To revisit this article, visit My Profile, then View saved stories .

- Backchannel

- Newsletters

- WIRED Insider

- WIRED Consulting

Richard Priday

The inside story of the great KFC chicken shortage of 2018

Why didn't the chicken cross the road? Because of a single point-of-failure in the chicken restaurant's supply chain and lack of contingency planning, that's why.

With over three quarters of its locations closed on Monday, KFC was thrust into the national news as the fried chicken shop that had run out of chicken. But as the details emerged, the blame was moved to DHL.

Having become the chain's new logistics partner on February 14, the day the crisis began to take shape, the company and its single warehouse in Rugby (as opposed to previous contract holder Bidvest's six) were put under intense scrutiny for their failure to deliver KFC's ingredients. What led to the break down of the supply chain? Are DHL wrong for using one depot? And how long until the situation returns to normal? We asked a pair of experts to find some answers.

At around 01:40 on February 14, a collision involving seven vehicles took place between junctions two and three of the M6. One man was killed, and two others injured. Police closed off the area between the two junctions to investigate, and eventually arrested a man on suspicion of causing death by dangerous driving. Shortly afterwards, a pair of lorries collided near junction one, although neither driver was injured.

These three junctions are in the vicinity of Rugby, where DHL's warehouse is located. With its lorries getting stuck in the traffic as soon as they left the depot, and no other locations to send deliveries from, the delays that would lead to the KFC chicken shortage began here. In a statement, DHL said it was working with KFC to re-open all its stores in the coming days. "Whilst we are not the only party responsible for the supply chain to KFC, we do apologise for the inconvenience and disappointment caused to KFC and their customers by this incident,” the spokesperson continued. KFC did not respond to a request for comment.

Many have questioned the wisdom of operating out of a single warehouse, but according to Richard Wilding, professor of supply chain management at Cranfield School of Management, this is apparently not uncommon.

"You have something called the 'golden rectangle' that is between Milton Keynes, Rugby, Daventry and Northampton," he says. "If you locate a facility in that rectangle, you can deliver overnight to just about anybody in the United Kingdom. This is quite a standard way of working for supply chains of this type."

By Parker Hall

By David Nield

By Julian Chokkattu

However, even if it is possible to use a single warehouse, Samir Dani, professor of logistics and supply chain management at the University of Huddersfield's Business School, thinks that it isn't always appropriate to do so. "Companies may operate out of one warehouse, but you have to think about the product. There are legality issues around the quality of the produce and the contamination that can happen is not handled properly. That's the problem with food, distribution can't be thought about like any other supply chain."

The lack of chicken began to hit on February 16. KFCs started to shut down locations in response to their missing ingredients, meaning that by February 18, only 266 of the 870 restaurants in the UK and Ireland were open. Locations in Northern Ireland and the Republic of Ireland have not been affected due to different logistical arrangements.

Dani says the cause of the crisis which shut over two thirds of KFC's locations will be debated for a long time to come, but believes the decision to use the single depot didn't help matters. "Serving the length and breadth of the country from one warehouse is a complex task anyway. The fact that it was a new warehouse, new IT system, and the handover was just happening, makes this a perfect storm."

But the full cause of the great chicken crisis is more complex. "Using a single location will not be the lone cause of this particular problem at all," says Wilding. "There will have been a number of elements which have come together. Demand, automation in the facility, the planning software, all those sorts of things interacting together. There may be a particular cause which will come out of this, but pinpointing that may be a tricky thing."

Dani thinks poor preparation may also be to blame. "It's a complex scenario, but I think it would mainly be the network planning. To send perishable products into the stores, you have to think about what kind of network you need, how many distribution centres? I think that planning may have had a failing of some kind. The IT systems may not have had the right checks before going live, if so, what were the contingency measures in those circumstances?" In a supply chain, he continues, disruption can happen for lots of reasons, but in the case of KFC a number of things have seemingly gone wrong at once.

Disruption is fairly common in supply chains. Wilding says that approximately ten per cent of chains experience disruption during a year. Normally these aren't noticeable because only a small number of locations or a certain item would be affected. But in KFC's case, with its specialised menu and single warehouse, the problem was much larger, and quickly noticed by customers.

In terms of returning to normality, Wilding says there are a few separate questions to consider. "How long will customers still be noticing the disruption? Probably for another few days. However, the overall disruption to the whole network, including the chicken farms and so on, that's going to go on for a longer period of time. Then you've got to ask how long it's going to take for KFC to rebuild confidence with its customer base."

It's safe to say that public confidence in KFC is shaken. Between phone calls to Tower Hamlets Police complaining about the limited menu, and a movement in Bristol to nationalise the chain to prevent future trouble, regaining the people's trust will be a formidable task for Colonel Sanders. No matter how finger lickin' good his products might be.

Dani thinks people are missing the point by focusing on just the restaurants and their customers. "The bigger question is from a sustainability and food waste perspective. KFC have 500 farmers in the network that deliver chickens, which is the beauty of the model because it lets them use fresh chicken. What's happening to the farmers in this situation? What's happening to the chickens that are in the system at the moment? How much of it is being wasted?"

Plenty, as it turns out. There have been reports of entire lorries of chicken spoiling in the depot, as drivers are kept waiting for hours just to enter; another driver said the temperature regulator on his trailer had been set incorrectly, leading to more food waste .

So, what can we learn from all of this? Perhaps it's the importance of planning for the worst. "I think in this scenario you cannot see any contingency planning in place," Dani says. "They are reacting to the situation as a crisis rather than saying that they had thought about this scenario and are going to go back to stability very quickly. So I think it's shown that they were not resilient enough."

For Wilding, the tale of KFC highlights an oft-overlooked area of competition. "The key thing to recognise is that competition is no longer between individual companies, it's between the supply chains they are part of."

"What makes up those supply chains is lots of different companies, lots of different relationships, all trying to manage processes, infrastructure, equipment, information systems and its staff, to make all of that perform in a synchronised way, so that the customer gets the chicken they want."

This article was originally published by WIRED UK

SCM Insight

Kfc supply chain management .

KFC (Kentucky Fried Chicken) is the world’s leading chain fast-food retail company. The company performs various steps in the supply chain process to bring the chicken from the farm to the customer’s plate. In fact, the chain brand employs the latest technology to streamline its supply chain processes. Today, we’ll discuss KFC supply chain management; key elements involved in the process, usage of technology, and logistical issues.

Elements of KFC Supply Chain Management Process

Some of the key elements involved in the KFC supply chain management process are as follows;

Procurement

KFC implements a complicated procurement process to make sure the right quantity and quality of material would reach the company so that the company would serve hundreds and thousands of customers. However, the procurement process begins with local suppliers, which allows the company to make sure fresh supplies and maintain the cost low. The company has established high standards for procuring high-quality ingredients to ensure sure safety

Inventory & Warehouse Management

KFC has to store raw supplies and ingredients, cooked dishes, and packaged goods in different warehouses across the world. The company faces the challenge of maintaining the inventory at a specific temperature to avoid the risk of spoilage and becoming unsafe for consumption.

However, the company employs the technology and tools to track inventory levels and analyze the quality of goods in various warehouses. It makes sure that the product remains in-stock and fresh when customers order it. However, the company also employs the latest technological tools to predict demand, so that they can manufacture the right amount and avoid stockouts.

KFC functions effectively with 3PL (3rd party logistics providers) to make sure safe transportation of food items from different suppliers to the distribution center for storing and processing. The 3PL are no small fries, they employ the latest state-of-the-art technology like the following;

- RFID tracking system

- Route optimization software

- Warehouse management system

In-Store Inventory Management

After the delivery of raw food items and supplies to the franchise or the hotel, they should rightly track the inventory level to know when to reorder and restock. KFC employs the in-store inventory management system to track everything from product consumption to the daily sales information of every store. It would help the company to ensure that the company has the right stock of chickens to fulfill customer orders.

Delivery System

KFC employs specific delivery vehicles to make sure the quick delivery of customer orders. They have the latest GPS technology installed in them to track the location of vehicles in real time. It means that the customers would feel good that their delivery would reach to them timely in excellent conditions.

KFC Employing Information Technology

The technological tools and equipment used in KFC supply chain management process are as follows;

Automation Technology

KFC implements automation technology throughout the supply chain process. The automation technology allows you to amplify the accuracy of orders, decrease the risk of errors, and reduce labor costs; it offers you access to inventory data in real-time. The automation of processes is as follows;

- Order fulfillment technology

- Inventory management

- AGVs (automated guided vehicles)

- Robotic arms to pick up products in the warehouse

Data visibility

KFC employs the latest technological tools to make sure the visibility and transparency of data, and it assists you in various business processes from procurement to delivery. It comprises of following steps;

- Tracking the weight of products and goods stored in the warehouse

- Dates of product expirations

- Stock level

- Tracking goods after received from suppliers

- Stop tracking after customers receive their orders

Employing technology

KFC employs a GPS-based truck for the delivery of goods across its network of hotels and restaurants. It helps the company to track the location of every shipment in real time to amplify their capabilities to fulfill their orders. However, the retail chain brand employs the combination of the latest technology and tools to ensure the smooth functioning of various supply chain processes. It results in the form of higher customer satisfaction levels and quick delivery time.

KFC Logistical Issues

Some of the main logistical issues that KFC is facing are as follows;

Fresh Ingredients

In order to provide tasty food to the customers, the key is to source the raw supplies and ingredients from various local suppliers and store them at the right temperature. For this purpose, the company employs 3PL service providers that have expertise in cold chain management. They would make sure that the cooked goods and ingredients remained fresh throughout the SC process.

Inventory Tracking

KFC should carefully track orders for the effective management of the inventory. The company employs an integration of technology and tools for this purpose like prediction software; an automated replenishment system, and an inventory tracking system. It would track the stock level and logistical partners at different times to ensure the timely delivery of goods with limited waste.

Conclusion: KFC Supply Chain Management

After an in-depth study of KFC supply chain management; we have realized that KFC is the world’s leading retail fast food chain brand. If you are learning about the SCM processes of KFC, then you should keep in mind the abovementioned elements, logistical challenges, and technological tools involved.

Ahsan is an accomplished researcher and has a deep insight in worldly life affairs. He goes Live 3 days a week on various social media platforms. Other than research writing, he’s a very interesting person.

Related Posts

Agri Supply Chain Management

Clinical Supply Chain Management

Inventory Planning in Supply Chain Management

An Insight Into KFC Supply Chain Strategy

Explore KFC’s intricate supply chain strategy, delving into the meticulous coordination behind each serving of their famous fried chicken.

In the bustling world of fast food, few names are as recognizable as KFC or Kentucky Fried Chicken. With its delectable range of fried chicken offerings and signature flavors, KFC has become a global phenomenon that has captured the hearts and palates of millions. Yet, behind the scenes of every finger-licking meal lies an intricate and well-orchestrated supply chain strategy that enables KFC to deliver its mouthwatering fare to eager customers worldwide consistently.

Unveil the future of supply chain management with DFreight, your ultimate digital freight forwarder . Our innovative online platform and mobile app bring efficiency and transparency to every step of your supply chain. Seamlessly manage shipments, track cargo in real-time, and optimize routes with just a few clicks. Experience the power of data-driven decision-making as we redefine how you connect with suppliers, distributors, and customers. Join us in transforming your supply chain strategy into a streamlined, agile, responsive powerhouse. Visit us today and embark on a journey toward smarter logistics with DFreight!

This blog post delves into the intriguing realm of KFC supply chain strategy. We’ll explore the integral role that supply chain management plays in the fast-food industry, where timely and reliable delivery of fresh ingredients and products is paramount. By understanding the intricate web of processes, partnerships, and technologies that underpin KFC’s supply chain, we gain insight into how the company has managed to maintain its iconic taste and quality across a sprawling global network of restaurants.

Table of Contents

KFC Supply Chain Strategy

Behind the enticing aroma of KFC ‘s crispy fried chicken lies a sophisticated and meticulously designed supply chain network that spans the globe. From sourcing the freshest ingredients to ensuring timely delivery to thousands of restaurants, KFC’s supply chain strategy is a testament to efficient logistics, innovative technologies, and strategic partnerships.

1. Network Structure and Distribution: KFC’s supply chain is organized to ensure a seamless flow of ingredients and products. It comprises multiple stages, including suppliers, distributors, warehouses , and restaurant outlets. The distribution process involves efficiently moving raw materials and finished products from suppliers to restaurants, adhering to strict quality and safety standards.

2. Global Sourcing: KFC sources its ingredients from various regions to maintain its signature flavors and quality. Chicken, a cornerstone of KFC’s menu, is sourced from multiple poultry suppliers worldwide. Spices and herbs are procured from diverse locations to maintain consistency in taste across different markets.

3. Inventory Management and Demand Forecasting: KFC employs advanced inventory management techniques to prevent wastage and stockouts. The company uses data analytics and historical sales data to forecast demand accurately. This ensures each restaurant has the necessary ingredients to fulfill customer orders without overburdening storage space.

4. Supplier Relationships: Strong relationships with suppliers are crucial to KFC’s supply chain strategy. KFC collaborates closely with its suppliers, promoting transparency and quality assurance. This partnership-driven approach helps maintain consistency in ingredient quality and ensures a steady supply chain flow.

5. Quality Control and Food Safety: KFC prioritizes quality control and food safety throughout its supply chain. Rigorous inspections, audits, and quality checks are performed at various stages, from sourcing to delivery. This thorough approach ensures that only the finest ingredients enter KFC’s kitchens.

6. Technological Integration: KFC harnesses technology to enhance supply chain efficiency. Advanced software systems help forecast demand, optimize distribution routes, and track inventory in real-time. This technological integration aids in minimizing waste, reducing lead times and improving overall operational agility.

7. Sustainability Initiatives: Recognizing the importance of sustainability , KFC has implemented green initiatives across its supply chain. From responsible sourcing of ingredients to eco-friendly packaging solutions, the company is dedicated to reducing its environmental footprint while maintaining its operational excellence.

8. Adaptability and Resilience: KFC’s supply chain strategy exhibits remarkable adaptability and resilience. The company continually adjusts its processes to accommodate changes in consumer preferences, market dynamics, and external factors like disruptions caused by natural disasters or pandemics.

KFC’s supply chain strategy is a harmonious blend of tradition and innovation. It ensures the timely availability of its iconic products and reflects KFC’s commitment to delivering quality, consistency, and a delightful customer experience at every restaurant worldwide. As we proceed through this exploration, we’ll uncover the intricate details that make KFC’s supply chain an accurate industry benchmark.

Supply Chain Challenges in the Fast-Food Industry

The fast-food industry, characterized by its rapid pace and high consumer demand, faces a unique supply chain challenge that requires innovative strategies to ensure smooth operations and customer satisfaction. As a global player in this industry, KFC is not exempt from these challenges. Let’s explore some of the common hurdles that fast-food chains like KFC encounter in their supply chain management:

1. Just-in-Time Inventory Management: Fast-food restaurants, including KFC, often rely on just-in-time inventory management to minimize storage costs and waste. However, this approach leaves little room for error. Any supply chain disruptions , such as ingredient delivery delays or unexpected demand spikes, can quickly lead to stockouts, affecting customer experience and revenue.

2. Seasonal Fluctuations and Demand Variability: Consumer preferences for specific menu items vary significantly based on seasons, holidays , and regional events. These fluctuations in demand can pose challenges in accurately forecasting and preparing the right ingredients, leading to shortages or excess inventory.

3. Quality Control and Safety Standards: Ensuring consistent quality and food safety is paramount in the fast-food industry. Any ingredient quality or safety compromise can lead to reputational damage and legal issues. This requires strict adherence to rigorous quality control measures throughout the supply chain, from sourcing to distribution.

4. Supplier Reliability: Fast-food chains rely on a network of suppliers to provide essential ingredients and materials. Suppose a critical supplier faces disruptions due to weather events, labor strikes, or geopolitical issues. In that case, it can cause ripple effects across the entire supply chain, impacting the availability of menu items.

5. Short Shelf Life of Ingredients: Many fast-food items, especially those that rely heavily on fresh ingredients, have a short shelf life. This adds complexity to inventory management, as restaurants must balance having enough stock to meet demand while avoiding wastage due to ingredient spoilage.

6. Geographical Considerations: Fast-food chains operate in diverse geographic regions with varying logistical challenges. Distance, transportation infrastructure, and local regulations can influence the efficiency of ingredient sourcing, distribution, and delivery.

7. Changing Consumer Preferences: Consumer tastes and preferences can change rapidly. Fast-food chains like KFC need to be agile in adapting their menus and sourcing strategies to meet these changing demands while maintaining their core brand identity.

8. Ethical and Sustainability Concerns: Increasingly, consumers expect transparency and ethical sourcing from the brands they support. Fast-food chains are pressured to source ingredients responsibly, reduce environmental impact, and support fair labor practices, adding complexity to supply chain decision-making.

9. Technology and Innovation: Technology can enhance supply chain efficiency but requires ongoing investments and adaptations. Implementing new technologies like inventory management systems, digital ordering platforms, and delivery logistics can be challenging, requiring careful planning and training.

Navigating these challenges requires a delicate balance between tradition and innovation. Fast-food chains like KFC must maintain the quality and taste that customers expect and adapt their supply chain strategies to address evolving consumer demands, market dynamics, and external disruptions. In the following sections, we’ll explore how KFC’s supply chain strategy tackles these challenges head-on, ensuring that the iconic taste and experience are consistently delivered to customers worldwide.

KFC’s Approach to Supply Chain Management

KFC’s approach to supply chain management blends precision with innovation . By harmonizing traditional quality control practices with cutting-edge technologies, KFC ensures the seamless flow of ingredients and products across its global network of restaurants.

The company’s emphasis on strong supplier partnerships fosters transparency and reliability, enabling consistent ingredient quality. With advanced data analytics driving demand forecasting and inventory management, KFC strikes a balance between meeting customer expectations and minimizing waste.

Furthermore, responsible sourcing practices and eco-friendly packaging solutions reflect KFC’s commitment to sustainability. This holistic approach allows KFC to navigate the intricate challenges of the fast-food industry while delivering a delightful dining experience to its patrons worldwide.

Future Trends of KFC Supply Chain

KFC’s supply chain is poised to embrace several transformative trends. Automation and robotics will likely play a more significant role in optimizing inventory management and order fulfillment , enhancing operational efficiency. The integration of blockchain technology could bring unprecedented transparency to sourcing, allowing customers to trace the journey of their meal from farm to table. As sustainability takes center stage, KFC’s commitment to eco-friendly practices might lead to innovative packaging materials and energy-efficient transportation innovations.

Additionally, the rise of data-driven insights will refine demand forecasting, reducing waste and enhancing customer satisfaction. By embracing these trends, KFC is shaping the future of its supply chain and ensuring its continued success in an evolving fast-food landscape.

In the previous blogs, we looked into the supply chains of famous and leading companies, which you can read about each of them in the section below.

KFC’s intricate supply chain strategy in global fast food is a testament to innovation, collaboration, and resilience. From sourcing the finest ingredients to delivering iconic flavors to countless tables worldwide, KFC’s commitment to excellence is evident at every stage of its supply chain.

As we’ve explored the layers of this strategy, we’ve uncovered the complexities that underlie the seemingly simple act of serving a delicious meal. With a blend of tradition and technology, KFC navigates challenges, adapts to change, and ensures that its customers experience the same finger-licking goodness no matter where they are. Through its unwavering dedication to quality, sustainability, and customer satisfaction, KFC’s supply chain inspires the fast-food industry and beyond.

How does KFC manage its global sourcing challenges?

KFC’s global sourcing strategy involves working with a network of suppliers worldwide. By partnering with reputable suppliers who understand KFC’s stringent quality requirements, the company ensures a consistent flow of ingredients. This approach allows KFC to overcome geographical challenges, ensuring that each restaurant receives the necessary ingredients promptly, regardless of its location.

How does KFC manage supply chain disruptions ?

KFC prioritizes adaptability and resilience in its supply chain strategy. The company employs risk management strategies, such as diversifying suppliers and maintaining buffer inventory. By staying agile and well-prepared, KFC is better equipped to navigate disruptions and minimize their impact on its operations.

What role does technology play in KFC’s supply chain management?

Technology is integral to KFC’s supply chain efficiency. Advanced software systems aid in demand forecasting, real-time inventory tracking, and optimization of distribution routes. These technological tools enable KFC to streamline operations, reduce waste, and respond swiftly to changing demands.

Air transportation is a convenient and fast way to move cargo and is suitable for small and large companies as well as individuals. You Might Also Like

Commodities

Most Popular

KFC Crisis Management Case Study: Preparing for the Unexpected

Crisis can strike unexpectedly and have a profound impact on a company’s reputation and bottom line.

The ability to effectively manage these crises becomes paramount, and one such case that captured global attention was the KFC crisis.

This blog post aims to delve into KFC crisis management case study examining the events of crisis and analyzing the company’s response.

By exploring the lessons learned from this event and studying best practices in crisis management, we can gain valuable insights into how businesses can navigate challenging situations, protect their brand reputation, and emerge stronger from adversity.

Join us on this journey as we uncover the intricacies of crisis management and uncover the key strategies necessary for successful resolution of a crisis.

Brief history of KFC as a global fast-food chain

Kentucky Fried Chicken, more commonly known as KFC, has established itself as a prominent global fast-food chain with a rich and fascinating history.

The story of KFC traces back to 1930 when Harland Sanders, a humble entrepreneur, started selling fried chicken from his roadside restaurant in Corbin, Kentucky. Known for his secret blend of 11 herbs and spices, Sanders’ fried chicken quickly gained popularity among the locals.

As word spread about the deliciousness of Sanders’ chicken, he began franchising his concept in the 1950s. This marked the beginning of KFC’s expansion into a worldwide phenomenon.

With its signature Southern-inspired flavors, crispy texture, and distinctive red and white branding, KFC grew rapidly across the United States and eventually ventured into international markets.

By the 1970s, KFC had become a global powerhouse, operating in numerous countries and serving millions of customers each day. Its success could be attributed not only to its mouthwatering fried chicken but also to its innovative marketing campaigns and strategic partnerships.

Over the years, KFC has continually evolved its menu to cater to changing consumer preferences, introducing new products like the famous KFC bucket, chicken sandwiches, and a variety of sides and desserts.

Today, KFC operates in more than 140 countries, with thousands of restaurants serving its iconic fried chicken to eager customers worldwide. The brand’s commitment to quality, consistency, and its unique blend of flavors has made KFC a beloved and recognizable name in the fast-food industry.

As we delve into the KFC crisis and its management, it is crucial to understand the significance of this global fast-food chain and its enduring legacy.

Through its journey, KFC has not only revolutionized the way people enjoy fried chicken but also faced its fair share of challenges, providing valuable lessons in crisis management for businesses worldwide.

Description of the specific crisis event

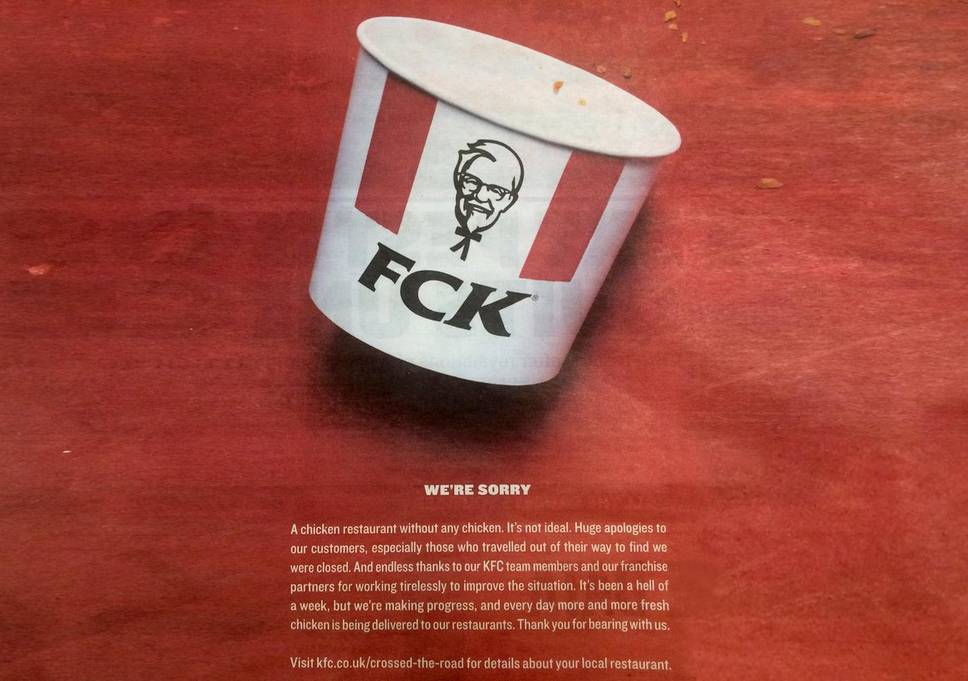

The specific crisis event that shook KFC and garnered significant attention occurred in February 2018. It all began when a major supply chain disruption caused a shortage of chicken, leading to the temporary closure of hundreds of KFC restaurants across the UK.

The shortage stemmed from issues with KFC’s new logistics partner, who experienced operational difficulties that disrupted the delivery of fresh chicken to the restaurants.

As a result, customers were met with signs on the doors of their local KFC branches, apologizing for the inconvenience and explaining the temporary closure.

Social media platforms quickly erupted with posts from disappointed and frustrated customers, expressing their disbelief at the absence of KFC’s famous fried chicken. The crisis intensified as the media caught wind of the story, further amplifying the negative publicity surrounding the situation.

The impact of this crisis was significant on multiple fronts. Not only did it disrupt the day-to-day operations of KFC restaurants, leading to financial losses, but it also tarnished the brand’s reputation.

Customers who had come to rely on the availability and quality of KFC’s chicken were left disappointed and turned to competitors for their fast-food cravings.

The incident also raised questions about KFC’s supply chain management and the robustness of their contingency plans.

In the face of this crisis, KFC found itself under immense pressure to resolve the supply chain issues, reopen the affected restaurants, and regain the trust of its customers.

The company’s crisis management strategy and subsequent actions would play a crucial role in determining the trajectory of their recovery and the restoration of their brand reputation.

Initial response from KFC

In the wake of the supply chain disruption and subsequent closure of numerous KFC restaurants, the company swiftly took action to address the crisis and communicate with its customers.

KFC acknowledged the issue and released an official statement expressing regret for the inconvenience caused. They emphasized their commitment to providing high-quality food and assured customers that they were working diligently to resolve the situation as quickly as possible.

To keep customers informed, KFC utilized various communication channels, including their official website and social media platforms. They provided regular updates on the progress of resolving the supply chain issues and reopening affected restaurants.

These updates included transparent information about the challenges faced, the steps being taken to rectify the situation, and estimated timelines for the restoration of normal operations.

Furthermore, KFC proactively engaged with customers on social media, responding to inquiries, and addressing concerns in a timely manner. They expressed gratitude for the patience and support shown by customers during this challenging time, striving to maintain an open line of communication and demonstrate their commitment to resolving the crisis effectively.

KFC also collaborated closely with its franchise partners and suppliers to mitigate the impact of the crisis. They worked together to explore alternative solutions, such as sourcing chicken from different suppliers or redistributing stock from unaffected locations to minimize disruptions and reopen restaurants as quickly as possible.

While the initial response from KFC showcased a proactive approach to crisis management, the subsequent actions and long-term strategies implemented would be crucial in determining the ultimate success of their recovery and the rebuilding of customer trust.

Evaluation of the initial response

The initial response from KFC in addressing the supply chain disruption and communicating with customers demonstrated several commendable aspects of crisis management. Here is an evaluation of their response:

- Prompt acknowledgement: KFC promptly acknowledged the issue and expressed regret for the inconvenience caused. This proactive approach demonstrated their commitment to taking responsibility and addressing the crisis head-on.

- Transparent communication: KFC provided regular updates to customers through various communication channels, including their website and social media platforms. By sharing transparent information about the challenges they were facing and the steps being taken to resolve the situation, they instilled a sense of transparency and honesty, which are essential during a crisis.

- Engaging with customers: KFC actively engaged with customers on social media, responding to inquiries and concerns. This demonstrated their willingness to listen to customers and address their concerns promptly, which can help in maintaining a positive brand image and customer loyalty.

- Collaboration with stakeholders: KFC collaborated closely with franchise partners and suppliers to find alternative solutions and minimize disruptions. This collaborative approach showcased their commitment to working together as a team and finding solutions collectively, which can be crucial in overcoming a crisis.

While the initial response from KFC showcased positive aspects, there are a few areas that could be further improved:

- Clear action plan : While KFC provided regular updates, it would have been beneficial to outline a clear action plan or steps being taken to rectify the supply chain issues. This would have provided customers with a better understanding of the progress being made and instilled confidence in the company’s ability to resolve the crisis.

- Compensation or alternative offerings: As an additional measure, KFC could have considered providing compensation or alternative offerings to customers affected by the closures. This could have helped in mitigating customer dissatisfaction and maintaining goodwill during the crisis.

- Proactive communication: While KFC was responsive to customer inquiries, there could have been a proactive approach to reaching out to customers who were directly affected by the closures. Proactively addressing customer concerns and offering support can go a long way in building trust and loyalty.

Communication channels used by KFC

KFC utilized various communication channels to address the crisis and keep customers informed. Here are some of the communication channels employed by KFC:

- Official Website: KFC utilized its official website as a primary platform for sharing updates and information regarding the supply chain disruption and restaurant closures. They dedicated a section or a prominent banner on the website to provide regular updates, explanations, and estimated timelines for the resolution of the crisis. This ensured that customers visiting the website could easily access the latest information.

- Social Media Platforms: KFC leveraged popular social media platforms such as Facebook, Twitter, Instagram, and YouTube to communicate with customers. They posted regular updates, statements, and videos to address the crisis, inform customers about the progress being made, and apologize for the inconvenience caused. Social media platforms allowed KFC to reach a broad audience, engage in two-way communication, and respond to customer inquiries and concerns promptly.

- Email Communication: KFC likely utilized email communication to reach out to customers who had signed up for their newsletters or loyalty programs. Through email updates, they could provide detailed information about the crisis, offer exclusive deals or promotions, and express their gratitude for customer support and patience during the challenging period.

- Press Releases and Media Statements: KFC would have issued press releases and media statements to communicate with the media and the public at large. These official statements would have outlined the details of the crisis, the actions being taken, and the company’s commitment to resolving the situation. Press releases and media statements are vital in shaping public perception and ensuring consistent messaging across various media outlets.

Lessons Learned from the KFC Crisis

Following are the key lesson learned form the KFC crisis management case study:

A. Importance of preparedness in crisis management

The KFC crisis highlighted the crucial lesson of the importance of preparedness in crisis management. Being prepared means having a well-defined crisis management plan in place, including clear protocols and procedures to follow when unforeseen events occur.

Companies should anticipate potential risks and develop contingency plans to mitigate their impact. In the case of KFC, having a robust supply chain backup plan and alternative supplier relationships could have helped minimize the disruption caused by the chicken shortage. By proactively preparing for crises, businesses can respond more swiftly and effectively, mitigating the negative consequences and safeguarding their reputation.

B. Effective communication during a crisis

Effective communication is a fundamental lesson learned from the KFC crisis. In times of crisis, open and transparent communication with stakeholders is paramount. Promptly acknowledging the crisis, providing regular updates, and being accessible to address concerns demonstrate a commitment to transparency and build trust with customers, employees, and the public.

KFC’s use of various communication channels, including their website and social media platforms, allowed them to disseminate information widely and engage directly with customers. By maintaining open lines of communication, companies can manage expectations, alleviate concerns, and retain customer loyalty during challenging times.

C. The role of transparency and honesty

Transparency and honesty emerged as critical factors in the KFC crisis. Being transparent about the causes of the crisis, the challenges faced, and the steps being taken to resolve it helps build trust and credibility. KFC’s acknowledgment of the supply chain disruption and their commitment to resolving the issue demonstrated honesty, which is essential for maintaining the confidence of customers and stakeholders.

By openly sharing information, companies can demonstrate accountability, showcase their efforts to rectify the situation, and reassure customers that their best interests are being prioritized. Transparency and honesty are vital components of effective crisis management, enabling organizations to navigate challenging situations while preserving their integrity.

Final Words

KFC crisis served as a significant case study in crisis management, highlighting important lessons that businesses can learn from. The crisis emphasized the importance of preparedness, emphasizing the need for robust contingency plans and alternative solutions to mitigate disruptions.

Effective communication emerged as a crucial aspect, with KFC demonstrating the power of transparent and timely communication through various channels. Transparency and honesty played a pivotal role in rebuilding trust and credibility. By openly addressing the crisis, sharing information, and taking accountability, KFC showed their commitment to their customers and stakeholders.

About The Author

Tahir Abbas

Related posts.

Digital Marketing KPI Examples that Drive Success

Crisis Communication Team and Its Role and Responsibilities

Organizational Restructuring Communication to Staff

- Click to set high contrast

- Leadership team

- Advisory board

- Our history

- RSM Faculty Council

- Honorary doctorates

- Accreditations

- Positive Change

- Institutional partners

- Corporate partners

- Meet our employees

- Open positions

- Admission requirements

- Tuition fees

- Scholarships

- Open online courses

- Bachelor Bedrijfskunde (Dutch)

- Bachelor International Business Administration

- MSc programmes

- Premaster programmes

- Executive Masters

- International Full-time MBA

- Executive MBA

- Global Executive MBA

- Cologne-Rotterdam MBA

- Programmes for individuals

- Programmes for organisations

- Part-time PhD programme

- Full-time PhD programme

- Career Centre

- International Office

- Study Advice

- Examination board

- Faculty directory

RSM Discovery

- Business-Society Management

- Marketing Management

- Organisation and Personnel Management

- Strategic Management and Entrepreneurship

- Technology and Operations Management

- Corporate Communication Centre

- Erasmus Centre for Leadership

- Partnerships Resource Centre

- Erasmus Centre for Data Analytics

- Erasmus Centre for Entrepreneurship

- Erasmus Initiative: Dynamics of Inclusive Prosperity

- Case Development Centre

- Erasmus Centre for Women and Organisations

- Institutions for Collective Action

- Erasmus Platform for Sustainable Value Creation

- Erasmus Centre for Study and Career Success

- Future students

- Current students

- Exchange students in & out

- Professionals

- Recruiters and organisations

- Researchers

- Journalists & media

- Future employees

Lessons from KFC's chicken shortage: responsiveness versus cost efficiency

- RSM Discovery home

Article: Wednesday, 7 March 2018

Last month’s interesting supply chain story , when Kentucky Fried Chicken (KFC) failed to deliver essential supplies of chicken to 750 of its 900 UK outlets, made it onto nearly every headline and news bulletin. The company was forced to close nearly two thirds of its branches around the UK, resulting in angry customers, and ridicule directed at the company trending on social media. Here’s what supply chain research can teach us about the reasons behind this spectacular supply chain breakdown.

The short version is simple enough: the fast food chain recently changed its logistics partner from Bidwest Logistics to DHL. This new partner operates on a totally different supply chain model, which was apparently not responsive enough to cope with KFC’s demands.

So, what’s the difference between the two models? New logistics partner DHL has a single warehouse in Rugby, in the UK Midlands. This warehouse is big enough and has enough capacity to service every region in the UK. This supply chain model is referred to as a centralised supply chain . Bidwest Logistics, on the other hand, was operating from six warehouses with moderate capacities situated around the country. Bidwest’s structure is known as a decentralised supply chain . It also has some facilities in other regions, each serving mostly regional customers.

Capacity versus lead time

Essentially, what we see in KFC’s recent decision is an attempt to navigate a trade-off faced by every manufacturer when building a new construction site or while choosing a logistics partner: that between capacity and delivery lead times. To maximise profits, you can’t have both, all of the time. In this case, obviously, short lead times lost out and hungry people were left without their buckets of chicken. Let’s look in more detail at the underlying trade-off.

Centralised means more for less

Centralised supply chains offer two advantages compared to decentralised supply chains. First, a centralised model helps to cut operational expenses significantly due to economies of scale and reduced fixed overhead costs, such as rent, insurance, and administration. As a result, centralised supply chains typically have higher storage and production capacities than the decentralised ones.

The second advantage is that the single massive warehouse in a centralised model does not need to be close to the most important – mostly urban – markets, so it can be built on a relatively cheap site, which drives down the cost of acquiring the land. Building additional capacity means expanding just one location, so that too is relatively cheap in the centralised model.

Responsiveness

But while a centralised strategy may reduce operational costs, being located further away from the company’s market bases adversely affects its responsiveness. This may become a problem when outlets have to be replenished frequently – as is the case with fresh produce – and when demand fluctuates rapidly.

Working in a decentralised model, with warehouses located close to markets, allows companies to reduce the lead times and to be more responsive to volatile customer demands. This strategy is effective for companies whose profitability and survival depend on meeting highly volatile customer demands.

The downside of this approach is that the cost of land per square metre is expected to be higher. Fast-growing companies that operate with a decentralised strategy face higher costs for additional warehouse capacity. They might have a hard time meeting the additional demand generated by the growth of their businesses.

We analysed this trade-off in a paper I recently published with Prof. Ralf W. Seifert from the Operations Management department at IMD. It was published in Production and Operations Management. We developed a framework that can help companies such as KFC that don’t have ambitious growth targets to decide the most effective supply chain strategies.

In short, our results showed that the strategic decision whether or not to centralise distribution capacity should be based on the company’s profit margins and uncertainty of demand. We have identified two ideal situations.

1. Centralised supply chains

work best for companies that have low profit margins and low demand uncertainty. In this case, having a high-capacity warehouse achieves economies of scale. Delivery lead times can be long, because customer demand is predictable.

2. Decentralised supply chains

are most effective when customer demand is uncertain and profit margins are high. This way, the higher margins can make up for higher costs of operating out of more and decentralised warehouses.

The problem with KFC

This framework can explain what went wrong with KFC. The company has a business model that operates with very low margins. What’s more, the food industry deals with intrinsically high uncertainties of demand, just like retail, fashion and sportswear. Here, decentralised supply chains can help to reduce mismatches between supply and demand, and improve customer fulfilment. Food and beverage company Nestlé, for example, operates successfully in 47 US states with 25 production facilities and 43 distribution centres for exactly this reason.

But by moving away from a decentralised system – probably under pressure to reduce costs – KFC introduced a big risk of being unable to cope with customer demand, or being left with costly surplus stock in its supply chain. This decision, to centralise its logistics, would be a logical one only if KFC’s outlets didn’t need frequent deliveries, and their demands were regular and very stable. Both of these conditions are simply not possible in this industry.

What else could they do?

What else could KFC have done? Our study shows that KFC could have reduced the high risk that it introduced to its supply chain in two ways. First, they could have continued to work with Bidwest Logistics and maintained the decentralised warehouses to keep responsiveness up. Second, to make this profitable, KFC could have improved its margins by increasing the breadth of its product offerings and charging higher prices for the new menus. This way it could have achieved a far better match between its business model and the design of its supply chains.

Share current page as Facebook post

Share current page as Twitter post

Share current page as LinkedIn post

Share current page as e-mail message

Share current page as WhatsApp message

Dr. Isik Bicer

Assistant professor.

York University

About Dr. Bicer

Isik Bicer, Ph.D., is an Assistant Professor of Operations Management and Information Systems at the Schulich School of Business, York University. His current research focuses on analyzing the impact of operational factors on financial parameters (e.g., stock price, capital structure, and return on assets) and designing operational strategies to ensure high customer-fulfillment rates in economically feasible ways. He uses methods from corporate finance, quantitative finance, and optimization theory to address these challenges. His research has appeared in the Financial Times listed journals such as Production and Operations Management and the Journal of Operations Management. He is also a member of Editorial Review Board of the Journal of Operations Management.

See profile

Journal: Production and Operations Management

Biçer, I. and Seifert, R.W., 2017. Optimal dynamic order scheduling under capacity constraints given demand‐forecast evolution . Production and Operations Management (STAR), 26(12), pp.2266-2286

Read the abstract

We consider a manufacturer without any frozen periods in production schedules so that it can dynamically update the schedules as the demand forecast evolves over time until the realization of actual demand. The manufacturer has a fixed production capacity in each production period, which impacts the time to start production as well as the production schedules. We develop a dynamic optimization model to analyze the optimal production schedules under capacity constraint and demand-forecast updating. To model the evolution of demand forecasts, we use both additive and multiplicative versions of the martingale model of forecast evolution. We first derive expressions for the optimal base stock levels for a single-product model. We find that manufacturers located near their market bases can realize most of their potential profits (i.e., profit made when the capacity is unlimited) by building a very limited amount of capacity. For moderate demand uncertainty, we also show that it is almost impossible for manufacturers to compensate for the increase in supply–demand mismatches resulting from long delivery lead times by increasing capacity, making lead-time reduction a better alternative than capacity expansion. We then extend the model to a multi-product case and derive expressions for the optimal production quantities for each product given a shared capacity constraint. Using a two-product model, we show that the manufacturer should utilize its capacity more in earlier periods when the demand for both products is more positively correlated.

Related articles

Rsm discovery 41 - global supply chains.

- Linh Nguyen

- Merieke Stevens

- Rob Zuidwijk

- Harwin de Vries

- Morteza Pourakbar

- Albert Veenstra

- Finn Wynstra

- Jan van Dalen

- Pieter Van den Berg

- Stef Lemmens

- Cynthia Qingxia Kong

Optimising container movements master thesis wins Jo van Nunen Award

Are your purchase decisions free from prejudice?

- Henk de Vries

Topic: Logistics

Four ways to improve coordination among humanitarian organisations

- Murat Tarakci

- Subscribe to the newsletter

- Visit Discovery home

Do you want to learn more about this subject?

Check out these rsm education programmes.

Advanced Management and Leadership Programme

- 2 Sept 2024

- More information

Diploma Programme in General Management

- 24 Jun 2024

- €15,425 depending on modules chosen *

- * see details on the page

Diploma Programme in Customs and Supply Chain Compliance

Your contact for more information:.

Danielle Baan

Science Communication and Media Officer

Dial 31(0)104082028

31(0)104082028

E-mail [email protected]

Erika Harriford-McLaren

Corporate Communications & PR Manager

Dial 31(0)104082877

31(0)104082877

E-mail [email protected]

Rotterdam School of Management, Erasmus University (RSM) is one of Europe’s top-ranked business schools. RSM provides ground-breaking research and education furthering excellence in all aspects of management and is based in the international port city of Rotterdam – a vital nexus of business, logistics and trade. RSM’s primary focus is on developing business leaders with international careers who can become a force for positive change by carrying their innovative mindset into a sustainable future. Our first-class range of bachelor, master, MBA, PhD and executive programmes encourage them to become to become critical, creative, caring and collaborative thinkers and doers.

RSM uses cookies to measure website statistics, enable social media sharing and for marketing purposes. By clicking accept cookies or by continuing to use this website, you are giving consent for us to set cookies when visiting this website. See our cookie policy for more information about cookies and how to adjust your cookie settings.

Logistics and Supply Chain Management: A Case Study of KFC

Added on 2023-06-04

About this Document

End of preview

Want to access all the pages? Upload your documents or become a member.

Logistics and Supply Chain Management for KFC lg ...

Supply chain management kfc lg ..., lscm5027 logistics and supply chain management assignment lg ..., logistics and supply chain management - doc lg ..., management of resources - kentucky fried chicken lg ..., logistics and supply chain management assignment (doc) lg ....

KFC Ran Out of Chicken in the UK: What Supply Chain Lessons Can We Learn?

More than half of the uk’s kentucky fried chicken stores recently closed because they ran out of chicken. here’s a look at what caused the issues and what supply chain lessons can be learned..

This guest post comes to us from Argentus Supply Chain Recruiting , a boutique recruitment firm specializing in Supply Chain Management and Procurement.

There’s another unfortunate entry in the annals of Supply Chain failures that burst into the wider world of business and pop culture: More than half of the UK’s Kentucky Fried Chicken stores recently closed because they ran out of chicken. We’ve written on the Argentus’ blog many times about Supply Chain misadventures , and how they can harm a brand’s reputation as well as profits – for example, maybe most memorably, in the case of Target, which had to retreat from the Canadian market after Supply Chain snafus led to empty shelves and disappointed customers.

Although Supply Chain Management is taking off in terms of recognition within business, it still doesn’t get a lot of attention from the wider world – until it fails, at which point the stresses and pressure of beleaguered Supply Chain teams become an object of fascination as the organization races to play catch up and get things back online.

KFC’s UK operations are the latest such story. On February 19 th , outlets began reporting about the closure of about half of the chain’s 900 stores in the country, due to delivery failures after changing their 3 rd Party Logistics (3PL) provider from Bidvest Logistics to DHL. A few weeks later, reports are that a number of stores are still closed, with front-line workers being encouraged to take holidays as the company sorts out its deliveries and tries to account for the failures. It’s no wonder that the closures have been met with derision across the internet: delivering chicken to the people is pretty much KFC’s #1 job.

So what has caused the issues, and what lessons are there to be learned?

According to the BBC , KFC recently switched its 3PL operations from food specialist Bidvest Logistics to international heavyweight DHL – the latter being a company with operations in a number of different industries, now navigating a country-wide Supply Chain out of one distribution centre location. In short, DHL took over the contract on Valentine’s Day, and delivery failures started to happen on February 16 th – an extraordinarily short time table for Supply Chain issues to get so dire that customers see disruptions.

While there’s some disagreement among experts about the exact cause of the failed deliveries, speculation is that many of the problems can be attributed to the fact that DHL has one distribution centre location serving the entire country – a bottleneck that wasn’t seen with the previous 3PL provider, who had six distribution centre locations.

While Supply Chains gain a lot of their competitive advantage from offering lower costs and greater efficiencies, it seems that the shift in providers was a cost-cutting maneuver that’s ended up costing the company’s brand — with some analysts predicting something on the order of 20% of a hit to the company’s share prices once the disruption finishes shaking its way through the system. It underscores the importance of sound planning and reliability in Supply Chain Management in an era where companies are looking to gain an edge with margins wherever they can. It’s also great evidence for what many of us know: an approach that puts cost-cutting first can cause more problems than it solves.

John Boulter, the Managing Director of DHL’s operations for retail in the UK and Ireland issued a statement saying, “The reasons for this unforeseen interruption of this complex service are being worked on with a goal to return to normal service levels as soon as possible. With the help of our partner QSL, we are committed to step by step improvements to allow KFC to reopen its stores over the coming days. Whilst we are not the only party responsible for the supply chain to KFC, we do apologize for the inconvenience and disappointment caused to KFC and their customers by this incident.”

Ouch. Boulter’s statement has two issues that, from our perspective, show a lack of the accountability necessary to restore credibility both with DHL’s immediate customer (KFC) and the wider base of customers disappointed that they can’t buy KFC’s fried chicken:

- The statement attempts to shift blame onto DHL’s other partners in the deliveries (particularly QSL) in a way that looks passive aggressive. Admitting responsibility is the first step to restoring credibility when responding to Supply Chain failures, and while DHL accepts some blame for the issues, the statement doesn’t go far enough.

- Going out of their way to describe the service as “complex” doesn’t do any favours for DHL in this situation. Of course modern Supply Chains are complex. Understanding that complexity, and being able to deliver anyway, should be considered table stakes for providers in 2018. To implicitly chalk delivery failures up to a complexity that your predecessor – in this case Bidvest Logistics – handled without issue for years, casts even more doubt on DHL’s competency. At the same time, the fact that analysts are having such agreeing on an explanation for these issues – despite the fact that KFC only has a few poultry suppliers in the UK – says a lot about just how complex modern-day Supply Chains have become.

Logistics failures leading to the closure of stores is pretty much the worst case scenario for Supply Chain teams everywhere, so all of us across the community are probably watching this story with bemused shock and sympathy for those involved.

Hopefully DHL – which is, after all, the biggest logistics provider in the world – can get these issues solved soon, but in the meantime, let us know in the comments: are there any further lessons you think that Supply Chain professionals can draw from KFC’s recent woes?

Related posts:

- 4 Takeaways from Marketo’s 2017 Marketing Predictions for the Supply Chain

- Top 10 Logistics Metrics to Measure Supply Chain Efficiency in Your Warehouse

- Top 10 Supply Chain and Logistics Posts of 2017

Related Posts

7 skills logistics leaders will need to manage the digital supply chain

Emerging career spotlight: Digital Supply Chain Manager

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Operational Strategies and Management of KFC: An Enquiry

EPRA International Journal of Research & Development (IJRD)

This is a business case report on one of the world largest fast food chain restaurants Kentucky Fried chicken (KFC) in accordance on its operation management and strategy. As the course requirement, the company has been selected on the preference of my own with a prior approval of the unit leader. The report critically analysis three operation management decision areas as design of goods and services, quality management and supply chain management of KFC with suggestions to better performance. Furthermore, it evaluates the strengths and weaknesses as well as strategies with recommendations for achieving competitive advantages. Finally, the report draws a conclusion with wrapping up the findings. KEYWORDS: Managing Quality, Supply Chain Management, SWOT Analysis, CSR

Related Papers

Piumi Tillekerathne

Critical analysis of the importance of Operations Management to the organization and how it has had an impact to the performance levels of the organization. Brief of KFC-Kentucky Fried Chicken Kentucky Fried Chicken a.k.a. KFC, is one of the leading fast food giants in the world. It is based in Louisville. It has been ranked third largest chain with more than 13000 outlets in more than 109 countries and serves approximately 12 million consumers every day. KFC is known for its original recipe for fried chicken, which is prepared using a blend of secret 11 herbs and spices (Buick, 1982). They are operating in an industry which is based on quick service and delivery to its consumers. They have managed to curtail the service time by more than 50% and improved the productivity of its employees. This helped them to outperform others and yield higher profits and sales figures (Fitzsimmons, Fitzsimmons and Bordoloi, 2014). They aim at providing continued superior service whilst non-stop improvement. It is highly crucial for them to improve the efficiently of their entire operation so as to be able to serve customers as quickly as possible. To achieve this, they have focused on all aspects, such as facility layout, quality management, total costs and infrastructure to match up with the desires and need of its consumers. i

A.M.M. Mubassher Shah

Journal of The Community Development in Asia

rivanti kawung

A fast-food restaurant, commonly known as a quick-service restaurant (QSR) in the business, is a type of eatery that specializes in fast food and offers limited table service. In the food sector, customer satisfaction and good feedback are the most important thing. Each company also has its main power source to maintain business. The goal of this study is to find how service quality can affect customer satisfaction. This study used a service quality model which is Servqual as a guide in determining customer satisfaction. The researchers chose Kentucky Fried Chicken (KFC) Restaurant in Malaysia for this case study. KFC Restaurant has many competitors in the fast-food restaurant industry. The solution to these issues is to develop ways to increase service quality and customer satisfaction.

Mohamed Abdelgawwad

Emiel Sanchez

In the food industry, it is important for an organization to leverage their customer's satisfaction and this can be achieved through superior customer service. The goals of this study were to investigate the causes and problems faced by the selected restaurant and to provide suggestions on how to improve the slow customer service based on the numerous domains of operations management. A local restaurant in Kuching (M alaysia) was selected for the case study. Slow customer service has been identified as the main problem. The causes of this problem were identified and classified into four categories which involved people, environment, equipment/materials and method/procedure. This study also offered ways to improve its operational performance and overcome the problem of poor service operations. The alternatives offered include (1) Quality Function Development which helped in determining what will satisfy the customers and where to put the quality effort, (2) Total Quality M anagement (TQM), (3) process focus which uses service blueprint to strengthen the interaction between customers and the restaurant, (4) layout , (5) human resource management, (6) practice of good supply chain management , and (7) maintenance to get the most benefits and trouble-free services out of the restaurant equipment by performing regular maintenance. This paper hopes to provide relevant insights for service quality and customer satisfaction improvement for restaurant service operations.

CERN European Organization for Nuclear Research - Zenodo

Justine Beryl Ruth Gumbao

Proceeding of International Conference on Family Business and Entrepreneurship

Farida Komalasari

This study integrates the Kano two‐dimensional quality model and quality function deployment (QFD) to construct a systematic mechanism for food and beverage service planning and improvement. This study adopts a three stage research framework: 1. Surveying food and beverage service needs, 2. Extracting key quality factors for food and beverage service, 3. Proposing methods for improving food and beverage service. Based on the results of this research, the most five important improvement action plans are personal professional skills and knowledge, increasing the visibility of restaurant advertising, providing immediate feedback to customers, standardizing quality of ingredient purchasing, and improving time efficiency of meal preparation.

RELATED PAPERS

2018 IEEE Conference on Control Technology and Applications (CCTA)

Soumya Kundu

Muhammad Sameer

Brid Phillips

Rosanne Martyr-Koller

redalyc.uaemex.mx

Felisa Torres

Caderno Prudentino De Geografia

Arthur Magon Whitacker

Journal of Urological Surgery

Libri Oncologici Croatian Journal of Oncology

Lidija Beketic-Oreskovic

Erich Wenneker

Abdullahi sulaiman jibril

Pakistan Journal of Biological Sciences

Prof. Nurul Absar

The Journal of Immunology

G. Li-Pat-Yuen

Archives of Medical Research

Marcelino hernandez

Neotropical Entomology

Analice Nonato Guimarães

Physical Review B

Norbert Esser

Journal of Food Biochemistry

Alireza Komaki

2007 10th International Conference on Computer and Information Technology

Kazi Shamsul Arefin

Journal of Functional Biomaterials

Sabrina Prete

丢失补做LSE毕业证 gtj

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

We know that many industries have unique planning requirements, so we’ve built solutions that support your industry-specific needs.

Featured industries

Predictor IA

For companies that BUY inventory Reduce excess, minimize stock-outs, place better orders

Predictor IBP

For companies that MAKE inventory Advanced demand and supply planning functionality

ERPs we integrate with

Why Netstock

article | Inventory Optimization

Supply chain blunders – the KFC fowl up

When it comes to disruptions in the supply chain, we may not be in control of external factors such as political, environmental, or, as we have recently seen, pandemics.

However, we are in control over what happens inside our operations. If every business owner ensured that the right systems, processes, and procedures were in place, this would dramatically mitigate the fallout from any external force that threatens the supply chain. A recent article titled All clouds have a silver lining suggests that now is the perfect time to re-assess your systems and solutions.

That aside, with all the fatigue on COVID19 related news, we decided to explore other supply chain disruptions that companies have faced and look at how, by aligning processes, strategies, and technologies with your customers and suppliers, you can prevent a lot of what has happened to other organizations from happening to yours. In this article, we look at a case in 2018 that caused a big issue for KFC in the United Kingdom and Ireland.

In a bid to make their supply chain more cost-effective, KFC decided to switch 3PL providers from Bidvest to DHL. Instead of this being a cost-cutting exercise, it became a very costly decision not only in terms of money but also reputational damage for both parties. It all began on the 14th Feb 2018 when trucks arrived at the DHL warehouse in Rugby UK. According to a BBC report , truck drivers were left waiting for hours due to problems getting into the warehouse. The depot had been used to store chickens before the correct permits were obtained.

Additionally, there were staffing issues, and lorry loads of chicken were left to go off because there were not enough people to offload. One driver reported that his delivery had to be scrapped as his truck’s temperature was set incorrectly at the Rugby depot. Three traffic junctions that were in the vicinity of Rugby where DHL’s warehouse is located were closed off due to 2 different traffic incidents. DHL trucks getting stuck in traffic jams exacerbated the situation, and so the chicken shortage began. The result, only 266 of 870 KFC outlets were left open, and the open outlets were left serving from a limited menu. The hatching and grow out time of chickens isn’t something that can be rushed. It was unlikely that the additional supply needed to rectify the spoiled stock shortage would have been quick to rectify, resulting in a few months before all stores were re-opened and able to supply the choice of the full menu.

Let’s take a look at a few lessons that can be learned from this story and some factors to consider if you are looking at switching providers:

The food industry differs when it comes to their supply chain than nonperishable goods companies. Having one warehouse to deliver from can work, but when the product is perishable, it makes more sense to ship from numerous locations to ensure not only on-time delivery but also that fresh and undamaged products reach their destination.

When changing providers, especially in such a considerable distribution run, you should have a contingency plan. Think of what can go wrong and have a plan in place to manage that.

When switching 3PL’s on a large contract, rather use a phased approach with your new provider. Allow them to manage a portion of the contract and see how that goes first. This way, you are spreading your risk, and if the new provider has any problems, the impact won’t be as catastrophic.

Conduct proper due diligence when looking at new providers. Check out their financial standing and see what other contracts they have, especially ones within the same market segment. Some 3PL’s are not as geared for the distribution of perishable goods as others are. Look at their infrastructure, how many warehouses do they have? How much of their operations are outsourced? Do they have the right transport equipment such as cold storage in their fleets? If the 3PL is utilizing subcontractors, make sure that you check them out as well.

Ensure that the new 3PL truly understands your business and that you define the key metrics upfront.

In some cases, it may be better if you have a broad distribution to allocate specific routes to different providers that are prevalent in these regions. This way, you aren’t dealing with subcontractors but with the companies directly, which will give you more visibility of your shipments on those routes. This will raise the costs of your logistics, but in some cases, it may be well worth it as you are assured of business continuity by having multiple providers. You can gauge their service levels and possibly narrow down your list by giving the top performers more of the contract.

In the situation where your customers are not only the end client but the franchise owners as well, treat logistics as a service function and not as a cost center.

Mistakes happen. How these mistakes are handled and fixed is what matters. A strong positive in the KFC story was the way their marketing managed the crisis. They were quick to inform the public and kept the public informed as and when they got updated information. Adding a slice of humor to their adverts held them in good stead and softened the blow to some extent. Their advert showed an empty bargain bucket with the company’s logo re-arranged to read as “FCK,” and the caption read “Huge apologies to our customers, especially those who traveled out of their way to find we were closed. “And endless thanks to our KFC team members and our franchise partners for working tirelessly to improve the situation.

In summary, if you are looking to make a change, no matter how big or small, remember that communication across the business is vital. If you have never embarked on a change like this, do some research and find someone that has. Learn from their experiences, or you may end up making bad decisions. With the correct process and procedures in place, the change should run smoothly.

Content published on Craig De Kock – LinkedIn

Related Articles

5 Steps to Selecting Demand and Supply Planning Software

Choosing the right supply and demand planning software for your business can be daunting. With so many options available, each claiming to be the perfect ... Read More

Utilizing AI for Efficient Inventory Management Systems

Inventory management, in its current form, has come a long way since it was managed on ledgers and Kardex.

Understanding the Reorder Point Formula in Inventory Management

Simply stated, the goal of inventory management is to have the right amount of inventory in the right place at the right time.

The Complete Guide to Inventory Management

Only the most efficient and agile businesses can survive in a world where global supply chains and online markets dominate.

Ready to get started?

Discover how Netstock’s Predictive Planning Suite™ accelerates inventory planning.

Switch language:

KFC and the supply chain fail

After a chicken shortage led KFC to temporarily close more than 700 of its 900 UK restaurants, an investigation into its supply chain failures continues. Management and logistics expert Gerry Brown speaks to Chris Evans about the ramifications for the Colonel and his partners

KFC’s supply chain debacle in the UK has dominated headlines for the past week, revealing significant problems with the chain’s new foodservice suppliers DHL, its relationship with Quick Service Logistics (QSL), failed deliveries, supervision issues and temporary store closures. Here management expert and former DHL operations director, Gerry Brown, outlines where things went wrong and the lessons learned.

Mistakes made

According to Brown (pictured), currently chairman of Novaquest Capital Management, a private equity firm focused on life sciences, there are a number of key factors that resulted in KFC’s supply chain failures. He details them below:

1) Only one distribution centre was used by DHL (as opposed to six under previous supplier Bidvest)

Chilled food logistics is complex and time sensitive. The KFC franchises will have been used to placing an order online and the next day they get it. Delivering the goods is not an easy thing to do. Bidvest had been doing it for some time using a number of distribution centres, so if there was a problem with one there were others to supply cover. Having one distribution centre is always risky. You’ve got all your eggs in one basket with no room to manoeuvre, and when you’re talking about ‘just in time’ then that makes it more difficult.

2) The computer systems used were different and provided by a partner – Quick Service Logistics

New systems have to be properly tested, rigorous and working. You have to know they’re functioning properly before you put them into one big distribution centre. The problem was it wasn’t a KFC or DHL system, it was a third party’s, which they weren’t used to.