How To Write a Business Plan for Concrete Block in 9 Steps: Checklist

By henry sheykin, resources on concrete block.

- Financial Model

- Business Plan

- Value Proposition

- One-Page Business Plan

- SWOT Analysis

- Business Model

- Marketing Plan

In the booming construction industry, the demand for concrete blocks is on the rise. As the backbone of many building projects, concrete blocks are essential for their durability, strength, and energy efficiency. If you're considering starting a concrete block manufacturing and distribution business, you're tapping into a market that shows no signs of slowing down.

The concrete block industry in the US has experienced significant growth in recent years. According to the latest statistics, the market size reached $5.85 billion in 2020 and is expected to continue expanding at a CAGR of 3.2% from 2021 to 2028 . This indicates a promising opportunity for entrepreneurs like yourself to enter the industry and carve out a successful niche.

But to turn this business idea into a profitable reality, you'll need a well-crafted business plan that outlines your strategy and approach. In this article, we'll guide you through the 9 essential steps to write an effective business plan for your concrete block venture.

Ready to get started? Let's dive into the details:

Identify the Target Market and Assess Potential Demand

Before starting a business in the concrete block industry, it is crucial to identify the target market and assess the potential demand for your products. This step will help you understand the market dynamics and tailor your business plan accordingly.

To identify the target market, consider the various sectors that use concrete blocks, such as construction companies, home builders, and contractors. Determine the size of each sector and their specific needs for concrete blocks.

Conduct thorough market research to gather information about the demand for concrete blocks in your target market. Identify potential customers and determine their preferences, requirements, and purchasing patterns.

Tips for identifying the target market and assessing potential demand:

- Attend industry trade shows and conferences to network with potential customers and gather market insights.

- Utilize online resources, market reports, and industry publications to gather data on market trends and customer preferences.

- Engage with industry experts and consultants who can provide valuable guidance on market analysis.

- Conduct surveys or interviews with potential customers to gather direct feedback on their needs and preferences.

- Consider demographic factors, such as population growth and urbanization trends, which can influence the demand for concrete blocks.

By thoroughly understanding your target market and assessing the potential demand for concrete blocks, you will be able to develop a more accurate business plan that meets the needs and expectations of your customers.

Conduct Market Research To Understand Competitors And Market Trends

Market research plays a crucial role in the success of any business, and the concrete block industry is no exception. By conducting thorough market research, you can gain valuable insights into your competitors and the current market trends, enabling you to make informed decisions and develop effective strategies.

Here are some important steps to consider when conducting market research:

- Identify your competitors: Start by identifying the key competitors in the concrete block industry. Look for companies that offer similar products or target the same customer base. Evaluate their strengths, weaknesses, and market share to understand their competitive advantage.

- Assess market trends: Stay up-to-date with the latest trends and developments in the concrete block industry. This includes changes in construction practices, emerging technologies, and evolving customer preferences. By understanding these trends, you can adapt your business strategies accordingly and stay ahead of the competition.

- Analyze customer needs: Conduct surveys or interviews to gather insights into customer needs and preferences. Understand what factors influence their purchasing decisions, such as price, quality, and delivery time. This information will help you tailor your products and services to meet customer demands effectively.

- Evaluate pricing strategies: Study the pricing strategies of your competitors to determine their pricing models, profit margins, and discounts offered. This will help you position your product competitively and set appropriate pricing levels to attract customers without compromising profitability.

- Utilize online resources: Explore industry publications, websites, and online forums for valuable information on competitors and market trends. These resources can provide insights into the latest industry news, product innovations, and customer reviews.

- Attend trade shows and conferences: Participating in industry events allows you to network with competitors, suppliers, and potential customers. It also provides an opportunity to observe new products and technologies in the market, giving you a competitive edge.

- Stay customer-focused: Regularly engage with your customers, seeking feedback and understanding their evolving needs. This will help you adapt your business strategies and product offerings to stay relevant in the market.

By conducting comprehensive market research, you can gain a deeper understanding of your competitors and market trends. This knowledge will empower you to make informed decisions, develop effective strategies, and position your concrete block business for success in a competitive market.

Determine The Size And Scope Of The Business Operations

Once you have identified your target market and assessed the potential demand for concrete blocks, it is important to determine the size and scope of your business operations. This step involves considering factors such as production capacity, distribution capabilities, and market reach to ensure that your business can meet the needs of your customers.

First, you need to assess the production capacity of your manufacturing facility. This includes evaluating the equipment you will need and the space required to produce concrete blocks efficiently. Consider the number of blocks you can produce per day or month, as well as any seasonal variations in demand.

Next, determine your distribution capabilities. Will you sell locally, regionally, or nationally? Assess the logistics of transporting your concrete blocks to your customers and consider partnering with distributors or freight companies to streamline this process.

Market reach is another important factor to consider. Will you focus on serving a specific geographic area or target customers in different regions? Understanding the market demand and competition in different areas will help you determine the size and reach of your business operations.

- Conduct a thorough analysis of your target market to identify potential areas for expansion or specialization.

- Consider the scalability of your business to accommodate future growth.

- Identify any unique selling propositions or niche markets that can give your business a competitive advantage.

By determining the size and scope of your business operations, you can effectively plan and allocate resources to meet customer demand and drive profitability. This step lays the foundation for developing a successful concrete block manufacturing and distribution business.

Outline The Organizational Structure And Staffing Requirements

When outlining the organizational structure for your concrete block business, it is important to consider the various departments and positions that will be needed to operate efficiently. This includes roles such as:

- Management team: Determine the key leadership positions needed, such as a CEO, COO, and CFO, who will oversee the overall operations and strategic decision-making.

- Production team: Hire skilled professionals who are experienced in the manufacturing process of concrete blocks, including machine operators, quality control technicians, and maintenance personnel.

- Sales and marketing team: As this business heavily relies on building relationships and promoting the benefits of concrete blocks, it is crucial to have a dedicated sales and marketing team to handle customer acquisition, lead generation, and brand promotion.

- Administrative staff: Support the day-to-day operations by hiring administrative staff who can handle tasks such as accounting, human resources, and customer service.

To effectively manage your staffing requirements, consider the following tips:

Assess Skills and Experience:

Consider future growth:, provide training and development:, delegate responsibilities:.

By outlining the organizational structure and staffing requirements for your concrete block business, you can ensure that you have the right people in the right positions to drive success and meet the demands of your target market.

Analyze The Costs Associated With Equipment, Raw Materials, And Initial Setup

Before starting a concrete block manufacturing business, it is essential to analyze the costs associated with equipment, raw materials, and initial setup. This analysis will help in determining the overall investment required for setting up the business and ensure that all necessary resources are available.

The first cost to consider is the expense of purchasing or leasing the necessary equipment for manufacturing concrete blocks. This may include concrete block making machines, mixers, molds, and other tools and equipment. It is crucial to research and compare prices from different suppliers to find the most cost-effective options that meet the required quality standards.

In addition to equipment costs, the analysis should also include an assessment of the raw materials needed for producing concrete blocks. This typically includes cement, sand, and gravel. Researching local suppliers and obtaining quotes will help determine the ongoing cost of these materials and ensure a reliable supply chain.

Furthermore, the initial setup costs should be considered, such as the cost of land, construction of a facility or warehouse, and utilities. These costs can vary significantly depending on the location and size of the business. Engaging with real estate agents or conducting market research on property prices will provide insights into the investment required for the initial setup.

- Research and compare prices for necessary equipment from different suppliers to find cost-effective options.

- Obtain quotes from local suppliers to determine the ongoing cost of raw materials.

- Engage with real estate agents or conduct market research to estimate the cost of land and construction.

- Consider any utility costs associated with the manufacturing facility.

- Consider purchasing used equipment in good condition to reduce costs.

- Explore the possibility of leasing equipment instead of buying, particularly for startup businesses.

- Develop relationships with reliable suppliers to negotiate better prices for raw materials.

- Consider the option of outsourcing certain aspects of the manufacturing process to reduce setup costs.

Develop A Pricing Strategy Considering Market Competition And Profit Margins

In order to develop an effective pricing strategy for your concrete block business, it is crucial to consider both market competition and profit margins. This will ensure that your pricing is competitive enough to attract customers while also allowing your business to generate a profit.

Market Competition:

- Research and analyze the pricing strategies of your competitors. This will give you insight into the current market rates for concrete blocks.

- Consider the unique selling points of your business, such as the quality of your blocks or any additional services you offer. This can allow you to justify charging a higher price than your competitors.

- Keep an eye on the market trends and adjust your pricing strategy accordingly. For example, if demand is high and supply is limited, you may be able to increase your prices.

Profit Margins:

- Calculate your costs accurately, including expenses related to raw materials, equipment, labor, and overhead.

- Determine the profit margin you would like to achieve for your business. This will depend on factors such as your business goals and the level of competition in the market.

- Take into account any discounts or promotional offers you may need to provide to attract customers. This should be factored into your pricing strategy.

- Regularly review and analyze your pricing strategy to ensure that it is helping you achieve your desired profit margins. Adjustments may be necessary as market conditions and costs change over time.

- Consider offering different pricing tiers or packages to cater to different customer segments.

- Monitor customer feedback and market demand to gauge the effectiveness of your pricing strategy.

- Regularly benchmark your pricing against your competitors to ensure you are staying competitive in the market.

Define Marketing And Sales Strategies To Reach Potential Customers

Defining effective marketing and sales strategies is crucial for reaching potential customers in the concrete block industry. By understanding your target market and their specific needs, you can tailor your approach to effectively promote your products and differentiate yourself from the competition.

1. Identify Your Target Market: Before developing your marketing strategy, it is essential to identify your target market. This could include construction companies, home builders, contractors, or even individual customers who may require concrete blocks for various projects. Understanding their needs, preferences, and purchasing behavior will help you design effective marketing campaigns.

2. Create a Strong Brand Identity: Building a strong brand identity is essential for establishing credibility and standing out from competitors. Develop a compelling brand message and visual identity that clearly defines your business and its unique selling proposition. Consistency across all marketing materials, including your website, logo, and packaging, will enhance brand recognition and customer trust.

3. Develop a Multi-Channel Marketing Strategy: Utilize a combination of online and offline marketing channels to reach your target market effectively. This can include creating a professional website, leveraging social media platforms, attending industry trade shows and events, and distributing informative brochures or catalogs to construction companies and builders.

4. Demonstrate Product Value: Educate your potential customers about the benefits of using concrete blocks in their building projects. Highlight the strength, durability, and energy efficiency of your blocks compared to other options. Providing case studies, testimonials, and data that demonstrate the value and quality of your products will help gain customer confidence and loyalty.

5. Offer Superior Customer Service: Customer service plays a crucial role in building long-term relationships with your customers. Ensure your sales team is knowledgeable, friendly, and responsive to inquiries. Promptly address any concerns or issues raised by customers, and strive to exceed their expectations at every interaction.

- Utilize search engine optimization (SEO) techniques to improve online visibility and drive organic traffic to your website.

- Consider offering special promotions or discounts to incentivize potential customers to choose your concrete blocks over competitors.

- Network and build relationships with key industry influencers, such as architects and contractors, who can recommend your products.

- Invest in professional photography and create visually appealing content to showcase your products on your website and marketing materials.

By defining effective marketing and sales strategies, you can effectively reach potential customers in the concrete block industry and position your business for success. Remember to continuously evaluate the effectiveness of your strategies and make necessary adjustments to stay competitive in the market.

Assess Regulatory Requirements And Obtain Necessary Permits And Licenses

When starting a concrete block manufacturing and distribution business, it is essential to understand and comply with the regulatory requirements in your area. This ensures that you operate legally and avoid potential penalties or disruptions to your operations. Below are some important steps to consider when assessing regulatory requirements and obtaining necessary permits and licenses:

- Research Local Regulations: Begin by researching the specific regulations and requirements for concrete block manufacturing and distribution in your local area. This may include zoning and land use regulations, environmental regulations, health and safety standards, and building codes. Understanding these regulations will help you determine the necessary permits and licenses you need to obtain.

- Identify Permit and License Requirements: Once you have a clear understanding of the local regulations, identify the specific permits and licenses you need to operate your business. This may include a business license, building permit, environmental permits, and occupational licenses, among others. Contact the relevant government agencies or consult with a business advisor to ensure you have a comprehensive list of requirements.

- Application Process: Familiarize yourself with the application process for each permit and license. This may involve completing application forms, providing supporting documents, and paying fees. Pay close attention to any deadlines or additional requirements that may be necessary.

- Engage with Regulatory Authorities: Reach out to the appropriate regulatory authorities to discuss your business plans and seek guidance on the application process. Building a positive relationship with these authorities can help streamline the process and ensure you obtain the necessary permits and licenses in a timely manner.

- Comply with Health and Safety Standards: Concrete block manufacturing involves working with heavy machinery and potentially hazardous materials. It is crucial to prioritize health and safety in your operations to protect your employees and mitigate potential risks. Familiarize yourself with the relevant health and safety regulations and ensure you implement appropriate measures and training programs.

- Consider consulting with a legal professional or business advisor who specializes in regulatory compliance to ensure you have a thorough understanding of the requirements.

- Start the permit and license application process well in advance to allow for any potential delays or unforeseen challenges.

- Maintain accurate records of all permits and licenses obtained, ensuring they are renewed or updated as required.

- Stay informed about any changes or updates to the regulatory requirements in your industry to ensure ongoing compliance.

- Do not hesitate to seek clarification or ask questions from the regulatory authorities to ensure you fully understand the requirements and expectations.

Create A Financial Plan And Secure Funding For Startup Costs

Creating a comprehensive financial plan is crucial to the success of your concrete block business. This plan will outline your projected revenue, expenses, and profit margins, providing a roadmap for your company's financial future. It will also serve as a valuable tool when seeking funding from investors or lenders.

To start, you'll need to research and estimate the costs associated with starting your business. This includes expenses such as equipment, raw materials, labor, permits, licenses, and marketing. Be sure to account for any ongoing costs to sustain your operations until you start generating steady revenue.

Additionally, research potential funding options that align with your financial needs and goals. This can include traditional sources such as banks and credit unions, as well as alternative financing options like small business grants or angel investors.

- Consider creating a detailed budget that outlines your anticipated expenses and funding sources. This will help you assess your financial needs and determine how much funding you require to launch your business.

- When approaching potential investors or lenders, be prepared to present a compelling business plan that demonstrates the profitability and growth potential of your concrete block business. Highlight key financial projections, such as revenue forecasts and return on investment.

- Consider seeking advice from financial professionals or consultants who specialize in business startup financing. They can provide valuable insights and help you navigate the funding process.

- Remember to continuously monitor and update your financial plan as your business progresses. This will allow you to make informed decisions and adjust your strategy as needed.

Tips for creating a successful financial plan and securing funding:

- Be realistic with your financial projections and avoid overestimating revenue or underestimating expenses.

- Consider starting small and gradually expanding your operations to minimize financial risks.

- Prepare a solid marketing and sales strategy to demonstrate your ability to attract customers and generate revenue.

- Seek feedback from industry experts or mentors who can provide valuable insights into the financial aspects of your business.

- Stay organized and keep thorough records of your financial transactions to instill confidence in potential investors or lenders.

In conclusion, writing a business plan for a concrete block manufacturing and distribution company involves several crucial steps. By identifying the target market, conducting market research, determining the size and scope of operations, outlining the organizational structure, analyzing costs, developing a pricing strategy, defining marketing and sales strategies, assessing regulatory requirements, and creating a financial plan, entrepreneurs can set themselves up for success in this industry.

By following this 9-step checklist, concrete block manufacturers can ensure that their business is well-planned, strategically positioned, and financially viable. It is essential to consider market demand, competition, operational needs, and regulatory compliance to achieve long-term success.

With a strong business plan in place, entrepreneurs can confidently secure funding, attract customers, and navigate the competitive landscape of the concrete block industry. By focusing on quality control, efficiency, and effective marketing strategies, businesses can position themselves as trusted suppliers of high-quality, durable, and energy-efficient concrete blocks.

$169.00 $99.00 Get Template

Related Blogs

- Starting a Business

- KPI Metrics

- Running Expenses

- Startup Costs

- Pitch Deck Example

- Increasing Profitability

- Sales Strategy

- Rising Capital

- Valuing a Business

- How Much Makes

- Sell a Business

- Business Idea

- How To Avoid Mistakes

Leave a comment

Your email address will not be published. Required fields are marked *

Please note, comments must be approved before they are published

Sample Concrete Block Making Business Plan

Do you need help starting a concrete block making company? If YES, here is a sample concrete block manufacturing Business Plan.

One of the basic needs of humanity is shelter. Every human being sees it as a necessity to have a roof over their head.

This explains why there is always a demand for shelter.

To meet this demand you will need to build houses, to build houses, you will need concrete blocks. The point I am driving at is that concrete block making business is a very lucrative business that you can consider doing.

However, as profitable as concrete block making business is, if you don’t know the right steps you need to take when you are starting it, you might not be able to profit from it. This is why it is essential to have a good knowledge of the business.

You need to know about the basic requirements, the equipment and the materials you will need, the risks involved and the right way to go about it. All of these and even more will be duly addressed in this article. Take your time to go through it.

CONCRETE BLOCK MANUFACTURING BUSINESS PLAN SAMPLE

A concrete block business is crucial to the building industry. If you have a strong desire to float your business, this concrete block industry business plan sample will be beneficial to you. You may have been influenced by one or more factors.

Whatever the case is, you need to have an understanding of the inner workings of the industry before you set sail.

It is assumed that at this point, you have done your study of what is required. All you need to do is put this into a definite plan. We are out to help you do this through this sample.

Many entrepreneurs don’t consider starting a concrete company when looking to start a business. Maybe because the business is not that common and popular like other businesses. If you are an entrepreneur with some civil engineering experience, you can start a concrete company.

For you to be able to venture into the construction industry, you will need to be very bold, self-motivated and creative as the industry is filled with talented craftsmen of which many are highly trained personnel.

Do you want to start a concrete company? Have you worked in a concrete company before? Working in a concrete company for years is a must if you want to start and succeed in the business. If you have no knowledge about the business and have not worked in a concrete company before, I will advise you to reconsider your action.

There is no magic about it. There is no way you can achieve success in a concrete company if you have not worked in that line before. Please, if you know you are the person I am talking to, kindly bookmark this post, close it and go work in a concrete industry for at least 5 years and learn whatever you need to learn to get yourself armed with necessary information.

Here is a sample business plan for starting a concrete block manufacturing company.

- A Detailed Concrete Business Plan

If you have done your homework, you should know by now that a business plan is a must-have resource for this business. A good business plan will let the entrepreneur see all of the details regarding the business.

Your business plan must include your startup cost, location, number of employees and their qualifications, marketing strategies, equipment that will be needed and their costs, etc.

One other good thing about a business plan is that investors and lenders will take you seriously and will consider funding your business.

- Source for Materials for the Concrete Company

One important aspect of the business is the materials you will use for your concrete. You must go out and shop for reliable suppliers and their prices. Choose a supplier that delivers good quality and must not disappoint.

The last thing you would ever want in your business is having a project delay because your supplier is yet to deliver the materials needed for the work to start.

If it happened, it will spoil your company’s name and your client won’t want to contact your company next time.

- Apply for Concrete Company License

This is also important when starting a concrete company. No client will want to work with you if you are not government approved. You must be a licensed contractor to be able to win contracts.

All paperwork must be taken care of starting from registering your company’s name to getting every necessary document and getting a concrete company license before you start operation. It is advisable to go to the local authorities and fulfill the requirement. It may be a lot of work but it is necessary.

- Choose a Location

The subject of the location should even be on your mind at the start of thinking about starting this business. The place you choose to site your concrete company should be a place that will be convenient for your clients and also close to where you can get raw materials for work.

The place must also be big enough to be used as a workplace for your workers and also to store materials. You can take a look at your competitors and get an insight into a good place to site your company.

- Build and Grow your Network

To grow your concrete company, you will need to network with other entrepreneurs in the concrete business by joining an association of concrete contractors. This will grow your business credibility, and as a member, you will have access to reliable suppliers and other contractors who may be able to refer you to potential clients to help you get started.

Establishing your network also entails you work with other concrete companies as a subcontractor. This way, you can build a portfolio for your company and have something to show potential clients.

- Buy the Right Equipment

You can’t work without equipment. Equipment you will need includes but not limited to are;

- Trucks (at least 2).

- Concrete Mixer

- Concrete Cleaners

- Spreaders and Tampers

- Concrete forms and Concrete Molds

These are some equipment that you will be needing to run a concrete company effectively.

- Get the Right Employees

In the concrete company, we have two types of employees. There are the administrative staff and the field workers or engineers. The administrative staff is the ones that take care of the paperwork. They should be intelligent and qualified for the job.

Also, your field workers must be professionals and skillful too. You must find the right team to work with if you will want to achieve success in the construction industry. Getting the right squad is an important factor you must be in mind.

- GET STARTED

After taking all the necessary steps listed above, the next requirement you will need to start your concrete block making business is capital. So, you must find a means to raise capital. When you have the capital, you can then get a suitable location and purchase the necessary equipment and materials you will need.

Some of the equipment you will need are concrete block molder, concrete mixer, and concrete block mixing machine, a stand by generator, block carriers, a borehole for water supply, a delivery vehicle, wheelbarrows, and head pans.

You will also need some materials like cement and sharp sand. After getting all these, the next thing is to employ competent and highly skilled workers to use the block making machine and then set the ball rolling. If you take these necessary steps, especially the step that involved getting the needed skill, there is a high possibility that your concrete block making business will succeed. So please, don’t ignore any of the steps I talked about. In fact,

I will suggest that you even do further research to learn more about the concrete block making business as there is more to it than what I have written.

CONCRETE BLOCK MANUFACTURING BUSINESS PLAN EXAMPLE

By using this as a guide, you will put together a plan that is easy to follow and implementable.

- Executive Summary

CornerStone LLC is a concrete block industry in Indiana that produces different sizes and shapes of concrete blocks and bricks primarily for the building industry. To take off on the right note, we have done a market survey and feasibility study. There is a lot of potential for our business. Although there is strong competition, our knowledge of this industry places us at an advantage.

Cornerstone is founded by Carl Colton and Geoffrey Martins, a Civil Engineer and Quantity Surveyor respectively.

They both have a combined 40 years of experience. This partnership is strategic as we will tap into the experience and expertise of our founders and workforce in penetrating a huge concrete block market.

- Our Products

Our products consist mainly of concrete blocks and bricks. These will come in different sizes as well as shapes to meet the demands of our clients. We are open to any innovation and changes that may arise in the future.

We any challenge and will quickly adapt to these changes immediately there is a shift in customer preferences. This allows us to remain relevant in the industry.

- Vision Statement

Our vision is to be among the leading and well-known concrete block brands in Indiana. To attain this height, we will set out to ensure that all our products meet the highest standards. Our customer care and after-services will be exceptional to endear us to our valued clients.

- Mission Statement

Our mission is to build a thriving business that will not only focus on profits but on providing solutions to building problems. We have modeled our business in such a way that it allows us easily adapt to innovation. We will also treat our clients on an individual basis as a way of providing greater satisfaction.

- Start-up Funding

We have pooled resources together towards achieving our long-term dream of setting up a formidable concrete block industry. Over 10 years, our founders Carl Colton and Geoffrey Martins have saved up the sum of $500,000.00 together.

An additional $300,000.00 will be raised through bank credit towards realizing our business. The sum $500,000.00 will go into the purchase of equipment, materials and other concrete block making machines.

We will also be renting a space for this purpose. The remaining sum of $300,000.00 will be used as running costs during a 3 to 5 month period until the business stabilizes.

- SWOT Analysis

We have hired reliable hands to analyze strengths, weaknesses, opportunities, and threats. The results obtained will influence our operations. We seek to streamline our efforts towards driving growth and reducing our risk exposure to the barest minimum. The following are the findings;

At Cornerstone LLC, our strength lies in our deep understanding of the housing market. The significant years of experience and expertise of the founders place us at an advantage to navigate our business to growth and profitability. We have also ensured that our staff meets our minimum qualification which is at least 5 years of experience in the concrete block industry.

This includes administration, production, marketing, and sales personnel. These are areas of strength that distinguish us from most concrete block businesses.

We are a new business with limited funding. This puts us at a disadvantage compared to major concrete block businesses that control a large share of the market. These also have huge financial resources at their disposal.

- Opportunities

There is currently an ongoing housing boom in Indiana that is predicted to last for over a decade. This presents us with significant opportunities for growth as there will be a steady demand for our concrete block products. We will exploit this opportunity in growing our business and establishing a reliable and solid brand.

Threats are ever-present reality businesses have to deal with. At Cornerstone LLC, we realize this and have identified ours. These threats come in the form of a recession. The housing bubble sparked by the financial meltdown of 2008 saw a crash in the value of mortgages. In the event this happens again, the negative impacts will reverberate across the industry and will directly affect the concrete block industry.

- Sales Projection

The market survey reveals the potential for rising demands for our products. Using available information obtained through an examination of demand and supply and the cost of goods and services, we have drawn a three-year sales projection for our business as follows;

- First Financial Year $500,000.00

- Second Financial Year $900,000.00

- Third Financial Year $1,400,000.00

- Target Market

We have identified our target market and it consists mainly of service construction companies. We have entered into talks with contractors that have resulted in agreements for the supply of our concrete block products. We have identified the required minimum standards and seek to attain these standards through the best means possible.

- Competitive Advantage

There has been a rising level of competitiveness in the concrete block industry. To attain and maintain a significant level of profitability, our experience in this industry will be of much benefit. We have a team that understands just how the industry works and where to concentrate our efforts.

Another advantage we have is our capacity to easily adapt to innovation. We have set in motion strategies that will enable us to switch our production efforts once there is a high demand for a new product.

- Marketing Strategies

Our marketing team is made of experts that have a deeper level of understanding of the forces of demand and supply.

We have also established a strong and valuable network with industry influencers. These enable us to adapt our services and products to suit rising demands. Our marketing department will continually develop the most effective strategies for creating an increased presence and reputation.

Having gone through our concrete block industry business plan sample, you can see that the steps highlighted are indispensable to produce a good plan. Following this format, you can carefully create a plan that is unique to your business and meets the best standards.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

- Blocks Making Machines

Business Plan Development for a Block Manufacturing Venture

- Business Plan Development for a…

Developing a comprehensive business plan is a critical step in launching a successful block manufacturing venture. A well-crafted business plan serves as a roadmap, providing a clear outline of your business goals, strategies, and financial projections. Below is a guide to help you structure and develop a robust business plan for your block manufacturing venture:

### Executive Summary:

1. **Business Name and Overview:** – Provide the name of your block manufacturing business and a brief overview of your venture.

2. **Mission Statement:** – Define the mission and vision of your business, outlining your long-term goals and values.

3. **Business Concept:** – Explain the concept behind your block manufacturing venture, highlighting the products you will produce and the market you intend to serve.

### Business Description:

1. **Company Overview:** – Provide details about the legal structure (e.g., LLC, corporation) and location of your block manufacturing business.

2. **Founding Date and Current Status:** – Specify when your business was founded and its current operational status.

3. **Founders and Management Team:** – Introduce the founders and key members of the management team, highlighting their relevant experience and roles.

4. **Facilities and Equipment:** – Describe the facilities and equipment you plan to use for block production, including their capacity and capabilities.

### Market Analysis:

1. **Industry Overview:** – Provide an overview of the construction materials industry, with a focus on the demand for concrete blocks.

2. **Target Market:** – Define your target market, including geographical areas and specific customer segments.

3. **Competitor Analysis:** – Conduct a thorough analysis of competitors in the block manufacturing industry. Identify their strengths, weaknesses, and market share.

4. **SWOT Analysis:** – Perform a SWOT analysis (Strengths, Weaknesses, Opportunities, Threats) for your block manufacturing business.

### Products and Services:

1. **Product Description:** – Detail the types of concrete blocks you plan to manufacture, including sizes, shapes, and any unique features.

2. **Quality Standards:** – Outline the quality standards and specifications that your blocks will adhere to.

3. **Customization Options:** – Describe any customization options or specialty products your business may offer.

### Marketing and Sales Strategy:

1. **Branding and Positioning:** – Explain how you will position your block manufacturing business in the market and establish a strong brand.

2. **Marketing Channels:** – Outline the channels you will use to reach your target market, including online and offline strategies.

3. **Sales Tactics:** – Detail your sales approach, including pricing strategies, promotions, and distribution channels.

4. **Customer Acquisition:** – Describe your plan for acquiring and retaining customers in the competitive construction materials market.

### Operations Plan:

1. **Production Process:** – Provide a detailed overview of the block production process, from raw material sourcing to packaging.

2. **Technology and Equipment:** – Specify the technology and machinery you will use, detailing their features and capabilities.

3. **Supply Chain Management:** – Outline your supply chain, including sources for raw materials and relationships with suppliers.

4. **Quality Control:** – Explain your quality control measures to ensure the consistency and reliability of your blocks.

### Financial Plan:

1. **Startup Costs:** – Detail the initial investment required for land, construction, machinery, permits, and other startup expenses.

2. **Revenue Projections:** – Provide detailed financial projections, including sales forecasts, expenses, and net profit over the next 3-5 years.

3. **Funding Requirements:** – Specify if you are seeking funding and outline how the funds will be used.

4. **Break-Even Analysis:** – Perform a break-even analysis to determine the point at which your business becomes profitable.

### Risk Analysis:

1. **Identify Risks:** – Identify potential risks and challenges that may impact your block manufacturing venture.

2. **Mitigation Strategies:** – Develop strategies to mitigate identified risks and ensure business continuity.

### Appendices:

1. **Supporting Documents:** – Include any additional documents, such as resumes of key team members, legal agreements, permits, or market research data.

### Conclusion:

Your business plan should be a dynamic document that evolves as your block manufacturing venture progresses. Regularly revisit and update your plan to reflect changes in the market, technology, and your business environment. A well-prepared business plan not only serves as a roadmap for your venture but also becomes a valuable tool for attracting investors, lenders, and potential business partners.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Post comment

Concrete Block Business Plan

Learn about our concrete block business plan by using our business planning tool.

Need help? +45 97 17 16 66

Done For You Business Plans

This article is for people wishing to purchase a concrete batching plant and plan to make the correct purchase decision. We have also completed some done for you business plan examples.

Click on a links below to review them:

- Interlocking business plan – net profit of >£400k

- Recycled concrete building block business plan – net profit of >£2m

How To Create Your Business Plan

Interlocking block business plan.

Concrete interlocking blocks are very popular can be used for many construction structures. For example material bays, retaining walls, buildings, temporary structures, for example, piling mats.

Executive Summary

By selling the interlocking blocks as retaining walls, you can add value by selling them as a solution rather than a commodity.

The business plan casts seventy interlocking blocks per day. The quantity of concrete is 50 m3 per day.

The batching plant we have selected is the 1200 model with a capacity of 15 m3 per hour. The daily output is 120 m3.

The extra capacity can produce other pre-cast concrete products or be sold by supplying concrete to construction sites and creating a concrete to collect business.

The breakeven volume of concrete to be sold each day is 16% of capacity.

When the plant runs at 50% capacity, the net profit with finance is £370,000 and without finance £428,000. You can review the table below to see the full range of capabilities and net profits.

To see how the business planning tool works, watch the video above.

The Done For You Business Plan

The done for you business plan is built up using a spreadsheet we have developed to make the process simple and easy. It can take just ten minutes to complete if all the data we need is at hand.

The business plan is based on the UK market and uses pounds as the currency. The business plan can be adjusted to use any currency and any market data.

The capacity we have allowed for the done for you business plan is 50%. We wanted to make a realistic business plan that can be developed over a period of time to deliver higher profits.

Profit & Loss

- Sales = £1,572,000

- Cost of sales = £961,200

- Gross Profit = £610,800

- Overhead = £186,024

- Net profit =£424,776

Variable Costs

The variable costs within the business plan are the costs of materials; these are mainly cement, sand, aggregate and chemicals. The business plan uses the cost to produce the concrete from the sales cost to give the variable cost. We have included a calculator to work out the cost for various concrete design strengths for accuracy.

The plant list includes everything you need to manufacture large quantities of interlocking blocks.

- FS1200 batching plant

- 25-ton cement silo

- Concrete elevator

- Second-hand forklift truck

- Second-hand bucket loader

- 30 600 x 600 x 1800 moulds

- 30 800 x 800 x 1600 moulds

- 10 600 x 300 x 1800 moulds

- Mould magnets, lifting bolts

- Lifting clamp

- Block turner

The plant list is costed out to allow us to work out the monthly finance required to purchase it. The monthly finance is then added to the overhead within the business plan.

The business will need people to run it. We have allowed for:

- One sales manager

- One transport and admin manager

- Three operatives to make the blocks and produce concrete.

As more capacity is added to the business plan, more operatives can be added.

The overhead sheet adds the people section automatically. We have then added overhead costs to run the business, such as fuel, office rent, marketing, banking, and finance. The overhead costs can be adjusted to suit your business.

The sales section of the business plan is the ultimate test to see if the plan will work.

It is vital that we know the market and the prices the market can take for the products and services being sold.

The model’s sales prices are based on the UK market and are accurate at the time of producing the plan. (2021)

From experience, we know each country is different, and the margin on concrete is different. We have designed our business planning tool to allow you to see if you can develop a good business in your country. We are here to help you.

What to do next

The next step is to review some of our done for you business plans and complete the form on the page or this page. We will then get in touch with you, and we can complete your business plan together. It usually only takes 30 minutes if you have all the information at hand.

Your Fibo Business Consultant

Hi, My name is Martin Fischer. I am more than happy to go through the business planning process with you. Why buy a plant if it does not earn you money?

Complete this form, and I will make time to help you develop a sustainable concrete business plan. We are an international business and can speak many languages. I am looking forward to our call.

Thanks, Martin.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.

Let's find the best solution for your project.

Fibo Intercon

A leading partner and supplier to the global concrete industry..

Fibo Intercon can design and supply a large range of concrete solutions for you. Let us help you find the best solution for your project.

- Concrete block machine

- Brick making machine

- Hollow block machine

- Paving block machine

- OUR REFERENCES

Hollow Blocks Business Plan

The hollow blocks business plan has gained immense popularity in recent times, not just within our country but also across the globe, particularly among those aspiring to establish a profitable business in the construction industry. Presently, the market for building materials is witnessing significant growth and there are new types of concrete blocks that are more efficient and cost-effective.

In this article, we will present a comprehensive and profitable business plan for the production of hollow blocks. It is a complementary piece to the main article on hollow block machines , which highlights the technical and operational aspects of concrete hollow blocks and the machines used in their production. By referring to this plan, prospective private developers or entrepreneurs can effectively select the required equipment based on their specific requirements and goals.

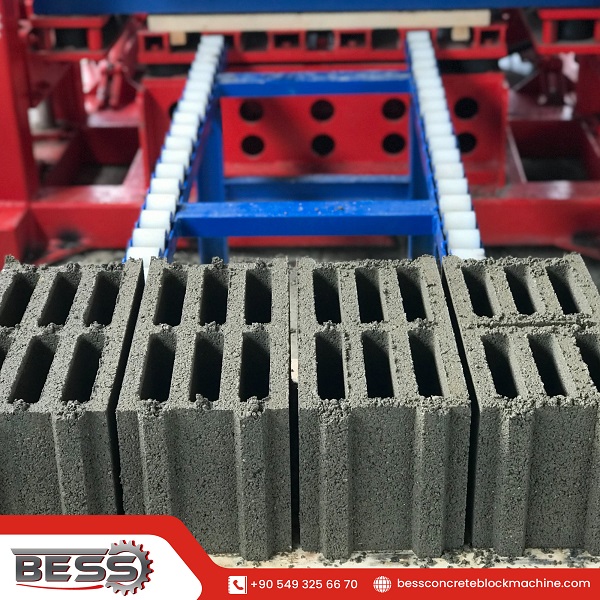

When establishing a business in this field, entrepreneurs can expect to encounter minimal complexities, as the production technology is straightforward, and the finished product can easily obtain mandatory certifications. This advantage leads to reduced investments and reduces challenges associated with marketing and product promotion to a minimum. The concrete block machine serves as the primary equipment for manufacturing various building materials from concrete. These materials are hollow blocks, solid blocks, styrofoam concrete blocks, paving blocks, curbstones, and other decorative products.

The Hollow Blocks Business Plan Includes The Following Items

* Market analyses for the concrete products

* Business plan for the production process

* Purchasing concrete hollow blocks machine

* Production technology

* Calculation of profit of the enterprise

You especially need to answer these questions for this business. Why do you choose this particular line of activity? What is the advantage of a hollow blocks production business? Concrete hollow blocks are a fairly popular material in construction. Demand for it increases significantly during the construction season. This is due to the following factors:

- Affordability: Hollow blocks have a lower price compared to other construction materials, making them highly demanded for the construction of cost-effective country houses.

- Lightweight nature: Hollow blocks, depending on the raw materials used, are lighter than alternative construction materials. This advantage reduces the total weight of the building.

- Environmentally friendly: These special concrete hollow blocks are manufactured using only cement, sand, water, and various additive materials, without the inclusion of harmful chemicals. This ensures their environmental friendliness.

- Effective insulation: With low thermal conductivity, hollow blocks contribute to reducing heating costs in houses or rooms by approximately 20-30%. This eliminates the need for additional expenses on heat-insulating materials.

Block Making Machine Details

For producing good quality hollow blocks, you need to purchase any kind of high-quality concrete hollow blocks making machine.

What equipment will be needed for the production of hollow blocks :

- Hollow block making machine

- Concrete mixers

- Aggregate hopper for raw materials such as cement, sand, water, and additives

- Conveyor belts for transferring the materials into the mixer

- concrete block mold

- supplying raw materials, water, and cement

Production Process Of Concrete Hollow Blocks

The production process of concrete hollow blocks consists of three main stages:

- Mixture Preparation: In this initial stage, different raw materials are combined and mixed in a concrete mixer to create mortar. The mixer blends the ingredients thoroughly to ensure a homogeneous mixture.

- Block Production: The second stage involves the actual production of the blocks. This is achieved using either semi-automatic or automatic concrete hollow block machines. These machines are capable of efficiently shaping and forming the blocks according to the desired specifications.

- Curing and Storage: The final stage entails curing and storing the produced blocks. Once the concrete hollow blocks are ready, they are transferred to a designated area for the curing process. After curing, the blocks are then stored until they are ready to be transported or used in construction projects.

After thoroughly mixing the mixture, it is important to pour it into the machine and activate the vibration and pressure. This ensures that the mixture is evenly distributed within the molds. As the concrete shrinks, additional portions of the mixture should be added until the molds are completely filled. Once the concrete has sufficiently shrunk, the molds can be removed, leaving the finished blocks on the pallet or a suitable surface. At this stage, a new batch of mixture can be poured in the molds.

Drying the blocks needs to be given a separate time: the first 24 hours the blocks dry as they were left after the machine. During drying, they sometimes need to be moistened with water, like any concrete product. After a day, the blocks are turned on their side and dried for another 24 hours. After 2 days, they can be stacked on pallets. further details are provided in brick making machine article. also, the prices of the machine are included.

Curing the blocks requires a separate period of time. Initially, the blocks are left to dry for the first 24 hours in the same position as they were left after the molding process. During the curing period, it may be necessary to occasionally moisten the blocks with water, as is common for concrete products. After one day, the blocks are collected from the pallets and dried for an additional 24 hours. After a total of two days, the blocks can be stacked or sold. More detailed information can be found in the brick making machine article, including pricing details.

When developing a hollow blocks business plan, a crucial decision arises regarding the choice of the hollow blocks machine to purchase. In our company, we specialize in manufacturing and currently offer a range of machines designed to cater to aspiring entrepreneurs entering the hollow blocks business. Our machines provide different options, ensuring that customers can select the most suitable one for their needs.

All of our machines possess the capability to produce a wide variety of concrete stone products, including concrete hollow blocks, paving blocks, curbstones, and more. By simply changing the mold, it becomes possible to manufacture different types of concrete stone products. As demonstrated, one of our automatic concrete hollow blocks machines showcases remarkable versatility by being able to produce nearly all kinds of concrete stone products.

As you embark on your hollow blocks business journey, our company stands ready to provide the necessary machinery, allowing you to explore diverse product offerings and seize opportunities in the market.

If you need to produce double-layer paving blocks with color, you will need double-hopper block making machines. This machine is called a paving block machine and they are categorized differently. These machines are a little more expensive than normal machines. you can read further details in its own article paving block machine .

The Advantages Of The Hollow Block Making Machine

* We are using high-quality materials for the concrete block machine.

* According to your demand you can buy any kind of machine-like full or mini plant, for each machine which we are producing in our company.

* We have different automation for the machines, semi-automatic or automatic.

* All machines are capable to produce almost all kinds of concrete stone products just enough to change the mold.

* High productivity - the machines can produce concrete hollow blocks, paving blocks, curbstones, and others.

*For more videos you can visit our youtube channel Bess Machine En .

It is strongly advisable to invest in high-quality hollow block machines when entering the hollow blocks business. By acquiring a reliable and reputable machine, you can ensure the production of concrete stone products without any deformations or cracks. If you choose to purchase any type of hollow block machine, it grants you the flexibility to manufacture various kinds of concrete stone products.

For more comprehensive information regarding our machines, we encourage you to reach out to us. We are readily available to provide all the necessary details, including technical specifications and pricing information. Our website also serves as a valuable resource where you can explore the range of machines we offer. As you embark on your hollow blocks business plan, rest assured that we are committed to assisting both new and experienced customers in finding the most suitable hollow block machine. The hollow blocks business presents itself as an ideal venture for individuals seeking a profitable and fitting opportunity.

OTHER ARTICLES

Bess manufactures concrete block machines, paving block machines and molds.Bess is an organization of the Beyazli Group of Companies. Bess has started its international business in 2007 and developed in a short time because of the high quality machines it produces, reasonable price compared to the quality and efficient aftersales system.

OTHER LINKS

- CONCRETE PAVING MACHINES

- HOLLOW BLOCK MACHINES

- FINGER CAR MACHINES

- COMPACT MACHINES

- CONCRETE PLANTS

- CRUSHING AND SCREENING PLANTS

RECENT ARTICLES

- Hand carrier / Semi-automatic system

- Forklift / Automatic system

- Hollow Block Models

- Paving Block Models

- Hollow Floor Block (Asmolen) Mould Models

- Curbstone Models

- Grasscrete Mould Models

Small To Medium AAC Blocks Manufacturing Business Plan

Is it profitable to open an AAC block manufacturing plant ? How long will I get a return from the initial investment? Is there any feasible business plan for starting an AAC block plant ? Many new starters in the building material industry are interested in these questions. In this article, we will discuss these most concerned aspects to help intended investors.

How much does it cost to set up an AAC block plant?

Several factors affect the price of setting up an AAC block plant such as the manufacturing process, the capacity of the plant, the equipment selection, the land cost, the raw materials, the labor cost, energy cost, etc. The annual capacity of a medium-scale AAC plant is 50,000 to 300,000 cubic meters. The cost of a small AAC block plant is about 100,000 wanyuan RMB . Here the small scale always refers to the AAC plant with an annual capacity below 50,000 cubic meters.

The expected profit of an AAC block plant

In terms of the current domestic market environment, the cost of each cubic AAC brick (including labor, electricity, and equipment depreciation) is about 90-120 yuan. The cost of the block varies according to raw material prices, and the selling price (ex-factory price) is between 180-260 yuan. Suppose the annual output is 100,000 cubic meters (300 days a year), the minimum profit is 90 yuan per cubic meter, then the profit is 30,000 yuan a day, and the profit of one year is 9 million yuan .

The business plan for a small to medium AAC block plant

There are several aspects needed to be taken into consideration when planning an AAC block plant. Before investing in the AAC production line, one should do some research. For example, the local raw material supply and the market demand greatly influence the cost and even decide if the business is profitable. If the raw material is short in future manufacturing, the rise of transportation cost is inevitable which leads to lower profit or even causes loss. The market demand is crucial because it decides the sales of end products AAC blocks. Other important aspects include the market capacity, the product life circle, the factory location, the production capacity, the machine selection, and the production process.

Raw material supply

The raw material is an important factor for reducing costs. The raw materials for an AAC plant mainly include fly ash, sand, lime powder, gypsum , etc. Choosing different raw materials or industrial solid waste tailings resources can effectively reduce the cost of raw materials in production. The distance to raw materials is the nearer the better. It is better not to beyond 100 km.

Site selection

The factory can be located in general industrial areas, or places with convenient transportation and superior water supply. The ideal place would be the ones that are near many construction projects including newly built and renovation of old houses. Especially the new development area, where AAC blocks are in large demand.

Land Investment

The land requirement for an AAC block plant varies depending on the production capacity. Take the small to medium-scale production plant for example, below is the required land estimation.

Manufacturing factory area: 20m (width)*60-100m (length)*6m (height)

Curing room: 300 m 2 -700 m 2

Total land area: 4000-10000 m 2

Energy consumption

It is planned to use a 380V/50HZ power supply for the construction of the aac block plant project, which must meet the power demand of this production line. The available cables can be introduced from trenches or overhead lines. The specific power depends on the actual situation. Below is an example of a small to medium AAC block production line:

Water consumption: 50-100 t/d

Electricity: 380V/50HZ

Total Power consumption: 150-300 Kw

Machine selection

Good technology and equipment can allow customers to obtain better profit margins. Fully automated equipment and high-end and sophisticated cutting saws can increase production and save a lot of labor and time, reduce the operating costs of enterprises, and greatly increase the profit margin of investment in the production of aerated brick equipment.

AAC block machines in a small AAC block plant

The AAC block machines mainly include the jaw crusher , the storage silos , the slurry tank , the pouring mixer , the cutting machine , the tilting table , the autoclaves , etc. The auxiliary equipment mainly includes the elevator, the trolley cart, the mold, the bottom plate, the broilers, the tilting crane, etc.

Autoclaved Aerated Concrete Market prospect survey

AAC block is a lightweight and efficient thermal insulation material widely used in the field of construction. As requirements for building energy saving are getting higher, the development prospect of aerated blocks is getting broader.

First of all, the autoclaved aerated concrete block has the characteristics of lightweight and good thermal insulation performance. It is much lighter in density than traditional insulation materials while also retaining heat better. Therefore, the AAC block can effectively reduce the energy consumption of buildings , and improve the energy-saving effect of buildings. Secondly, the construction of the AAC blocks is simple, which can reduce the labor intensity of the construction workers, shorten the construction period and reduce the construction cost. At the same time, the AAC block has good fire resistance, does not produce toxic gases, and is harmless to the environment and human health. In addition, the AAC blocks have broad application prospects. It can also be used to make construction materials such as building templates and insulation boards.

In the future, as people have higher requirements for building energy conservation, the market demand for AAC blocks will continue to increase. At the same time, with the continuous advancement of technology and the continuous improvement of production technology, the performance and quality of the AAC blocks will be further improved. Therefore, the development prospect of the AAC blocks is very broad. From the statistics of Allied Market Research, the global AAC blocks and panels market was valued at $19 billion in 2021 and is projected to reach $34.4 billion by 2031, growing at a CAGR of 6.2% from 2022 to 2031.

China National United Equipment Group Co., Ltd.

sALES rep PH +86 13683722138

No. 33, West Huangchenggen South Street, Xicheng District, Beijing, China

©2023-2025 China National United Equipment Group Co., Ltd. All rights reserved

Instant Download, Editable on Mac & Windows

Works with Excel & Google Sheets

- Executive Summary

- Products & Services

- Market Analysis

- Marketing Plan

- Management Plan

- Financial Plan

I. Executive Summary

Company description.

Solid Foundations Concrete Block Co. takes pride in providing high-quality, locally manufactured concrete blocks to cater to the booming construction industry in Austin, Texas. Our strategically located facility ensures efficient delivery of our products to meet the growing demand for urban development and infrastructure projects. With a focus on sustainability, our state-of-the-art machinery enables us to produce a variety of block sizes while minimizing our environmental footprint.

Our company offers exceptional turnaround times and personalized customer service, setting us apart from competitors. We target local and regional construction firms, real estate developers, and government entities for infrastructure projects. Our short-term goals include building strong partnerships and securing contracts, while our long-term goals involve expanding into new markets and investing in technology upgrades to streamline production and reduce costs.

The construction industry in Texas is facing a severe shortage of high-quality concrete blocks, resulting in delayed project timelines, inconsistent block quality, reliance on distant suppliers, and limited customization options. Existing suppliers struggle to meet the increasing demand, leading to significant challenges for contractors, developers, and retailers. This underserved market is in need of a reliable and efficient local supplier to address these critical pain points and provide a sustainable solution to the shortage of high-quality concrete blocks.

At Solid Foundations Concrete Block Co., we offer a comprehensive range of high-strength concrete blocks that address the diverse needs of the construction industry. With a focus on variety, customization, and rapid turnaround times, our products provide innovative solutions for construction projects of all sizes. Additionally, our commitment to sustainability and eco-consciousness sets us apart in the market, positioning our products as reliable, durable, and flexible solutions for residential, commercial, and industrial construction needs.

Mission Statement

At Solid Foundations Concrete Block Co., our mission is to provide the construction industry with high-quality concrete blocks, delivered with unparalleled speed and reliability. With a steadfast commitment to sustainability and personalized customer service, we aim to build enduring relationships with our clients and contribute to the development of a greener, more efficient construction sector.

Key Success Factors

- Strategic Location: Situating the manufacturing facility near urban growth areas for quick and reliable product delivery.

- High-Quality & Consistent Products: Ensuring that the concrete blocks maintain exceptional strength and uniform quality, setting them apart from competitors.

- Sustainable Practices: Embracing eco-conscious production methods to appeal to environmentally conscious consumers and businesses.

- Efficient Customer Service: Providing personalized support and rapid response times to nurture long-term client relationships.

- Flexibility in Production: Offering custom block sizes and make-to-order services to meet diverse construction needs.

Financial Summary

This section provides a snapshot of the projected financial performance and requirements for Solid Foundations Concrete Block Co.

The company anticipates the need for $4 million in initial funding to cover setup, equipment, and operational costs. Anticipated ROI stands at a strong 25% in 2024 , increasing to 30% in 2026 .

In summary, the financial outlook reflects a positive trajectory with increasing revenue, profitability, and return on investment over the next three years.

Funding Requirements

As a startup in the concrete block manufacturing industry, Solid Foundations Concrete Block Co. requires initial funding to cover setup, operational, and marketing costs. The funding will be pivotal in establishing a strong market presence, ensuring product quality, and enabling efficient business operations.

II. Products & Services

Problem worth solving.

The construction industry in Texas is currently facing a dire shortage of high-quality concrete blocks, causing significant challenges for contractors, developers, and retailers. The existing suppliers often struggle to meet the increasing demand for concrete blocks, leading to delayed deliveries, inconsistent block quality, and sourcing products from distant suppliers. This state of affairs has created a problematic situation for the local construction ecosystem in multiple ways:

- Extended Project Timelines: Due to delayed deliveries, construction projects are often prolonged, leading to increased costs and potential penalties for missing deadlines.

- Inconsistent Block Quality: Contractors and developers face issues related to the structural integrity and consistency of the concrete blocks, impacting the overall quality of their projects.

- Reliance on Distant Suppliers: With the lack of reliable local suppliers, contractors and retailers have to source concrete blocks from distant regions, incurring higher transportation costs and longer lead times.

- Limited Customization: The current suppliers often cannot fulfill custom orders within reasonable time frames, limiting the options available for unique project specifications.

Solid Foundations Concrete Block Co. aims to address these pain points by providing a sustainable solution to the shortage of high-quality concrete blocks in the local market. Our strategic location and commitment to efficient production will ensure quick and reliable delivery of products, addressing the current challenges faced by our target customer base. By understanding the specific pain points and challenges of our potential customers, we are committed to providing a comprehensive solution that elevates the overall standard of concrete block supply within the construction industry.

Our Solution

At Solid Foundations Concrete Block Co., our primary product offering is high-strength concrete blocks designed to meet the diverse needs of the construction industry. We have carefully engineered our products to address the specific needs of our target market and offer innovative solutions that set us apart from traditional block manufacturers.

- Variety of Sizes and Strength Grades: Our concrete blocks are available in a range of sizes and strength grades, allowing our customers to choose the most suitable option for their construction projects. Whether it's a small residential renovation or a large-scale infrastructure development, our diverse product line covers all requirements.

- Custom Order System: To further cater to the unique needs of our clients, we have developed a streamlined system for processing and fulfilling custom orders. This feature sets us apart from competitors and provides added value to customers requiring non-standard block specifications.

- Rapid Turnaround Times: Our state-of-the-art manufacturing process ensures quick production and distribution of our high-quality concrete blocks. This allows our customers to maintain project timelines and minimize construction delays, addressing a critical pain point in the industry.

Our products are not only innovative in their design and functionality, but they also emphasize sustainability and eco-consciousness, aligning with the growing demand for environmentally responsible construction practices. By manufacturing locally and employing green processes, we reduce the environmental impact of our operations while providing a unique selling point that resonates with our target market.

Real-world applications of our products include seamless integration into residential, commercial, and industrial construction projects. From foundation work to landscaping and infrastructure development, our concrete blocks offer reliability, durability, and flexibility, making them indispensable in various construction scenarios.

By offering a comprehensive range of concrete block solutions and incorporating sustainable practices, our products are well-positioned to capture a significant market share and meet the evolving needs of the construction industry.

Unique Selling Proposition

At Solid Foundations Concrete Block Co., our unique selling proposition lies in our unwavering commitment to delivering exceptional value to our customers. By analyzing and contrasting our offering with key competitors in the market, we have identified distinct advantages that set us apart in terms of price, quality, technology, customer service, and innovation.

- Competitive pricing with flexible volume-based contracts

- High-strength, consistent quality concrete blocks

- State-of-the-art machinery for precision manufacturing

- Personalized support and quick response to inquiries

- Sustainable production practices and custom block sizes

Development Stage and Future Plans

At present, Solid Foundations Concrete Block Co. is in the final stages of setting up the manufacturing facility and securing the necessary machinery and equipment. Extensive research and development have been conducted to ensure that our concrete blocks meet the highest standards of strength and quality. Initial testing phases have yielded promising results, and feedback from industry professionals has been overwhelmingly positive, citing the exceptional strength and consistency of our products.

The next critical phase will involve the commencement of production operations and the fulfillment of our initial orders. The team is focused on maintaining the quality and consistency of our concrete blocks while prioritizing efficient logistics and timely delivery. Customer feedback will continue to be a driving force in refining our processes and product offerings, ensuring that we consistently meet the needs and expectations of our clients.

The above timeline reflects the key milestones achieved and planned for the development of Solid Foundations Concrete Block Co. Each milestone represents a crucial step in our journey to establish a strong presence in the market and achieve our business objectives.

III. Market Analysis

The concrete block manufacturing industry is an integral part of the construction and infrastructure development sector, providing essential building materials for a wide range of projects. Understanding the dynamics and trends within this industry is crucial for the success of Solid Foundations Concrete Block Co.

- Industry Size: The concrete block manufacturing industry in the United States has an estimated market value of $3.4 billion, with an annual production volume of approximately 1.7 billion units.

- Growth Rate: Historically, the industry has experienced a steady growth rate of 3-5% annually, attributed to ongoing urbanization and the need for reliable building materials. Projections indicate a continuation of this growth trend over the next five years.

- Market Dynamics: Major trends in the industry include a shift towards sustainable and eco-friendly production practices, an increasing demand for high-strength and durable building materials, and a growing preference for locally sourced products to reduce transportation costs. Challenges within the industry revolve around the volatility of raw material prices, the need to adopt advanced manufacturing technologies, and the pressure to comply with stringent quality standards.

- Key Players: Leading companies in the concrete block manufacturing industry include national suppliers with extensive distribution networks, smaller regional manufacturers catering to local demands, and innovative companies prioritizing sustainable production methods.

- Regulatory Environment: The industry is subject to regulations related to environmental impact, workplace safety, product quality standards, and zoning restrictions for manufacturing facilities. Compliance with these regulations is essential for operational sustainability.

- Customer Segments: Primary customer segments within the industry encompass construction firms, real estate developers, infrastructure contractors, landscaping companies, and DIY enthusiasts. Each segment has unique requirements for concrete blocks based on project scale and specific applications.