, J., & Krishnan, S.. Simulation of inverted perovskite solar cells. In Proceedings of the ASME 2018 12th International Conference on Energy Sustainability . June 24–28, 2018, Lake Buena Vista, FL, USA. https://doi.org/10.1115/ES2018-7227 .

Aseena, S. et al. Solution-synthesized Cu 2 O as a hole transport layer for a ZnO-based planar heterojunction perovskite solar cells fabricated at room temperature. J. Electron. Mater. 51 , 1692–1699. https://doi.org/10.1007/s11664-022-09442-9 (2022).

Download references

Acknowledgements

The authors are very grateful to Dr. Marc Burgelman of the University of Gent in Belgium for providing the SCAPS-1D simulation program.

This work did not receive any funding support.

Author information

Authors and affiliations.

Department of Electrical and Electronics Engineering, University of Benin, Benin City, Nigeria

Emmanuel A. Nyiekaa, Timothy A. Aika & Patience E. Orukpe

Department of Physics, Federal University of Health Sciences, Otukpo, Nigeria

Eli Danladi

Department of Chemical Engineering, University of Benin, Benin City, Nigeria

Christopher E. Akhabue

Department of Electrical and Electronics Engineering, Joseph Sarwuan Tarka University, Makurdi, Nigeria

Emmanuel A. Nyiekaa

You can also search for this author in PubMed Google Scholar

Contributions

EAN conceived the idea, design, simulate and also carry out the writing and typesetting of the manuscript. TAA sourced for review materials used in the manuscript and preparation of figures. ED screened the review materials and identified relevant literatures and generation of data used in the manuscript. CEA and PEO supervised, edit the manuscript and made corrections accordingly.

Corresponding author

Correspondence to Emmanuel A. Nyiekaa .

Ethics declarations

Competing interests.

The authors declare no competing interests.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Nyiekaa, E.A., Aika, T.A., Danladi, E. et al. Simulation and optimization of 30.17% high performance N-type TCO-free inverted perovskite solar cell using inorganic transport materials. Sci Rep 14 , 12024 (2024). https://doi.org/10.1038/s41598-024-62882-7

Download citation

Received : 06 April 2024

Accepted : 22 May 2024

Published : 26 May 2024

DOI : https://doi.org/10.1038/s41598-024-62882-7

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- SCAPS-1D software

- Perovskite solar cell

- Hole transport layer

- Light absorber

- Electron transport layer

By submitting a comment you agree to abide by our Terms and Community Guidelines . If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

Sign up for the Nature Briefing newsletter — what matters in science, free to your inbox daily.

An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- Materials (Basel)

Photovoltaic Cell Generations and Current Research Directions for Their Development

Associated data.

Not applicable.

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and manufacturing technologies. The introduction describes the importance of photovoltaics in the context of environmental protection, as well as the elimination of fossil sources. It then focuses on presenting the known generations of photovoltaic cells to date, mainly in terms of the achievable solar-to-electric conversion efficiencies, as well as the technology for their manufacture. In particular, the third generation of photovoltaic cells and recent trends in its field, including multi-junction cells and cells with intermediate energy levels in the forbidden band of silicon, are discussed. We also present the latest developments in photovoltaic cell manufacturing technology, using the fourth-generation graphene-based photovoltaic cells as an example. An extensive review of the world literature led us to the conclusion that, despite the appearance of newer types of photovoltaic cells, silicon cells still have the largest market share, and research into ways to improve their efficiency is still relevant.

1. Introduction

Concerns about climate change and the increase in demand for electricity due to, among other things, an ever-growing population, necessitate efforts to move away from conventional methods of energy production. Rising carbon dioxide levels in the atmosphere caused by the use of fossil fuels is one of the factors causing ongoing climate change. Switching to renewable energy will produce energy with a smaller environmental footprint compared to fossil fuel sources. We are able to harness the full potential of sunlight energy to develop the best possible energy harvesting technologies capable of converting solar energy into electricity [ 1 ].

The currently used solar energy is very marginal—0.015% is used for electricity production, 0.3% for heating, and 11% is used in the natural photosynthesis of biomass. In contrast, about 80–85% of global energy needs are met by fossil fuels. The difficulty with fossil fuels is that their resources are limited and hostile to the environment due to their CO 2 emissions. For instance, for every ton of coal burned, one ton of carbon dioxide is released into the atmosphere. This emitted carbon dioxide is toxic to the environment and is a primary cause of global warming, the greenhouse effect, climate change, and ozone depletion [ 2 ].

The necessity of finding new renewable energy forms is extremely relevant and urgent today. That is why mankind must find alternative sources of energy to provide a clean and sustainable future. Within this context, solar energy is the best option among all alternative renewable energy sources due to its widespread accessibility, universality, and eco-friendly nature [ 3 ].

The most common metric used to evaluate the performance of photovoltaic technologies is conversion efficiency, which expresses the ratio of solar energy input to electrical energy output. The efficiency combines multiple component characteristics of the system, such as short-circuit current, open-circuit voltage, and fill factor, which in turn are dependent upon basic material features and manufacturing defects [ 4 ].

The cost-effectiveness of making a photovoltaic cell and its efficiency depend on the material from which it is made. Much research in this field has been carried out to find the material that is the most efficient and cost-effective for building photovoltaic cells. The specifications for an ideal material for PV solar cells include the following [ 5 ]:

- The cells are expected to have a band gap between 1.1 and 1.7 eV;

- Should have a direct band structure;

- Need to be easily accessible and non-toxic; and

- Should have high photovoltaic conversion efficiency [ 5 ].

A key problem in the area of photovoltaic cell development is the development of methods to achieve the highest possible efficiency at the lowest possible production cost. Improving the efficiency of solar cells is possible by using effective ways to reduce the internal losses of the cell. There are three basic types of losses: optical, quantum, and electrical, which have different sources of origin. Reducing losses of any kind requires different, often advanced, methods of cell manufacturing and photovoltaic module production. An upper efficiency limit for commercially accessible technologies is determined by the well-known Shockley–Queisser (SQ) limit, taking into account the balance between photogeneration and radiative recombination [ 6 ].

However, the greatest potential lies in the ability to reduce quantum losses, as they are intimately connected with the material properties and internal structure of the cell. Relevant here is the concept of band gap, which defines the minimum required energy of a photon incident onto the cell surface for it to take part in the photovoltaic conversion process. There is a relationship between the efficiency of the cell and the value of the band gap, which in turn is highly dependent on the material from which the photovoltaic cell is made. The basic, commonly used material for solar cells is silicon, which has a band gap value of about 1.12 eV, but by introducing modifications in its crystal structure, the physical properties of the material, especially the band gap width, can be affected [ 7 ].

The dominant loss mechanisms in conventional photovoltaic cells are the inability to absorb photons below the band gap and the thermalization of solar photons with energies above the band gap energy. Third-generation solar cell concepts have been proposed to address these two loss mechanisms in an attempt to improve solar cell performance. These solutions aim to exploit the entire spectrum by incorporating novel mechanisms to create new electron–hole pairs [ 8 ].

Major development potential among these concepts for improving the power generation efficiency of solar cells made of silicon is shown by the idea of cells whose basic feature is an additional intermediate band in the band gap model of silicon. It is located between the conduction band and the valence band, and its function is to allow the absorption of photons with energies below the width of the energy gap, resulting in higher quantum efficiency (a higher number of excited electrons in relation to the number of photons incident onto the surface of the cell) [ 9 ]. Currently, many directions of research development on the introduction of intermediate bands in semiconductors can be identified. One of them is the use of ion implantation, where two methods can be distinguished: introduction of dopants with extremely high concentrations to the substrate of the semiconductor, and implantation of the layer of silicon with high-dose metal ions [ 10 ].

The improvement of solar cell efficiency involves reducing various types of losses affecting the resultant cell efficiency. The National Renewable Energy Laboratory (NREL) runs a compilation of the highest verified research cell conversion efficiencies for different photovoltaic technologies, compiled from 1976 to the present ( Figure 1 ). Cell efficiency results are given for each semiconductor family: multi-junction cells; gallium arsenide single-junction cells; crystalline silicon cells; thin film technologies; emerging photovoltaic technologies. The latest world record for an individual technology is indicated by a flag across the right edge containing the efficiency and technology symbol [ 11 ].

NREL Best Research-Cell Efficiencies chart [ 11 ].

Photovoltaic cells can be categorized by four main generations: first, second, third, and fourth generation. The details of each are discussed in the next section.

2. Photovoltaic Cell Generations

In the past decade, photovoltaics have become a major contributor to the ongoing energy transition. Advances relating to materials and manufacturing methods have had a significant role behind that development. However, there are still numerous challenges before photovoltaics can provide cleaner and low-cost energy. Research in this direction is focused on efficient photovoltaic devices such as multi-junction cells, graphene or intermediate band gap cells, and printable solar cell materials such as quantum dots [ 12 ].

The primary role of a photovoltaic cell is to receive solar radiation as pure light and transform it into electrical energy in a conversion process called the photovoltaic effect. There are several technologies involved with the manufacturing process of photovoltaic cells, using material modification with different photoelectric conversion efficiencies in the cell components. Due to the emergence of many non-conventional manufacturing methods for fabricating functioning solar cells, photovoltaic technologies can be divided into four major generations, which is shown in Figure 2 [ 13 ].

Various solar cell types and current developments within this field [ 14 ].

The generations of various photovoltaic cells essentially tell the story of the stages of their past evolution. There are four main categories that are described as the generations of photovoltaic technology for the last few decades, since the invention of solar cells [ 15 ]:

- First Generation: This category includes photovoltaic cell technologies based on monocrystalline and polycrystalline silicon and gallium arsenide (GaAs).

- Second Generation: This generation includes the development of first-generation photovoltaic cell technology, as well as the development of thin film photovoltaic cell technology from “microcrystalline silicon (µc-Si) and amorphous silicon (a-Si), copper indium gallium selenide (CIGS) and cadmium telluride/cadmium sulfide (CdTe/CdS) photovoltaic cells”.

- Third Generation: This generation counts photovoltaic technologies that are based on more recent chemical compounds. In addition, technologies using nanocrystalline “films,” quantum dots, dye-sensitized solar cells, solar cells based on organic polymers, etc., also belong to this generation.

- Fourth Generation: This generation includes the low flexibility or low cost of thin film polymers along with the durability of “innovative inorganic nanostructures such as metal oxides and metal nanoparticles or organic-based nanomaterials such as graphene, carbon nanotubes and graphene derivatives” [ 15 ].

Examples of solar cell types for each generation along with average efficiencies are shown in Figure 3 .

Examples of photovoltaic cell efficiencies [ 16 ].

2.1. First Generation of Photovoltaic Cells

Silicon-based PV cells were the first sector of photovoltaics to enter the market, using processing information and raw materials supplied by the industry of microelectronics. Solar cells based on silicon now comprise more than 80% of the world’s installed capacity and have a 90% market share. Due to their relatively high efficiency, they are the most commonly used cells. The first generation of photovoltaic cells includes materials based on thick crystalline layers composed of Si silicon. This generation is based on mono-, poly-, and multicrystalline silicon, as well as single III-V junctions (GaAs) [ 17 , 18 ].

Comparison of first-generation photovoltaic cells [ 18 ]:

- Solar cells based on monocrystalline silicon (m-si)

Efficiency : 15 ÷ 24%; Band gap : ~1.1 eV; Life span : 25 years; Advantages : Stability, high performance, long service life; Restrictions : High manufacturing cost, more temperature sensitivity, absorption problem, material loss.

- Solar cells based on polycrystalline silicon (p-si)

Efficiency : 10 ÷ 18%; Band gap : ~1.7 eV; Life span : 14 years; Advantages : Manufacturing procedure is simple, profitable, decreases the waste of silicon, higher absorption compared to m-si; Restrictions : Lower efficiency, higher temperature sensitivity.

- Solar cells based on GaAs

Efficiency : 28 ÷ 30%; Band gap : ~1.43 eV; Life span : 18 years; Advantages : High stability, lower temperature sensitivity, better absorption than m-si, high efficiency; Restrictions : Extremely expensive [ 18 ].

The first generation concerns p-n junction-based photovoltaic cells, which are mainly represented by mono- or polycrystalline wafer-based silicon photovoltaic cells. Monocrystalline silicon solar cells involve growing Si blocks from small monocrystalline silicon seeds and then cutting them to form monocrystalline silicon wafers, which are fabricated using the Czochralski process ( Figure 4 a). Monocrystalline material is widely used due to its high efficiency compared to multicrystalline material. Key technological challenges associated with monocrystalline silicon include stringent requirements for material purity, high material consumption during cell production, cell manufacturing processes, and limited module sizes composed of these cells [ 19 ].

A picture showing ( a ) the Czochralski process for monocrystalline blocks and ( b ) the process of directional solidification for multicrystalline blocks [ 21 ].

Multicrystalline silicon blocks are produced through melting high-purity silicon and crystallizing it in a big crucible by directional solidification process ( Figure 4 b). There is no reference crystal orientation in this process, as in the Czochralski process, and therefore, silicon material with different orientations is produced. The most commonly used base material for solar cells are p-type Si substrates doped with boron. The n-type silicon substrates are also used for the fabrication of high-efficiency solar cells, but they present additional technical challenges, such as achieving uniform doping along the silicon block in comparison to p-type substrates [ 20 ].

In the production of crystalline solar cells, six or more steps need to be carried out sequentially. These typically include surface texturing, doping, diffusion, oxide removal, anti-reflective coating, metallization, and firing. At the end of the process, the cell efficiency and other parameters are measured (under standard test conditions). The efficiency of photovoltaic cells is determined by the material quality that is used in their manufacture [ 21 ].

The theoretical efficiency threshold for first-generation PV cells appears to have been estimated at 29.4%, and a sufficiently close value was reached as early as two decades ago. At the laboratory scale, reaching 25% efficiency was recorded as early as 1999, and since then, very minimal improvements in efficiency values have been achieved. Since the appearance of crystalline silicon photovoltaic cells, their efficiency has increased by 20.1%, from 6% when they were first discovered to the current record of 26.1% efficiency. There are factors that limit cell efficiency, such as volume defects. Breakthroughs in the production of these cells include the introduction of an aluminum back surface field (Al-BSF) to reduce the recombination rate on the back surface, or the development of Passivated Emitter and Rear Cell (PERC) technology to further reduce the recombination rate on the back surface [ 22 ].

2.1.1. Al-BSF Photovoltaic Cells

Silicon solar cells with distributed p-n junctions were invented as early as the 1950s, soon after the first semiconductor diodes. Originally, boron diffusion in arsenic-doped wafers was used to form p-n junctions, but now, the industry standard is phosphor diffusion in boron-doped wafers. After the transition in the 1960s from n-type wafers to p-type wafers, the implementation of an aluminum back-surface field (Al-BSF) by fusing the back contact to the substrate made it possible to reduce recombination on the back side ( Figure 5 ). This fairly simple contact screen printing design held a dominant position, with 70–90% of the market share for the past several decades [ 23 ].

Silicon solar cell structure: Al-BSF [ 1 ].

Standard aluminum back surface field (Al-BSF) technology is one of the most widely used solar cell technologies due to its relatively simple manufacturing process. It is based on depositing Al entirely on the full rear-side (RS) in a screen-printing process and forming a p+ BSF, which helps repel electrons from the rear-side of the p-type substrate and improves the cell performance. The process flow of Al-BSF solar cell fabrication is shown in Figure 6 . Standard commercial solar cell design consists of a front side with a grid and a rear-side with full area contacts [ 24 ].

Al-BSF solar cell manufacturing process [ 21 ].

2.1.2. PERC Photovoltaic Cells

The efficiency of the industrial Al-BSF cell, however, reached about 20% around 2013. It has therefore become attractive to replace the fully contacted Al-BSF cell with a PERC (Passivated Emitter and Rear Cell) structure with local back contacts to achieve enhanced electrical and optical properties ( Figure 7 ). The passivated emitter and rear contact (PERC) solar cell improves the Al-BSF architecture by the addition of a passivation layer on the rear side to improve passivation and internal reflection. Aluminum oxide has been found to be a suitable material for rear side passivation [ 25 ].

Silicon solar cell structure: PERC [ 1 ].

The capability of this cell structure was demonstrated as early as the 1980s, although it was limited to laboratory processing because of its high cost relative to the yield gain. Moving the PERC technology into mass industrial production in theory involved a comparatively small industry threshold, as only two steps needed to be added to the Al-BSF process, i.e., passivation of the back surface and precise calibration of local back contacts. Nevertheless, decades passed before a profitable PERC process could be developed. A number of reasons led to the implementation of PERC in low-cost, high-volume production, and the increase in productivity to levels ranging from 22% to 23.4% [ 26 ]:

- Introduction of aluminum oxide back surface passivation by plasma-enhanced chemical vapor deposition (PECVD) and formation of local back surface field (BSF) by laser ablation of back passivation layer and Al alloy;

- Introduction of a selective emitter process in low-cost manufacturing, a “back-etching” process, or through a laser doping process;

- Reducing the width of front metallization fingers from about 100 μm to less than 30 μm in high-volume production while reducing contact resistance for lightly phosphorus-doped silicon;

- Adding a low-cost hydrogenation step at the end of the cell formation process to passivate volume defects and inactivate boron–oxygen complexes responsible for light-induced degradation (LID); and

- Reappearance of monocrystalline silicon wafers as a result of cost reduction in silicon ingot production by the Czochralski method and the introduction of diamond wire cutting [ 27 ].

2.1.3. SHJ-Type Photovoltaic Cells