Advertisement

Smart supply chain management in Industry 4.0: the review, research agenda and strategies in North America

- Original Research

- Published: 02 May 2022

- Volume 322 , pages 1075–1117, ( 2023 )

Cite this article

- Guoqing Zhang ORCID: orcid.org/0000-0003-0821-8787 1 na1 ,

- Yiqin Yang 1 na1 &

- Guoqing Yang 2 na1

26k Accesses

50 Citations

Explore all metrics

The emerging information and communication technologies (ICT) related to Industry 4.0 play a critical role to enhance supply chain performance. Employing the smart technologies has led to so-called smart supply chains. Understanding how Industry 4.0 and related ICT affect smart supply chains and how smart supply chains evolve with the support of the advanced technologies are vital to practical and academic communities. Existing review works on smart supply chains with ICT mainly rely on the academic literature alone. This paper presents an integrated approach to explore the effects of Industry 4.0 and related ICT on smart supply chains, by combining introduction of the current national strategies in North America, the research status analysis on ICT assisted supply chains from the major North American national research councils, and a systematic literature review of the subject. Besides, we introduce a smart supply chain hierarchical framework with multi-level intelligence. Furthermore, the challenges faced by supply chains under Industry 4.0 and future research directions are discussed as well.

Similar content being viewed by others

Supply chain disruptions and resilience: a major review and future research agenda

Artificial intelligence-driven innovation for enhancing supply chain resilience and performance under the effect of supply chain dynamism: an empirical investigation

Predictive big data analytics for supply chain demand forecasting: methods, applications, and research opportunities

Avoid common mistakes on your manuscript.

1 Introduction

Supply chains (SC) play a crucial role in manufacturing and service operations. Supply chain management (SCM), which is a systematic approach to managing flows of assets from sourcing raw materials, product manufacturing, to delivering to end customers significantly affects the business goals of the partners in supply networks. The wide disruptions due to the COVID-19 pandemic demonstrated the importance of supply chain flexibility and resilience. Thus, developing a resilient and smart supply chains is an indispensable yet challenging task for manufacturers and other stakeholders. The emergence of new (ICT) technologies, such as big data analysis, internet of things (IoT), blockchain, etc., makes it possible to develop smart supply chains.

Driven by new technologies (push) and the need for adapting to constantly changing markets (pull), Industry 4.0 provides a new platform for smart manufacturing and brings manufacturers close to customers (Lasi et al., 2014 ). Industry 4.0 can provide a cyber-physical system to integrate the customer needs into the different stages of manufacturing. Horizontal integration across the entire value creation network is one character of Industry 4.0 (Saucedo-Martínez et al., 2018 ). This entire value creation network is typically coincident with the supply chains. Thus, supply chain management is an important factor that impact the performance of the smart manufacturing under Industry 4.0. Supply chains should keep pace with Industry 4.0. Zhang ( 2015 ) indicated that smart manufacturing needs smart or even smarter supply chains for support since the supply chains affect the availability of the input for manufacturing, the interaction of multiple functions of production, the efficiency of the finished goods delivery to customers, and responsiveness of the network.

The smart supply chain (SSC) is to use advanced technologies, especially emerging ICT, to link the processes in the different partners of a SC to form an intelligent connected system (Wu, 2016 ). There are some works exploring the different new technologies and their impacts on supply chains under Industry 4.0, such as IoT on SCM (Ben-Daya et al., 2019 ), internet of things (IoT) embedded sustainable SC (Manavalan & Jayakrishna, 2019 ), big data analytics in SCM (Nguyen et al., 2018 ). However, most of those works rely completely on academic literature, with only a few exceptions. For example, Harris et al. ( 2015 ) discussed recent development of information and communication technologies (ICT) in multimodal transportation based on major EU framework projects and indicated that comparing with rather dated and narrow view of journal publications, the national research projects represent the current major efforts and reflect the cutting-edge technology and the state of art in research and development. Since academic literature, ongoing cutting edge national research projects, and national strategies bring about different perspective and focus, reviewing these different resources will provide a comprehensive overview of current research and development and application of emerging advanced technologies, as well as vision and road map for future development and implementation of relevant technologies.

New technologies emerging from Industry 4.0, such as ICT, show promise in improving supply chain performance in various ways (Colin et al., 2015 ). However, to the best of our knowledge, this is the first work to combine the discussion of national strategies, ongoing research projects with literature review to present a comprehensive review in smart supply chain under Industry 4.0. In addition, how to incorporate those advanced technologies to SCM with different decision levels among the different stages of smart supply chains remains a challenging and under explored problem.

This research mainly aims to fill the gaps and focuses on North America, one of the leading regions on the subjects, to perform an in-depth analysis. Our work intends to answer the following questions:

How does smart supply chain evolve with the support of advanced ICTs under Industry 4.0?

What are the cutting-edge developments about the smart supply chain under Industry 4.0 and the relationship between national strategies and ongoing project in smart supply chain?

To answer the questions mentioned above, this paper uses an integrated method to review the current developments of smart supply chains, the impacts of Industry 4.0 and related technologies. Besides academic literature, profiles of currently funded projects and National strategies in North American region in terms of Industry 4.0 are reviewed. The challenges faced by supply chains under Industry 4.0 and some research directions are discussed as well. The main contributions of this paper therefore are three-fold: first, we present a comprehensive summary on the existing research and research effort on smart supply chains under Industry 4.0; Second, we create a smart supply chain framework to reflect the dynamics and development of smart supply chain; third, we propose some research directions to lay the foundation for further research in the areas.

The paper is organized as follows: Sect. 2 introduces the review methods and materials, which is followed by proposed smart supply chain framework in Sect. 3 . National strategies on advanced manufacturing (AM) in US and Canada are discussed in Sect. 4 . Section 5 analyses the ongoing research projects on ICT applications on smart supply chains. Section 6 provides a review of existing studies on smart supply chain management (SSCM) under Industry 4.0. Section 7 presents some challenges from supply chains perspective and future research directions. Finally, Sect. 8 concludes with a summary of the insights generated from the review.

2 Review methods and materials

To analyze the current developments of smart supply chains, and to study the impacts of Industry 4.0 and related ICT technologies, an integrated qualitative and quantitative method is conducted. The following three resources are examined and analyzed: government strategies in North American region, research projects from the major national research councils, and academic literature, as shown in Table 1 . In the table, we use “x” to represent the resource used mainly for the related topic, for example, ongoing projects from national grants are used to all four topics.

To introduce national strategy of North America region on Industry 4.0 and advanced manufacturing, we conducted a search with google and government official websites which are supplemented by other database such as SCOPES. To capture the latest trends and current major effort of Industry 4.0 related new technologies in SCM, we identified some active projects, mostly started in the last 5 years, from both National Science Foundation (NSF) and the Natural Sciences and Engineering Research Council of Canada (NSERC) award databases, where both NSF and NSERC are the major federal funding agency or council for university based research in US and Canada respectively to advance the progress of science.

A systematic review of both academic and practice literature is provided to analyze the smart supply chains under Industry 4.0, with the focus on the impacts of relevant new technologies including big data, internet of things, cyber-physical systems, blockchains, 3D printing. Our emphasis is on the latest progress (recent 5 years) and their impacts on the performance of supply chains. The different combinations of keywords “supply chain” (including “supply chains”, “logistics”, “inventory”, “sourcing”, “pricing”, and “supply network”) with one of the technologies such as big data , machine learning (ML), IoT , etc., are used in literature search.

For literature review, we separate the extant research works into development supply chain and fulfillment supply chain. The former focuses on the decision-making for building the new supply chain which is mainly at a strategic level, whereas the latter is about the issues regarding daily operations to satisfy the demand, which is primarily in tactic and operation levels. For fulfillment supply chain, we follow APICS supply chain operations reference (SCOR) model (Huan et al., 2004 ), which is widely recognized as a supply chain framework. It should be mentioned that this work is not all-inclusive, but is meant to cover the latest and main progress in the area to reflect the current status and future trends.

3 A smart supply chain framework

Although the concept of smart supply chain has been widely used in the literature, the definitions and concepts of the smart supply chains are inconsistent and often incomplete. The concept is often referred to in terms of different stages/drivers of supply chains, technologies involved, applications, and characteristics:

Smart drivers of supply chains: such as smart logistics & transportation (Barreto et al., 2017 ; Harris et al., 2015 ), smart warehouse (Liuet et al., 2018 ). Most work reported in the literature belongs to this category.

Data streams/digital aspects: using different analytics models to analyse real-time data flows and historical data repositories (Ivanov, Dolgui, et al., 2019 ; Ivanov, Tsipoulanidis, et al., 2019 ).

Technologies aspects: The integration of modern technologies, such as IoT and big data, into SC leads to a SSCM (Wang & Ranjan, 2015 ).

Characteristics: Several characteristics of a SSC are proposed, such as instrumented, interconnected, and intelligent by IBM (Butner, 2010 ), adaptability by Leończuk et al. ( 2019 ), and instrumented, interconnected, intelligent, automated, integrated, and innovative by Wu et al. ( 2016 ).

We intend to define a “smart supply chain” as a supply chain that integrates the partners can self-organize and automatically adapt to environmental changes, and makes intelligent decision that best achieve business goals. The characteristics include being integrated, intelligent, adaptive, and self-optimizing. SSC is a dynamic evolving process that extends vertically and horizontally in terms of integration, along with the technology development and business innovation.

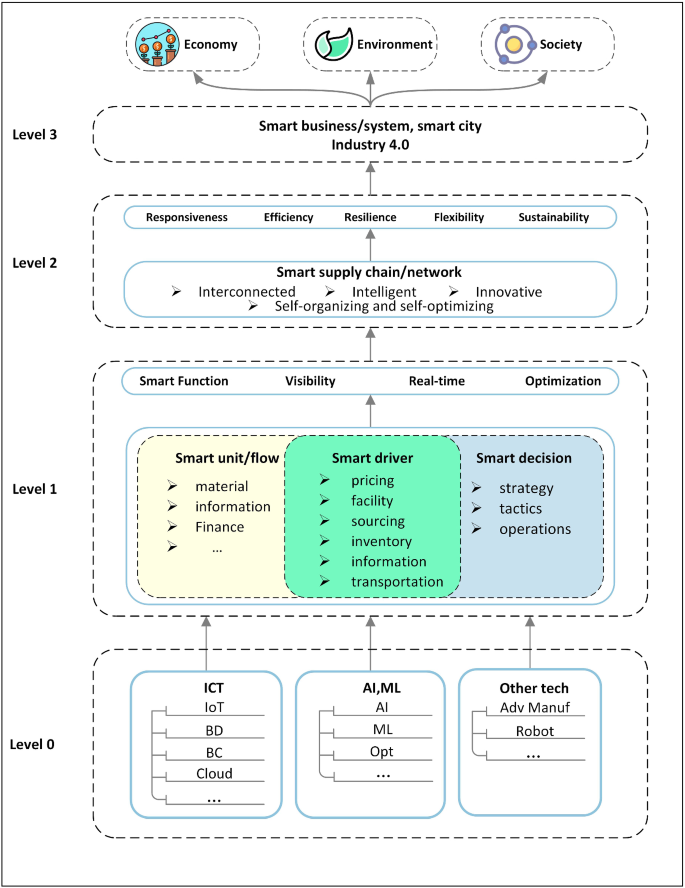

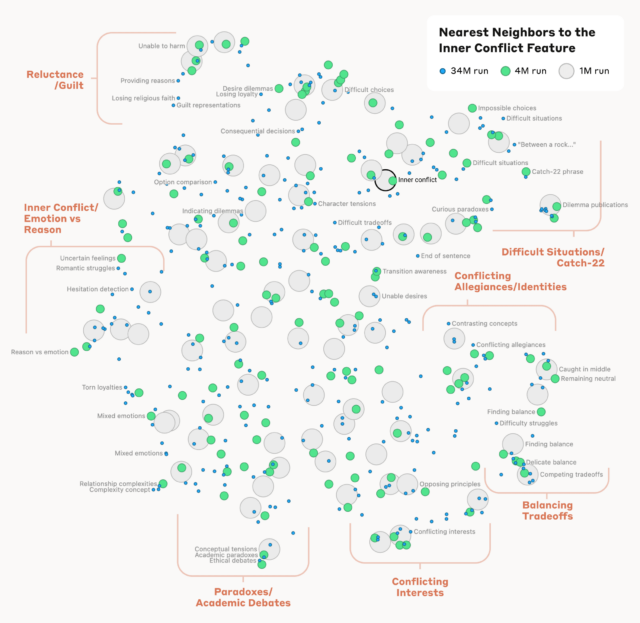

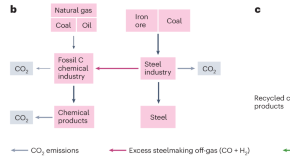

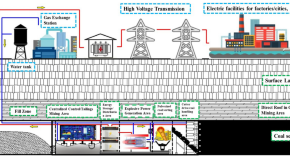

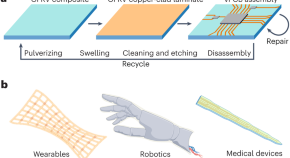

With the development and integration of ICT and artificial intelligent (AI), supply chains evolve from single partner/flow intelligence to multi-partner or whole supply network intelligence, and ultimately, to promote and realize the digitalization and intelligentization of different business/system/industries. To reflect the process, we present a multi-level smart supply chain framework as Fig. 1 . The hierarchy of the smart supply chain also reflects different stages and scopes of SCM to which ICT, AI&ML, and other technologies are applied.

Smart supply chain management hierarchical framework

Level 0 of the framework consists of smart technologies or drivers which provide the basis of smart supply chains, including ICT, AI&ML, and other technologies. ICT includes IoT, big data (BD), cloud, block chains (BC), 3D printing, and so on. AI&ML refer to artificial intelligent, machine learning, optimization, etc. The other technologies include AM, robotics, digit-twin, intelligent transportations, drone, supply chain finance and banking 4.0, and so forth.

Level 1 is the initial stage of smart supply chain which mainly applies the ICT/AI to improve single driver/flow/partner/level (operational, tactical or strategic) of supply chain, or to one level such as smart internal supply chains in a manufacturing group, smart logistics, intelligent inventory management system, etc.

Level 2 is the smart supply chain that implements intelligent decisions in all flows (material, information, finance), all levels (operational, tactical or strategic) among the connected partners of the supply chain. The smart SC is interconnected, intelligent, and self-organizing, and can reconfigure and self-optimize the network in response to environmental change and change in business goals. The smart supply chain would demonstrate superior performance in all key aspects, including responsiveness, efficiency, resilience, and flexibility.

Level 3 is the smart business/system/industry that the SC supports: such as smart automotive manufacturing under Industry 4.0, smart retailing, smart healthcare service, even smart city. That indicates that the ultimate goal of the smart supply chain is to match and support business strategy, to facilitate the implementation of Industry 4.0 so as to achieve the economic, environmental, and social goals.

4 National strategies on Industry 4.0 and advanced manufacturing in North America

4.1 industry 4.0 and ict.

The fourth industrial revolution, i.e., Industry 4.0, is driven by innovative technologies, especially advanced Information and Communication Technologies. The advanced ICT impact almost all stages of the manufacturing process. Such advanced ICT is also a critical driver for improving manufacturing supply chain responsiveness and efficiency simultaneously (Chopra & Meindl, 2014 ) and plays a central role in SCM (Apiyo & Kiarie, 2018 ).

To push Industry 4.0 transition in manufacturing, several government-led initiatives were launched to facilitate this transition. National strategies on AM were proposed to improve the competitiveness and strengthen their technological innovation capability in manufacturing areas, and identify the challenges and the directions for future research agenda at a strategic level. Here we mainly introduce the recent national manufacturing strategies in USA and Canada.

4.2 US national strategy on advanced manufacturing: advanced manufacturing partnership (AMP) and manufacturing USA

It is noted that the terminology of Industry 4.0 is rarely used in US national strategies. Instead, advanced manufacturing and related technologies are the theme of the national strategies.

4.2.1 Advanced manufacturing partnership and AMP 2.0

The U.S. has been a world leader in manufacturing for more than one century. AMP was launched by President Obama in 2011 to bring together industry, academia, and government to revitalize manufacturing sector in United States and to strengthen the Nation’s global competence.

The second phase of AMP (AMP2.0) was launched in 2013. To strengthen the ecosystem for sustaining American leadership in advanced manufacturing, the AMP 2.0 Steering Committee further developed a set of specific, targeted, and actionable recommendations around three integrated pillars identified by AMP in 2012: including Innovation, Talent, and Business Climate. Cyber-physical system (CPS), big data, IoT, and cloud-based implementations are listed as the emerging technologies for generating data and “soft” intelligence.

It is noted that “supply chain” is mentioned 30 times in the report and more than 90 times in the annexes about manufacturing technology areas. This demonstrates that the initiative not only aims at improving actual manufacturing process in machinery, plant, enterprise scope, but also extends to the performance of whole supply chains and its important role to manufacturing excellence.

The recent project on AMP 2.0 awarded by NSF is Kentucky AMP for Enhanced Robotics and Structures (NSF- RII- 1849213 , 2019). This five-year project aims to produce new materials for 3D printing, and embed sensors, power sources and displays in 3D printed objects.

4.2.2 Manufacturing USA or the national network for manufacturing innovation

Manufacturing USA is an interagency network that focuses on coordinating public and private investment in developing manufacturing technologies. The original program of the Initiative was the National Network for Manufacturing Innovation (NNMI) launched in 2012 and then NNMI is changed to Manufacturing USA in 2016 (RAMI Act, 2014 ). Currently the network of Manufacturing USA consists of 14 manufacturing institutes. Each institute focuses on a different advanced manufacturing technology area.

There are annual reports published by National Institute of Standards and Technology (NIST), U.S. Department of Commerce, to document the progress of the Manufacturing USA program. The latest one is Fiscal Year 2017 published on September 26, 2018, and some of highlights are (NIST, 2018 ):

The number of institutes of Manufacturing USA increased substantially in 2017 from 8 to 14. Six new institutes are added with the sponsorship of the departments of Energy, Defense and Commerce. Their locations, and technology focus can be found in NIST ( 2018 ).

The total commitments of support have grown to more than $3 billion over the program’s life contributed by federal funds ($1 billion) and other investment.

Total memberships increased to 1291, and 65 percent of the members are from industry, and small and medium-sized enterprises (SME) accounted for 65 percent of the industry members.

The fourteen institutes conducted almost 270 projects focusing on application oriented research and development, and those projects are of high priority to broad industry sectors.

4.2.3 American leadership strategy in advanced manufacturing

The quadrennial Strategy for American Leadership in AM was released by the White House in October 2018 (OSTP, 2018 ). The strategic plan is to be achieved by pursuing three goals: new manufacturing Technology development, workforce training and education, and U.S. manufacturing SC enhancement (OSTP, 2018 ). For each goal, the strategy identifies four or five strategic objectives, action priorities and expected outcomes in the four years.

Smart and digital manufacturing is one of technical priorities for the first objective in the first goal, and the two concepts are defined. The objective of smart manufacturing is to optimize different levels’ performance (from unit, factory, to SC) by means of integration with IoT and software. It is indicated that the integration of ICT with operation technologies can result to significant increase in productivity.

The third goal is to improve U.S. manufacturing SC. The terminology of “supply chain” appears 43 time in the document, which shows supply chain is one of the themes in both the strategy and advanced manufacturing. A diverse array of challenges faced by U.S. manufacturers are indicated. One of the program priorities is SC enhancement. It is indicated that new technologies, such as big data, IoT and digitalization will improve production and impact future manufacturing SC.

Comparing the emerging technologies mentioned in the report and annexes of AMP 2.0 proposed in 2014, the strategy proposed in 2018 includes much more new technologies that are enablers for advanced manufacturing: industrial IoT, big data and analytics, AI, ML, 3D printing, industrial robotics, cloud computing, cyber physical systems are mentioned in the strategy, while ML, AI, and 3D printing do not appear in AMP 2.0 in 2014. Industrial IoT is one of critical enablers and platforms that affect the implementation of intelligent manufacturing and SC. Cybersecurity is the issue highlighted in the strategies, and blockchain is not mentioned in both the AMP 2.0 report and the new strategy.

4.2.4 America’s supply chains

A 100-day review report was released by the white house on June 8, 2021 under Executive Order (EO) 14,017, “America’s Supply Chains” (Sullivan and Deese, 2021 ). The report assessed SC vulnerabilities in four key sectors: large capacity batteries for electric vehicles (EV); critical minerals and materials; semiconductor manufacturing and advanced packaging; and advanced pharmaceutical ingredients (APIs) and pharmaceuticals.

The findings from the review were summarized in the following aspects: SC resilience and security are critical for U.S. economy and security; a new method based on U.S.’ strengths should be developed to implement resilient SC; the specific strategy and action for each sector should be recommended with consideration of unique SC features in the sector.

The report stated that the COVID-19 pandemic and SC disruption show vulnerabilities of U.S. SC. The report identified five key “inter-related” factors that have contributed to U.S. SC vulnerabilities, including low production capacity, short-termism in private markets and misaligned incentives industrial policies, global SC and coordination it made six recommendations in production capacity and innovation, market development, international business rules, and others. It was mentioned that the second phase will review the SC of six important sectors and a report released in February 2022 was expected.

4.3 Canada national strategy on Industry 4.0 and advanced manufacturing

Accounting for approximately 11 percent of Canada’s GDP, Manufacturing is a cornerstone of Canada’s modern economy, and is also the largest investor in research and development in Canada (Industry Canada, 2015 ).

4.3.1 Canada's innovation and skills plan

To address the changing nature of global economy and growing competition from other countries, the Canadian government introduced an Innovation and Skills Plan in its federal Budget, 2017 . The plan reflects a national effort to target three objectives, including being a world innovation leader, to generate more skilled jobs with good payment for Canadians, and to expand the middle class. The plan will target six crucial sectors including advanced agri-food, manufacturing, digital industries, clean technology, clean resources, and bio-sciences/health (Canada Budget, 2017 ).

4.3.2 Economic strategy table–advanced manufacturing

Proposed in Budget, 2017 , the Economic Strategy Tables are a forum established by Innovation, Science and Economic Development Canada to develop the strategies in the six sectors that significantly contribute to the economy of Canada. A leader from each of the six industries chairs the related Table, and those chairs also meet to discuss the common issues in the Tables. The Economic Strategy Tables provide a new path to enhance the collaboration between government and industry (ISED, 2018a ). Advanced manufacturing and digital industry are the two among the sectors and are also related to Industry 4.0

The advanced manufacturing strategy table proposes the vision of Canada’s manufacturing: made better in Canada . The two targets of advanced manufacturing table are to increase both sales and exports by 50% by 2023 (ISED, 2018b ). A series of actions and proposals are recommended to hit these targets.

To reduce the potential risk of adopting new technologies, such as Industry 4.0 and other advanced manufacturing, and ICT, a network of Canadian advanced manufacturing technology adoption centres (CANADVANCE) is established. The network integrates industry, governments, and academia to facilitate the development of new technologies related to Industry 4.0. The table also encourages the investment in ICT to reduce the gap with USA and adoption of Industry 4.0 in SMEs.

4.3.3 Economic strategy table–digital industries

ICT industry is one of important sectors in Canada (more than 39,000 companies) and contributes significantly to highly skilled jobs (almost 600,000 professionals) and to one-third of research & development investment in private enterprises (ISED, 2018c ). The digital industries table targets establishing more Canadian digital companies, especially large and innovative companies, and increasing the business revenue, which can be implemented by the three measures: skilled workers, digitalization of society, and use of data/Intellectual property.

Canada launched Biomanufacturing and Life Sciences Strategy 2021. The goals are to be well prepared for future pandemics and benefits from the effect of biomanufacturing.

Table 2 summarizes the USA and Canada national strategies on Industry 4.0 and advanced manufacturing. Some features of the national strategies include:

The advanced manufacturing has significant contributions to national economy. The goal of the strategies on advanced manufacturing is to enhance the national competitiveness. The vision and objectives on advanced manufacturing or Industry 4.0 are defined, and challenges and actions are identified.

The collaborations among private sectors, academia, and government are encouraged to develop a long-term partnership and strategy, which also include the joint investment to promote the critical technologies. New organizations or research institutes are established to engage the innovation or implement the latest manufacturing technologies and ICTs.

Education, training, and knowledge updates for high quality personals or skilled workers are recommended as one of pillars in the strategies.

Manufacturing supply chain is one of the themes in the national manufacturing strategies.

SMEs play an important role to advance and implement the new technologies

New advanced technologies and new ICTs attract significant attentions, which are critical for digitalization and innovation of manufacturing.

Biomanufacturing and related supply chain attract significant attentions to cope with pandemics.

5 Research agenda on impacts of emerging ICT on SCM in North America

To observe the latest research status and interests on the emerging ICT underpinning industry 4.0 and their impacts on supply chains, we analyze the active projects conducted in NSF and NSERC, which represent the major national foundation agency for science and innovation in US and Canada respectively.

In Table 3 , the numbers in Abstract & Title and Title only display the numbers of projects with the keywords in “abstract or title” and in “title only” respectively. The number in Applied to SC is the projects that mainly study supply chain application of the related technology. The search returns much higher numbers when only looking at SC keywords in abstract. However many of the projects do not involve in SC research. From Table 3 , we can see.

There are several hundred research projects on each of the new emerging ICT technologies, except blockchain in both NSF and NSERC, which reflects significant effort on those technology related fields.

Machine learning, AI, Big data, and IoT are the hot research areas, and both NSF and NSERC have highest active projects in the areas.

Following the above point, however, the number of ongoing projects that focus on studying the influence of the technologies on SC is relatively low. For example, only 6 NSF active projects are found that study how to use big data to improve SC performance, though 29 projects have both big data and SC related keywords in their abstracts. Those projects for education and conference purpose, or with different focuses, such as building and infrastructure, etc., are excluded.

“Industry 4.0” itself is not commonly used in research grants in North America, especially in NSF. Among the 20 projects in NSF that has Industry 4.0 in titles, 15 projects are from advanced tech education program and used for education and training to prepare workforce for Industry 4.0; two are used to support workshop or conference, and two for student experiences; only one project is about design tools. Three projects that are related to SCM are all about Industry 4.0 seminar/workshop or curriculum development. We also search the projects in Industrial IoT that is usually considered as an alternative terminology for Industry 4.0 in US, and comes out with only 7 projects have IIoT in titles.

Though blockchain is relatively a new topic, the relative percentage with the keyword in titles is the highest among all technologies included in this table, which shows blockchain itself is the focus of the research, instead of applications.

We also search the active projects on digital twin, a relative new technology that combines simulation and digital technology. There are 4 NSF and 9 NSERC projects including digital twin in titles. Only one NSF project is relevant to SC: The model for the counterfeit part network developed is an essential component of a digital twin for the SC for critical systems (NSF-D-ISN-2039958, 2020).

Table 4 presents a summary of selected NSF and NSERC active projects that focus on the study of impacts of emerging ICT on supply chains. These projects are categorized in terms of the technologies involved, such as big data, blockchain, internet of things, Cyber-physical systems, 3D printing, Machine Learning, etc. The application area, objectives/benefits, methods or technologies are described for each project.

5.1 Blockchain

The research projects with the focus on the impact of blockchain technology in SC emerged only since 2018. However, the number of the approved projects increased significantly from 2019. Considering production of goods and services is becoming increasingly distributed and decentralized, a scalable Semantically-Enhanced Blockchain Platform is studied to overcome the trust-tax barrier among organizations (NSF-CSR-1764025, 2018). The feasibility of blockchain networks to connect farmers to consumers and improve SC sustainability is evaluated and investigated in the project (NSF-CNH2-S-1924178, 2019). The application of blockchain to healthcare system is proposed in a project (NSF-STTR-1913753, 2019) where it is highlighted that how to increase blockchain’s transaction speed is important. The current blockchain design is resource-intensive, in terms of storage, computation, and communication, which is one of the main roadblocks in the proliferation of blockchain applications (NSF-1937357, 2019). When increasingly applications of blockchain in organizations, the project focusing on Inter-blockchain Communication (IBC, NSF- CAREER- 1846316, 2019) present privacy-preserving IBC protocols that consider privacy and availability trade-offs. The project of NSF-1940394 (2020) aims to build a blockchain platform for companies in a pharmaceutical SC to enhance the medicine traceability.

In NSERC, more than half of the projects with topics focusing on blockchain are Engage grant projects, which are short term industry-academic research collaborations. The main applications of blockchain are IoT and energy: generic and extendable architecture for smart grids (NSERC-CRD-Capretz 2018), and high-performance blockchain infrastructure for IoT applications (NSERC-CRD-Zhang, 2018 , NSERC-Strategic-Gong, 2018). There are two projects on SC applications: one is about SC and asset management software platforms (NSERC-Williamson, 2019) and the other are about data driven SC (NSERC-DG-Zhang, 2019). It is interesting to note that there are 6 NSERC discovery grants (5 years term) with blockchain shown in the titles in 2020, mainly in computer sciences and engineering. It indicates the research feasibility on blockchain technology is recognized.

Technologies studied in those projects mainly focus on security and privacy mechanisms, performance and scalability, speed of transactions, resources, distributed ledger and network, data sciences, where smart contract and distributed Ledger Blockchain technology attract research attention.

5.2 3D printing technology

3D printing technology has completely changed the manufacturing process and affects manufacturing supply chains significantly. The current research projects about the impacts of 3D printing on SC mainly focus on distributed manufacturing and SC (NSF-SBIR-1937914), cost and risk analysis (NSF-1634858, 2016), complexity of supply chains caused by 3D printing (NSF - SBIR - 1914249, 2019). The application areas include autonomous manufacturing, healthcare (NSF-1634858, 2016), shifting accessibility and agility of manufacturing (NSF-SBIR-1937914, 2019), respiratory ventilator for COVID-19 clinical care (NSF-SBIR-2036836, 2021), and future EcoManufacturing and supply chain (with US$9 million, NSF-FMRG-2037026, 2021). 3D printing is considered as the next supply chain revolution (NSERC-DG-Bijvank,2016). How to simultaneously achieve the three objectives of 3D printing- print time, print cost and print quality–remains to be investigated in 3D printing technologies (NSF1914249, 2019 ) .

5.3 Big data

Ways to increase the value of data, especially big data analytics (BDA) in SCM have attracted significant attentions in both academics and industries (Nguyen et al., 2018 ). There are 210 and 164 projects with the focus on big data in NSF and NSERC respectively. The work about the applications of big data into supply chains in NSF projects includes software supply chain, food aid supply chain and food industry, pricing, data-driven service, customer analysis, shrimp industry, and transportation.

Software supply chain: The project of NSF-1633437 uses the big data-based approach to quantify and mitigate risks in software SC, particularly with evidence based approaches.

Food industry and supply chain: Three NSF projects study the big data related technologies for food security and hunger relief. The national science foundation research traineeship (NRT) award with US$3 million (NSF-NRT-1735258, 2017) uses computational data science to improve strategies for hunger relief and food security. Challenges in hunger relief work arise from not only the uncertainty of supply and demand but also from variations in information collected by different humanitarian organizations and the government and private sector. Several technological gaps are identified for food safety, security and traceability of all raw materials in whole SC from 'Farm to Fork' (NSF-1822092, 2019). It is suggested newer sensors with big data analytics will enable the food companies to improve food safety, quality, and traceability. A smart service system is proposed in the project with $1.1 million (NSF-1718672, 2017). The sonar and analytics platform is used to improve shrimp farming and make "big data" available to the farmer, the buyers, as well as the scientific community (NSF-SBIR-1913107, 2019). The project (by Elkafi Hassini, NSERC-DG-CISE, 2020) investigates big data based optimization model and algorithms with applications in smart food SC. Pricing: The project of NSF-2017957, 2020) presents a dynamic model to study how big data affects dynamic personalized pricing.

Transportation and logistics : Monitoring and coordinating large fleets of self-driving vehicles (SDV) with a real-time system is studied in the project (NSF-1663657). The research of projects (NSF-2027678, 2020, NSF- 2027412, 2020 ) brings together rapidly unfolding health data related to COVID-19 with real-time data on mobility from location-based apps and algorithms to understand the current status and make better decisions during the pandemic.

General SCM : Most projects from NSERC on applying big data into supply chain are for a general SCM, instead of for a specific industry sector. Those applications include rebate program in supply chains, close-loop and SSCM. A new framework to support big data analytics of rebate programs is studied in the project (NSERC-EG-McGregor, 2015). To minimize waste across CLSC networks, the project (NSERC-DG-Amin, 2017) studies the closed loop supply chains for four types of products: paper, tires, computers and hazardous materials and the impact of big data on CLSC are to be investigated as well. The project of smart supply chain (NSERC-DG-Zhang, 2019) studies the challenges and opportunities of supply chains under digital business environments and develop smart supply chain strategies and solutions via data driven optimization and big data technologies.

5.4 Cyber physical system (CPS)

A fundamental problem faced by SCM is to ensure that physical parts arrive from the desired source and are not swapped or modified. Either tampered cyber component or physical component will lead to significant cyber-physical security risk. To ensure the integrity of both the cyber and physical components in industries relying on complex distributed SC, one research project uses physical measurement techniques to provide parts of a physically unclonable identity, and the cyber signing methods to build chains of trust (NSF- CPS -1932213, 2019). Another project aims to disrupt operations of illicit supply networks (NSF- EAGER -1842577, 2018). The investigators use hybrid ML and analytics to analyze data from both physical inventory and cyber activity to discover illicit activities. There are at least 5 NSF projects study transportation with cyber-physical systems. The project of NSF-1947613, 2019 develops novel data based robust algorithms for real-time control and optimization for a transportation network. A project (NSF-1454737, 2015) is designed to overcome challenges related to allocation and scheduling of robotic vehicles. To improve the resilience of civil infrastructures, address supply and demand uncertainties, the project (NSF-1453126, 2015) works on developing a practical design toolkit for CPS. The project (NSF-2115149, 2021) provides a user-centric solution considering decentralization and privacy for secure vaccination coordination that can aid researchers and planners of the current and future pandemics.

5.5 Internet of things

The 10 NSF projects that applies IoT to SC activities mainly study IoT or sensor development, system for shipping, drone, containers, and advanced manufacturing. An innovative ground robot-drone network system is proposed to review inventory and trace item locations with passive RFID in the environments of warehouses, retail stores, hazmat storage facilities (NSF-1923163). To address hardware security issues in integrated circuit's global and distributed supply chain, light-weight resistive random access memory (RRAM) technology is proposed (NSF-1903631), which is used as a unique signature for each IoT device in the supply chain. The IoT technologies for next generation mobile communication systems are studied in Auburn university RFID lab, which are used to storage, retail, and SCM (NSF-1822055, 2018). The project of NSF-SBIR-2025896 (2020) aims to develop advanced real-time tracking systems with new 5G and IoT technologies that reduce the container shipping costs. NSF-2044711 (2021) focuses on designing and building a system for tracking RFID tags. The main goal is to provide an easy to deploy and scalable solution for different applications in the SC. Among 11 NSERC projects, there are three DG grants that applied IoT for network interdiction and fortification planning (NSERC-DG-Vidyarthi, 2017), monitoring and localization of people, and general smart SC. The other eight are applied or collaborative research and development, mainly for real time tracking, resource management, yard management, SC digital platform, etc. Most of those projects mainly focus on the technologies of IoT and its network that has potential applications to SCM. However, there are very few research with a focus on the impacts of IoT on SC, such as supply network, warehouse operations, etc.

5.6 Machine learning and AI

The numbers of ongoing projects on ML and AL in both NSF and NSERC are among the highest among the new technologies, especially ML. However, there are very few research projects focusing on applying AI or ML to supply chains in NSF: only 5 AI for SCM and 5 ML for SCM are found. Among NSERC grants, there are 22 projects that involved ML in SCM (including 10 industry-driven collaborative research and development projects) and 7 projects that involved AI in SCM.

The NSF projects on study of ML in SC include ML based supply chain analysis to thwart illegal logging, operational seasonal forecasting, consumer behavior-aware learning, planning and operating shared mobility, supporting resilient and high-availability elastic network slicing. The 22 NSERC projects include the following aspects: 7 projects on logistics and transportation: algorithms for vehicle routing, transportation safety and sustainability, traffic prediction in bike-sharing systems, real-time planning, stochastic optimization of network design and transportation problems, urban mobility and traffic data, urban mining logistics; 4 on market and finance : reusing simulation for financial and actuarial applications, platforms and internet market design, pricing and risk management in environmental financial derivatives, and real estate transaction and pricing; 5 on general SC and production: SC analytics, smart SC, electronic components product SC optimization, generalized sequential data mining, and appliance disaggregation and optimal scheduling; 2 on food and farms: real time data analytics for mushroom farms, SCM at Nestlé Canada; 3 on inventory and warehouse : healthcare inventory management, lateness management in cross-docking, adaptive recognition of images for warehouse inventory cataloging. Most of the projects are applied or collaborative research and development projects.

AI applications in SC in NSF include the COVID-19 therapeutics SC, a smart container for mobile blood banking system, real-time monitoring for warehouse and outdoor inventory management, illicit narcotic supply networks. In NSERC: 6 projects on AI are also relevant to ML, mainly in logistics and transportation, and the other is about inventory tracking system.

In summary, the ML and AI applications mainly focus on logistics and transportation, inventory and warehouse, food, consumer behavior, thwarting illegal logging. After the pandemic, more projects study healthcare SC using ML. The functions or purposes of the projects are concentrated in ML or AI based optimization, simulation, forecasting, scheduling, pricing, and real-time data analysis. Besides the ones mentioned, there are 4 NSERC and 5 NSF projects focusing on studying ML or AI based optimization algorithms respectively, and those projects mention the applications in SC.

The emerging ICTs are related and integrated in Industry 4.0. Thus, some projects explore how to use multi-ICTs in supply chains, such as, supply chain analysis to thwart illegal logging (NSF- D-ISN 2039771, 2021), a digital technology platform for supply chains (NSERC-CRD-Bhuiyan, 2018), and smart supply chain via data-driven optimization (NSERC-DG-Zhang, 2019).

The above review summarizes research projects from both NSF and NSERC on each emerging ICT technology and its impacts on supply chains. Some of the findings are:

Comparing to the articles that explore almost all drivers of supply chains, the number and scope of projects on the emerging ICTs in supply chains are less than expected, though the number of research projects that focus on the technique innovation itself is high. Considering the potential significant impacts of these technologies, lots of issues on the deployment of those technologies in supply chains are to be addressed, and thereby more research projects are expected. In addition, how to facilitate the research in the area and how to overcome the barriers need to be studied as well.

The number of projects on blockchain increases obviously in 2019 but mainly focus on technical challenges. Smart contract and distributed ledger blockchain technology are two critical aspects that attract research attentions. Applications mainly focus on energy, foods supply chains, healthcare system, smart markets, and IoT. But very few researches have been conducted in SCM, indicating that research on how to use blockchain in SC and logistics is still in its infancy. In addition, digital twin has attracted attentions in recent years with 25 and 21 projects in NSF and NSERC respectively but the research about its application to SC is very little.

The ongoing projects on 3D printing mainly focus on printing quality, cost, time, risk, and platforms. A couple of projects studied service logistics for 3D-printed spare parts and distributed SCM system with 3D printing, however, there lacks enough research about the effects of 3D printing on SC. The ability to print the finished goods or components will affect the supply network, supply selection, facility location and capacity, inventory, push–pull decoupling point, lead times, and transportation. Thus, the new manufacturing process brought by 3D printing technologies will significantly change supply chains, including how to satisfy the customer demands: where, when, and how to produce the products.

The projects on big data in supply chains mainly explore the applications in food industry and its supply chain, data driven service, supply chain rebate and customer analysis, and transportation.

Comparing to other emerging ICTs, the total number of projects studying the impact of ML in supply chain is highest, which mainly benefits from NSERC several industry collaborative research programs. The application areas focus on logistics and transportation, inventory and warehouse, and food SC, ML based optimization and potential applications to SC also attracts some research effort.

The research on cyber-physical system mainly studies how to improve supply chain resilience and coordination between manufacturing and supply chains with real time data and information enabled by CPS, especially for distributed networks.

Research on IoT in supply chains include improving food safety and traceability, creating innovative ground robot-drone with RFID, and enabling data communications and security.

As a system integrating the operations of physical and software components, cyber physical system has a potential to improve performance in complex supply chain network. However, issues exist regarding the adoption and implementation of this technology: integrity, security, and resilience are main focuses of relevant research currently supported by NSF.

6 Smart supply chain management under Industry 4.0

A review of the latest literature on ICTs in SC under Industry 4.0 is presented in this section. The literature is categorized into development SC and fulfillment SC, where the former is to establish the supply network and the latter is the supply process to fulfill the customer demand. Table 5 in Appendix summarizes Industry 4.0 related ICTs’ impacts on the different process of development and fulfillment supply chains. Warehouse is one of the most important facilities in SCM, and almost every part of the supply chain is closely related to it. Considering the role of warehouse in a smart supply chain and rapid development in recent years, an additional section, Sect. 6.3 , is devoted to review the automated warehouse and the progress of applying new ICT in warehouse management.

6.1 Smart supply chain: development and strategic decision

The supply chain development can be supported entirely by new Industry 4.0 technologies. New technologies can enable traditional supply chains to move toward intelligent, connected, efficient and excellent supply chain and operation management (Dallasega et al., 2018 ). In this section, we discuss the applications of Industry 4.0 technologies to strategy development SCM in three categories: design/new techniques, strategic source, and strategic network.

6.1.1 Design/new techniques

As the most advanced technologies, how to combine Industry 4.0 technologies with SCM is full of challenges. Some new thoughts/principles and techniques will be designed to suit new conditions. Ghobakhloo ( 2018 ) summarizes the principles and technology trends adopted strategically for Industry 4.0 technologies in manufacturing industry. For a specific technology, such as 3D printing, Berman ( 2012 ) points out that it can change the product designing process. 3D printing breaks the time and space limits in the production process, does not require assembly, and is economical and efficient to design and modify the products. Majeed and Rupasinghe ( 2017 ) discuss the operations to manage better and optimize and automate processes in an Enterprise Resource Planning (ERP) system through the use of RFID technology in the fashion apparel and footwear industry. Saberi et al. ( 2019 ) identify and categorize four blockchain technology adoption barriers in supply chain operations. They also point out that the blockchain-led SCM still belong to the early stages of development. Manuel Maqueira et al. ( 2019 ) reveal cloud computing technology can help the participants in the supply chain to integrate effectively. Additionally, the developing simulation methods can support the supply chain design and operation processes (Gunal & Karatas, 2019 ).

6.1.2 Strategic source

New technologies can connect the suppliers, manufacturers, retailers and customers, and the applications help the players understand the whole chain easily, especially for the information flows among them. Based on the valuable information, the managers can foretaste the demand and choose the optimal source suppliers and partners. For instance, Xing et al. ( 2016 ) propose a cloud-based life-cycle assessment platform to help the footprint assessment and resource management in green supply chain. Mladineo et al. ( 2017 ) consider a cyber-physical production network, which helps the company make the partner selection decisions to design a new virtual enterprise production network. IoT is crucial and enable Industry 4.0 technology for the sourcing process in supply chain (Ben-Daya et al., 2019 ). IoT implication needs the trust and information sharing in the supply chain and organizations, while the risks such as leakage of data should also receive high attentions (Birkel & Hartmann, 2019 ). In addition, since application of IoT could bring high operating costs, the adoption decisions are always related to price, total revenues and transportation efficiency (Sun et al., 2020 ).

6.1.3 Strategic network

The new technologies bring help and challenges to the supply chain network design process. Big data approach can effectively improve the data acquisition and data quality in the supply chain, especially for the estimation of important parameters before designing the network (Zhao et al., 2017 ). Blockchain linkage can record the intra-and inter-organizational activities in supply chain network, and help some environmentally manufacturing process designs (Kouhizadeh & Sarkis, 2018 ). The new production strategies supported by Industry 4.0 technologies require highly customized supply network design, sustainable manufacturing process, integration of different complex systems, and control of resilient and digital manufacturing networks (Panetto et al., 2019 ). Big data-based decision support technologies are widely used in the design and control of manufacturing supply chain network management, and can be used in their decision support systems. Cloud computing can effectively reduce costs, improve supply chain resilience, flexibility, and maximize the use of resources to improve the overall efficiency of its supply chain network (Sundarakani et al., 2019 ). Meanwhile, 3D printing may affect supply chain service companies to build their supply chain network. Logistic severe provider company explored the opportunities for adding 3D printing capabilities to their existing logistics offering, electing to partner with an existing manufacturer, 3D printing company (Eyers et al., 2019 ).

6.2 Fulfillment smart supply chains

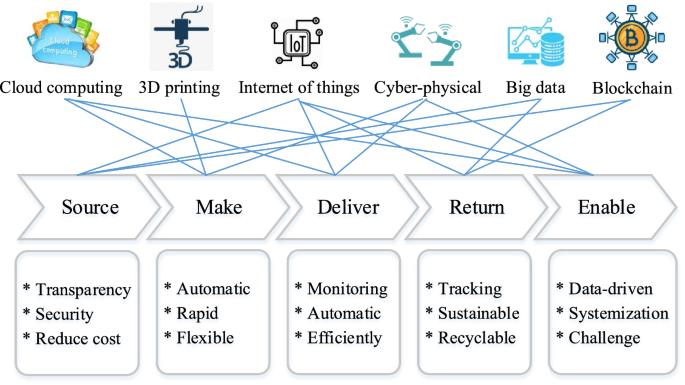

In this subsection, we follow APICS supply chain operations reference (SCOR) model (Huan et al., 2004 ) to summarize the extant literature on Industry 4.0 related ICTs in supply chains fulfillment processes, which consists of plan, source, make, deliver, return and enable.

Industry 4.0 technologies can make the planning and scheduling operations be more reasonable, flexible and reactive in the data-driven, connected, and resilient supply chains. Ivanov, Dolgui, et al. ( 2016 ), Ivanov, Sokolov, et al. ( 2016 )) investigate short-term supply chain scheduling in smart factories based on collaborative cyber-physical systems. Zhong et al. ( 2017 ) point out the big data analytics with IoT technology can make the logistics plans and schedules be more precise, practical and reasonable. Li et al. ( 2017 ) show that planning and scheduling process plays a key role in additive manufacturing facilities employing 3D printing technology for characteristics such as material efficiency, part convenience, and production flexibility. Dolgui et al. ( 2019 ) present a survey and summarized the job scheduling operation problems in a customized, reconfigurable assembly system that is based on Industry 4.0 principles.

6.2.2 Source

Industry 4.0 technologies can help companies to reduce sourcing costs, increase sourcing security, reduce sourcing throughput, increase flexibility and quality, and improve the relationship between the involved parties (Ivanov, Dolgui, et al., 2019 ; Ivanov, Tsipoulanidis, et al., 2019 ). Singh et al. ( 2015 ) apply cloud computing technology to reduce the carbon footprint in the entire beef supply chain logistics from the farms to the retailers. Francisco and Swanson ( 2018 ) discuss the technology adoption of Blockchain for supply chain transparency to track and trace the product processes. Kamble et al., ( 2019a , 2019b ) find that a good IT infrastructure, including strong internet connectivity, with the capability to connect the suppliers and customers, is critical to the adoption of IoT in the retail food business. Muñuzuri et al. ( 2020 ) describe the main technical features of a modular IoT system to optimize, manage and monitor container movement along a port-based intermodal corridor. Li ( 2020 ) finds that the platform prefers to reduce channel costs by investing in smart supply chain technologies.

Industry 4.0 involves advanced technologies that will benefit manufacturing, with the ultimate objective of making machines produce by themselves (Gunal & Karatas, 2019 ). Many technologies are already being applied into the manufacturing sectors in supply chain. Ivanov, Dolgui, et al. ( 2016 ), Ivanov, Sokolov, et al. ( 2016 )) propose a dynamic model for short-term supply chain scheduling in smart factories based on collaborative cyber-physical systems. 3D printing technology supports the new additive, digital, and rapid manufacturing process (Rogers et al., 2016 ). Mrugalska and Wyrwicka ( 2017 ) present a literature review about lean production and Industry 4.0 to show the possibility of linking these two approaches. Some examples are also provided. Cloud manufacturing that integrated new technologies can transform the manufacturing industry into service-oriented, highly collaborative and innovative manufacturing (Ren et al., 2017 ). The smart manufacturing based on the data from sensors, robots, and the cyber-physical system can boost productivity and improve quality (Khakifirooz et al., 2018 ). Moktadir et al. ( 2018 ) find that ‘lack of technological infrastructure’ is the most pressing challenge for implementing Industry 4.0 in manufacturing industries. Buer et al. ( 2018 ) discuss the relationships between Industry 4.0, lean manufacturing, performance, and environmental factors. Panetto et al. ( 2019 ) summarize the challenges for cyber-physical manufacturing enterprises of the future. Alcácer and Cruz-Machado ( 2019 ) investigate the big data used in the manufacturing process and summarize the manufacturing data lifecycle. Cloud operations and industrial artificial intelligence technologies improve flexible production networks based on autonomous mobile robots in terms of flexibility and productivity (Fragapane et al., 2020 ).

6.2.4 Deliver

Logistic and inventory management in the supply chain are improved significantly by applying the Industry 4.0 technologies. Some researchers also call this process under these new technologies as Logistics 4.0. Barreto et al. ( 2017 ) claim that “Smart Logistic” can increase flexibility, adapt to market changes and bring the company closer to customer needs. The existing solutions that support Logistics 4.0 are summarized according to the technologies: cloud computing, internet of things, cyber-physical systems, big data, 3D printing, and so on (Winkelhaus & Grosse, 2020 ). Qu et al. ( 2016 ) investigate a production logistics synchronization system for manufacturers applying public logistics services under smart cloud manufacturing. Mohr and Khan ( 2015 ) find that the adoption of 3D printing in various parts of the supply chain has the potential to produce a reduction in the demand for global physical goods transportation and inventory. IoT technology has been successfully applied to supply chain logistics enhancements, such as quality of production and distribution (Jayaram, 2016 ), operational efficiency in logistics and supply chain (Tu, 2018 ) and warehouse management system (Lee et al., 2018 ). Dolgui et al. ( 2020 ) investigate blockchain-oriented smart contract design in the supply chain with multiple logistics service providers.

6.2.5 Return

Industry 4.0 technologies through data collection and sharing can be beneficial for sustainable operations management decisions and new business models. Post-consumer product and packaging can be tracked and traced using sensors, RFID tags and barcodes to improve the returns process. Zhao et al. ( 2017 ) propose a green supply chain network design model with recycling centers, and the parameters are capitalized on a big data analysis. 3D printing is an important technology that can provide replacement parts for all types of machines and has the ability to recycle waste material (Berman, 2012 ). Development of new repair and remanufacturing capability that made use of the 3D printing knowledge to manufacture parts used in the repair process (Eyers et al., 2019 ). Joshi and Gupta ( 2019 ) investigate the effect of product design on product recovery using IoT. They propose a system to receive sensors and RFID tags embedded End-Of-Life products to satisfy various products, components, and materials demands. In Northern Europe, blockchain-based technology offers financial incentives in the form of crypto tokens for the disposal of recyclables such as plastic containers, cans or bottles (Saberi et al., 2019 ).

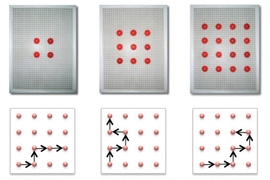

6.2.6 Enable

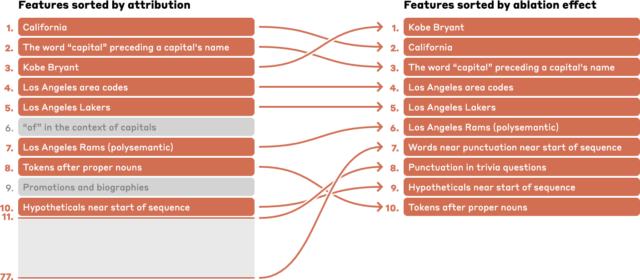

Some primary Industry 4.0 technologies have been applied in SCM to make it efficient. However, there are still some challenges with new technologies and advanced applications to improve the performance of the whole supply chain. de Sousa Jabbour et al. ( 2018 ) discuss the rule of critical success factors for implementing Industry 4.0 and environmentally-sustainable manufacturing. They present some social managemental factors such as management leadership, empowerment, top management commitment, organizational culture, and communication. Mohammed et al. ( 2017b ) investigate a Halal meat SC network design problem with a RFID-enabled monitoring system. Shafique et al. ( 2018 ) find that IoT adoption in green supply chain has positive effects on supplier integration and customer integration. de Vass et al. ( 2018 ) reveal a positive effect of IoT on the internal supply chain functions of retail firms, and significant improvement in sustainable firm performance. Schneider ( 2018 ) synthesizes the managerial challenges of Industry 4.0 into some interrelated clusters, such as strategy, planning, cooperation, human resources and so on. Martín-Gómez et al. ( 2019 ) develop a holistic framework for integrated and adaptive sustainable SCM at multiple scales and levels, using the digital and Industry 4.0. Based on the lessons from COVID-19 pandemic, Ivanov ( 2020b ) introduce a new notion the viable supply chain, which is an underlying SC property spanning agility, resilience, and sustainability. The performance brought by Industry 4.0 technologies is summarized in Fig. 2 .

The performance of Industry 4.0 for fulfillment supply chain

6.3 Smart warehouse

Warehouse inventory management plays a crucial role in SCM. Leveraging the Industry 4.0 technologies, the smart and automated warehouse becomes a popular, especially for e-commerce companies. According to the functions of the warehouses, we classify them into four kinds: warehouse, distribution center, fulfillment, and cross-docking.

The warehouse and distribution center with Industry 4.0 technologies become a key support part to smart manufacturing process. Smart warehouse management uses IoT technology and Big Data to make the monitoring, tracking, and location of the various materials and products in a warehouse environment. Avilés-Sacoto et al. ( 2019 ) present a literature review of SCM and inventory management fields affecting by Industry 4.0, especially for data-driven, new technology supported operations. Liu et al. ( 2018 ) investigate how to apply cyber-physical systems techniques in smart warehouses. They use RFID tags and NFC tags Wi-Fi Access Points to collect the CPS data and accurate the location of the concerned objects. Mohammed et al. ( 2017a ) investigate the design and optimization of a RFID-enabled automated warehousing system using the multi-objective optimization approach. Lee et al. ( 2018 ) develop a warehouse management system that uses IoT technology and advanced data analysis methods to achieve smart logistics for Industry 4.0. Tao et al., ( 2018 ) propose a conceptual framework to support the big data perspective in data-driven smart manufacturing, where the inventory data are collected from manufacturing information systems. Fernández-Caramés et al. ( 2019 ) apply Unmanned Aerial Vehicles (UAV) and blockchain technologies to design a system for the autonomous warehouse.

With the development of e-commerce, some retailer companies need the warehouses to become the place of picking and packing the customers’ orders. The latest technologies are applied to the fulfillment and cross-docking parts. Boysen et al. ( 2019 ) investigate a new generation of smart warehouses capable of meeting the needs of final customers in the business-consumer (B2C) segment of online retailers and adapting to the small orders, large assortments, tight schedules, and varying workloads of e-commerce inventory. Tjahjono et al ( 2017 ) indicate that simulation and big data analysis do not affect warehouse KPI. They can use data to analyze the sequence of loading and reduce the truck time in the dock and increase the utilization of truck. Simulation also can be used to improve the load/unloading process. Azadeh et al. ( 2019 ) summarized the new robotic automated picking systems. In picking and matching processes of distribution centers, many robots are used to increase productivity, such as the Kiva-Systems warehouse robot (Ivanov, Dolgui, et al., 2019 ; Ivanov, Tsipoulanidis, et al., 2019 ), the KIVA warehouse (Weidinger et al., 2018 ) and mobile-rack warehouses (Wang et al., 2021 ). Table 6 summarizes the different features of smart warehouses in the related literature.

7 Research opportunities and challenges of smart SCM under Industry 4.0

Innovations and new technologies, such as emerging ICTs and Industry 4.0, will affect how they will function in SC and what future SC is (OSTP, 2018 ). The previous reviews on both active projects and literatures have shown the development of advanced manufacturing, and applications of different emerging ICTs on supply chains. In this section, the challenges and research opportunities of SSCM under Industry 4.0 are identified and thus, future research directions in the areas are presented.

7.1 Impacts and benefits of Industry 4.0 and ICTS on SCM

The emerging technologies can be applied to assist making decisions from strategic design, tactical planning, to operation scheduling to form data-driven, connected, and resilient supply chains. The supply chain and organization performances can be improved with utilization of ICTs and Industry 4.0, evidenced with the cases and reported research.

7.1.1 Development supply chains and strategic decisions

Designing and developing manufacturing SC under advanced manufacturing environment, such as Industry 4.0, should understand and leverage the new technologies, with considering the features of customer demands and market variation. The aforementioned literature review shows most emerging technologies have impact on designing, strategic sourcing, and network decision making: 3D printing for sharing designs and outsourcing manufacturing (Berman, 2012 ), RFID for optimizing process of ERP system (Majeed & Rupasinghe, 2017 ), Industry 4.0 for smart wood supply chain (Müller et al., 2019 ). The active project at the strategic level mainly focus on big data, blockchain for food supply network, 3D printing for distributed network,

7.1.2 Visibility and traceability provide by IoT

The enhanced real-time visibility provided by IoT can improve information sharing, efficiency, and environment impact (Geerts & O'Leary, 2014 ). The project (NSF-1822092, 2018) leverages IoT systems and data integration to integrate and streamline the entire food supply chain in the US from 'Farm to Fork' and to improve food safety, quality, and traceability.

7.1.3 Cost reduction due to automation, IoT, and 3D printing

Smart factory increases automation while lowering labor cost, and reacts faster to unexpected events and process disturbances. The new materials, large-scale objects, integrated and distributed manufacturing and supply chain network will largely enhance the benefits, including cost and lead time reduction, of 3D printing (NSF-1914249, 2019 ). IBM IoT platform can help the enterprises reducing maintenance costs and managing demand, configuration, quality, etc., by connected devices, analytics, mobility and enterprise asset management (IBM, 2018 ; Russo-Spena et al., 2019 ). Berman ( 2012 ) indicates 3D printing has the ability to share designs and outsource manufacturing, which improves the speed and ease of designing and modifying products, and save the costs.

7.1.4 Fast responsiveness to market with distributed network and information sharing

Decentralized logistics reacts faster to requirements . Short lead time for replenishment can lower cycle inventory, one NSF project works on developing a practical design toolkit which improves resilience and incentive schemes for CPS (NSF-CAREER-1453126, 2015). With the support of GE’s iFIX industrial automation software, Subaru’s drive plant in Indiana becomes the fastest automaker in USA (Brendan, 2019 ).

7.1.5 Resilience and risk control

The supply chain resilience and risk management can be improved with ICTs, and flexible supply network design. Industry 4.0 assisted smart system may lead to SC resilience improvement (Ralston & Blackhurst, 2020 ). The report (OSTP, 2018 ) highlights the importance of SC resiliency and indicates that actions in different dimensions are needed to implement robust, advanced manufacturing SC. The influence of Industry 4.0 and digitalization on controlling of SC’s disruption risk is evaluated in Ivanov, Dolgui, et al. ( 2019 ), Ivanov, Tsipoulanidis, et al. ( 2019 )), and the discussion about the impact of COVID-19 on SC is reported in Ivanov ( 2020a ). The pandemic brings huge damage to the global supply chains, and clearly shows the lack of resilience in supply chains (Golan et al., 2020 ). Javaid et al., ( 2020 ) report the main technologies in Industry 4.0 have been applied in fighting COVID-19 successfully.

7.1.6 Efficiency and accuracy

French Railways operator SNCF uses IBM Watson IoT to improve rail safety and operational efficiency (IBM-News, 2017 ). With GE Digital’s software, Cascades Tissue Group can see in real-time if there’s a problem. The software helps them to achieve reduced production downtime, increased operational efficiency, and smarter decisions based on data-driven insights (GE-Digital, 2019 ). Robots in Amazon’s fulfillment centers increased efficiency and safety (Amazon-Blogs, 2019 ). Warehouse accuracy and efficiency can be significantly improved with IoT system.

7.2 Challenges of supply chains under Industry 4.0

While the Industry 4.0 and new ICTs provide opportunities to improve the supply chain performances, there are many challenges on the way to achieve the goals.

7.2.1 Availability, reliability, and limitation of technologies

How to catch up the rapid development of innovation and new technologies is one of challenges for U.S. Manufacturing identified in the report by OSTP ( 2018 ), especially for small and medium-sized manufacturers. Moktadir et al. ( 2018 ) indicate that the lack of technological infrastructure is the most pressing issue for Industry 4.0 implementation in manufacturing sector. In terms of technology, there is a wide gap between emerging jobs and skilled worker. Thus training, education, and knowledge updates are very important to implement smart manufacturing supply chains.

There are some limitations brought about by new technologies themselves. For example, as one of the authors observed, automated warehouse has limited flexibility to deal with high variation of demands (e.g. double or triple of regular demand during a promotion). It is difficult for automated DC to increase the capacity in a very short period, whereas traditional distribution center can handle the high variation by hiring temporary workers.

7.2.2 Smart factory needs smarter supply chains/logistics

Without suitable materials/parts and fast delivery to customers, the production in smart factory simply does not work. Zhang ( 2015 ) proposes that Smart factory/service needs smart, even smarter, supply chain/logistics. The smart supply chain is data driven with real-time visibility, and is connected, optimized, and intelligent. It has several features:

Time: planning in advance but flexible to changes, arriving just in time (lead time must decrease)

Scope: multi-levels, multi-function, multi-partners, multi-channel, and updating dynamically

Integration: high cooperation and coordination for whole supply chains

New business models, highly customized products/service, decentralized decision-making, global economics.

The following challenges/barriers are identified to achieve smart supply chains:

Industry 4.0 requires high cooperation and coordination for whole supply chains

Supply chain processes must be designed to operate in this digital business world

Individualization and increased product variety add difficulty to planning

Shorter product life cycle adds difficulty to procurement

Decentralization can increase facility and delivery cost

Both variety and short life cycle generates obstacles to achieve strategic fit.

7.2.3 Information sharing and trust establishments among organizations

New technologies, like IoT, CPS and different IT systems, provide the methods/tools to share the information among different partners in supply chains. However, there are barriers for information sharing in many situations. Trust among the organizations is one of them. Usually it takes a long time and lots of effort to establish trust between partners. Besides, a fundamental problem faced by SCM is to ensure that physical parts arrive from the desired source and are not swapped or modified. The integrity of both the cyber and physical components in industries relies on complex distributed supply chains (NSF- CPS -1932213, 2019).

7.3 Future research of smart supply chain under Industry 4.0

Based on the reviews on both active projects and literatures, we find that the research on smart chain management using emerging ICTs under Industry 4.0 is still at an early stage. Here we just outline some of the promising research topics in the areas.

Further analysis about impacts of Industry 4.0 and related ICTs on supply chain . Several review papers have been published, such as the impact of IoT on SC (Ben-Daya et al., 2019 ), ICT in multimodal transport transportation (Harris et al, 2015 ), block chain technology for future supply chain (Wang et al., 2020 ), and digitalization and Industry 4.0 on SC risk control (Ivanov, Dolgui, et al., 2019 ; Ivanov, Tsipoulanidis, et al., 2019 ), just to name a few. However, the rapid development of technology and innovation advances modern manufacturing and change industry 4.0 environment, which affect every aspect of supply chain. The new requirements and features of supply chain and related decision problems from different level under Industry 4.0 and new ICTs should be investigated so that to facilitate the evolution of supply chains.

Smart supply chain with new business model under Industry 4.0 . The business model is one of the managerial challenges of Industry 4.0 (Schneider, 2018 ). Benefiting from advance technologies, many new business models have been developed, such as dual-channel or omni channel retailing and supply chains, as well as drone delivery. The innovation and deployment of technologies lead to availability of real time data, lower operation cost, and increased information sharing. However, high uncertainty, wide distributed manufacturing and customers, and short delivery time are challenges faced by retailers and manufacturers. Some examples under the topics are: how to develop new supply network with emerging delivery tools (e.g., drones, self-driving vehicles), the challenges and opportunities of supply chains under digital business environments (NSERC-DG-Zhang, 2019), and how to facilitate the development of business model that are based on Industry 4.0 technologies for SMEs. The small and medium-sized manufacturers (SMM) are important parts of manufacturing supply chains, and can be key sources to develop and test new processes and new business models with emerging technologies (OSTP, 2018 ).

Blockchain technology for trust establishment and smart contract . As mentioned in the previous section, how to establish “trust” among organizations is essential to connect different partners in manufacturing SC systems under Industry 4.0. However, a notable extension of blockchain is Ethereum smart contract, which provides mechanisms for secure computation between entities that do not trust each other (NSERC-Strategic-Gong, 2018). Blockchain technology's ability to provide trusted consensus and data processing generates interest in potential supply chain applications, such as multiple domains of SCM (Kamble et al., 2019a , 2019b ) and a scheduling control methodology to blockchain-oriented smart contract design (Dolgui et al., 2019 ). Nevertheless, the application of blockchain to SCM is still in its early stages (Saberi et al., 2019 ).

Distributed manufacturing and supply chains with 3D printing . 3D printing will change the supply network by transferring centralized to distributed manufacturing and affect logistics by shopping raw materials for 3D printing, instead of parts. With the supply network, the manufacturer also will postpone finished goods production and affect the inventory strategy. However, our reviews on active projects and literature found that most current research focuses on materials and manufacturing process of the 3D printing and little research study the relationship between 3D printing and supply networks, logistics and other drivers of supply chains.

Modeling and algorithms for planning and scheduling of complex supply chain system . The connected manufacturing system and SC under Industry 4.0 can be very complex and also geographically dispersed. To make the system work efficiently, the decisions on different levels should be made timely and efficiently. Modeling, optimization and simulation approaches can be effective tools to achieve the goal. Theory and algorithm for control and optimization, and modeling and simulation are two of ten technical gaps identified in AMP 2.0 (AMP2. 0 , 2014 ). Several desired and promising topics include: (a) Algorithms for a dynamic and short-term schedule : the network may have dynamic structures that evolve over time. (b) Data-driven modeling and algorithms : how to incorporate the tremendous trove of data of supply chains into optimization models for better decisions. The stochastic and robust optimization models can be a tool for the incorporation. (c) Design of tailored decomposition algorithms : the integrated problem is usually large scale and might be computationally intractable with general purpose optimization solvers. Using the problem features and developing iterative data-driven solution methods with decomposition approaches will be promising. (d) Integration of optimization with machine learning . Machine learning is a promising method for data analysis to determine parameters, forecast demand, and detect future risks.

Data-driven self-organizing smart supply chains . The supply chain is one of the largest sources of big data for global companies (DHL, 2016 ). One topic is to study dynamic and self-organizing configuration of the supply network with industry IoT and cloud computing (Ivanov, Dolgui, et al., 2019 ; Ivanov, Tsipoulanidis, et al., 2019 ). The problem involved is how to quickly establish and reconfigure a supply network based on the available real-time information, such as capacity, inventory, and lead time of parts/materials either in potential suppliers or in other facilities (connected factories), to produce a new product or when the original supply network is interrupted. Resiliency and sustainability of supply chains also should be considered.