- Advisera Home

- ISO in General

Partner Panel

ISO 9001 Documentation Toolkits

Iso 9001 training.

- Documentation Toolkits

- White Papers

- Templates & Tools

Where to Start

New ai tool.

- Live Consultations

- Consultant Directory

- For Consultants

Carlos Pereira da Cruz

- Get Started

ISO 9001:2015 Case study: Context of the organization as a success factor in manufacturing company

Clause 4.1 of ISO 9001:2015 is causing lot of ambiguities and raising more questions than answers to most quality practitioners. Defining context of the organization basically means determining the foundation of your QMS and where your company stands in terms of internal and external issues related to the QMS. This requirement of clause 4 can seem too general, and there is a risk of going too wide when defining the internal and external issues. In fulfilling this clause, you should focus only on issues that can affect the customer satisfaction and delivery of quality product and/or service.

This simple example will help you understand how to determine context of the organization according to ISO 9001 in small or midsize production company and give some inspiration in your implementation project.

Small company from the South East Europe, let’s call it ABC Company, produces terrace and staircase metal fences and exports its products for some time in Germany. Since the projects are being more and more lucrative, their German customers required implementation of ISO 9001. First milestone in implementation of the standard was definition of context of the organization .

Internal context

The country where ABC Company is located is not an EU member and yet over 90% of its products are exported to Germany, particularly metal fences. Their product delivery includes not only the production of the metal fences but also installation on the buildings and production of metal fixtures for furniture industry. Considering that the company employees cannot stay in Germany more than three months without getting a working visa, the employees are organized into teams where one team is abroad in charge of installation of the products while other two teams are working at home location on production and assembly of the fences. Once this three months period expires, the team abroad switch with one of the teams located at home location. Each team has a mechanical engineer in charge and several shift managers that control and supervise the rest of employees. Employees are highly skilled for the operation they conduct so there is no so much formalism in reporting and getting instructions from superiors.

External context

Since the most of the products are delivered to Germany, the company is obliged to apply German and EU regulations regarding product quality, environmental protection and occupational health and safety. Being present on German market for 5 years, the company identified all legal requirements together with requirements of their customer which is one big German construction company and they are one of the subcontractors. Domestic market has far less requirements but it is struggling and prices on the foreign markets are more favorable so the future direction of the company is to meet requirements of it foreign customer and try to find another customers in EU countries.

Documenting context of the organization

The CEO of ABC Company decided to conduct SWOT analysis to furtherly examine the context of the organization and ensure inputs for further identification of risks and opportunities .

Table: SWOT analysis

The CEO decided that the records of SWOT analysis will be included in QMS documentation; however, he did it reluctantly since information in the SWOT analysis can be considered as sensitive and he doesn’t feel comfortable showing them to the third party (e.g. certification auditor) but he did it at the insistence of Quality Manager. The final solution was to require from the certification body an NDA (Non Disclosure Agreement) and make sure that the information provided during the audit will be confidential and protected.

What’s next?

Information gathered through process of defining context of the organization will be used as an input for further phases in implementation of ISO 9001. The fact that only one kind of product is delivered to the customer who requires ISO 9001 certificate can influence the decision about the scope of QMS (for more information, see: How to define the scope of the QMS according to ISO 9001:2015 ), other issues identified can lead to actions to address risks and opportunities (for more information, see: How to address risks and opportunities in ISO 9001 ) or can even influence the business plan and overall strategy of the company in the future years in terms of expanding to another markets and seeking for more reliable suppliers.

To learn more about ISO 9001 requirements and particularly context of the organization, try our free online training: ISO 9001:2015 Foundations Course .

Strahinja Stojanovic is certified as a lead auditor for the ISO 13485, ISO 9001, ISO 14001, and OHSAS 18001 standards by RABQSA. He participated in the implementation of these standards in more than 100 SMEs, through the creation of documentation and performing in-house training for maintaining management systems, internal audits, and management reviews.

Related Products

ISO 9001 Documentation Toolkit

Integrated iso 9001/14001/45001 toolkit.

ISO 9001 Foundations Course

Upcoming free webinar.

Suggested reading

You may unsubscribe at any time. For more information, please see our privacy notice .

The Lean Post / Articles / Lean Management Case Studies Library

Lean Management Case Studies Library

By Chet Marchwinski

May 16, 2014

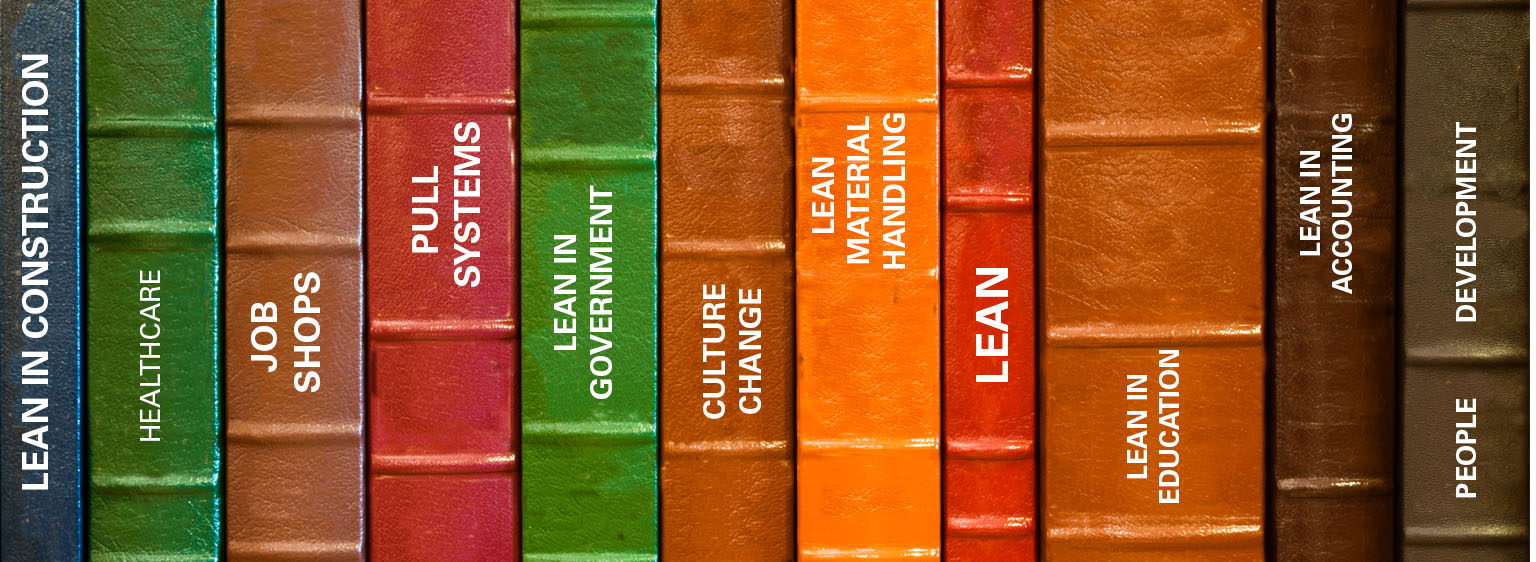

Learn how a variety of businesses and organizations used lean management principles to solve real business problems. We’ve arranged the examples in 16 categories to help you find the ones right for your environment.

Lean Management Examples from a Variety of Businesses

The following case studies of lean management principles in action show you how a variety of real businesses solved real business problems under diverse conditions.

We’ve arranged the stories in 16 categories to help you find the examples you need. There is some overlap. For instance, a “Lean Manufacturing” case study may also appear with “Privately Held Companies.”

Lean Manufacturing

- Logistics, Supply Chain, and Warehousing

- Lean Material Handling

- Job Shops (Low-volume, High-mix Manufacturing); Tool and Die

- Lean in Government

- Lean Healthcare

- Lean Accounting

- Lean Construction

- Lean in Office and Service Processes

- Lean in Education

Problem Solving

Pull Systems

Culture Change

People Development

Privately Held Companies

Maintenance

Many of the executives who took part in these transformations are interviewed in LEI’s Senior Executive Series on Lean Leadership . After reading the case studies, be sure to get their personal perspectives on leading change. (Feel free to link to this page, but please respect the copyrights of LEI and journalists by not copying the articles.)

Are you doing something new or notable in the practice of lean management? Let us share what you learned with the lean community. For more information, contact LEI’s Director of Communications Chet Marchwinski at cmarchwinski at lean dot org

Thrustmaster Turns Around

Learn how Thrustmaster of Texas successfully adopted lean thinking and practices to make sustainable improvements in a short period of time, and how other manufacturers of highly engineered, low-volume products can follow their lead using the Lean Transformation Framework.

Lean + Circular Principals = a New True North for Manufacturer

SunPower’s lean journey resembled most others until it defined a new mission, a new True North by combining lean principals with those of the “circular economy” to launch what it is calling a CLean Transformation.

Sustain Your Lean Business System with a “Golden Triangle” After a medical device maker took a hit to margins to fight off global competition, it rebuilt them by lifting its lean operating system to a higher level and keeping it there with a “golden triangle” of sustainability.

Followup Story:

Manufacturing Balancing Act: Pull Versus ERP

In this follow-up to “Sustain Your Lean Business System with a ‘Golden Triangle,’” a case study about Phase 2 Medical Manufacturing, the company needs warehouse space to keep pace with sales growth spurred by the lean transformation. Instead, it expands a pull system by connecting the plan-for-every-part database that underpins one-piece flow production with ERP, typically associated with big batch production.

Cultivating a Lean Problem-Solving Culture at O.C. Tanner If you are in the “appreciation business”, you have to live it in your own workplace. For O.C. Tanner that meant a lean transformation had to show the company appreciated and wanted people’s problem-solving ideas. Here’s a report on that effort, including what worked and what didn’t.

Lean Partnership with Dealer Network Helps Vermeer Reduce End-to-End Inventory on Top Sellers

A lean transformation had taken heavy-equipment manufacturer Vermeer away from batch manufacturing, but batch ordering by dealers was delaying how quickly they got equipment like brush chippers. Learn how it began converting its domestic industrial-line distribution network to lean replenishment, improving service to end customers and improving cash flow for Vermeer and its dealers.

Herman Miller’s Experiment in Excellence At Herman Miller, the lean management effort helps it build problem solvers as well as world-class office furniture. And as this case study shows, lean practices also helped it weather a brutal recession.

Build Your “House” of Production on a Stable Foundation Rigorous problem solving creates basic stability in a machining intensive facility.

A Journey to Value Streams: Reorganizing Into Five Groups Drives Lean Improvements and Customer Responsiveness An approach to creating a value -stream culture centered on autonomy, entrepreneurialism, and lean principles.

Change in Implementation Approach Opens the Door at EMCO to Greater Gains in Less Time A relatively quick, intensive project accelerates the rate of improvement and creates a showcase facility for spreading lean concepts.

Creating the Course and Tools for a Lean Accounting System A lean accounting implementation fills the frustrating disconnect between shop-floor improvements and financial statements.

For Athletic Shoe Company, the Soul of Lean Management Is Problem Solving After taking a lean tools approach to change, management re-organized the transformation around problem solving and process improvement to create a culture that engaged people while boosting performance.

Knife Company Hones Competitiveness by Bucking the Status Quo An iconic family-owned company turns to lean manufacturing to reduce costs by at least 30% to keep its U.S. operations open.

Lean Transformation Lives and Dies with Tools and Dies After a failed first try at just-in-time production , a company transforms tool maintenance, design, and fabrication to create a solid foundation for a second attempt.

Seasoned Lean Effort Avoids “Flavor-of-the-Month” Pitfall A look at how one company’s approach to what new tools it introduced, in what order, and how it prevented each new technique from being viewed as a “flavor of the month” fad.

Shifting to Value-Stream Managers: a Shop-Floor Revolution Leads to a Revolution in Plant Organization

Two years into a lean transformation, the low-hanging fruit has been plucked and progress has started to slow. Read how a Thomas & Betts plant recharged the transformation and reached higher levels of performance by using value-stream managers to span functional walls.

Using Plan-Do-Check-Act as a Strategy and Tactic for Helping Suppliers Improve

At Medtronic’s Neuromodulation business unit, the plan-do-check-act cycle is used on a strategic level to guide overall strategy for selecting and developing key suppliers as well as on a tactical level for guiding lean transformations at supplier facilities.

back to top

Logistics, Supply Chain, and Warehousing How a Retailer’s Distribution Center Exemplifies the Lean Precept “Respect for People,” and Reaps the Benefits

To make sure training engaged and resonated with people after previous attempts at a lean transformation faltered, LifeWay matched lean management tools and principles to its Bible-based culture and language.

Lean management case study series: Lean in Distribution: Go to Where the Action Is!

Starting with daily management walkabouts and standard work , this distributor had laid the groundwork for steady gains for years to come, just two years after its first kaizen workshop .

Putting Lean Principles in the Warehouse

Executives at Menlo Worldwide Logistics saw an opportunity to leapfrog the competition by embracing lean in its outsourced warehousing and receiving operations.

Lean Thinking Therapy Spreads Beyond the Shop

A company expands the lean transformation from the shop floor to international distribution, domestic shipping, and product development.

Sell One, Buy One, Make One: Transforming from Conventional to Lean Distribution

Large inventories to cover fluctuations in demand once characterized Toyota’s service parts distribution system — but no more. Here’s how one DC made the switch.

Material Handling

Following Four Steps to a Lean Material-Handling System Leads to a Leap in Performance

Creating the critical Plan for Every Part was one step in a methodical four-step implementation process to replace a traditional material-handling system.

Low-volume, High-mix Manufacturing; Tool and Die

The Backbone of Lean in the Back Shops

Sikorsky managers apply the lean concept of “every part, every interval” (EPEI) to level the mix in demand and create flow through a key manufacturing cell .

Landscape Forms Cultivates Lean to Fuel Growth Goals

With single-item orders 80% of the time, a low-volume, high-mix manufacturer decided single-piece flow cells were the best way decided the best way to add new products without having to constantly reconfigure production.

Lean Transformation Lives and Dies with Tools and Dies

After a failed first try at just-in-time production, a company transforms tool maintenance, design, and fabrication to create a solid foundation for a second attempt.

Canada Post Puts Its Stamp on a Lean Transformation

The “ inventory ” of mail already is paid for, so moving it faster doesn’t improve cash flow as in lean manufacturing. But Canada Post discovered that traditional batch-and-queue postal operations could benefit from lean principles.

Lean Thinking in Government: The State of Iowa

This story examines a kaizen event at a veterans home and more broadly at the lean effort in Iowa government.

Lean Thinking Helps City of Chula Vista with Budget Crunch

Goodrich Aerostructures’ Chula Vista plant introduces city government to lean thinking and practices so in order to maintain municipal services without resorting to further cuts in the workforce.

Using Lean Thinking to Reinvent City Government

Grand Rapids, MI, turns to lean principles to consolidate operations, eliminate wasted time and effort, and streamline to improve productivity while providing the quality of service that residents want.

Transforming Healthcare: What Matters Most? How the Cleveland Clinic Is Cultivating a Problem-Solving Mindset and Building a Culture of Improvement

The Cleveland Clinic reinvents its continuous improvement program to instill a problem-solving mindset and the skillset to solve everyday problems among the clinic’s thousands of caregivers.

View from the Hospital Floor: How to Build a Culture of Improvement One Unit at a Time

In order to do more and improve faster, the Cleveland Clinic is rolling out a methodology for building a “culture of improvement” across the 48,000-employee hospital system as this followup to the above story shows. Here’s how it works according to the people making the changes.

Dentist Drills Down to the Root Causes of Office Waste

Dentistry is a job shop that Dr. Sami Bahri is out to improve fundamentally for the benefit of patients through the application of lean principles.

Lean management case study series: Pediatric Hospital in Tough Market Pegs Growth to Lean Process Improvement

Lean improvement projects at Akron Children’s Hospital have saved millions of dollars, increased utilization of expensive assets, and reduced wait times for patients and their families.

Lean Design and Construction Project an Extension of Lean Commitment at Akron Children’s Hospital

Input from nurses, doctors, therapists, technicians, and patient parents heavily influenced design decisions..

“Pulling” Lean Through a Hospital

A thoughtful rollout of lean principles in the ER and eye-opening results created a “pull” for lean from other departments.

Best in Healthcare Getting Better with Lean

Mayo Clinic, Rochester, MN, stresses to doctors that the lean effort is aimed not at changing the moment of care, the touch moment between doctor and patient, but the 95% of the time when the patient is not in the doctor’s office

Fighting Cancer with Linear Accelerators and Accelerated Processes

Cross-functional team design and implement a lean process to dramatically increase the number of patients with brain and bone metastases receiving consultation, simulation, and first treatment on the same day without workarounds or expediting.

Massachusetts General Looks to Lean

A proton therapy treatment center, for many adults and children the best hope of beating cancer, applies lean principles to increase capacity.

New Facility, New Flow, and New Levels of Patient Care: The wait is over for patients at the Clearview Cancer Institute in Alabama

Physicians and staff have tirelessly reengineer processes and patient flow to eliminate as much waiting and waste as possible.

The Anatomy of Innovation

At a hospital in Pittsburgh, the emerging vision for the “hospital of the future” is described as giving the right patient, the right care, at the right time, in the right way, all the time.

Creating the Course and Tools for a Lean Accounting System

A lean accounting implementation fills the frustrating disconnect between shop-floor improvements and the financial statement.

Knife Company Hones Competitiveness by Bucking the Status Quo

An iconic family-owned company turns to lean manufacturing to reduce costs by at least 30% to keep its U.S. operations open.

Office and Service Processes

The “inventory” of mail already is paid for, so moving it faster doesn’t improve cash flow as in lean manufacturing. But Canada Post discovered that traditional batch-and-queue postal operations could benefit from lean principles.

Lean Landscapers

At an Atlanta landscaping company, lean practices are making inroads into a service industry in unusual yet fundamental ways.

LSG Sky Chefs Caters to New Market Realities

Business at airline caterer LSG Sky Chefs dropped 30% when airlines cut flights after the terrorist attacks on September 11, 2001. Sky Chefs responded with a rapid launch of a lean initiative.

leveraging Lean to Get the Oil Out

Aera Energy LLC, a California oil and gas company, relies on lean principles to improve key processes, including drilling new wells, repairing existing ones, and maximizing the number of barrels of crude pumped each day.

Columbus Public Schools Use Process Thinking to Improve Academic Achievement.

Columbus, OH, public schools, experiment with lean tools and process thinking to remove wasteful activities that don’t help them help students learn.

Lean Inroads into Alabama Academia

How the University of Alabama in Huntsville integrated lean concepts throughout its industrial engineering curriculum.

Linking Lean Thinking to the Classroom

Value-stream mapping is one of many activities included in the Ford Partnership for Advanced Studies (Ford PAS), an academic program designed to link high-school classroom learning to the skills needed in college and business.

Build Your “House” of Production on a Stable Foundation

Rigorous problem solving creates basic stability in a machining intensive facility.

For Athletic Shoe Company, the Soul of Lean Management Is Problem Solving

After talking a lean tools approach to change, management re-organized the transformation around problem solving and process improvement to create a culture that engaged people while boosting performance.

Toothbrush Plant Reverses Decay in Competitiveness

The rapid introduction of a lean system, beginning with just-in-time production and pull, helps a highly automated Midwest plant fight off overseas competition by reducing lead times and inventory while augmenting the plant’s advantage in service.

A Journey to Value Streams: Reorganizing Into Five Groups Drives Lean Improvements and Customer Responsiveness

An approach to creating a value-stream culture centered on autonomy, entrepreneurialism, and lean principles.

Making Lean Leaders — Ariens internship program develops lean and leadership skills

Besides making snow-blowers, mowers, and string trimmers, Ariens Co., of Brillion, WI, makes lean leaders.

Starting with daily management walkabouts and standard work, this 84-year-old, family-owned distributor laid the groundwork for steady gains for years to come, just two years after its first kaizen workshop.

Sustain Your Lean Business System with a “Golden Triangle”

After a medical device maker took a hit to margins to fight off global competition, it rebuilt them by lifting its lean operating system to a higher level and keeping it there with a “golden triangle” of sustainability. You’ll recognize two elements of the triangle right away: visual control and standardized work . The third, accountability management or a kamishibai system, is probably less well known but just as critical.

Cultivating a Lean Problem-Solving Culture at O.C. Tanner

If you are in the “appreciation business”, you have to live it in your own workplace. For O.C. Tanner that meant a lean transformation had to show the company appreciated and wanted people’s problem-solving ideas. Here’s a report on that effort, including what worked and what didn’t.

Lean Thinking in Aircraft Repair and Maintenance Takes Wing at FedEx Express

A major check that used to take 32,715 man-hours was cut to 21,535 hours in six months. That translated into a $2 million savings, which dovetailed with the company’s emphasis on reducing costs during the recession.

Construction

Input from nurses, doctors, therapists, technicians, and patient parents heavily influenced design decisions—from incorporating emergency room hallways that protect the privacy of abused children to the number of electrical outlets in each neonatal intensive care room.

Virtual Lean Learning Experience (VLX)

A continuing education service offering the latest in lean leadership and management.

Written by:

About Chet Marchwinski

Chet has been a humble, unwashed scribe of the lean continuous improvement movement since books by Taiichi Ohno and Shigeo Shingo first hit North America in the 1980s. At LEI, he contributes to content creation, marketing, public relations, and social media. Previously, he also wrote case studies on lean management implementations in…

Leave a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Be the first to learn of new learning opportunities and the latest practical, actionable information. Subscribe to an LEI newsletter.

Join us on social, privacy overview.

MACHINEMETRICS BLOG

Machine vs. production monitoring: the road to production..., 2024 product releases: an inside look, introducing batch connect machines, introducing condition monitoring workflows.

Ready to empower your shop floor?

- MachineMetrics

- Product Updates

- Data Science

- Lean Manufacturing

Machine Monitoring

IoT in Manufacturing: Top Use Cases and Case Studies

Updated May 17, 2021

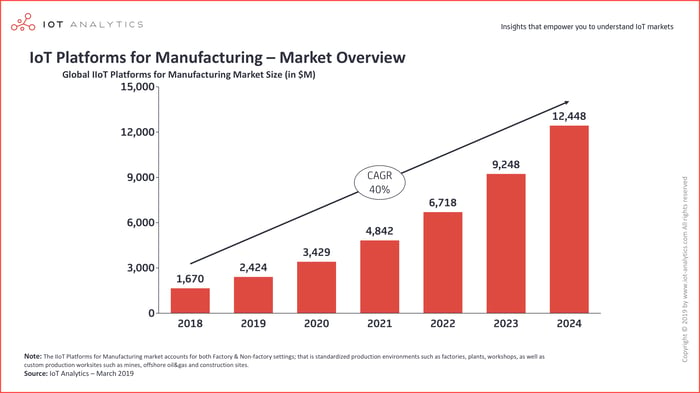

Within this article, we’ll be discussing practical IoT applications in manufacturing and use cases of industrial IoT technology in manufacturing

What is IoT?

What is iiot, the benefits of iot in manufacturing.

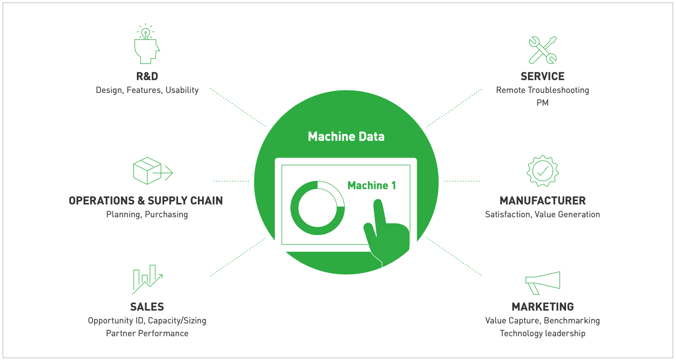

IoT represents a digital transformation in manufacturing processes and business operations. Using it alongside an advanced machine data platform can be transformational. And there are many benefits of IoT in manufacturing:

Process Optimization

Inventory Management

Predictive Maintenance

IoT in Manufacturing Use Cases [+Case Studies]

Remote monitoring.

Learn more about remote monitoring for machine builders and OEMs.

Supply Chain Management and Optimization

- Real-time tracking of assets and products

- Automation of warehouse tasks

- Digitized paperwork management

- Forecasting accuracy improvement

- Greater control of inventory

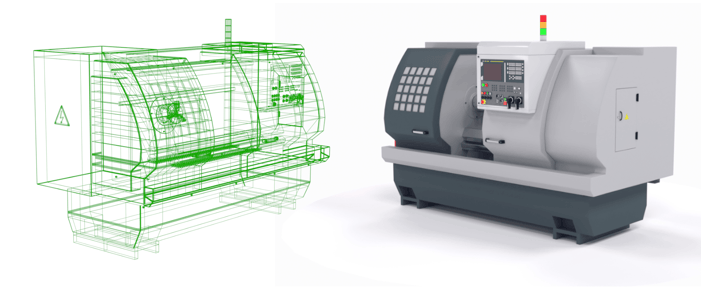

Digital Twins

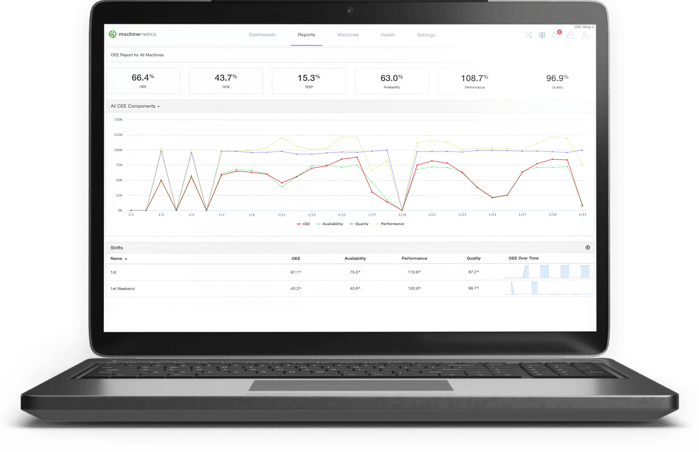

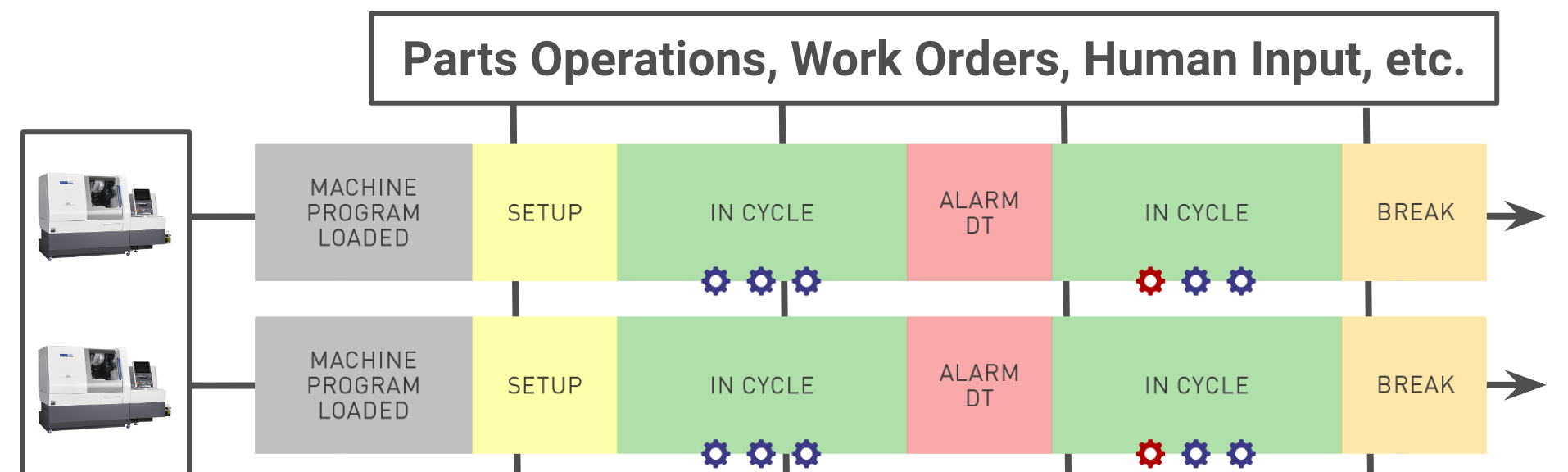

Real-Time Machine Monitoring

Production visibility.

Integrating Systems

Compiling kpis.

Asset Utilization

Difficulties of Adopting IoT in Manufactur ing

1. large investments are required and the roi is questionable, 2. concerns about data security, 3. employees who aren’t qualified, 4. integration with operational technology and older systems, how to use iot and machine data for remote operations, boosting your operational efficiency with iiot, subscribe to our mailing list, related posts, read the latest.

Lists by Topic

- MachineMetrics (382)

- Lean Manufacturing (72)

- Industry 4.0 (50)

- Manufacturing data (23)

- Manufacturing News (20)

- Data Science (15)

- data collection (14)

- Product Updates (12)

- Machine Monitoring (10)

- manufacturing analytics (10)

- Connected Factory (9)

- Smart Manufacturing (9)

- industrial iot (9)

- CNC Machines (8)

- Productivity (8)

- Downtime (7)

- Industrial Automation (7)

- Tool Monitoring (7)

- Big Data (6)

- Data Visualisation (5)

- Edge Computing (5)

- Maintenance (5)

- Process Optimization (5)

- Shop Floor (5)

- digital manufacturing (5)

- Automotive (4)

- Machine Learning (4)

- Quality Assurance (4)

- Aerospace and Defense (3)

- Contract Manufacturing (3)

- Data Cleaning (3)

- Death of MES (3)

- Heavy Machinery Manufacturing (3)

- MES software (3)

- Medical Device Manufacturing (3)

- OEE Software (3)

- Oil and Gas Manufacturing (3)

- capacity (3)

- continuous improvement (3)

- inustrial IOT (3)

- preventative maintenance (3)

- security (3)

- 8 wastes (2)

- Condition Monitoring (2)

- Dashboards (2)

- Internet of things (2)

- Production Monitoring (2)

- Strategic Partnerships (2)

- management (2)

- press release (2)

- real-time analytics (2)

- Digital Transformation (1)

- Downtime Categorization (1)

- FANUC FOCAS (1)

- Line Balancing (1)

- Machine Tool Distributors (1)

- Machinery (1)

- Manufacturing Innovation (1)

- Production Scheduling (1)

- Quality Control (1)

- Supply Chain (1)

- Turnkey contracts (1)

- coaching (1)

- elon musk (1)

- employee engagement (1)

- link roundup (1)

- manufacturing (1)

- manufacturing software (1)

- networks (1)

- release notes (1)

844-822-0664

Easthampton Office

116 Pleasant St, Suite 332, Easthampton, MA 01027

Edge Platform

Cloud Platform

APIs & Applications

Production Monitoring

Condition Monitoring

For Machine Builders and Distributors

For Developers

Aerospace & Defense

Contract Manufacturers

Heavy Machinery

Medical devices

Oil & Gas

Precision Metalworking

ERP Integration

Metal Stamping & Fabrication

Tool, Die & Mold CNC

ROI Calculator

Waste Calculator

Connectivity Hub

Partner Program

Privacy Policy

Data Processing Addendum

Service Level Agreement

Website Terms

How to Overcome the Challenges of Creating Manufacturing Case Studies

Why are manufacturing case studies so important?

Well, the industrial buying trends have been pointing in this direction for years: You would be wise to have customer-centric copy on your website for when prospects visit to do their research. But the pace of the digital content revolution has surpassed even what some of us in the business have expected.

The typical B2B buying process now involves six to 10 decision-makers, according to Gartner. Each person is independently scouring online for five to six content pieces to bring to the table.

And what do these prospects want to see? High on that list will be how your product, service, or solution has worked for others. Which brings us to the topic on hand: manufacturing case studies. Why don’t we see more of these in the industrial marketing ecosystem?

In the latest edition of the Industrial Marketer podcast, co-hosts Joey and Nels discuss how case studies and success stories are under-utilized and under-appreciated as a content marketing tool.

What Is a Manufacturing Case Study?

Many marketing terms have lost their original meaning and been diluted in application.

A white paper, for example, has its origins in government and academia as an in depth report on policy or research findings. Now the term “white paper” signals little more than promotional information about technical features or how a product or service functions as a solution.

The “case study” originated in clinical medicine, but it became more synonymous with business when graduate business schools began digging into why things worked, or why they didn’t work. A traditional case study drafted for manufacturing marketing purposes includes:

- Background

The power of a case study is in the outcome, with key statistics or metrics that demonstrate the real-world proof of your solution in the marketplace. And therein lies the rub.

Hurdles — Real & Imagined — to Producing Case Studies

In recent memory, it certainly feels like the manufacturing community has increased the number of hurdles to doing case studies and raised the height of those hurdles. Ask your clients for information to do a manufacturing case study and you are likely to hear objections around:

- Proprietary information – This includes trade secrets about products and materials but also who is doing work for whom. Many manufacturers will tell you the less competitors know the better.

- Performance metrics – Clients are hesitant to share financial information about anything, but many are now hesitant to share information about cycle times, error rates or anything related to production.

- Contact terms with that client – The belief is that if a client knows the details of how much your innovation has reduced cycle times and increased your margin, they will use that information against you in the next negotiation.

The results have meant a near death knell for the traditional manufacturing case study. Nowadays, instead of a metric-filled recap that could be a digital marketer’s dream content, what we see are vague references to saving time and money for an entity in a large industrial sector.

So, what are industrial marketers to do if they want to create manufacturing case studies that will land with their target audiences?

Reframe Case Studies as Success Stories

For practical purposes, what we really are talking about in industrial marketing circles when we say “case studies” is offering real-world proof of success with your solution. We are talking about success stories and even testimonials.

In lieu of a traditional case study full-combo platter of company name, solution and real metrics, industrial marketers should be creative about telling success stories in any way they can. Find ways to get your clients to say yes to bragging on their successes. For example, you can reduce the format to be framed around two key categories: the challenge and the solution.

Here is a great way to frame the challenge: “Our (industry) customer challenged us with designing and manufacturing a (application) to achieve (objective).” This approach can be replicated for many situations. Be specific about what you are being asked to do. That’s what is important to prospects. Play to your strengths. Use examples that you know will resonate with your ideal customers.

For solutions, be clear about what you were able to accomplish. You can describe specs or dimensions or materials without giving away trade secrets. In the end, you might not be able to say much more regarding results than, “All design specifications were met.” But even that can be a powerful statement to a prospect. You were asked to help a client do something, and you did. If you can’t go into details about the results, go into details about how you met the challenge.

Leverage Customer Testimonials

Don’t underestimate the power of a customer testimonial, especially in video format. Work with your customer to get the most possible value from a testimonial. Listen to what they want to say, and encourage them to address the areas that are important to you. Maybe you develop a script for them.

A testimonial is like a reference. Get a range of testimonials, from new customers to your most loyal. Map out a list of possible testimonials — e.g., one customer might be able to address how you improved their cycle time. Another customer might talk about how you helped with quality. Maybe you solved a vexing issue for a new customer.

A group of testimonials can tell a powerful story. And you also could be sitting on a gold mine of nuggets that you could sprinkle throughout your website in FAQs, on product pages, and on the main page each industry you serve. Don’t forget: More people than ever are researching your products and services. In the absence of traditional manufacturing case studies, success stories and testimonials can help get them farther along the buying journey.

Listen to the Podcast for More on Manufacturing Case Studies

For more insights into how to implement a CRM in a way that will help you drive growth, tune into Episode 28 of the Industrial Marketer podcast.

Subscribe to the Industrial Marketer Podcast

The Industrial Marketer podcast comes out twice a month. To subscribe, visit our Buzzsprout show page and select your podcast platform of choice.

And if you have any ideas for topics you’d like us to cover on the podcast — or here on the Industrial Marketer website — send us a message on Facebook or Twitter and let us know!

Tags: content marketing , content strategy , Industrial Marketing Podcast

About the Author

Nels Jensen is a veteran B2B journalist, Senior Content Creator at INDUSTRIAL , and co-host of the Industrial Marketer podcast. His early career was in sports. He says business is a lot like sports; people keep score and there are winners and losers.

TUNE IN TO THE PODCAST

Fellow industrial marketers.

- B2B Marketing Insider

- Industrial Marketing Today

- Manufacturing Innovation Blog

- Marketing Maven

- The Thomas Blog

Popular Articles

- The Key Elements of Workforce Recruitment Messaging

- How to Get Started With B2B Marketing Webinars

- 3 Ways to Improve Your Manufacturing Audience Targeting

- How Manufacturers Can Experiment with AI Marketing

SCM Case Studies With Examples

What is an scm case study.

- Procurement

- Product lifecycle management (PLM)

- Inventory management

- Demand planning

- Order management

- Warehousing

- Transportation

- Customer service

What’s Included in SCM Case Studies?

- Client profile —company type, industry, and a brief history and description of the company

- The situation —the circumstances that initially caused the company to become interested in a new SCM solution

- The challenges —the problems and issues the company was facing that an SCM solution could solve

- The process —the heart of the case study, as it shows how the SCM vendor, reseller, or service provider—or TEC—performed its services in a way that met or exceeded the client’s goals and expectations

- The results —the benefits to the client at the end of the day

- Vendor/service provider profile —brief description of the vendor, reseller, or service provider—or TEC—including contact information

The Benefits of an SCM Case Study in the Selection Process

Because modern SCM software is generally quite complex, it can be difficult for companies to determine which SCM solution is the right one for their needs. Fortunately, there is a lot of documentation and research that companies can reference to assist them. As a category, SCM case studies can be of particular value because they describe how other companies overcame challenges inherent in the SCM software selection process. In the best case, organizations, such as manufacturing and distribution companies, can find SCM case studies that feature companies like theirs with similar needs and circumstances.

How TEC's SCM Case Studies Can Help You Find the Best-Fit SCM Software

TEC is a software service provider; we are not a vendor or reseller. As an industry-leading software advisory firm, we focus on three areas that are of critical importance to our clients:

- evaluation and selection

- implementation oversight

- vendor/reseller contract negotiations

TEC case studies show how our advisory services helped companies of varying types, sizes, and industries succeed in all three areas.

TEC’s SCM Software Selection Process

Selecting enterprise software presents some significant issues. The complexity of today’s enterprise software can be a challenge for companies that lack the appropriate in-house expertise. Most companies are unused to cataloging their processes and goals and then matching them to software features and functions. And while vendors sell software every day, companies seldom make a software purchase, giving vendors a built-in advantage when it comes to contract negotiations. Finally, software implementation is a specialty of its own, requiring specific expertise and oversight in this process. As you can see right below, TEC’s software selection process provides assistance in all these areas with a proven methodology developed over hundreds of successful selection projects and implementations.

- Assess : Assess the client’s business processes and goals, gaps in key processes, and discover their functional requirements

- Review : Review SCM solutions and vendor capabilities to meet the client’s business needs

- Identify : Identify the shortlist of SCM vendors and their partner(s)

- Demonstration : Assess SCM solution demonstrations scripted to the client’s business processes

- Proposal : Create and distribute SCM request for proposal (RFP) to vendors to clarify deliverables and project total cost of ownership (TCO)

- Reference : Evaluate SCM vendor and their partner(s) through reference checks from real-world clients on previous projects

- Contract : Perform contract review and price negotiations on behalf of the client for cost savings

- Implementation : Perform oversight and monitor the implementation of the SCM application(s) to enable successful transformation and business growth

TEC’s proven methodology is backed by our decision support software TECAdvisor , ensuring that every software selection decision is driven by data and is an impartial evaluation of the current enterprise software market.

Learn More with Our Free Library of SCM Case Studies

Refine results.

- Enterprise Resource Planning (ERP) 536

- Discrete Manufacturing ERP 127

- Process Manufacturing ERP 122

- Mixed-Mode ERP 112

- ERP for Small Manufacturing Business 100

- Distribution ERP 83

- ERP for Service Industry 35

- ERP for Small Business 33

- Engineer-to-Order (ETO) 121

- Supply Chain & Logistics 299

- Supply Chain Management (SCM) 158

- Inventory Management 87

- Manufacturing Execution Systems (MES) 57

- Merchandising Software 18

- Supply Relationship Management (SRM) 29

- Transportation Management Systems (TMS) 25

- Demand Management Software 27

- RFID Software 5

- Warehouse Management Systems (WMS) 97

- Business Intelligence & Data Analytics 247

- Spreadsheet 1

- Business Process Management (BPM) 100

- Enterprise Performance Management 60

- Business Intelligence (BI) and Data Management 181

- Customer Relationship Management & Support 219

- Call Center 6

- Event Management 1

- Proposal Management 10

- Contract Management 2

- Sales Force Automation Software 21

- Customer Relationship Management (CRM) 185

- Field Service Management (FSM) 80

- Configure Price Quote (CPQ) 33

- Benefits Administration 12

- Compensation Management 6

- Human Resources 24

- Performance Management 14

- Time & Attendance 11

- Workforce Management 15

- Learning Management Systems (LMS) 75

- Talent Acquisition Software 14

- Talent Management Systems 43

- Human Capital Management (HCM) 83

- Financial 130

- Billing & Invoicing 17

- Point of Sale (POS) 2

- Accounting and Financial Software 85

- Asset Management 122

- Facility Management 6

- Computerized Maintenance Management System 109

- Asset Management (EAM) 97

- Product Lifecycle Management (PLM) 115

- Process PLM 15

- Discrete PLM 16

- Regulatory and Compliance PLM 26

- Fashion PLM 22

- Retail PLM 48

- Information & Document Management 69

- Document Management Systems (DMS) 58

- Enterprise Content Management (ECM) 52

- Content Management System (CMS) 17

- IT & IT Security 57

- Help Desk 6

- Virtual Private Network (VPN) 1

- Remote Access 3

- Network Security 16

- E-commerce 31

- Web Content Management (WCM) 6

- Communication & Collaboration 31

- Collaboration 2

- Project Management 8

- Project and Process Management (PPM) 23

- Marketing 23

- Marketing Automation 23

- Design/Creative 9

- Computer-Aided Design (CAD) 9

- Industry-Specific 3

- Property Management 3

- Manufacturing 41

- Wholesale and Retail Trade 21

- Food and Beverage Products 8

- Chemical Products 5

- Pharmaceutical and Botanical Products 4

- Transportation 4

- Construction 3

- Motor Vehicles and Other Transport Equipment 3

- Agriculture and Forestry 2

- Health Care and Social Work 2

- Hotels and Restaurants 2

- Life and Natural Sciences 2

- Mining & Quarrying 2

- Public Administration and Defense 2

- Publishing and Media 2

- Telecommunications 2

- Warehousing 2

- Electronics and High-tech Components 1

- Industry Independent 1

- Insurance 1

- Recreational, Cultural, and Sporting Activities 1

Publication Types

- Blog Posts 1,216

- White Papers 772

- Case Studies 158

- Industry Reports 65

- Brochures 41

- Software Reviews 40

- Buyer's Guides 14

- Datasheets 14

- Accreditation Reports 6

- Plex Systems 9

- Pronto Software 7

- Synergy Resources 6

- Technology Evaluation Centers 6

- Demand Management Inc. 5

- Microsoft 5

- Blue Yonder 4

- AFS Technologies, Inc. 3

- Bamboo Rose 3

- MSM Solutions 3

- AppFinity Software Corp. 2

- Cadre Technologies, Inc 2

- Cameleon Software 2

- Chiron Technologies, Inc. 2

- Dassault Systèmes 2

- Habanero Consulting Group 2

- LOGO Business Solutions 2

- NGC (New Generation Computing) 2

- Nucleus Research 2

- Waer Systems Limited 2

- Arena Solutions (a PTC Business) 1

- Know the option you’re looking for? Type in the search field.

Top Publications

How to Write a Great Manufacturing Case Study

Case studies provide your manufacturing company an incredible opportunity to showcase your expertise, product value, and customer service. While testimonials are great, case studies go a step above by highlighting a customer story from start to finish. Continue reading to learn some key tips to make your case studies stand out and resonate with your prospects.

- Write About Your Most Relatable Customer Story

Do you have a clear understanding of who your ideal prospects are? Check out our blog Why Developing Buyer Personas is Invaluable for Manufacturers to get a crystal clear vision of the ideal prospects you’d like to close as customers. When your prospects read your case studies, the goal is to have them resonate with the story.

To do this, we suggest highlighting an industry-specific need the customer had and explain how your product or service was the solution. Ultimately, you want your ideal prospects to read the case study and say ‘I have that same problem’ or ‘If they helped XYZ Company, they must be a trusted industry supplier.’

Media Appointments That Are Out of This World – Case Study, Fabrisonic LLC.

- Don’t Cut Out the Details

Unlike a testimonial, a case study is meant to be in a long format. An excellent case study really allows your audience to get to know your customer, understand your company’s relationship with them, and fully explains in detail your work together.

Make sure in your case study that you explain the challenge your customer had and how you helped them with their unique goals and challenges. If you and the customer went back and forth with a few design iterations before landing on the final part design, don’t cut that out. Allow your readers to see the full picture and understand all that went into the project. Need help writing content? Our experienced writers are available to help.

- Legitimize the Story with Metrics and Visuals

To have an effective case study that your prospects will read and engage with your company, it is essential to include metrics to legitimize your story. Did you create a product in record time? Include in the story how much quicker you got your solution to your customer. Did switching their product manufacturing from another process to your process save them money? Include a quote from your customer talking about cost-savings.

Felber PR rebrands PMI

Include tangible results so your readers have a clear understanding of what you could do for them. When you are done writing your story (and it’s been approved by your customer to go live), don’t forget to add customer-approved high-resolution visuals or videos. Photos, infographics, and videos are a phenomenal way to enhance your story and get your message across to prospects.

Are you saying to yourself, this is great but I’ll never be able to get my customers to participate in case studies, don’t fret. Check out our blog, How to Convince Your Stubborn Manufacturing Customers to Participate in Case Studies for our tried and true tips to get them to say yes!

Leave a Reply

Leave a reply cancel reply.

You must be logged in to post a comment.

Felber PR & Marketing 8963 Darrow Rd Twinsburg, Ohio 44087-2109 Phone: 330.963.3664

Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study

The TQM Journal

ISSN : 1754-2731

Article publication date: 15 October 2021

Issue publication date: 17 December 2021

The aim of this study is to develop an in-depth case study on the implementation on Lean six sigma (LSS) in Schnell S.p.A., Italian company leader of an important multinational industrial group, highlighting the benefits that can be achieved from a careful application of this method, the main challenges and organizational learning from its implementation.

Design/methodology/approach

The study has been developed with a qualitative approach, creating a single in-depth case study, with the participant observation of researchers in the project which lasted 4 months. Periodic weekly meetings were done with the working group to exchange feedback on the development of the project to share opinions and data.

A project has been developed to stabilize the procurement process of a pull-type production cell, which experienced delays in supply lead times. The causes of the problems in their process of managing the supply of the production cell were found and some inefficiencies in the internal process of fulfillment of supply orders have been intercepted, the optimization of which has allowed the generation of an automatic system for sending supply orders, coming directly from the production line.

Originality/value

This study described the path and dynamics of the transformation process that business organizations undertake for optimizing their profitability and competitive advantage, placing emphasis on an innovative methodology for conducting business process improvement projects, which constitutes its operating philosophy on the effective and efficient use of company resources and skills, to guarantee to the company the achievement of a lasting and defensible competitive advantage over time.

- Lean thinking

- Lean production

- Quality management

- Continuous improvement

Murmura, F. , Bravi, L. , Musso, F. and Mosciszko, A. (2021), "Lean Six Sigma for the improvement of company processes: the Schnell S.p.A. case study", The TQM Journal , Vol. 33 No. 7, pp. 351-376. https://doi.org/10.1108/TQM-06-2021-0196

Emerald Publishing Limited

Copyright © 2021, Federica Murmura, Laura Bravi, Fabio Musso and Aleksandra Mosciszko

Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

The development of an effective quality improvement or continuous improvement strategy is a key factor for long-term success of modern organizations. Over the last decade, Lean Six Sigma (LSS) has become one of the most popular and proven business process improvement methodologies organizations have ever witnessed in the past ( Antony et al. , 2017 ), and it has been accepted globally as a management strategy for achieving Process Excellence ( Gijo et al. , 2019 ).

Lean Six Sigma is a management strategy for improving corporate productivity and profitability, that aim to maximize the Customer satisfaction by reducing constraints which the company organization is subject in terms of activities that do not create value for the Customer. In practice, LSS is an improvement strategy that analyze quantitative data on business performance to identify, eliminate and control problems and inefficiencies related to manufacturing cost, service cost, quality, productivity and customer satisfaction ( Singh and Rathi, 2019 ; Snee, 2010 ) throughout the business processes.

The objectives of quality and efficiency, supported by Lean Six Sigma, are made by DMAIC: a structured method for improving the performance of existing processes ( Sordan et al. , 2020 ), based on the application of the concepts Define, Measure, Analyze, Improve and Control. It provides a standardized guideline for the elaboration of improvement projects and provides different statistical tools and techniques appropriate to each phase of the DMAIC cycle ( Sordan et al. , 2020 ) able to lead to the root causes of business problems and to eliminate the wastes and reduce the variation, thus, ensuring substantial improvement in business processes ( Bhat et al. , 2020 ).

The term LSS was first introduced into literature around 2000 LSS, while LSS teaching was established in 2003 as part of the evolution of Six Sigma ( Timans et al. , 2012 ). Since that time, there has been a noticeable increase in LSS popularity and deployment in the industrial world ( Shah et al. , 2008 ) and researchers had the interest to publish more papers on LSS to try to come up with a comprehensive approach to achieve continuous improvement. However, as suggested by Albliwi et al. (2015) , there are still many gaps that need to be addressed in LSS literature such as benefits, motivation factors, challenges and limitations ( Pepper and Spedding, 2010 ; Laureani and Antony, 2012 ), and there is also a lack of research in the relation between LSS and organizational learning and in recent years a lot of systematic literature reviews on the topic have been published on the topic but only few case studies have been analyzed in the research field to cover this gap.

Therefore, the aim of this study is to cover this gap, by developing an in-depth case study on the implementation on LSS in an Italian company leader of an important multinational industrial group, that is Schnell S.p.A., that constitutes its main research and production center and provides technological, organizational and commercial support for the entire group. Schnell operates in over 150 countries around the world through its 11 subsidiaries, over 50 agents and resellers, and a dense network of service centers.

This research work has the objective of highlighting the benefits that can be achieved from a careful application of LSS method in the company, the main challenges and also organizational learning from LSS implementation, showing its application in details in an important reality like that of Schnell S.p.A.

The paper is structured as follows: Section 2 depicts the theoretical background, describing the merging of Lean Production and Six Sigma and defining the critical success factors of lean six sigma implementation; Section 3 defines the methodology used, Section 4 presents and discusses the results of the case study while the last section draws the main conclusions.

2. Literature review

2.1 the merging of two quality philosophies: lean production and six sigma.

The LSS notion was announced to the world in 2002, when Michael George used it for the first time in the book “Lean Six Sigma: Combining Six Sigma with Lean Speed” ( Sordan et al. , 2020 ; Sreedharan and Raju, 2016 ). He is the founder and Chief Executive Officer of the George Group, one of the largest LSS project consulting firms in the United States.

Although its appearance is quite recent, LSS arise from two complementary but different approaches ( Sordan et al. , 2020 ): Toyota Production System (TPS), a famous organizational orientation developed in Japan, from the 1960s and 1980s, spread with the concept of “Lean Thinking”; and Six Sigma, a technical quality management program, introduced by Motorola Corporation in manufacturing arena in 1987 ( Singh and Rathi, 2019 ).

The synergy between Lean and Six Sigma created a data-driven ( Sreedharan and Raju, 2016 ) and top-down business strategy to improve the quality and productivity of organizations ( Singh and Rathi, 2019 ; Sordan et al. , 2020 ).

When we talk about Lean Thinking, we are talking about a business culture, based on respect, trust and cooperation between employees and oriented by a constant search for perfection that allows to reach the highest quality of products and services offered by the company and consequently to maximize customer satisfaction.

To achieve this goal of perfection and to optimize profits, corporate actions must be aimed at a constant effort to reduce costs and wastes of tangible and intangible resources, by distinguishing valued-added activities from non-value-added activities and eliminating wastes that increases cost without adding value in the eyes of the customer ( Antony et al. , 2017 ; Cudney et al. , 2014 ): activities that are unnecessary and not required for the operations of the business ( Jayaram, 2016 ).

Lean Thinking emphasizes on productivity improvement along with speed to respond to customer needs and create a streamlined, high-quality system that produces finished products at the pace of customer demand with little or no waste ( Lande et al. , 2016 ).

Wastes are called Muda, and they can be defined as real sins that hinder the ideals of perfection. The eight types of waste are defined as transport, inventory, motion, waiting, overproduction, overprocessing, defects and non-utilized skills ( Gijo et al. , 2019 ). To identify and eliminate Muda, Lean strategy brings a set of proven tools and techniques that allow to reduce lead times, inventories, set up times, equipment downtime, scrap, rework and other wastes of the hidden factory ( Lande et al. , 2016 ). Corbett (2011) affirms that while lean focuses on the elimination of waste and improving flow, it has some secondary effects: quality is improved; the product spends less time in the process, thereby reducing the chances of damage and obsolescence.

But we have to remember that the commitment to Lean Thinking must start at the top management level and should be cascaded down to various levels across the organization to improve flow and efficiency of processes ( Antony et al. , 2017 ).

Six Sigma (SS) is a business process improvement and problem-solving approach ( Lande et al. , 2016 ) that seeks to find and eliminate causes of variability, as well as defects or mistakes in business processes, by focusing on process outputs which are critical in the eyes of customers ( Antony et al. , 2017 ). The main objective of Six Sigma is to obtain “zero defect” or, in statistical terms, to reduce defects up to 3.4 parts per million opportunities ( Singh et al. , 2019 ).

To study variability, Six Sigma utilizes a problem-solving methodology to define, measure, analyze, improve and control processes and implement cost-effective solutions leading to significant financial savings ( Singh et al. , 2019 ) not only for manufacture sectors but also remove the defects throughout the corporations ( Singh and Rathi, 2019 ). This methodology is called DMAIC and it emphasizes on variation reduction, defect reduction and process evaluation (the effectiveness issue).

The complementarity between both approaches can be justified when the deficiencies inherent in each of them are observed, acting in isolation ( Sordan et al. , 2020 ). Both had produced tremendous results but had limitations: Lean is not well suited to resolving complex problems that require intensive data analysis, and advanced statistical methods, and, Six Sigma implementation showed how not every problem can be resolved with only a big data collection ( Antony et al. , 2017 ).

Lean does not address variation within a process; rather it addresses variation between end-to-end processes which appears in the form of waste. One of the major limitations of Lean is that it cannot be used to tackle problems related to process stability and capability ( Gijo et al. , 2019 ) and it tends to work best with “solution known” problems, where we realize that we are not operating to best practices, Lean implements them and make rapid improvements with minimal data collection ( Hoerl and Gardner, 2010 ). Six Sigma is most effective when used for improvement projects intended to drive processes towards process entitlement, in situations where the solution to the problem is unknown ( Snee and Hoerl, 2007 ).

As stated by Pepper and Spedding (2010) if lean is implemented without Six Sigma, there is a lack of tools to fully exploit the improvement of its potential. Conversely, if Six Sigma is adopted without lean thinking, there would be a cache of tools for the improvement team to use, but no strategy or framework to bring one's application to a system.

Combining Lean manufacturing principles and Six Sigma tools and techniques enables organizations to form a powerful improvement combination ( Hoerl and Gardner, 2010 ; Lande et al. , 2016 ) that has allowed many organizations to solve more problems quicker ( Antony et al. , 2017 ). It is a successful integration because Lean focuses on improving the flow of information and materials between the steps in the process and Six Sigma works to improve the value-adding transformations which occur with in the process steps ( Antony et al. , 2017 ).

LSS defines an approach, but of course does not dictate the specific progression of the project or dictate the unique mix of tools to be used, which of course needs to be problem specific ( Hoerl and Gardner, 2010 ). The appropriate blend of Lean and Six Sigma tools useful on any one problem therefore depends on the nature of the specific problem being solved ( Antony et al. , 2017 ).

The marriage between these two methodologies provides a more integrated, coherent and holistic approach to continuous improvement ( Pepper and Spedding, 2010 ) and has led to the creation of a breakthrough managerial concept ( Sordan et al. , 2020 ; Chiarini, 2012 ) with the aim to create a new business culture that breaks the link with the traditional way of working in all productive functions. LSS adds a new task to daily working duties: the recovery of operational efficiency through training growth of people, extensive use of data culture and problem-solving methodologies; all activities that simultaneously allow the improvement of quality, the costs and business complexities reduction, the increasing revenue ( Galdino de Freitas and Gomes Costa, 2017 ; Jayaram, 2016 ) and, finally, greater reliability of the services provided to the end customer. The application of LSS methodology results in reduced waste, defects and improve process, which in turn provide high-quality products at minimum cost, and this leads to customer delight, which ultimately raises the societal living standard ( Singh et al. , 2019 ; Jayaram, 2016 ), the well-being of employees and the quality of the work environment (Galdino de Freitas and Gomes Costa, 2017 ).

LSS aims not only to improve financial results through the improvement of company production processes, but it targets to help organizations build an adequate relationship with society, employees and the environment ( Galdino de Freitas and Gomes Costa, 2017 ).

Both Lean and SS require a company to focus on its products and customers and LSS as a part of management strategy to increase the market share and maximize profit ( Lande et al. , 2016 ). It produces benefits in terms of better operational efficiency, cost-effectiveness and higher process quality, because it promotes total employee participation from both top-down and bottom-up as a win-win practice to both management and staff members ( Gijo et al. , 2019 ).

2.2 Critical success factors of lean six sigma implementation

Lean Six Sigma strategy is versatile in nature and has a lot of applications in a variety of industries.

It can be applied in manufacturing as well as non-manufacturing environment ( Singh and Rathi, 2019 ). It has broad applicability in service, healthcare, government, non-profits, education ( Antony et al. , 2017 ) automotive, textile, steel and aerospace industries ( Sordan et al. , 2020 ). Although LSS has its roots in manufacturing, it is proven to be a well-established process excellence methodology in almost every sector despite its size and nature ( Gijo et al. , 2019 ). It is useful in small-and medium-size organizations as well as large organizations ( Antony et al. , 2017 ).

LSS is also suitable for less experienced organizations: Bhat et al. (2020) write about the successful deployment of LSS strategy in an Indian industry with orthodox industrial practices, limited manpower, constrained capital and confined knowledge on scientific improvement practices, and the research proves that even a novice user can effectively participate and implement LSS with proper mentoring to enhance the system.

Regardless of the sector in which the LSS is applied, this shows the spread of LSS in various organizations as one of the best strategies for organizational excellence ( Sreedharan and Raju, 2016 ). But it is important to remember that achieving maximum strategic and management efficiency cannot be based on the replication of principles and models of Lean approach.

Each organization is immersed in different social, cultural and economic conditions. For this reason, lean tools must be sized and customized on business contexts and simultaneously the entire business organization must be adapted to the changes that Lean Six Sigma generates and that it needs to be applied effectively ( Lande et al. , 2016 ; Raval et al. , 2018 ; Singh et al. , 2019 ; Gijo et al. , 2019 ).

These requirements for cultural change are the main critical success factors for LSS ( Sreedharan and Raju, 2016 ).

Critical success factors are the actions and processes that must be controlled by the management ( Lande et al. , 2016 ) during the implementation of a LSS project.

Top management involvement and commitment ( Lande et al. , 2016 ; Gijo et al. , 2019 ). The top management involvement and commitment are essential for successful implementation ( Pepper and Spedding, 2010 ) of any LSS initiative. It must personally support all improvement initiatives and integrate the LSS culture into entire organizations. Its active participation can multiply the positive project effects and make a significant impact at all levels ( Gijo et al. , 2019 ). If the top management will not take initiatives and not show their full involvement it could cause the failure of LSS implementation ( Singh et al. , 2019 ).

Employee involvement, empowerment and training ( Lande et al. , 2016 ; Gijo et al. , 2019 ; Bhat et al. , 2020 ). The cultural growth of internal staff is the heart of LSS programs because it offers necessary tools to create a clear vision of the project, to focus on teamwork and, above all, to fight the resistance to cultural and operational changes ( Singh et al. , 2019 ; Sunder and Antony, 2018 ). Employee training also contributes to gain a high level of internal communication which facilitates the implementation of LSS ( Lande et al. , 2016 ; Singh et al. , 2019 ; Gijo et al. , 2019 ; Bhat et al. , 2020 ). Training is necessary to create a supporting infrastructure (the belt system) and a holistic approach to improvement including area of application and methodology used ( Antony et al. , 2017 ). The belt system includes Master Black Belt, Black Belt, Green Belt, Yellow Belt and depending on the complexity of the problem considered and skills required to solve it, the appropriate Belts are selected ( Gijo et al. , 2019 ) to play the role of leadership and guidance of the project team.

Linking LSS to business strategy and customer satisfaction ( Lande et al. , 2016 ). Improvement projects must be closely linked with maximizing customer satisfaction. Top management defines business objectives and identifies improvement projects capable of guaranteeing greater remuneration in terms of optimizing company productivity and profitability, as well as projects that can be reached using available resources, which do not require high investments and which allow to obtain undisputed results with limited deadlines in a limited period of time. Improper linkage between organizational objective and customer's requirement leads to failure of LSS implementation ( Singh et al. , 2019 ; Singh et al. , 2019 ; Gijo et al. , 2019 ).

3. Methodology

The study is a conceptual development and it has been developed with a qualitative approach, creating a single in-depth case study of Schnell S.p.A. that derives from a Group Purchasing Excellence Project. The case study allowed for examining in depth the implementation of a Lean Six Sigma improvement project for the transformation and simplification of the production process of the Schnell “Alfa” and “Beta” machines with the aim to reduce the delivery times of its products ( Yin, 1994 ). The case study was developed with the participant observation of researchers in the project which lasted 4 months, starting from November 4, 2019 to March 4, 2020. As for the participant observation, the researcher was directly involved in the LSS implementation activities, collaborating with the working group in the figure of the project manager, and facing directly obstacles and problems that emerged during these stages of the same (par. 4.2.1.1 will define the detailed description of the project). Periodic weekly meetings were done with the entire working group to exchange feedback on the development of the project, to share opinions and data. Participant observation activity was triangulated with secondary data, such as company reports and the website, collected during the period of support in the company. Secondary data have been used mostly to describe Schnell history, structure and the services it offers to customers.

Minitab 19 statistical analysis software was used to describe and summarize the data collected during the project and shown in the result section.

4. Results and discussion

4.1 company profile: schnell s.p.a.

Schnell S.p.A. is an Italian company that has been operating for almost 60 years in the manufacturing sector of automatic machines and plants for processing iron for reinforced concrete. It was born in 1962 thanks to the devotion of a group of entrepreneurs, driven by the dream of transforming the tiring and dirty world of iron working, into a modern industry, dedicated to conquering the global market. The company embarks on its own path by offering a first innovative solution that allowed faster binding of the reinforcing bars, flanked by the production of construction site machinery for cutting and bending the bars. The rise in the automatic machinery sector has started with the development of mechanisms for the production of cylindrical cages; however, the real change of course compared to its competitors will take place with the addition of electric servomotors, used, before now, only in fields such as robotics and military industry. Thanks to this type of instrumentation, Schnell machines are characterized by high power, speed, reliability and precision. They guarantee to the customer the achievement of economies of scale and better production techniques due to the high productivity offered, reduced set up times and low maintenance costs. Schnell S.p.A. offers the market a high range of machines and systems that allow a variety of processing of iron for reinforced concrete, including straightening, stirrup bending and shaping machines for bending, shaping and cutting iron in rolls or bars; cage making machines for the formation of cylindrical poles and cages for construction; machines and plants for the production of electrowelded mesh; machines for wire straightening and cold rolling lines; rotor straightening machines for processing steel wires for the industrial sector; machines for the production of prefabricated insulating panels for building construction; software for the management of iron processing centers using Schnell automatic machines. As a result of the high quality of these products, Schnell S.p.A. has managed to win the trust of its customers all over the world, reaching a turnover of over 100 million euros.

The Schnell Group is characterized by a staff of over 700 employees worldwide, and is made up of 5 production plants; 7 centers for installation, sales, spare parts and after-sales services; Schnell Software (Spain), which is a center for the creation and development of software systems for the management and organization of production carried out using Schnell machines and Schnell Home S.r.l., production center of machines for the construction of innovative elements for building construction, called “Concrewall”. Achieving a highly competitive advantage over its competitors in the same sector was possible due to constant investments in research, development and technological innovation of products and processes. Product innovation, since the company is always ready to respond to market needs through the development of a customer-oriented approach, which allows to offer integrated and customized production solutions. Process innovation, since, as stated in the “Integrated Quality Policy” and “Purchasing Excellence Group Program” of Schnell S.p.A., the efforts of the whole company are oriented to create effective methods of managing internal operational processes, with a view to maximizing end customer satisfaction.

As a result of the constant commitment in this direction, at the end of 2007, Schnell S.p.A. managed to obtain the quality system certification according to the ISO 9001 standard, delivered by the prestigious certification body TUV Italy, and renewed in 2019 in compliance with the updates undergone by the standard in September 2015.

The important results obtained in terms of product and process quality was also possible due to the dissemination and application of Lean Manufacturing principles and methodologies.

4.2 The development of the lean six sigma project in Schnell S.p.A

The layout of the cell, the equipment and the production tools have been designed and arranged horizontally following the phases of the process;

The production plans were planned on order, therefore, on the basis of the orders received from its customers, following the production theories with the pull logic;

The manufacturing of the machines was organized in small batches conducted with the one-piece flow system;

The management of the entire procurement process of raw materials and production components has been entrusted to the Kanban system;

The line operators have been trained to complete all manufacturing operations in complete autonomy.

The products supplied with their own identification codes;

Periodicity of reordering;

Minimum order quantity;

Delivery Lead Time (in working days);

Safety Stock Level: quantity of products to be held in the warehouse as a mandatory stock;

Technical specifications of production;

Specifications for packaging and delivery.

For further stabilization of the production process, aimed at increasing product quality, the characterizing element of the In-Lining Line was to reach a Free-Pass quality level. This qualitative incoming methodology has allowed a high reduction in the variability of the external production process, of the components characterized therein, while requiring significant direct and indirect investments by sourcing.

The entire In-Lining apparatus is governed by a vital element for the correct planning of the production phases: the supply Lead Time.

This index represents the time elapsing from the time of issue of the purchase order to the time of actual receipt of the goods. It allows to efficiently plan the supply of production components, and therefore, to define the periods for sending purchase orders.

Lead time of supply;

On-time Delivery (the ratio between the number of orders processed on time and the number of total orders processed, in the period considered).

With a view to Project Management, a work team was set up with the task of studying and analyzing the procurement process of the In-Lining line, and the phases of the Plan-Do-Check-Act (PDCA) and DMAIC approach were followed for the implementation of the project.

4.2.1 “Define” phase

The objective of the first phase of the project was to identify all the aspects necessary to define the process to be improved, therefore, to develop a planning prospectus called Project Charter containing: the representation of the problem detected, the objectives to be achieved, the requirements required from the customer, the inputs and outputs of the process and the metrics necessary to measure it, the enhancement of the current process and possible savings achievable by improving the process, the team members, and finally, the deadlines of the project phases.

4.2.1.1 Project description

Analyzing the lead times of supply of the supplying process of the In-Lining Line, conducted with the Kanban system, it was reported that the most important supplier in terms of quantity, tends not to respect the agreed delivery terms.

Upper specification limit (USL) = LEAD TIME 5 days (working);

Lower specification limit (LSL) = LEAD TIME 2 days (working).

Analyze the deliveries to the line of the last available calendar period, from 01/11/2018 to 31/10/2019;

Perform stratification of the detected deliveries, until the root causes are reached;

Define the initiatives and control charts to ensure the stability of the procurement process over time.

Lead Time of supply;

Defects per Unit – DPU;

Defects Per Million of Opportunity – DPMO;

Sigma Level.

The project team was made up of the members defined in Table 1 .

The implementation of the DMAIC phases was organized through the Gantt Chart ( Figure 1 ), with the aim of a precise subdivision over time of the individual activities to be carried out, while all the information that defines the project was collected in the Project Charter document of Figure 2 .

4.2.1.2 Project risk analysis

During the planning of the project, different potential risks were identified that could affect the smooth running of the project. These were found in relation to different sources from which they could derive (see Table 2 ).

Severity (P): expresses the potential damage that the occurrence of the risk could cause in the implementation of the project;

Occurrence (G): expresses the probability that the risk may occur;