An official website of the United States government

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

Preview improvements coming to the PMC website in October 2024. Learn More or Try it out now .

- Advanced Search

- Journal List

- v.11(12); 2010 Dec

Fermenting knowledge: the history of winemaking, science and yeast research

Paul j chambers.

1 Australian Wine Research Institute, PO Box 197, Glen Osmond, Adelaide, SA 5064, Australia

Isak S Pretorius

In the second article of the ‘Food and Science' series, Paul Chambers and Isak Pretorius explain the central role of yeast in wine making and how biotechnology can contribute to improving the quality of wine.

Wine has been with us since the dawn of civilization and has followed humans and agriculture along diverse migration paths ( Fig 1 ). Serendipity presumably played a part in its genesis more than 7,000 years ago: damaged grapes spontaneously fermented in harvesting vessels; curious farmers tasted the resultant alcoholic beverage; the curious farmers liked what they tasted and enjoyed its effects; said farmers preferred fermented grape juice to the unfermented fruit. The fate of the grape was sealed.

One might argue that the most important test tube in the birth and growth of the modern life sciences is the fermenter…

A generalized scheme of the spread of Vitis vinifera noble varieties of grapevine and winemaking from their centre of origin in Asia Minor to other parts of the world.

One might argue that the seeds of science and technology, particularly biotechnology, were also sown at this time. Empirical observations of natural events and processes were harnessed in repeat ‘experiments'—which is to say, vintages—and improvements were made by trialling modifications to practices, retaining those that were beneficial and discarding failures, with the results communicated down through the generations. At that time, there was no EMBO reports or alternative means by which to facilitate horizontal dissemination of information, but the principle of development— sans peer review—is clear: experimentation and invention lead to progress—technological and otherwise—and new knowledge is shared and built upon.

Of course, early inventions and innovations in grape and wine production were based on little or no knowledge of the biology of grapevines or the microbes that drive fermentation. In fact, it would be several thousand years before it was even known that microscopic organisms exist: using a primitive microscope, Antonie van Leeuwenhoek observed cells for the first time in 1680 ( Fig 2 ).

Selected milestones that mark the path of research in microbiology and yeast biology that have affected, directly or indirectly, wine science and winemaking.

Scientific knowledge grows at an exponential rate, and nowhere is this more evident than in the historical milestones of chemistry and biology that have shaped our understanding of the biology of the microorganisms that drive fermentation ( Fig 2 ). This progress has been adorned with some of the most significant names in the chemical and biological sciences, including van Leeuwenhoek, Lavoisier, Gay-Lussac, Pasteur, Buchner and Koch. One might argue that the most important test tube in the birth and growth of the modern life sciences is the fermenter, and the most important model organism has been the yeast Saccharomyces cerevisiae —commonly known as baking, brewing or wine yeast. As readers might know, this is exemplified in the origin of the word enzyme—‘en' meaning within and ‘zyme' meaning leaven. Yeast has been integral to pioneering work in microbiology and biochemistry, particularly in the fields of metabolism and enzymology ( Barnett, 1998 , 2000 ; Barnett & Lichtenthaler, 2001 ).

Throughout the early decades of the twentienth century the place for S. cerevisiae in fundamental research was affirmed, and there are several good reasons for this. Our close relationship with this yeast in food and beverage production over millennia tells us that it is safe to work with; as confirmed by its ‘Generally Recognised as Safe' designation by the US Food and Drug Administration. In addition, it is inexpensive, easy to grow and can be stored for long periods in suspended animation. Perhaps the most important thing is that it has accessible genetics that can be followed through sexual and asexual cycles ( Barnett, 2007 ).

The 1970s set the stage for another explosion of knowledge, sparked by the advent of gene technology and driven by a convergence of genetics, biochemistry, cell biology, microbiology, physical and analytical chemistry, as well as computing brought together under the banner of molecular biology ( Fig 3 ). Yeast molecular biology was established when Gerald Fink's group in the USA demonstrated that yeast could be transformed with foreign DNA ( Hinnen et al, 1978 ). In the same year, Jean Beggs in the UK developed a shuttle vector between Escherichia coli and S. cerevisiae that enabled cloning in yeast ( Beggs, 1978 ). The research community now had a eukaryotic host that was amenable to genetic engineering, benefiting both fundamental research and offering the potential of precise engineering of novel strains for industrial applications. It was the first host cell for industrial-scale production of a recombinant vaccine against hepatitis B and a recombinant food-grade enzyme, chymosin, which is used in cheese processing ( Pretorius et al, 2003 ).

Selected milestones that mark the path of research in genetics and molecular biology that have affected, directly or indirectly, wine science and winemaking.

Ever since, S. cerevisiae has been one of the most important model organisms in molecular biology and emerging fields; breakthroughs and technological advances in molecular, systems, and now synthetic biology rarely happen without S. cerevisiae figuring somewhere prominently in the story ( Fig 3 ). The international yeast science community has been particularly progressive and proactive in establishing large collaborative projects and building resources that are available to the scientific community. S. cerevisiae was the first eukaryote to have its genome sequenced ( Goffeau et al, 1996 ), a feat that was achieved through an international effort that involved 600 scientists, which paved the way for the first chip-based gene array experiments ( Schena et al, 1995 ). It was the first organism to be used to build a systematic collection of bar-coded gene deletion mutants ( Winzeler et al, 1999 ; Giaever et al, 2002 ), in which there are deletion strains for most of the open-reading frames in the S. cerevisiae genome. This has enabled high-throughput functional-genomic experiments, and anyone seeking information on just about any aspect of S. cerevisiae biology has access to the amazing community resource: the Saccharomyces Genome Database (SGD; http://www.yeastgenome.org/).

All of this is important to wine research; our winemaking workhorse is centre stage in thousands of research projects worldwide, so we know more about this humble eukaryote than any other organism on the planet. It is therefore unsurprising that wine research has benefited enormously from the privileged place that S. cerevisiae occupies in life sciences research. This is particularly evident in the impact that advances in molecular biology and related fields have had on winemaking.

In the hands of molecular biologists, S. cerevisiae is the most tractable of organisms; it is amenable to almost any modification that modern biology can throw at a cell. This makes it an ideal host for generating variants with improved and even exotic phenotypes that will benefit winemaking. The following gives some examples of current research and directions in this field.

In modern winemaking, fermentations are driven largely by single-strain inoculations; pure cultures of selected strains of S. cerevisiae are added to grape must as soon as possible after crushing. This ensures greater control of vinification, leads to more predictable outcomes and decreases the risk of spoilage by other microorganisms. There are many—probably hundreds of—different yeast strains available, and the winemaker's choice can substantially effect the quality of the wine ( Lambrechts & Pretorius, 2000 ; Swiegers et al, 2005 ).

One of the reasons for the yeast-induced variation in wine quality is that, during fermentation, S. cerevisiae produces an abundance of aroma-active secondary metabolites and releases many aroma compounds from inactive precursors in grape juice, which greatly affect the sensory properties of the wine ( Swiegers & Pretorius, 2007 ). Thus, any genetic variation in wine yeast that affects the production or release of sensorially important molecules will affect wine quality. In this context it has been demonstrated, for example, that different commercial yeast strains generate wines with very different profiles of volatile thiols ( Swiegers et al, 2009 ). These thiols—which are present in grape juice as non-volatile cysteinylated precursors ( Tominaga et al, 1998 )—are often described as ‘passionfruit', ‘tropical fruits' and ‘citrus' by tasters, flavours that are particularly important in wine varieties such as Sauvignon Blanc ( Dubourdieu et al, 2006 ).

Molecular biology and its tools are crucial to our understanding of the genetic and molecular bases of yeast-driven volatile thiol release from non-volatile precursors in grape juice. Howell et al (2005) have used bioinformatic tools and the SGD to identify candidate S. cerevisiae carbon–sulphur lyase genes that might be involved in the release of volatile thiols from cysteinylated precursors during fermentation. The researchers used targeted gene deletion to remove these candidate carbon–sulphur lyases from the wine and laboratory yeast strains, and they identified four genes that potentially contribute to the release of these important aroma molecules.

Swiegers et al (2007) then engineered a wine yeast, VIN13, to constitutively express a carbon–sulphur lyase gene, tna A, from E. coli . Sensory analysis revealed that, compared with its non-engineered relative, this transgenic yeast, VIN13 (CSL1), had a positive impact on the release of volatile thiols from a Sauvignon Blanc grape juice. The authors commented that wine assessors preferred the VIN13 (CSL1)-derived experimental wines to the relatively neutral VIN13-derived wines.

A similar approach has been used to engineer yeasts for the enhanced production of fruity esters ( Lilly et al, 2006a ) and to increase the production of higher, fusel alcohols ( Lilly et al, 2006b )—all of which contribute to the flavour profiles of wines. Although this work is in the early stages of development, it shows the value of yeast molecular biology, and the amazing resources that come with it.

Wine alcohol content is of growing importance to the wine industry. In some wine regions, it has been increasing during recent decades ( Godden & Muhlack, 2010 ). The main reason for this increase is that grapegrowers tend to leave fruit on the vine as long as possible to increase fruity characters—which develop as berries mature—and reduce undesirable ‘green' characters. This practice, however, produces fruit with a higher sugar content, which translates to higher ethanol concentrations in the wine.

A recent review by Kutyna et al (2010) discusses several metabolic engineering strategies that have been explored to generate wine yeasts that can divert some carbon metabolism away from ethanol production, with the aim of decreasing ethanol yields during vinification. Understanding the central metabolism of yeast and the genes that drive it has been crucial to this work. Candidate genes that are likely to influence ethanol yields can be identified from a range of sources, including the SGD, and then manipulated and cloned as required. Several laboratories have targeted the glycerol-3-phosphate dehydrogenase isozymes GPD1 and GPD2 , which divert carbon from glycolysis to glycerol production ( Michnick et al, 1997 ; Remize et al, 1999 ; de Barros Lopes et al, 2000 ).

Increased expression of either of the GPD paralogues increased glycerol and decreased ethanol yields. However, increased Gpd activity also led to increased amounts of acetic acid in the fermentation product. This was probably owing to rectification—by one or more of the five aldehyde dehydrogenase isozymes—of a redox imbalance that resulted from excessive Gpd-driven oxidation of NADH. Aldehyde dehydrogenase isozymes drive the oxidation of acetaldehyde to acetic acid with concomitant reduction of coenzymes NAD + or NADP, depending on which isozyme is involved ( Navarro-Aviño et al, 1999 ). This might be good for a yeast cell struggling with an imposed redox imbalance, but an increase in acetic acid production is not good news for winemakers; excessive vinegar is not desirable in wine. This problem was alleviated by knocking out one of the five aldehyde dehydrogenase isozymes, ALD6 ( Eglinton et al, 2002 ; Cambon et al, 2006 ).

Similar approaches have targeted S. cerevisiae pyruvate decarboxylase isozymes, alcohol dehydrogenase isozymes and glycerol transporters, leading to increased glycerol yields and reduced ethanol production ( Kutyna et al, 2010 ). However, while there are probably several good candidate ‘low-ethanol' wine yeast strains sitting in various labs around the world, none have been tested in commercial-scale, industrial fermentations. This is largely because consumers are generally unaccepting of genetically modified organisms (GMOs) in foods and beverages.

Another area of ongoing research in wine yeast molecular biology is the development of strains that flocculate—that is, form clumps—at the end of fermentation. This facilitates the process of settling them out of suspension and separating them from the wine, thereby reducing the need for clarification. The timing of flocculation is crucial; it must not happen too early, as yeast in large flocs are inefficient at sugar utilization and can generate suboptimal—stuck or sluggish—fermentations ( Pretorius, 2000 ).

Generally, wine yeasts are not good at flocculation; they do not form large clumps that settle out of suspension. Many years of research using laboratory strains of S. cerevisiae led to the identification and characterization of genes that encode cell-surface glycoproteins—including lectin-like flocculins—that cause, among other things, flocculation and subsequent settling to the bottom of the fermentation vessel ( Pretorius, 2000 ).

Recent findings have identified a problem with extrapolating basic research on laboratory strains to those used in industry; yeasts domesticated for different purposes have different phenotypes. Work by Govender et al (2008) on the flocculation genes FLO1 , FLO5 and FLO11 , for example, demonstrated the potential ability of engineered ADH2 - or HSP30 -promoter/ FLO gene combinations to switch on flocculation at the end of fermentation; ADH2 and HSP30 are both upregulated in stationary-phase cells, so their promoters are suitable candidates to drive the expression of genes in later stages of wine fermentation.

The results of this work were promising, but, when they were carried over to wine yeast, the findings were rather different. There were even substantial differences between wine yeast strains, leading the authors to caution that “optimisation of the flocculation pattern of individual commercial strains will have to be based on a strain-by-strain approach” ( Govender et al, 2010 ). Nonetheless, controlled expression of FLO genes at the end of fermentation remains a plausible technique for improving the performance of wine yeast, but the strategies required to achieve a desirable outcome might be more complex than was originally thought.

While the complexity of biological systems is a cause for excitement and wonder to most biologists, it can make engineering novel strains for industrial applications trickier than molecular biology and biotechnology textbooks might suggest. For those of us working on industrial yeast strains, it might be pertinent to directly tackle the issue of complexity and use systems biology approaches to better understand the workings of yeast metabolism. This should lead to more accurate modelling of metabolic processes for better-informed manipulations, to achieve targeted, predictable outcomes.

However, molecular biologists face one important obstacle to this progress: near worldwide refusal to permit the use of GMOs in the production of foods and beverages…

S. cerevisiae has been at the forefront of ‘-omics' research. This provides us with enormous opportunities to improve understanding of wine yeast complexity, which, in turn, will inform the design of new strains for industrial applications. Increased and improved knowledge from a huge number of studies investigating strains of S. cerevisiae at the various -omic levels gives wine yeast scientists a head start in this field ( Borneman et al, 2007 ; Petranovic & Vemuri, 2009 ).

One of the most interesting developments has come from the sequencing of a wine yeast genome, and its comparison with the genomes of a laboratory strain and an opportunistic pathogenic S. cerevisiae ( Borneman et al, 2008 ). The authors found a difference of about 0.6% in sequence information between the wine yeast and the other strains. They also found, perhaps more importantly, 100 kb of additional genome sequence in the former; enough to carry at least 27 genes. Open reading frames (ORFs) in the additional sequences do not resemble anything found in other strains of S. cerevisiae , but seem to be similar to genes found in distant fungal relatives. BLAST searches have indicated that some of the genes that are specific to wine yeast are similar to those encoding cell-wall proteins. This might contribute to the greater robustness of wine yeast, compared with laboratory strains. Other genes might encode proteins associated with amino acid uptake, which is significant in the context of wine sensory attributes; amino acid metabolism is central to the production of many sensorially important volatile aroma compounds.

Novo et al (2009) published similar findings from a different wine yeast strain (EC1118) and suggested that the extra sequence was probably the result of horiziontal gene transfer. Further work using functional genetics—to determine the effects of knocking out and overexpressing the ORFs—should enable characterization of the phenotypes of these ORFs, determine their relevance in the context of winemaking and might also reveal their origins.

There have also been numerous studies describing transcriptomic, proteomic and metabolomic analyses of wine-yeast fermentations. This work is beginning to provide insights into wine-yeast fermentations, but it is still early days. It should also be noted that much of the -omics work on wine yeast has used resources and databases that are based on laboratory strains. It is now clear that there are genomic differences between wine and lab strains of S. cerevisiae , and these might affect -omics data acquisition and analysis. For example, gene-array chips based on the reference laboratory strain S288c will not include the additional ORFs found in wine strains. This does not suggest that earlier work is invalid, but that there are likely to be gaps in it.

As the various -omics fields progress, it should be possible to build systems-based mathematical models of metabolism that will facilitate the in silico design of new wine yeast strains ( Borneman et al, 2007 ). In parallel, we see the emergence of synthetic biology where, yet again, S. cerevisiae is a key player. It should not be too long before we have customised S. cerevisiae genomic components—regulatory elements to control the expression of targeted genes, or cassettes carrying genes encoding metabolic pathways to shape wine-relevant traits, for example—available ‘off the shelf' for designing, building and refining metabolic processes in our wine yeast. But are consumers ready for this brave and exciting new world?

The engineered wine yeast strains described in this paper show the potential of novel yeast strain development to improve wine quality. But molecular biologists face a major obstacle to this progress: near world-wide refusal to permit the use of GMOs in the production of foods and beverages, at least in ‘developed' countries ( Gross, 2009 ; Pretorius & Høj, 2005 ). Wine industries in most parts of the world have eschewed the use of GMOs in commercial winemaking, leaving most new-generation wine yeasts on the laboratory shelf, where they await more enlightened times.

Two genetically modified wine yeast strains have been released to market in a limited number of countries including the USA, Canada and Moldova: ML01 and 522 EC− . ML01, a transgenic wine yeast, has genes that enable it to perform malolactic fermentation (MLF), a deacidifying secondary fermentation in which malic acid—present in grape juice—is decarboxylated to lactic acid. MLF is usually performed by the lactic acid bacterium Oenococcus oeni after alcoholic fermentation. However, this bacterium is rather fastidious, being inhibited by a range of conditions that are typical of fermented grape juice—low pH, high alcohol content, poor nutrient availability and the presence of sulphur dioxide—and can become ‘stuck' or take considerable time to complete fermentation ( Davis et al, 1985 ). In addition, lacitic acid bacteria can produce a range of biogenic amines, which are associated with health risks ( Lonvaud-Funel, 2001 ).

A wine yeast that completes both primary and secondary fermentations should therefore have great potential in the wine industry. The genetically modified wine yeast ML01 carries two foreign genes—the Schizosaccharomyces pombe malate transporter gene ( mae1 ) and the O. oeni malolactic enzyme gene ( mleA )—which are both chromosomally integrated and regulated by the S. cerevisiae PGK1 promoter and terminator ( Husnik et al, 2006 ). This enables the host wine yeast to perform MLF, in parallel with alcoholic fermentation.

The researchers went to great lengths to ensure the safety of ML01. The transgenes came from microorganisms found in wine, there were no antibiotic resistance genes or vector sequences carried by the yeast and transcriptome and proteome analysis showed no important differences in gene expression profiles between the genetically modified strain and its parent. The FDA granted ‘Generally Regarded As Safe' status to ML01, but it has not been widely adopted, even in countries where it is approved for use. This is largely owing to concerns about export markets that do not tolerate GMOs. In fact, wine industries in many countries have banned the use of GMOs in wine production, in order to avoid jeopardizing their exports. exports.

The genetically modified wine yeast 522 EC− was engineered to reduce the risk of ethyl carbamate production during fermentation. Ethyl carbamate, a potential carcinogen, is the product of yeast-derived urea reacting with ethanol. It is usually produced at such low levels—if at all—that it is not a cause for concern, but it sometimes can make an appearance in some wine-producing regions.

S. cerevisiae is able to degrade urea before it is secreted and release ammonia instead, thereby reducing the risk of generating ethyl carbamate. This is achieved by the action of an enzyme encoded by DUR1,2 , but this gene is repressed by nitrogen and therefore downregulated throughout much of wine fermentation. Coulon et al (2006) placed a copy of DUR1,2 behind a constitutive ( PGK1 ) S. cerevisiae promoter, which led to a reduction in ethyl carbamate yields. Interestingly, this genetically modified yeast is self or cis cloned; it carries no foreign DNA and therefore is not transgenic. Nonetheless, because it was generated by using techniques that involved the manipulation of DNA in vitro , the regulations of many countries classify it as a GMO. Again, to the best of our knowledge, this yeast is not being used in the industry. This might be because ethyl carbamate production is not a widespread problem, but it probably also reflects the influence of GMO bans and the reluctance of winemakers to risk losing market share in countries that harbour strong anti-GMO sentiment.

Who knows what bottled masterpieces await us as we sculpt novel yeast strains in the laboratory using molecular, systems and synthetic biology

Winemaking, science and technology have interwoven histories and have grown together over the millennia, benefiting from each other. Although science is an important part of an oenologist's training and scientific methods and equipment are routinely employed in the winery, winemakers are not scientists per se . They are, perhaps more appropriately regarded as artisans, with the emphasis on the ‘art'. As for many human endeavours, the Arts progress with developments in technology; think of the use of acrylic paint in the fine arts since its introduction in the 1950s, or David Hockney's use of a Polaroid camera to create photocollages. In the way that acrylic paint and photography have provided more options to artists, enabling them to broaden their horizons, yeast science and technology is adding to the winemaker's palette. Who knows what bottled masterpieces await us as we sculpt novel yeast strains in the laboratory using molecular, systems and synthetic biology. The only real obstacle that we face is consumer acceptance of GMOs; we can only hope that rationality will eventually prevail.

Science & Society Series on Food and Science

This article is part of the EMBO reports Science & Society series on ‘food and science' to highlight the role of natural and social sciences in understanding our relationship with food. We hope that the series serves a delightful menu of interesting articles for our readers.

Acknowledgments

Research at the Australian Wine Research Institute (AWRI) is financially supported by Australia's grapegrowers and winemakers through their investment body, the Grape and Wine Research Corporation, with matching funding from the Australian Government. Systems biology research at the AWRI uses resources provided as part of the National Collaborative Research Infrastructure Strategy (NCRIS), an initiative of the Australian Government, in addition to funds from the South Australian State Government. AWRI's collaborating partners within this NCRIS-funded initiative—which is overseen by Bioplatforms Australia—are Genomics Australia, Proteomics Australia, Metabolomics Australia (of which the Microbial Metabolomics unit is housed at the AWRI) and Bioinformatics Australia.The AWRI is part of the Wine Innovation Cluster in Adelaide.

The authors declare that they have no conflict of interest.

- Barnett J (1998) A history of research on yeasts: Work by chemists and biologists, 1789–1850 . Yeast 14 : 1439–1451 [ PubMed ] [ Google Scholar ]

- Barnett J (2000) A history of research on yeasts: Louis Pasteur and his contemporaries, 1850–1880 . Yeast 16 : 755–771 [ PubMed ] [ Google Scholar ]

- Barnett J (2007) A history of research on yeasts: Foundations of yeast genetics . Yeast 24 : 799–845 [ PubMed ] [ Google Scholar ]

- Barnett J, Lichtenthaler F (2001) A history of research on yeasts: Emil Fischer, Eduard Buchner and their contemporaries, 1880–1900 . Yeast 18 : 363–388 [ PubMed ] [ Google Scholar ]

- Beggs J (1978) Transformation of yeast by a replicating hybrid plasmid . Nature 275 : 104–109 [ PubMed ] [ Google Scholar ]

- Borneman AR, Chambers PJ, Pretorius IS (2007) Yeast systems biology: modelling the winemaker's art . Trends Biotechnol 25 : 349–355 [ PubMed ] [ Google Scholar ]

- Borneman AR, Forgan A, Pretorius IS, Chambers PJ (2008) Comparative genome analysis of a Saccharomyces cerevisiae wine strain . FEMS Yeast Res 8 : 1185–1195 [ PubMed ] [ Google Scholar ]

- Cambon B, Monteil V, Remize F, Camarasa C, Dequin S (2006) Effects of GPD1 overexpression in Saccharomyces cerevisiae commercial wine yeast strains lacking ALD6 genes . Appl Environ Microbiol 72 : 4688–4694 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Coulon J, Husnik JI, Inglis DL, van der Merwe GK, Lonvaud A, Erasmus DJ, van Vuuren HJJ (2006) Metabolic engineering of Saccharomyces cerevisiae to minimize the production of ethyl carbamate in wine . Am J Enol Vitic 57 : 113–124 [ Google Scholar ]

- Davis C, Wibowo D, Eschenbruch R, Lee T, Fleet G (1985) Practical implications of malolactic fermentation—A review . Am J Enol Vitic 36 : 290–301 [ Google Scholar ]

- de Barros Lopes M, ur-Rehman A, Gockowiak H, Heinrich A, Langridge P, Henschke P (2000) Fermentation properties of a wine yeast over-expressing the Saccharomyces cerevisiae glycerol 3-phosphate dehydrogenase gene ( GPD2 ) . Aust J Grape Wine Res 6 : 208–215 [ Google Scholar ]

- Dubourdieu D, Tominaga T, Masneuf I, Gachons C, Murat M (2006) The role of yeasts in grape flavor development during fermentation: The example of Sauvignon Blanc . Am J Enol Vitic 57 : 81–88 [ Google Scholar ]

- Eglinton J, Heinrich A, Pollnitz A, Langridge P, Henschke P, De Barros Lopes M (2002) Decreasing acetic acid accumulation by a glycerol overproducing strain of Saccharomyces cerevisiae by deleting the ALD6 aldehyde dehydrogenase gene . Yeast 19 : 295–301 [ PubMed ] [ Google Scholar ]

- Giaever G et al. (2002) Functional profiling of the Saccharomyces cerevisiae genome . Nature 418 : 387–391 [ PubMed ] [ Google Scholar ]

- Godden P, Muhlack R (2010) Trends in the composition of Australian wine 1984–2008 . Aust NZ Grapegrower Winemaker 558 : 47–61 [ Google Scholar ]

- Goffeau A et al. (1996) Life with 6000 genes . Science 274 : 563–567 [ PubMed ] [ Google Scholar ]

- Govender P, Bester M, Bauer FF (2010) FLO gene-dependent phenotypes in industrial wine yeast strains . Appl Microbiol Biotechnol 86 : 931–945 [ PubMed ] [ Google Scholar ]

- Govender P, Domingo J, Bester M, Pretorius IS, Bauer FF (2008) Controlled expression of the dominant flocculation genes FLO1 , FLO5 , and FLO11 in Saccharomyces cerevisiae . Appl Environ Microbiol 74 : 6041–6052 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Gross M (2009) European dissent over GM crops . Curr Biol 19 : 267–268 [ PubMed ] [ Google Scholar ]

- Hinnen A, Hicks J, Fink G (1978) Transformation of yeast . Proc Natl Acad Sci USA 75 : 1929–1933 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Howell K, Klein M, Swiegers J, Hayasaka Y, Elsey G, Fleet G et al. (2005) Genetic determinants of volatile-thiol release by Saccharomyces cerevisiae during wine fermentation . Appl Environ Microbiol 71 : 5420–5426 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Husnik J, Volschenk H, Bauer J, Colavizza D, Luo Z, Van Vuuren HJ (2006) Metabolic engineering of malolactic wine yeast . Metab Eng 8 : 315–323 [ PubMed ] [ Google Scholar ]

- Kutyna D, Varela C, Henschke P, Chambers P, Stanley G (2010) Microbiological approaches to lowering ethanol concentration in wine . Trends Food Sci Technol 21 : 293–302 [ Google Scholar ]

- Lambrechts MG, Pretorius IS (2000) Yeast and its importance to wine aroma—A review . S Afr J Enol Vitic 21 : 97–129 [ Google Scholar ]

- Lilly M, Bauer FF, Lambrechts MG, Swiegers JH, Cozzolino D, Pretorius IS (2006a) The effect of increased yeast alcohol acetyltransferase and esterase activity on the flavour profiles of wine and distillates . Yeast 23 : 641–659 [ PubMed ] [ Google Scholar ]

- Lilly M, Bauer FF, Styger G, Lambrechts MG, Pretorius IS (2006b) The effect of increased branched-chain amino acid transaminase activity in yeast on the production of higher alcohols and on the flavour profiles of wine and distillates . FEMS Yeast Res 6 : 726–743 [ PubMed ] [ Google Scholar ]

- Lonvaud-Funel A (2001) Biogenic amines in wines: role of lactic acid bacteria . FEMS Microbiol Lett 199 : 9–13 [ PubMed ] [ Google Scholar ]

- Michnick S, Roustan JL, Remize F, Barre P, Dequin S (1997) Modulation of glycerol and ethanol yields during alcoholic fermentation in Saccharomyces cerevisiae strains overexpressed or disrupted for GPD1 encoding glycerol 3-phosphate dehydrogenase . Yeast 13 : 783–793 [ PubMed ] [ Google Scholar ]

- Navarro-Aviño J, Prasad R, Miralles V, Benito R, Serrano R (1999) A proposal for nomenclature of aldehyde dehydrogenases in Saccharomyces cerevisiae and characterization of the stress-inducible ALD2 and ALD3 genes . Yeast 15 : 829–842 [ PubMed ] [ Google Scholar ]

- Novo M et al. (2009) Eukaryote-to-eukaryote gene transfer events revealed by the genome sequence of the wine yeast Saccharomyces cerevisiae EC1118 . PNAS 106 : 16333–16338 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Petranovic D, Vemuri G (2009) Impact of yeast systems biology on industrial biotechnology . J Biotechnol 144 : 204–211 [ PubMed ] [ Google Scholar ]

- Pretorius IS (2000) Tailoring wine yeast for the new millennium: novel approaches to the ancient art of winemaking . Yeast 16 : 675–729 [ PubMed ] [ Google Scholar ]

- Pretorius IS, du Toit M, van Rensburg P (2003) Designer yeasts for the fermentation industry of the 21st Century . Food Technol Biotechnol 41 : 3–10 [ Google Scholar ]

- Pretorius IS, Høj PB (2005) Grape and wine biotechnology: Challenges, opportunities and potential benefits . Aust J Grape Wine Res 11 : 83–108 [ Google Scholar ]

- Remize F, Roustan JL, Sablayrolles JM, Barre P, Dequin S (1999) Glycerol overproduction by engineered Saccharomyces cerevisiae wine yeast strains leads to substantial changes in By-product formation and to a stimulation of fermentation rate in stationary phase . Appl Environ Microbiol 65 : 143–149 [ PMC free article ] [ PubMed ] [ Google Scholar ]

- Schena M, Shalon D, Davis R, Brown P (1995) Quantitative monitoring of gene expression patterns with a complementary DNA microarray . Science 270 : 467–470 [ PubMed ] [ Google Scholar ]

- Swiegers JH et al. (2007) Engineering volatile thiol release in Saccharomyces cerevisiae for improved wine aroma . Yeast 24 : 561–574 [ PubMed ] [ Google Scholar ]

- Swiegers JH, Bartowsky EJ, Henschke PA, Pretorius IS (2005) Yeast and bacterial modulation of wine aroma and flavour . Aust J Grape Wine Res 11 : 139–173 [ Google Scholar ]

- Swiegers J et al. (2009) The influence of yeast on the aroma of Sauvignon Blanc wine . Food Microbiol 26 : 204–211 [ PubMed ] [ Google Scholar ]

- Swiegers J, Pretorius IS (2007) Modulation of volatile sulfur compounds by wine yeast . Appl Microbiol Biotechnol 74 : 954–960 [ PubMed ] [ Google Scholar ]

- Tominaga T, Gachons C, Dubourdieu D (1998) A new type of flavor precursors in Vitis vinifera L. cv. Sauvignon Blanc: S -Cysteine conjugates . J Agric Food Chem 46 : 5215–5219 [ Google Scholar ]

- Winzeler E, Shoemaker D, Astromoff A, Liang H, Anderson K, Andre B et al. (1999) Functional characterization of the S. cerevisiae genome by gene deletion and parallel analysis . Science 285 : 901–906 [ PubMed ] [ Google Scholar ]

Role of commercial enzymes in wine production: a critical review of recent research

- Review Article

- Published: 02 May 2020

- Volume 58 , pages 9–21, ( 2021 )

Cite this article

- Francisco Espejo ORCID: orcid.org/0000-0003-0134-6364 1

2047 Accesses

27 Citations

Explore all metrics

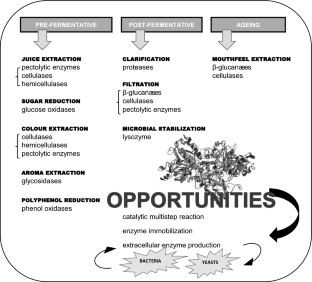

Purified enzymes of microbial origin are applied in the beverage industry since decades because of their ability to enhance products and processes with minimal side effects and low costs. Commercial enzymes are widely used during different wine making steps providing a broad range of effects, such as to maximise juice yield, improve aroma compounds, flavour enhancement, colour extraction in red wines, and contribute in the removal of dissolved unwanted colloidal particles and pectin substances during wine stabilization and filtration. This review presents a study of recent advances in the application of commercial enzymes in the wine making of red, white and sweet wines that have been made in essentially the last 13 years (2005–2018). Literature has been critically analysed to discover general rules about previous research. Special attention is paid to the safety of enzyme application due to allergic issues. Future research efforts should be concentrated on application of immobilizated enzymes and the use of microorganisms with potential enzymatic side activities during wine production.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Microbial enzymes: industrial progress in 21st century.

Enzymes in Brewing and Wine Industries

Implications of new research and technologies for malolactic fermentation in wine.

Agouridis N, Bekatorou A, Nigam P, Kanellaki M (2005) Malolactic fermentation in wine with Lactobacillus casei cells immobilised on de-lignified cellulosic material. J Agric Food Chem 53(7):2546–2551

CAS PubMed Google Scholar

Aguilar CN, Gutiérrez-Sánchez G (2001) Review: sources, properties, applications and potential uses of tannin acyl hydrolase. Food Sci Technol Int 7(5):373–382

CAS Google Scholar

Ahumada K, Martínez-Gil A, Moreno-Simunovic Y, Illanes A, Wilson L (2016) Aroma release in wine using co-immobilized enzyme aggregates. Molecules 21:1485

PubMed Central Google Scholar

Alcalde M (2007) Laccases: biological functions, molecular structure and industrial applications. In: Polaina J, MacCabe AP (eds) Industrial enzymes: structure, function and applications. Springer, Dordrecht, pp 461–476

Google Scholar

Apolinar-Valiente R, Williams P, Mazerolles G, Romero-Cascales I, Gómez-Plaza E, López-Roca JM, Ros-García JM, Doco T (2014) Effect of enzyme additions on the oligosaccharide composition of Monastrell red wines from four different wine-growing origins in Spain. Food Chem 156:151–159

Armada L, Fernández E, Falqué E (2010) Influence of several enzymatic treatments on aromatic composition of white wines. LWT Food Sci Technol 43:1517–1525

Baiano A, Previtali MA, Viggiani I, De Gianni A (2016) Maceration procedures alternative to the standard vinification in red: the case of Nero di Troia wine. Eur Food Res Technol 242:825–835

Bautista-Ortín AB, Martínez-Cutillas A, Ros-García JM, López-Roca JM, Gómez-Plaza E (2005) Improving colour extraction and stability in red wines: the use of maceration enzymes and enological tannins. Int J Food Sci Technol 40:867–878

Bindslev-Jensen C, Skov PS, Roggen EL, Hvass P, Brinch DS (2006) Investigation on possible allergenicity of 19 different commercial enzymes used in the food industry. Food Chem Toxicol 44:1909–1915

Bleve G, Tufariello M, Vetrano C, Mita G, Grieco F (2016) Simultaneous alcoholic and malolactic fermentations by Saccharomyces cerevisiae and Oenococcus oeni cells co-immobilized in alginate beads. Front Microbiol 7:943

PubMed PubMed Central Google Scholar

Bozaran AA, Bozan B (2013) The influence of pectolytic enzyme addition and prefermentative mash heating during the winemaking process on the phenolic composition of Okuzgozu red wine. Food Chem 138(1):389–395

Breiteneder H, Radauer C (2004) A classification of plant food allergens. J Allergy Clin Immunol 113(5):821–830

Cabaroglu T, Selli S, Canbas A, Lepoutre JP, Günata Z (2003) Wine flavor enhancement through the use of exogenous fungal glycosidases. Enzyme Microb Technol 33(5):581–587

Capounová D, Drdák M (2002) Comparison of some commercial pectic enzyme preparations applicable in wine technology. Czech J Food Sci 20(4):131–134

Castro-López L, Gómez-Plaza E, Ortega-Regules A, Lozada D, Bautista-Ortín AB (2016) Role of cell wall deconstructing enzymes in the proanthocyanidin-cell wall adsorption-desorption phenomena. Food Chem 196:526–532

Claus H, Mojsov K (2018) Enzymes for wine fermentation: current and perspective applications. Fermentation 4:52

Dal Magro L, Goetze D, Ribeiro CT, Paludo N, Rodrigues E, Hertz PF, Klein MP, Rodrigues RC (2016) Identification of bioactive compounds from Vitis labrusca L. variety Concord grape juice treated with commercial enzymes: improved yield and quality parameters. Food Bioprocess Technol 9(2):365–377

Di Profio F, Reynolds AG, Kasimos A (2011) Canopy management and enzyme impacts on Merlot, Cabernet franc, and Cabernet Sauvignon. II. Wine composition and quality. Am J Enol Vitic 62(2):152–168

Doco T, Williams P, Cheynier V (2007) Effect of flash release and pectinolytic enzyme treatments on wine polysaccharide composition. J Agric Food Chem 55(16):6643–6649

Ducasse MA, Canal-Llauberes RM, de Lumley M, Williams P, Souquet JM, Fulcrand H, Doco T, Cheynier V (2010) Effect of macerating enzyme treatment on the polyphenol and polysaccharide composition of red wines. Food Chem 118:369–376

EFSA (2009) Scientific opinion: guidance of the Scientific Panel of Food contact materials, enzymes, flavourings and processing aids (CEF) on the submission of a dossier on food enzymes for safety evaluation by the Scientific Panel of Food contact material, enzymes, flavourings and processing aids. EFSA J 1305:1–26

El Darra N, Turk MF, Ducasse MA, Grimi N, Maroun RG, Louka N, Vorobiev E (2016) Changes in polyphenol profiles and color composition of freshly fermented model wine due to pulsed electric field, enzymes and thermovinification pretreatments. Food Chem 194:944–950

PubMed Google Scholar

Escribano R, González-Arenzana L, Garijo P, Berlanas C, López-Alfaro I, López R, Gutiérrez AR, Santamaría P (2017) Screening of enzymatic activities within different enological non- Saccharomyces yeasts. J Food Sci Technol 54(6):1555–1564

CAS PubMed PubMed Central Google Scholar

Espejo F, Armada S (2010) Effect of enzyme addition in the making of Pedro Ximenez sweet wines using dynamic pre-fermentative maceration. S Afr J Enol Vitic 31(2):133–142

Fia G, Canuti V, Rosi I (2014) Evaluation of potential side activities of commercial enzyme preparations used in winemaking. Int J Food Sci Technol 49(8):1902–1911

Gao Y, Fangel JU, Willats W, Vivier MA, Moore JP (2016) Effect of commercial enzymes on berry cell wall deconstruction in the context of intra-vineyard ripeness variation under winemaking conditions. J Agric Food Chem 64(19):3862–3872

Gómez-Plaza E, Romero-Cascales I, Bautista-Ortín AB (2010) Use of enzymes for wine production. In: Bayindirli A (ed) Enzymes in fruit and vegetable processing. Chemistry and engineering applications. CRC Press, Boca Ratón, pp 215–243

González-Neves G, Gil G, Favre G, Baldi C, Hernández N, Traverso S (2013) Influence of winemaking procedure and grape variety on the colour and composition of young red wines. S Afr J Enol Vitic 34(1):138–146

González-Pombo P, Fariña L, Carrau F, Batista-Viera F, Brena BM (2014) Aroma enhancement in wines using co-immobilizated Aspergillus niger glucosidases. Food Chem 143:185–191

Guérin L, Sutter D-H, Demois A, Chereau M, Trandafir G (2009) Determination of activity profiles of the main commercial enzyme preparations used in winemaking. Am J Enol Vitic 60(3):322–331

Kelebek H, Canbas A, Cabaroglu T, Selli S (2007) Improvement of anthocyanin content in the cv. Öküzgӧzü wines by using pectolytic enzymes. Food Chem 105:334–339

Kelebek H, Canbas A, Selli S (2009) Effects of different maceration times and pectolytic enzyme addition on the anthocyanin composition of Vitis vinifera cv. Kalecik karasi wines. J Food Process Preserv 33:296–311

Kirsch S, Fourdrilis S, Dobson R, Scippo M-L, Maghuin-Rogister G, De Pauw E (2009) Quantitative methods for food allergens: a review. Anal Bioanal Chem 395:57–67

Kirschner S, Belloni B, Kugler C, Ring J, Brockow K (2009) Allergenicity of wine containing processing aids: a double-blind, placebo-controlled food challenge. J Investig Allergol Clin 19:210–213

Liburdi K, Benucci I, Esti M (2014) Lysozyme in wine: an overview of current and future applications. Compr Rev Food Sci Food Saf 13(5):1062–1073

Maicas S, Mateo JJ (2005) Hydrolysis of terpenyl glycosides in grape juice and other fruit juices: a review. Appl Microbiol Biotechnol 67(3):322–335

Marangon M, Van Sluyter SC, Robinson EM, Muhlack RA, Holt HE, Haynes PA, Godden PW, Smith PA, Waters EJ (2012) Degradation of white wine haze proteins by Aspergillopepsin I and II during juice flash pasterurizatin. Food Chem 135:1157–1165

Masino F, Montevecchi G, Arfelli G, Antonelli A (2008) Evaluation of the combined effects of enzymatic treatment and aging on lees on the aroma of wine from Bombino bianco grapes. J Agric Food Chem 56(20):9495–9501

Minussi RC, Rossi M, Bologna L, Rotilio D, Pastore GM, Durán N (2007) Phenols removal in musts: strategy for wine stabilization by laccase. J Mol Catal B Enzym 45(3–4):102–107

Ortega-Heras M, Pérez-Magariño S, González-Sanjosé ML (2012) Comparative study of the use of maceration enzymes and cold pre-fermentative maceration on phenolic and anthocyanic composition and colour of a Mencía red wine. LWT Food Sci Technol 48(1):1–8

Pastorello E, Farioli L, Pravettoni V, Ortolani C, Fortunato D, Giuffrida M, Garoffo L, Calamari A, Frenna O, Conti A (2003) Identification of grape and wine allergens as endochitinase 4, a lipid-transfer protein, and a thaumatin. J Allergy Clin Immunol 111(2):350–359

Pinelo M, Arnous A, Meyer AS (2006) Upgrading of grape skins: significance of plant cell-wall structural components and extraction techniques for phenol release. Trends Food Sci Technol 17(1):579–590

Pogorzelski E, Wilkowska A (2007) Flavour enhancement through the enzymatic hydrolysis of glycosidic aroma precursors in juices and wine beverages: a review. Flavor Fragr J 22(4):251–254

Puértolas E, Saldaña G, Condón S, Álvarez I, Raso J (2009) A comparison of the effect of macerating enzymes and pulsed electric fields technology on phenolic content and color of red wine. J Food Sci 74(9):C647–C652

Río Segade S, Pace C, Torchio F, Giacosa S, Gerbi V, Rolle L (2015) Impact of maceration enzymes on skin softening and relationship with anthocyanin extraction in wine grapes with different anthocyanin profiles. Food Res Int 71:50–57

Rizzi C, Mainente F, Pasini G, Simonato B (2016) Hidden exogenous proteins in wine: problems, methods of detection and related legislation-a review. Czech J Food Sci 34(2):93–104

Rocha SM, Coutinho P, Delgadillo I, Dias A, Cardoso M, Coimbra M (2005) Effect of enzymatic aroma release on the volatile compounds of white wines presenting different aroma potentials. J Sci Food Agric 85(2):199–205

Röcker J, Schmitt M, Pasch L, Ebert K, Grossmann M (2016) The use of glucose oxidase and catalase for the enzymatic reduction of the potential ethanol content in wine. Food Chem 210:660–670

Rodriguez-Nogales JM, Fernández-Fernández E, Vila-Crespo J (2016) Enzymes in winemaking. In: Ray RC, Rosell CM (eds) Microbial enzyme technology in food applications. CRC Press, Boca Raton, pp 315–332

Romero-Cascales I, Ros-García JM, López-Roca JM, Gómez-Plaza E (2012) The effect of a commercial pectolytic enzyme on grape skin cell wall degradation and colour evolution during the maceration process. Food Chem 130(3):626–631

Rusjan D, Srlič M, Košmer T, Prosen H (2009) The response of monoterpenes to different enzyme preparations in Gewürztraminer ( Vitis vinifera L.) wines. S Afr J Enol Vitic 30(1):56–64

Rusjan D, Strlič M, Košmerl T, Prosen H (2012) Contribution of enzyme preparations to the linalool content of wines made from the non-aromatic grapevine variety Furmint ( Vitis vinifera L.). J Int Sci Vigne Vin 46(2):139–143

Samoticha J, Wojdylo A, Chmielewska J, Politowicz J, Szumny A (2017) The effects of enzymatic pre-treatment and type of yeast on chemical properties of white wine. LWT Food Sci Technol 79:445–453

Sampaio TL, Kennedy JA, Vasconcelos MC (2007) Use of microscale fermentations in grape and wine research. Am J Enol Vitic 58(4):534–539

Sarrouh B, Santos TM, Miyoshi A, Dias R, Azevedo V (2012) Up-to-date insight on industrial enzymes applications and global market. J Bioprocess Biotech S 4:002

Schmidtke LM, Blackman JW, Agboola SO (2012) Production technologies for reduced alcoholic wines. J Food Sci 71(1):R25–R41

Schweigert MK, Mackenzie DP, Sarlo K (2000) Occupational asthma and allergy associated with the use of enzymes in the detergent industry-a review of the epidemiology, toxicology and methods of prevention. Clin Exp Allergy 30:1511–1518

Servili M, De Stefano G, Piaquadio P, Sciancalepore V (2000) A novel method for removing phenols from grape must. Am J Enol Vitic 51(4):357–361

Søndergaard HA, Grunert KG, Scholderer J (2005) Consumer attitudes to enzymes in food production. Trends Food Sci Technol 16(10):466–474

Soto Vázquez E, Río Segade S, Orriols Fernández I (2010) Effect of the winemaking technique on phenolic composition and chromatic characteristics in young red wines. Eur Food Res Technol 231:789–802

Spagna G, Barbagallo RN, Greco E, Manenti I, Pifferi PG (2002) A mixture of purified glycosidases from Aspergillus niger immobilised by inclusion in chitosan gels for oenological application. Enzyme Microb Technol 30(1):80–89

Spök A (2006) Safety regulations of food enzymes. Food Technol Biotechnol 44(2):197–209

Sun W-X, Hu K, Zhang J-X, Zhu X-L, Tao Y-S (2018) Aroma modulation of Cabernet Gernischt dry red wine by optimal enzyme treatment strategy in winemaking. Food Chem 245:1248–1256

Torresi S, Frangipane MT, Garzillo AM, Massantini R, Contini M (2014) Effects of a β-glucanase enzymatic preparation on yeast lysis during aging of traditional sparkling wines. Food Res Int 55:83–92

Ugliano M (2009) Enzymes in winemaking. In: Moreno-Arribas MV, Polo MC (eds) Wine chemistry and biochemistry. Springer, New York, pp 103–126

Vassilopoulou E, Karathanos A, Siragakis G, Glavi S, Sinaniotis A, Douladiris N, Fernandez-Rivas M, Clausen M, Papadopoulos NG (2011) Risk of allergic reactions to wine, in milk, egg and fish-allergic patients. Clin Transl Allergy 1:10

Verhoeckx KC, Vissers YM, Baumert JL, Faludi R, Feys M, Flanagan S, Herouet-Guicheney C, Holzhauser T, Shimojo R, van der Bolt N, Wichers H, Kimber I (2015) Food processing and allergenicity. Food Chem Toxicol 80:223–240

Verma AK, Kumar S, Das M, Dwivedi PD (2013) A comprehensive review of legume allergy. Clin Rev Allergy Immunol 45:30–46

Wüthrich B (2011) Allergic and intolerance reactions to wine. Allergologie 34(8):427–436

Yang H, Li J, Shin HD, Du G, Liu L, Chen J (2014) Molecular engineering of industrial enzymes: recent advances and future prospects. Appl Microbiol Biotechnol 98(1):23–29

Zietsman AJ, Moore JP, Fangel JU, Willats WG, Trygg J, Vivier MA (2015) Following the compositional changes of fresh grape skin cell walls during the fermentation process in the presence and absence of maceration enzymes. J Agric Food Chem 63(10):2798–2810

Download references

Author information

Authors and affiliations.

Department of Quality, Navisa Industrial Vinícola Española S.A., Avda. José Padillo s/n, 14550, Montilla, Córdoba, Spain

Francisco Espejo

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Francisco Espejo .

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Reprints and permissions

About this article

Espejo, F. Role of commercial enzymes in wine production: a critical review of recent research. J Food Sci Technol 58 , 9–21 (2021). https://doi.org/10.1007/s13197-020-04489-0

Download citation

Revised : 02 February 2020

Accepted : 24 April 2020

Published : 02 May 2020

Issue Date : January 2021

DOI : https://doi.org/10.1007/s13197-020-04489-0

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Wine making

- Biotechnology

- Find a journal

- Publish with us

- Track your research

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Wine Making

Wine is an undistilled alcoholic beverage made from fermented fruit juice. Meanwhile, fermentation refers to the catabolic and anaerobic process of transforming sugar into carbon dioxide and ethanol with the help of bacteria, preferably in the dark. For this experiment, it aims to create wine in a laboratory by learning the process on how to produce and by appreciating the role of each material in the product. The experiment started with the preparation of each ingredient, specifically, fruit juice, active yeast, and refined sugar, and the measurement of their required weights. Next, 50 mL of fruit juice was warmed on a hot plate and then refined sugar was dissolved into the heated juice. After that, the juice heated again to a temperature of 70°C. Active yeast was added and mixed with the hot juice. The mixture was then combined with the remaining fruit juice and its density was determined using a hydrometer or pycnometer. Then, the mixture was transferred in a bottle with a cotton wad or balloon as a cover and was left to ferment in a dark room for a week. After a week, the wine was decanted and filter before being placed in a packaging bottle. The same process was repeated for the remaining wine formulations. The results showed that the wine made from the W1 formulation was much paler than from W2 and W3. It was also observed that the specific gravity of all the wines was greater before fermentation occurred. From the ingredients, yeast acted as the fermenting agent which converted the sugar compounds from the fruit juice and from the refined sugar into alcohol. Also, sugar was used to balance sweetness and to produce more alcohol in the wine since the sugars in the fruit juice is not sufficient to reach the desired ethanol content for wines.

Related Papers

IJESRT Journal

Wine is an alcoholic beverage made from fermented grapes or other fruits. Many tropical fruits such as mango, jackfruit, litchi, banana and cashew apple have been shown to be suitable for fermentation, mainly because of their appropriate taste, flavour, availability, high sugar and water content and overall chemical composition (Muniz et al. 2008). The natural chemical balance of these fruits lets them ferment without the addition of sugars, acids, enzymes, water, or other nutrients. Yeast consumes the sugars in the fruits and converts them into alcohol. Study was conducted to produce red wine without using any sugar and making use of the kitchen yeast strain i.e saccharomyces cereisiae and was tested for the different physical and chemical characteristics of the wine such as acidity ,sugar content and other quantitative and qualitative tests. The wine was produced in simple lab conditions and using simple lab utensils and instruments so this techniques may very well reduce the overall cost of wine production. The production and tests were conducted in small scale but this technique can be converted to large scale with few changes.

Dr. P. Saranraj

Fruit is an essential part of your diet using essential part of vitamin and minerals that contribute to overall strength for your health. Fruit wines are undistilled alcoholic beverages usually made from grapes or other fruits such as peaches, plums or apricots, banana, elderberry, or black current which are nutritive, more tasty, and mild stimulants. These fruits undergo a period of fermentation and aging. They usually have an alcohol content ranging between 5 and 13%. Wines made from fruits are often named after the fruits. No other drinks, except water and milk, have earned such universal acceptance and esteem throughout the ages as has wine. Wine is a food with a flavor like fresh fruit which could be stored and transported under the existing conditions. Being fruit-based fermented and undistilled product, wine contains most of the nutrients present in the original fruit juice. The nutritive value of wine is increased due to the release of amino acids and other nutrients from yeast during fermentation. Fruit wines contain 8–11% alcohol and 2–3% sugar with energy value ranging between 70 and 90 kcal per 100 ml. The present explained about the fermentation of wine and its quality analysis. In this present review, we discussed about fermentation, history of fermentation, Saccharomyces cerevisiae and alcoholic fermentation, fermentation of fruit juice into wine, classification of wine, factors influencing fermentation and wine quality, and Indian wine market.

George Vierra

Wine is an alcoholic beverage made from fermented grapes or other fruits. The natural chemical balance of grapes lets them ferment without the addition of sugars, acids, enzymes, water, or other nutrients. Yeast consumes the sugars in the grapes and converts them into alcohol. Different varieties of grapes and strains of yeasts produce different types of wine such as red wine ,white wine, sparkling wine, rose wine etc. Study was conducted to produce red wine without using any sugar and making use of the kitchen yeast strain i.e Saccharomyces cereisiae and was tested for the different physical and chemical characteristics of the wine such as acidity ,sugar content and other quantitative and qualitative tests. The wine was produced in simple lab conditions and using simple lab utensils and instruments so this techniques reduces the overall cost of wine production. The production and tests were conducted in small scale but this technique can be converted to large scale with few changes.

PRODUCTION OF WINE FROM THE FERMENTATION OF ORANGE JUICE BY Saccharomyces cerevisiae

Oladimeji ishaq Hassan

The fermentation of orange juice by Saccharomyces cerevisiae isolated from palm wine was carried out. The fermentation was done in two phases; the aerobic phase which lasted for 5 days and the anaerobic phase which lasted for 9 days. Some physicochemical parameters were monitored during the aerobic and anaerobic phase of fermentation. These were pH, titratable acidity, specific gravity, sugar content and alcohol concentration. The result of the physicochemical analysis showed that during aerobic fermentation there was a decline in the pH from 3.6 to 2.4; an increase in titratbable acidity from 9.10 to 16.8g/l. During anaerobic phase the pH increased from 3.0 to 4.3 while the titratable acidity decreased from 16.4 to 9.7g/l. The yeast counts increased from 5.5 ×106 to 6.9×106 cells/ml; alcohol content increased from 0 to 5.4% during aerobic fermentation, while during anaerobic there was a drop in yeast counts from 7.1×106cells/ml to 6.3×106 cells/ml; and the alcohol content increased from 5.8 to 9.6%. The sugar content and specific gravity in the wine dropped throughout during aerobic and anaerobic fermentation with sugar content dropping from initial value of 50.80 mg/ml to 2.87 mg/ml, while the Specific gravity dropped from 1.040 to 0.980osp.gr. On the 9th day of the anaerobic phase the fermentation was terminated by opening the fermentation tank, the wine was then clarified, racked and bottled.

Suna Ertunç

Summary: The goal of this study was to examine the effects of operating parameters on ethanol concentration (ethanol) in apple wine production process. Examined parameters were temperature (T), pH and sulphurdioxide concentration (SO2). Experiments were planned and executed according to a full two-level factorial experimental design method. The studied levels were 18°C and 25°C for temperature, 3 and 4 for pH and 50 and 150 ppm for SO2. Ethanol concentration of apple wine for each set of experiments was determined by GC/MS. Experimental data were analyzed by using both graphical and quantitative Exploratory Data Analysis (EDA) Techniques. The main effect of each factor on sugar consumption rate (SCR) was also examined. The results show that the effect of examined operating parameters on ethanol was negative. High temperature level caused faster fermentation rate than the one caused by low temperature. Low level of pH and high level of SO2 inhibited the activities of both harmful mic...

Journal of Food Engineering

Y. Kourkoutas

International Journal of Current Microbiology and Applied Sciences

Pooja Nikhanj

Alice Vilela , Fernanda Cosme

Thi Hường Trần

This application note presents a simple and rapid method for the simultaneous determination of Saccharose, Glucose, Fructose, Ethanol and Glycerol. The method is designed for the quality and process control of wine. All five substances are baseline separated and no hydrolysis of Saccharose was observed. An extra sample preparation is not necessary, just a dilution. This method works with water as a low cost eluent.

RELATED PAPERS

The Future of Food Preservation: Packaging Advancements for Sustainable Food Solutions

Yusufu Kasato

Journal of the Courtauld and Warburg Institute

Allegra Iafrate

2016 IEEE International Conference on Big Data (Big Data)

Nectarios Koziris

Applied Sciences

Zsolt conka

jose hugo ordoñez Flores

Jurnal Kacapuri : Jurnal Keilmuan Teknik Sipil

Al-Adl : Jurnal Hukum

22_013 ARYA KUSUMA

Frontiers in Neuroscience

Tanvir Kabir

Economía y Negocios

RENE FARUK GARZOZI PINCAY

Juan Carlos Márquez Cañizares

Vladimir Kvint

Memorandum: Memória e História em Psicologia

Camila Souza

Computing Meaning

一模一样加拿大范莎学院毕业证 uofs文凭证书英文录取通知原版一模一样

Shima Rahimi Moghaddam

Andrzej Kruszewski

Sophie Piron

Revista Brasileira De Agroecologia

Antonio Cardoso

Journal of Comparative Physiology B

Caroline Romestaing

Arzneimittelforschung

Muhammad Hammami

Konan Arsène KANGA

Historia Mathematica

Marie-Helene Labarthe

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Skip to content

- Skip to search

- Skip to footer

Products, Solutions, and Services

Want some help finding the Cisco products that fit your needs? You're in the right place. If you want troubleshooting help, documentation, other support, or downloads, visit our technical support area .

Contact Cisco

- Get a call from Sales

Call Sales:

- 1-800-553-6387

- US/CAN | 5am-5pm PT

- Product / Technical Support

- Training & Certification

Products by technology

- Software-defined networking

- Cisco Silicon One

- Cloud and network management

- Interfaces and modules

- Optical networking

- See all Networking

Wireless and Mobility

- Access points

- Outdoor and industrial access points

- Controllers

- See all Wireless and Mobility

- Secure Firewall

- Secure Endpoint

- Secure Email

- Secure Access

- Multicloud Defense

- See all Security

Collaboration

- Collaboration endpoints

- Conferencing

- Cisco Contact Center

- Unified communications

- Experience Management

- See all Collaboration

Data Center

- Servers: Cisco Unified Computing System

- Cloud Networking

- Hyperconverged infrastructure

- Storage networking

- See all Data Center

- Nexus Dashboard Insights

- Network analytics

- Cisco Secure Network Analytics (Stealthwatch)

- Video endpoints

- Cisco Vision

- See all Video

Internet of Things (IoT)

- Industrial Networking

- Industrial Routers and Gateways

- Industrial Security

- Industrial Switching

- Industrial Wireless

- Industrial Connectivity Management

- Extended Enterprise

- Data Management

- See all industrial IoT

- Cisco+ (as-a-service)

- Cisco buying programs

- Cisco Nexus Dashboard

- Cisco Networking Software

- Cisco DNA Software for Wireless

- Cisco DNA Software for Switching

- Cisco DNA Software for SD-WAN and Routing

- Cisco Intersight for Compute and Cloud

- Cisco ONE for Data Center Compute and Cloud

- See all Software

- Product index

Products by business type

Service providers

Small business

Midsize business

Cisco can provide your organization with solutions for everything from networking and data center to collaboration and security. Find the options best suited to your business needs.

- By technology

- By industry

- See all solutions

CX Services

Cisco and our partners can help you transform with less risk and effort while making sure your technology delivers tangible business value.

- See all services

Design Zone: Cisco design guides by category

Data center

- See all Cisco design guides

End-of-sale and end-of-life

- End-of-sale and end-of-life products

- End-of-Life Policy

- Cisco Commerce Build & Price

- Cisco Software Central

- Cisco Feature Navigator

- See all product tools

- Cisco Mobile Apps

- Design Zone: Cisco design guides

- Cisco DevNet

- Marketplace Solutions Catalog

- Product approvals

- Product identification standard

- Product warranties

- Cisco Security Advisories

- Security Vulnerability Policy

- Visio stencils

- Local Resellers

- Technical Support

The State of Food and Agriculture 2023

Revealing the true cost of food to transform agrifood systems.

Year of publication 2023

Place of publication Rome, Italy ;

Pages 150 p.

Publisher FAO ;

Product type Book (series)

ISBN 978-92-5-138167-0

Series title The State of Food and Agriculture (SOFA)

Series number 2023

Synopsis (short abstract) Agrifood systems generate significant benefits to society, including the food that nourishes us and jobs and livelihoods for over a billion people. However, their negative impacts due to unsustainable business-as-usual activities and practices are contributing to climate change, natural resource degradation and the unaffordability of healthy diets. Addressing these negative impacts is challenging, because people, businesses, governments and other stakeholders lack a complete picture of how their activities affect economic, social and environmental sustainability when they make decisions on a day-to-day basis.The State of Food and Agriculture 2023 looks into the true cost of food for sustainable agrifood systems. The report introduces the concept of hidden environmental, health and social costs and benefits of agrifood systems and proposes an approach – true cost accounting (TCA) – to assess them. To operationalize the TCA approach, the report proposes a two-phase assessment process, first relying on national-level TCA assessments to raise awareness and then moving towards in-depth and targeted evaluations to prioritize solutions and guide transformative actions. It provides a first attempt at national-level assessments for 154 countries, suggesting that global hidden costs from agrifood systems amount to at least to 10 trillion 2020 PPP dollars. The estimates indicate that low-income countries bear the highest burden of the hidden costs of agrifood systems relative to national income. Despite the preliminary nature of these estimates, the analysis reveals the urgent need to factor hidden costs into decision-making for the transformation of agrifood systems. Innovations in research and data, alongside investments in data collection and capacity building, are needed to scale the application of TCA, especially in low- and middle-income countries, so that it can become a viable tool to inform decision- and policymaking in a transparent and consistent way.

- Read the full digital report

- Read the In Brief

- Read the Policy Brief

- Read the Interactive story: Beyond the price tag

- Watch the Video: State of Food and Agriculture 2023. Revealing the true cost of food to transform agrifood systems

- Read the press release: Hidden costs of global agrifood systems worth at least $10 trillion

Read the background papers:

- Hidden costs of agrifood systems and recent trends from 2016 to 2023

- Accounting for the hidden costs of agrifood systems in data-scarce contexts

- The role of true cost accounting in guiding agrifood businesses and investments towards sustainability

- True cost accounting applications for agrifood systems policymakers

Help us improve your reading experience

FAO. 2023. The State of Food and Agriculture 2023. Revealing the true cost of food to transform agrifood systems . Rome.

https://doi.org/10.4060/cc7724en

Read on Google Books and buy online

Language English

Also available in:

Related items.

Showing items related by metadata.

Background paper for The State of Food and Agriculture 2023

Users also downloaded

Showing related downloaded files

IMAGES

VIDEO

COMMENTS

Fruit Wine Production: A Review. Shrikant Baslingappa Swami*, N.J. Thakor. and A.D. Divate. Department of Agricultural Process Engineering, College of Agricultural Engineering and Technology, Dr ...

This study was aimed at comparative evaluation of red wine produced from Hibiscus sabdariffa L. and Citrus sinensis juice using Saccharomyces cerevisiae isolated from palm wine Original Research ...

Merlot grapes were harvested with three maturity levels (21.1, 23.1, and 25.1 Brix), and processed with or without the application of microwave-assisted extraction (MW).

Wine process modeling is a critical facet of wine science. In this work, we reviewed different models of wine fermentation kinetics, from the earliest unstructured models through modern Genome Scale Metabolic Models. We also examined the heterogeneity of wine fermentations, and discussed how an understanding of heat transfer, mass transfer, and ...

Fermentation is a well-known natural process that has been used by humanity for thousands of years, with the fundamental purpose of making alcoholic beverages such as wine, and also other non-alcoholic products. From a strictly biochemical point of view, fermentation is a process of central metabolism in which an organism converts a carbohydrate, such as starch or sugar, into an alcohol or an ...

Abstract. In the second article of the 'Food and Science' series, Paul Chambers and Isak Pretorius explain the central role of yeast in wine making and how biotechnology can contribute to improving the quality of wine. Wine has been with us since the dawn of civilization and has followed humans and agriculture along diverse migration paths ...

3.4 Making Red and Rosé Wines: Essential Features 211 . 3.4.1 Maceration Techniques and Re d Wine Styles 211 ... Major Research Establishments. Prominent Grapevine Breeding Centres, and Grapevine Collections. Information on Vine Varieties ... Figure 3-20 Ways of making rosé wine . 226 Figure 3-21 Methods for producing sparkling wine. ...

Shelf life of pineapple is about 2-3 days making limited availability in fresh market. An alternative and profitable method of winemaking from pineapple is widely acceptable. Many investigators have carried out much research on pineapple composition, and on cultivation aspects and this review will give the detailed up to date knowledge on

Purified enzymes of microbial origin are applied in the beverage industry since decades because of their ability to enhance products and processes with minimal side effects and low costs. Commercial enzymes are widely used during different wine making steps providing a broad range of effects, such as to maximise juice yield, improve aroma compounds, flavour enhancement, colour extraction in ...

Introduction. The world area under vines and the volume of wine production in 2017 have not changed significantly over the last 15 years since 2002, however, the value of wine exports in US$ has more than doubled (Anderson and Pinilla 2017).Wine production faces new challenges such as global warming (van Leeuwen and Darriet 2016) and increasing competition from the emergence of new markets and ...

The titrable acidity showed for ginger wine is 2 to 3.5mg/ml but for amla it is 8.9 to 5.5mg/ml. the commercial wine had a value higher than ginger i.e., 4.2mg/ml. Thus the studies showed that the pH (except ginger), specific gravity and alcohol content were higher for commercial wine.

Wine holds immense cultural and historical importance across societies. This study developed a wine formulation using readily available ingredients: pumpkin, papaya, and millets.

This study has revealed that much acceptable wine with quality could be produced from apple with Saccharomyces cerevisiae isolated from palm wine. Sensory evaluation results showed there were no significant differences (p > 0.05) in flavor, taste, clarity and overall acceptability between apple wine and a reference wine.

In the current research, effect of pectinase on the quality of the jamun wine was evaluated. Jamun wine was prepared from three different must types viz., juice, pulp+skin and pulp+skin+seed. The must was macerated with 0.25 and 0.50 % of pectinase enzyme. The other must parameters viz., TSS and pH was adjusted to 24°B and 3.2, respectively.

to naturally produce a stable, drinkable wine. Recently, grapes are recommended as the main fruits that used for wine production. Despite that, several studies have observed the suitability of other fruits as substrates for the purpose of wine production [5,6,7,8,4]. Grapes, which is usually the no 1 fruit of choice for wine production in the

Noah Moonen et al. Article | Published online: 3 Apr 2024. Determination of malvidin-3,5-diglucoside content in wines from Cabernet Cortis and three Italian-resistant hybrids, with preliminary evaluation of oenological glycosidases for enzyme-induced breakdown of malvidin-3,5-diglucoside and malvidin-3-glucoside. E. Serni et al.

for tartness. Tartaric and malic acid have a significant effect on wine pH. pH of wine is associated with wine colour, spoilage and stability. Sulfur dioxide is widely used in the wine industry as sanitizing agent and antioxidant and a slight decrease in pH in the range of 3.0-5.0 increases the antiseptic action of sulfur dioxide. 4.

The nutritive value of wine is increased due to the release of amino acids and other nutrients from yeast during fermentation. Fruit wines contain 8-11% alcohol and 2-3% sugar with energy value ranging between 70 and 90 kcal per 100 ml. The present explained about the fermentation of wine and its quality analysis.

alcohol or an acid. The fermentation process turns grape juice (must) into wine. This is a complex. chemical reaction whereby the yeast interacts with the sugars (glucose and fructose) in the must ...

Wine Making. Christian John R Castro. Wine is an undistilled alcoholic beverage made from fermented fruit juice. Meanwhile, fermentation refers to the catabolic and anaerobic process of transforming sugar into carbon dioxide and ethanol with the help of bacteria, preferably in the dark. For this experiment, it aims to create wine in a ...

After introducing yeast, the grapes sit on the skins to ferment, usually about 4-5 days. This is more common with red and purple grapes than with white. Fermentation is the process where sugars are turned into alcohol. While waiting for fermentation to start, resist the urge to look in on its progress for a few days.

Cisco+ (as-a-service) Cisco buying programs. Cisco Nexus Dashboard. Cisco Networking Software. Cisco DNA Software for Wireless. Cisco DNA Software for Switching. Cisco DNA Software for SD-WAN and Routing. Cisco Intersight for Compute and Cloud. Cisco ONE for Data Center Compute and Cloud.

Wine is a product strictly connected to tradition and today the consumers are increasingly. expecting wine to be produced in a sustainable way ( Bisson et al., 2002;Capitello &Sirieix, 2019 ...

Author FAO. Publisher FAO ; Product type Book (series) ISBN 978-92-5-138167-. Series title The State of Food and Agriculture (SOFA) Series number 2023. Full item page. Synopsis (short abstract)Agrifood systems generate significant benefits to society, including the food that nourishes us and jobs and livelihoods for over a billion people.

Open PDF in Browser. Do you have a job opening that you would like to promote on SSRN? Place Job Opening. Paper statistics. Downloads. 6,702. Abstract Views. 10,671. Rank. ... Chicago Booth Research Network Papers. Subscribe to this free journal for more curated articles on this topic FOLLOWERS. 50. PAPERS. 490. Feedback. Feedback to SSRN ...

Rice wine is an alcoholic beverage produced via the fermentation of cereals, primarily rice wi th starter c ultures. It is produced and consumed globally, especially in Asian countries. With the ...