S&OP: A Comprehensive Overview of Sales and Operations Planning

Published: June 22, 2023

To create a quality product and provide an outstanding customer experience, your business processes must be fine-tuned. Every step — from manufacturing to delivery — should be well-executed.

That’s why sales and operations planning, or S&OP, is important. It aligns demand, supply, and financial planning, helping you make the best decisions for your business.

Let's demystify sales and operations planning (S&OP) and learn more about the S&OP process.

Table of Contents

Sales and Operations Planning Process

S&op metrics, top s&op software to use.

- Myths about S&OP

Sales and Operations Planning Best Practices

The purpose of S&OP is to coordinate across business units, increase transparency, balance supply and demand, and achieve profitability. S&OP can occur monthly, yearly, or even on a two- or three-year basis, depending on the company and its goals.

Here are some key benefits of sales and operations planning (S&OP):

- Increased transparency between departments.

- Informed decision-making about a product's demand and supply.

- Improved inventory management.

- Better sales and budget forecasting.

- A clear understanding of a product's lifecycle and its management.

- Streamlined processes that enhance the overall customer experience.

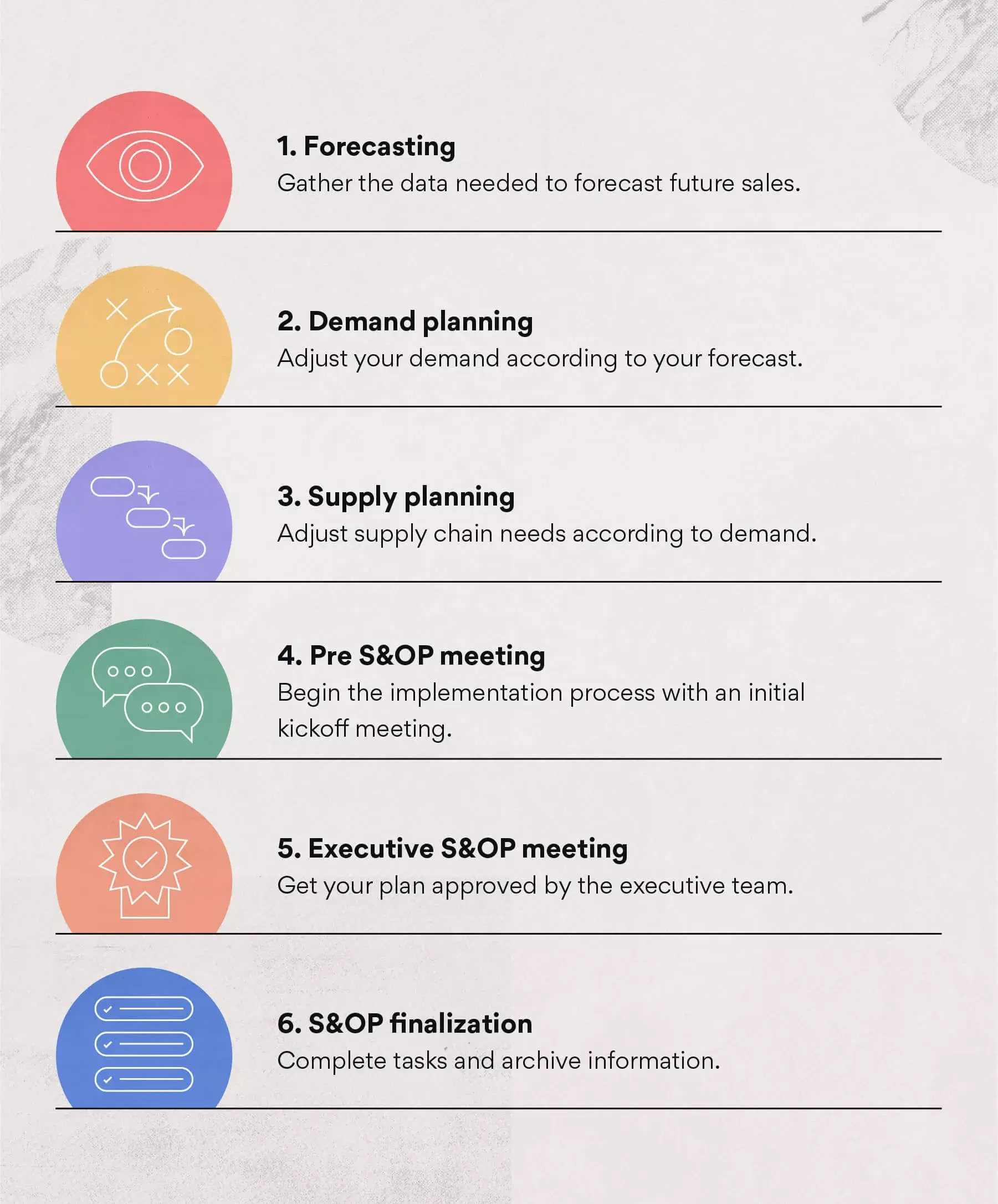

The S&OP process includes forecasting, demand and supply planning, and executive review. The goal is to coordinate sales and operations planning across business functions so they're all on the same page. The exact steps can vary depending on the company, its products, and its industry.

Free Sales Plan Template

Outline your company's sales strategy in one simple, coherent sales plan.

- Target Market

- Prospecting Strategy

You're all set!

Click this link to access this resource at any time.

1. Forecasting

At this stage of the S&OP process, data is gathered about prior sales, and forecasts are made for future sales. It's important to consider any internal and external factors impacting sales (e.g., industry, customers, competition). Any trends will be identified and analyzed.

2. Demand Planning

Demand planning is when cross-functional collaboration comes into play. The forecasts are analyzed. Then, adjustments are made to inventory and customer service policies based on the product demand and sources of demand. The demand can be measured in either revenue or units of a product.

3. Supply Planning

During supply planning, representatives from finance, operations, and materials evaluate capacity. They'll determine if there are any constraints on people, machinery, and suppliers. From there, a supply plan is created that will account for any capacity constraints.

4. Pre-S&OP Meeting

During this stage of the S&OP process, leaders from finance, sales, marketing, operations, materials, product management, and human resources meet to collaborate. They‘ll compare the forecasts to the demand and supply plans. Then, they’ll consider the plan's financial impact.

5. Executive S&OP Meeting

In this stage, executives meet to analyze all the forecasts, plans, and recommendations from the pre-S&OP meeting. By the end of the executive S&OP meeting, a final sales and operations plan will be approved.

6. Finalize and Implement

Once the sales and operations plan has been approved, it is time for implementation. After implementation, the S&OP should be evaluated regularly to ensure success.

When evaluating your S&OP process, there are some key metrics you can use to gauge performance.

Demand and Supply S&OP Metrics

Demand and supply metrics will help you determine if your forecasts are accurate and if the demand matches the supply.

- Demand forecast versus actual

- Production forecast versus actual

- Inventory turnover

- Capacity utilization

- On-time delivery

- Accuracy in order delivery

- Cycle times

Financial S&OP Metrics

These metrics show you how the business is performing from a financial perspective.

- Total sales in a period (e.g., month, quarter, year)

- Total sales versus forecast

- Gross margin

- Working capital versus plan

Which tools should you use for your sales and operations planning? Instead of solely relying on spreadsheets, here are some software options to streamline your S&OP.

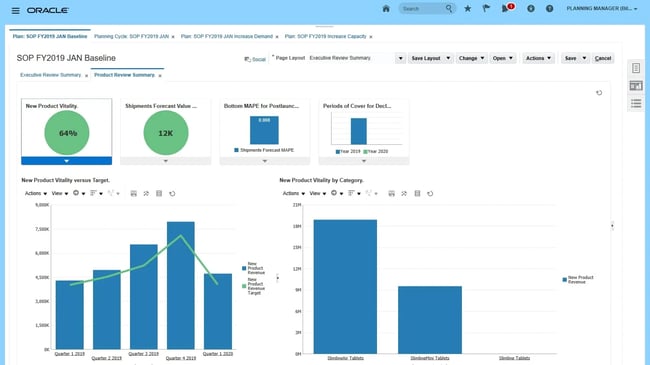

1. Oracle S&OP Cloud

Pricing: Available upon request.

Best for: Large-scale businesses.

Oracle provides process templates you can use to make your sales and operations planning run smoother. You can monitor each stage of the process, and dashboards allow you to see KPI summary graphics. This allows you to collaborate with colleagues and assign tasks.

Plus, it integrates with Excel.

Pro tip: Oracle S&OP Cloud is tailored primarily toward larger businesses. It includes features that suit the needs of enterprise-level customers. That includes social collaboration resources, accommodations for organizations with several users, and aggregate planning capabilities.

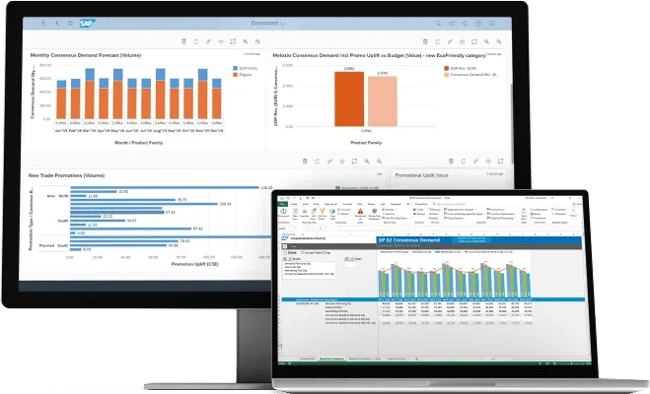

2. SAP Integrated Business Planning

Best for: Those who need a multifaceted solution, extending beyond S&OP for supply chain planning.

The SAP Integrated Business Planning software makes your S&OP planning quick and agile. Key features include scenario planning, simulations, and advanced analytics so you can stay on top of forecasts and hit your financial targets.

SAP Integrated Business Planning contains resources that allow for effective sales and operations planning, but the solution's capabilities extend well beyond the practice.

What we love: This tool combines S&OP, forecasting and demand, response and supply, demand-driven replenishment, and inventory planning to ensure business continuity through supply chain disruption.

3. Infor Sales and Operations Planning

Best for: Businesses looking for an accessible interface.

With the Infor Sales and Operations Planning software, you can synchronize demand and supply imbalances, coordinate across business units, and analyze performance. It even includes predictive financial analysis so you can see how business decisions will impact the bottom line.

Infor S&OP‘s user interface’s ease of use is one of the software‘s biggest draws. You don’t need to be an IT specialist to leverage it — allowing users closer to your sales and operations planning to manage and keep tabs on the process.

What we love: If you want a straightforward solution that keeps things simple without sacrificing functionality, look into Infor's sales and operations planning resources.

4. Vanguard IBP S&OP by Wolters Kluwer

Best for: Businesses interested in a collaborative solution.

Vanguard Predictive Planning is an excellent resource for any organization trying to support its S&OP infrastructure with an AI-based, end-to-end impact analysis solution.

Vanguard can provide your business with a comprehensive overview of your sales, demand, supply, and production to inform accurate, constraint-based plans — among a wide array of other features and benefits.

One aspect of Vanguard IBP S&OP is its resources for collaboration across all facets of your sales and operations planning. The platform includes business intelligence software that enables end-users to create their own charts, reports, and dashboards.

What we love: Vanguard Predictive Planning offers automated, easily adjustable workflows, visible scenario modeling, cross-department insights, and other features that foster collaboration between sales, operations, and finance.

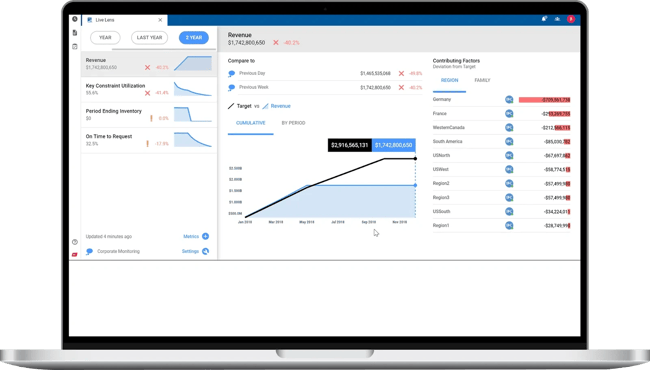

5. Kinaxis Rapid Response S&OP

Best for: Businesses looking for solid out-of-the-box features.

Kinaxis Rapid Response S&OP is a sales and operations planning solution that can help you improve business outcomes, take more centralized control of your S&OP, reduce costs in supply chain planning, foster collaboration, and generally increase efficiency throughout the S&OP process.

While Kinaxis Rapid Response S&OP does feature some degree of customization, it differentiates itself from the competition with its standard features.

What we love: Its out-of-the-box dashboards can help you accurately gauge performance immediately — with features accounting for revenue value, ending inventory value, margin percentage, and other key S&OP performance indicators.

Myths About S&OP

There are many myths about sales and operations planning. Here are some of those myths and why they aren’t true.

1. S&OP is not necessary for organizational growth.

Because S&OP doesn’t immediately drive leads and revenue for a business, it’s easy to think that it’s not integral to the growth of a business. On the contrary, S&OP is a management process that can help businesses of all sizes — from small startups to huge enterprises — achieve their business goals, outpace their competitors, and ensure continued success.

S&OP helps businesses gain better visibility into the supply chain, predict market changes, and make business decisions before the product reaches the customers. This way, they can match the market demand with adequate supply and generate as much revenue as possible.

2. S&OP is just a review of historical data.

While historical data is critical for benchmarking and analyzing past business decisions, it shouldn’t be the main focus of S&OP. Instead, effective S&OP processes should leverage past data to make predictions about future demand and gauge their ability to meet that demand through product innovation and stellar marketing.

Businesses should also ensure that they can provide great customer service to match the demand, and executives must make business decisions that they can afford to put into motion and generate profits from. These precautions can help businesses prepare themselves to adapt to rapid market changes and stay competitive in the long term.

3. Spreadsheets are just as effective as S&OP systems.

Many people believe that spreadsheets are the most effective and cheapest tool for S&OP — and that they should be used in place for actual S&OP systems. This couldn’t be further from the truth.

While spreadsheets are great for documenting data and making the case for an S&OP process, using them for supply chain planning is not feasible. Not only is spreadsheet-based planning time-consuming, but it opens up room for many errors and cannot scale alongside rapid business growth.

If you’re a fast-growing business, you’re better off using a purpose-built S&OP system that’ll show you real-time analytics and allow you to respond quickly to changes as they occur.

4. S&OP processes are difficult to manage.

The only way supply chains can be truly effective in today’s economy is when businesses collaborate closely with their trading partners.

When a company incorporates trader partner insights into its processes, the company’s credibility, as well as that of its executives, will increase, especially when their performance exceeds planning assumptions.

Thankfully, the advent of technology makes it much easier to effectively integrate trading partner insights into S&OP processes, which leads to better demand stream visibility, satisfied customers, and healthier profit margins.

5. S&OP is rigid and unchanging.

This particular myth stems from a misconception that an S&OP process can only be successful if it follows the standard 5-step process: product, demand, supply, financial, and executive reviews. In truth, an S&OP doesn’t have a fixed process that’ll guarantee great results for all companies or industries.

Companies need a flexible S&OP process to predict, plan for and manage changes in market conditions. This means that each company has to tailor its S&OP process to conform to its unique business structure.

1. Have executive ownership of your S&OP.

Successful sales and operations planning takes a certain degree of guidance and direction. With S&OP, you‘re essentially trying to facilitate cohesion between conflicting elements of your business — that’s not a responsibility that can be vaguely managed without clearly defined and engaged leadership.

The practice requires firm and active executive ownership — typically from someone like a CEO or general manager.

There's bound to be some kind of tension between the supply and demand sides of your organization, so you need a central figure ensuring that there are definitive, understood, and consistently enforced standards for how both parties will work with one another.

2. Keep things simple.

Companies conducting S&OP have tended to trip themselves up by overcomplicating the process — most notably when it comes to metrics.

If you try to keep tabs on too many factors between the supply and demand sides of your business, your planning might wind up being inefficient, and the visibility you're trying to maintain between departments could be clouded.

Instead of trying to measure everything you can think of, determine the most meaningful, relevant metrics for gauging how both sides of your business are working together — whether that be measurements of how forecasts are stacking up to actual sales figures, inventory turnover, or any particularly pertinent indicators of how sales and operations are interacting.

Try to keep the number of metrics you‘re tracking between 10 and 15 — make those choices count, and don’t let this side of the process get away from you.

3. Maintain records.

Successful sales and operations planning is an ongoing process. It leans, in large part, on your ability to learn from your previous hitches and hiccups. That's why you need to keep detailed records of your previous plans and processes.

Document most — if not all — aspects of your S&OP efforts. Those reference points can be central to your planning's sustained success.

4. Stress cross-functional engagement.

Cross-organizational collaboration is at the core of any and all sales and operations planning. Stakeholders from every impacted facet of the business need to be included and involved in the process.

Your sales and operations planning won‘t be particularly helpful or productive if you’re only considering your sales org's contributions and interests while ignoring other departments like operations and finance.

S&OP rests on your ability to foster cohesion through visibility. Every party involved needs to have a clear understanding of how the others are performing and where they're coming from.

That information needs to flow freely between stakeholders. If you want to get the most out of your sales and operations planning, you need to keep everyone in the loop and stress cross-functional engagement.

Incorporating S&OP Processes Into Your Business

Over the years, sales and operations planning has evolved from a simple demand-supply alignment process into an advanced business management process that streamlines business functions and enables companies to correctly predict market trends and make the best decisions about their product development.

With sales and operations planning, you can keep virtually every aspect of your company on the same page — allowing for a smoother functioning, more cohesive organization.

Editor's note: This post was originally published in October 2020 and has been updated for comprehensiveness.

Don't forget to share this post!

Related articles.

9 Strategic Planning Models and Tools for the Customer-Focused Business

A Straightforward Guide to Qualitative Forecasting

4 Clever and Effective Ways to Simplify Your Sales Process From Seasoned Sales Experts

![presentation s&op How to Develop a Strategic Plan for Business Development [Free Template]](https://blog.hubspot.com/hubfs/Copy%20of%20Featured%20Image%20Template%20Backgrounds-2.png)

How to Develop a Strategic Plan for Business Development [Free Template]

Lead Distribution Methods and Best Practices

Lead Routing: How to Precisely Implement and Route Key Prospects

The 25 Best Lead Distribution Software in 2022

Return on Sales: How to Calculate It and What You Need to Know

30 Key Interview Questions and Answers for Sales Operations Role

How Using a Document Library Can Improve Your Sales Process

Outline your company's sales strategy in one simple, coherent plan.

Powerful and easy-to-use sales software that drives productivity, enables customer connection, and supports growing sales orgs

Sales and Operations Planning (S&OP): Process, Challenges, and Expert Tips

By Kate Eby | April 19, 2017 (updated December 14, 2021)

- Share on Facebook

- Share on LinkedIn

Link copied

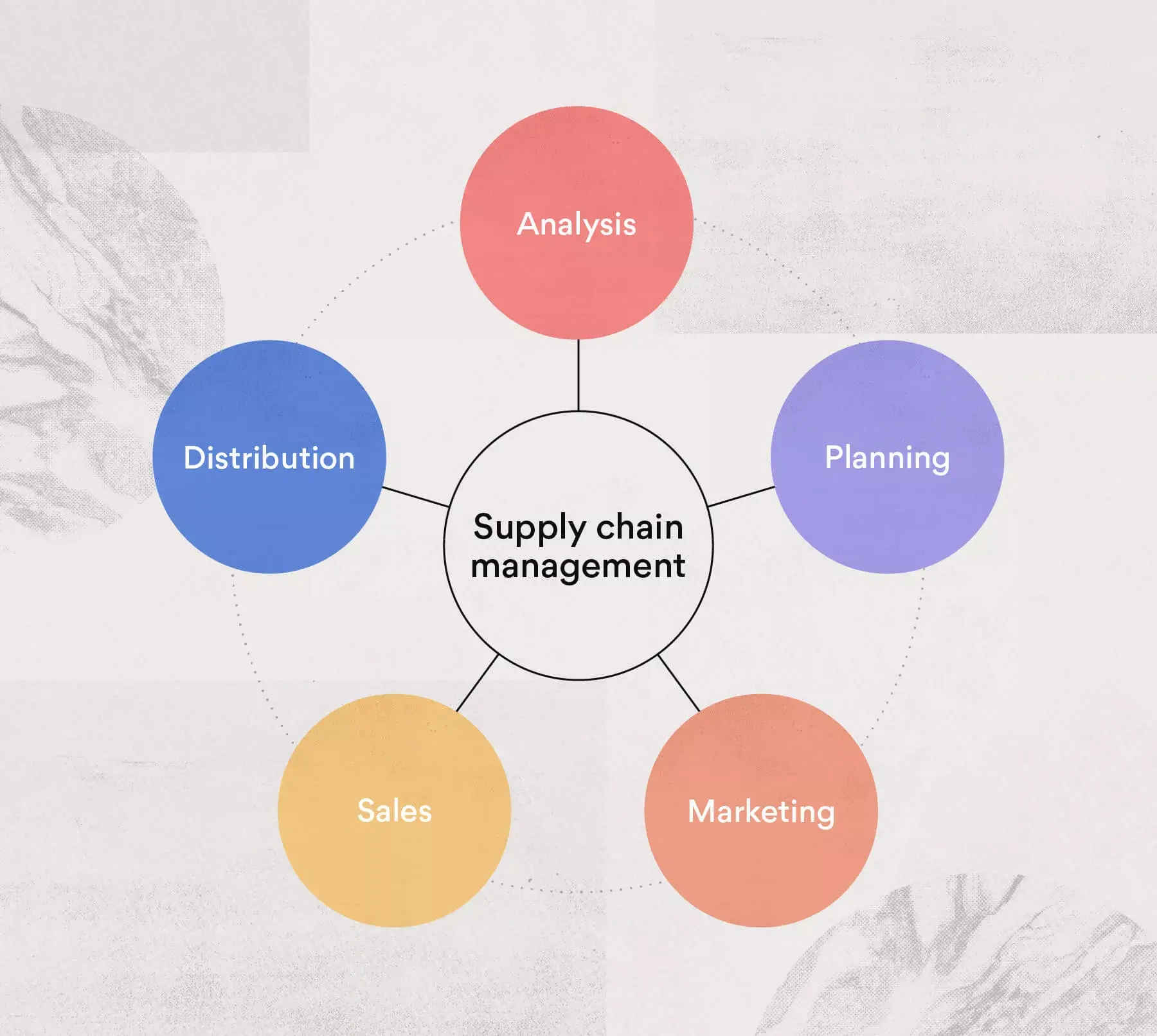

Sales and operations planning (S&OP) is a popular process that aligns a company’s diverse functions while balancing supply and demand. S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity). This allows them to continuously match high-level strategy with day-to-day operational tactics in all departments. Simply put, a company can run into trouble if it sells far more than it produces, or if it produces far more than it sells. The goal of sales and operations planning is to keep everything in balance.

With sales and operations planning, executives can manage the entire supply chain, optimize resources, and maximize profits. The high-level strategy in the annual business plan is integrated and aligned with the sales plan, production plan, marketing plan, new product development (NPD) plan, inventory/backlog plan, financial plan, and more. The sales and operations process alerts executives to timely adjustments they should make in any area.

Here’s how the American Production and Inventory Control Society (APICS) defines S&OP: “The function of setting the overall level of manufacturing output (production plan) and other activities to best satisfy the current planned levels of sales (sales plan and/or forecasts), while meeting general business objectives of profitability, productivity, competitive customer lead times, etc., as expressed in the overall business plan.”

In this article, you will learn about the sales and operations planning process and best practices, including steps for success and a discussion of common challenges. You’ll hear experts give their insights and tips, and they’ll provide their thoughts on the future of S&OP.

Benefits of Sales and Operations Planning

Sales and operations planning, sometimes called aggregate planning, started in the 1980s as a way to manage problems caused by overproduction or underproduction, including wasted resources, poor customer service, and the hit on a company’s bottom line. Before the 1980s, companies tended to rely on more siloed approaches, focusing planning efforts on the product level. Today, major companies such as Coca-Cola, Procter and Gamble, Eli Lilly, and Dow Chemical use sales and operations planning. At its best, S&OP offers distinct benefits that old-school business plans can’t achieve:

- Better data and collaboration between departments allow for frequent adjustments in the supply chain, which better balances supply and demand.

- Companies can better optimize resources, which reduces waste and increases efficiency.

- In turn, this newfound efficiency enables companies to maximize their profitability continuously.

- Improved inventory and backlog management allows for more timely customer service.

- As companies stagnate, S&OP can fuel a resurgence by finding ways to adjust to changing internal or external conditions.

- Unbiased, more actionable data can lead to better Key Performance Indicators (KPIs) for each department, tying in directly with the company’s KPIs .

- As data flows more seamlessly between departments, it is more timely and accurate - this allows the company to operate off one set of numbers rather than siloed, disputable data. You may hear people in the field refer to “one set of numbers to run the business.”

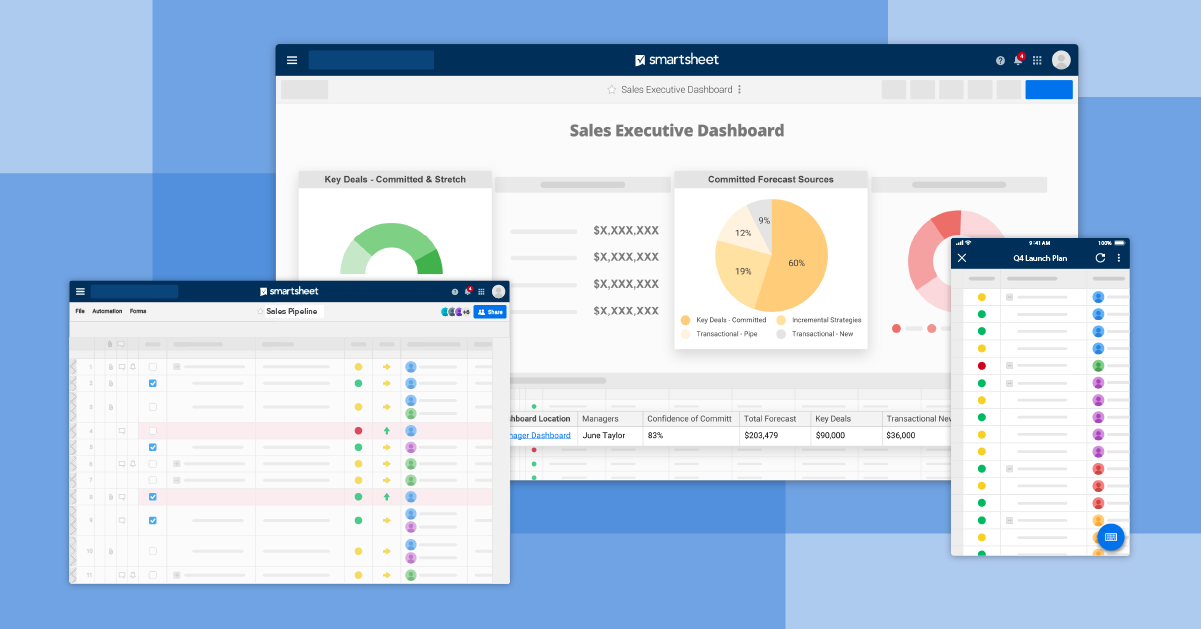

Keep deals moving forward with sales pipeline management in Smartsheet

Smartsheet is a cloud-based platform that allows sales teams to effectively manage pipelines by creating one location to track and manage efforts, surface open and at-risk opportunities, and provide real-time visibility to improve forecasting. See Smartsheet in action.

Watch a free demo

Approaches to the Sales and Operations Planning Process

While approaches vary among industries and companies, they typically focus on a monthly S&OP planning process with a long-term planning horizon ranging from 18 to 36 months. The annual overall business plan ties in with all other company plans, which are regularly reviewed for alignment. Consistent, structured meetings (that require participant preparation), are held. These are often weekly meetings to prepare for the monthly S&OP executive meeting, where the big decisions are made; therefore, it’s essential to have the right people present. During the meeting, attendees review tactical plans in every area to ensure alignment with the company’s business plan. These typically include the sales, production, human resource, engineering, marketing, new product development (NPD), inventory/backlog, strategic initiatives, and financial plans. The meeting participants represent the various departments and are empowered to make decisions then and there, as is necessary for the process to work.

Companies may use top-down planning or bottom-up planning. In top-down planning, a single sales forecast drives the process: managers create tactical plans and divide resources based on that. Bottom-up planning is used when the manufacturing schedule isn’t stable: instead of operating from the top with a sales forecast, they work from the bottom by analyzing what is needed to produce various products or product families.

Once that work is complete, companies solidify production plans, which can be level, chased, or mixed. In level, production remains constant, usually to increase cost-efficiency and keep the cost of holding inventory low. In chased, production always chases demand. It’s used when the cost of gearing up is relatively low and/or when the inventory storage cost is high. In mixed production, a custom plan takes the best advantage of the various factors in different situations.

Step-by-Step Practices for the Sales and Operation Process

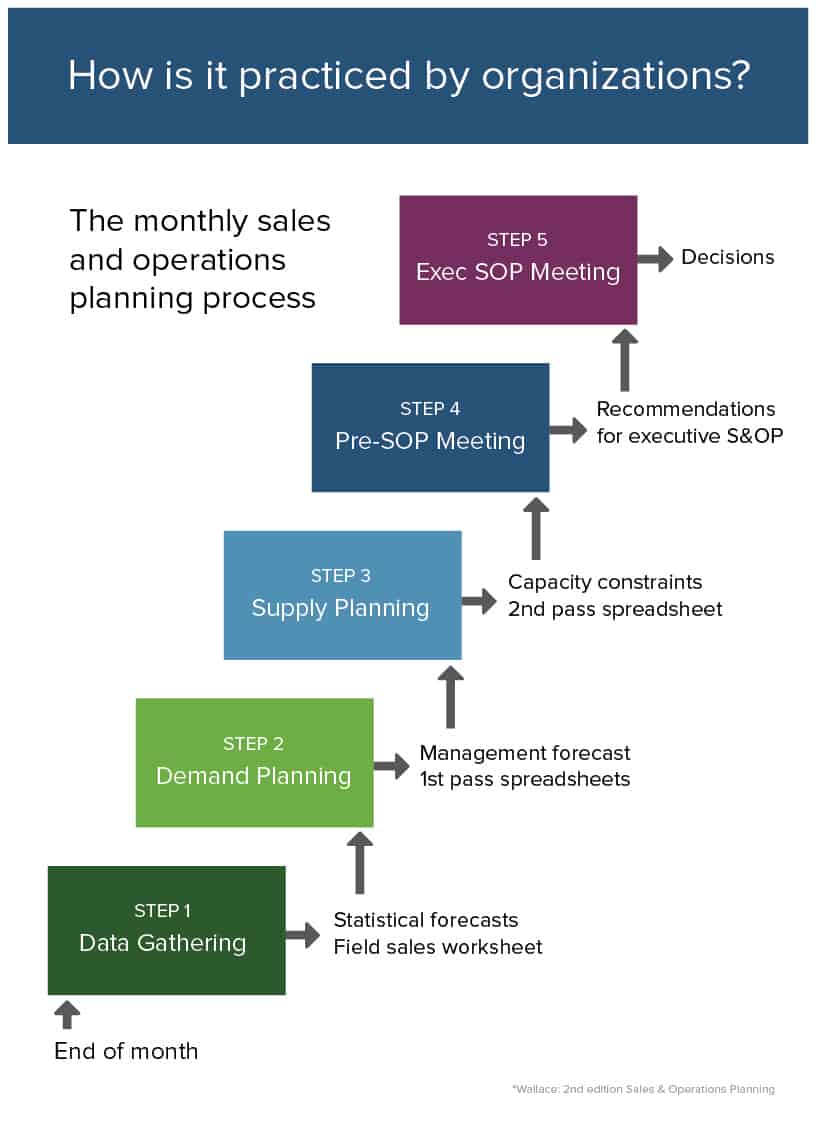

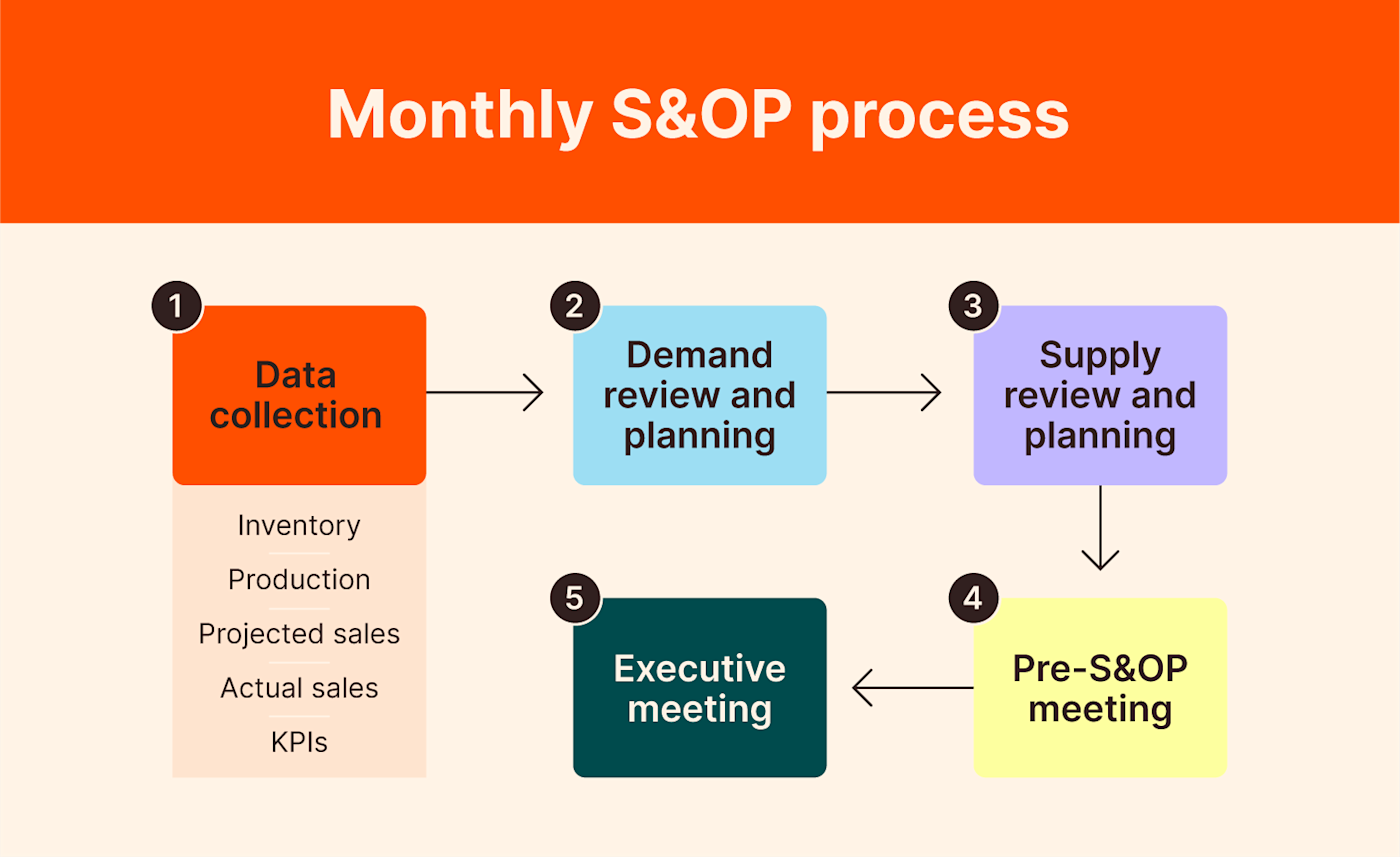

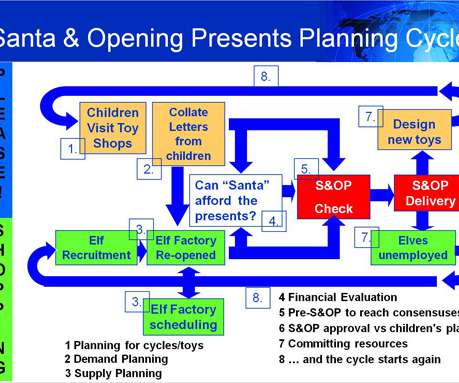

A company might follow one of a few slight variations of the step-by-step S&OP process. The accompanying graphic shows a monthly five-step process: data gathering, demand plan, supply plan, pre-S&OP, and finally the executive S&OP meeting, where decisions are made.

Sales and Operations Planning Tips from the Pros

Suresh Dalai is a retail operations professional based in Singapore.

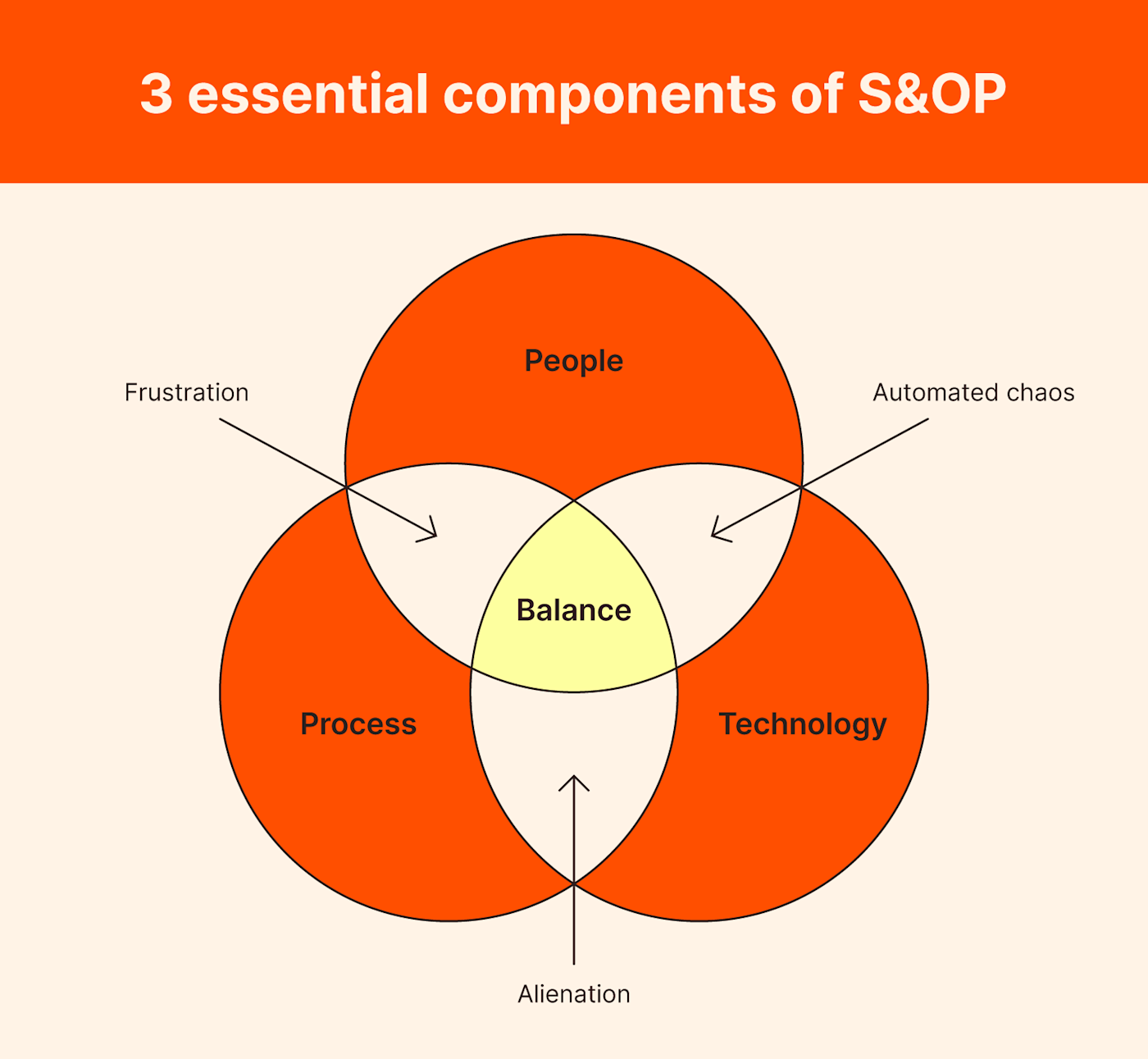

He has been implementing S&OP best practices for more than 20 years in Asia and the U.S., previously with retailers such as Levi Strauss and Ermenegildo Zegna, and retail consultancy Kurt Salmon Associates. He advises focusing on people, process, and practice:

- People: “Ensure that the implementation is heavily cross-functional and that different functions are bringing different perspectives to the table. Ensure that people are engaged in the process by clarifying roles and accountabilities, fostering an environment for open discussions, and helping people understand that their most important role is in making sure that you smoothly hand off your finished product to the next person in the process.”

- Process: “Clearly define the end-to-end process steps, and delineate who is Responsible, Accountable, Consulted, Informed (RACI) . Finally, develop a calendar so that activities are done timely, and make sure someone is facilitating that calendar.”

- Practice: “Make sure people understand that a well-executed S&OP process does not happen overnight, that it takes practice, and that it is OK to make mistakes along the way. Instilling a culture of continuous improvement is key.”

Kyle Brost , Principal at the Choice Group, offers these three sales and operations tips:

- “First, make sure a diverse group of people across the organization are able to participate in the process. S&OP is not just about balancing supply with demand, it is about aligning the organization. And without including people from across the organization, it’s easy to end up with a great plan that never gets executed.

- Second, if alignment is a key component of S&OP, there has to be something to align to, and this should be the high-level strategy for the organization. Effective S&OP isn’t a stand-alone effort, it really is the bridge between the strategy of the organization and operational execution. When strategy and S&OP are disconnected, you end up executing perfectly on all the wrong things.

- Third, as part of the plan, try to assume and predict where it will fail and build mitigation plans. This way, when challenges to the plan surface, the organization isn’t caught off guard. Rather, they anticipated them and already know what to do about them.”

Jeffrey J. Fox, Founder of management consulting firm Fox and Company , gives these three tips for cross-department sales planning processes:

- “Never lose sight that the goal is to increase profitable revenues. Too many companies morph this planning process into a new department, a new set of procedures, bureaucratic stuff that strangles selling.

- Cross-selling between business units is hard for lots of reasons. Everyone who isn’t in the field thinks it’s easy. There are lots of legitimate barriers. Do not expect a guy in Unit A to sell products made by Unit B. That is never going to happen. Incentives must be such that the guy in Unit A is encouraged to get his customer to buy something from Unit B. This incentive can be a finder’s fee, a referral fee, or something else. And Unit B has to teach Unit A, not how to sell, but how to recognize opportunities for Unit B (and vice-versa). Have low expectations. Even though it is the Holy Grail for many multi-product, multi-division companies, success is elusive.

- One good objective … is to design a product forecasting system that overlays Units A and B. Forecasting is tough, but doable. A good forecasting model helps balance inventory, directs supply chain managers, and impacts sales compensation. A good management technique is to establish a three-month task force to get it done, and include salespeople on the task force. If it goes past three months, it is doomed.”

Ali Mirza, President of Rose Garden Consulting , offers this advice:

- Make sure different departments are speaking the same local language. Take the time to be clear. Many times, they’re using terms differently. “I don’t think sales and operations necessarily understand each other. … It boils down to communication.”

- To do a good sales forecast, account for changing circumstances. Historical data needs to be placed in the context of what’s happening now. At a smaller company, a top seller’s personal problem, such as a divorce, could even have a large impact. “Base your forecast off of real events.”

Here’s a quick look at more sales and operational planning tips and best practices:

- Be aware that the biggest factors affecting a business are often external, so create S&OP initiatives to deal with them. External factors include the actions of your customers, partners, and competitors, among other things.

- Leaders need to step in to get beyond department conflicts that can otherwise drag down the whole company.

- Use technology, including S&OP dashboards and spreadsheets, to communicate key company information.

- Integrate supply data with demand data. Too often, various spreadsheets and systems don’t “talk” to each other effectively, which results in siloed data.

- Don't get lost in data. Focus on what really matters with KPIs, both within teams and company-wide.

- Use S&OP to deal with an unconstrained demand for products. Too often, companies don’t temper their sales goals with a realistic view of what they can supply, especially in the short term. S&OP helps balance supply and demand.

- Use a phased, incremental approach to developing S&OP. Remember, it doesn’t happen overnight.

How to Know if Your Sales and Operation Plan Is Successful

Here’s how you know when you’re succeeding, says Dalai: “At a simplistic level, people are not blaming each other; rather, they are admitting mistakes, praising good efforts, and lending help to other people on the team when needed. When most of the conversation is about what the other person or function did wrong, it is a good indication that S&OP is not working well. More technically, there are KPI’s related to how well the sales and operation plan is working; for example, in retail, KPIs would be:

- High stock fill rates or low stock-out rates

- Good inventory turns and high sell-throughs

- Timely execution of inventory flows from the factory to distribution center to the shop.”

As Dalai notes, different industries and companies will have their own KPIs to measure S&OP success.

As the Choice Group’s Brost explains, “To know if your plan is succeeding requires answering two questions. First, did we execute the plan we had in place? And second, did we achieve the results we hoped for? The first question has to be answered first because it is your leading indicator. You can never know if the plan was successful until you know if you actually executed the plan. Once you know if you executed the plan, then you can ask if it delivered the desired results; these desired results should have been defined as part of the plan. For example, what ROI can we identify from our investment of resources in various parts of the plan? , and what ROI do we require to justify those investments? ”

Understanding Sales and Operations Planning Terms

Terminology can get confusing, as different people often have differing interpretations. Here are answers to frequently asked questions regarding S&OP-related topics and organizations.

- How does a sales plan differ from a sales operations plan? A sales plan typically sets sales goals and describes tactics to achieve them. A sales operations plan may refer to either a sales operations department plan, or to the entire concept of sales and operations planning (S&OP).

- What is aggregate planning? This term is sometimes used interchangeably with sales and operations planning (S&OP). More specifically, it may refer to production planning that gives executives a view into necessary resources and their costs.

- What is integrated business planning? This is similar to sales and operations planning in that it involves planning throughout the supply chain. Some may use the term interchangeably with S&OP, while others say it’s an extension of S&OP (or a more mature version of it).

- What is an operational plan? A detailed plan that specifies how a team or department will contribute to the company’s goals.

- What does AOP mean? The annual operations plan (AOP) lays out the company’s targets for sales and supply.

- What is Enterprise Resource Planning? Enterprise resource planning (ERP) is the system or process by which a company (usually a manufacturer) integrates its various departments. ERP software tries to incorporate key pieces of information from the departments or teams.

- What is the Institute for Supply Management? It is a nonprofit, educational organization for people employed in the supply management profession.

- What is the Supply Chain Council? In 2014, the Supply Chain Council merged into the American Production and Inventory Control Society, or APICS. The council is now known as the APICS Supply Chain Council.

- What is the SCOR planning model? The Supply Chain Operations Reference (SCOR) model is endorsed by the Supply Chain Council. It’s a cross-industry, standard diagnostic tool for supply chain management.

- What is SOP vs. S&OP? SOP is completely different. It stands for standard operating procedure, and is a set way of performing tasks in a given organization.

Common Challenges in Sales and Operations Planning

Challenges in sales and operations planning are common. A 2013-14 survey by Supply Chain Insights found that only 43 percent of companies say their S&OP process is effective. Here’s what the experts say about the most common difficulties in sales and operations planning today:

Suresh Dalai: “It [the challenge] is in the quality of the collaboration among functional team members. Each member has to know their role, be accountable, and make sure that each member communicates well so that the next person in the process understands what the person before him/her has done. And when mistakes occur, team members need to be able to come together and openly discuss what/who came up short and learn from it. In fact, a process does not have to be great. The people - and how well they work together - can make it great.”

Kyle Brost: “The reality of S&OP is that it’s a process heavily reliant on historical data, which very likely doesn’t predict the future. Recognize going into the process that a number of market and organizational factors will influence the success of your sales and operations plan. The biggest challenge is being able to identify patterns and draw connections between internal and external factors that may influence supply/demand and your S&OP process. Because this is challenging, too many organizations default to just relying on the historical supply and demand data that they have. Additionally, recent sales and operations experiences often get weighted more than they should, because they are fresh in people’s minds. Try to avoid making big decisions based on a single recent experience.”

Ali Mirza: Sales forecasting remains a frequent problem. It’s often arbitrary, such as a five percent sales growth being based more off of where the company wants to be than what it can realistically achieve. “Sales managers are expected to grow their territory, so they forecast a growth goal. … Nine times out of 10, the forecast is incorrect,’’ Mirza says. People in sales will often say that it’s not arbitrary, that they do have a rationale behind the forecast, but “typically, the rationale and logic is also flawed.” They need to consider the various changing factors at play and not just look at the historical data.

Here’s an overview of other common S&OP difficulties:

- Sudden changes in supply and demand (such as with a new product)

- Lack of executive support

- Inadequate engagement between departments

- Focusing on a single target number instead of a range

- Too many numbers and not enough focus

- Conflicting numbers

- Lack of documentation (which leads to repeating history)

- S&OP software that requires organizational change for effective use

- Organizational change required by the process itself

- An S&OP leader who doesn’t act as the necessary profit center manager

- Executives who fail to understand supply chain complexity

- Translating the planning process to effective execution

What Does the Future Look Like for Sales and Operations Planning?

Two experts weighed in on the future for sales and operations planning.

Dalai sees people as being key to the future. “Increasingly sophisticated technologies and analytics will continue to be released to improve the S&OP process and effectiveness. However, at the end of the day, it is the cross-functional collaboration - people understanding what they have to do and trusting that other people will do their part - that drives success in S&OP. And this cannot be achieved by technology or analytics,” he says.

Brost foresees S&OP having a growing relationship with Organizational Network Analysis , a structured way of visualizing how information and decisions flow in an organization. “I see S&OP and Organizational Network Analysis merging in time. The best business decisions are usually arrived at by combining quantitative data with qualitative data - S&OP is the quantitative piece and Organizational Network Analysis is the qualitative piece,” he says. “Also, executing on the sales and operations plan requires strong insight about how work is actually done in the organization, not just how the processes are mapped on paper. When organizations can combine these two approaches, the result will be a much more powerful plan that factors in the nuances of the organization itself.”

Effectively Manage Sales Operations Planning with Smartsheet

Empower your people to go above and beyond with a flexible platform designed to match the needs of your team — and adapt as those needs change.

The Smartsheet platform makes it easy to plan, capture, manage, and report on work from anywhere, helping your team be more effective and get more done. Report on key metrics and get real-time visibility into work as it happens with roll-up reports, dashboards, and automated workflows built to keep your team connected and informed.

When teams have clarity into the work getting done, there’s no telling how much more they can accomplish in the same amount of time. Try Smartsheet for free, today.

Discover why over 90% of Fortune 100 companies trust Smartsheet to get work done.

Solving your most complex planning challenges

Explore Industry Research

What do Gartner, Forrester, and IDC have in common? They all named Anaplan a planning leader.

Your success is the heart of our success

Hear from our customers at Anaplan Connect 2024

Join us for a day of connected inspiration from your industry-leading peers who have found the answer in agile, connected enterprise planning.

Transform how you see, plan and lead your business

Get started today.

Explore on-demand demos to discover how our modeling and planning capabilities are designed to meet the specific and unique needs of your business.

Transform how you see, plan, and lead your business

We’d love to find out how we can help you

Events, training, and content for your planning journey

Visit our blog and newsroom

Your hub for Anaplan updates, insights, perspectives, and innovations.

Powerful partnerships to drive your digital transformation and deliver game-changing strategies.

Solutions for your business, your industry, from the world’s leading alliances.

- wrappers --> Supply Chain

The ultimate guide to the sales and operations planning (S&OP) process

- Share on Twitter

- Share on Facebook

- Share on LinkedIn

The platform for orchestrating performance.

Review our in-depth S&OP guide complete with a step-by-step process, best practices, and software evaluation tips.

Sales and operations planning (S&OP) is a supply chain planning process to help business leaders make decisions on a wide range of topics including:

- Balancing demand plans with supply plans

- Making planning adjustments in sales and operations execution (S&OE)

- Introducing new products and phasing out of old products

- Examining proposals and investments related to markets and suppliers

- Ensuring annual operating plans and company KPIs are met

While the process is designed and executed by supply chain leaders, interdepartmental communication is critical to success. Data support from partners in finance, sales and marketing, procurement, engineering, and operations are usually required.

With an eye on financial and business impact, the goal of S&OP is to enable executives to make better-informed decisions through a dynamic connection of plans and strategies across the business. Often repeated on a monthly basis with weekly touch points by key participants, S&OP enables effective supply chain management and focuses the resources of an organization on delivering what their customers need while staying profitable.

Keep reading to learn how effective S&OP works and how you can elevate your organization’s S&OP process to drive tangible profitability.

The six steps of the S&OP process

1. Product review: In this first phase of the S&OP process, planners involved in R&D, product development, and new product introduction analyze the health of products in the market, examine product pipelines, and arrive at decisions about product planning. These decisions might include setting dates for new production or sunsetting to determine project prioritization and resource allocation.

2. Demand review: The goal of this phase is an unconstrained forecast or consensus demand planning , incorporating a holistic picture of independent and dependent demand. Factors influencing independent and dependent demand may include marketing, new product introduction, consumer trends, product hierarchy, and interplant part demand.

3. Supply review: The goal of this phase is a supply plan that syncs with the consensus demand plan. Ideally, these two plans work in unison. The supply plan should balance customer service and minimize inventory as well as operating costs. A baseline production plan and rough-cut capacity plan are developed, along with alternate supply plans that factor in capacity and demand variations.

4. Finance review: In this phase, financial performance for the previous month is consolidated to provide inputs for analyzing the current month’s S&OP cycle. Finance owns this process and it can include different categories or views, including product, geography, customer, and channel. Actual costs are compared with budgets and forecasts to analyze forecast accuracy over a rolling time frame.

5. Pre-S&OP: Pre-S&OP is a series of meetings conducted with leaders at various levels that showcase the connectivity of plans across product, demand, supply, and finance. Ideally, these meetings center around a cloud-based platform that houses all the plans in a single place. The purpose of pre-S&OP is to identify key gaps and disconnects and create strategies to handle those issues. The plans are reviewed in shared dashboards and actual versus variance is analyzed, keeping targets and budgets in mind.

6. Executive S&OP: The finish line is in sight. The final phase of S&OP brings all plans and data together in a unified, cloud-based platform to be used in executive S&OP meetings. “What-if” scenarios and the associated risks are reviewed, and decision points are noted so leadership knows when they’ll need to make the appropriate choices. Any key decisions that weren’t resolved in the first five phases are addressed in this phase, the reasons for escalation are examined, and decision deadlines are set.

Revitalizing your S&OP process enables you to return to growth. Read our white paper to learn how next-gen S&OP serves as the ideal forum for integrated planning.

S&OP best practices to follow

Executive support and participation.

The most important S&OP vital sign is whether your executive stakeholder is directly involved in the process by participating and providing leadership in each S&OP meeting. In this context, the executive leader is the head of the organization in the position of CEO, president, managing director, general manager, or P&L owner.

S&OP is successful because it aligns planning across functions in order to meet company objectives and improve performance. Compromise is often required between functional areas, and at times, functional leaders may disagree on the best approach. The S&OP meeting provides a forum for routine decision-making where the executive leader considers team recommendations and decides the course of action. When the executive leader is not committed to this decision-making forum, functional leaders will find other ways to resolve their issues and the result is friction, confusion, and under performance.

Cross-functional scope

The S&OP process drives cross-functional alignment and collaboration. S&OP success depends on participation by all functional leaders — such as VPs of product, sales, marketing, supply operations, and finance — to provide a synchronized effort to reach the company’s goals. Just as the competitiveness of an eight-person rowing crew would be compromised by an empty seat, the absence of any functional area from the S&OP process handicaps the ability to deliver customer value and financial performance.

The consequences of an empty S&OP seat show up in many ways depending on the seat’s owner and can result in poor coordination on new product introductions, unexpected sales, unexpected promotions, material constraints, or capacity constraints. The result is mismatched product volume, mix, location, or timing, all of which negatively affect the company’s performance. If a check of your S&OP process reveals an empty seat in a team that at a minimum should include the leaders of product, sales, marketing, supply operations, and finance, you have likely found an opportunity to improve S&OP performance.

Constructive issue resolution

By its very nature, S&OP produces disagreement. After all, it is the process of developing the tactical plans necessary to achieve the corporate strategy. Functional heads are certain to have different opinions about the best approach. The S&OP team needs to be able to have candid and constructive discussions about issues and challenges, otherwise, tactical plans will not align with strategy, compromising the S&OP program and corporate performance.

Don’t let your tech hold you back

The selection of an S&OP software solution typically includes an initial evaluation of functional and technical criteria to determine what the solution does and whether it fits company requirements. More difficult to evaluate, but equally important, is the question of how a solution works and how it fits with a company’s unique business operations.

Key points to consider when evaluating S&OP software

Process compromise.

Place high priority on the solution’s fit to your business operations. Depending on the solution type, more time (and in some cases, a pilot) may be required for fit confirmation.

Ease of deployment

Longer implementation times increase the risk that the solution will be outdated upon completion because of changing business conditions or opportunities. Minimize time to value in both the solution selection and project planning phases. Plan for demonstrable value in 8–12 weeks. Avoid anything longer.

Ease of change

Change is inevitable. Technology must flex with the business or it becomes a friction point and slows the business down. Be cautious if minor modifications require more than an hour to get into production. Avoid those that take more than a day.

Business-user administration

Modern solutions can be administered by a business user without significant support from IT. This is a welcome development since most IT departments operate at capacity. Avoid a solution if technical resources are needed for application administration.

No change orders

Business user self-service eliminates the need for change orders to the technology provider or system integrator. Change orders are expensive and time-consuming and place a formal project justification and approval process between you and flexibility.

The bottom line

With Anaplan, sales and operations planning (S&OP) is unified across all relevant business units into one cloud-based, connected platform. When plans and data from sales performance management, financial planning and analysis, product, marketing planning, and supply chain work in sync, executives can make better-informed decisions that maximize profitability.

Continue your deep dive with these additional S&OP resources

- 2022 Gartner Magic Quadrant for Supply Chain Solutions

- 2022 Forrester Total Economic Impact of Anaplan

- The Digital Twin: Supply Chain Planning Revolutionized

Explore more information about Anaplan for S&OP

- Product overview

- All features

- App integrations

CAPABILITIES

- project icon Project management

- Project views

- Custom fields

- Status updates

- goal icon Goals and reporting

- Reporting dashboards

- workflow icon Workflows and automation

- portfolio icon Resource management

- Time tracking

- my-task icon Admin and security

- Admin console

- asana-intelligence icon Asana Intelligence

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Campaign management

- Creative production

- Content calendars

- Marketing strategic planning

- Resource planning

- Project intake

- Product launches

- Employee onboarding

- View all uses arrow-right icon

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Work management resources Discover best practices, watch webinars, get insights

- What's new Learn about the latest and greatest from Asana

- Customer stories See how the world's best organizations drive work innovation with Asana

- Help Center Get lots of tips, tricks, and advice to get the most from Asana

- Asana Academy Sign up for interactive courses and webinars to learn Asana

- Developers Learn more about building apps on the Asana platform

- Community programs Connect with and learn from Asana customers around the world

- Events Find out about upcoming events near you

- Partners Learn more about our partner programs

- Support Need help? Contact the Asana support team

- Asana for nonprofits Get more information on our nonprofit discount program, and apply.

Featured Reads

- Project planning |

- Sales and operations planning (S&OP): A ...

Sales and operations planning (S&OP): A project manager’s guide

Sales and operations planning is a six-step process that can help you achieve focus and alignment in all areas of your organization. Learn what the steps are and the impact this type of plan can have on your team.

Have you been struggling to align teams at your organization? It’s a problem many project managers face. Thankfully, there’s a solution.

Sales and operations planning is a six-step business process where a leadership team achieves focus and alignment in all areas of an organization. This involves aligning everything from the supply chain to product demand and adjusting needs where necessary. While it might sound tough, you can improve organizational clarity and alignment with this step-by-step guide.

What is sales and operations planning (S&OP)?

Sales and operations planning is an essential process that aligns operational plans with strategic business goals. It entails working together across different departments to balance supply and demand, improve business performance, and increase customer satisfaction.

Accurate demand forecasting, coordination of inventory levels, production capacity, and resource allocation are essential for this process. Such coordination fosters efficient operations that align with the overarching business objectives. Maintaining operational efficiency requires adapting plans based on market trends.

S&OP example

Consider a consumer electronics company that uses S&OP to prepare for an anticipated surge in customer demand for its latest product. By incorporating simulations and analyses into its demand forecast, the company can align its procurement schedules, manufacturing plans, and logistics strategies accordingly. Advanced analytics and dashboards provide real-time visibility, enabling adjustments to be made proactively to avoid supply chain disruptions. As a result, when the surge occurs, the company has the necessary working capital to meet the surge without falling into the pitfalls of overstocking or inventory shortages.

This example highlights how S&OP helps businesses make informed decisions and respond flexibly to market demands to safeguard customer satisfaction while optimizing inventory management.

Sales and operations planning process

Are you optimizing your S&OP process to its full potential? S&OP unfolds through a series of steps, typically observed in monthly meetings. Although the exact terminology and sequence might differ from one organization to another, they invariably share certain indispensable elements.

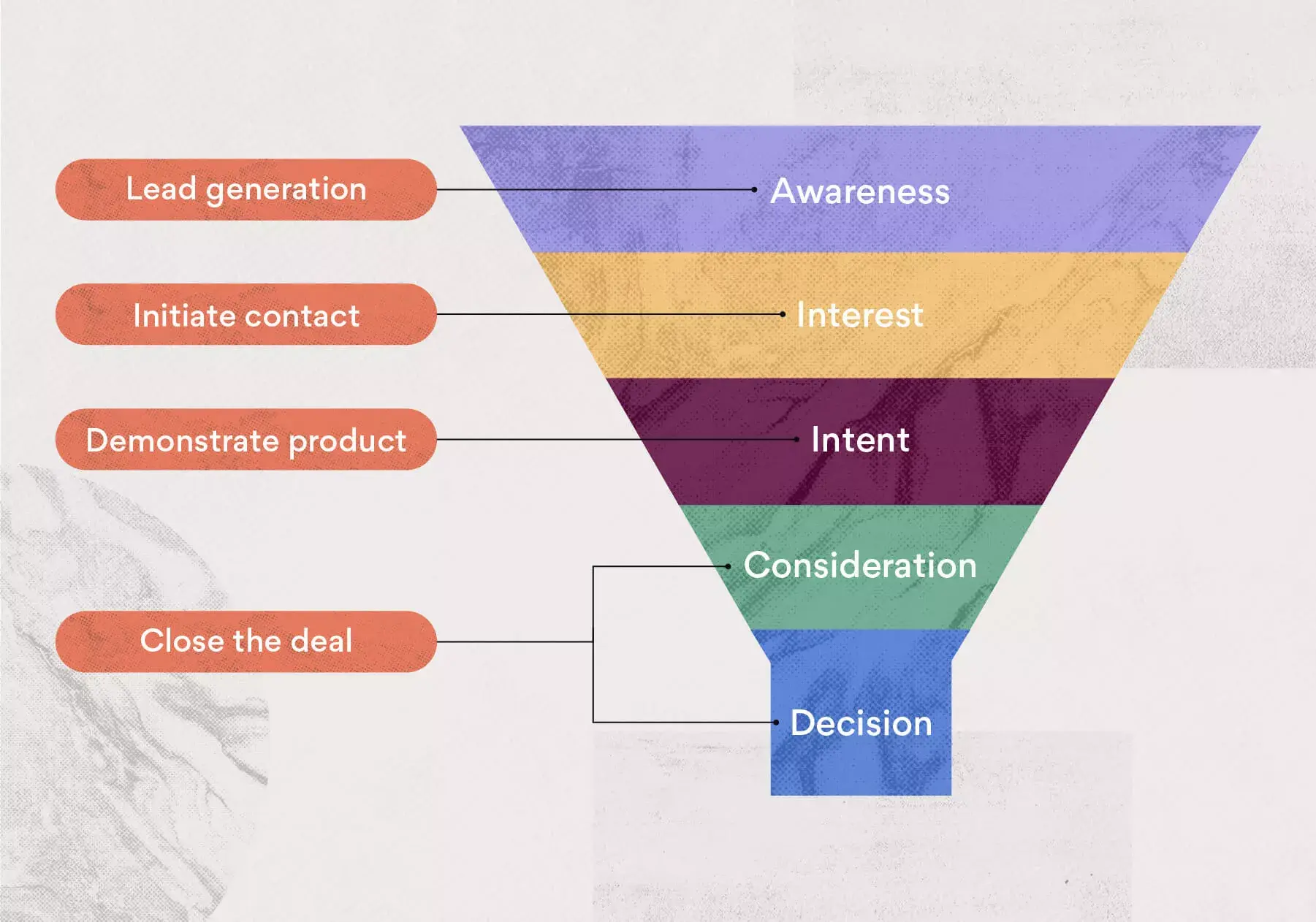

1. Forecasting

The first step in the sales and operations planning process is forecasting, which involves gathering the data needed to properly forecast future sales. The types of data gathered will depend on your line of focus but might include internal factors—such as current processes, cash flow, and inventory—as well as external factors—such as industry trends and competition.

These initial forecasts will help you properly plan and execute your S&OP and ensure that your data is recent and accurate. Along with internal and external forecasting, there are a few different types of forecasting methods you can use. These include lead analysis, opportunity stage, and intuition planning.

The type of forecasting method you use is up to you and may require some trial and error to find the right match. Whichever one you use, aim to collect enough data to move onto step two, which involves adjusting product demand based on forecasting findings.

Lead analysis forecasting

Lead analysis forecasting focuses on building relationships with your customers and analyzing lead sources to convert qualified traffic into sales. By assigning values to different leads, you’ll be able to better predict revenue generation and sales forecasting.

A sales pipeline template, like the one pictured below, is a simple workflow to help you document, track progress, and prioritize leads. You can then analyze past pipelines to forecast future sales.

![presentation s&op [Product UI] Sales pipeline template in Asana, spreadsheet-style view (Lists)](https://assets.asana.biz/transform/f9ef4865-4d5a-4eb7-bc6e-d6e5d6d2869a/Inline-Lists-Sales-Pipeline-2x-jpg?io=transform:fill,width:2560&format=webp)

This method involves analyzing:

The number of leads acquired

The conversion rate of acquired leads

The revenue generated per lead

The medium by which the leads were acquired

Analyzing this data from recent months or even years can help your team properly estimate which numbers to include in your S&OP.

Opportunity stage forecasting

Opportunity stage forecasting involves breaking each sales pipeline into smaller stages. A sales pipeline is a summary of upcoming sale opportunities. By reviewing sales opportunities, you can create a manageable plan and a clear strategy for each step of the customer lifecycle.

A sales pipeline can help you anticipate revenue and cash flow, discover resource gaps, and identify skill shortages. To do this, separate your pipeline into eight different stages:

Prospecting: In this stage, narrow down the potential company or contact and begin communicating with the prospect. This is usually achieved with an initial meeting.

Demonstration: In the second stage, use your meeting to give an elevator pitch and product demonstration to your prospect.

Investigation: During the investigation stage, take the information you learned from your demonstration and determine if your product or service is the right fit for your prospective customer.

Trial: Once you’ve determined that it is the right fit, your customer tests your product to see if it solves their problem.

Proposal: After the customer determines that they want to use your product, send them a proposal with additional details, including the price of the partnership.

Roadblocks: Once your product is implemented within the customer’s business, work together to solve any initial roadblocks. A roadblock could be an issue with the contract or product.

Negotiations: After solving the roadblocks, make any last-minute changes to the proposal before closing the sale with any necessary legal paperwork.

Closed win/loss: A successful negotiation results in a closed win, where the proposal has been signed and accepted. If the proposal is rejected, it is considered a closed loss.

Once each pipeline is broken down into the above stages, sales teams analyze the data to predict future outcomes.

Intuitive forecasting

Intuitive sales forecasting relies on verbal data given by sales reps. To use this forecasting method, communicate with the sales team about new leads in the pipeline, anticipate revenue from said leads, and configure the likelihood of the deal being closed.

While more subjective than the other two methods, intuitive forecasting is a good fit for teams looking for a quick and general forecast rather than a precise and accurate forecast. It’s also a good choice if your organization doesn’t have historical data to analyze.

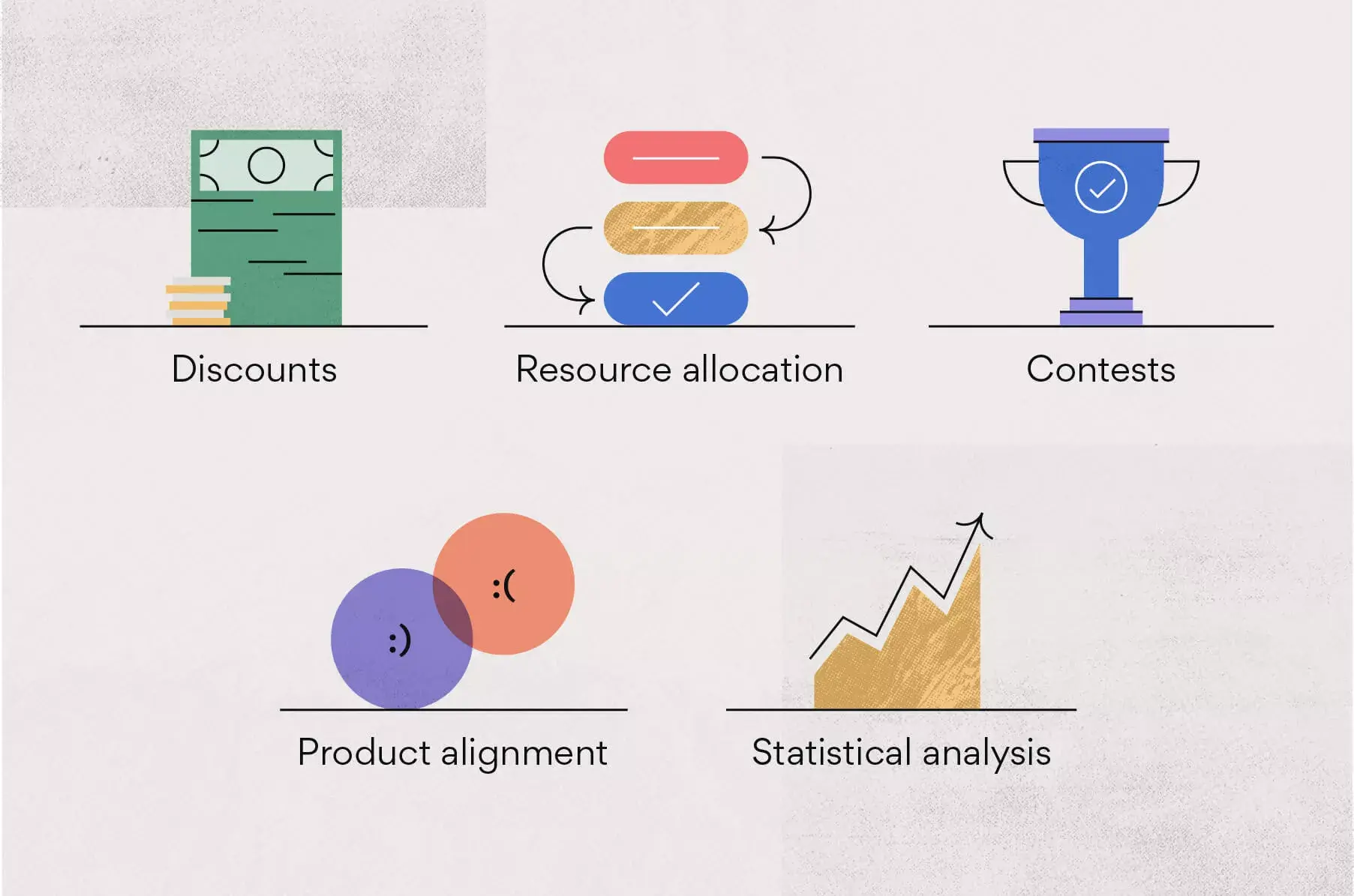

2. Demand planning

The next step in the planning process is adjusting your demand according to the forecast you gathered in the previous step. Analyze your forecasts based on internal and external factors, and make adjustments to inventory numbers as needed. Then, use that information to create a project schedule .

There are three parts to a successful demand planning process, including:

Trade promotion

Product portfolio management

Statistical analysis

You may also choose to perform demand shaping in this stage, which is where you implement tactics such as price incentives and cost modifications to meet your demand goals. While helpful, it’s not always required.

Trade promotion management

Trade promotion management is the planning and processing of trade spend, sometimes with the help of software tools. Trade promotion is used during demand planning to implement special product pricing, which then increases demand for said products.

Trade promotion includes a variety of activities, including:

Discounts: Some of the most common promotions companies use are discounts. This is when one or many products are sold at a lower price to incentivize sales.

Bundles: A bundle promotion is when a variety of product families are sold together, sometimes at a discounted price, instead of individually. Not only does this incentivize purchasing multiple products, but it’s also a great way to show how your products work together.

Rebates: A rebate is an after-purchase product discount. Since they require consumers to claim or send their offer in some way, they have a lower completion rate, ranging between 5 and 80% .

Contests: Another form of promotion is through contests. A contest campaign involves offering a prize for purchasing, such as a free product or cash offer.

Trade promotion is heavily intertwined with marketing, but whereas marketing can focus on a variety of different performance metrics, trade promotion focuses solely on driving direct sales. Implementing these tactics can help increase demand for your product and, in turn, drive sales.

Product portfolio management can help you manage all aspects of the products your company sells, otherwise known as your product portfolio. These aspects can include anything from evaluating performance to prioritizing product value.

Product portfolio management may also include:

Product alignment: Aligning products based on offering, branding, uniqueness, and price to create a cohesive product portfolio.

Product analysis: Analyzing products based on their position in the market and the impact they have to help grow your portfolio.

Low profitability elimination: Eliminating less profitable products to keep your portfolio performing well and help bring in steady value growth.

Resource allocation : Allocating and scheduling resources for product development to meet market demand.

Portfolio managers lead these aspects of your product roadmap and ensure the team has the right tools to create efficiency.

Statistical analysis

Statistical analysis is the collection and interpretation of data to identify patterns and trends. This involves using data analytics to spot needed changes to product demand.

Statistical analysis includes the following steps:

Identify the nature of the data

Explore the relation of the data to market trends

Summarize how the data relates to market trends

Prove, or disprove, the validity of the relationship

These steps help build a comprehensive understanding of product data such as demand, price, and market demand. This can help clarify your strategic plan and ensure your demand planning is backed up by data.

3. Supply planning

Addressing supply chain disruptions requires cross-team collaboration in the planning phase, with finance, operations, and product leaders working together to adjust their supply chain needs.

This step is based on the previous inventory adjustments and aims to determine whether there are constraints associated with people, suppliers, machinery, or technology. After analyzing those factors, the team can create a supply plan that outlines what changes need to be made.

If you only need to make simple changes, organize your supply plan similar to a business case . Otherwise, schedule recurring meetings with supply stakeholders for team alignment. You might also want to implement additional measures, including unifying supply chain and enterprise planning, anticipating the end customer, and leveraging data.

Unify supply chain and enterprise planning

While supply planning involves adjusting supply and demand needs, enterprise planning involves managing the strategic and operational goals of product supply.

Unifying both the goals and the needs of your supply chain ensures all areas, from executive to consumer, are aligned and forecasted for the same outcome.

Anticipate demand

You may begin anticipating supply and demand during the initial forecasting phase of your S&OP based on internal data. But during the supply phase, you will anticipate demand based on the end consumer.

You can do this by reviewing internal data from your demand forecasts and external data that you’ve gathered on your customers. This information is typically obtained through data gathering activities that track customer patterns, such as shopping behaviors, frequented competitors, and target market research.

Leverage real-time data

Using real-time data in your supply planning phase can ensure that the data you collected in the initial phases is being leveraged appropriately across all areas of your supply chain.

This task can be performed manually or enhanced with AI tools, such as business process automation , that apply advanced analytics and dashboards to automate data gathering and ensure information is correctly assigned to consumer profiles.

Collecting this data can help you adjust supply chain processes to enhance efficiency and make the necessary inventory adjustments.

4. Pre-S&OP meeting

Once the forecasting and product plans have been made, it’s time to begin the implementation process with an initial kickoff meeting . This is a chance for department heads from the previous phase—as well as human resources, marketing, sales, and any other teams that may be affected—to meet to discuss the changes.

A meeting agenda template can help you prepare for your meeting and ensure you cover the important topic points the first time around.

![presentation s&op [List view] Meeting agenda template in Asana, spreadsheet-style view](https://assets.asana.biz/transform/a073ff73-8c95-4796-819f-717ffa6daf64/inline-project-planning-sales-and-operation-planning-6-2x?io=transform:fill,width:2560&format=webp)

Some questions to discuss during this meeting include:

What are the financial implications of these changes?

How will they affect cash flow?

Will this help prevent business uncertainty?

The purpose of this meeting is to consider the financial and customer-facing implications of the supply changes. Since no one person will be able to speak to each of these considerations, it’s important to bring each leader in to speak to their unique knowledge.

5. Executive S&OP meeting

Once the initial meeting has taken place and the implications have been identified and resolved, it’s time for the executive meeting. The purpose of this meeting is to get the executive team's approval for the previous supply change plans, also known as your aggregate S&OP plan.

Since you’ve already had an initial meeting, it should be easy to supply the executives with the necessary information. Consider sending out a meeting brief the day before about what you plan to discuss.

If the proposal gets rejected, you’ll need to make revisions to the initial project plan . If it gets approved, you can move on to implementing your S&OP.

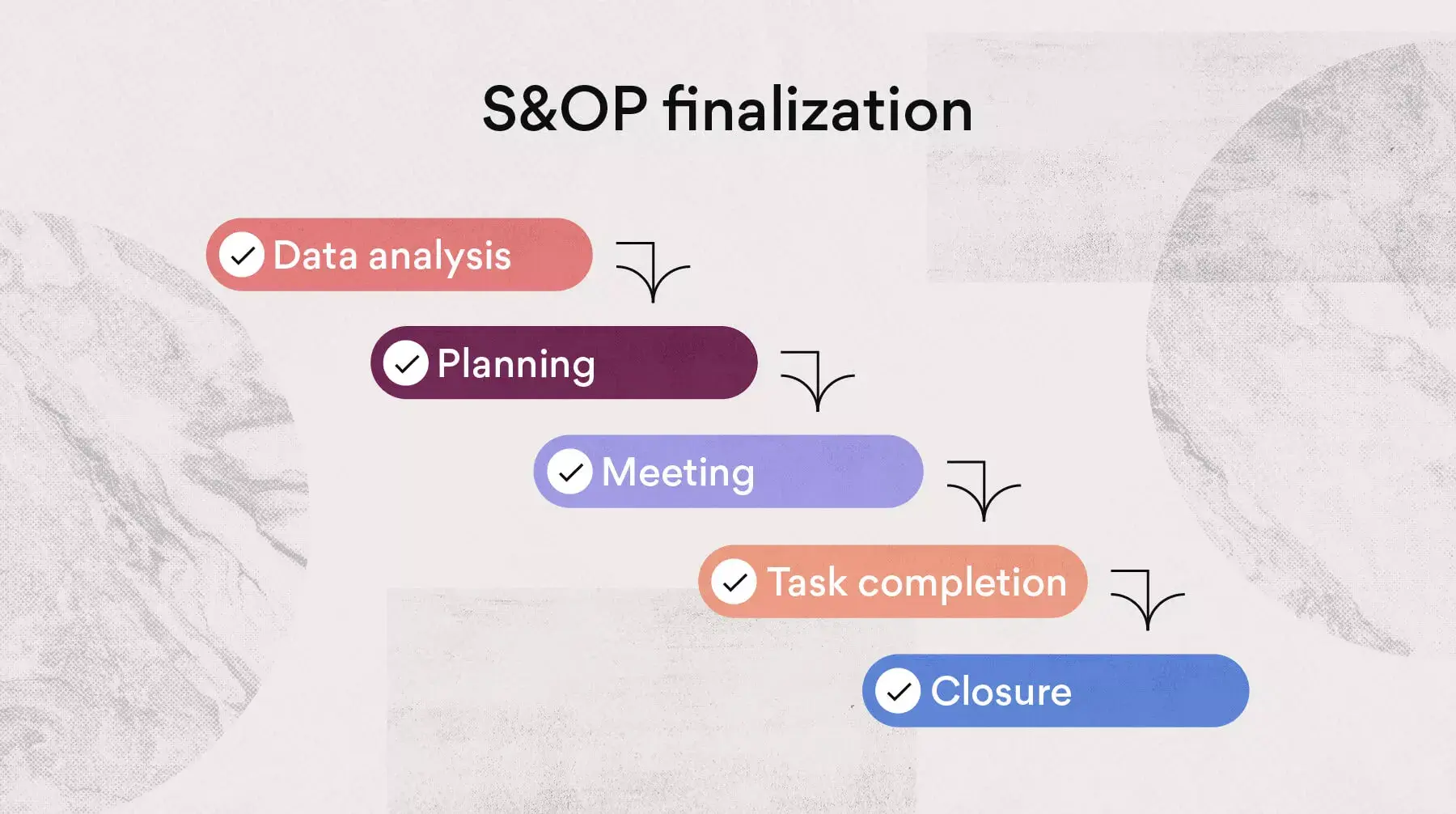

6. S&OP finalization

In order to finalize and ultimately implement your S&OP process, you should delegate tasks to the appropriate project stakeholder . In addition, store information in a shared space to create team visibility and give access to resources in real time.

Once tasks have been completed and the S&OP has ultimately been implemented, keep a close eye on changes to your supply-and-demand system. This is especially important as it pertains to cash flow and ensuring your business is safe from financial mishaps.

You can do so by reviewing KPI metrics such as:

Demand and production forecast

Inventory turnover

Capacity utilization

On-time delivery

Accuracy in order delivery

Total sales

Gross margin

Keeping an eye on these changes can help correct any issues in real time before they have negative effects on profitability.

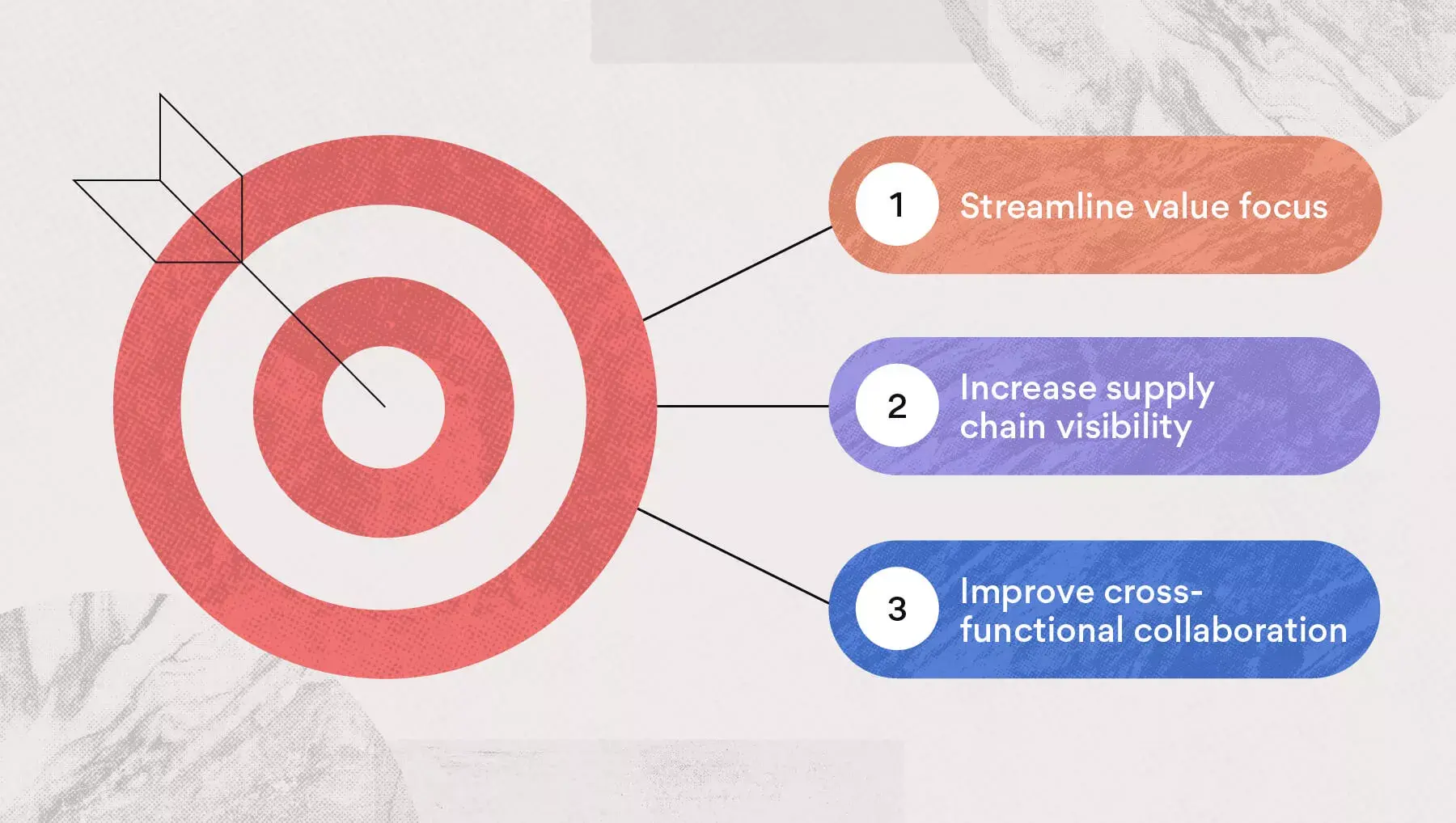

Sales and operations planning benefits and impact

Implementing a sales and operations plan can have a positive impact on a number of different aspects of your organization. From streamlining value to cross-functional collaboration and teamwork, S&OP can improve your overall sales strategy. Let’s look at some of the benefits and the impact they can have on your team.

Streamline value focus

By bringing the executive team together frequently to analyze business alignment, an S&OP plan creates a cohesive value focus for each department.

Not only is this important in order to create organizational clarity from the top down, but it also makes problem-solving and tough decision-making easier to solve. This is because everyone has clear expectations of where the value lies and what steps are needed to get there.

Team impact: Drives value for your internal team and your external customers, as well as helps you create a cohesive business plan backed by data.

Increase supply chain visibility

In large organizations, it can be challenging to create supply chain visibility with various teams working in their own silos. With an S&OP, the department leaders have more visibility into the supply chain management plan. As a result, they can choose to continue this visibility to lower-level team members.

The benefit of supply visibility is that it allows various departments to make decisions based on the organizational demand plan.

Team impact: Leads to a more streamlined production plan and delivery rate, which supports customer satisfaction and improves sales.

Improve cross-functional collaboration

Another key benefit of an S&OP plan is improved collaboration between teams, departments, and leaders. This is a direct result of the recurring teamwork between leaders to align all aspects of the business.

Cross-functional collaboration can create a more cohesive dynamic between business units and help foster a more enjoyable team-centric environment.

Team impact: Improves cross-departmental communication and efficiency, which means fewer missed deadlines and a quicker product lifecycle.

How to choose sales and operations software

In order to get started with a sales and operations planning solution of your own, it can be helpful to use software tools that can streamline and automate tasks for you. In addition, they coordinate information in one place, making it accessible in real time, no matter where your team is located. Use a sales planning template to track and manage tasks in one place. By sharing this template with stakeholders, you can also organize plans and keep project objectives clear across multiple teams.

![presentation s&op [Old Product UI] Sales planning project in Asana, spreadsheet-style view with project deliverables (Lists)](https://assets.asana.biz/transform/7a722185-c69a-4c92-b033-ba6de7a27c7d/inline-what-are-project-deliverables-2-2x?io=transform:fill,width:2560&format=webp)

Along with implementing sales and operations planning software, it’s helpful to integrate other aspects of supply chain planning, such as inventory planning, demand planning, and supply planning, in order to create the most effective plan possible.

Here are some solutions based on select needs that you can implement to create a more robust S&OP process:

For large teams

For large businesses that are looking to scale their sales and operations processes, it’s important to reduce waste and automate as many tasks as possible. This will create a more efficient process and give more time back to those who need it.

Here are some software features to consider when looking to scale a large business:

Automation : Business process automation can save your team time by eliminating the busywork and creating more efficiency throughout your organization.

Risk management : In order to reduce project waste, you need to prevent risks from happening in the first place. A risk register can help to track these issues in real time.

Advanced analytics : Evaluating analytics before, during, and after projects can help your team make continuous improvements.

While these aren’t the only features an S&OP tool offers, it’s important to check these boxes in order to properly plan for business growth.

For supply chain needs

Supply chain management has multiple moving parts, which is why implementing software can help streamline and improve your current product development processes.

Some software features that can help teams hedge against supply chain disruptions are:

Product planning: The right tool can make launching a new product a breeze by providing a way to plan and communicate with team members. It can also help with the inventory management process by tracking your team’s progress along the way to ensure deadlines are met.

Forecasting: Forecast accuracy is essential when creating an efficient supply chain. Not only for internal purposes but even more so for customer-facing needs to prevent poor experience on their end. The right tool will help by providing digestible data in visual spreadsheets.

Production: Production needs consist of everything from a sales plan to product sourcing and lead times. S&OP software can help organize these tasks and ensure team members are notified when production dependencies are met.

The bottom line? The right tool can help your supply chain meet your bottom dollar.

For collaboration capabilities

If there’s one thing that sets teams up for success, it’s collaboration. Empowering your team to work together can help create transparency and accountability.

Here are some features the right software tool can offer:

Aligned communication: The right tool should host communication in one central dashboard, making it easy for teams to connect about projects, tasks, and tactical plans.

Assigned tasks: Assigning team members to tasks can create accountability and can also organize dependencies to ensure work doesn’t fall through the cracks.

Aligned work and goals: Connecting work to project goals can keep team members on the same page and help keep OKRs top of mind.

Automated task reminders: With collaboration software , you can automate reminders and ensure they get to the right stakeholders without unnecessary manual work.

While collaboration can help with many business areas, it’s especially important when looking to create a robust S&OP plan that helps align multiple teams within your organization.

S&OP best practices

Effective sales and operations planning is essential for managing the intricacies of market demands and supply chain obstacles. One common problem that S&OP can solve is the misalignment between various departments that leads to inefficiencies, stock discrepancies, and missed opportunities.

By adopting best practices in sales and operations planning, organizations can synchronize cross-functional efforts and ensure a cohesive approach to meeting market demands and achieving business goals.

Are you leveraging the latest data?

How recent are the data inputs fueling your strategy? Effective sales and operations planning hinges on using real-time inputs for all planning activities. This involves rigorous data gathering and the application of advanced analytics to uncover insights that inform your actions. Ensuring your data is up-to-date allows for agile responses to market changes and more accurate forecasting.

Have you tested your strategies with simulations?

How resilient are your financial plans? Simulations offer a powerful tool for stress-testing your strategies against various market scenarios. By incorporating decision-making trials that factor in budget constraints and working capital, you can identify the most productive strategies for resource allocation, risk mitigation, and seizing growth opportunities.

Who owns your S&OP process?

Is there a clear leader steering your S&OP efforts? Identifying an internal owner for your sales and operations planning process is critical for ensuring focus and accountability. This person should have a thorough understanding of your business goals and the ability to coordinate across departments. Assigning this responsibility ensures that strategies are executed cohesively and aligned with overall business objectives.

Align your team with an S&OP

Implementing a sales and operations planning process to keep your teams and ultimately your entire organization aligned. From streamlining your value focus to improving cross-departmental collaboration, use an S&OP to take your business to new levels.

Pair an S&OP plan with work management software to reduce busywork and improve overall efficiency. Ready to make the move? Check out how Asana can help you implement an S&OP process of your own.

Related resources

How to use a feasibility study in project management

How to track utilization rate and drive team profitability

How to accomplish big things with long-term goals

Smooth product launches are simpler than you think

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

S And Op Powerpoint Presentation Slides

Introducing our content ready S And Op Powerpoint Presentation Slides. Make a strategic plan by including mission goals, objectives, strategies and financial projection with the help of readily available operational plan PPT graphics. Showcase the business strategy that will help in accomplishing business goals and to secure a competitive position in the market. Estimate future financial outcomes for a company or project with the help of sales & operations management PowerPoint templates. Utilize our professionally designed business operations analysis PPT slideshow and provide a clear picture of how a team, section or department will contribute to the achievement of the organization’s goals. Also, mention operational objectives such as cost and volume, quality, efficiency, and flexibility. With the help of supply and demand PPT slide deck, You can also represent the performance objectives that will allow you to know how effectively a business generates revenue from total assets, working capital, fixed assets. This download this ready to use integrated business planning ppt Presentation to focus on future actions.

- Add a user to your subscription for free

You must be logged in to download this presentation.

Do you want to remove this product from your favourites?

PowerPoint presentation slides

Enhance your audiences knowledge with this well researched complete deck. Showcase all the important features of the deck with perfect visuals. This deck comprises of total of thirty four slides with each slide explained in detail. Each template comprises of professional diagrams and layouts. Our professional PowerPoint experts have also included icons, graphs and charts for your convenience. All you have to do is DOWNLOAD the deck. Make changes as per the requirement. Yes, these PPT slides are completely customizable. Edit the colour, text and font size. Add or delete the content from the slide. And leave your audience awestruck with the professionally designed S And Op Powerpoint Presentation Slides complete deck.

People who downloaded this PowerPoint presentation also viewed the following :

- Business Slides , Flat Designs , Concepts and Shapes , Complete Decks , All Decks , Communication Process , Business Plan Development , Proposals , General , Strategy , Strategy Proposal

- Business process ,

- Strategic ,

- Strategic planning

Content of this Powerpoint Presentation