Welding and Fabrication Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business ideas » Construction & Engineering Industry » Welding and Fabrication

Are you about starting a welding and fabrication business ? If YES, here is a complete sample welding and fabrication business plan template & feasibility report you can use for FREE .

When we look around where we work or reside, we will sure note items that you that was produced by a wielder or has been through a welding process. This is why the services of skilled wielder will always be needed and the craft will keep getting attractive.

It is believed that the wielding industry is one industry that shows a substantial return in your investment at every turn and moment. When starting a wielding business, you go need to go for welding training. You also need to be certified, and to get certified, you need to undergo certain trainings in welding.

A Sample Welding and Fabrication Business Plan Template

1. industry overview.

This ever blooming industry seems to be growing the fastest with recent years showing maximum growth. The welding industry has been approximately stated to grow at the very least 6% per year. Conventional electric arc welding equipment and filler metals represent over two-thirds of this total.

This industry has many segments and each segment of the industry and each welding process have its own growth patterns noted after accurate research. It’s important to note that Welding is now the universally accepted method of permanently joining all metals.

The welding industry is considered a mature industry but it is still a growing industry from different perspectives. The true impact of welding on the metalworking industry should be measured in the value of the parts produced by welding, the amount of money saved by the use of welding over other metal fabrication processes, and in the value of products made possible by welding.

Facts on ground has gone a long way to show the growth of the welding equipment and materials industry, which also serves as an indication of the projected growth for the future.

2. Executive Summary

Sonic Welders (SW) is an established wielding and fabrication business that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. We at SW are very much dedicated to providing the highest quality workmanship, reaching the agreed delivery dates, and actualizing the custom work exactly in accordance with the customer’s concept a d astonishing designs.

Our focus at SW is to find out who our future target clients are and understand our marketing strategy, and to expand our operations and marketing so it can substantially increase profitability while also serving the united states of America. Sonic Welder will be established in Thunder Bay, Wisconsin.

Marquette is the county seat of Marquette County and it’s in the upper peninsula of Lake Superior. SW is a business built or established as a sole proprietorship and is owned by Nathan Cardozo who has over 27 years of experience in the wielding and fabrication industry and has built a reputation of excellence and quality work that is very important in the industry.

We at SW plan to manufacture and sell aluminium boat docks and also perform other welding and fabrication services for truck bodies and commercial equipment. We at SW plan to gain our market share in the following target markets: Marinas in Marquette, Lake Superior Upper Peninsula (boat owners), Commercial Customers, Agricultural Entities, and Local Municipalities.

3. Our Products and Services

We at SW primarily wield, fabricate and sell aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to fabricate and repair truck bodies, and perform aluminium repair jobs. All unused scrap metals will also be recycled by Sonic Welders.

The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy. We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

We at SW also plan to raise revenues through the distribution of welding supplies, gasses, and related items that will be bought primarily by local contractors (and also individuals that do their own welding). We at SW expect gross margins of 50% on all welding products sold in our company.

4. Our Mission and Vision Statement

- Our vision at SW is to become the recognized local leader in our targeted market for all wielding and fabrication activities.

- Our mission at SW is to build the best quality product, supply over the top service at installation, and provide exceptional customer service after the sale of the product.

Our Business Structure

It is very important to note that the backbone and founder of SW is Nathan Cardozo. Nathan Cardozo got a dual degree from UC Berkeley, one in business, the second in mechanical engineering . We believe that Nathan Cardozo chose these fields because of his interest in parts construction and general engineering theories and application.

Nathan also believed that it would be very crucial for him to have a business background for possible future application. Sonic Welders will be run solely for now by Nathan Cardozo. He will be in charge of product procurement, order taking, customer service, and assorted other activities.

But as he moves to grow the business, by travelling to the trade shows, doing all necessary things as well as ramping up sales to accommodate the distributor sales, Nathan Cardozo will employ workers that will cover a wide range of services for the company. These workers include;

Chief Executive Officer

Service and Production Supervisor

Operations Manager

- Sales and Marketing Executive

- Welding and Fabrication Engineers / Technicians

Client Service Executive

5. Job Roles and Responsibilities

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counselling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results; developing incentives; developing a climate for offering information and opinions; providing educational opportunities.

- In charge of providing direction for the business

- Creating, communicating, and implementing the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- In charge of signing checks and documents on behalf of the company

- Evaluates the success of the organization

- Serve as project manager of the organization; works directly with employees

- Develops strategic plan by studying new automobile technological, and financial opportunities; presenting assumptions; recommending objectives.

- Accomplishes subsidiary objectives by establishing plans, budgets, and results measurements; allocating resources; reviewing progress; making mid-course corrections.

- Coordinates efforts by establishing procurement, production, marketing, field, and technical services policies and practices; coordinating actions with corporate staff.

- Builds company image by collaborating with customers, government, community organizations, and employees; enforcing ethical business practices.

- Maintains quality service by establishing and enforcing organization standards.

- Maintains professional and technical knowledge by attending educational workshops; reviewing professional publications; establishing personal networks; benchmarking state-of-the-art practices; participating in professional societies.

- Make certain that the service and production department perform efficiently, coordinate employee efforts, and facilitate communications between management and computer repairs and maintenance engineers and technicians

- Make sure s that the organization works in line with international best practices.

- In charge of overseeing the smooth running of HR and administrative tasks for the organization

- Defining job positions for recruitment and managing interviewing process

- Carrying out staff induction for new team members

- In charge of training, evaluation and assessment of employees

- In charge of arranging travel, meetings and appointments

- Oversee the smooth running of the daily office and factory activities.

Sales and Marketing Manage r

- Manage external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Model demographic information and analyse the volumes of transactional data generated by customer

- Identifies development opportunities; follows up on development leads and contacts; participates in the structuring and financing of projects; assures the completion of development projects.

- Writing winning proposal documents, negotiate fees and rates in line with organizations’ policy

- In charge of handling business research, market surveys and feasibility studies for clients

- In charge of supervising implementation, advocate for the customer’s needs, and communicate with clients

- Develop, execute and evaluate new plans for expanding increase sales

- Create new markets cum businesses for the organization

- Empower and motivates the sales team to meet and surpass agreed targets

Accountant / Cashier

- In charge of preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports; analyses financial feasibility for the most complex proposed projects; conducts market research to forecast trends and business conditions.

- In charge of financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting for one or more properties.

- In charge of developing and managing financial systems and policies

- In charge of administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the business

- Serves as internal auditor for the business

Welding and Fabrication Engineers and Technicians

- In charge of developing welding and fabrication techniques, procedures, and application of welding equipment to problems involving fabrication of metals, utilizing knowledge of production specifications, properties and characteristics of metals and metal alloys, and engineering principles: Conducts research and development investigations to develop and test new fabrication processes and procedures, improve existing or develop new welding equipment, develop new or modify current welding methods, techniques, and procedures, discover new patterns of welding phenomena, or to correlate and substantiate hypotheses.

- Tasked with preparing technical reports as result of research and development and preventive maintenance investigations.

- Builds welding procedures to guide production and welding personnel relating to specification restrictions, material processes, pre- and post-heating requirements which involve use of complex alloys, unusual fabrication methods, welding of critical joints, and complex post heating requirements.

- In charge of evaluating new developments in welding field for possible application to current welding problems or production processes.

- Responsible for directing and coordinating technical personnel in performing inspections to ensure workers’ compliance with established welding procedures, restrictions, and standards; in testing welds for conformance with national code requirements; or testing welding personnel for certification.

- In charge of contacting personnel of other agencies, engineering personnel or clients to exchange ideas, information, or offer technical advice concerning welding matters.

- May perform experimental welding to evaluate new equipment, techniques, and materials.

- Welcomes clients and potential clients by greeting them in person or on the telephone; answering or directing inquiries.

- Make sure s that all contacts with clients (e-mail, walk-In centre, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Serves as a auto parts sell attendant

- Manages administrative duties assigned by the creative director in an effective and timely manner

- Consistently stays abreast of any new information on the organizations’ products, promotional campaigns etc. to Make sure accurate and helpful information is supplied to clients when they make enquiries

6. SWOT Analysis

We at SW believe will have the plan and capabilities to take over the welding industry. We hope to build and maintain an extensive shop which can handle all welding and fabrication issues. We have adequate plans to make our business the best in the industry, which is why we contacted Mandolin Business Consultants to do our SWOT Analysis for us.

Mandolin Business Consultants are known for the experience and agility they posses in terms of business consulting and analysis.

They were very thorough with their dealings and outlined below is a summary of the SWOT Analysis they conducted for us. The following SWOT analysis captures the key strengths and weaknesses within our company, and describes the opportunities and threats facing us at SW.

- Outstanding reputation.

- Quality – we at SW will guarantee all of our work, using the highest quality materials available and the most experienced fabricator available.

- Customer Care – we at SW will go extra time to make sure the customer is satisfied with the service provided.

- Experience – Over 27 years in the construction business, Nathan Cardozo is a talented, experienced fabricator, with a strong work ethic.

- Our weaknesses at SW come from the lack of funding to grow the business. Grant money will be used to purchase equipment, company expansion, create website, advertise, and hire an employee.

Opportunities

- Growing market with a significant percentage of our target market still not knowing we exist.

- Strategic alliances offering sources for referrals and joint marketing activities to extend our reach.

- Increasing sales opportunities beyond our “lake area” to include the many other lakes in the [STATE] area.

- The only obstacle to our success at SW would be further downswings in the economy of the world

7. MARKET ANALYSIS

- Market Trend

After due research, it is believed that semiautomatic welding will greatly increase, machine and automatic welding will increase modestly, but manual welding is decreasing at least as a percentage of the total. Furthermore, it is now evident that the following must be considered with regard to the future of welding:

- There will be continuing need to reduce manufacturing costs and to improve productivity, since wage rates for the people in manufacturing industries will keep on increasing, the cost of metals for producing weld metals and filler metals will also continue to be more expensive, and energy and fuel costs will increase and shortages may occur.

- Also there will be a continuing trend towards the use of higher-strength materials, particularly in the steels and lighter-weight materials.

- There will be more use of welding by manufacturing industries, probably decreasing the use of castings.

- There will be a trend towards higher levels of reliability and higher-quality requirements.

- The trend towards automatic welding and automation in welding will accelerate.

Productivity in this very industry is considered the amount of welding that can be done by a welder in a day. Productivity can be determined by several factors, the most important of which is the operator factor or duty cycle. Operator factor for a welder is the number of minutes per eight-hour period that is spent actually welding.

The different methods of welding have different average duty cycles. Manual welding has the lowest operator factor with semiautomatic welding approximately double and machine welding the next highest, with automatic welding approaching 100%.

Efforts will be made to utilize those processes that have the highest-duty cycles. The expected trend will be away from manual welding towards semiautomatic welding and to machine or automatic welding when possible.

Another factor affecting productivity of welders relates to the deposition rate of the welding process. The higher current processes have the highest deposition rates, thus the submerged arc welding process and the electro slag welding process will remain important as costs must be reduced.

8. Our Target Market

We at SW hope to focus on our ability to complete any project with the required equipment by having all the necessary tools.

Sonic Welders market segmentation scheme is fairly straightforward, and focuses on the target markets of the lake marinas within the banks of Lake Superior, local municipality contracts , agricultural entities, and commercial and residential customers.

We also understand that our prospective customers will prefer a certain quality of work and timeliness and it is our duty at SW to deliver on their expectations. We at SW know that there will always be a need for fabrication companies.

We understand that the customers within the fabrication industry want exceptional workmanship and affordable rates. We believe that our prospective customers will appreciate the quality service that we are hoping to offer, as well as the knowledgeable and experience of our owner.

We believe that these customers have the option to go elsewhere, but they understand that giving their business to SW will be of more advantage to them because we at SW deliver the dedication that they desire. We know Boat dock fabrication is seasonal but with aggressive marketing efforts could expand company operations and reach many more markets along the lakes. Our target market may include;

- Marinas around the mighty Lake

- Agricultural entities in Marquette

- Local Municipalities

Our competitive advantage

It is a known fact that Welding will continue to be a highly efficient and economical method for maintaining structural integrity when joining metals and non-metals, including plastics and composites. We also believe that the welding industry will continue to maintain a strong reputation for producing reliable and cost-effective welded components in the global market.

We have also noted after extensive research that the industry due to a growing need for welded components and a decline in skilled workforce is focused on continual design advancements in welding machines (particularly welding automation) to further enhance efficiency.

The competition in this industry is becoming heavy and unbelievable, which is why we are making all plans efficiently to make sure we take over the market.

We at SW have a strong competitive edge in the industry due to the many fabrication services we hope to offer. We hope that by building a business based on satisfying clients, SW simultaneously build defences against competition. We at SW plan to continue helping clients understand what we offer them and why they need it.

We at SW also plan to become a leading provider of fabrication services in the local area. We believe that to achieve this, we have to invest in many ways that will pay off in competitive advantages for our customers, by pre-job conferencing upon request and assisting in the technical or conceptual design.

9. SALES AND MARKETING STRATEGY

- Sources of Income

It is very important to note that the US fabricated metal parts manufacturing industry includes about 55,000 companies with about 0 billion in combined annual revenue. Major companies in specialty segments include Ball Corporation, Flowserve, Mueller Industries, Snap-On, and The Timken Company.

We believe that because of the special manufacturing processes involved for individual parts, most companies make a limited range of products.

We also have noted after extensive research that the industry as a whole is fragmented: the largest 50 companies account for about 20 percent of revenue. But concentration can be high in industry segments such as boiler, cutlery, metal can, and spring manufacturing.

We at SW plan to get revenues by wielding, fabricating and selling aluminium boat dock in the Marquette area of upstate Wisconsin. We also plan to get funds by fabricating and repairing truck bodies, and performing aluminium repair jobs.

All unused scrap metals will also be recycled by us. The first revenue stream is extremely important to us at SW as our bottom line is to make sure that the welding services we render are in continued demand despite deleterious changes in the general economy.

We also believe that this revenue stream has very high margins and will make sure that the profitability of our enterprise on a monthly basis.

10. Sales Forecast

Our primary ethics at SW is to maintain an excellent customer relation skills and work ethic; these skills we believe will be useful in making customers comfortable in believing us to provide their construction services. We believe that maintaining our customer’s satisfaction is an implicit part of building a relationship that will encourage repeat business.

Our sales projections at SW are based on our promising foundation, our planned increase investment in advertising for our business and future expansion will make us even more appealing to prospective customers. Our Sales forecast for the coming three years in as follows;

- First Year-: $650,000

- Second Year-: $1,100,000

- Third Year-: $2,452,000

- Marketing Strategy and Sales strategy

We at SW totally understand that satisfied customers will aid our business by referring our company to other clients who need our services. We at SW plan to serve the metal fabrication market segment. Our specific choice of target markets at SW is based on an in-depth understanding of our prospective customer’s needs.

We believe that our skills and capabilities will allow us to very well compete and develop our reputation within our business area. This is the reason why we believe that obtaining grant funding and developing a marketing strategy will improve our profitability levels and help us in building a strong customer base.

We at SW plan to use a direct sales force and relationship selling to reach its target markets. These channels are most appropriate because of time to market, reduced capital requirements, and fast access to established distribution channels.

We also plan to advertise in Yellow Pages and local newspapers, and create a website with information, construction background, and contact information will be available online. References to the website will be mentioned in all other forms of advertising once the website is in effect.

SW is a member of the Marquette Lake Association and will obtain a mailing list for potential customers. But we believe that our marketing budget will allow our employed marketing firm the leverage to push us to the top.

11. Publicity and Advertising Strategy

We at SW plan to use email marketing campaigns as an outreach to our prospective customers. We all know that technology that incorporates video with email and offers very powerful, robust and dynamic features. Another advantage is in communicating through the use of streaming video embedded within the email.

We at SW believe that the use of this technology will give us a strong competitive edge and outreach to the community. We at SW are also planning to incorporate an email drip campaign with video into our marketing efforts.

We believe that this technology will more effectively market to our customer and potential customer base. We understand that it is cost effective (averaging about $99 per month), especially when compared to the $1,000’s spent on print advertising, mailing and postage.

We believe that the built-in analytics provide immediate feedback as to the campaigns effectiveness and who actually viewed the message. We also hope that the Auto responders with a specific message can be utilized as an immediate follow-up tool.

It is important to note that we at SW hope that this new email marketing campaign technology will serve to position us to achieve and sustain name recognition in front of our current market within the local community.

We believe that this type of marketing is cost effective and efficient. The first thing most of us do every day is check our email in-box. It is also worthwhile to state that we at SW are currently unaware of any of our competitors incorporating the use of this technology within their operation.

12. Our Pricing Strategy

We at SW know that we are in a purely competitive industry where each business must be a price taker. Meaning that a business that has no ability to affect the market price of its services, regardless of how much work it does is destined for a meltdown.

Therefore, putting it, that marginal revenue (the revenue incurred by producing or servicing one more unit) is equal to the price charged. Furthermore, because the demand curve is essentially horizontal, we at SW plan to at total capacity without affecting the price in the market.

This means that we at SW must strive or look to charge our clients at the market price (or lower). We believe that the price we charge will depend on the workload and duration of the said work, and we understand that as long as marginal costs do not surpass revenues, the method to increase short-run profits is to service automobiles at maximum capacity.

- Payment Options

We at SW after extensive research understand that payment options are the forces that bring any business closer to the heart of the people, and we hope to make use of that extensively. We will be bringing payment options that are unique and will make the payment for the service we offer very easy for our customers.

- Payment by via bank transfer

- Payment via POS machine

- Payment via online bank transfer

- Payment via mobile money

- Payment with cash

To provide all these outstanding services, we have partnered with a renowned bank in the country and we hope to make use of that relationship. Our bank account numbers will be made available on our website and promotional materials so that it will be easier for clients to make payments when necessary.

13. Startup Expenditure (Budget)

It is very important to note that no matter how breath taking your ideas and goals might be or how attractive your business plan might be, without proper and enough financing your ideas are just like water poured on a rock.

It is a known fact that in every business enterprise fund is a big ingredient that can move a business to the limelight and without a detailed business plan; a business won’t be able to land substantial funds from prospective investors. We have analysed the market and have decided on how we plan to spend our start up fund.

These are the key areas where we will spend our start – up capital on;

- Business incorporation fees in the United States of America will cost – $750.

- The budget for Liability insurance, permits and license will cost – $3,500

- Acquiring a work facility that can accommodate a good number of cars per time for at least 6 months (Re – Construction of the facility inclusive) will cost – $100,000.

- The amount required to purchase the needed tool box and repair equipment – $25,000

- Equipping the office (computers, printers, projectors, markers, servers / internet facility, furniture, telephones, filing cabinets, and electronics) will cost – $30,000

- Amount required to purchase the needed software applications to run our business – $3,500

- Launching an official Website will cost – $500

- Amount need to pay bills and staff members for at least 2 to 3 months – $70,000

- Additional Expenditure such as Business cards, Signage, Adverts and Promotions will cost – $5,000

From our detailed cost analysis above, we will be needing approximately two hundred and fifty dollars ( $250,000 ) to start SW. Everything has been put in place and every fact made sure of, that is to enable us achieve our goal and objectives.

Generating Funding / Start up Capital for Sonic Welders

Sonic Welders (SW) is an established wielding and fabrication business owned by Nathan Cardozo that is engaged in the production of aluminium boat docks that will suit and satisfy the diverse designs and concepts of the customer. The business will be funded by him until we decide to accept investors or partners. Ways we hope to raise our start up capital may include;

- Generate part of the start – up capital from personal savings

- Generate part of the start – up capital from friends and other extended family members

- Generate part of the capital from the bank (loan facility).

Note: Nathan Cardozo has been able to raise $100,000 ( $70,000 from personal savings and $30,000 as soft loans from family and friends ) and we are at the final stages of obtaining a loan facility of $100,000. We have verified all the necessary procedures to actualize or get our start up cost.

14. Sustainability and Expansion Strategy

We at SW understand that our business being medium in nature requires a simple organizational structure. We believe that the implementation of this organizational form calls for Nathan Cardozo to make all of the major management decisions in addition to monitoring all other business activities.

Nathan Cardozo started working in the metal fabrication industry after working in the salt mines for several years and now brings over 27 years of experience to the success of the Company. Our management philosophy at SW is based on responsibility and mutual respect.

We believe that SW will maintain an environment and structure that will bring about productivity and respect for customers and fellow employees. At Sonic Welders, everybody is considered as an individual and we strive to the very last point to respect their dignity and recognize their merit.

We believe that our employees will be encouraged to have a sense of security and pride in their jobs. We will also afford equal opportunity for employment, development, and advancement for those qualified. Our employees at SW will be committed to:

- Afford a safe work environment to protect employees, the employees of customers and subcontractors, and the public.

- We will also supply safe products for customers.

- We will also without setbacks keep on improving the company’s safety program to reduce the risk of accidents and occupational illness in a changing work environment.

- We will advice our employees to participate in accident prevention programs and take personal responsibility for their own and their co-workers’ health and safety.

- Regulatory compliance and contribution to high safety standards for our industry.

- Monitoring workplaces, enforcing safe work practices, and communicating the company’s safety performance to employees and other stakeholders.

Checklist/Milestone

- Business Name Availability Check: Completed

- Business Incorporation: Completed

- Opening of Corporate Bank Accounts various banks in the United States: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of All form of Insurance for the Business: Completed

- Conducting Feasibility Studies: Completed

- Leasing, renovating and equipping our facility: Completed

- Generating part of the start – up capital from the founder: Completed

- Applications for Loan from our Bankers: In Progress

- Writing of Business Plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents: In Progress

- Design of The Company’s Logo: Completed

- Graphic Designs and Printing of Packaging Marketing / Promotional Materials: Completed

- Recruitment of employees: In Progress

- Purchase of the Needed software applications, furniture, office equipment, electronic appliances and facility facelift: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business (Business PR): In Progress

- Health and Safety and Fire Safety Arrangement: In Progress

- Establishing business relationship with banks, financial lending institutions, vendors and key players in the industry: In Progress

Related Posts:

- Dump Truck Business Plan [Sample Template]

- Home Remodeling Business Plan [Sample Template]

- Excavation Company Business Plan [Sample Template]

- Mobile Manufactured Home Business Plan [Sample Template]

- Engineering Consulting Business Plan [Sample Template]

Business Tips

Starting a metal fabrication business: what you need to know, november 07, 2023.

Starting a metal fabrication business is no small feat, but with the right prep work and planning, your custom metal shop can thrive! If you are considering setting up a metal fabrication business, you need to have a solid business plan in place first and foremost. So, check out the following insightful overview to help you get started.

Determine the types of services you will offer

First things first, you need to determine the type of metal fabrication services you will offer. Standard services include cutting, welding, shaping, grinding, and repairs. Depending on your level of expertise, you could also provide speciality processes, such as casting, powder coating, and powder metallurgy . You can make sure your metal fabrication business stands out from the competition by offering more specialised services.

Determine the equipment you will need

The type of fabrication services you decide to offer will determine the equipment you need to obtain. You may need to purchase tools like lathes, press brakes, lasers, shears, welding machines, and machining centres. Thankfully, such equipment does not have to be bought new. You will find a wide variety of high-quality used machinery for sale , which can help you reduce your initial financial outlay for tools and equipment.

Determine how many employees you will need

Once you know what types of services you will provide and what machinery you will use, you can work out how many employees you will need . You will also want to think about bringing in specialists who can perform specific jobs well. For example, you may want welders or smiths who are highly qualified and experienced. By pooling a team of experienced experts, you can ensure that your operations run smoothly from day one.

Determine how many customers your business can handle

To help you know how many employees to hire initially, you need to know how much work your metal fabrication business can handle, on a weekly or monthly basis. So, determine how many customer jobs you could realistically take on. Other factors, like the equipment capacity and the size of your space, will also contribute to working out how many customers you can handle.

Many large and established metal fabricators handle over 120,000 sheets of steel in a month. You will probably not be able to handle that much when your business is just starting, but as your company grows, you will be able to take more jobs over time. As a new business, it is worth opting to cater for either commercial or household clients to start with, but you also have the option of catering to both.

Evaluate the competition

To determine things like the type of services you will offer and what type of clients you will work for, it is essential you evaluate the competition in your area . By understanding the competition, such as the type of services they provide and their strengths and weaknesses, you can decide how to position your metal fabrication business against established companies.

Perform market analysis

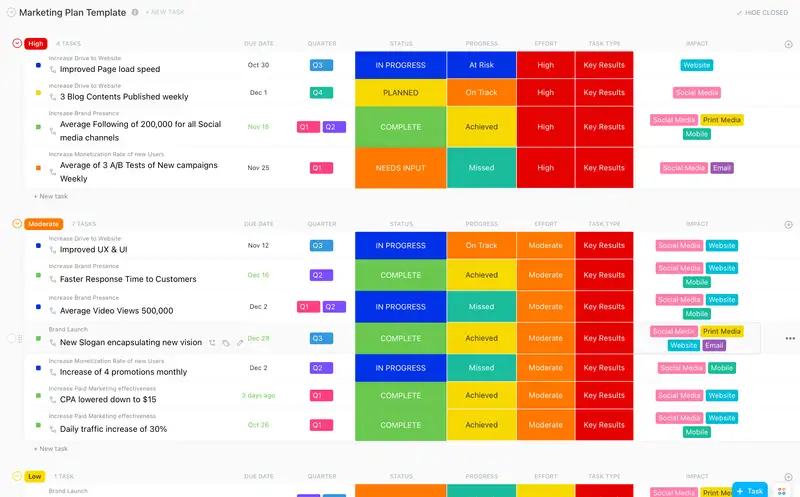

You also need to look at the metal fabrication market as a whole to help you define your target market and your plans for catering towards that specific audience. By gaining relevant market analysis data (by using these market research methods ) and processing it via charts or graphs, you can come up with a solid plan for progression.

Get the appropriate insurance

When you start your own metal fabrication business, a major requirement is obtaining the appropriate insurance. Your employees will be regularly working with dangerous tools and equipment, so there is always the chance of accidents and injuries occurring at your workplace. Compare and contrast different insurance providers and get quotes from them so that you can decide on the best insurance option for your fabrication business.

Come up with sales and marketing strategies

You need to outline pricing and sales information before you can begin operating your metal fabrication business. In turn, that allows you to come up with appropriate sales and marketing strategies . You can have the best machine shop and the most experienced and qualified employees in the world. But unless you have a solid marketing strategy for gaining customers , your business will fail before it has even gotten off the ground. So, rationalise why your target audience will purchase your services and how you intend to reach them via marketing and advertising efforts.

Raise capital and write a financial plan

Before you can begin any business, you need funds behind you . Most new businesses either save up capital to invest in the firm or take out small business loans. But you also have the option of gaining individual investors . The amount of money you will need for your new fabrication business will largely depend on the type of service your business will offer. Once you have worked out details like the type of machinery you need, how many employees you require, and your marketing costs, you will have a much more accurate idea of how much initial money is required to set up and run your business . And it is essential you write a financial plan. That should include:

- The amount needed to start or maintain your business.

- The amount needed over the next two, three, and five years.

- Plans of how you will use your funds .

- Anticipations of additional funds required.

- Ongoing expenses, such as salaries, insurance, and marketing costs.

Bringing your vision and expertise in metalwork to the marketplace is an exciting endeavor. With strategic preparation and a passion for the trade, your custom fabricated products can find buyers and make your metal shop thrive.

More must-read stories from Enterprise League:

- A list of marketing automation examples that you must know.

- 16 fiction books every entrepreneur should read as soon as possible.

- The golden rules you need to build a steady buyer-seller relationship .

- Things to consider before deciding on a business location .

- Best virtual networking events to get you back in the game.

Related Articles

5 tips to establish yourself as a thought leader in your industry

Jan 26, 2024

It doesn’t matter if you are starting your own business or just passionate about your industry, setting yourself as someone with key insights has benefits.

The best POS System for your business in 2024

Jan 24, 2024

Find out which are the best POS systems to improve business efficiency and follow the proven tips we’ve listed to make sure you choose the best POS system for your business.

How to turn your hobby into a business in 2024

Dec 20, 2023

How long have you been dreaming to turn a hobby into a business and swim in cash? Stop dreaming, read our article and take action.

Most Popular

- 15 innovative blockchain business ideas in 2024 04 Jun, 2024

- Top 15 candy business ideas in 2024 03 Jun, 2024

- What successful businesses have: Does yours measure up? 31 May, 2024

- 15 innovative recycling business ideas in 2024 31 May, 2024

- Unlocking seamless board meetings with iDeals board software 31 May, 2024

- Sample Business Plans

- Construction, Architecture & Engineering

Welding Business Plan

Demand is increasing for welding services. Many different businesses, including manufacturing, transportation, and construction, use welding. Because of this, there is a constant need for welders who can deliver excellent services.

Anyone can start a new business, but you need a detailed business plan when it comes to raising funding, applying for loans, and scaling it like a pro!

Need help writing a business plan for your welding business? You’re at the right place. Our welding business plan template will help you get started.

Free Business Plan Template

Download our free business plan template now and pave the way to success. Let’s turn your vision into an actionable strategy!

- Fill in the blanks – Outline

- Financial Tables

How to Write A Welding Business Plan?

Writing a welding business plan is a crucial step toward the success of your business. Here are the key steps to consider when writing a business plan:

1. Executive Summary

An executive summary is the first section planned to offer an overview of the entire business plan. However, it is written after the entire business plan is ready and summarizes each section of your plan.

Here are a few key components to include in your executive summary:

Introduce your Business:

Start your executive summary by briefly introducing your business to your readers.

Market Opportunity:

Welding services:.

Highlight the welding services you offer your clients. The USPs and differentiators you offer are always a plus.

Marketing & Sales Strategies:

Financial highlights:, call to action:.

Ensure your executive summary is clear, concise, easy to understand, and jargon-free.

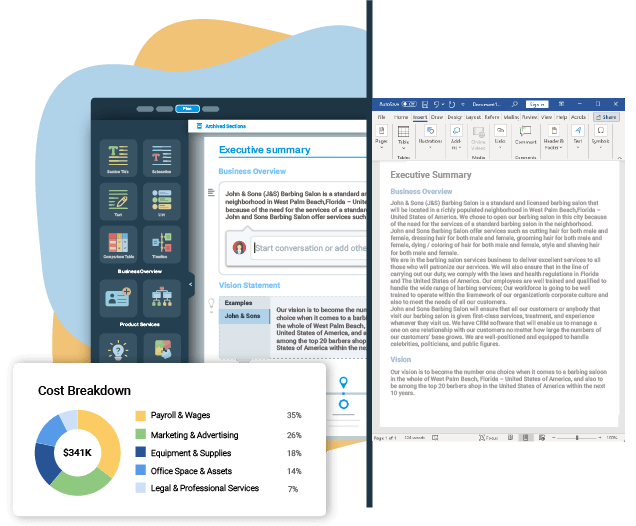

Say goodbye to boring templates

Build your business plan faster and easier with AI

Plans starting from $7/month

2. Business Overview

The business overview section of your business plan offers detailed information about your company. The details you add will depend on how important they are to your business. Yet, business name, location, business history, and future goals are some of the foundational elements you must consider adding to this section:

Business Description:

Describe your business in this section by providing all the basic information:

Describe what kind of welding company you run and the name of it. You may specialize in one of the following welding businesses:

- General welding services

- Aluminum welding

- Mobile welding

- Specialty welding services

- Heavy steel fabricating

- Describe the legal structure of your welding company, whether it is a sole proprietorship, LLC, partnership, or others.Explain where your business is located and why you selected the place.

Mission Statement:

Business history:.

If you’re an established welding service provider, briefly describe your business history, like—when it was founded, how it evolved over time, etc.

Future Goals

This section should provide a thorough understanding of your business, its history, and its future plans. Keep this section engaging, precise, and to the point.

3. Market Analysis

The market analysis section of your business plan should offer a thorough understanding of the industry with the target market, competitors, and growth opportunities. You should include the following components in this section.

Target market:

Start this section by describing your target market. Define your ideal customer and explain what types of services they prefer. Creating a buyer persona will help you easily define your target market to your readers.

Market size and growth potential:

Describe your market size and growth potential and whether you will target a niche or a much broader market.

Competitive Analysis:

Market trends:.

Analyze emerging trends in the industry, such as technology disruptions, changes in customer behavior or preferences, etc. Explain how your business will cope with all the trends.

Regulatory Environment:

Here are a few tips for writing the market analysis section of your welding business plan:

- Conduct market research, industry reports, and surveys to gather data.

- Provide specific and detailed information whenever possible.

- Illustrate your points with charts and graphs.

- Write your business plan keeping your target audience in mind.

4. Welding Services

The product and services section should describe the specific services and products that will be offered to customers. To write this section should include the following:

Welding services:

Mention the welding services your business will offer. This list may include services like,

- Metal fabrication

- Welding & repair services

- On-site welding services

- Structural steel & pipe welding

- Custom artistic welding

Describe each service

: Provide a detailed description of each service you provide, including the process involved;

Quality measures

: This section should explain how you maintain quality standards and consistently provide the highest quality service.

Additional Services

In short, this section of your welding plan must be informative, precise, and client-focused. By providing a clear and compelling description of your offerings, you can help potential investors and readers understand the value of your business.

5. Sales And Marketing Strategies

Writing the sales and marketing strategies section means a list of strategies you will use to attract and retain your clients. Here are some key elements to include in your sales & marketing plan:

Unique Selling Proposition (USP):

Define your business’s USPs depending on the market you serve, the equipment you use, and the unique services you provide. Identifying USPs will help you plan your marketing strategies.

Pricing Strategy:

Marketing strategies:, sales strategies:, customer retention:.

Overall, this section of your welding company business plan should focus on customer acquisition and retention.

Have a specific, realistic, and data-driven approach while planning sales and marketing strategies for your welding business, and be prepared to adapt or make strategic changes in your strategies based on feedback and results.

6. Operations Plan

The operations plan section of your business plan should outline the processes and procedures involved in your business operations, such as staffing requirements and operational processes. Here are a few components to add to your operations plan:

Staffing & Training:

Operational process:, equipment & machinery:.

Include the list of equipment and machinery required for welding, such as welding machines, welding tools & accessories, welding consumables & accessories, cutting equipment, etc.

Adding these components to your operations plan will help you lay out your business operations, which will eventually help you manage your business effectively.

7. Management Team

The management team section provides an overview of your welding business’s management team. This section should provide a detailed description of each manager’s experience and qualifications, as well as their responsibilities and roles.

Founders/CEO:

Key managers:.

Introduce your management and key members of your team, and explain their roles and responsibilities.

Organizational structure:

Compensation plan:, advisors/consultants:.

Mentioning advisors or consultants in your business plans adds credibility to your business idea.

This section should describe the key personnel for your welding business, highlighting how you have the perfect team to succeed.

8. Financial Plan

Your financial plan section should provide a summary of your business’s financial projections for the first few years. Here are some key elements to include in your financial plan:

Profit & loss statement:

Cash flow statement:, balance sheet:, break-even point:.

Determine and mention your business’s break-even point—the point at which your business costs and revenue will be equal.

Financing Needs:

Be realistic with your financial projections, and make sure you offer relevant information and evidence to support your estimates.

9. Appendix

The appendix section of your plan should include any additional information supporting your business plan’s main content, such as market research, legal documentation, financial statements, and other relevant information.

- Add a table of contents for the appendix section to help readers easily find specific information or sections.

- In addition to your financial statements, provide additional financial documents like tax returns, a list of assets within the business, credit history, and more. These statements must be the latest and offer financial projections for at least the first three or five years of business operations.

- Provide data derived from market research, including stats about the industry, user demographics, and industry trends.

- Include any legal documents such as permits, licenses, and contracts.

- Include any additional documentation related to your business plan, such as product brochures, marketing materials, operational procedures, etc.

Use clear headings and labels for each section of the appendix so that readers can easily find the necessary information.

Remember, the appendix section of your welding business plan should only include relevant and important information supporting your plan’s main content.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.

This sample welding business plan will provide an idea for writing a successful welding plan, including all the essential components of your business.

After this, if you still need clarification about writing an investment-ready business plan to impress your audience, download our welding business plan pdf .

Related Posts

Woodworking Business Plan

Painting Business Plan

10 Best Business Plan Software

Important Key Elements of Business Plan

Key Business Problem Statement Examples

Steps for Creating Business Plan

Frequently asked questions, why do you need a welding business plan.

A business plan is an essential tool for anyone looking to start or run a successful welding business. It helps to get clarity in your business, secures funding, and identifies potential challenges while starting and growing your business.

Overall, a well-written plan can help you make informed decisions, which can contribute to the long-term success of your welding company.

How to get funding for your welding business?

There are several ways to get funding for your welding business, but self-funding is one of the most efficient and speedy funding options. Other options for funding are:

- Bank loan – You may apply for a loan in government or private banks.

- Small Business Administration (SBA) loan – SBA loans and schemes are available at affordable interest rates, so check the eligibility criteria before applying for it.

- Crowdfunding – The process of supporting a project or business by getting a lot of people to invest in your business, usually online.

- Angel investors – Getting funds from angel investors is one of the most sought startup options.

Apart from all these options, there are small business grants available, check for the same in your location and you can apply for it.

Where to find business plan writers for your welding business?

There are many business plan writers available, but no one knows your business and ideas better than you, so we recommend you write your welding business plan and outline your vision as you have in your mind.

What is the easiest way to write your welding business plan?

A lot of research is necessary for writing a business plan, but you can write your plan most efficiently with the help of any welding business plan example and edit it as per your need. You can also quickly finish your plan in just a few hours or less with the help of our business plan software .

Can a good welding business plan help me secure funding?

Indeed. A well-crafted welding business plan will help your investors better understand your business domain, market trends, strategies, business financials, and growth potential—helping them make better financial decisions.

So, if you have a profitable and investable business, a comprehensive business plan can certainly help you secure your business funding.

What's the importance of a marketing strategy in a welding business plan?

Marketing strategy is a key component of your welding business plan. Whether it is about achieving certain business goals or helping your investors understand your plan to maximize their return on investment—an impactful marketing strategy is the way to do it!

Here are a few pointers to help you understand the importance of having an impactful marketing strategy:

- It provides your business an edge over your competitors.

- It helps investors better understand your business and growth potential.

- It helps you develop products with the best profit potential.

- It helps you set accurate pricing for your products or services.

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

Welding Business Plan Template

Written by Dave Lavinsky

Welding Business Plan

Over the past 20+ years, we have helped over 500 entrepreneurs and business owners create business plans to start and grow their welding companies.

If you’re unfamiliar with creating a welding business plan, you may think creating one will be a time-consuming and frustrating process. For most entrepreneurs it is, but for you, it won’t be since we’re here to help. We have the experience, resources, and knowledge to help you create a great business plan.

In this article, you will learn some background information on why business planning is important. Then, you will learn how to write a welding business plan step-by-step so you can create your plan today.

Download our Ultimate Business Plan Template here >

What is a Welding Business Plan?

A business plan provides a snapshot of your welding business as it stands today, and lays out your growth plan for the next five years. It explains your business goals and your strategies for reaching them. It also includes market research to support your plans.

Why You Need a Business Plan for a Welding Business

If you’re looking to start a welding business or grow your existing welding company, you need a business plan. A business plan will help you raise funding, if needed, and plan out the growth of your welding business to improve your chances of success. Your welding business plan is a living document that should be updated annually as your company grows and changes.

Sources of Funding for Welding Businesses

With regards to funding, the main sources of funding for a welding business are personal savings, credit cards, bank loans, and angel investors. When it comes to bank loans, banks will want to review your business plan and gain confidence that you will be able to repay your loan and interest. To acquire this confidence, the loan officer will not only want to ensure that your financials are reasonable, but they will also want to see a professional plan. Such a plan will give them the confidence that you can successfully and professionally operate a business. Personal savings and bank loans are the most common funding paths for welding companies.

Finish Your Business Plan Today!

How to write a business plan for a welding business.

If you want to start a welding business or expand your current one, you need a business plan. The guide below details the necessary information for how to write each essential component of your welding business plan.

Executive Summary

Your executive summary provides an introduction to your business plan, but it is normally the last section you write because it provides a summary of each key section of your plan.

The goal of your executive summary is to quickly engage the reader. Explain to them the kind of welding business you are running and the status. For example, are you a startup, do you have a welding business that you would like to grow, or are you operating an established welding business that you would like to sell?

Next, provide an overview of each of the subsequent sections of your plan.

- Give a brief overview of the welding industry.

- Discuss the type of welding business you are operating.

- Detail your direct competitors. Give an overview of your target customers.

- Provide a snapshot of your marketing strategy. Identify the key members of your team.

- Offer an overview of your financial plan.

Company Overview

In your company overview, you will detail the type of welding business you are operating.

For example, you might specialize in one of the following types of welding businesses:

- Aluminum welding: Aluminum welders can produce a variety of aluminum products such as baseball bats, bicycle frames, and golf clubs.

- Heavy steel fabricating: This type of welding business specializes in large projects using thick metals to manufacture products such as industrial tanks and agriculture machines.

- Mobile welding: This type of business specializes in small welding projects in residential homes or commercial businesses.

- Truck trailer manufacturing: This type of welding business specializes in manufacturing tuck trailers, trailer decks, and trailer bodies.

- Underwater welding: This type of business specializes in welding services that require the welder to be submerged in water such as working on dams, pipelines, and nuclear power facilities.

In addition to explaining the type of welding business you will operate, the company overview needs to provide background on the business.

Include answers to questions such as:

- When and why did you start the business?

- What milestones have you achieved to date? Milestones could include the number of customers served, the number of projects completed, and reaching $X amount in revenue, etc.

- Your legal business Are you incorporated as an S-Corp? An LLC? A sole proprietorship? Explain your legal structure here.

Industry Analysis

In your industry or market analysis, you need to provide an overview of the welding industry.

While this may seem unnecessary, it serves multiple purposes.

First, researching the welding industry educates you. It helps you understand the market in which you are operating.

Secondly, market research can improve your marketing strategy, particularly if your analysis identifies market trends.

The third reason is to prove to readers that you are an expert in your industry. By conducting the research and presenting it in your plan, you achieve just that.

The following questions should be answered in the industry analysis section of your welding business plan:

- How big is the welding industry (in dollars)?

- Is the market declining or increasing?

- Who are the key competitors in the market?

- Who are the key suppliers in the market?

- What trends are affecting the industry?

- What is the industry’s growth forecast over the next 5 – 10 years?

- What is the relevant market size? That is, how big is the potential target market for your welding business? You can extrapolate such a figure by assessing the size of the market in the entire country and then applying that figure to your local population.

Customer Analysis

The customer analysis section of your welding business plan must detail the customers you serve and/or expect to serve.

The following are examples of customer segments: individuals, schools, families, and corporations.

As you can imagine, the customer segment(s) you choose will have a great impact on the type of welding business you operate. Clearly, individuals would respond to different marketing promotions than corporations, for example.

Try to break out your target customers in terms of their demographic and psychographic profiles. With regards to demographics, including a discussion of the ages, genders, locations, and income levels of the potential customers you seek to serve.

Psychographic profiles explain the wants and needs of your target customers. The more you can recognize and define these needs, the better you will do in attracting and retaining your customers.

Finish Your Welding Business Plan in 1 Day!

Don’t you wish there was a faster, easier way to finish your business plan?

With Growthink’s Ultimate Business Plan Template you can finish your plan in just 8 hours or less!

Competitive Analysis

Your competitive analysis should identify the indirect and direct competitors your business faces and then focus on the latter.

Direct competitors are other welding businesses.

Indirect competitors are other options that customers have to purchase from that aren’t directly competing with your product or service. This includes businesses that provide other forms of manufacturing methods, welders who use other types of techniques or materials, and companies that use their own in-house welders. You need to mention such competition as well.

For each such competitor, provide an overview of their business and document their strengths and weaknesses. Unless you once worked at your competitors’ businesses, it will be impossible to know everything about them. But you should be able to find out key things about them such as

- What types of customers do they serve?

- What type of welding business are they?

- What is their pricing (premium, low, etc.)?

- What are they good at?

- What are their weaknesses?

With regards to the last two questions, think about your answers from the customers’ perspective. And don’t be afraid to ask your competitors’ customers what they like most and least about them.

The final part of your competitive analysis section is to document your areas of competitive advantage. For example:

- Will you make it easier for customers to acquire your product or service?

- Will you offer products or services that your competition doesn’t?

- Will you provide better customer service?

- Will you offer better pricing?

Think about ways you will outperform your competition and document them in this section of your plan.

Marketing Plan

Traditionally, a marketing plan includes the four P’s: Product, Price, Place, and Promotion. For a welding business plan, your marketing strategy should include the following:

Product : In the product section, you should reiterate the type of welding company that you documented in your company overview. Then, detail the specific products or services you will be offering. For example, will you provide heavy welding, underwater welding, trailer manufacturing, or aluminum fabrication services?

Price : Document the prices you will offer and how they compare to your competitors. Essentially in the product and price sub-sections of your plan, you are presenting the products and/or services you offer and their prices.

Place : Place refers to the site of your welding company. Document where your company is situated and mention how the site will impact your success. For example, is your welding business located in a busy retail district, a business district, a standalone facility, or is it a mobile operation? Discuss how your site might be the ideal location for your customers.

Promotions : The final part of your welding marketing plan is where you will document how you will drive potential customers to your location(s). The following are some promotional methods you might consider:

- Advertise in local papers, radio stations and/or magazines

- Reach out to websites

- Distribute flyers

- Engage in email marketing

- Advertise on social media platforms

- Improve the SEO (search engine optimization) on your website for targeted keywords

Operations Plan

While the earlier sections of your business plan explained your goals, your operations plan describes how you will meet them. Your operations plan should have two distinct sections as follows.

Everyday short-term processes include all of the tasks involved in running your welding business, including answering calls, meeting with clients, sending invoices and collecting payments, etc.

Long-term goals are the milestones you hope to achieve. These could include the dates when you expect to acquire your Xth customer, or when you hope to reach $X in revenue. It could also be when you expect to expand your welding business to a new city.

Management Team

To demonstrate your welding business’ potential to succeed, a strong management team is essential. Highlight your key players’ backgrounds, emphasizing those skills and experiences that prove their ability to grow a company.

Ideally, you and/or your team members have direct experience in managing welding businesses. If so, highlight this experience and expertise. But also highlight any experience that you think will help your business succeed.

If your team is lacking, consider assembling an advisory board. An advisory board would include 2 to 8 individuals who would act as mentors to your business. They would help answer questions and provide strategic guidance. If needed, look for advisory board members with experience in managing a welding business or successfully running a small welding operation.

Financial Plan

Your financial plan should include your 5-year financial statement broken out both monthly or quarterly for the first year and then annually. Your financial statements include your income statement, balance sheet, and cash flow statements.

Income Statement

An income statement is more commonly called a Profit and Loss statement or P&L. It shows your revenue and then subtracts your costs to show whether you turned a profit or not.

In developing your income statement, you need to devise assumptions. For example, will you employ 3 welders, and will each welder work for 8 hours per day at an hourly wage of $50 per hour? And will sales grow by 2% or 10% per year? As you can imagine, your choice of assumptions will greatly impact the financial forecasts for your business. As much as possible, conduct research to try to root your assumptions in reality.

Balance Sheets

Balance sheets show your assets and liabilities. While balance sheets can include much information, try to simplify them to the key items you need to know about. For instance, if you spend $50,000 on building out your welding business, this will not give you immediate profits. Rather it is an asset that will hopefully help you generate profits for years to come. Likewise, if a lender writes you a check for $50,000, you don’t need to pay it back immediately. Rather, that is a liability you will pay back over time.

Cash Flow Statement

Your cash flow statement will help determine how much money you need to start or grow your business, and ensure you never run out of money. What most entrepreneurs and business owners don’t realize is that you can turn a profit but run out of money and go bankrupt.

When creating your Income Statement and Balance Sheets be sure to include several of the key costs needed in starting or growing a welding business:

- Cost of welding equipment and supplies

- Payroll or salaries paid to staff

- Business insurance

- Other start-up expenses (if you’re a new business) like legal expenses, permits, computer software, and equipment

Attach your full financial projections in the appendix of your plan along with any supporting documents that make your plan more compelling. For example, you might include your facility location lease, or a list of successful welding projects completed.

Writing a business plan for your welding business is a worthwhile endeavor. If you follow the template above, by the time you are done, you will truly be an expert. You will understand the welding industry, your competition, and your customers. You will develop a marketing strategy and will understand what it takes to launch and grow a successful welding business.

Welding Business Plan Template FAQs

What is the easiest way to complete my welding business plan.

Growthink's Ultimate Business Plan Template allows you to quickly and easily write your welding business plan.

How Do You Start a Welding Business?

Starting a welding business is easy with these 14 steps:

- Choose the Name for Your Welding Business

- Create Your Welding Business Plan

- Choose the Legal Structure for Your Welding Business

- Secure Startup Funding for Welding Business (If Needed)

- Secure a Location for Your Business

- Register Your Welding Business with the IRS

- Open a Business Bank Account

- Get a Business Credit Card

- Get the Required Business Licenses and Permits

- Get Business Insurance for Your Welding Business

- Buy or Lease the Right Welding Business Equipment

- Develop Your Welding Business Marketing Materials

- Purchase and Setup the Software Needed to Run Your Welding Business

- Open for Business

Learn more about how to start your own welding business .

Don’t you wish there was a faster, easier way to finish your Welding business plan?

OR, Let Us Develop Your Plan For You

Since 1999, Growthink has developed business plans for thousands of companies who have gone on to achieve tremendous success. Click here to see how a Growthink business plan writer can create your business plan for you.

Other Helpful Business Plan Articles & Templates

BizFundingResource.com

Sheet Metal Fabrication Service Business Plan and SWOT Analysis

Sheet Metal Fabrication Service Business Plan, Marketing Plan, How To Guide, and Funding Directory

The Sheet Metal Fabrication Service Business Plan and Business Development toolkit features 18 different documents that you can use for capital raising or general business planning purposes. Our product line also features comprehensive information regarding to how to start a Sheet Metal Fabrication Service business. All business planning packages come with easy-to-use instructions so that you can reduce the time needed to create a professional business plan and presentation.

Your Business Planning Package will be immediately emailed to you after you make your purchase.

Product Specifications (please see images below):

- Bank/Investor Ready!

- Complete Industry Research

- 3 Year Excel Financial Model

- Business Plan (26 to 30 pages)

- Loan Amortization and ROI Tools

- Three SWOT Analysis Templates

- Easy to Use Instructions

- All Documents Delivered in Word, Excel, and PDF Format

- Meets SBA Requirements

Sheet metal fabrication services are always in demand given that many of the products that they produce are used for construction as well as for specialized product fabrication. As such, these businesses are able to generate substantial gross margins from the production of custom parts as well as roofing from sheet metal components. Typically, the gross margin generated from each sale usually produce margins of 50% to 75% depending on the type of product being manufactured at the facilities. The barriers to entry for a new sheet metal fabrication service are considered to be moderately low. Typically, these businesses have a startup cost of $150,000 to $500,000 depending on the type of equipment that will be purchased in conjunction with providing sheet metal fabrication. The additional underlying costs for these businesses can be somewhat significant given that they require a number of employees and they have high energy usage. However, the gross margin generated from sales almost always able to cover all operating expenses plus any underlying debt service that is associated with the business. In lieu of directly purchasing much of the equipment that is used for sheet metal fabrication – some entrepreneurs will choose to be specific equipment in order to keep their capital expenditure or cost down.

Given the high gross margins, strong economic stability, and significant assets – almost all financial institutions are willing to provide a significant amount of capital support for a sheet metal fabrication business. Of course, a sheet metal fabrication service business plan is going to be required. This document should have a three-year profit and loss statement, cash flow analysis, balance sheet, breakeven analysis, and business ratios page. Within the business plan, a substantial amount of information regarding the targeted demographics should be included as well. This includes discussing the types of businesses will be targeted, their annual revenues, their annual expenditure with the sheet metal fabrication service, number of employees, and their target market radius.

Usually, the sheet metal fabrication service has a target market radius of 100 miles. However, these businesses can readily expand by offering their services on an ongoing basis. This allows some sheet-metal fabrication companies to operate in a nationwide capacity. Usually, the most common types of companies that you sheet-metal fabrication services or construction businesses, real estate developers, roofing contractors, painting contractors, and related businesses where sheet-metal is frequently used as part of their overall contracting or manufacturing processes.

A sheet metal fabrication service marketing plan should be developed as well. This marketing plan should feature a number of different components. First, an online component should be developed that showcases the proprietary website that will be developed by the sheet metal fabrication service in order to have people find the business quickly over the Internet. As many small businesses and large businesses alike now use the Internet to source service providers.

The company’s proprietary website should feature information regarding services rendered, time for two delivery, hours of operation, preliminary pricing information, as well as relevant contact information. This website may also feature e-commerce functionality where individuals and businesses can upload CAD produced files so that the company can produce sheet-metal components to exact specifications of customers. This functionality is now becoming more commonplace among many businesses and as such the sheet metal fabrication company can have a significant competitive advantage by end to grading these types of functions into its website.

Presence on social media is not necessary for you sheet-metal fabrication service but it can help boost visibility among individual hobbyists as well as smaller contractors. There are a number of communities on major social networking platforms such as FaceBook, Twitter, Instagram, and Google+ where people that have shared interest regarding hobbies or their careers as contractors can discuss relevant topics. As such, a presence on social media can help boost visibility in the business if the owner operator decides to become part of these online communities.

Once the online component has been developed it is time to produce the marketing aspects for traditional marketing operations. This includes sending flyers and brochures specific to the demographics that were discussed above. Again, an average target market radius for a new sheet metal fabrication services usually around 100 miles. As such, lists can be purchased so that these companies can be effectively targeted. There are a number of online companies where the directories of specialized businesses can be acquired for a relatively low fee.